Dedusting and dehumidifying method for air with freezing method and equipment thereof

A technology of gas dust removal and freezing method, applied in gas dust removal, condensed non-gaseous material gas purification, separation methods, etc., can solve problems such as affecting human health, increasing dust concentration, hidden safety hazards, etc., saving energy consumption and reducing relative humidity. , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

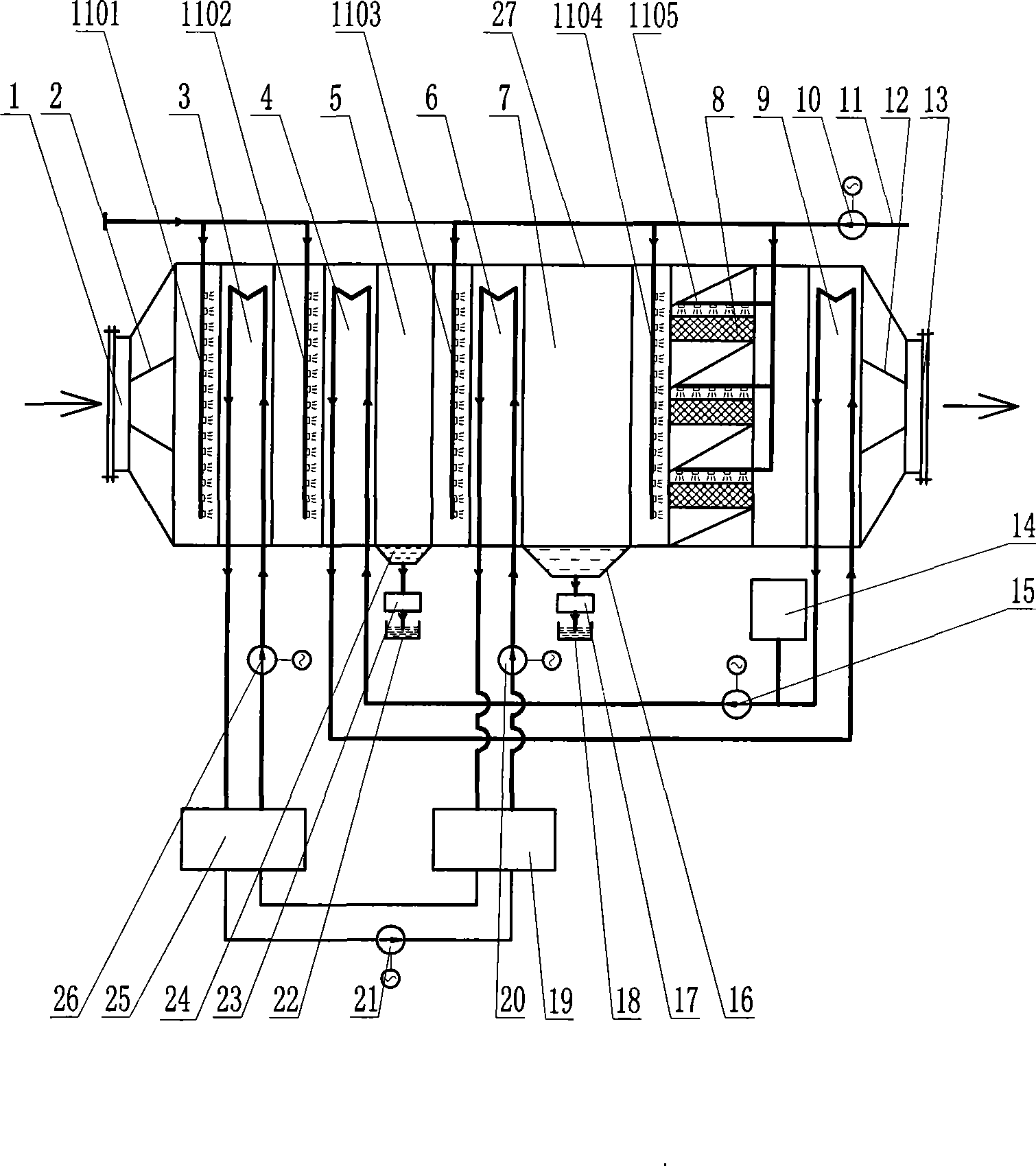

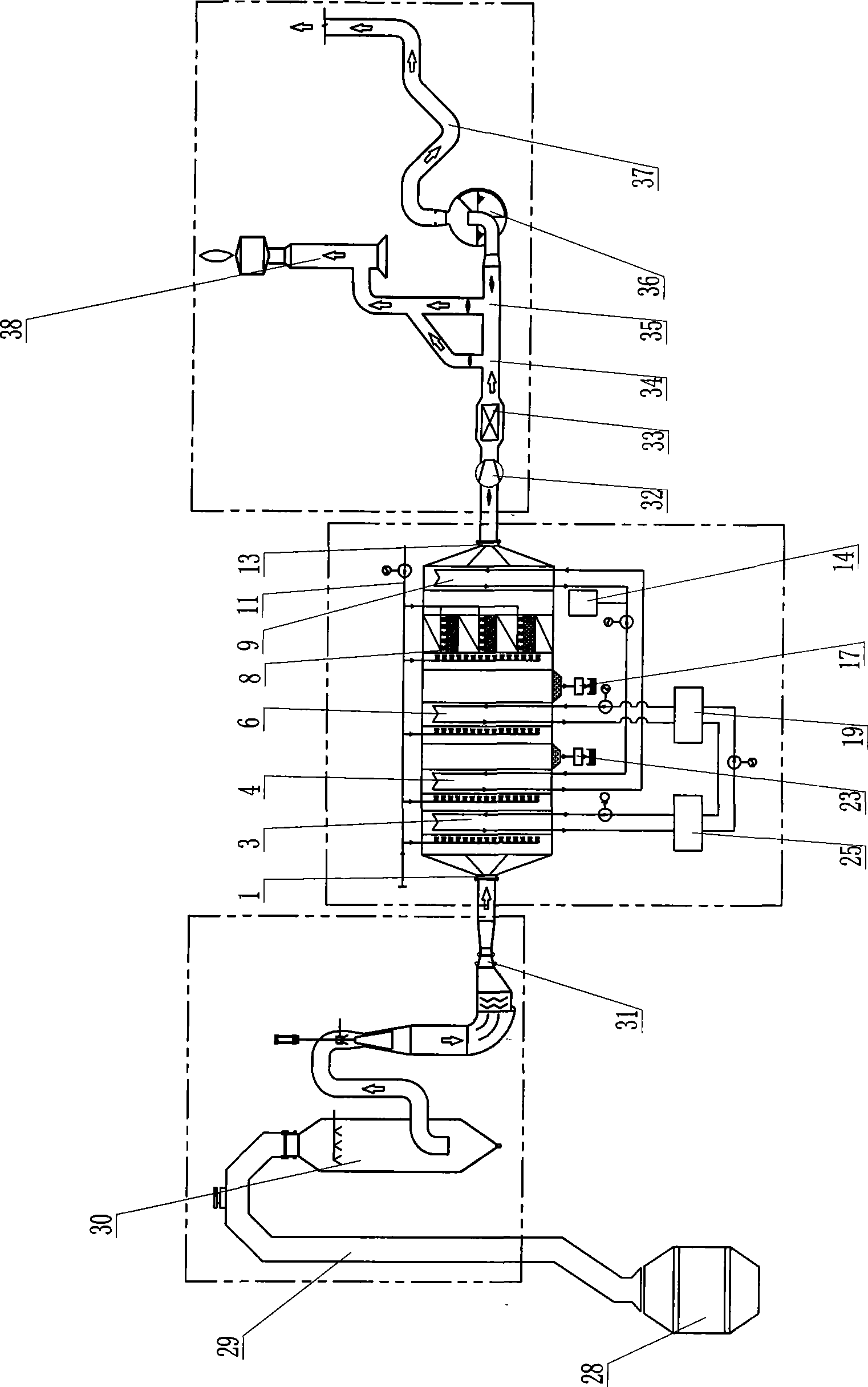

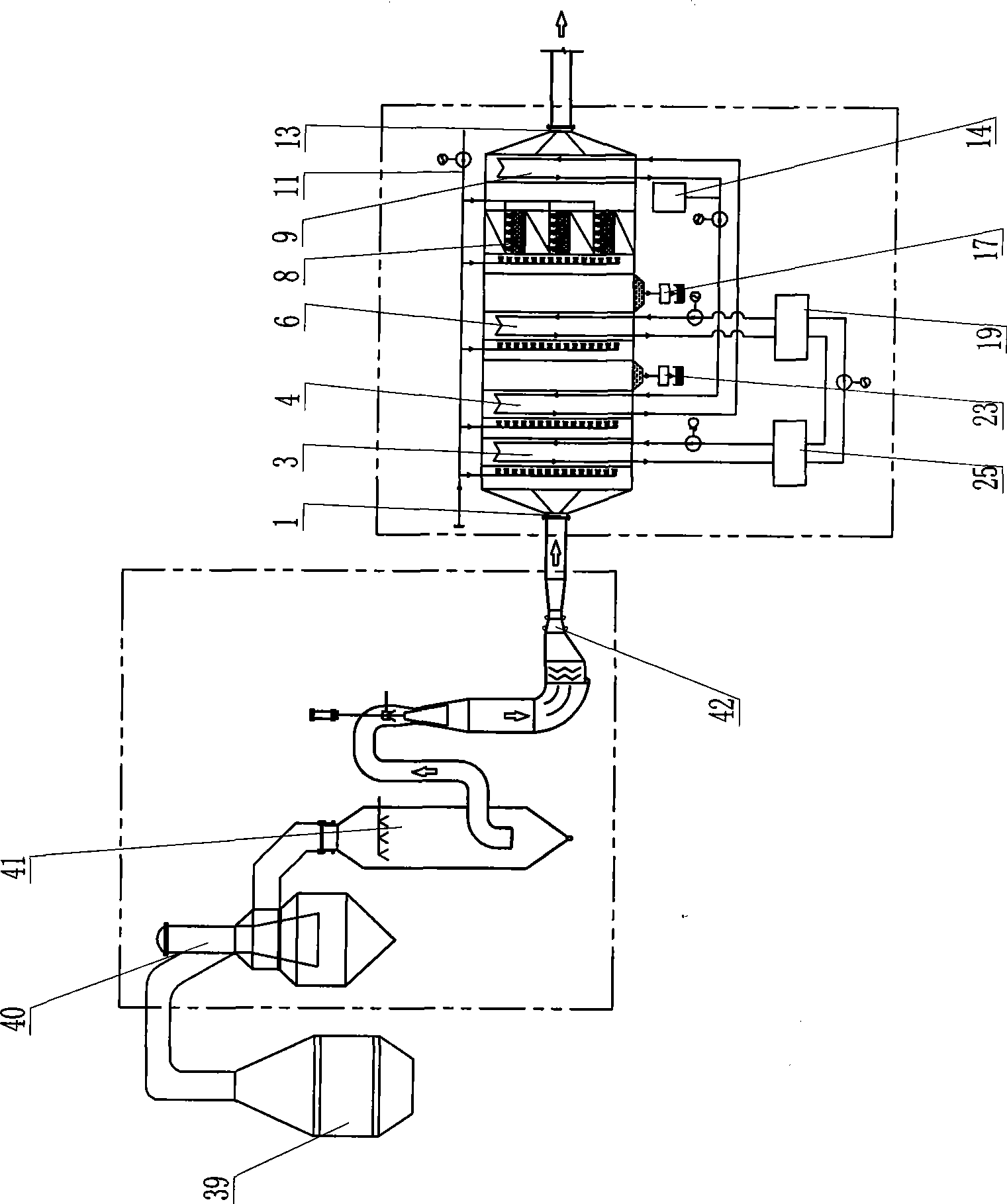

[0024] like figure 1 As shown, the present invention includes a housing 27, the two ends of the housing 27 are provided with a gas inlet 1 and a gas outlet 13, and the gas inlet 1 and the gas outlet 13 are respectively connected to the gas delivery pipeline. Inlet deflector 2, pre-cooler 3, self-circulating cooler 4, first drainage section 5, cooler 6, second drainage section 7, demister 8, reheating heater 9 and outlet deflector 12 sequence The device is installed in the housing 27 between the gas inlet 1 and the gas outlet 13. The above-mentioned precooler 3, self-circulating cooler 4, cooler 6 and reheating heater 9 can all use bare tube or finned tube heat exchangers Structure, precooler 3 is connected with cooling equipment 25 through pipeline and water pump 26, and cooling equipment 25 is the cooling tower or othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com