Mass concrete-based temperature field research method and temperature control method

A large-volume concrete and temperature control method technology, applied in the direction of thermometers, thermometer applications, instruments, etc., can solve the problem of not being able to provide temperature control methods for mass concrete pouring temperature control, and being unable to grasp the temperature distribution law and mechanism characteristics of the temperature field. Affect the quality of concrete pouring and the safety of the entire project, so as to avoid the waste of cooling resources, ensure the overall quality of the project, and ensure the quality of pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

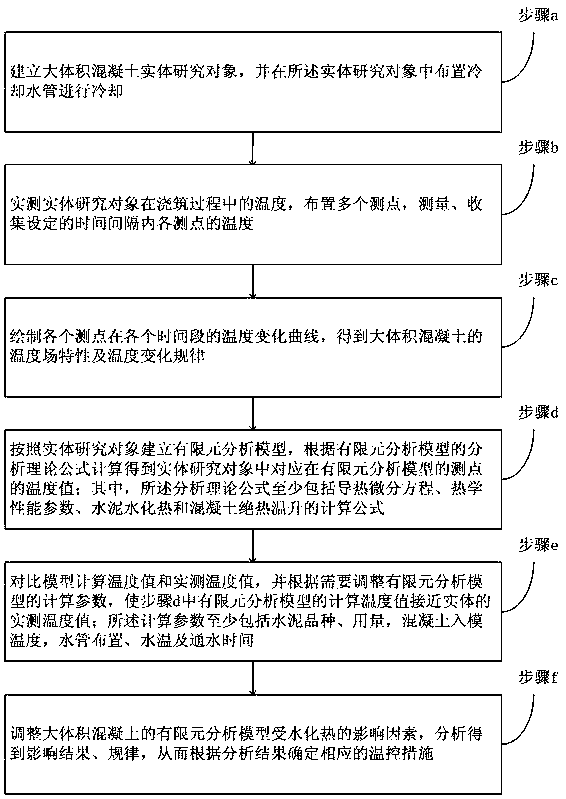

[0107] Such as figure 1 As shown, the temperature field research method based on mass concrete includes the following steps:

[0108] a. Establish a mass concrete entity research object, and arrange cooling water pipes in the entity research object for cooling;

[0109] b. Measure the temperature of the entity research object during the pouring process, arrange multiple measuring points, measure and collect the temperature of each measuring point within the set time interval;

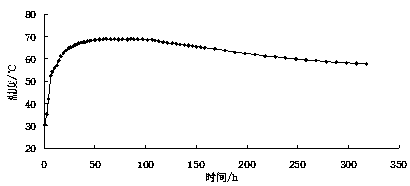

[0110] c. Draw the temperature change curve of each measuring point in each time period to obtain the temperature field characteristics and temperature change law of mass concrete;

[0111] d. Establish a finite element analysis model according to the entity research object, and calculate the temperature value corresponding to the measuring point of the finite element analysis model in the entity research object according to the analysis theory formula of the finite element analysis model; wherein, the...

Embodiment 2

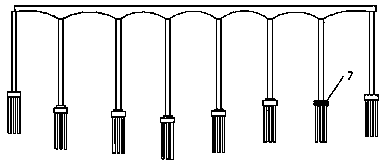

[0127]Embodiment 2: This embodiment takes the steps in Embodiment 1 as an example to describe the operation process of the research method in detail. In this embodiment, the pier cap of a certain railway bridge in China is taken as an example for illustration, as figure 2 As shown in the figure, select a pier cap 7 in the figure, see the specific location figure 2 In the black spot that won the bid, the pier cap is a large-volume concrete structure.

[0128] The size of the pier abutment is 19.2m×13m×4m, and concrete with a volume greater than 1 cubic meter is limited to mass concrete. The strength grade of concrete is C40, and the dosage of each component in each cubic meter of concrete is: P.42.6 (low alkali) cement 291kg, sand 750kg, stone 1080kg, admixture (fly ash) 125kg, water reducer 4.16kg , Water 154kg. Steel formwork is used during construction, and two layers of cooling water pipes are pre-arranged in the concrete pouring front cap, using DN50 (2-inch pipe) gal...

Embodiment 3

[0195] Embodiment 3: In this embodiment, the research method is obtained based on the research method of the mass concrete temperature field, and the factors affecting the heat of hydration of the mass concrete are analyzed and studied. Still taking the pier cap of Example 2 as the object, the influence of cement type and dosage on the heat of hydration of mass concrete is analyzed, and a finite element model is also established for analysis.

[0196] Analyze the impact of cement varieties on the heat of hydration of mass concrete. According to the situation of the pier cap in Example 2, the amount of cement used per cubic meter of concrete is 291kg. In the absence of cooling water pipes, ordinary silicate is now selected. Cement, medium heat Portland cement, high early strength Portland cement, fly ash cement (20% fly ash), other calculation parameters remain unchanged, the finite element analysis model is established, and the numerical calculation is carried out. Concrete ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com