Blocking cleaning process for COREX smelting reduction furnace dust-removal system

A technology of dust removal system and reduction furnace, which is applied to furnaces, shaft furnaces, descaling devices, etc., can solve the problems of high dust temperature, high gas nitrogen content, large amount of hot cyclone accumulation, etc. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

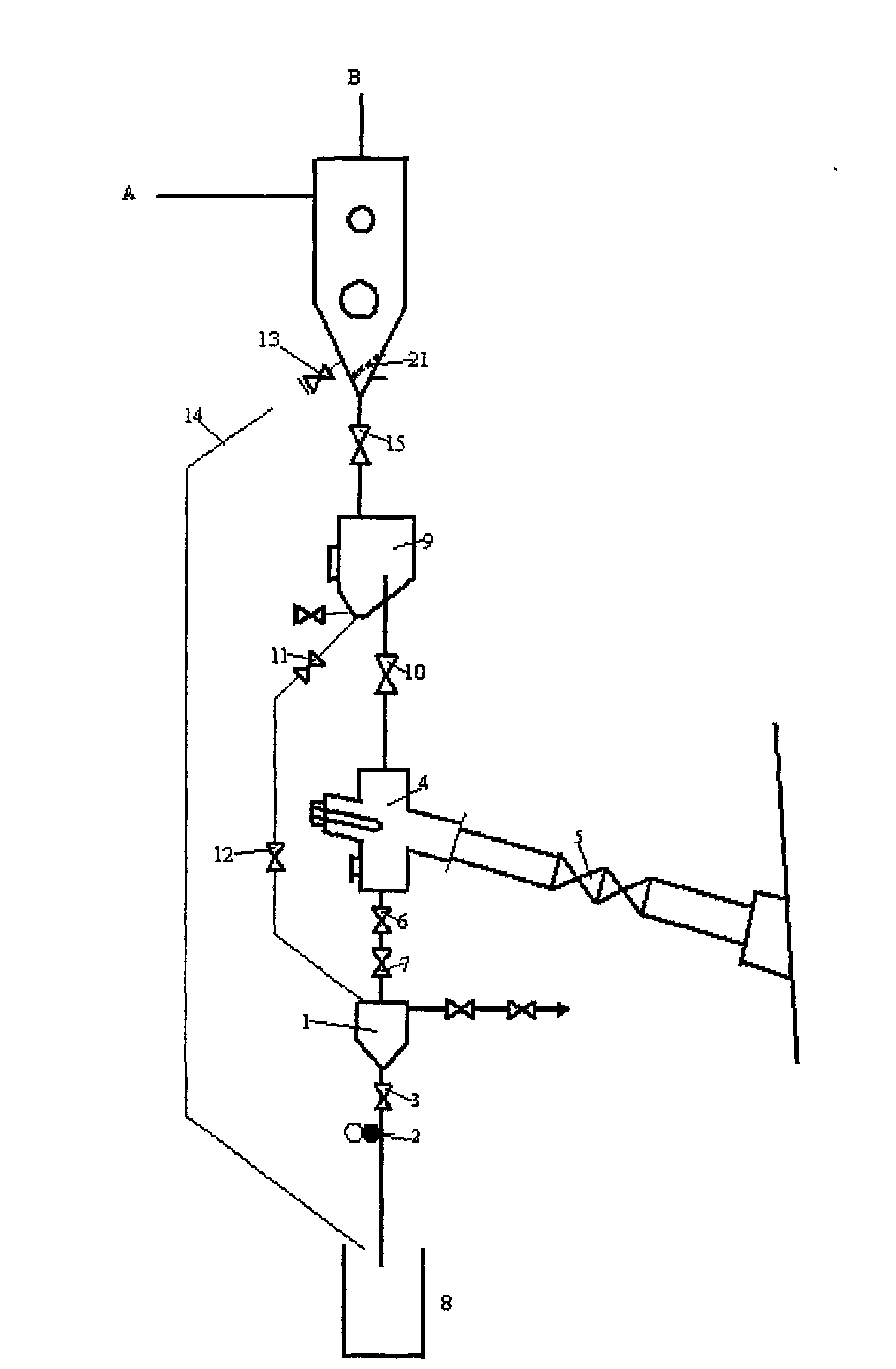

[0028] Such as figure 1 as shown, figure 1 Among them, A is the gas inlet with dust, and B is the gas outlet. The cleaning process of the dust removal system of the COREX smelting reduction furnace of the present invention includes two steps of cleaning the dust back blowing system and hot cyclone cleaning;

[0029] The so-called dust blowback system clearing includes:

[0030] (1) Dredge collection tank 1, dredge by opening glasses valve 2 and ash discharge valve 3;

[0031] (2) Unclog TP chamber 4: first open the burner shut-off valve 5, then open the nitrogen valve of TP chamber 4, after 20 minutes, close the nitrogen valve of TP chamber, open the first valve 6 and the second valve 7, and let the dust pass through The collection tank 1 enters the dustbin 8, and finally the blind plate of the TP chamber 4 is opened to check the cleaning o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com