Molten glass conduit structure, and device and method using conduit structure

一种熔融玻璃、导管的技术,应用在玻璃炉设备、玻璃制造设备、制造工具等方向,达到削减制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0161] Hereinafter, the present invention will be described more specifically based on examples. However, the present invention is not limited thereto.

[0162] In the examples shown below, the monolithic refractory (castable refractory) having the composition shown in Table 1 was used for the monolithic refractory layer.

[0163] [Table 1]

[0164] Content (%)

[0165] The heterogeneity of the molten glass due to the monolithic refractory layer was evaluated in the following procedure.

[0166] The glass blank was placed on the monolithic refractory, and after holding at 1200°C in Example 1 and 1300°C in Example 2 for one week, it was cooled to room temperature in about 6 hours. The monolithic refractory layer was cut out with the glass adhered thereto, the cross-section was ground, and the glass composition near the interface between the monomorphic refractory and the glass blank was quantitatively analyzed with an electron probe microanalyzer (EPMA). Moreover, ...

Embodiment 4

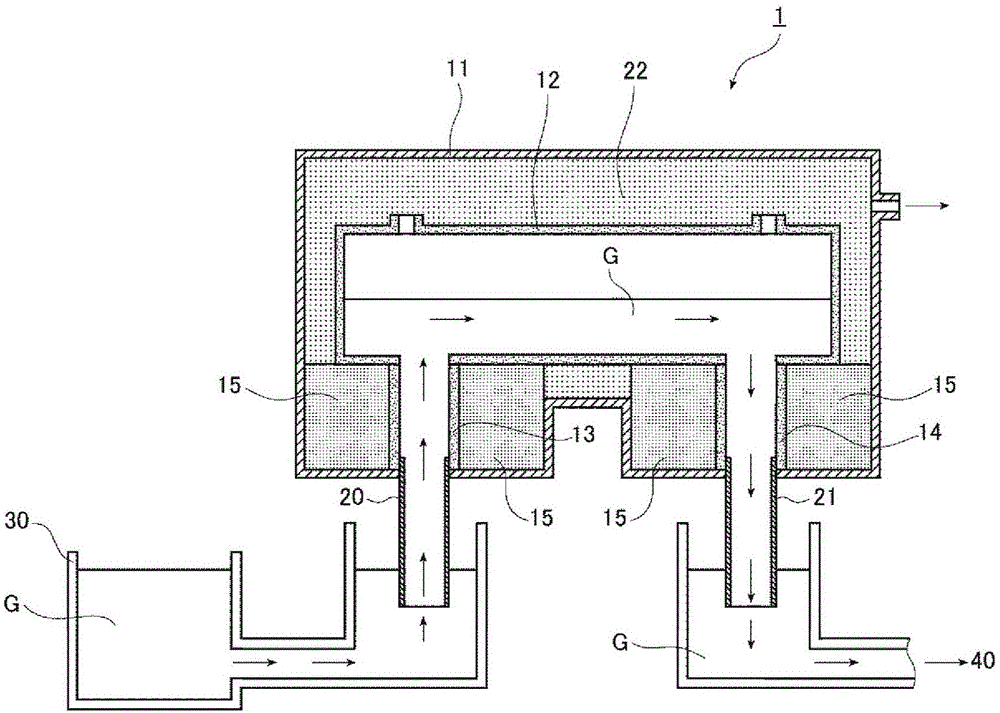

[0179] In this example, use figure 1 The vacuum degassing device 1 shown is used to implement the vacuum degassing of molten glass. In the vacuum degassing device 1, the riser 13, the downcomer 14 and their peripheral positions have figure 2 structure shown.

[0180] The structural materials of each part of the vacuum degassing apparatus 1 are as follows.

[0181] ·Decompression housing 11: stainless steel

[0182] ·Decompression degassing tank 12: electroformed brick

[0183] ·Rising tube 13, down tube 14: electroformed brick

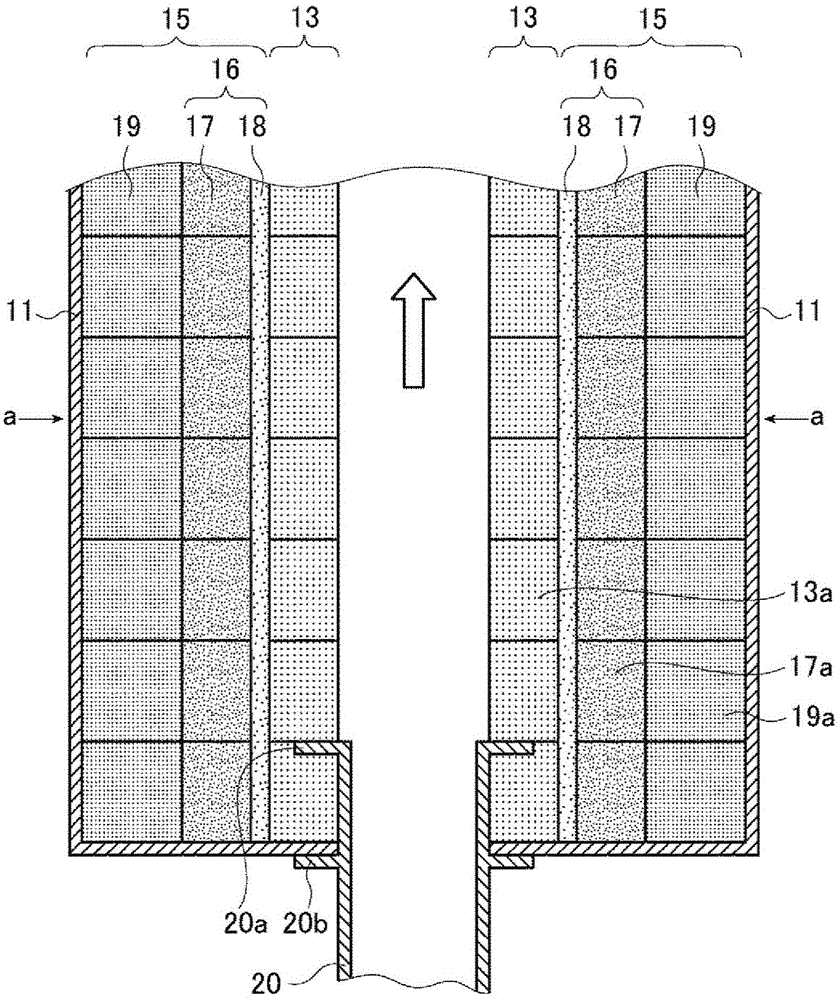

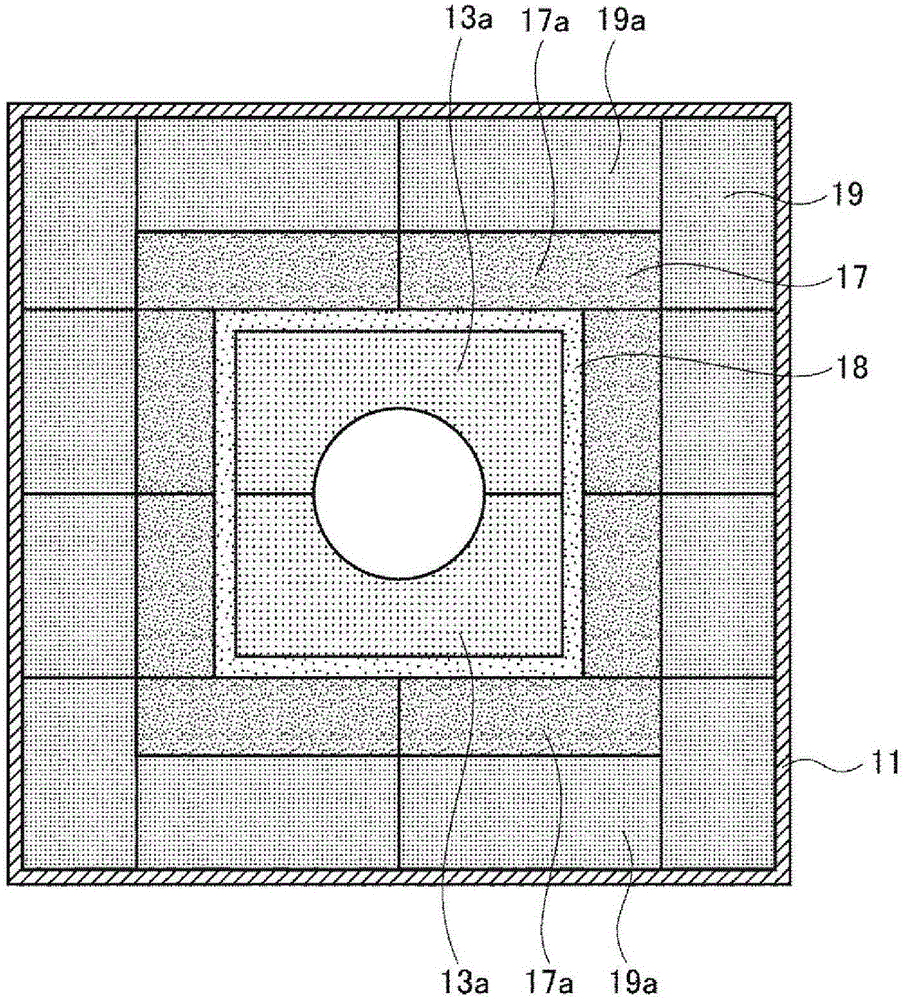

[0184] The riser 13 is constructed by combining two electroformed bricks 13a (alumina electroformed bricks) to form image 3In the shape shown, they are stacked along the long axis direction of the riser pipe 13 . The structure of the downcomer 14 is also the same as that of the riser 13 .

[0185] · Extension tubes 20, 21: Platinum

[0186] Around the ascending pipe 13 and the descending pipe 14, there are figure 2 The support 15 of the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com