Production line system and automated warehouse used in the system

A production line and processing line technology, which is applied in the field of production line systems for manufacturing color filter sheet-like plate products, can solve the problems of limited improvement and difficulty in high operation rate of the production line, etc., and achieve the effect of preventing the reduction of the operation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

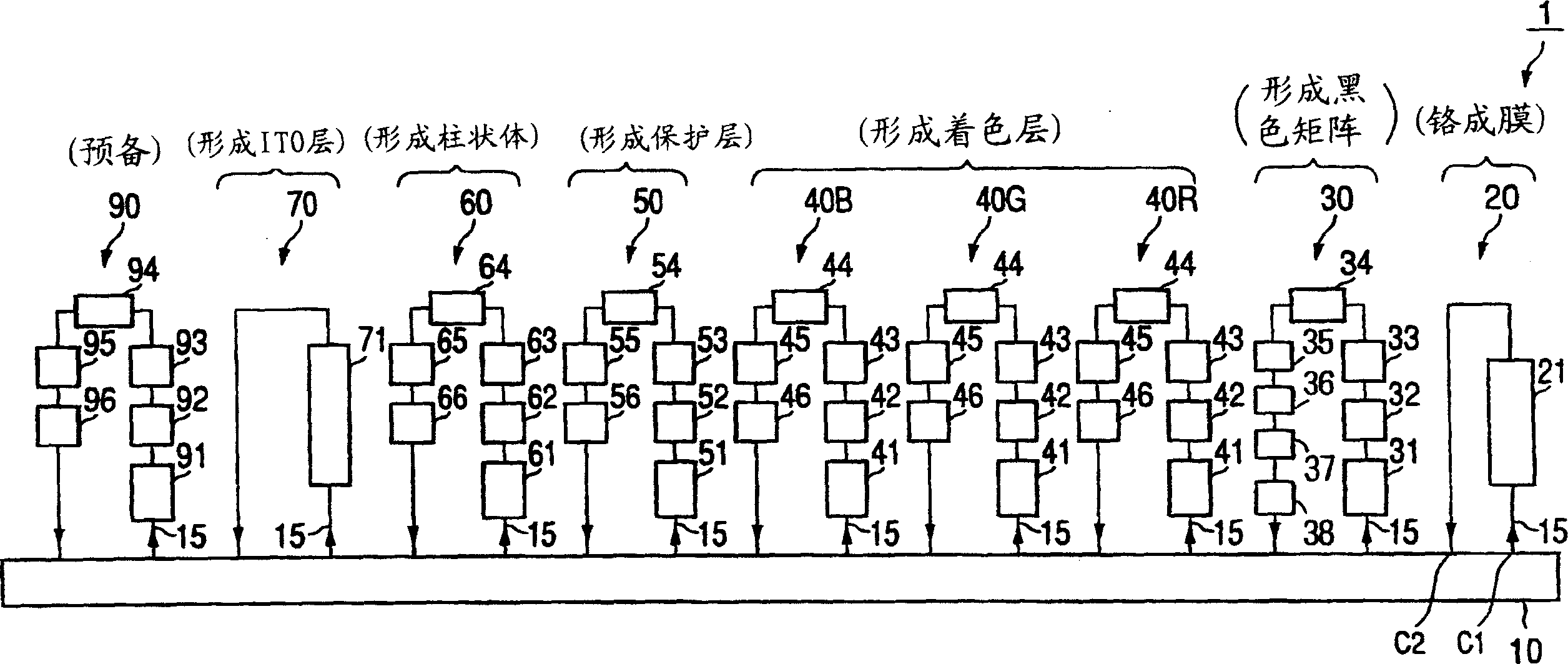

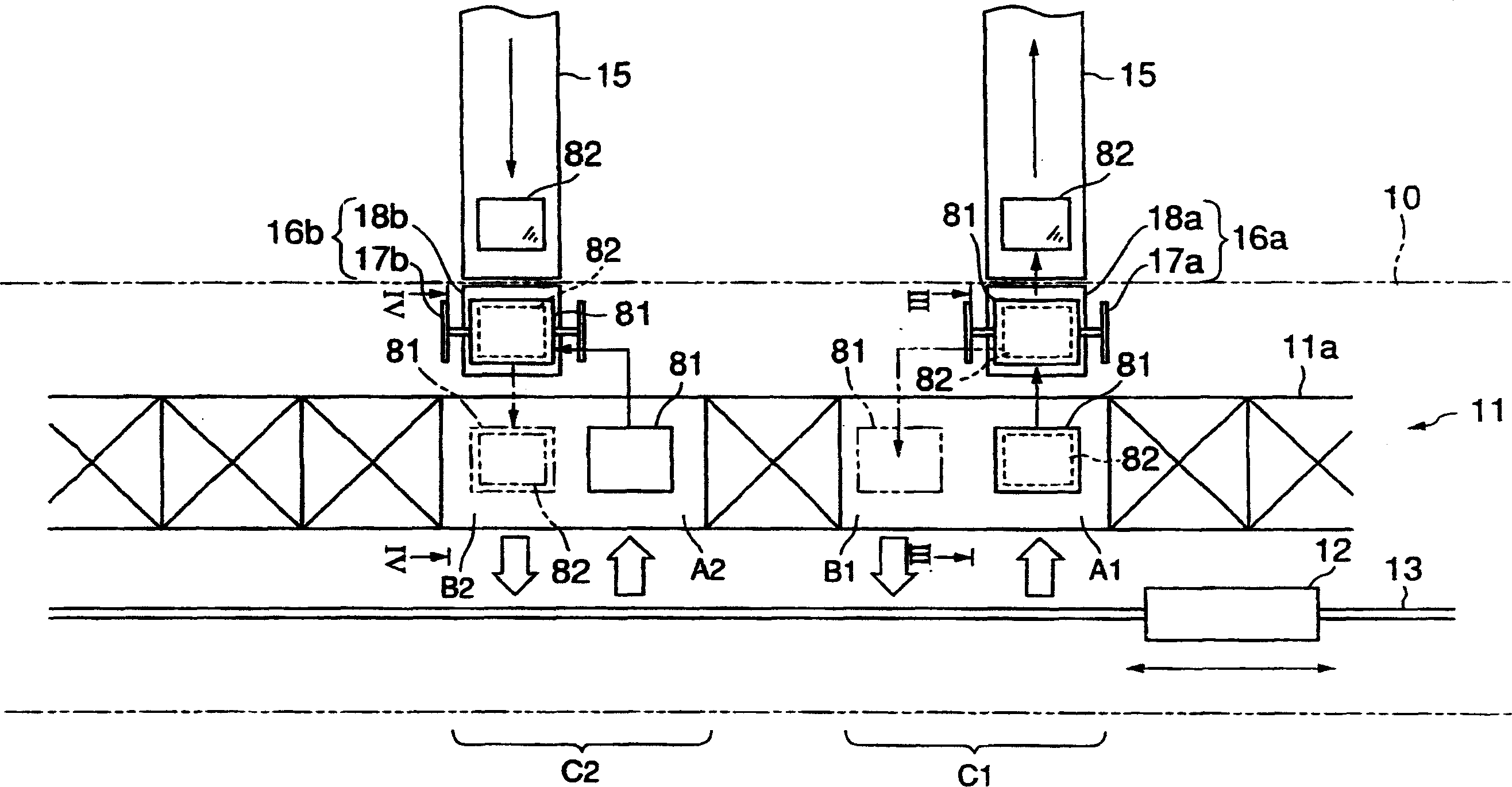

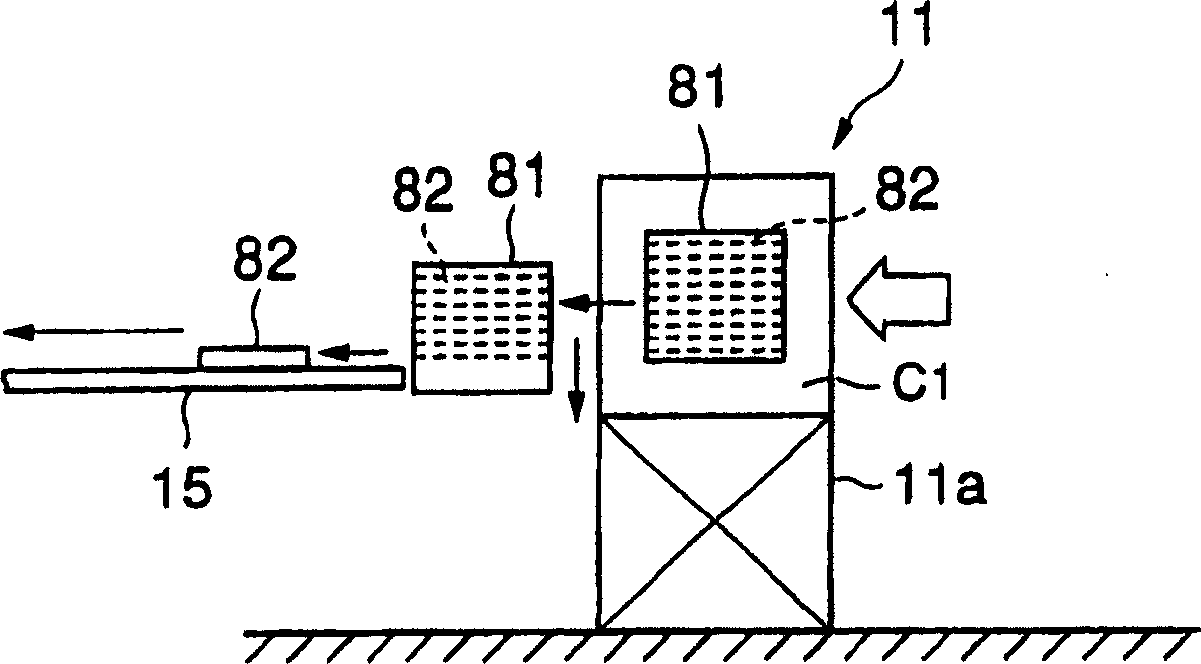

[0061] Such as figure 1 As shown, the production line system 1 of the first embodiment of the present invention has a stacking and lifting type hub device 10 that stores a plurality of substrate-containing boxes or empty boxes that store a plurality of glass substrates. A plurality of delivery positions (export position C1 and import position C2) of the device 10 are respectively connected, and various processes for manufacturing color filters are performed with respect to the glass substrate stored in the box after the substrate in the storage hub device 10 is stored. A plurality of processing lines 20, 30, . . . 70, 90 are processed. In addition, the hub device 10 is arranged in a linear extension on the horizontal setting surface, and each processing line 20, 30, ... 70, 90 is laterally outward in an inverted U shape from the side of the hub device 10 on the setting surface. stretch mode setting.

[0062] First, use figure 1 , the configuration of the processing lines 20...

no. 2 Embodiment

[0094] Below, use Image 6 A second embodiment of the present invention will be described. In addition, in the second embodiment of the present invention, except for (1) in the plate making line that realizes the processing steps including photolithography processing, a common defect detection device that detects common defects occurring at the same position of a plurality of glass substrates to be processed is equipped. As for the inspection machine, (2) there is a board inspection line for inspecting (correcting if necessary) the processed boards processed by each processing line; The other aspects of the substrate regeneration line that regenerates common defects or individual defects detected by the individual defect inspection machine included in the inspection machine or the substrate inspection line are substantially the same as those of the above-mentioned first embodiment. In the second embodiment of the present invention, the same parts as those in the above-mention...

manufacture example

[0114] Specifically, the color filter sheet is manufactured by sequentially processing the glass substrate 82 according to a predetermined order using the processing lines 20, 30, . . . . , 70 at the unloading position C1, among the substrate-stored cassettes 81 stored in the stocker 11, the cassettes 81 for accommodating the glass substrates processed up to the previous processing steps are selectively positioned. In addition, the manufacture of the color filter sheets due to the processing lines 20, 30, ..., 70, for example, follows (1) chromium film formation (processing line 20), (2) formation of black matrix (processing line 30), ( 3) Formation of red colored layer (processing line 40R), (4) formation of green colored layer (processing line 40G), (5) formation of blue colored layer (processing line 40B), (6) formation of protective layer ( Processing line 50), (7) columnar body formation (processing line 60), (8) ITO layer formation (processing line 70) are performed in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com