Composite rare earth zirconate thermal barrier coating ceramic material and preparation method thereof

A technology of thermal barrier coatings and ceramic materials, applied in the field of thermal barrier coating ceramic materials and their preparation, can solve the problems of phase change, high thermal conductivity, low thermal expansion coefficient, etc., achieve simple operation process, and enhance high temperature phase stability Sexual, no shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

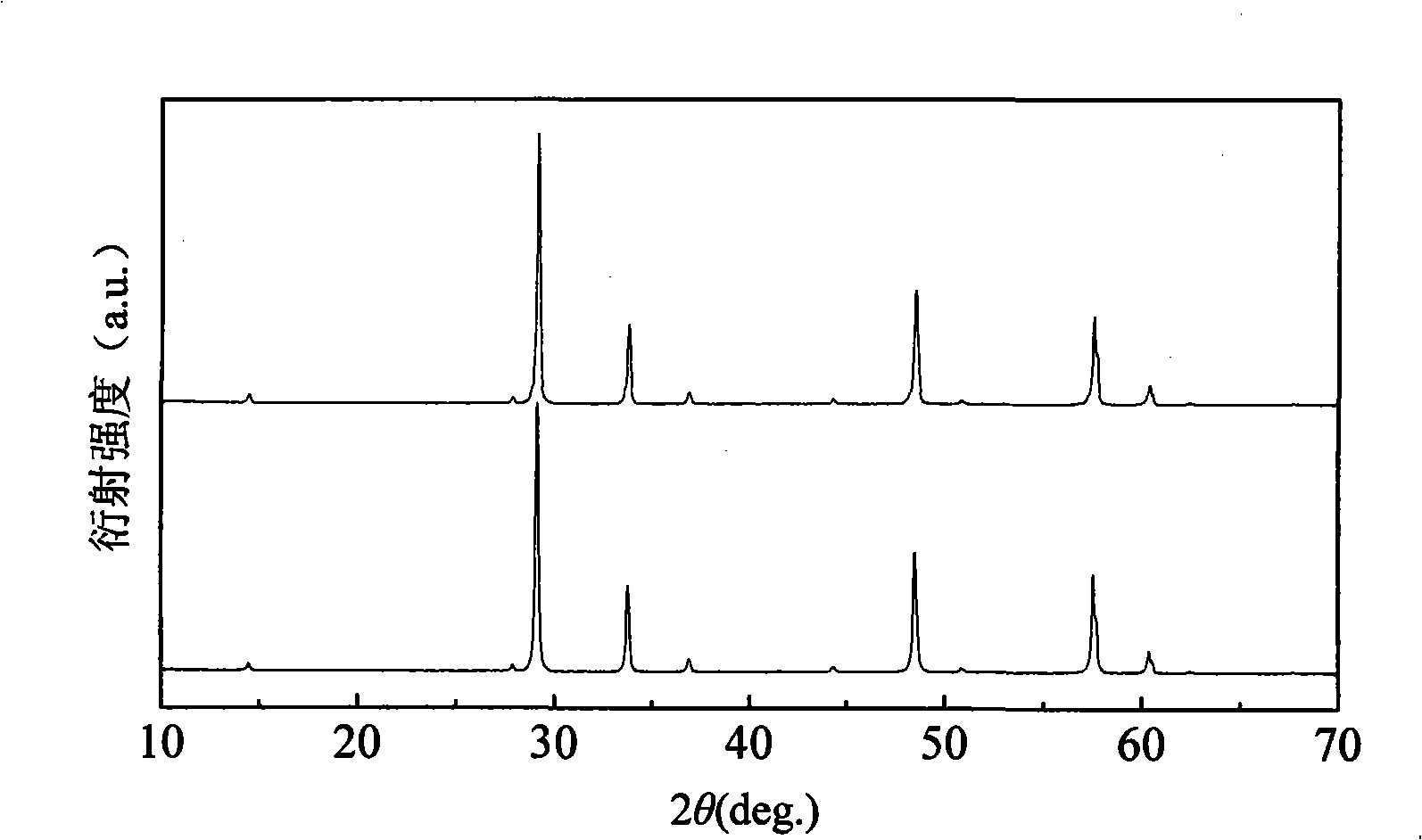

[0012] Specific implementation mode one: the molecular formula of the composite rare earth zirconate thermal barrier coating ceramic material in this implementation mode is (Ln x Yb 1-x ) 2 Zr 2 o 7 , in molar ratio by 2 moles of zirconia, x moles of rare earth oxide Ln 2 o 3 and 1-x moles of rare earth oxide Yb 2 o 3 Made; where 02 o 3 Ln in is one of Nd, Sm, Gd; rare earth oxide Ln 2 o 3 Ln in is composed of two or more rare earth elements in Nd, Sm and Gd.

[0013] In this embodiment, the rare earth oxide Ln 2 o 3 The Ln in is composed of two or more rare earth elements in Nd, Sm and Gd, and the composition elements can be in any proportion relationship.

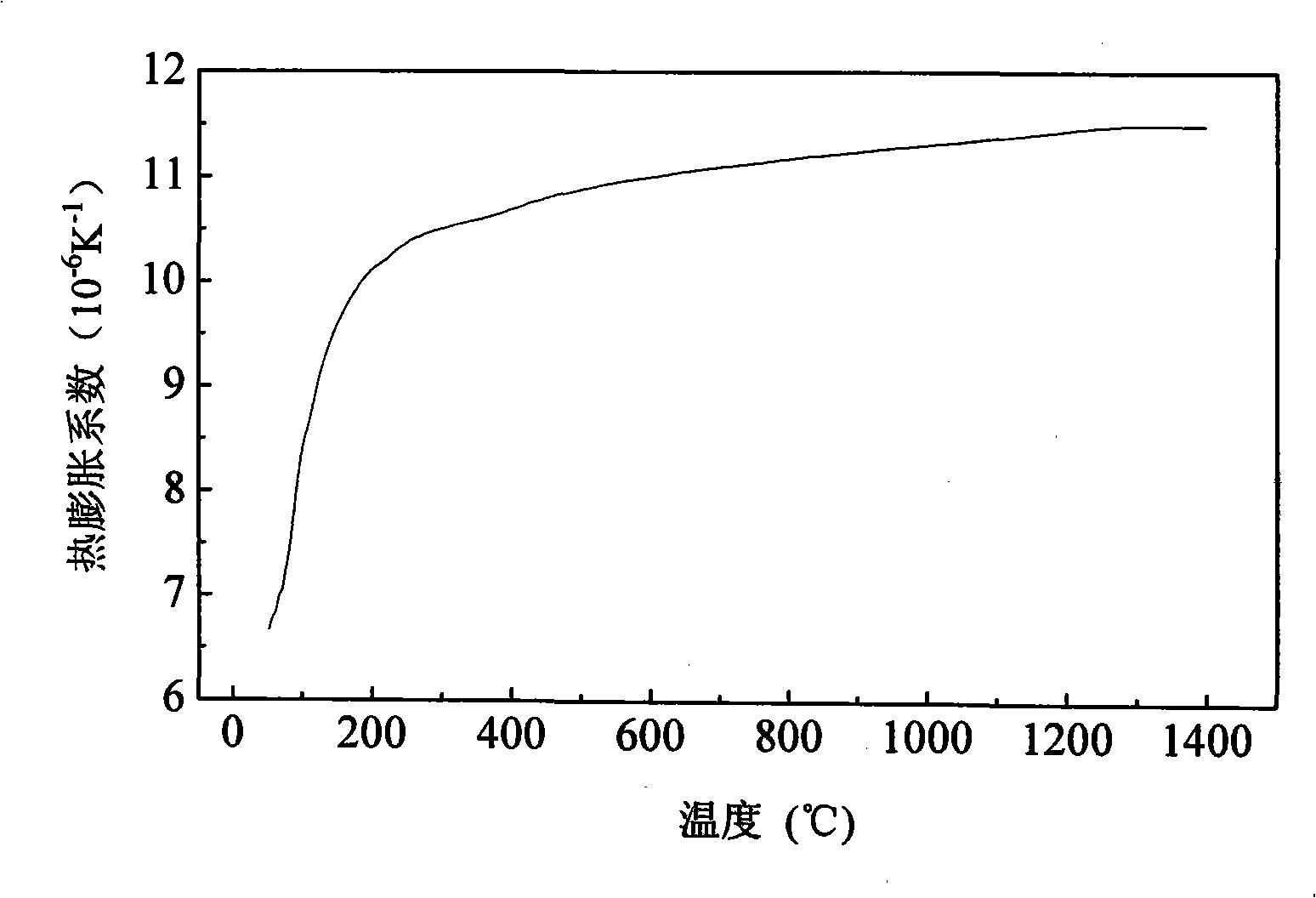

[0014] In this embodiment, the thermal conductivity and thermal expansion coefficient of the composite rare earth zirconate thermal barrier coating ceramic material prepared by selecting different raw material components at 1400°C are shown in Table 1.

[0015] Table 1

[0016] chemical formula

[...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the rare earth oxide Ln 2 o 3 Ln in the medium is composed of two or more rare earth elements, and the relationship between the rare earth elements can be any ratio. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific Embodiment Three: In this embodiment, the composite rare earth zirconate thermal barrier coating ceramic material is prepared according to the following method: 1. The molar ratio is 2 moles of zirconia and x moles of rare earth oxide Ln 2 o 3 and 1-x moles of rare earth oxide Yb 2 o 3 Mix to obtain a mixed powder; 2. Add deionized water equal to the volume of the mixed powder, and ball mill for 6 to 12 hours to obtain a mixed solution; 3. Dry the mixed solution at a temperature of 120°C to obtain a dried Mix the powder; 4. Put the dried mixed powder into the air atmosphere, raise the temperature from room temperature to 1000-1250 °C at a heating rate of 5 °C / min, and heat-preserve it for 4-12 hours, then cool to room temperature, and then ball mill 22-26 hours to obtain powder A; 5. Heat powder A from room temperature to 1250-1350 °C at a heating rate of 5 °C / min, heat-preserve for 4-12 hours, cool to room temperature, and ball mill for 22-26 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com