Circle substrate firing furnace

A sintering furnace, circulation technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of loss of sintering temperature stability of sintering furnace, reproducibility of sintering treatment, etc. Low efficiency, reduced heat loss, and easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

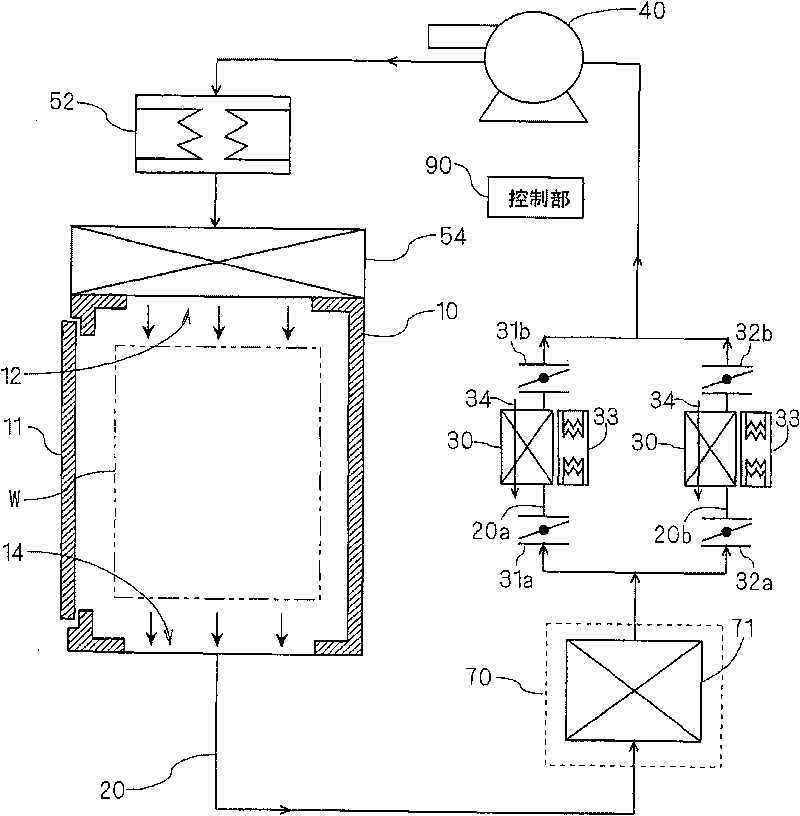

[0035] figure 1 It is a figure which shows the whole structure of 1st Embodiment of the circulation type substrate firing furnace of this invention. This substrate firing furnace fires a rectangular glass substrate W on which color ink, etc. The main body part 10, the circulation path 20 for circulating the hot air, the catalyst filter part 70 carrying the catalyst for decomposing organic matter on the filter, the adsorption tower 30 for adsorbing the moisture and carbon dioxide contained in the hot air, and the circulation Fan 40, main heater 52 for heating hot air, metal filter 54. In addition, a control unit 90 is provided on the substrate firing furnace.

[0036]The furnace main body portion 10 is a housing capable of accommodating the glass substrates W in multiple layers (40 layers in the present embodiment). The inner side of the furnace main body portion 10 is formed as a substantially quadrangular prism-shaped heat treatment space. A plurality of forks (not shown)...

no. 2 approach

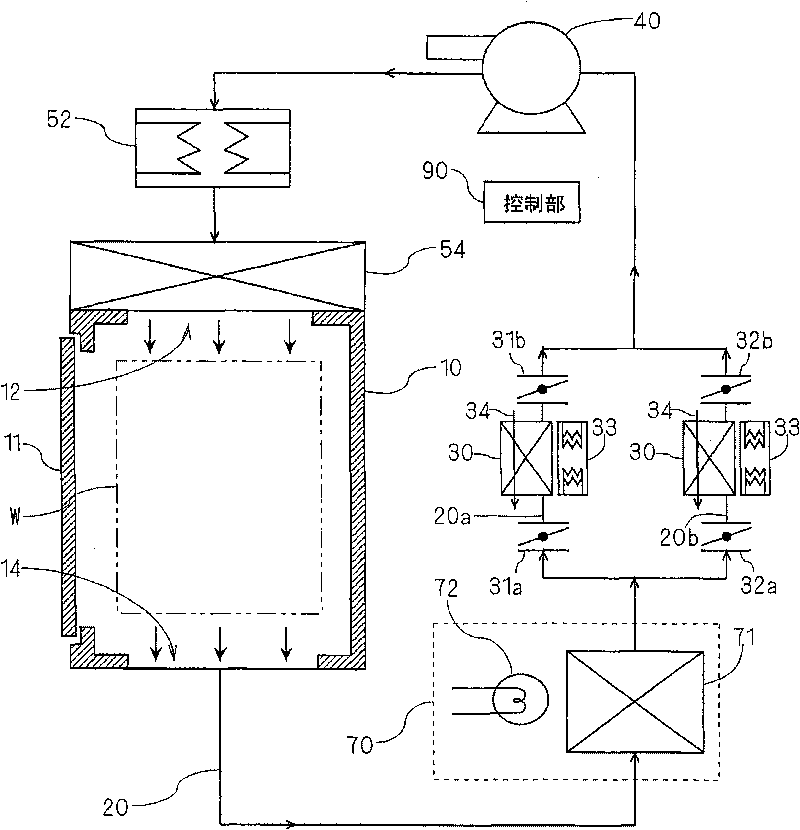

[0059] Next, a second embodiment of the present invention will be described. figure 2 It is a figure which shows the whole structure of the circulation type substrate firing furnace of 2nd Embodiment. exist figure 2 In , the same reference numerals are assigned to the same elements as those in the first embodiment. The difference between the substrate firing furnace of the second embodiment and the first embodiment is that the catalyst filter unit 70 has a light source 72 in addition to the catalyst filter 71 .

[0060] In the second embodiment, part of the catalyst carried on the catalyst filter 71 is mixed with titanium oxide (TiO 2 ). A light source 72 included in the catalyst filter unit 70 irradiates light to the catalyst filter 71 . The photocatalyst carried on the catalyst filter 71 acts as a catalyst by receiving light from the light source 72 . Other configurations of the substrate firing furnace of the second embodiment are the same as those of the first embod...

no. 3 approach

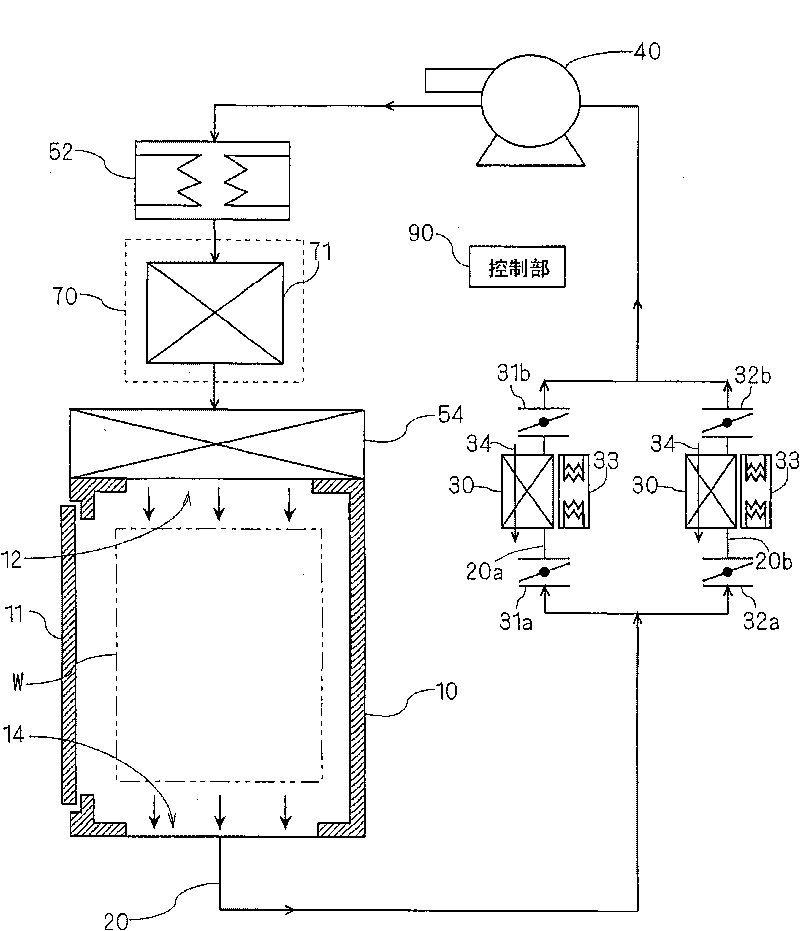

[0063] Next, a third embodiment of the present invention will be described. image 3 It is a figure which shows the whole structure of the circulation type substrate firing furnace of 3rd Embodiment. exist image 3 In , the same reference numerals are assigned to the same elements as those in the first embodiment. The circulation type substrate firing furnace of the third embodiment differs from the first embodiment in the arrangement position of the catalyst filtering unit 70 .

[0064] Such as image 3 As shown, in the third embodiment, a catalyst filter part 70 is provided, and the catalyst filter part 70 is provided on the downstream side of the main heater 52 in the circulation path 20 and is located between the main heater 52 and the furnace main body part 10. between. Other configurations of the substrate firing furnace of the second embodiment are the same as those of the first embodiment.

[0065] In the third embodiment, the hot air discharged from the hot air o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com