Circulating fluidized bed boiler cyclone separator composed of one-time bent pipe panel

A technology of circulating fluidized bed and cyclone separator, which is applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, lighting and heating equipment, etc. It can solve the problems of long start-up time, thick thickness, heavy workload, etc., and achieve The effect of ensuring product quality, reducing manufacturing costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

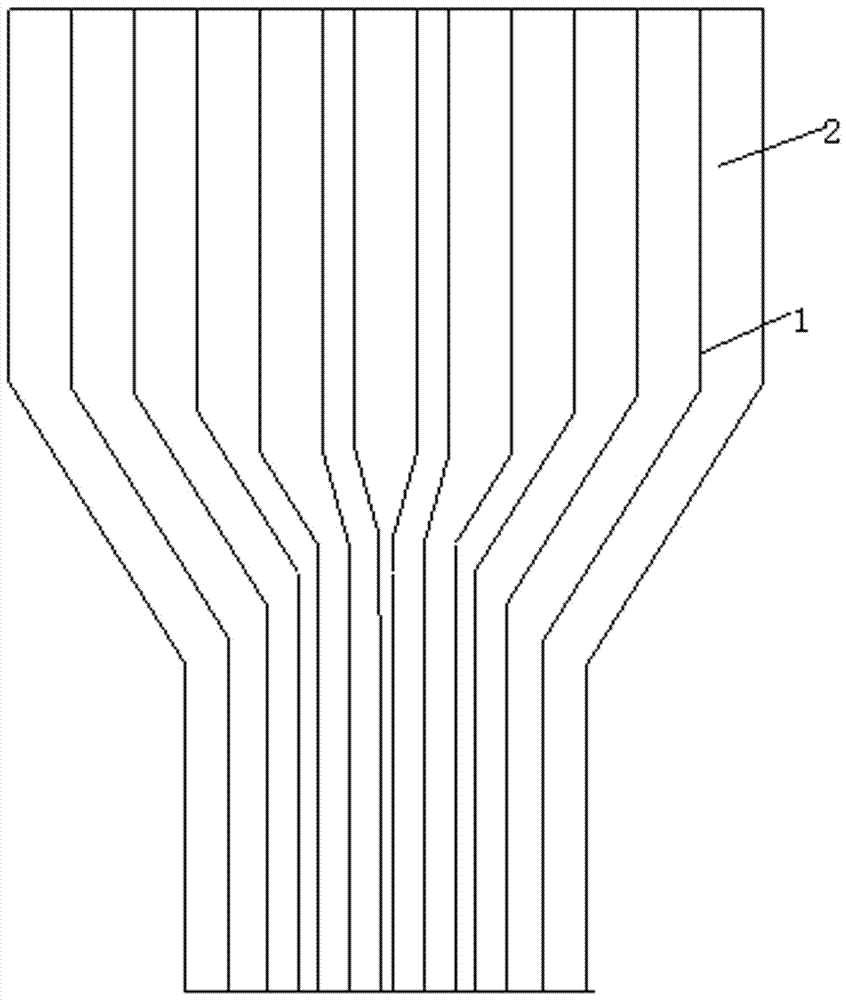

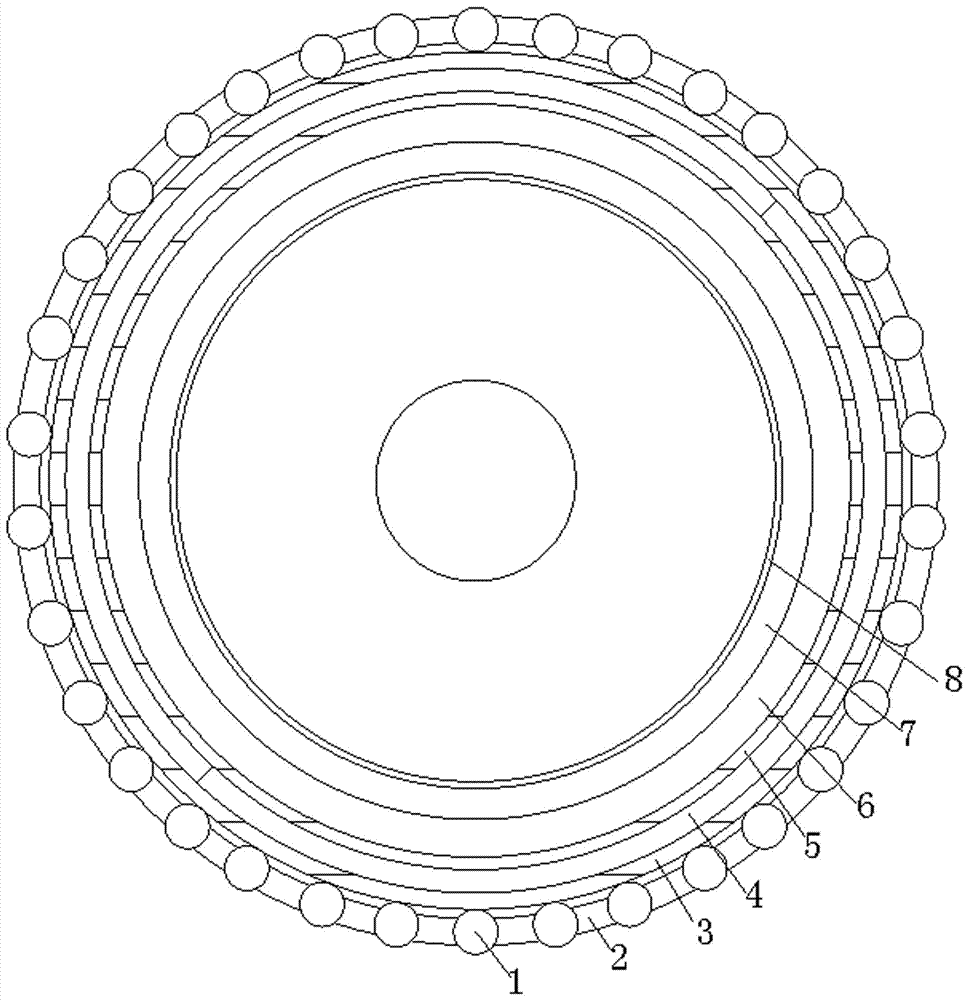

[0015] Such as Figure 1-2 As shown, the present invention is a cyclone separator for a disposable elbow tube panel of a circulating fluidized bed boiler. It is composed of flat steel 2 arranged between two adjacent disposable elbows 1, and a heat insulating layer 3 is arranged on the inner side of the tube panel, and the heat insulating layer 3 is an airgel felt heat insulating layer, and the heat insulating effect is Well, a heat-insulating and refractory layer 4 is arranged inside the heat-insulating layer 3, and the heat-insulating and refractory layer 4 is a diatomite heat-insulating and refractory layer. Diatomite has good heat-insulating and refractory propert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com