Solid pattern casting special paint and preparation method thereof

A technology of real casting and coating, which is applied in casting molding equipment, coating, casting and other directions, can solve the problems of high manufacturing cost, black pollution of working environment, and inability to apply manual painting, so as to maintain integrity and prevent model deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

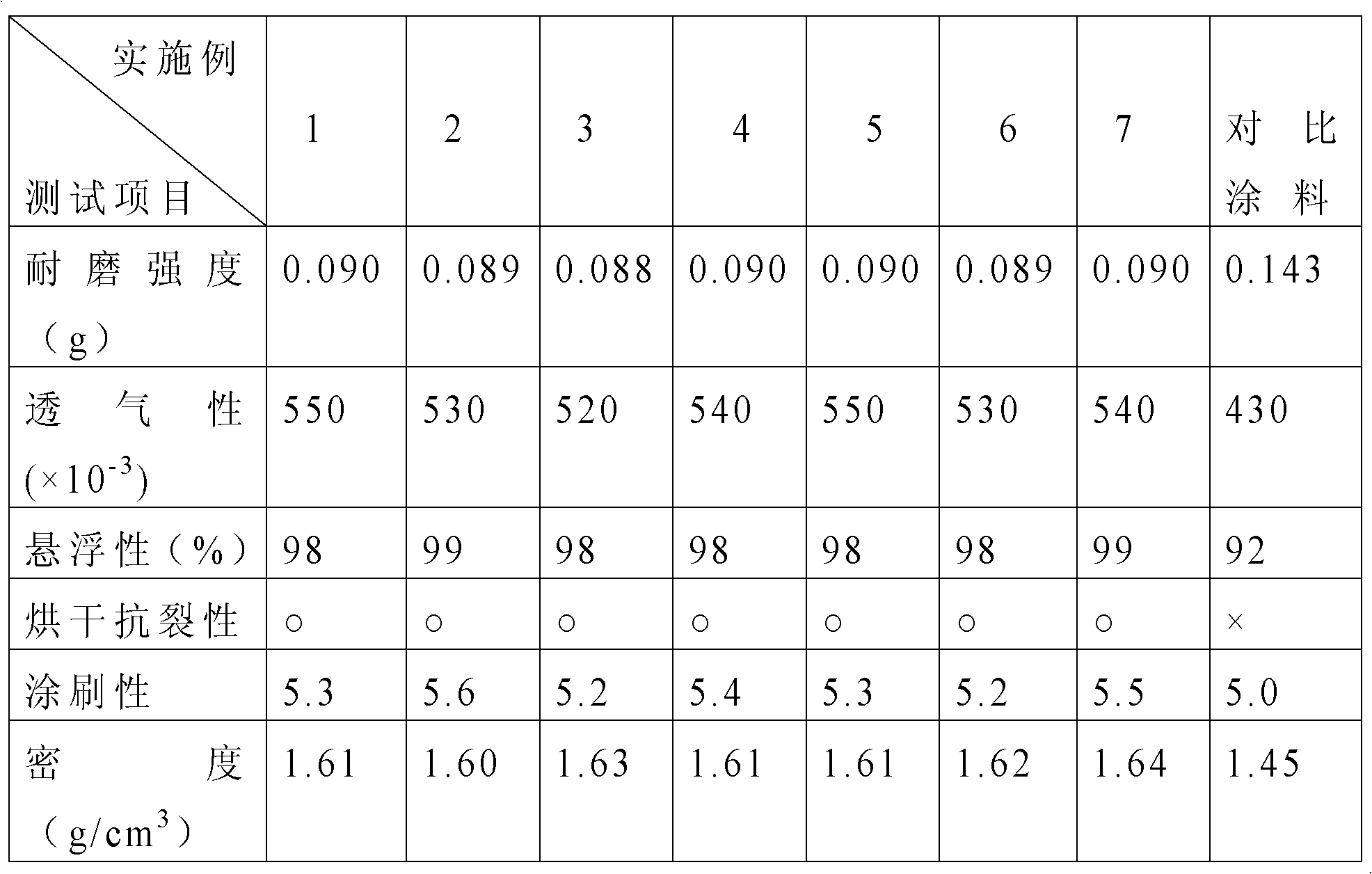

Embodiment 1

[0026] The mass percentage of each component of the special coating for full mold casting is: 35% of high alumina bauxite clinker, 25% of flake graphite powder, 2.8% of architectural emulsion, 3% of silica sol, 0.5% of sodium hexametaphosphate, iron oxide 2% red powder, 6% composition of bentonite powder and 2% CMC aqueous solution, 0.8% sodium methylene bis-naphthalene sulfonate, and 24.9% water.

[0027] Wherein, the mass ratio of bentonite powder to CMC aqueous solution is 1:3; the particle size gradation of the high alumina bauxite clinker is: 5-10% of the balance on the 200-mesh sieve, and 15-20% on the 250-mesh sieve; The particle size distribution of the flaky graphite powder is: 80% of the balance on the 200 mesh sieve.

Embodiment 2

[0029]The mass percentage content of each component of the special coating for full mold casting is: 30% of high alumina bauxite clinker, 30% of flake graphite powder, 2.7% of white latex, 4.5% of water glass, 0.5% of aluminum sulfate, and 1% of iron oxide red powder %, the composition of bentonite powder and 2% CMC aqueous solution with a mass fraction of 5%, polycarboxylate calcium calcium 1.3%, and water 25%.

[0030] Among them, the mass ratio of bentonite to CMC aqueous solution is 1:2; the particle size distribution of high alumina bauxite clinker is: 5-10% of the balance on the 200 mesh sieve, 20-25% of the balance on the 250 mesh sieve; The particle size gradation of graphite powder is: the balance on 200 mesh sieve is 70%.

Embodiment 3

[0032] The mass percentage of each component of the special coating for full mold casting is: 40% of high alumina bauxite clinker, 20% of flake graphite powder, 3.2% of water-soluble resin, 3.0% of silica sol, 0.5% of sodium hexametaphosphate, oxidation 2% of iron red powder, 6% of the composition of bentonite powder and 2% CMC aqueous solution with a mass fraction of 6%, 1.3% of sodium methylene bis-naphthalene sulfonate, and 24% of water.

[0033] Among them, the mass ratio of bentonite powder to CMC aqueous solution is 1:2.5; the particle size distribution of high alumina bauxite clinker is: 5-10% of the balance on the 200-mesh sieve, 15-20% on the 250-mesh sieve; The particle size gradation of the graphite powder is: the balance on the 200 mesh sieve is 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com