Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

410 results about "Cook stove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A biomass cook stove is heated by burning wood, charcoal, animal dung or crop residue. Cook stoves are commonly used for cooking and heating food in rural households. Nearly half of the world's population, approximately 3 billion people, use solid fuels such as coal, wood, animal dung, and crop residues for their domestic energy needs. Among those who use indoor cooking stoves, the poorest families living in rural areas most frequently use solid fuels, where it continues to be relied on by up to 90% of households. Households in developing countries consume significantly less energy than those in developed countries; however, over 50% of the energy is for cooking food. The average rural family spends 20% or more of its income purchasing wood or charcoal for cooking. The urban poor also frequently spend a significant portion of their income on the purchase of wood or charcoal. Deforestation and erosion often result from harvesting wood for cooking fuel. The main goal of most improved cooking stoves is to reduce the pressure placed on local forests by reducing the amount of wood the stoves consume, and to reduce the negative health impacts associated with exposure to toxic smoke from traditional stoves.

Cooking stove having a smooth-top glass ceramic cooktop, and a smooth-top glass ceramic cooktop with a glass ceramic cooktop cooking surface, method for production of stoves with smooth-top glass ceramic cooktops and smooth-top glass ceramic cooktops

InactiveUS6515263B2Easy to cleanHot plates heating arrangementsHeating element materialsVisibilityMetallurgy

There is disclosed a stove, with a smooth-top cooktop, for cooking food, the stove comprising: a stove body; a smooth-top cooktop to cook food thereon; and at least one heat source disposed adjacent to a cooking surface of said cooktop. The cooktop comprises glass ceramic with an upper layer and an inner layer, with the upper layer comprising a different glass ceramic material than the inner layer. The upper layer is configured to minimize surface defects such as fissures, cracks, pits, and pores. The inner layer is configured to provide resistance to impact to the upper layer from cooking utensils being dropped onto the upper layer of the smooth-top cooktop, and at least the inner layer of the glass ceramic being configured to obscure visibility of the at least one heat source, through the upper layer of the glass ceramic.

Owner:SCHOTT AG

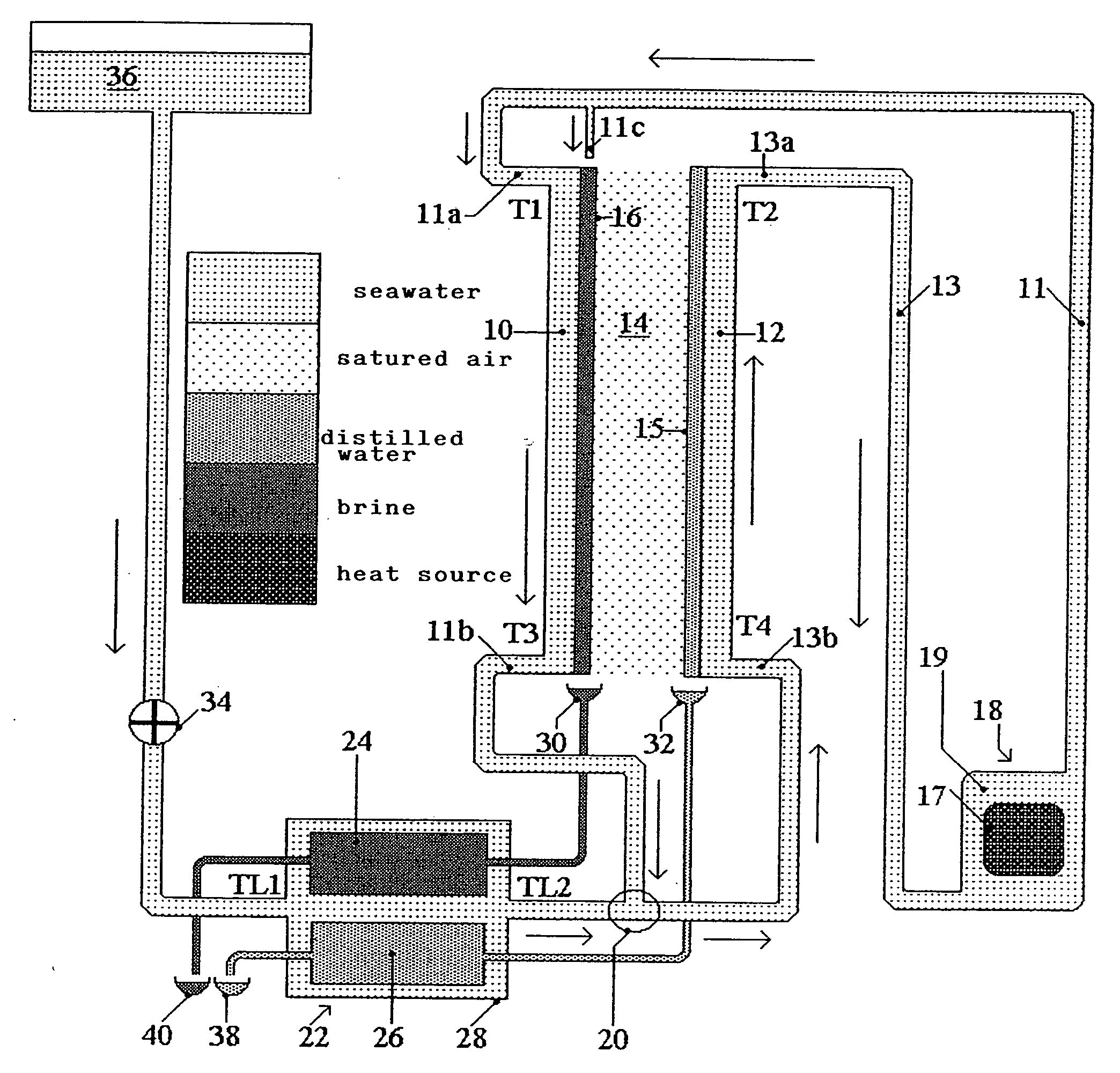

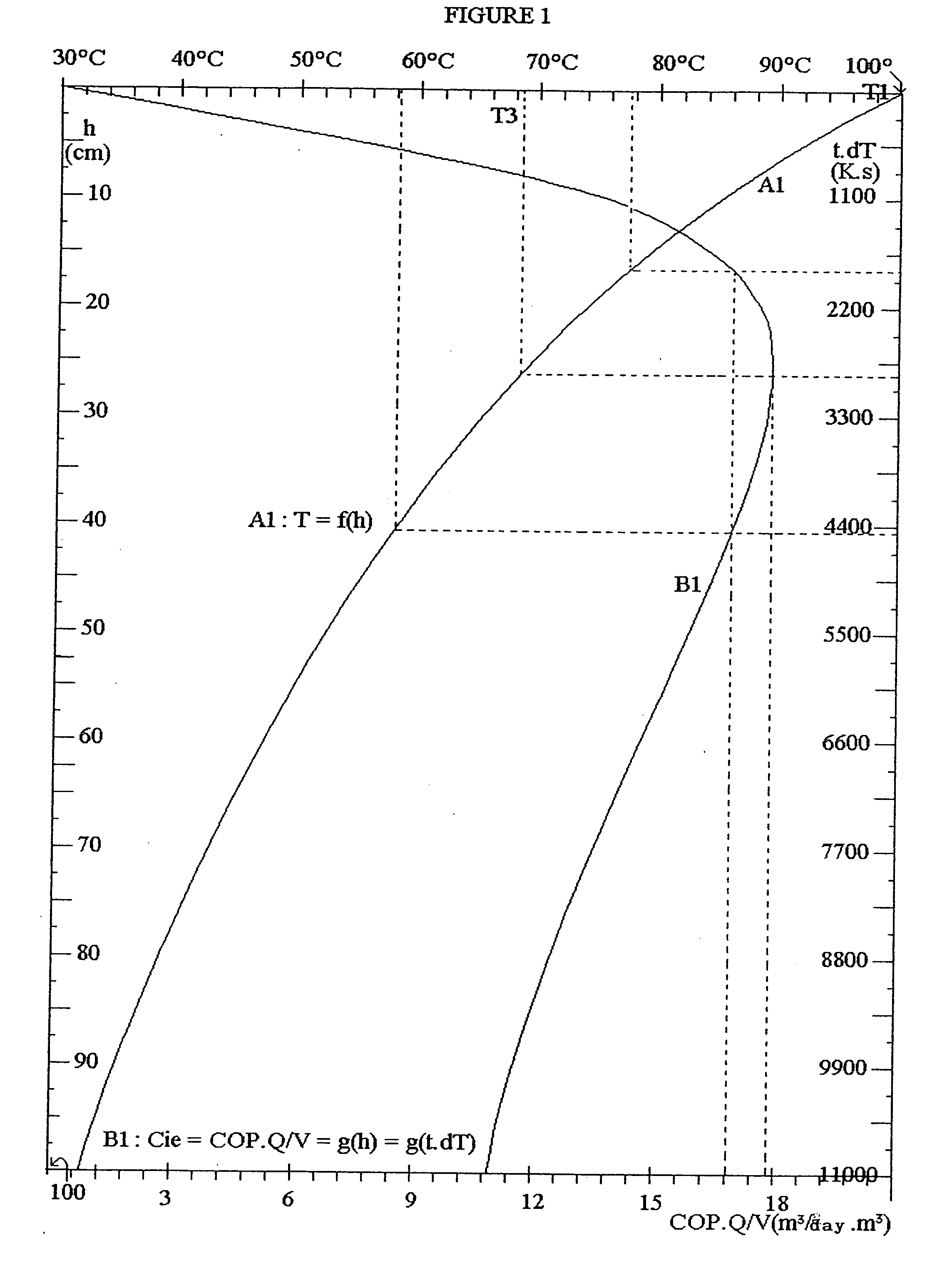

Distillation methods and devices in particular for producing potable water

InactiveUS20060272933A1Improve efficiencyHigh densityGeneral water supply conservationAuxillariesEngineeringSeawater

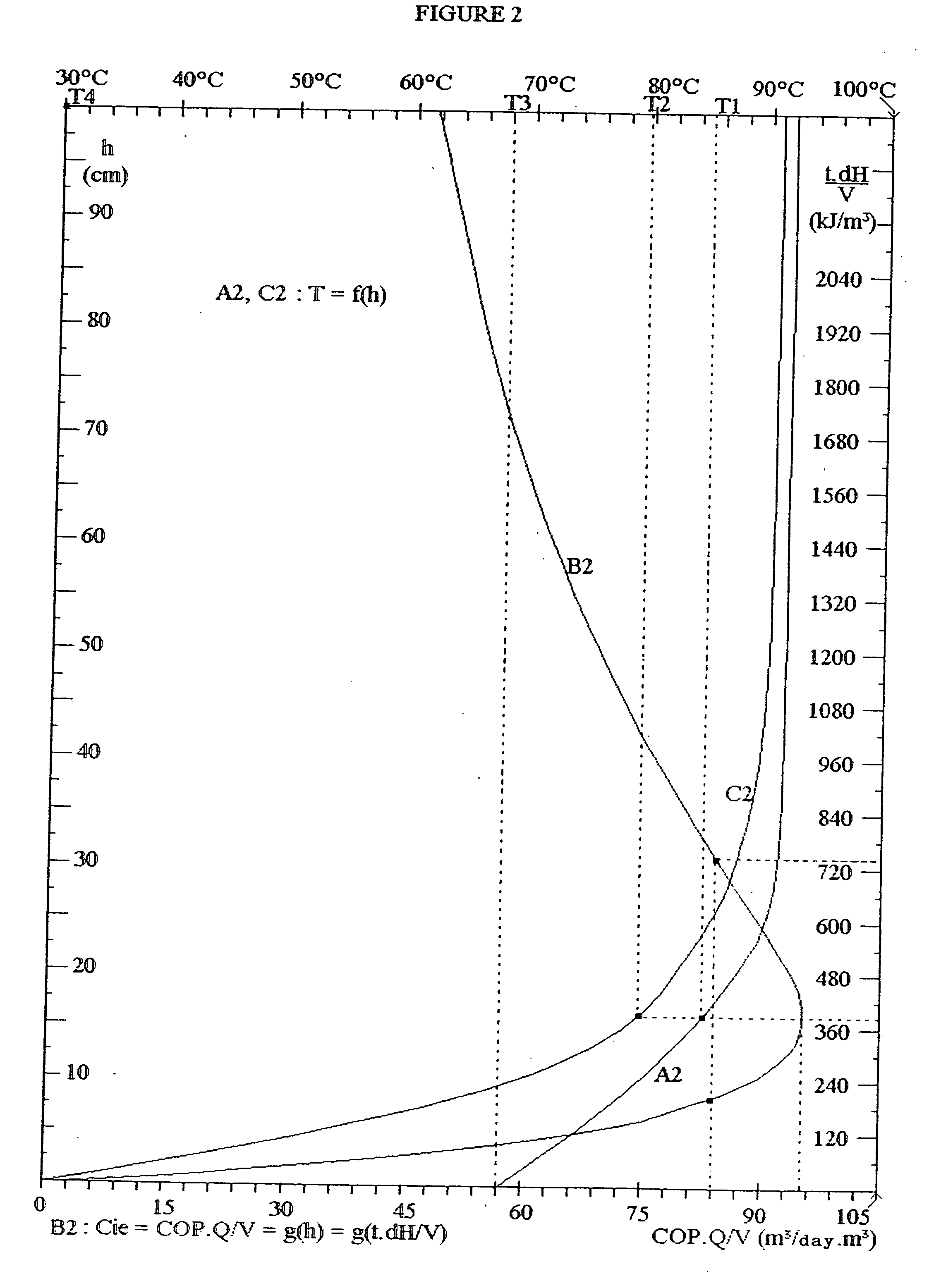

The inventive device is embodied in the form of a chamber-oven for diffusing vapour and saturated hot air which circulate in a closed circuit by natural convection. Said device is embodied in the form of a domestic-use solar energy collecting device provided with a greenhouse whose surface is equal to 1 m2 and produces from 50 to 100 litres / day of distilled water. The device comprises a distillation unit arranged between two furnaces (59′, 79′) in a temperature-controlled container (48′). Said distillation unit comprises 100 flat thin hollow plates having a surface of 20 dm2 by face and an active volume of 200 dm3. The fine and tensioned walls (54) of said plates are provided with a hydrophilic coating (60′) and internal (56′) and inter-plate (58′) spaces. The lower chimney (59′) comprises a greenhouse (118′, 119′) whose bottom is embodied in the form of an impermeable black layer provided with a thin hydrophilic carpet on the rear part thereof. Saturated hot air at a temperature of 80° C. enters inside (56′) hollow plates from bellow and exits from the top at a temperature of 50° C. A high chimney (79′) is provided with a monoblock heat exchanger (84′) which is transversed by a non-potable water to be distilled which, afterwards is spread warm (40° C.) over the hydrophilic coating (60′). During passage through the heat exchanger (84) the air is cooled to 30° C. and moved down by gravity to the inter-plate spaces (58′) and exits therefrom at a temperature of 78° C. The distilled water condensed in the plates and by the heat exchanger is collected and removed. Brine is received in the bottom of the inter-plate space and distributed along the thin hydrophilic carpet of the bottom (122′) of the greenhouse. An air current passes along said hot carpet is heated and saturated and enters the plates. The brine liquor finally flows in an air-preheating tank (63′) which is emptied each morning. The greenhouse can be substituted by a heating tube transversed by a heating fluid or associated with another steam-jet tube. The more powerful chamber-ovens can produce at least 200 m3 / day of distilled water for collective consumption. Said invention can be used for salt removal from seawater, co-generating electricity and potable water and for producing food concentrates.

Owner:THE THIRD MILLENIUM WATER

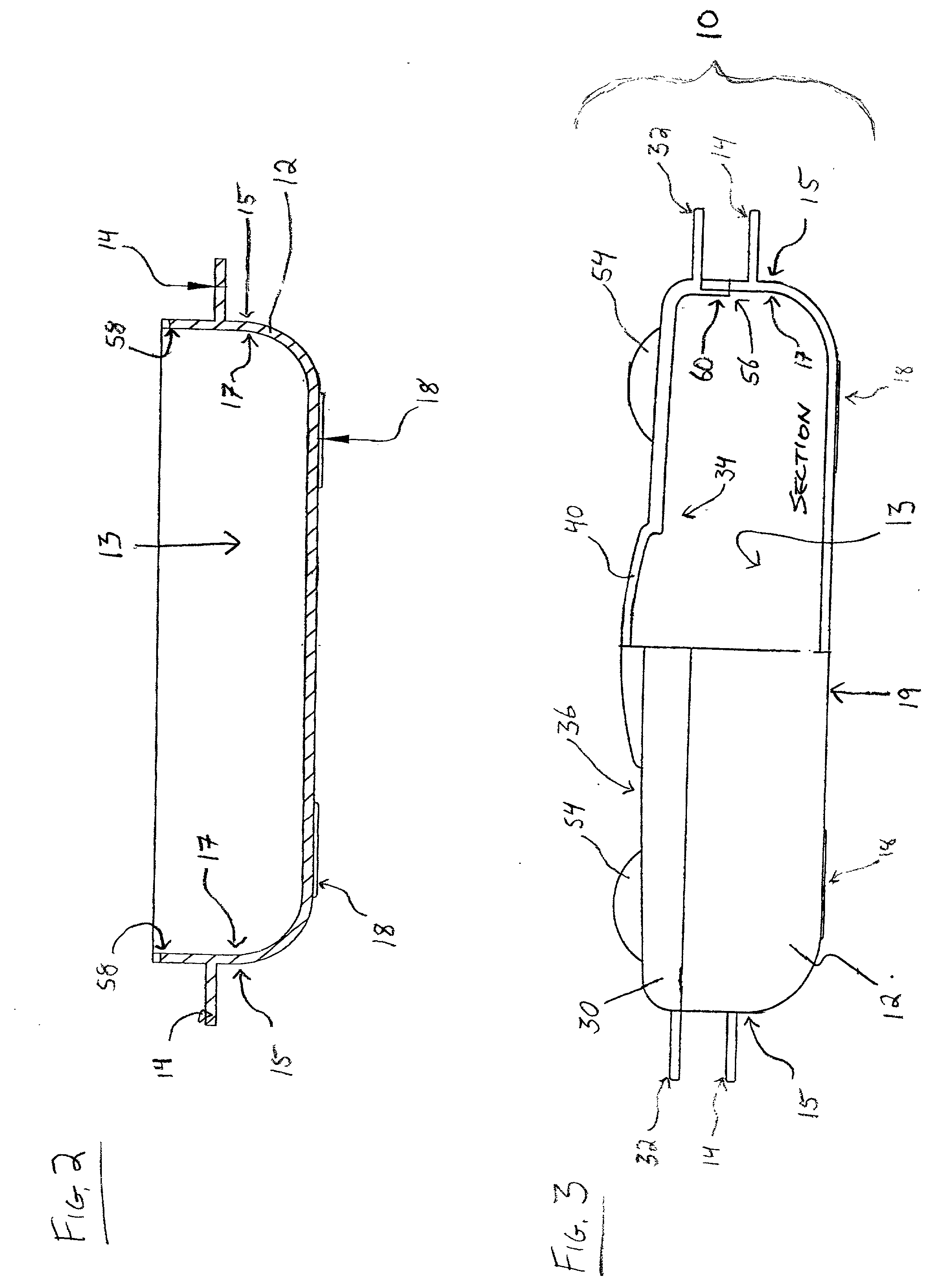

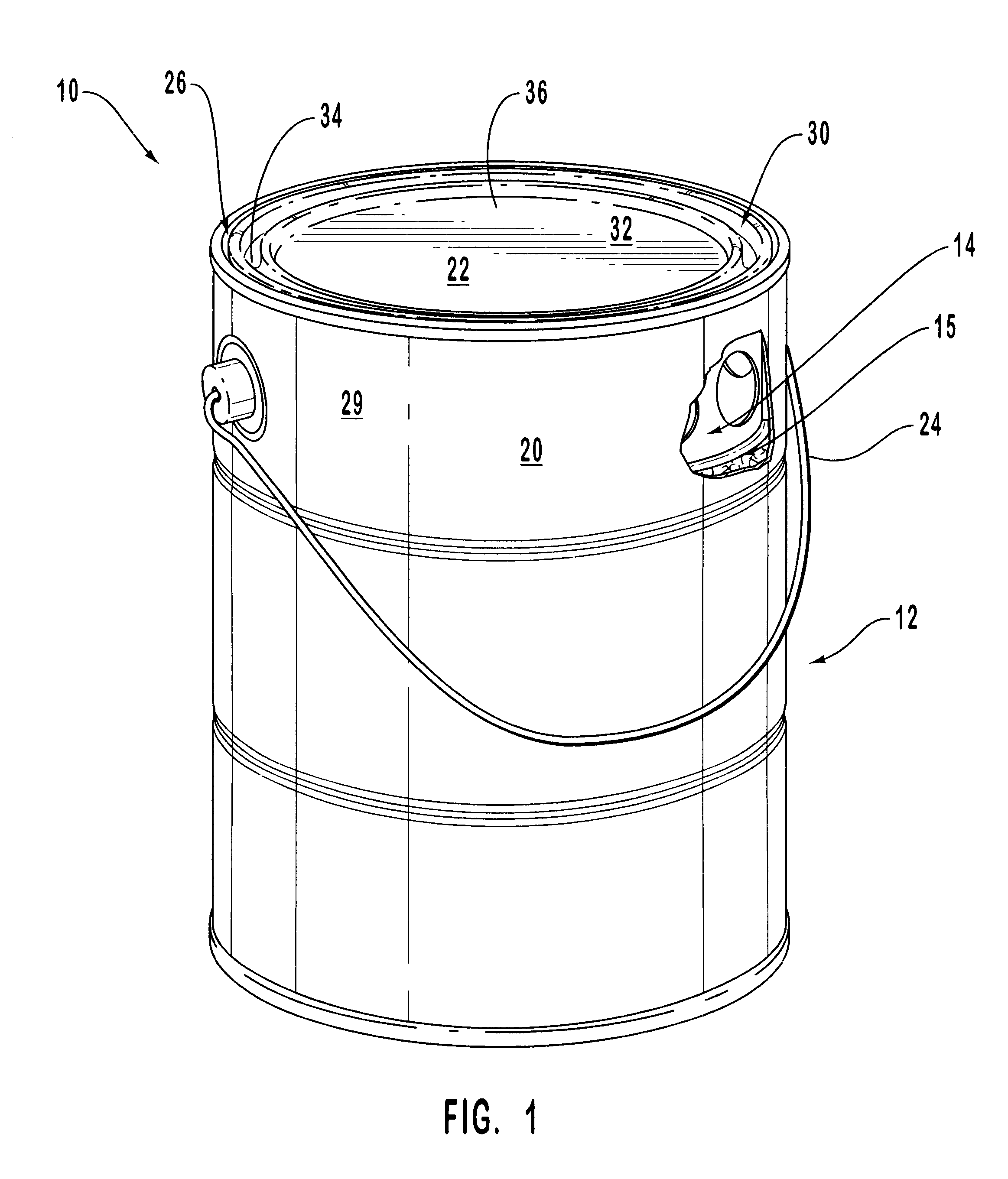

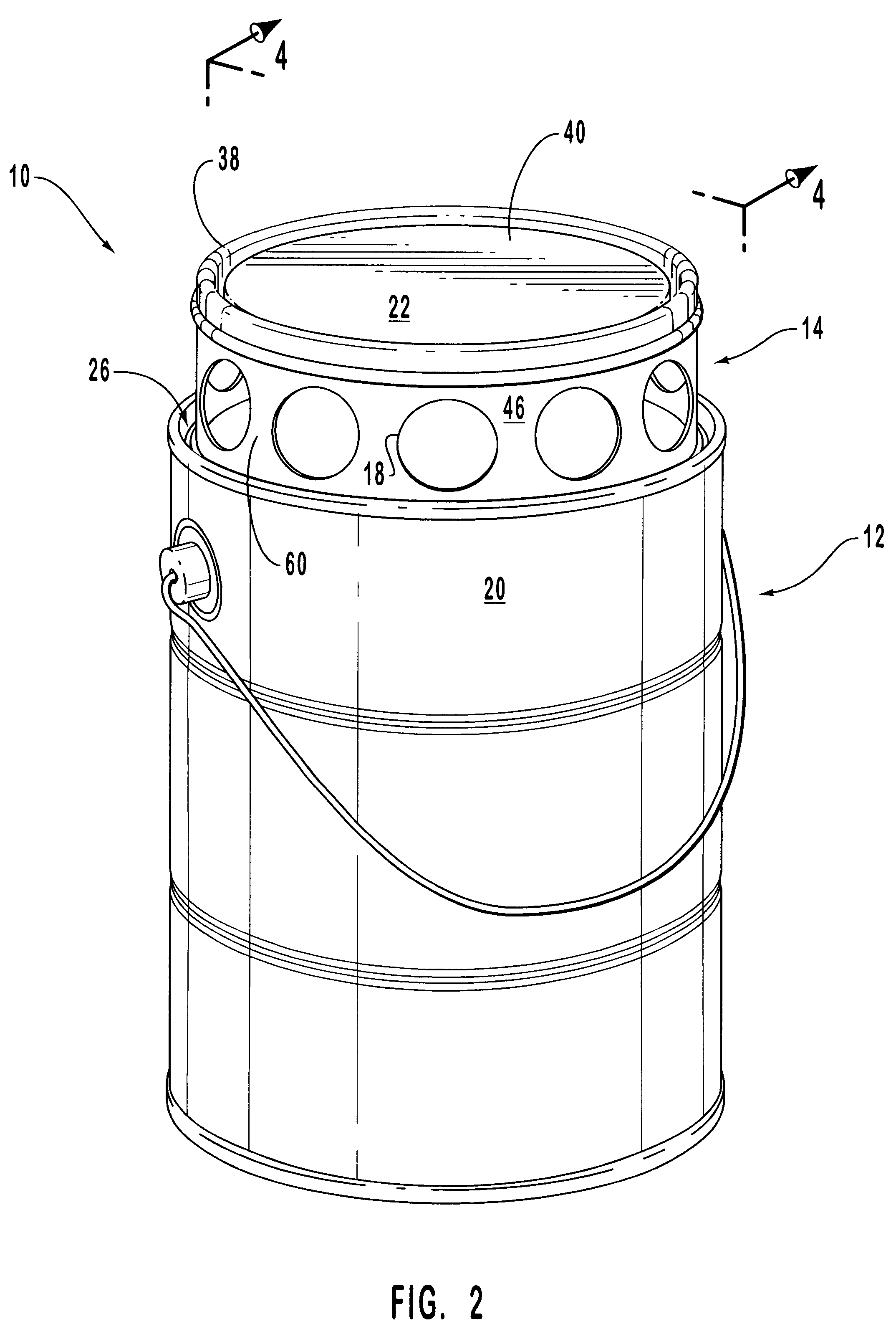

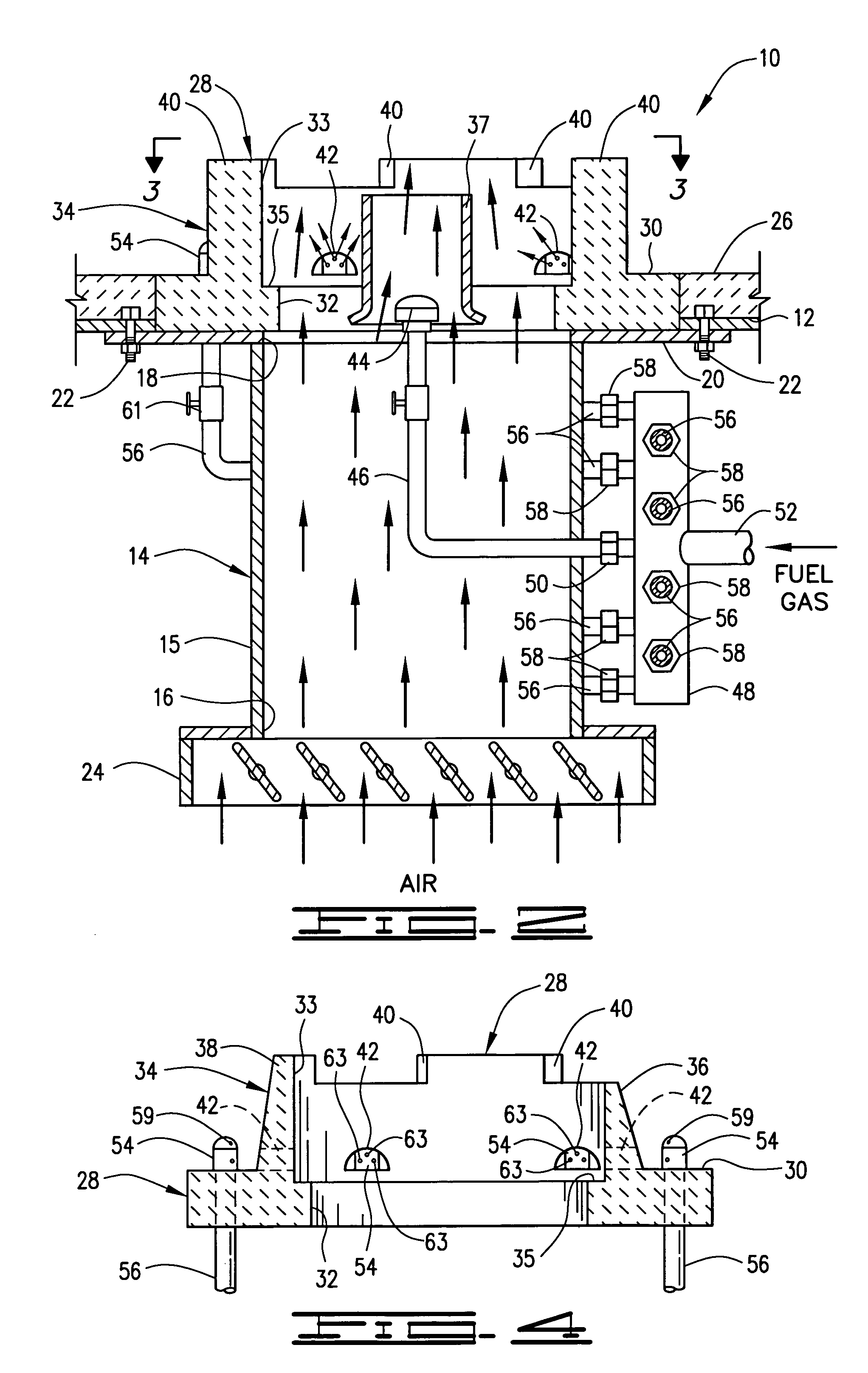

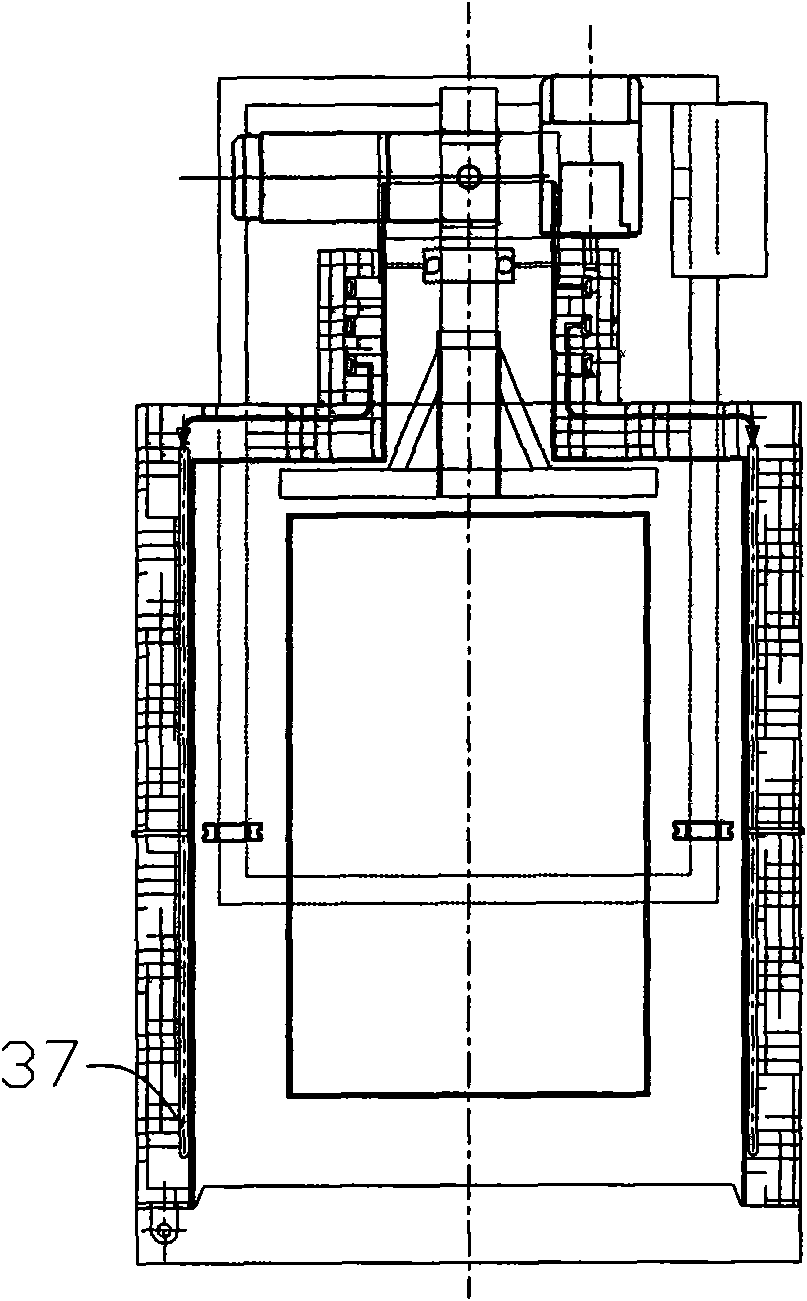

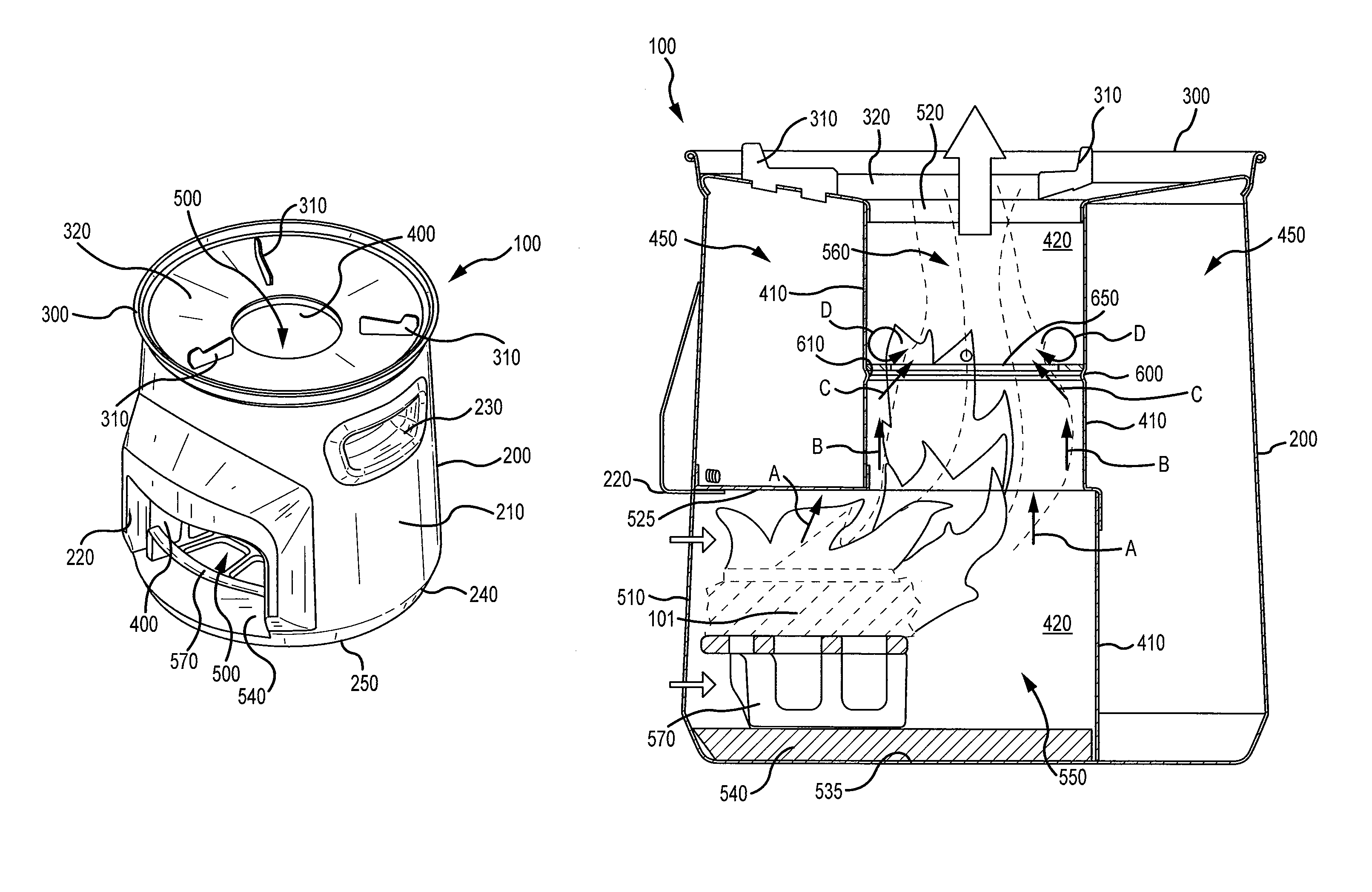

Cook stove assembly

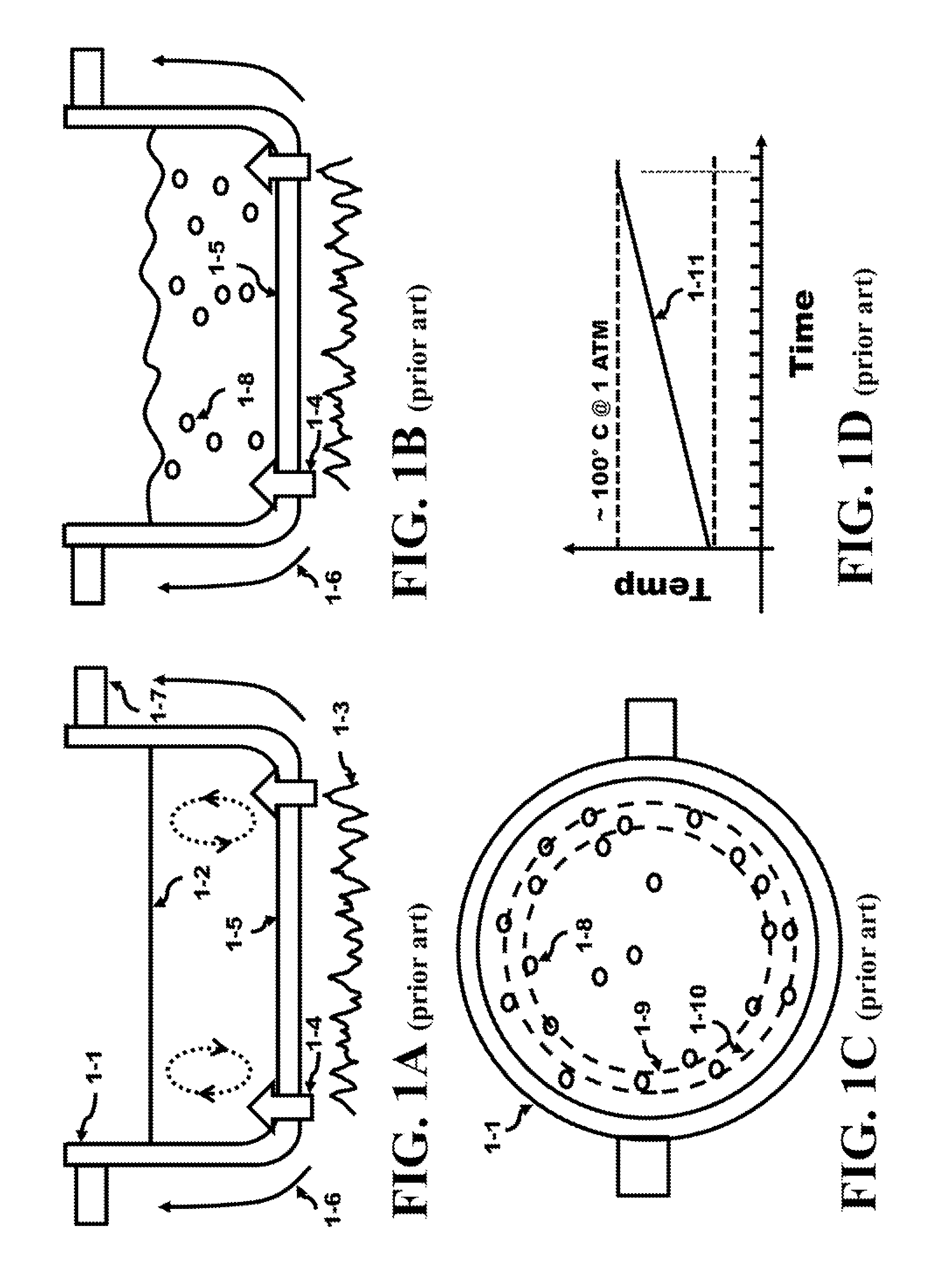

InactiveUS20100258104A1Increase productionReduce productionLighting and heating apparatusCombustion-air/flue-gas circulation for stovesCombustion chamberDirect combustion

A combustion chamber, having an upper part and a lower part, may include an annular constriction, in combination with the combustion chamber, to aid in directing partially combusted gases such as carbon monoxide away from the periphery of the combustion chamber back toward its center, and into the flame front. The annular constriction may also impede the flow of partially combusted gases located at the periphery, thus increasing the time these gases spend within the combustion chamber and increasing the likelihood that any products of incomplete combustion will undergo combustion. The combustion chamber may further comprise a dual burner cooktop for directing combustion gases and exhaust to multiple cooking vessels. In further embodiments, the combustion chamber may be made of, lined, or clad with a metal alloy comprising iron, chromium, and aluminum.

Owner:COLORADO STATE UNIVERSITY +1

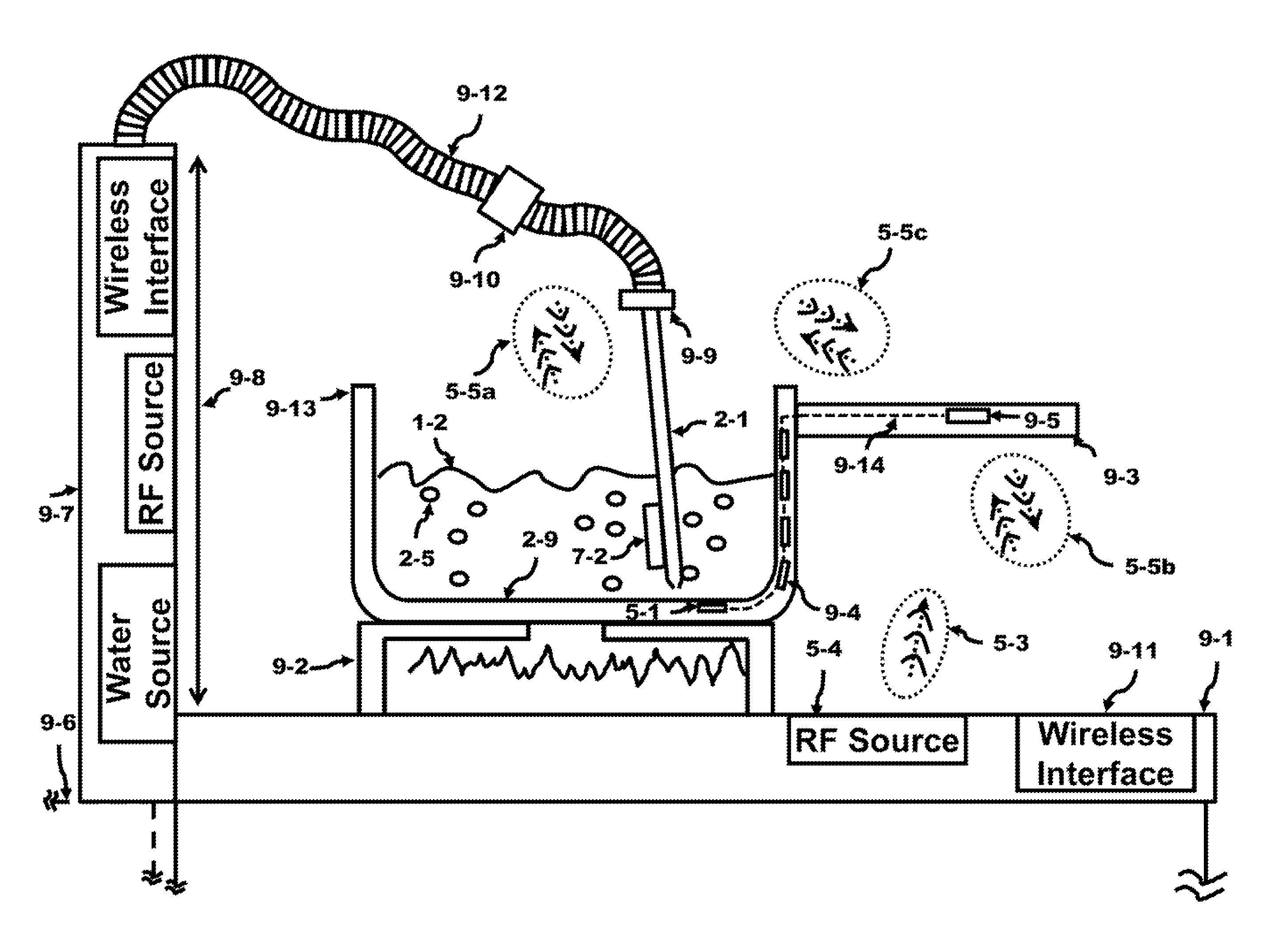

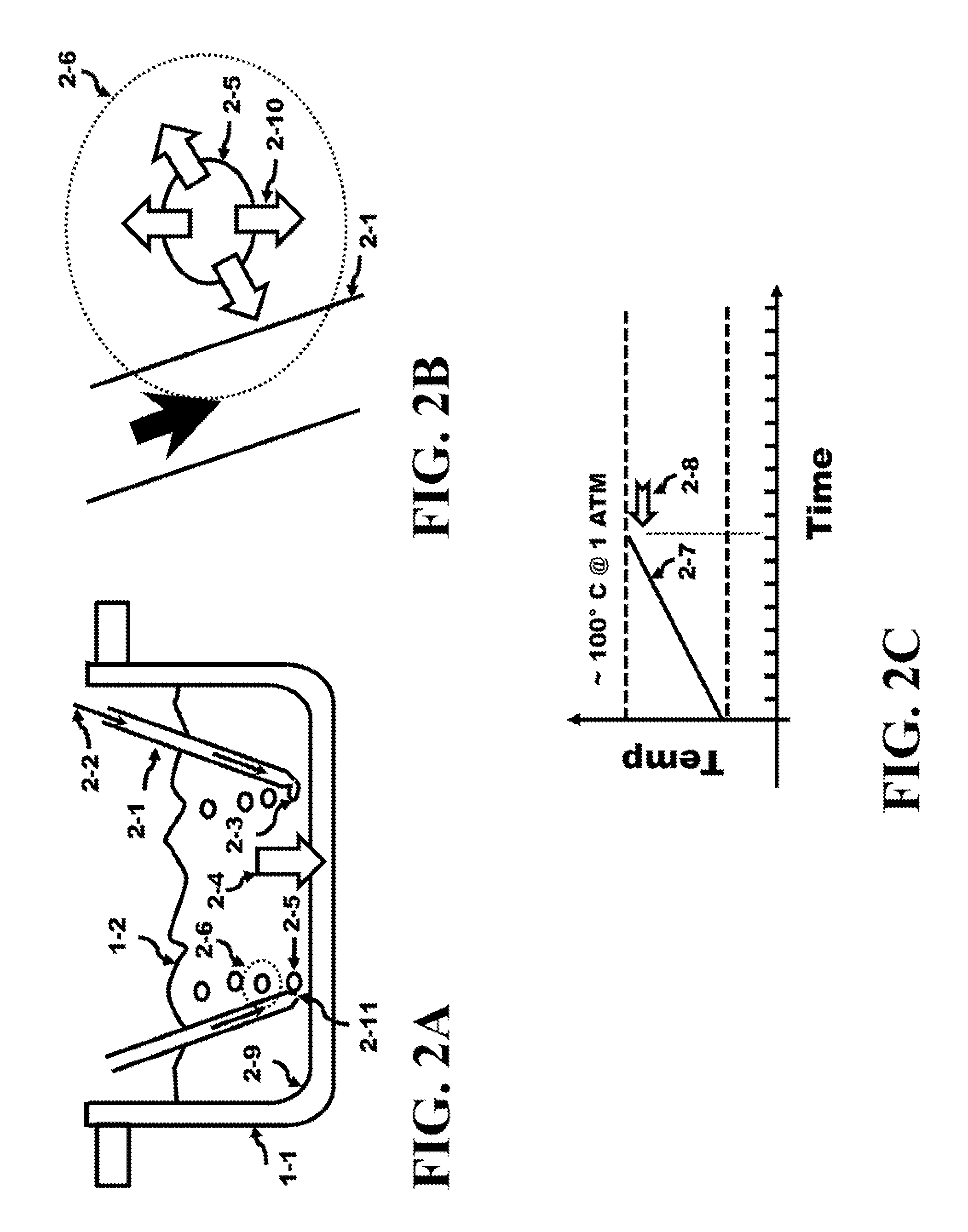

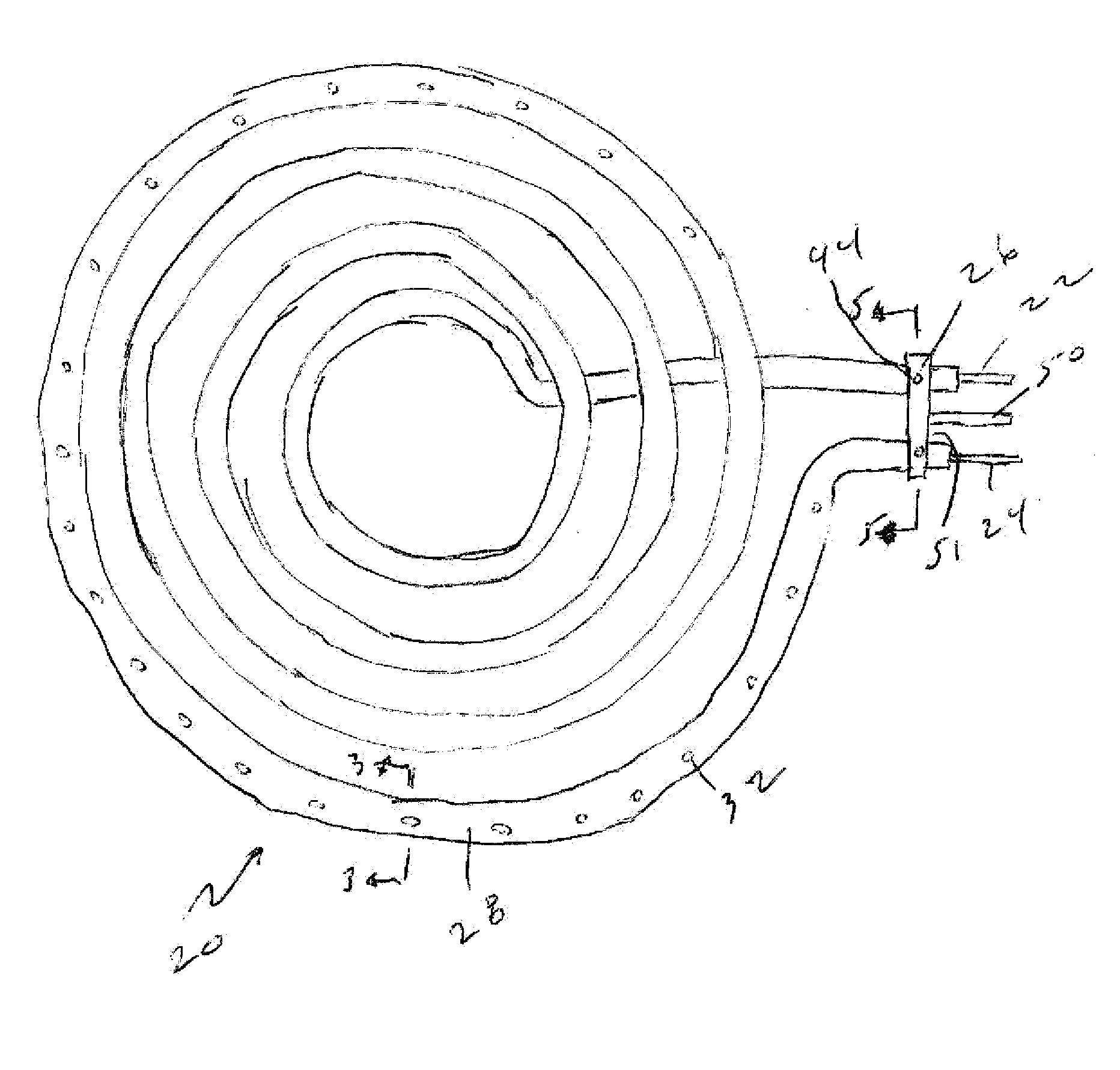

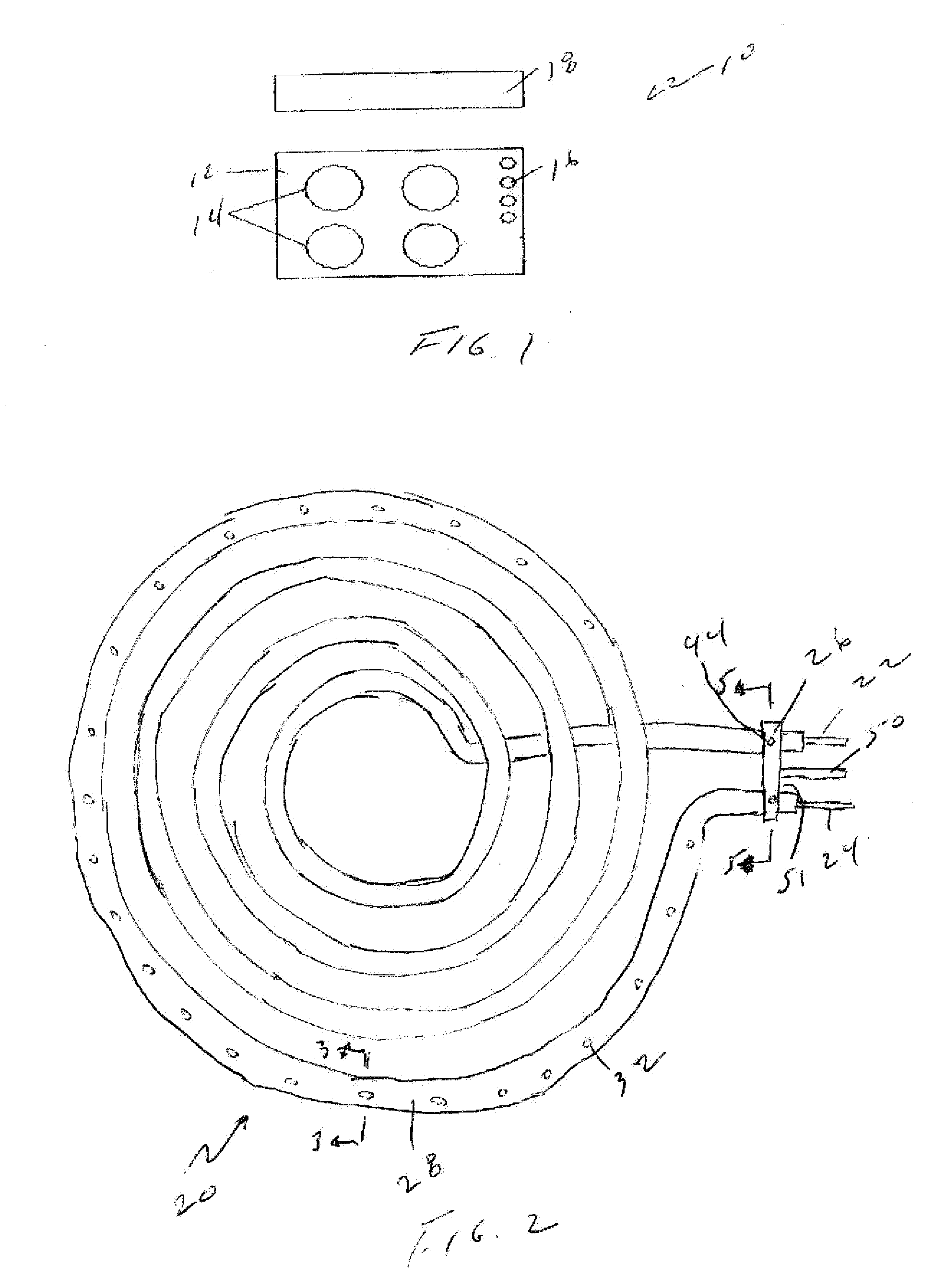

Method and apparatus for quickly cooking comestibles

ActiveUS9545168B2Maximize cooking without losing significant nutrients of the comestiblesConcern for seepage is reducedBoiling over preventionWater-bath cooking vesselsRadio frequency energyThermodynamics

Steam heating used with conventional heating techniques achieves a rapid boiling point. An intelligent electronic control system which uses sensors placed at various points in the system to monitor and / or control cooking, interacts with the Internet to determine cooking steps, powers embedded electronics in vessels by RF energy, and adjusts the heating temperatures of the contents of the vessel as a function of time. A stove will provide configurable tubes with a coupling unit at their end to attach various steam wands easily moved into position that provide this steam to vessels placed on a grill. Delicate cooking of comestibles can be achieved by maintaining a controlled temperature or cycling the temperature to maximize cooking without losing significant nutrients of the comestibles. Small coupling holes introduce steam at the bottom surface of a vessel to efficiently cook comestibles. The coupling holes have a radius which stratifies the Young-Laplace equation.

Owner:TRACKTHINGS

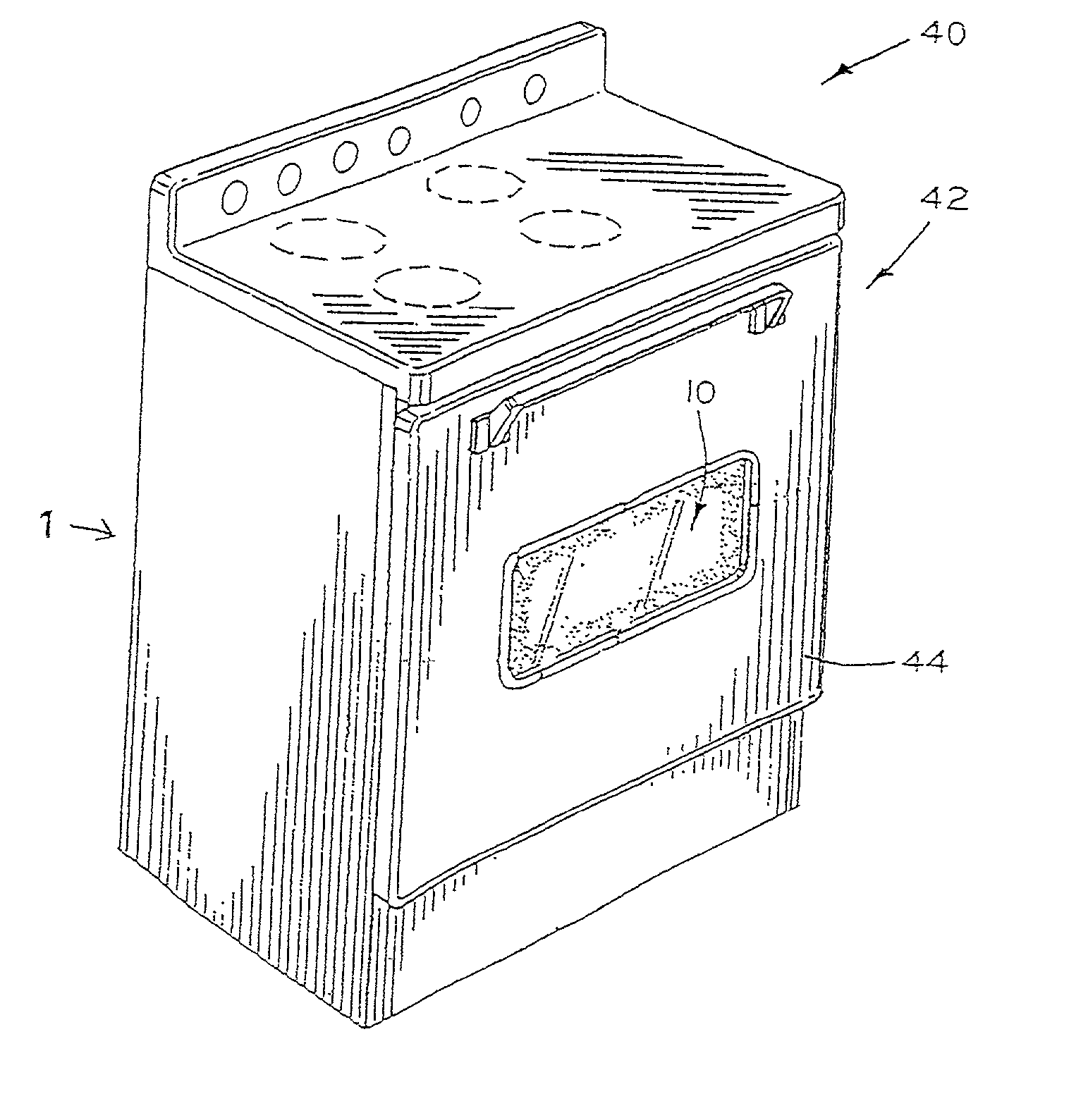

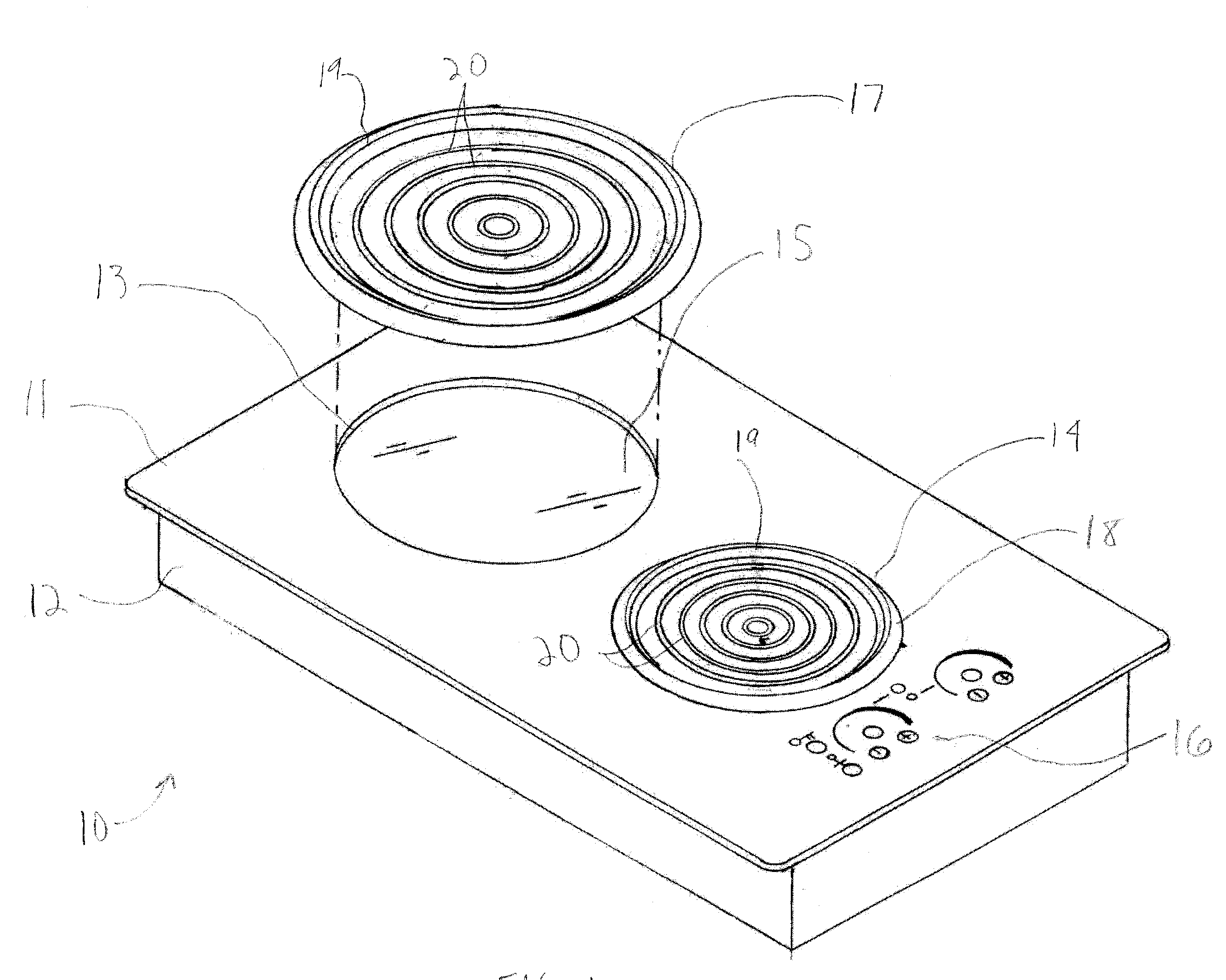

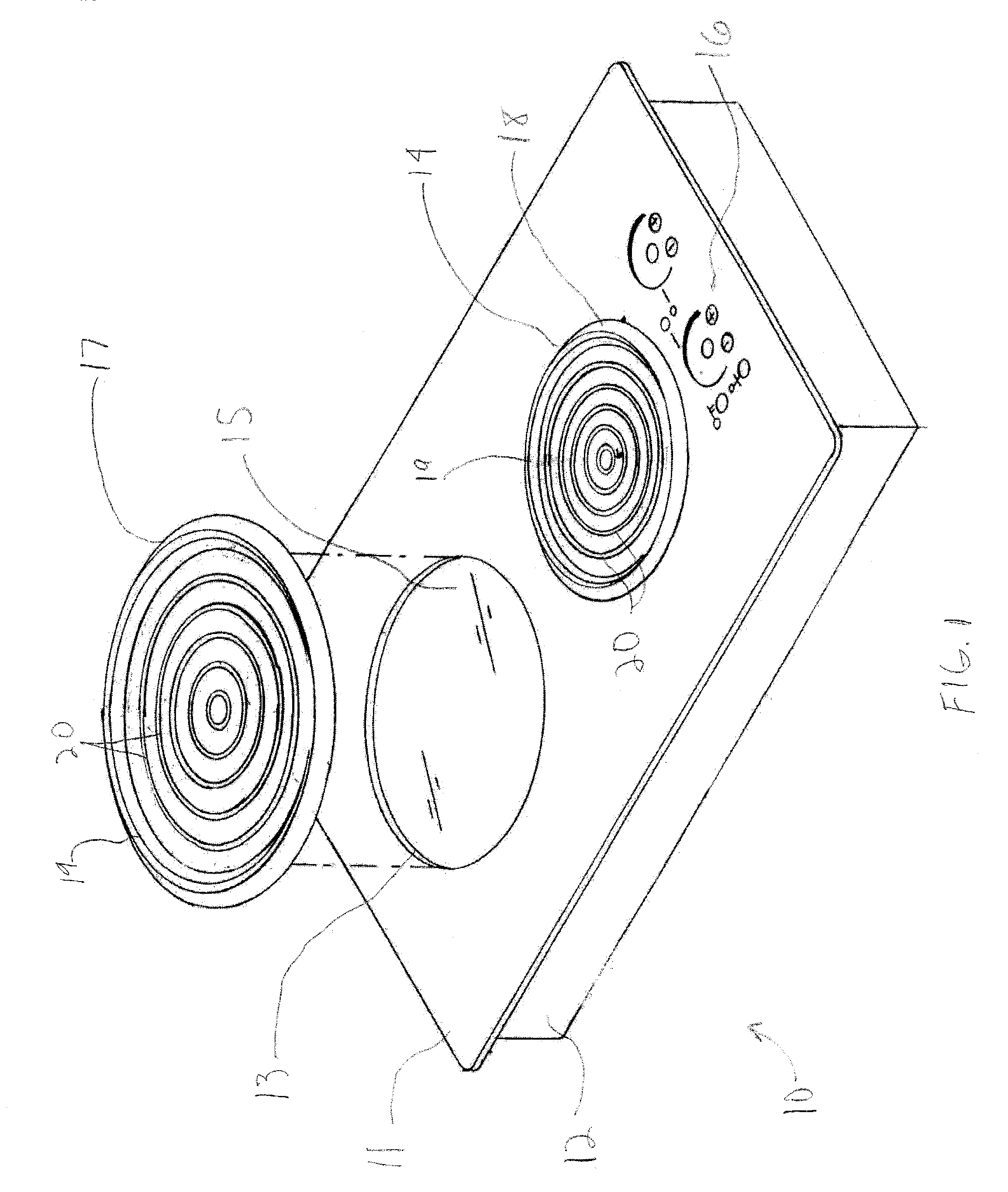

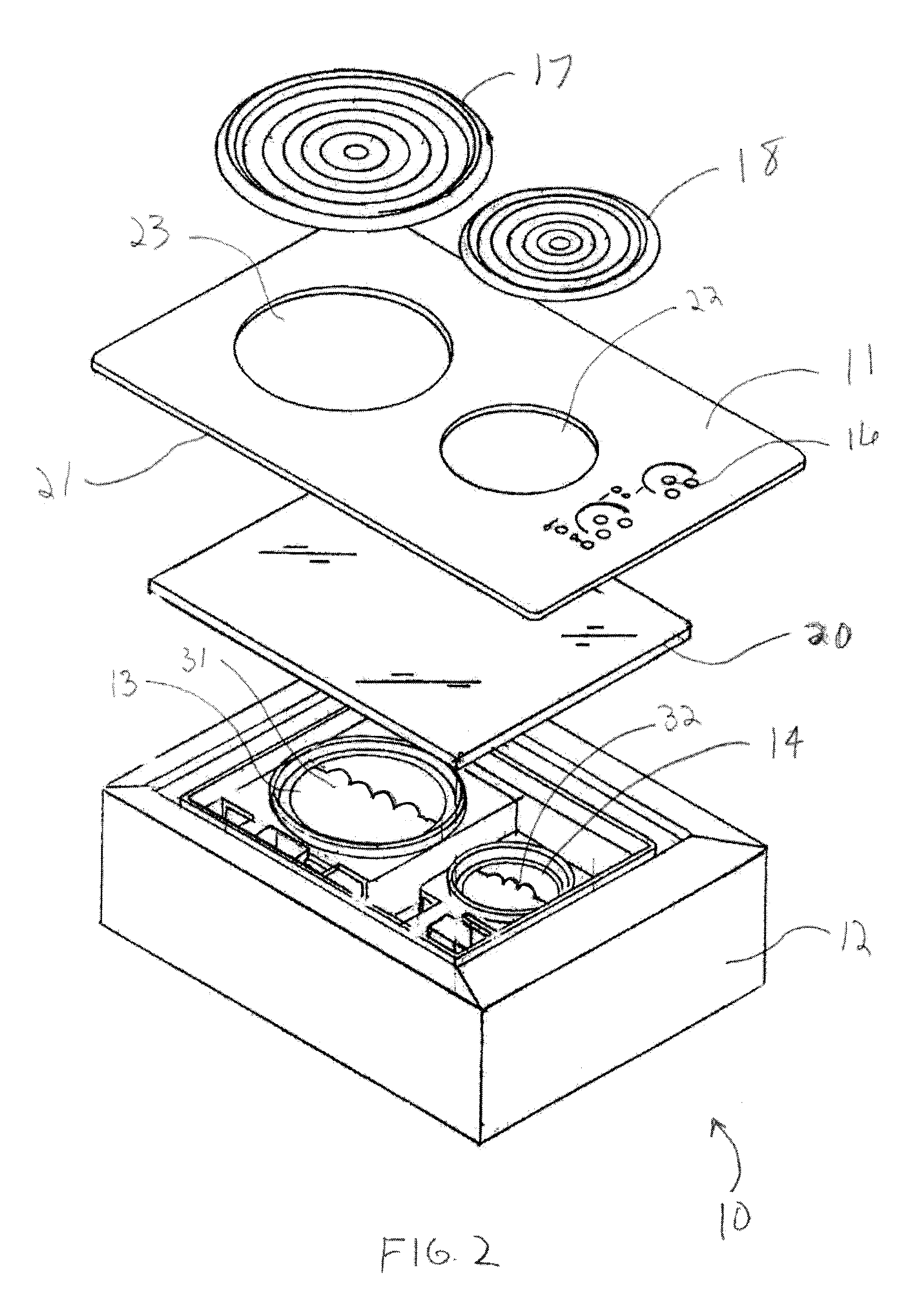

Cooking stove and method for production and components thereof

InactiveUS6930289B2Easy to implementPromote absorptionDomestic stoves or rangesDoors for stoves/rangesProcess engineeringIndustrial engineering

A cooking stove having a cook top, or hob, for cooking food, components thereof, and method of production. The stove has a stove body, a smooth-top cook top with a cooking surface to cook food thereon, and a heat source disposed adjacent to the cooking surface. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, the abstract is not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:SCHOTT AG

Cooking stove having a smooth-top glass ceramic cooktop, and a smooth-top glass ceramic cooktop with a glass ceramic cooktop cooking surface, method for production of stoves with smooth-top glass ceramic cooktops and smooth-top glass ceramic cooktops

InactiveUS20020026932A1Easy to cleanStoves/ranges foundationsLighting and heating apparatusGlass-ceramicCook stove

There is disclosed a stove, with a smooth-top cooktop, for cooking food, the stove comprising: a stove body; a smooth-top cooktop to cook food thereon; and at least one heat source disposed adjacent to a cooking surface of said cooktop. The cooktop comprises glass ceramic with an upper layer and an inner layer, with the upper layer comprising a different glass ceramic material than the inner layer. The upper layer is configured to minimize surface defects such as fissures, cracks, pits, and pores. The inner layer is configured to provide resistance to impact to the upper layer from cooking utensils being dropped onto the upper layer of the smooth-top cooktop, and at least the inner layer of the glass ceramic being configured to obscure visibility of the at least one heat source, through the upper layer of the glass ceramic.

Owner:SCHOTT AG

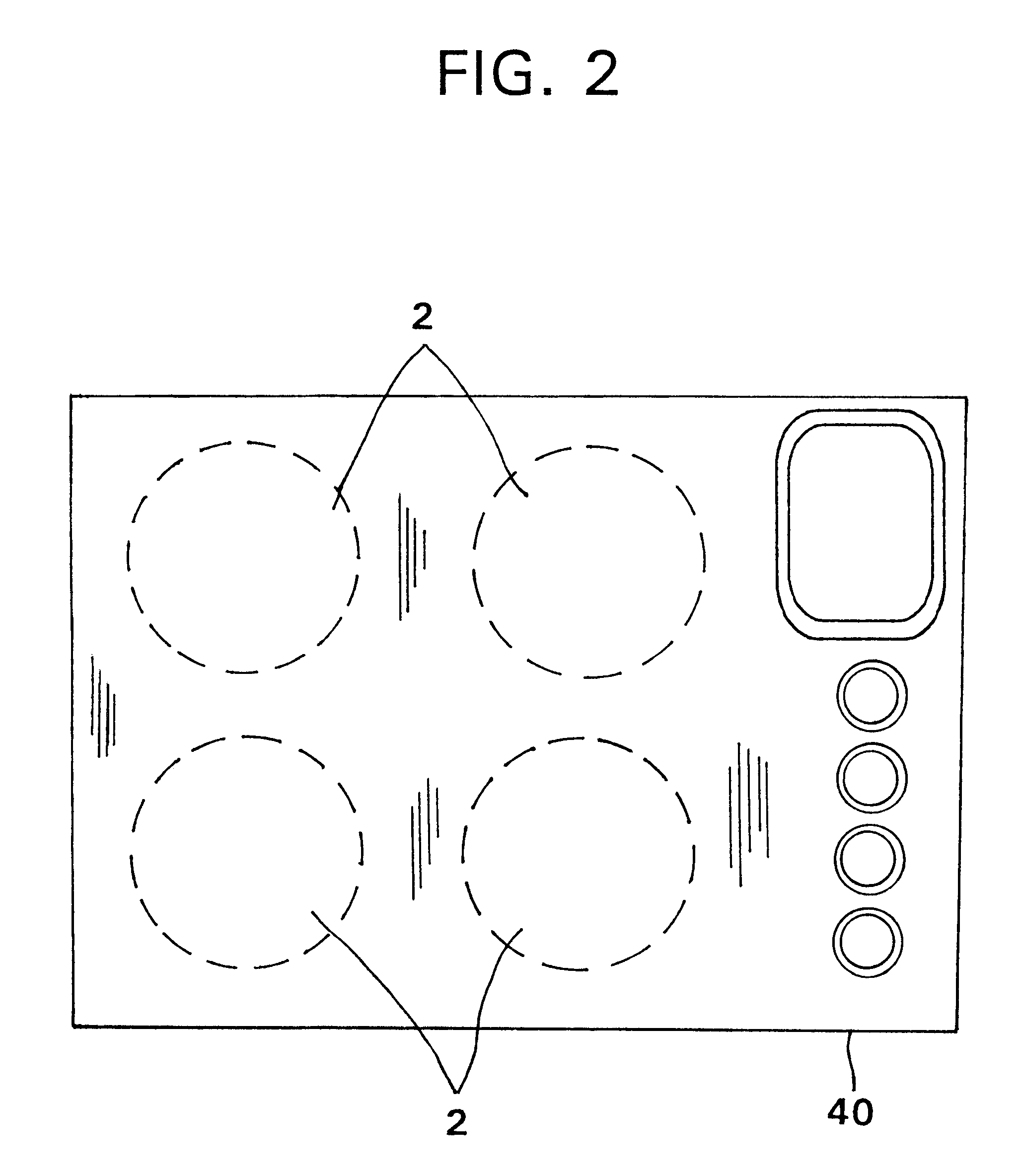

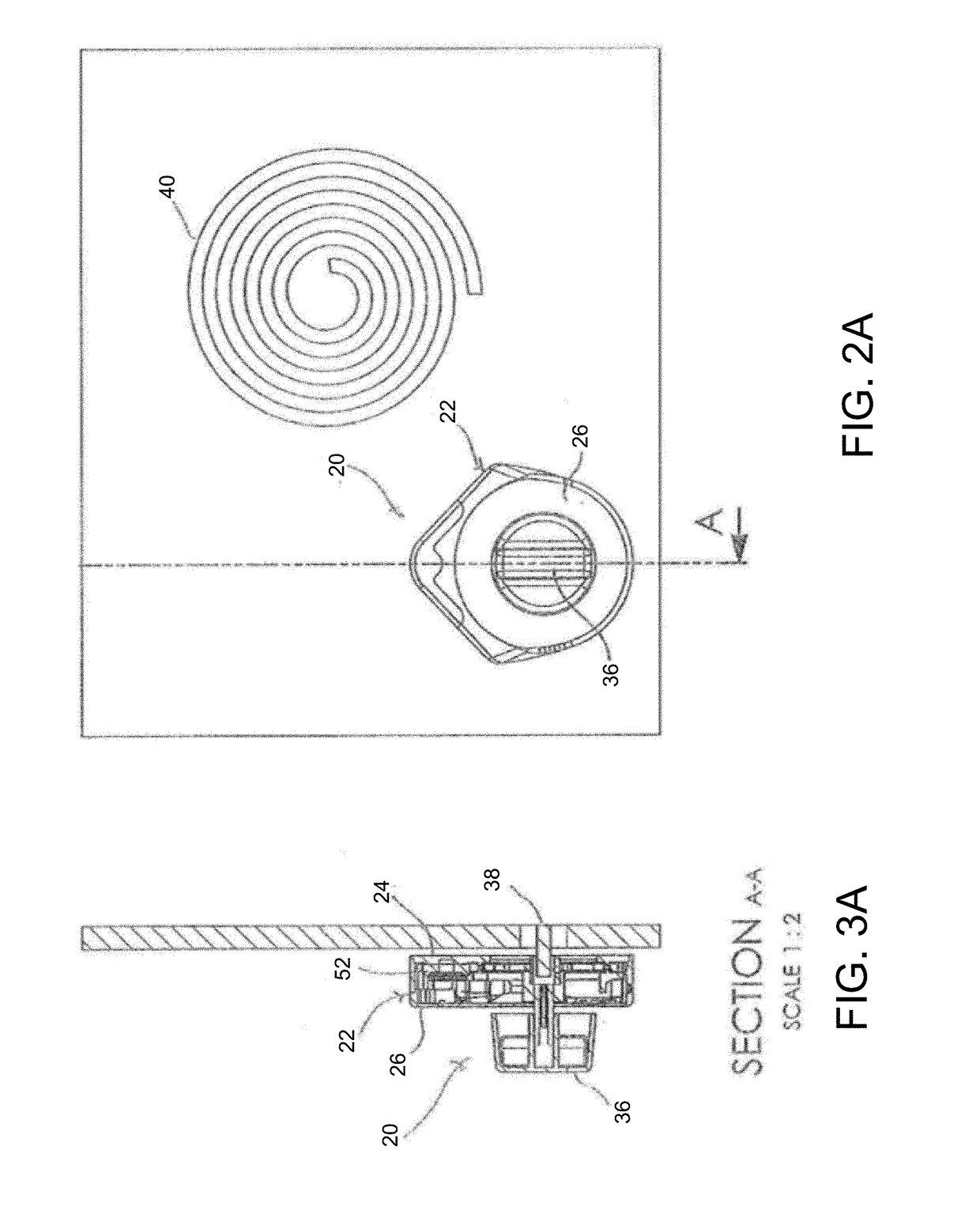

Induction Cook-Top Apparatus

ActiveUS20090289054A1Improve convenienceImprove securityMetal working apparatusElectrical componentsEngineeringProcess engineering

An induction stove assembly that utilizes pads between the cook-top of the stove and cooking vessels placed on the stove for heating. The pads are easily removable and interchangeable with other similar pads. The pads help protect the cook-top from damage, make clean-up more efficient, and insulate the cook-top from excessive heating.

Owner:KENYON INT

Egg, omelets and the like cooking method and apparatus

InactiveUS20020041920A1The process is convenient and fastCost effectivenessCooking-vessel materialsMilk preparationMicrowave ovenProcess engineering

A novel apparatus and method for cooking eggs or similar meals on a stove or in a microwave oven is provided. The cooking device enables users to cook a variety of egg type meals. The device provides the user with a manner to quickly and easily create omelets or scrambled type meals by mixing the eggs, or the like. The device provides an easy and neat manner to create "sunny side up" eggs, or the like.

Owner:PRODS OF TOMORROW

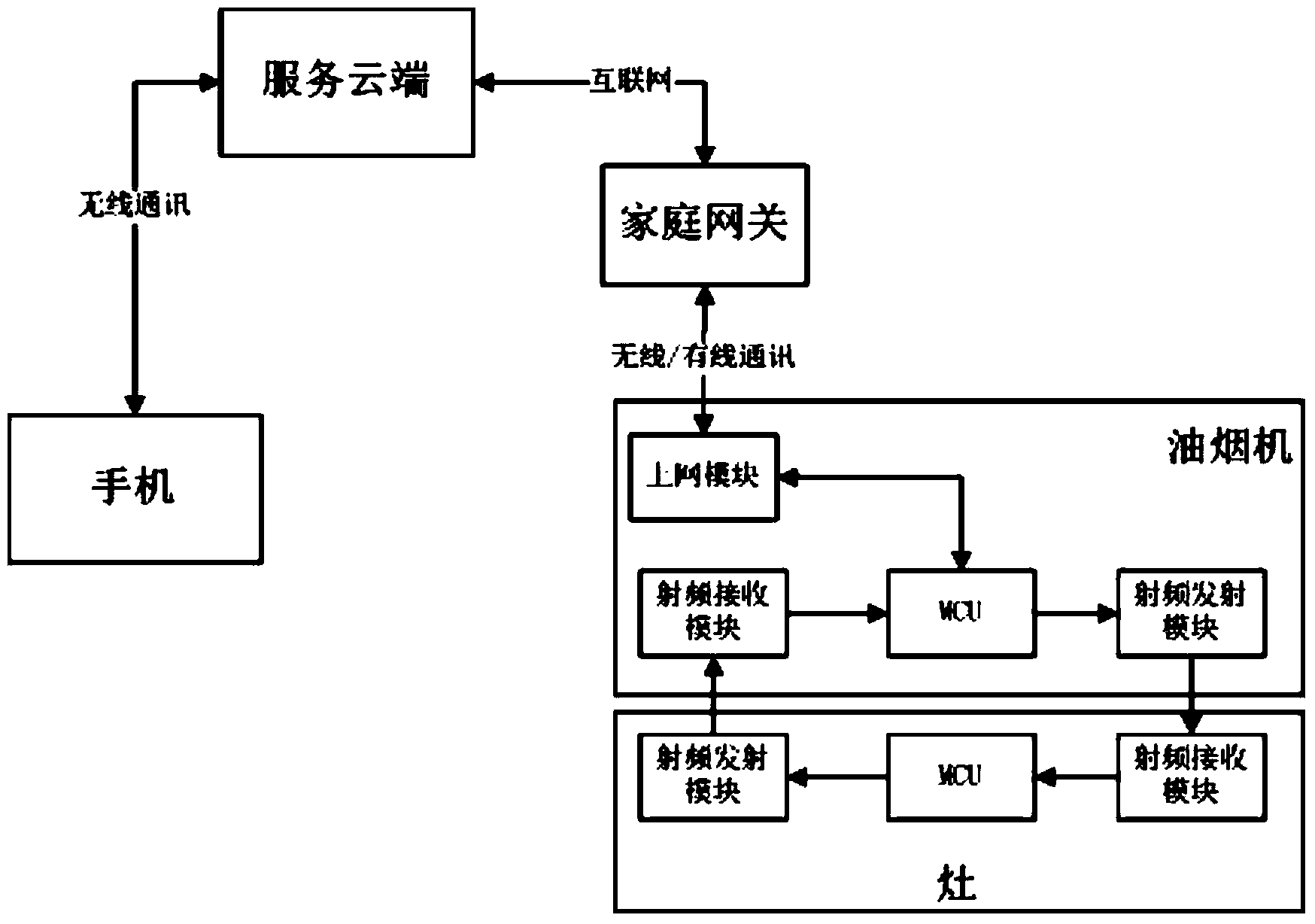

System and method for monitoring range hood and cooking stove in remote mode based on mobile phone

InactiveCN104298203ARemote monitoring of working statusImprove securityDomestic stoves or rangesLighting and heating apparatusUser needsEngineering

The invention relates to mobile phone remote monitoring technologies, and discloses a system and method for monitoring a range hood and a cooking stove in a remote mode based on a mobile phone. The range hook and the cooking stove can be monitored according to needs in a remote mode, or the working state of the range hook and the working state of the cooking stove can be controlled in a remote mode, and therefore the using safety of fuel gas is improved. According to the system and method, when a user needs to conduct state inquiry or control on the range hood and / or the cooking stove, a control instruction is sent to a cloud server, the cloud server inquires the range hood matched with a mobile phone terminal, the control instruction is forwarded, the range hood sends the control instruction specific for the cooking stove to the cooking stove through a radio frequency emission module, the cooking stove feeds information back to the range hood according to the control instruction, after the range hood conducts corresponding operation according to the instruction specific for the range hood, the state information of the range hood and the feedback information of the cooking stove are together sent to the cloud server, and then the cloud server sends the information to the mobile phone terminal. The system and method are suitable for conducting remote monitoring on the range hood and the cooking stove in a family.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

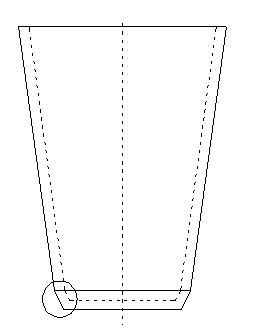

Wet process for building 3t intermediate frequency electric furnace

The invention relates to a wet process for building a 3t intermediate frequency electric furnace. By the process, 3t of materials can be melted, and the service life is prolonged. The process comprises the following steps of: (1) manufacturing a steel crucible die which has a shape of a truncated hollow cone; (2) paving an insulation layer and a thermal insulation layer by using two layers of asbestos cloth; (3) paving a furnace bottom, namely paving two layers of asbestos cloth at the furnace bottom in a staggered mode; (4) paving a furnace wall, namely paving two layers of asbestos cloth next to the inner wall of an induction coil from top to bottom, ensuring that each layer is flat and does not have any wrinkle, adhering longitudinal joints for lapping by using water glass, staggering joints of two adjacent layers, and adhering the asbestos cloth which stretches out of the upper plane to a fireproof brick plane at an upper opening of the furnace by using the water glass; (5) preparing a furnace lining material from refined quartz sand; (6) manually knotting a furnace lining, brushing a layer of water glass before filling, and tamping a filler; and (7) baking the furnace and sintering, namely baking only by using firewood after the furnace is built by the wet process, adding 50 to 60kg of firewood into a hearth for several times, and completely combusting to bake the furnace lining.

Owner:HANGZHOU ZHONGQIANG ROLLER

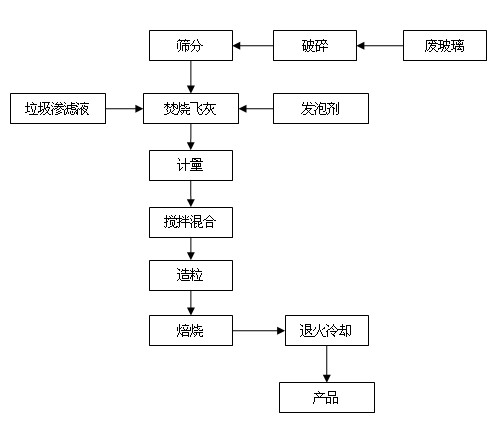

Method for preparing ceramsite by using waste incineration fly ash and waste glass

InactiveCN102643109ACause secondary pollutionEfficient curingSolid waste disposalCeramicwareFoaming agentHardness

The invention relates to a method for preparing ceramsite by using waste incineration fly ash and waste glass. The method includes the steps that waste glass is broken and ball ground to 200 meshes, and then waste incineration fly ash, rubbish leachate and a foaming agent are added according to certain proportion; and the mixture is stirred evenly, granulated and placed in a furnace to go through a pre-heating stage, a temperature rising stage and a heat preservation anneal stage to obtain the glass ceramsite. The glass ceramsite prepared through the preparation method is good in structural strength, low in water absorbing rate, large in hardness, good in chemical stability and wide in an application range. Simultaneously, dioxin pollutant in raw materials can be decomposed and damaged, heavy metal is cured in firing products, a toxic leaching standard of our country is met, and a purpose of disposing the rubbish leachate and the waste incineration fly ash is achieved simultaneously. The glass ceramsite produced through the method meets requirements of building aggregate, and the method not only turns waste into wealth, but also protects environment.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

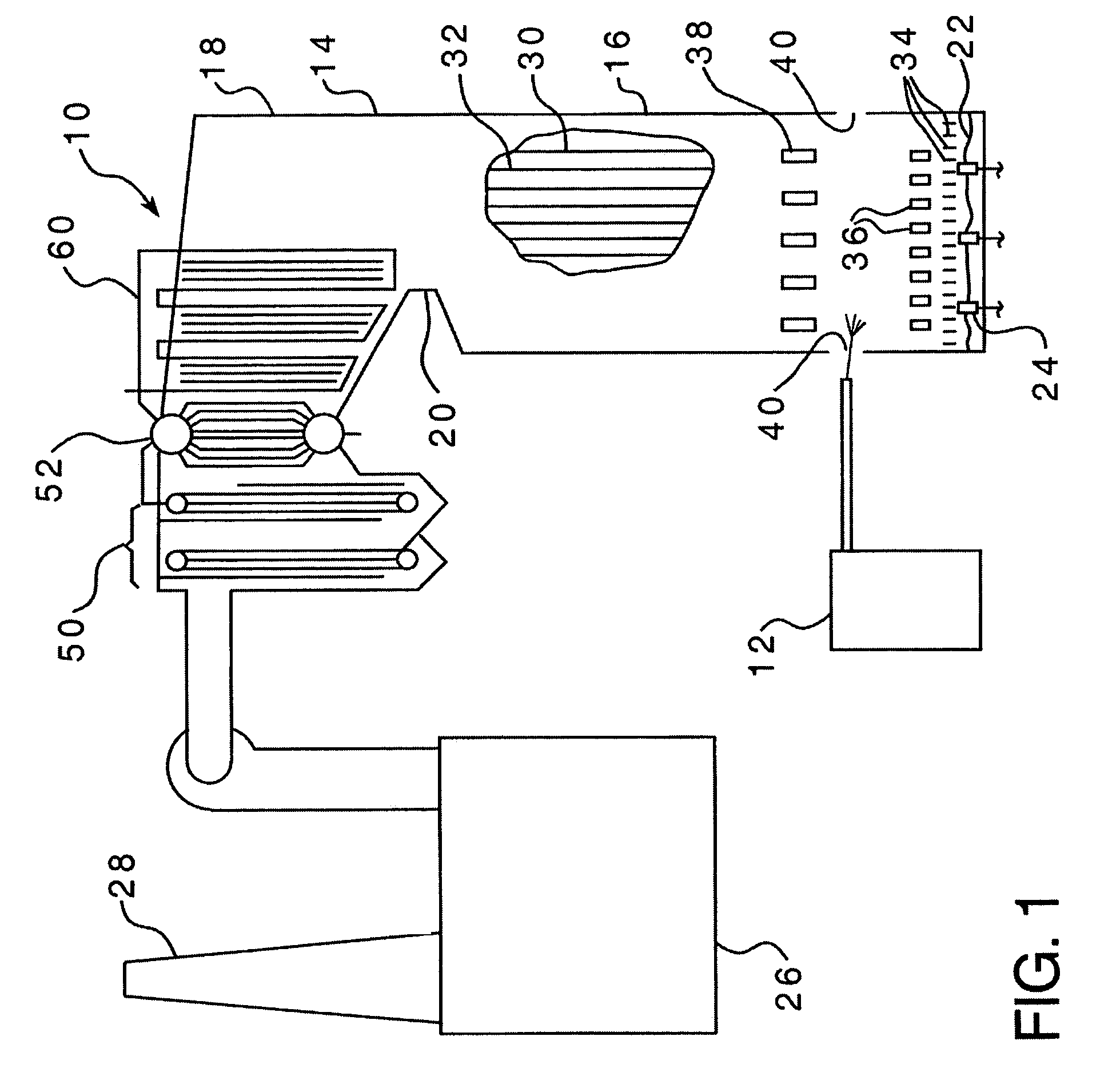

Method of managing the cleaning of heat transfer elements of a boiler within a furnace

A method of cleaning a heat transfer element within a boiler furnace is provided. The method includes the steps of allowing a furnace to operate and deposit ash on a heat transfer element, determining an efficiency rate for at least one cleaning element, and managing the cleaning element based on the efficiency rate.

Owner:INT PAPER CO

Heating method for controlling decarburization in heavy rail billet furnace

InactiveCN101967541AEnsure complete combustionReduce oxidation burnFurnace typesHeat treatment furnacesPollutant emissionsReducing atmosphere

The invention provides a heating method for controlling decarburization in a heavy rail billet furnace in a heat accumulation heating mode. The heating process comprises a pre-heating section, a heating section and a soaking section. A furnace pressure measurement point is positioned at the pre-heating section; the full furnace is controlled at positive pressure; when the billet temperature is controlled to be less than 1,000 DEG C, the atmosphere in the furnace is oxidizing atmosphere, and the air consumption coefficient is between 1.05 and 1.25; and when the billet temperature is controlledto be more than or equal to 1,000 DEG C, the atmosphere in the furnace is weak reducing atmosphere, the air consumption coefficient is between 0.9 and 1.0. Aiming at the operation and decarburizationcharacteristics of the heat accumulation heating furnace different from the traditional heating furnace, the segment control method is adopted on the control aspects of atmosphere in the furnace and temperature, and a limit low-oxygen concentration burning process is realized. The method has the advantages of low heated billet surface decarburization, low oxidized burning loss, high furnace energy utilization, low pollutant discharge, low production cost and the like, is simple, convenient and feasible, and can achieve good effect of saving materials and energy at the same time of improving the heating quality of products.

Owner:武钢集团有限公司

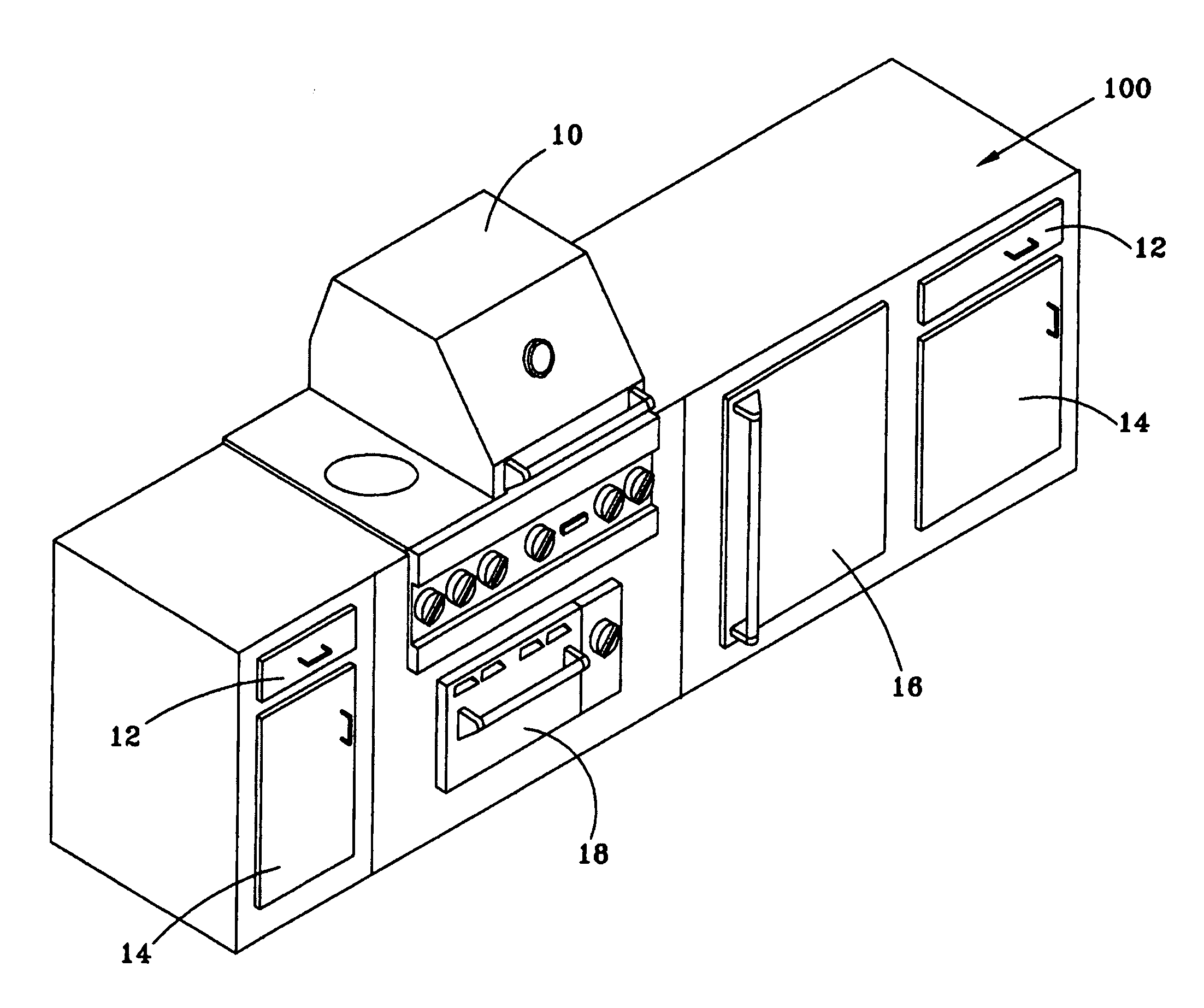

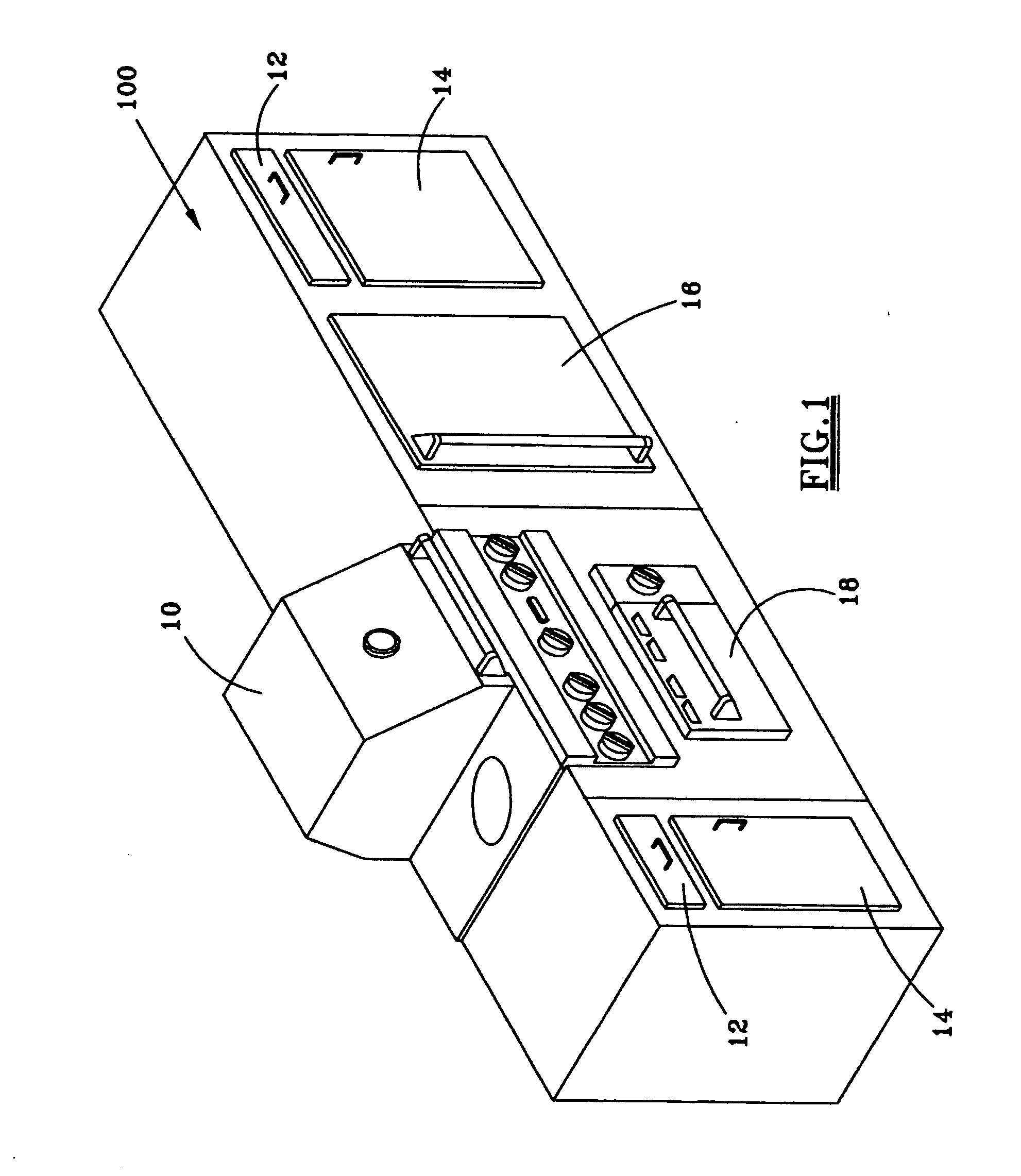

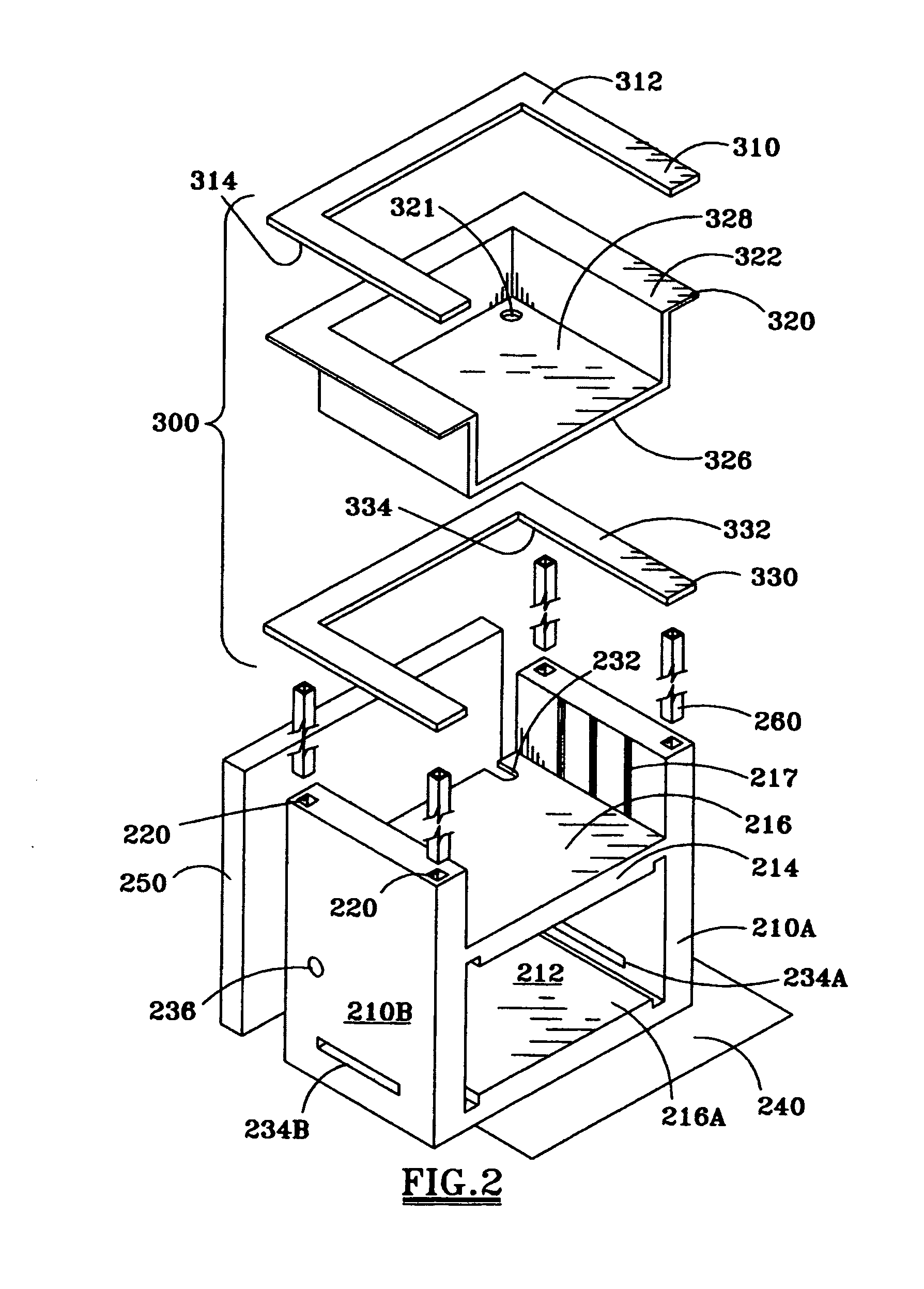

Modular outdoor kitchen apparatus and methods

InactiveUS20080163862A1Adapt to the environmentSufficient integrityDomestic stoves or rangesLighting and heating apparatusStructural loadBiomedical engineering

A unitary kitchen assembly and method is provided. A method comprises the steps of tooling an expanded polystyrene member to have circumferential surfaces and recessed surfaces, the recessed surfaces comprising a compartment for accepting a stove element, insulating the compartment in the expanded polystyrene member such that the stove element is sufficiently insulated with respect to the compartment to protect the heat integrity of the member at temperatures that the stove element operates, and providing at least one of structural load points or a urethane / quartz aggregate exterior coating for supporting the expanded polystyrene member for providing structural integrity to the member such that the member can receive weighted objects thereupon without compromising the structural integrity of the expanded polystyrene member. A unitary kitchen assembly is provided comprising an expanded polystyrene member comprising a plurality of circumferential surfaces having a plurality of extremities remote one from the other, a plurality of interior surfaces, the interior surfaces for accepting an element selected from the group consisting of shelves, refrigerators, warmers, drawers and storage spaces, and a plurality of recessed surfaces, the recessed surfaces comprising a compartment for accepting a stove element. An insulation for engaging the stove element and the compartment sufficient to protect the heat integrity of the member at temperatures that the stove element operates. And, at least one of a plurality of structural load point supports extending through the expanded polystyrene member, or a urethane / quartz aggregate exterior coating for supporting the expanded polystyrene member for providing structural integrity to the member.

Owner:OPS

Portable, self-contained stove and system

InactiveUS6293274B1Prolonged burning lifeEffective spaceDomestic stoves or rangesLiquid heating fuelEngineeringMechanical engineering

Owner:FIREFLY INNOVATIONS LLC +2

Fire suppression system

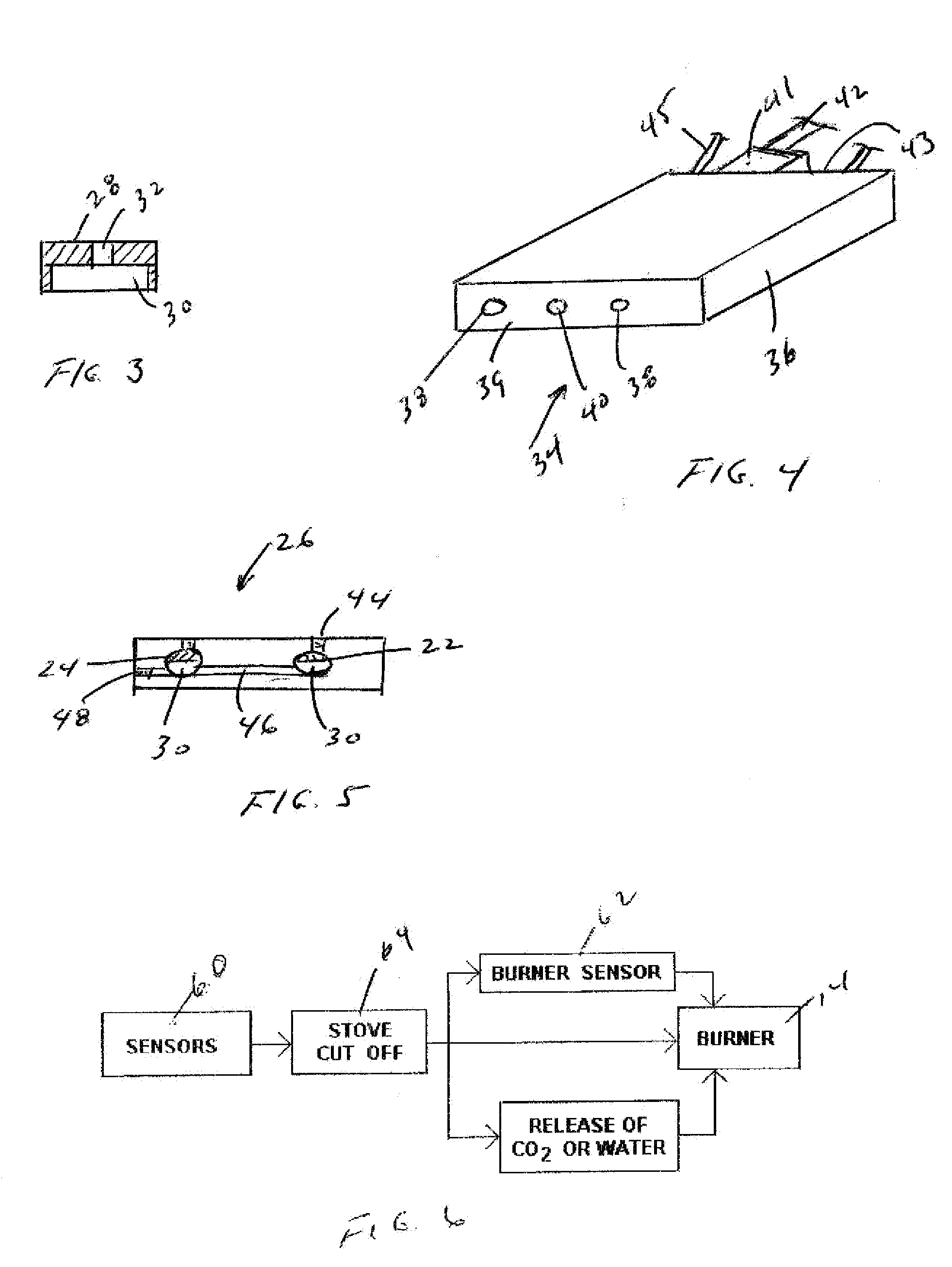

An improved fire extinguishing system for residential and commercial cook stoves and ranges includes one or more heat and / or smoke sensors connected to a control circuit. A cut-off switch activated by the heat and / or smoke sensors is provided to interrupt the flow of gas or electric power to the cook stove burners. The burners are in fluid communication with a source of a fire suppressant. Upon sensing a fire on the cook stove, fluid communication is established between the burners and fire suppressant for rapidly cooling the burners and extinguishing the fire.

Owner:HOWETH JO ANN P +1

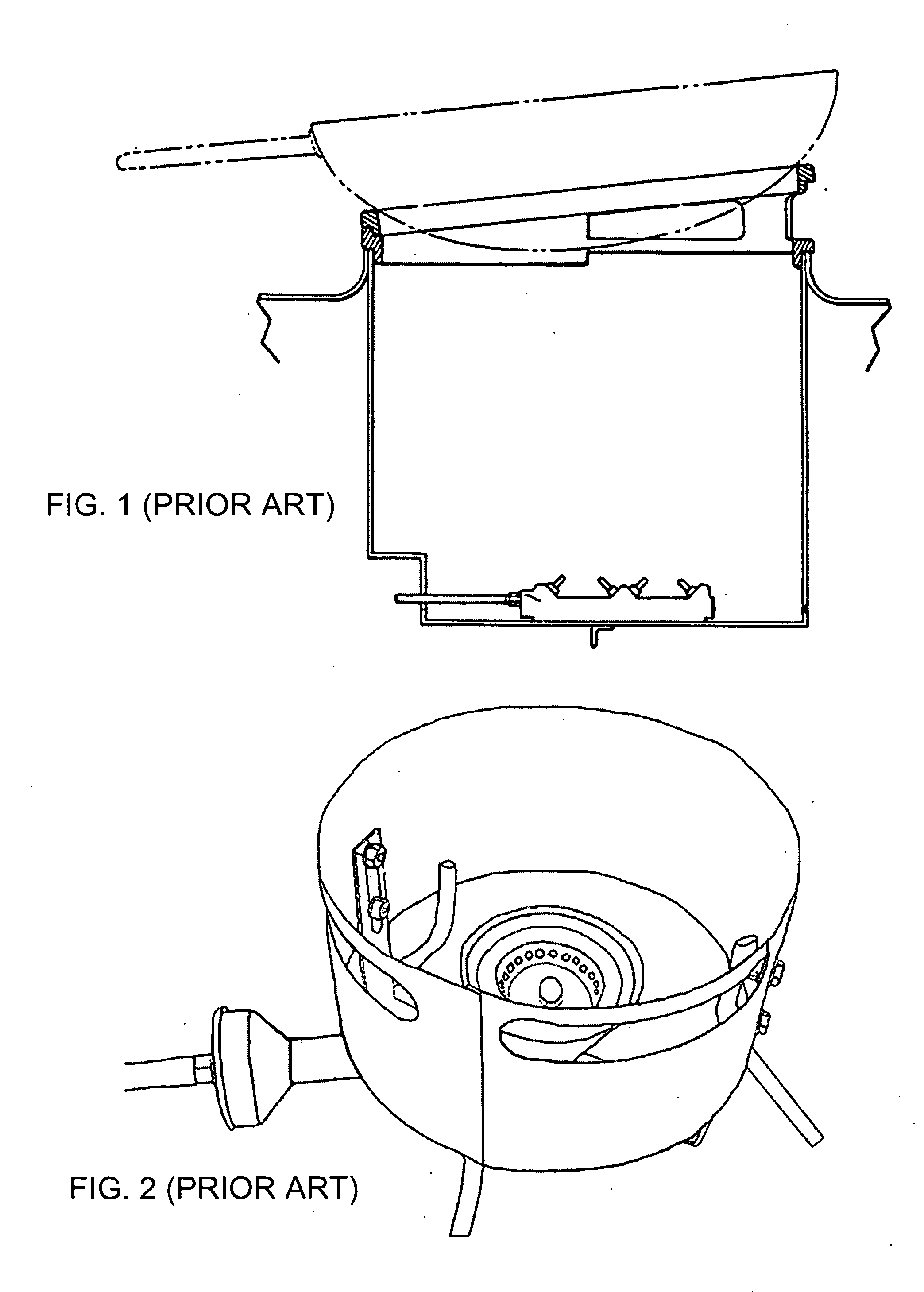

Outdoor Cook Stove

InactiveUS20100154770A1Increase powerSimple burner constructionDomestic stoves or rangesCooking fumes removalCombustorEngineering

A portable outdoor stove is provided which includes a burner primarily comprising an outer and inner pieces bolted tightly to form a small gas / air mixture chamber for accepting and maintaining high pressure gaseous fuel, a wind guard of cylinder shape capable of tightly coupled with a cooking vessel and possessing slot opening of less than 180° toward its top for exhaust outlet, adjustable means for supporting the burner and positioning flame from burner onto bottom of cooking vessel, short or long legs to support the wind guard and the cooking vessel. A protection guard can be put around the first wind guard preventing an operator accidentally touching the wind guard during cooking.

Owner:ZHOU DONGSHENG

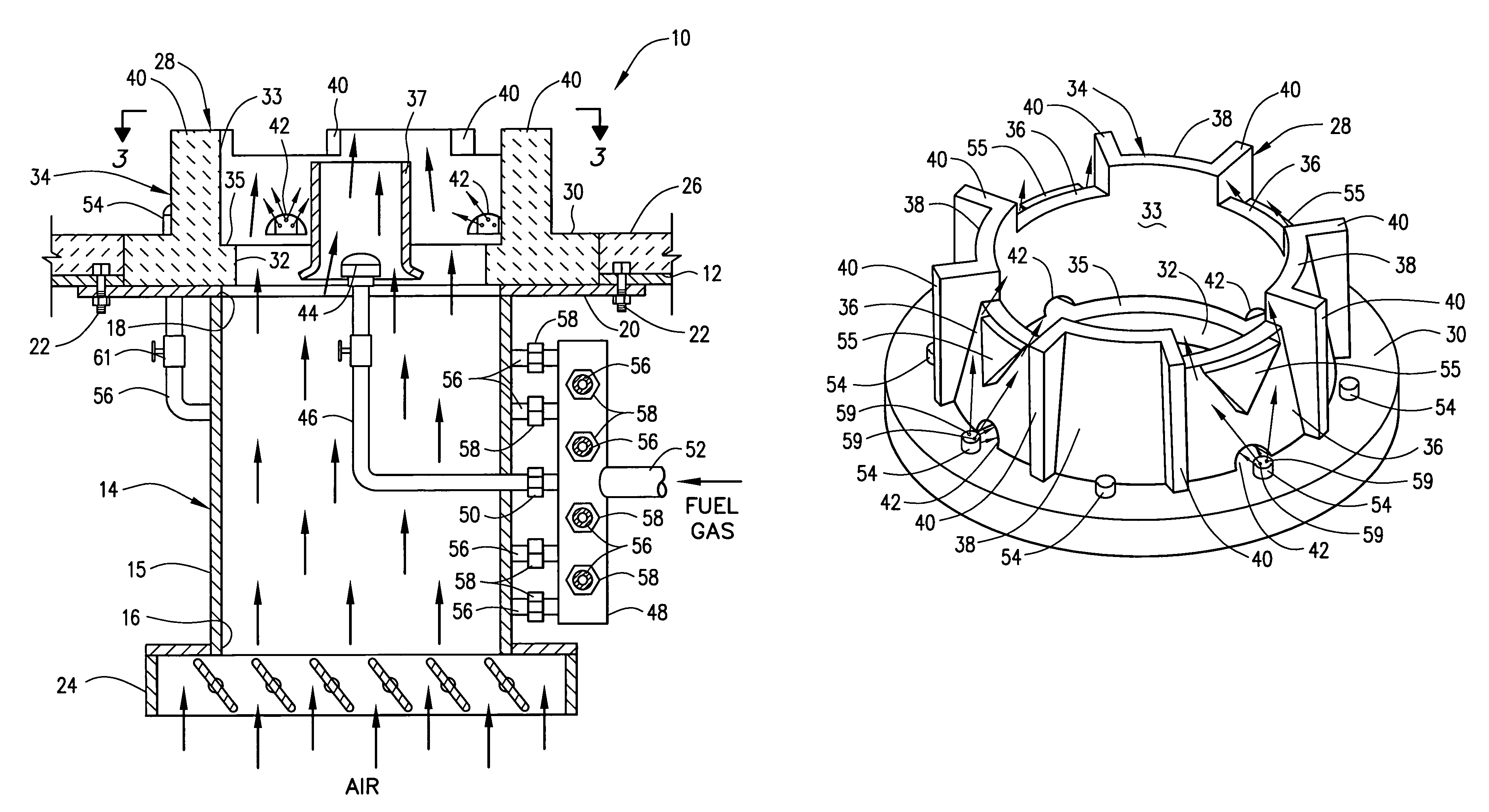

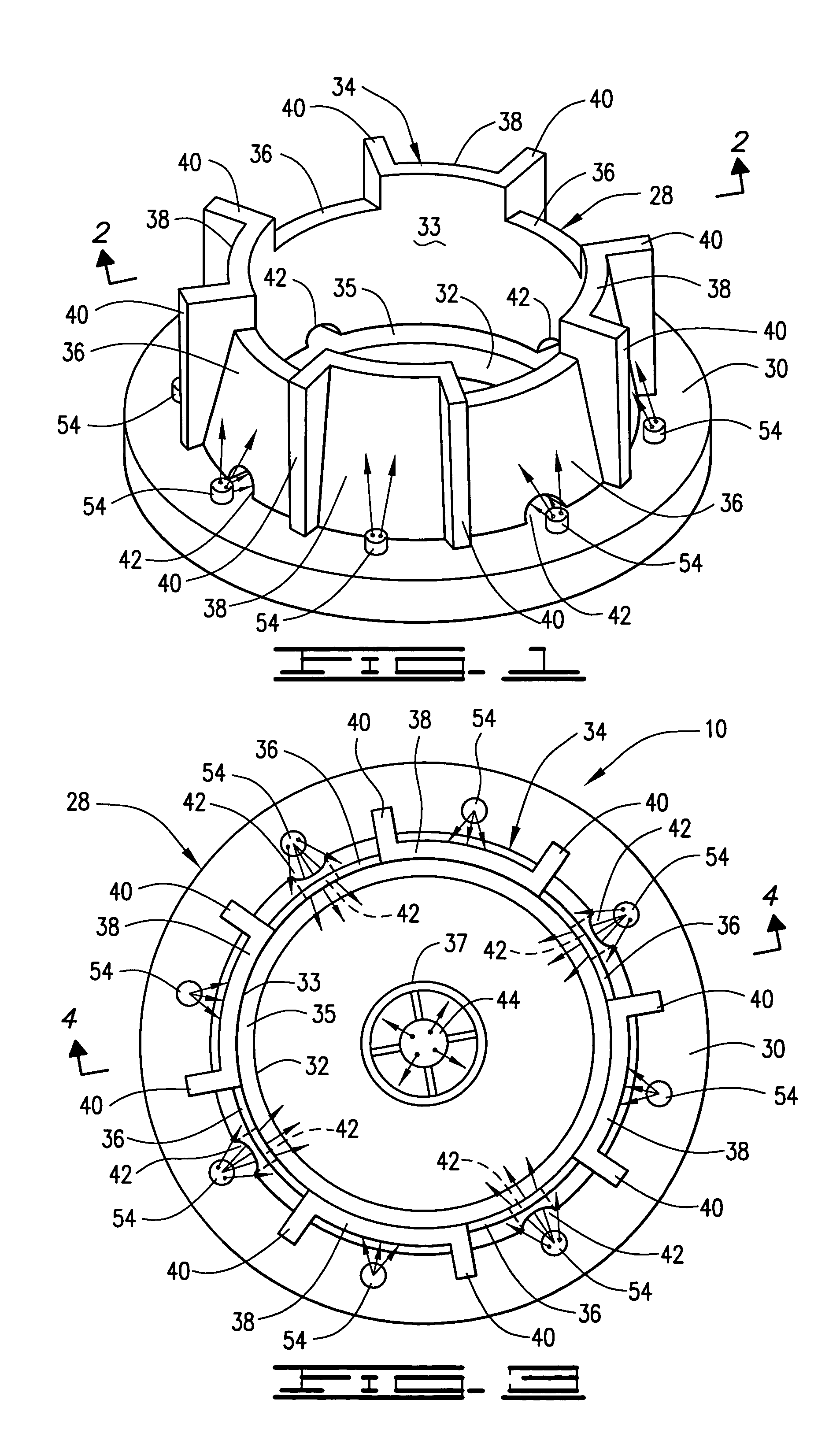

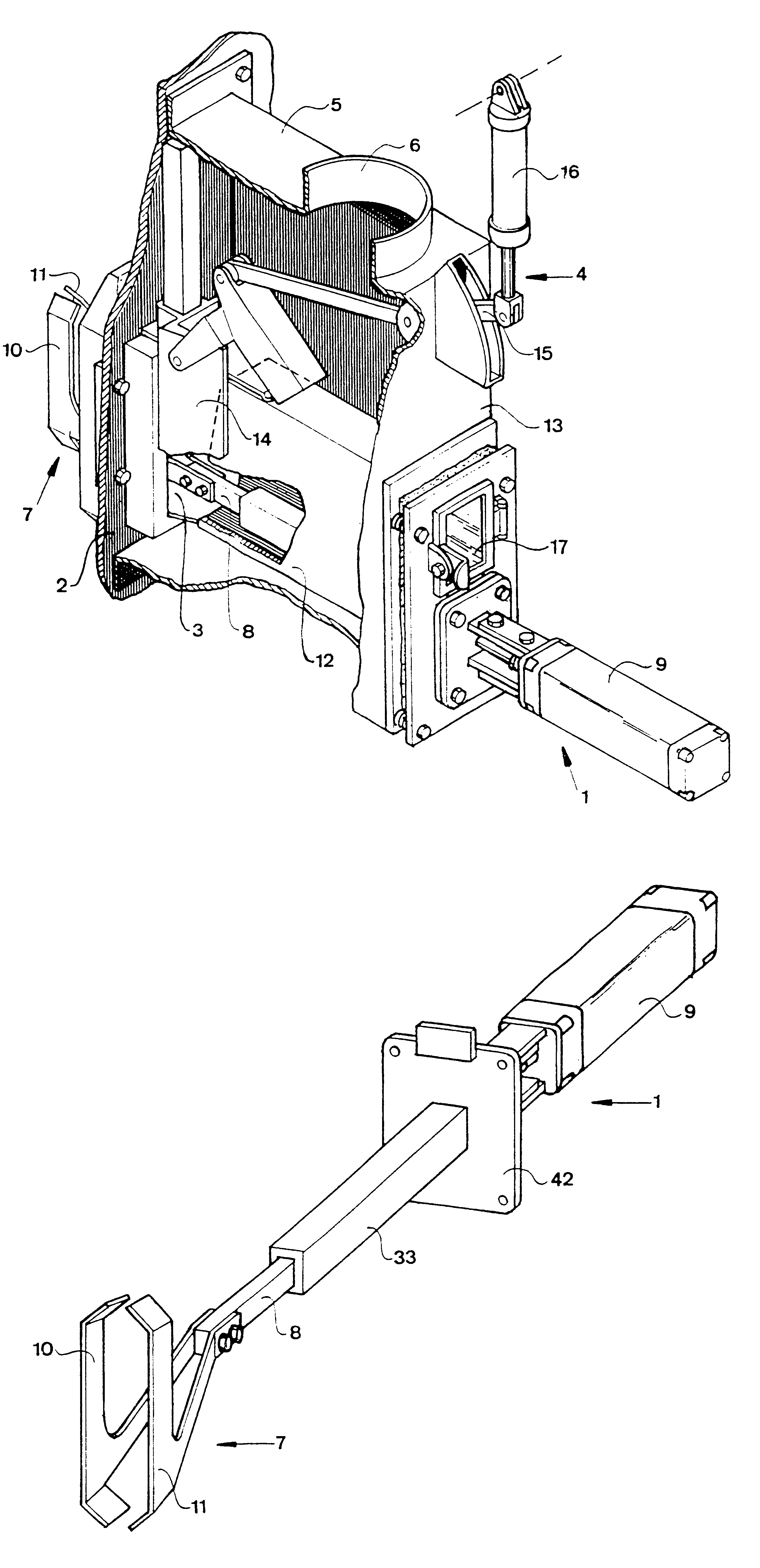

Compact low NOx gas burner apparatus and methods

ActiveUS7198482B2Increase the turndown ratioShorten the lengthCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsFlue gas

Compact low NOx gas burner apparatus and methods for discharging fuel gas and air mixtures into furnace spaces wherein the mixture is burned in folded flame patterns and flue gases having low NOx content are formed are provided. A burner apparatus of the invention is basically comprised of a housing having a burner tile attached thereto and means for introducing air therein. The burner tile has an opening therein with a wall surrounding the opening which extends into a furnace space. The exterior sides of the wall are divided into sections by radially positioned baffles with alternate sections having the same or different heights and slanting towards the opening at the same or different angles. Primary fuel gas mixed with flue gases and air is discharged through the burner tile. Secondary fuel gas is discharged adjacent to the external slanted wall sections whereby the secondary fuel gas mixes with flue gases in the furnace space. The resulting fuel gas-flue gases streams mix with the fuel gas-flue gases-air mixture discharged through the burner tile and the resulting mixture is burned in the furnace space.

Owner:JOHN ZINK CO LLC

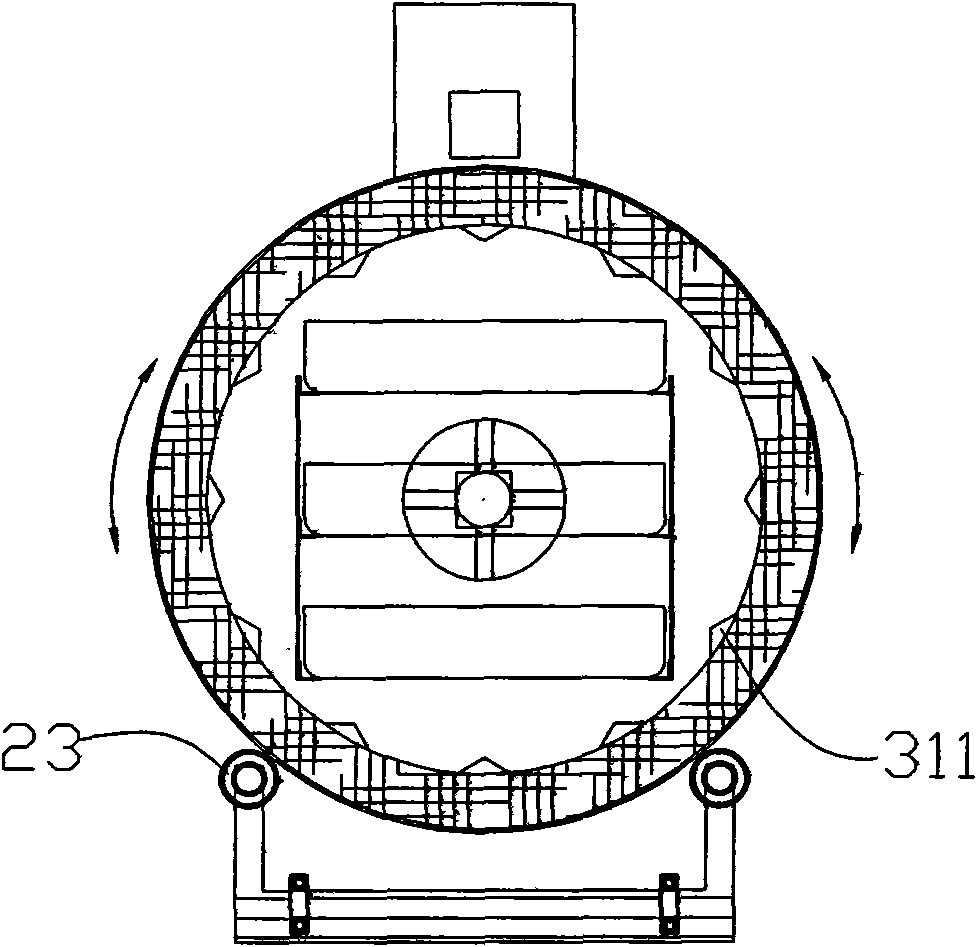

Multi-functional food cooking stove

InactiveCN101589910AReduce the human factorEnvironmental protection and energy savingCooking vesselsRoasting apparatusFunctional foodEnergy conservation

The invention relates to a multi-functional food cooking stove, which comprises a pedestal, a swing frame, a swing motor and a rotating motor, wherein the swing motor is used for driving the swing frame to swing upwards and downwards; the rotating motor is used for driving a stove body to rotate; the stove body is arranged on the swing frame and is in a hollow cylindrical shape approximately; the first end of the stove body is provided with a sealing stove door, and the second end is provided with a flange with a smoke vent and a first bearing connected with the flange; the stove body also comprises a seasoning inlet supporting pipe; one end of the seasoning inlet supporting pipe is fixed on the swing frame, while the other end extends into an inner stove; the first bearing is sleeved on the seasoning inlet supporting pipe; a heating device is used for heating the stove body; and an auxiliary device is arranged closed to the second end of the stove body and used for venting smoke and throwing seasonings and water. The stove body of the multi-functional food cooking stove can rotate and can swing upwards and downwards. The multi-functional food cooking stove is suitable for cooking various foods, integrates multiple functions, such as frying, steaming, baking, braising and the like, can produce various dishes in batches in a standardized way, and also has the advantages of energy conservation, environmental protection and the like.

Owner:马鞍山市中亚机床制造有限公司

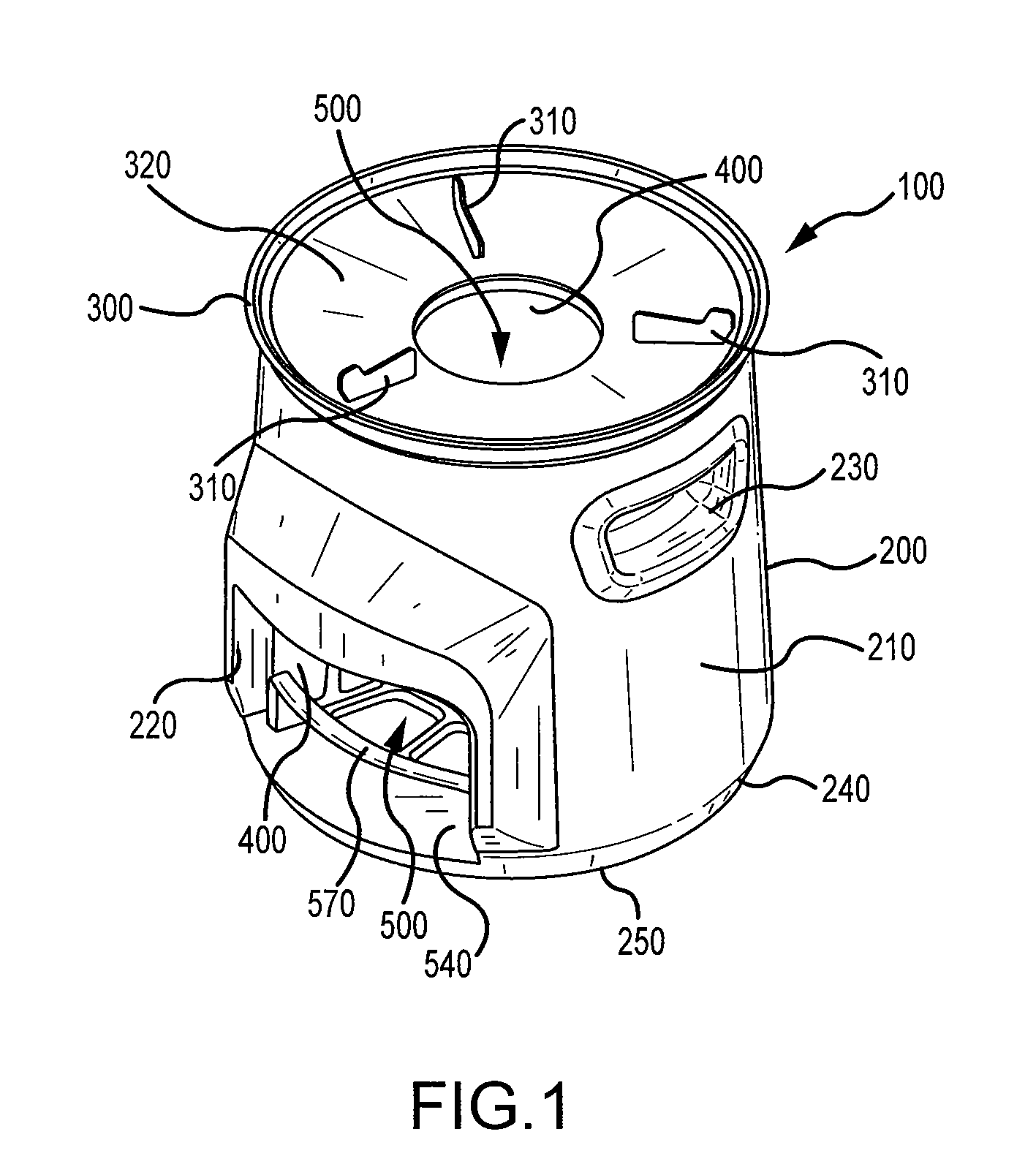

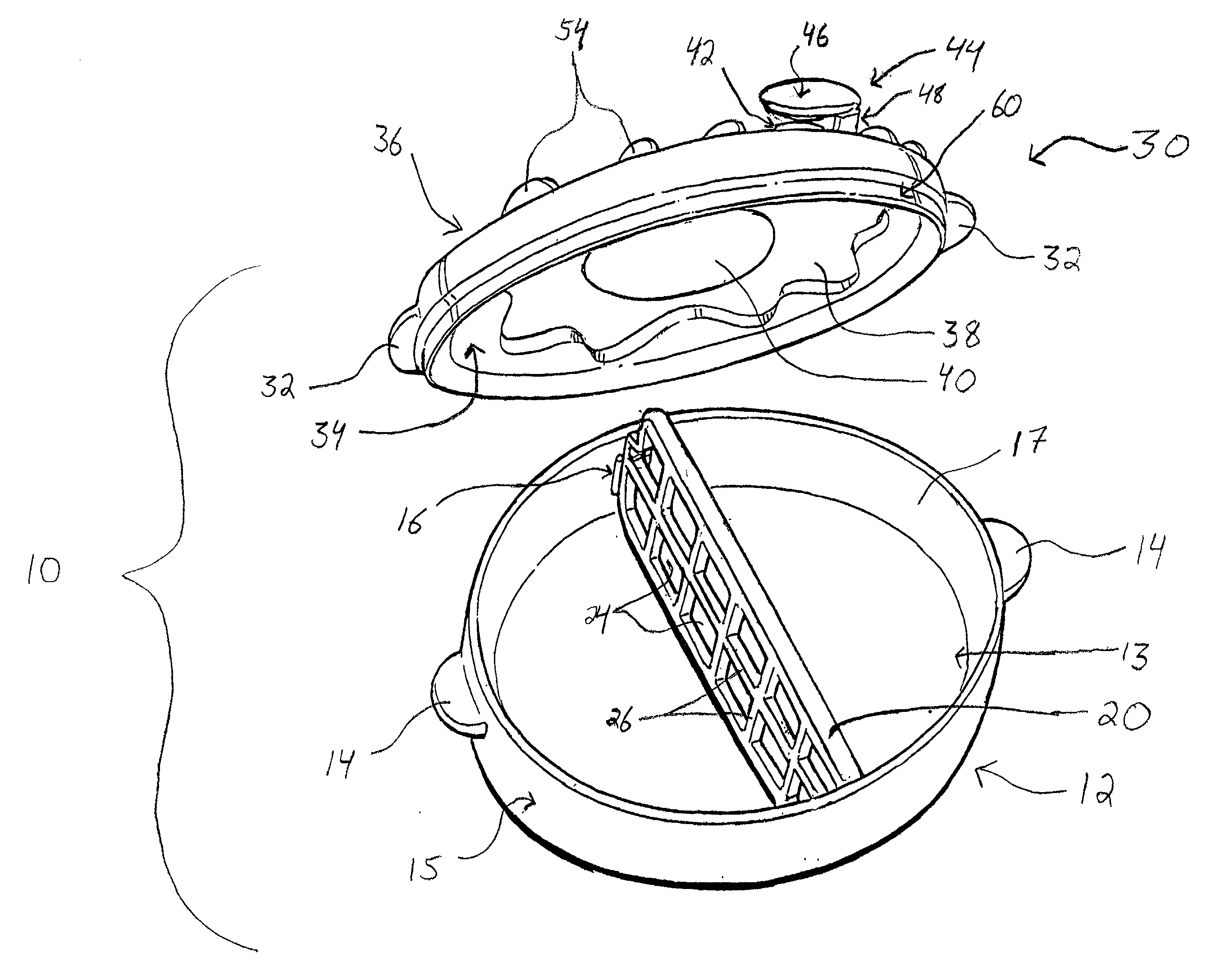

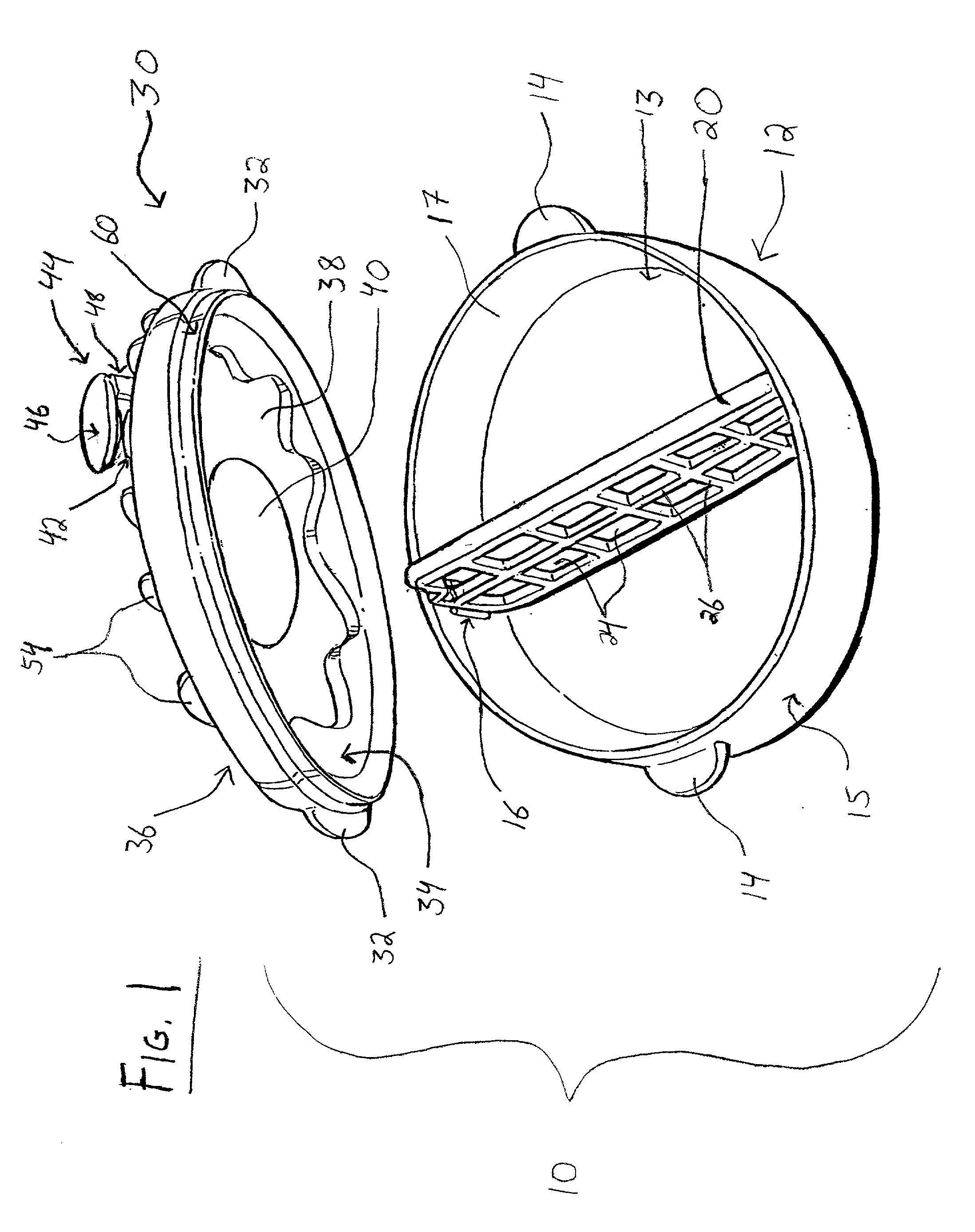

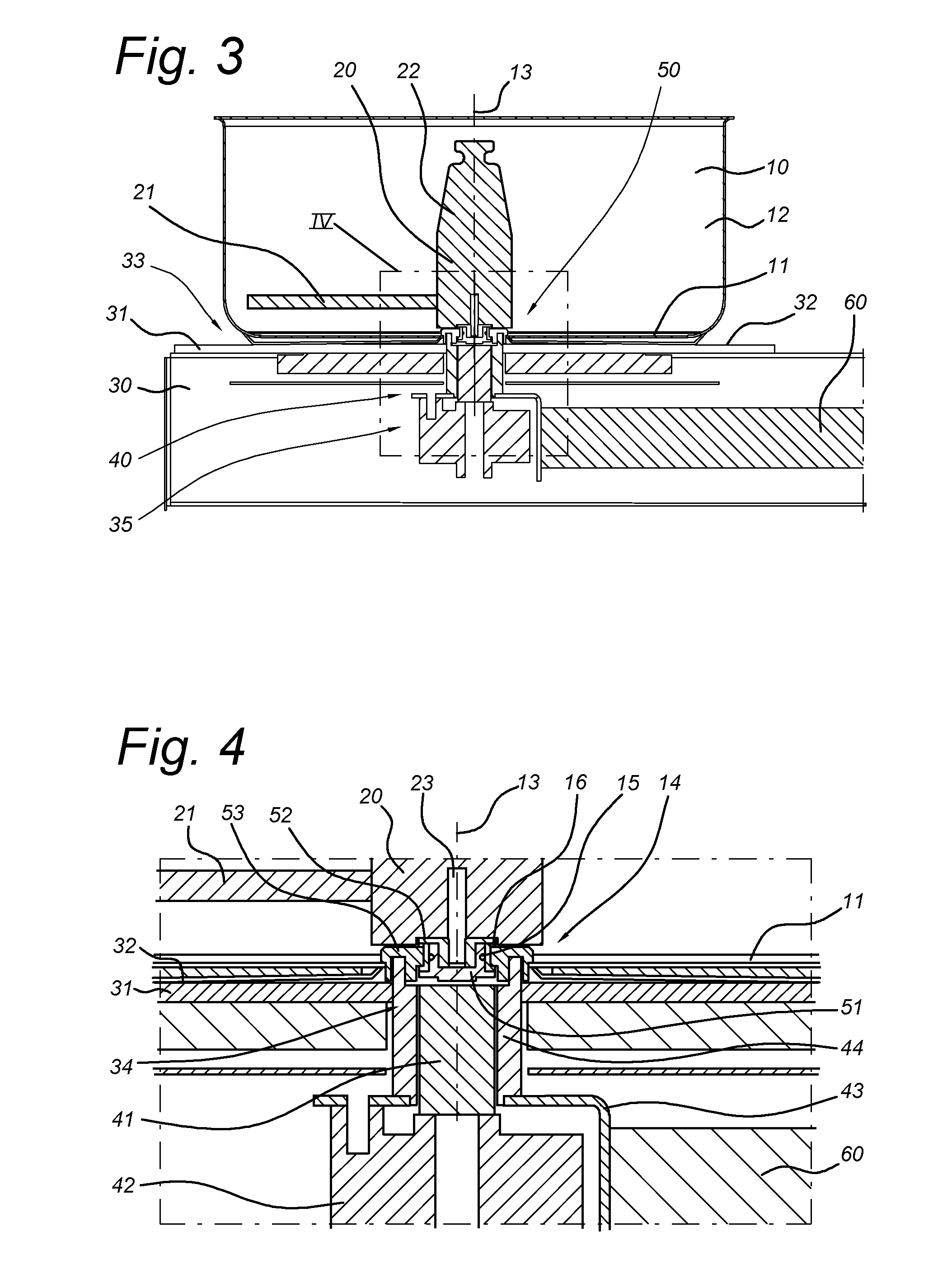

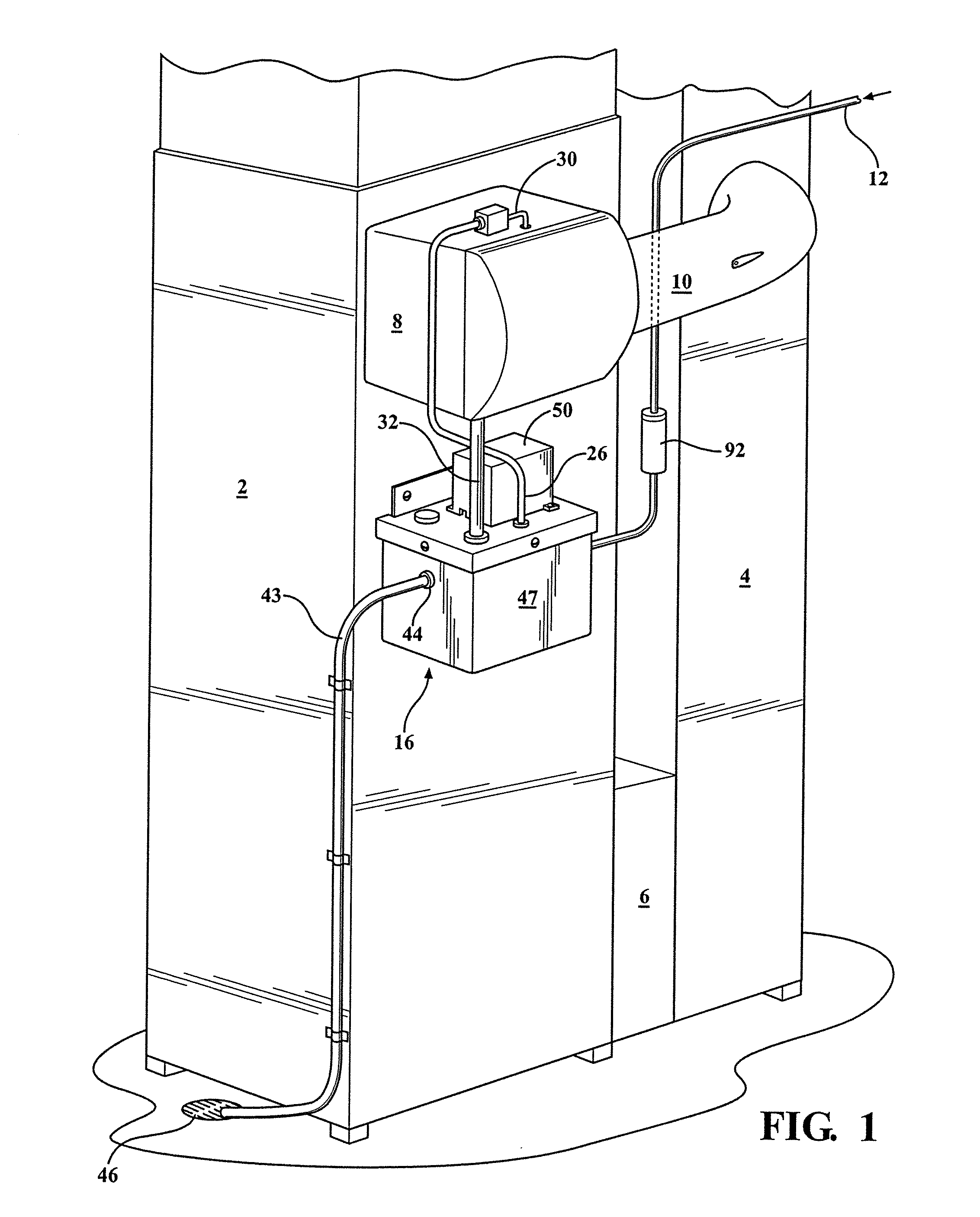

Cooking stove having a drive assembly for driving a food processing assembly in a pan

InactiveUS20150182070A1Protection from damagePrevent leakageDomestic stoves or rangesLighting and heating apparatusCouplingFood processing

A cooking stove (30) has a drive assembly (40) for driving a food processing assembly (20) in a pan (10) to be used with the cooking stove (30), wherein the drive assembly (40) is associated with a stove base of the cooking stove (30). In particular, the drive assembly (40) comprises driven movement transferring means (41) which are movably arranged in the cooking stove (30), having a coupling portion (47, 48a, 48b) which is adapted to couple to the food processing assembly (20), and pan fixating means (44) for engaging the pan (10) and thereby preventing the pan (10) from moving with the movement transferring means (41) during operation of the drive assembly (40). At least a component (41, 44) of the drive assembly (40) and at least a top component (31) of the stove base are displaceable with respect to each other in the cooking stove (30).

Owner:KONINKLJIJKE PHILIPS NV

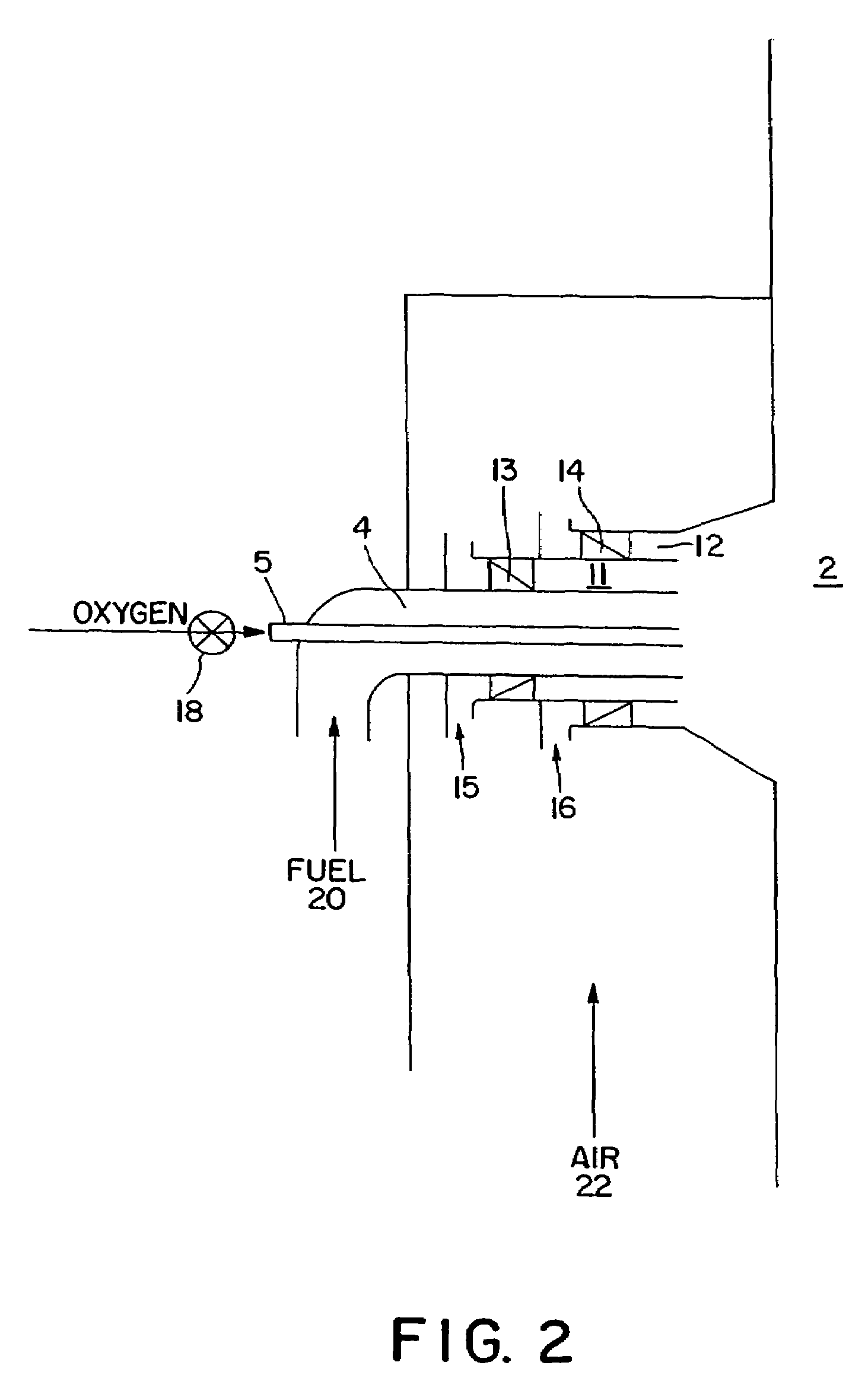

Burner system employing flue gas recirculation

InactiveUS6866502B2Reduce nitrogen oxide emissionsAccelerate emissionsDomestic stoves or rangesFluegas recirculationCombustorFlue gas

System for reducing NOx emissions from burners of furnaces such as those used in steam cracking. The system includes a furnace having at least one burner, the at least one burner including a primary air chamber; a burner tube including a downstream end, an upstream end in fluid communication with the primary air chamber for receiving air, flue gas or mixtures thereof and fuel, a venturi portion positioned between the downstream end and the upstream end, and a burner tip mounted on the downstream end of the burner tube adjacent the first opening in the furnace for combusting the fuel downstream of the burner tip; and a fuel orifice located adjacent the upstream end of the burner tube for introducing fuel into the burner tube; a source of flue gas, said source positioned so as to enable the flue gas to achieve a temperature of less than 2000° F. at least one passageway for conducting flue gas from the source to the primary air chamber; and inspirating means, the inspirating means including the venturi portion effective for drawing flue gas from the source, through the at least one passageway and the primary air chamber in response to an inspirating effect of uncombusted fuel exiting the fuel orifice, the uncombusted fuel flowing through the burner tube from its upstream end towards its downstream end, whereby the flue gas is mixed with air at the upstream end of the burner tube prior to the zone of combustion of the fuel.

Owner:EXXONMOBIL CHEM PAT INC

Automatic safety device and method for a stove

Device and method are described for operational control of a knob on a stove or range. In some examples, a safety device, a sensor relay device, and method are described for automatically positioning an operational shaft of a burner to an Off position such that the power supplied to the burner is terminated upon the occurrence of a safety event.

Owner:INIRV LABS INC

Device for regulating and cleaning an air intake

InactiveUS6431125B1Easy to checkEasy to regulateRotary drum furnacesBoiler cleaning apparatusEnvironmental engineeringMechanical engineering

Owner:LT PROD SKUTSKAR

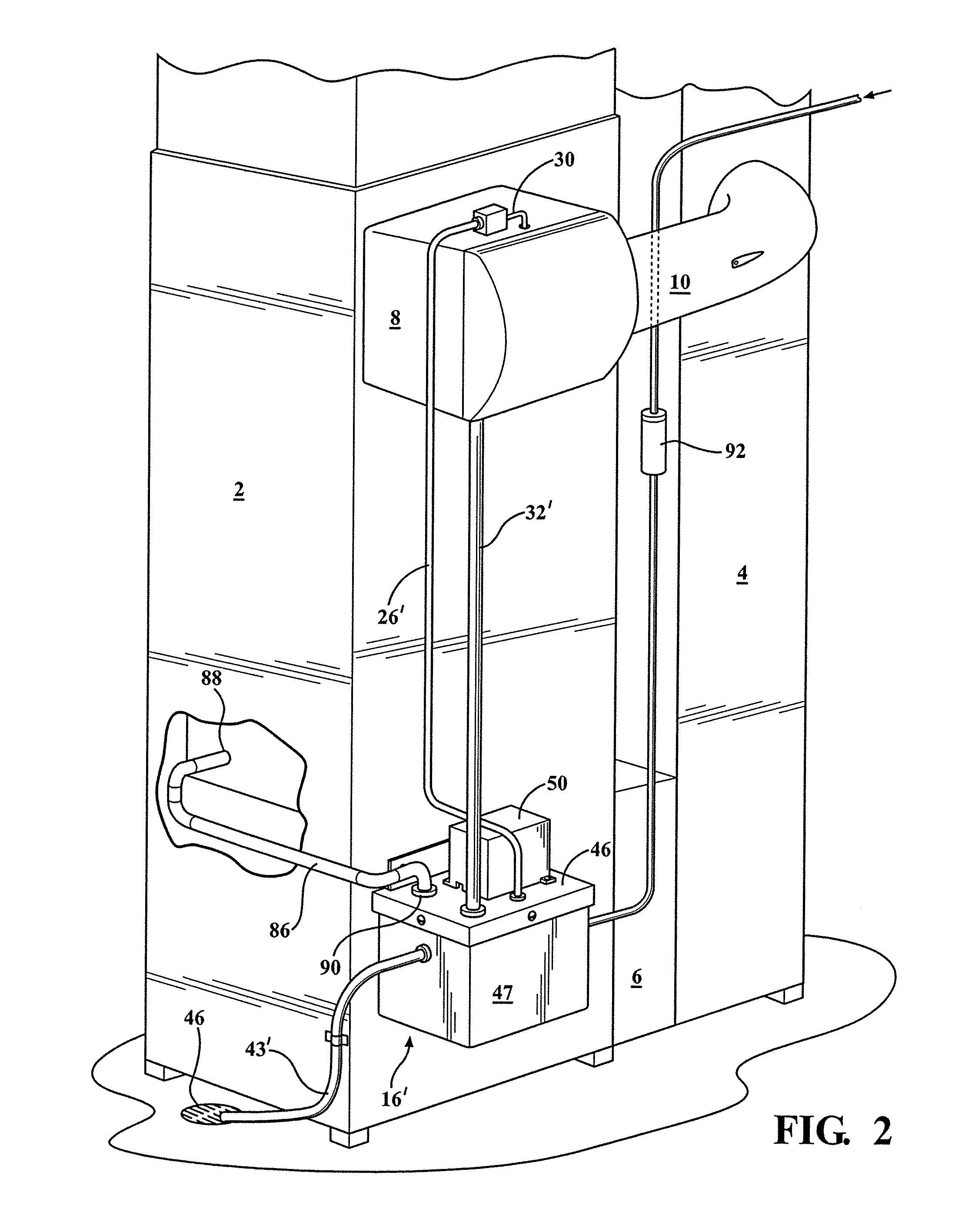

After market installable closed loop humidifier system and kit utilizing high efficiency furnace condensate water or city water inlet for humidifying an enclosed space

ActiveUS20160265795A1Low costImprove efficiencyMechanical apparatusCondensate preventionFluid supplyCook stove

A retrofit kit and assembly for establishing closed loop water supply to a humidifier associated with a furnace. A reservoir defining housing is adapted to being mounted to an external location of the furnace. A fluid supply communicates to the housing and can include either of a float valve actuated city water inlet line or a water condensate line extending from the furnace. An outlet extends from a location of the housing to the humidifier. A return line extends from the humidifier to a further location of the housing. An overflow drain extends from another location of the housing and communicates any excess volume of water to a floor drain.

Owner:KOPP GARY E

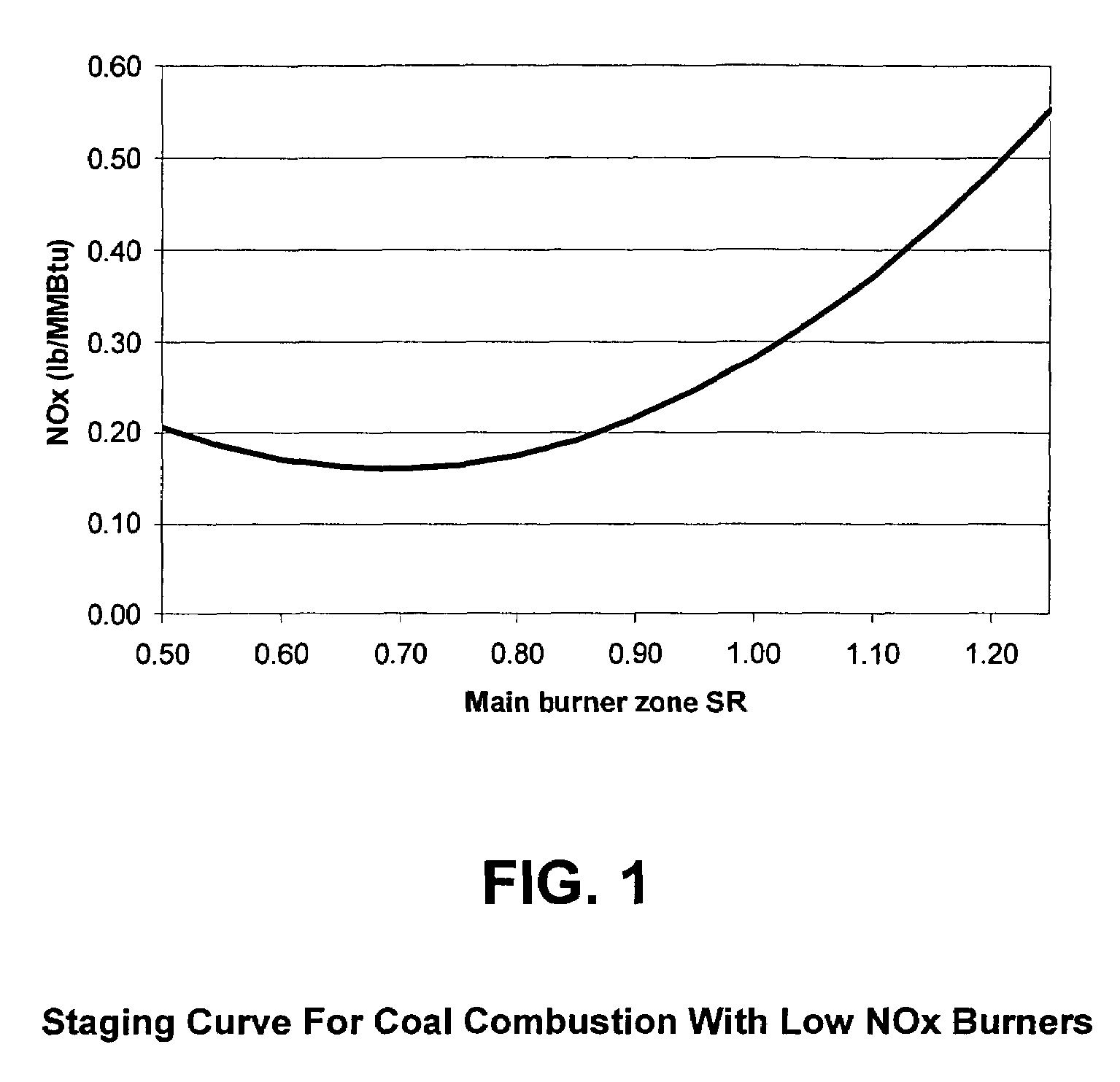

Method of operating furnace to reduce emissions

InactiveUS7497682B2Reduce nitrogen oxide contentRaise the ratioStaged combustionSolid fuel combustionCombustorEngineering

Emissions of NOx and CO are reduced from combustion devices such as coal-fired furnaces by increasing the stoichiometric ratio of burner(s) having a lower average temperature and increasing the stoichiometric ratio of burner(s) having a higher average temperature.

Owner:PRAXAIR TECH INC

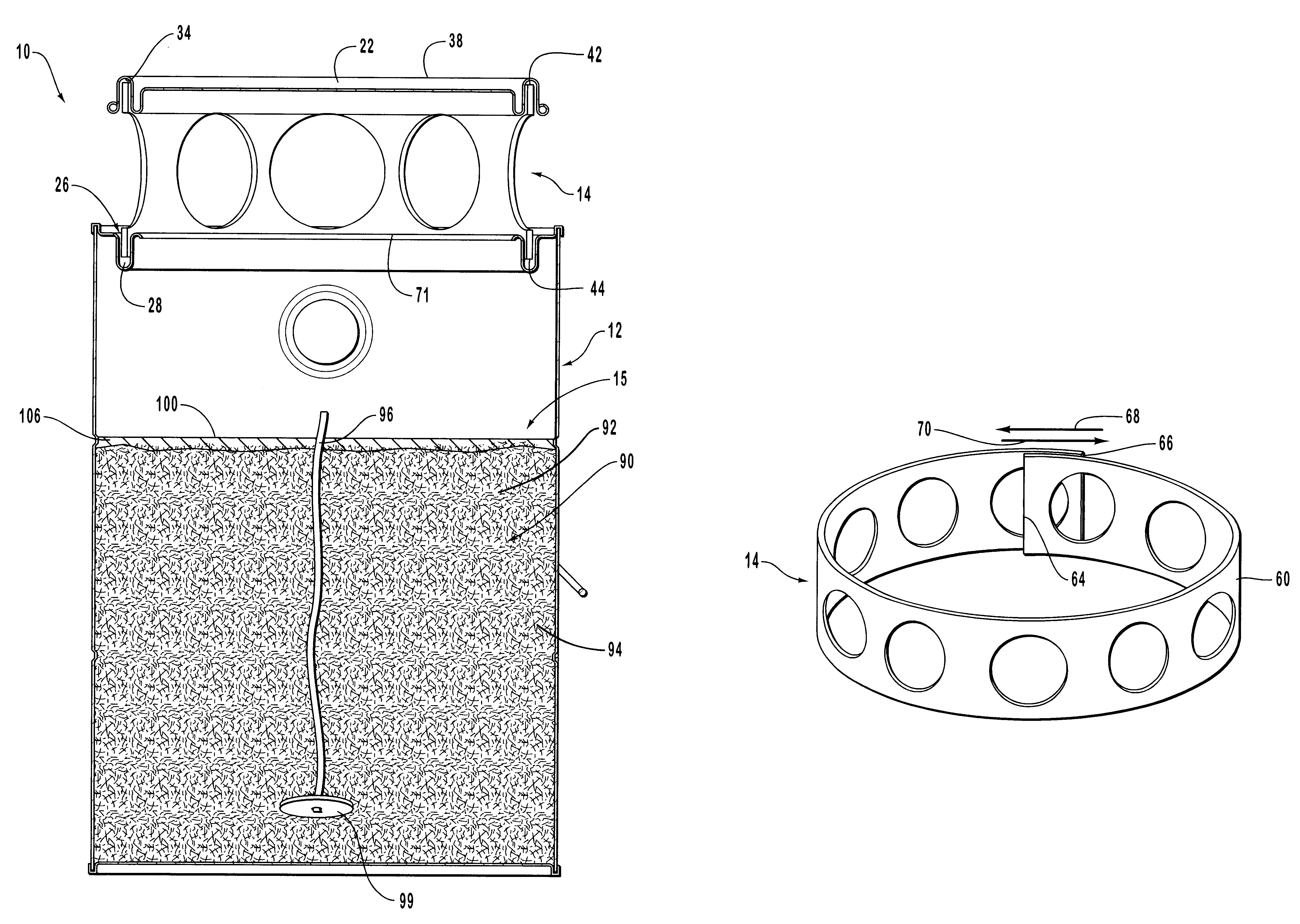

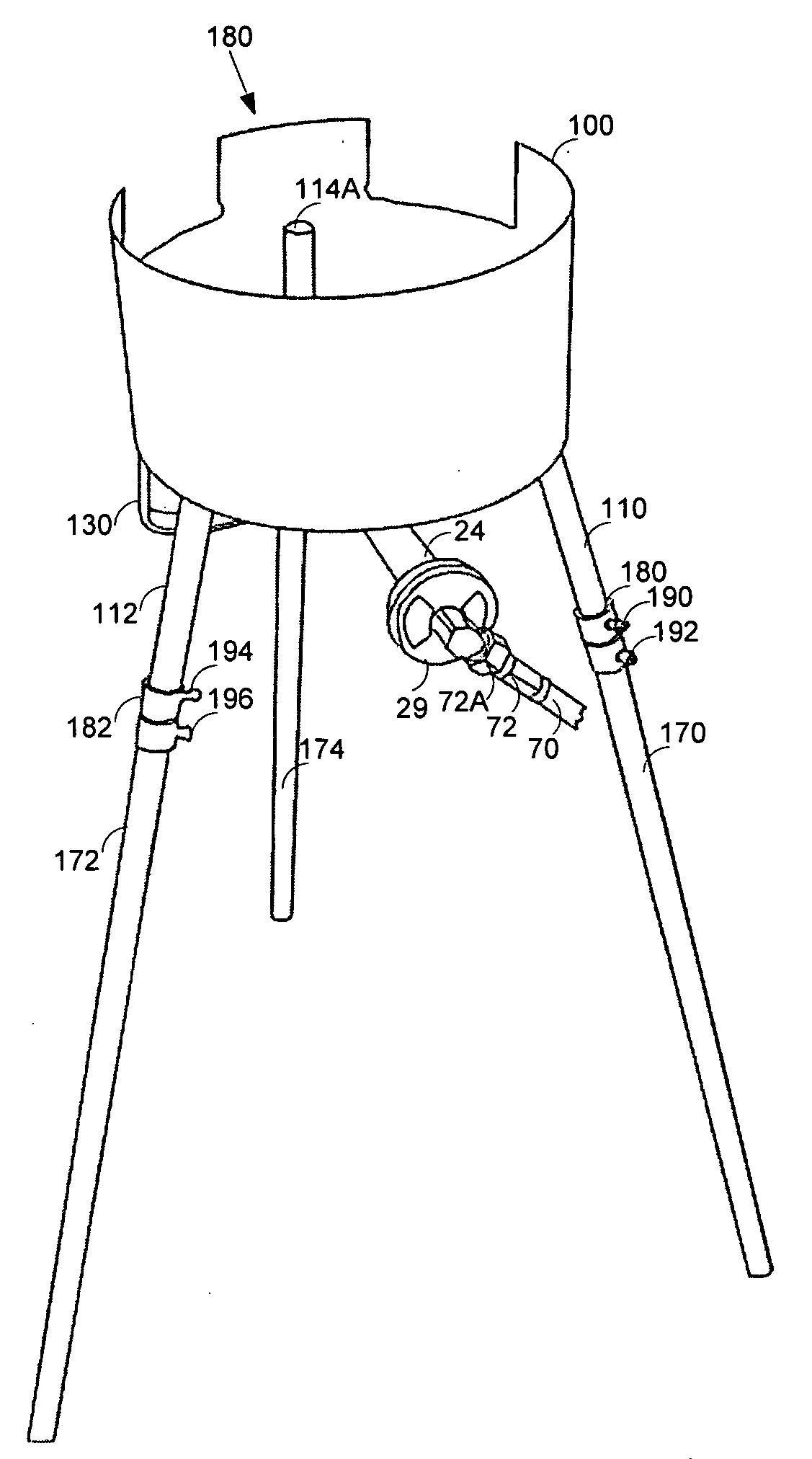

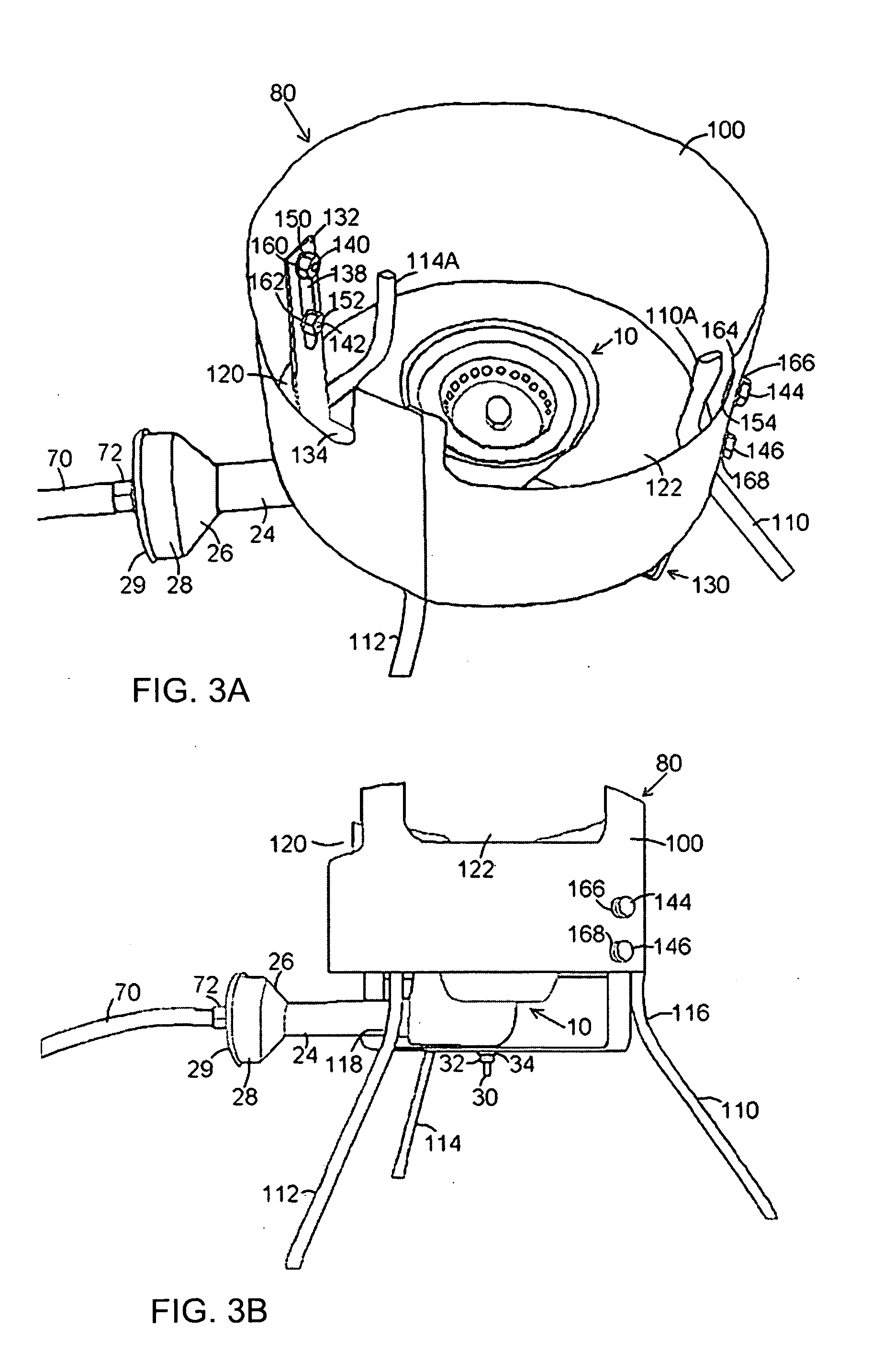

Cook stove assembly

InactiveUS8899222B2Lessen production of productReduce productionStoves/ranges foundationsCombustion-air/flue-gas circulation for stovesCombustion chamberMetal alloy

A combustion chamber, having an upper part and a lower part, may include an annular constriction, in combination with the combustion chamber, to aid in directing partially combusted gases such as carbon monoxide away from the periphery of the combustion chamber back toward its center, and into the flame front. The annular constriction may also impede the flow of partially combusted gases located at the periphery, thus increasing the time these gases spend within the combustion chamber and increasing the likelihood that any products of incomplete combustion will undergo combustion. The combustion chamber may further comprise a dual burner cooktop for directing combustion gases and exhaust to multiple cooking vessels. In further embodiments, the combustion chamber may be made of, lined, or clad with a metal alloy comprising iron, chromium, and aluminum.

Owner:COLORADO STATE UNIVERSITY +1

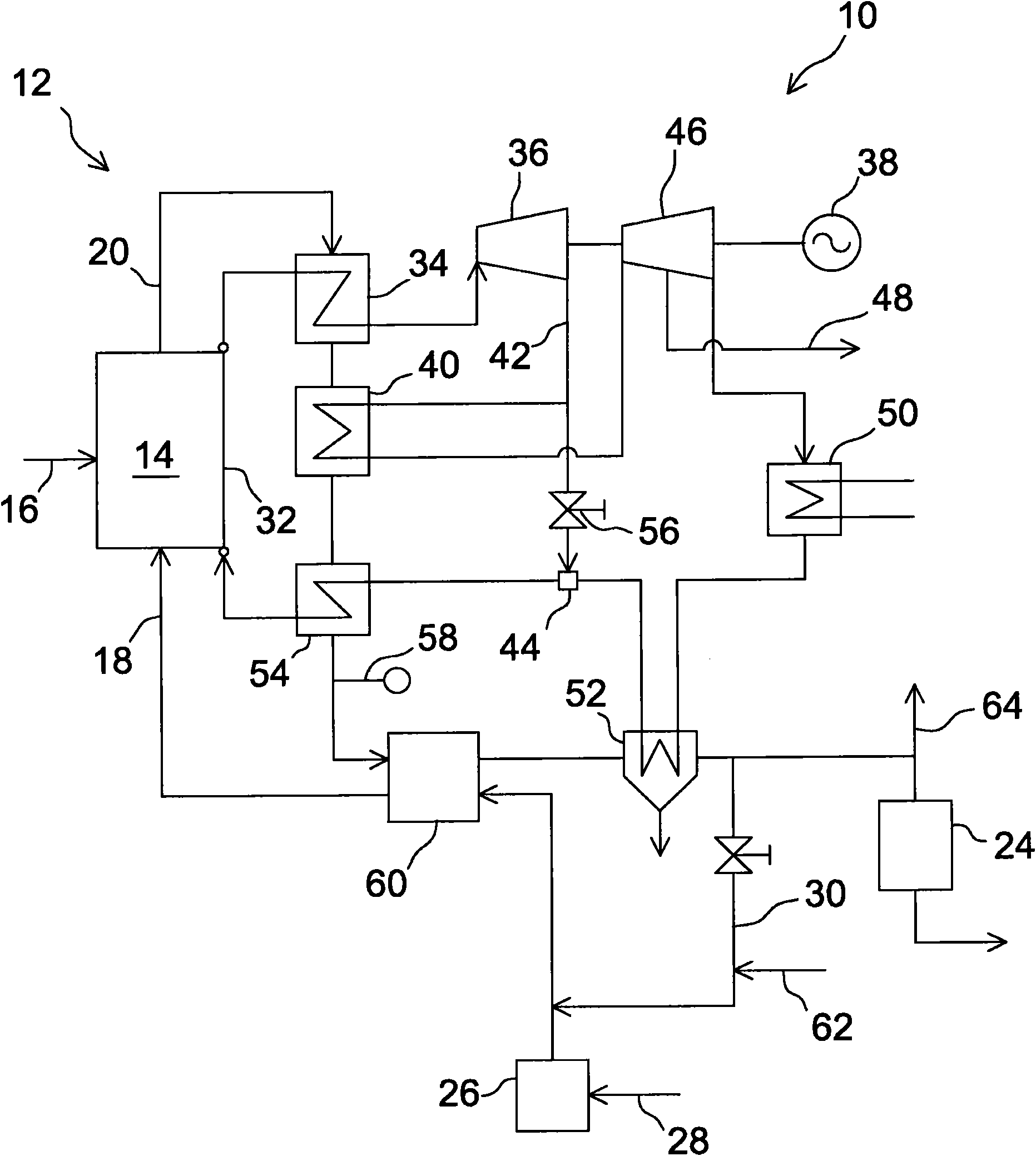

Oxyfuel combusting boiler system and a method of generating power by using the boiler system

InactiveCN102016241AAvoid corrosionNet power loss minimizedIndirect carbon-dioxide mitigationSteam engine plantsFlue gasExhaust fumes

Carbonaceous fuel is combusted with an oxidant gas in a furnace of a boiler system to generate power. Oxidant gas is fed into the furnace for combusting the fuel to produce exhaust gas, the exhaust gas is discharged from the furnace via an exhaust gas channel, a stream of feedwater is conveyed from a final economizer arranged in the exhaust gas channel to evaporating and superheating heat exchange surfaces arranged in the furnace and in the exhaust gas channel for converting the feedwater to superheated steam, the superheated steam is converted in a high-pressure steam turbine for generating power, a first portion of steam is extracted from the high-pressure steam turbine for preheating the feedwater, a second portion of steam is conveyed from the high-pressure steam turbine to reheating heat exchange surfaces arranged in the exhaust gas channel for generating reheated steam, and the reheated steam is expanded in an intermediate pressure steam turbine for generating power. The oxidant gas can be a mixture of substantially pure oxygen and recycled exhaust gas, and the ratio of the first and second portions of steam can be controlled to obtain a desired flue gas temperature in the exhaust gas channel downstream of the final economizer.

Owner:KAUTEX TEXTRON GMBH & CO KG

Method for recovering waste heat of high-temperature fuel gas of smelting furnace

ActiveCN104154763ARelieve stressExtend your lifeCombustion processEnergy industryRecovery methodProcess engineering

The invention relates to a method for recovering waste heat of high-temperature fuel gas of a smelting furnace. The method is characterized in that a conventional heat exchanging type combustion mode is operated when the furnace is started or in low-temperature combustion, and a thermal storage type combustion mode is operated when the temperature of the furnace is higher than 950 DEG C. The method is realized through a system for recovering waste heat of high-temperature fuel gas of the smelting furnace. The system comprises the smelting furnace, a thermal storage type regenerative burner system, a fume exhaust induced draft fan, a fuel gas circulation fan and a convection and radiation heat exchanger. According to the waste heat gradient utilization principle and difference of heating loads of the furnace, waste heat resources of fuel gas are recovered in the thermal storage mode and the heat exchanging mode properly, the advantages of the two modes are fully utilized, the waste heat recovery methods are automatically switched according to different temperatures of fuel gas in the furnace, the fuel gas is preheated and returns to the furnace through a flowing fire blocking wall in the furnace, high-temperature fuel gas waste heat is recycled to the maximum extent, waste heat recovery efficiency is improved, energy is effectively conserved, and it is guaranteed that the system can safely and stably operate.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Glass top plate for drop-in type cooking stove

InactiveCN1892116APrevent intrusionStoves/ranges foundationsDomestic stoves or rangesCombustionEngineering

The glass top plate is provided with a top plate main body 6 made of glass, and a front frame body 7 and a rear frame body 8 using a metal extrusion-molded material. The front frame body 7 has a first vent holes 11 on left and right sides, and a second vent hole 12 on a bottom face. The rear frame body 8 has third vent holes 13 on left and right sides, and a fourth vent hole 14 on a bottom face. The second vent hole 12 and the fourth vent hole 14 face a cooking stove opening 1a of a counter top 1, and they are communicated with the cooking stove body. When combustion of a burner 9 is carried out, combustion air in the cooking stove body is consumed, and air is supplied into the cooking stove body from the first vent holes 11 and the second vent hole 12 in the front frame body 7, and from the third vent holes 13 and the fourth vent hole 14 in the rear frame body 8. By this, even when the space between the wall face W and the rear frame body 8 is narrow, air can be sufficiently supplied into the cooking stove body.

Owner:RINNAI CORP

Task processing method of intelligent dining

InactiveCN103106550AReduce waiting time for foodOptimization of serving orderResourcesMultilevel feedback queueDecision model

The invention discloses a task processing method of intelligent dining. Multiple multi-level feedback queue arithmetic of decision models without being seized is used to carry out restaurant serving orders. Firstly, classifying time of a course cooking, according to the number of stoves which can work at the same time, classifying the cooking time; then, arranging a multi-level feedback queue to classification of each time, each stove corresponds to a multi-level feedback queue, dishes corresponding to the classification are ordered and then enter into the multi-level feedback queue. The task processing method of the intelligent dining is based on the multi-level feedback queue arithmetic, a concept of priority is added, and a process scheduling algorithm is amended according to practical situations, so that task processing method of the intelligent dining can be practically applied in serving meals. Compared with traditional experience-type serving orders, the multi-level feedback queue arithmetic is capable of reducing conditions of overlong time of customers waiting serving and optimizing the serving orders.

Owner:WUXI NANLIGONG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com