Safe and energy-saving smelting furnace body and smelting device employing same

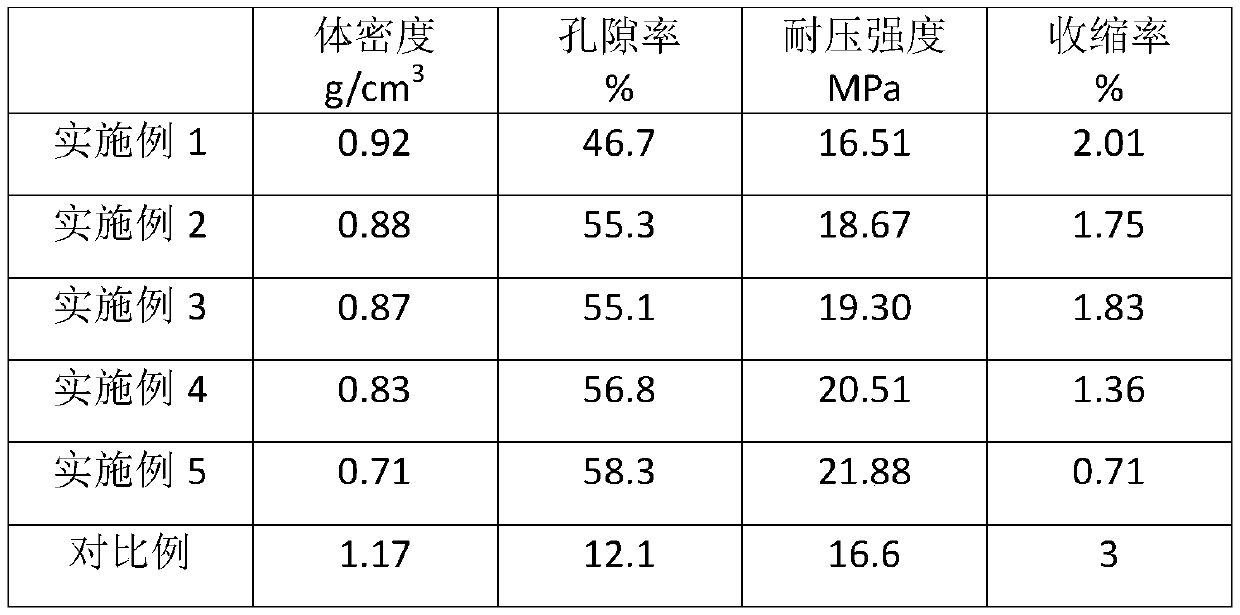

A technology of smelting furnace and furnace body, applied in the field of smelting equipment, can solve the problems of easy volume change, high construction cost and large shrinkage rate of the furnace body, achieve low-temperature shrinkage rate, high safety and energy saving, and improve the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The safe and energy-saving smelting furnace body of this embodiment includes a steel shell and an inner lining arranged in the steel shell. The inner lining includes a refractory brick layer, and the refractory brick layer is made of mullite lightweight bricks. It is made of water and the following raw materials: 40kg of alumina aggregate, 20kg of coal gangue, 10kg of fly ash, 5kg of silicon carbide, 8kg of expansion agent, 20kg of binder, and 5kg of pore-forming agent; the amount of water is 18kg. The alumina aggregate is alumina; the expansion agent is kyanite; the binder is clay; the pore-forming agent is graphite. The particle size of alumina is 200 mesh. The particle size of coal gangue is 0.5mm. The particle size of fly ash is 15 μm. Silicon carbide is black silicon carbide with a particle size of 5 μm. The particle size of kyanite is 120 mesh. The particle size of the clay is 400 mesh. The particle diameter of graphite was 20 μm.

[0039] The preparation me...

Embodiment 2

[0044] The safe and energy-saving smelting furnace body of this embodiment includes a steel shell and an inner lining arranged in the steel shell. The inner lining includes a refractory brick layer, and the refractory brick layer is made of mullite lightweight bricks. It is made of water and the following raw materials: 10kg of alumina, 25kg of bauxite, 15kg of kaolin, 15kg of coal gangue, 5kg of fly ash, 3kg of black silicon carbide, 5kg of green silicon carbide, 3kg of andalusite, 5kg of kyanite, Clay 8kg, sodium carboxymethyl cellulose 2kg, graphite 5kg, polystyrene 2kg; the amount of water is 20kg.

[0045] The particle size of alumina is 200 mesh. The particle size of bauxite is 200 mesh. The particle size of kaolin is 2 μm. The particle size of coal gangue is 0.5mm. The particle size of fly ash is 15 μm. The particle size of black silicon carbide is 5 μm. The particle size of green silicon carbide is 5 μm. The particle size of andalusite is 120 mesh. The particle ...

Embodiment 3

[0054] The safe and energy-saving smelting furnace body of this embodiment includes a steel shell and an inner lining arranged in the steel shell. The inner lining includes a refractory brick layer, and the refractory brick layer is made of mullite lightweight bricks. It is made of water and the following raw materials: 15kg of alumina, 25kg of bauxite, 10kg of kaolin, 18kg of coal gangue, 5kg of aluminate cement, 7kg of fly ash, 1kg of black silicon carbide, 3kg of green silicon carbide, and 2kg of andalusite , kyanite 3kg, clay 15kg, sodium carboxymethylcellulose 3kg, graphite 3kg, polystyrene 3kg; the amount of water is 25kg.

[0055] The particle size of alumina is 200 mesh. The particle size of bauxite is 200 mesh. The particle size of kaolin is 2 μm. The particle size of coal gangue is 0.5mm. The particle size of fly ash is 15 μm. The particle size of black silicon carbide is 5 μm. The particle size of green silicon carbide is 5 μm. The particle size of andalusite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com