Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

885results about "Incrustation removal devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

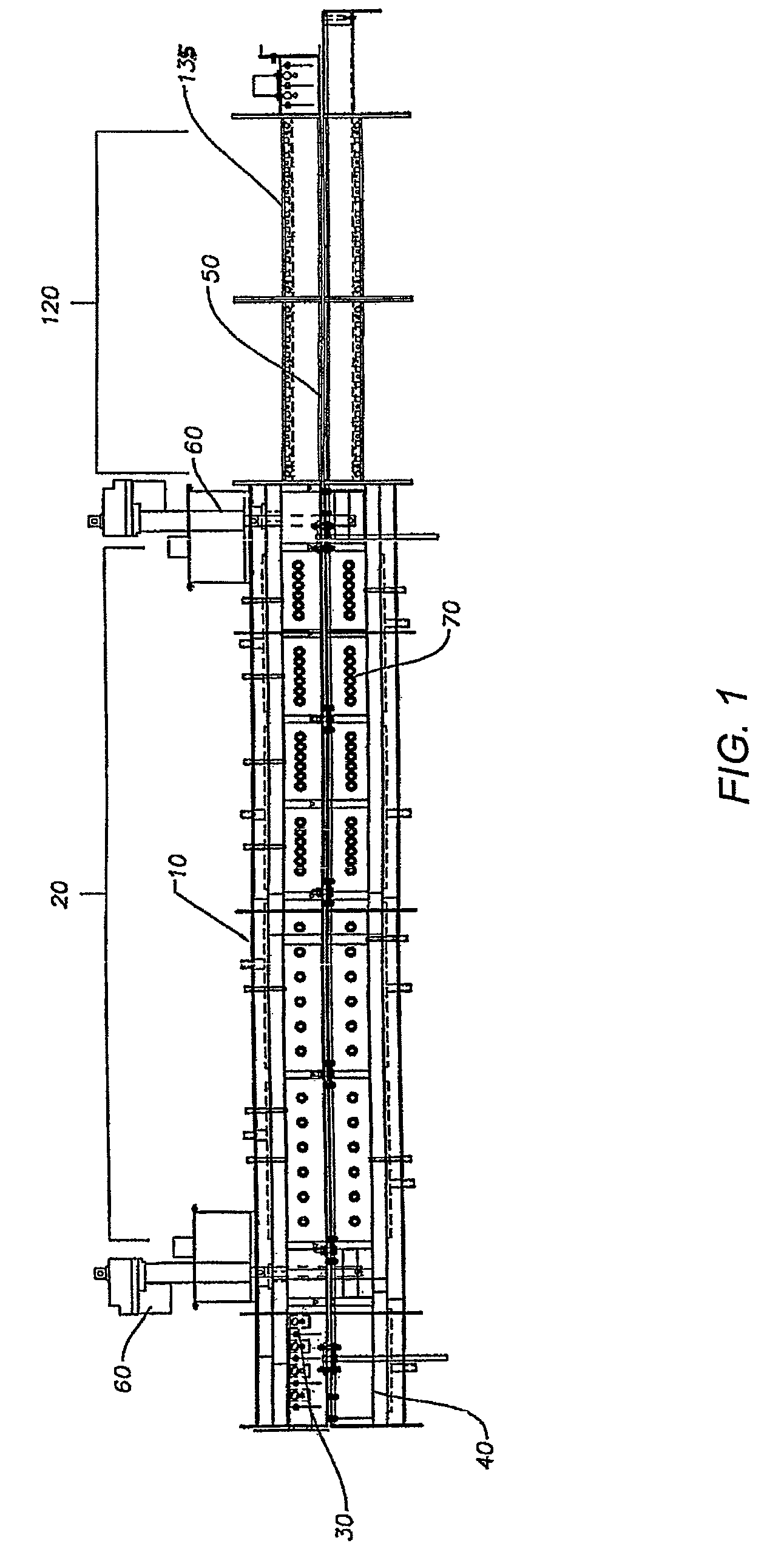

System and method for component maintenance

InactiveUS20140265068A1Keep the flowReduce the possibilityCharge manipulationManufacturing convertersMarine engineeringMolten metal

Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain and degas molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel is pulled through the vessel by the pump as it is degassed. This helps maintain a generally constant flow of molten metal through the degassing vessel. Other aspects relate to a system and method for efficiently performing maintenance on components positioned in a vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

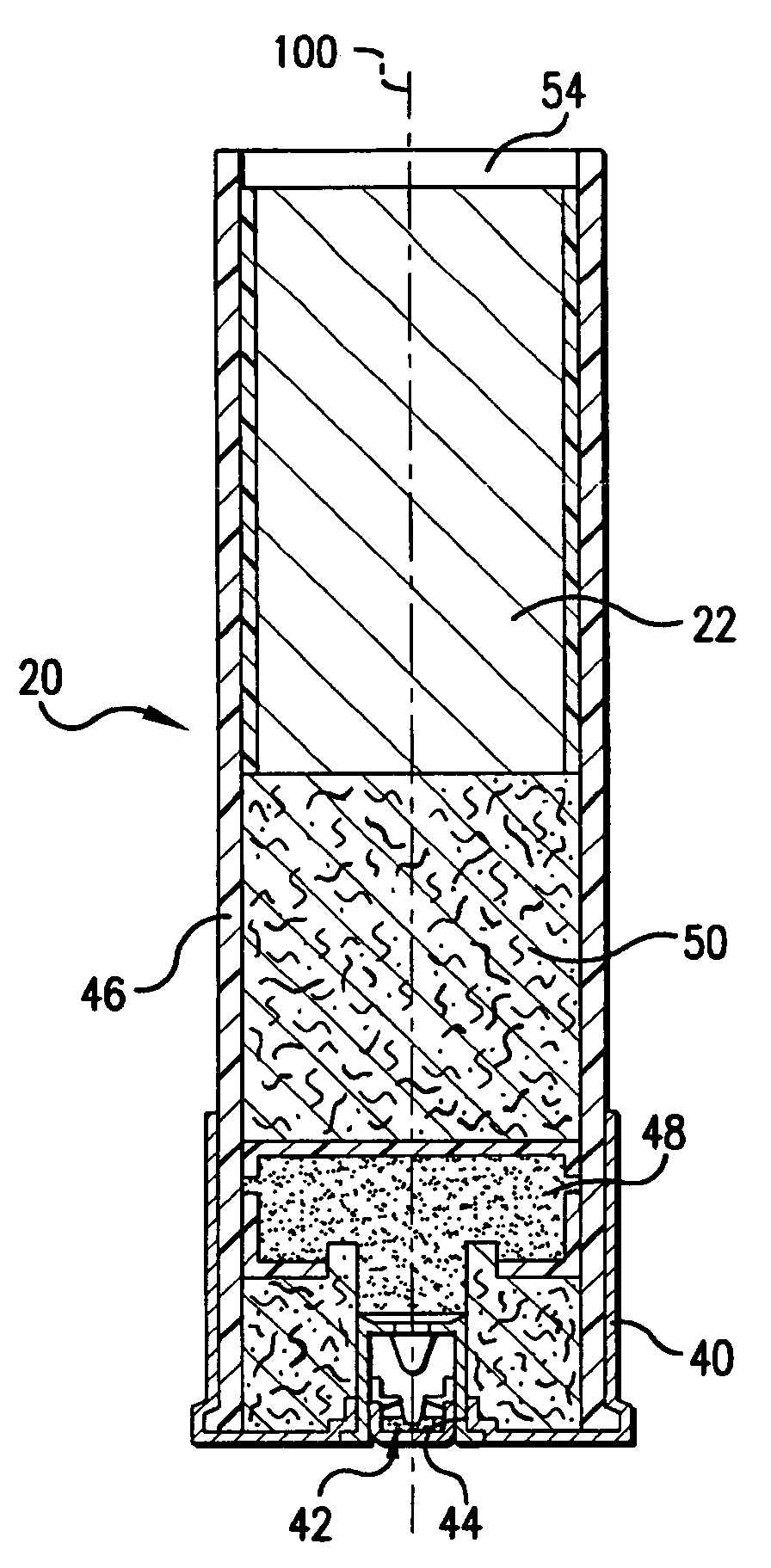

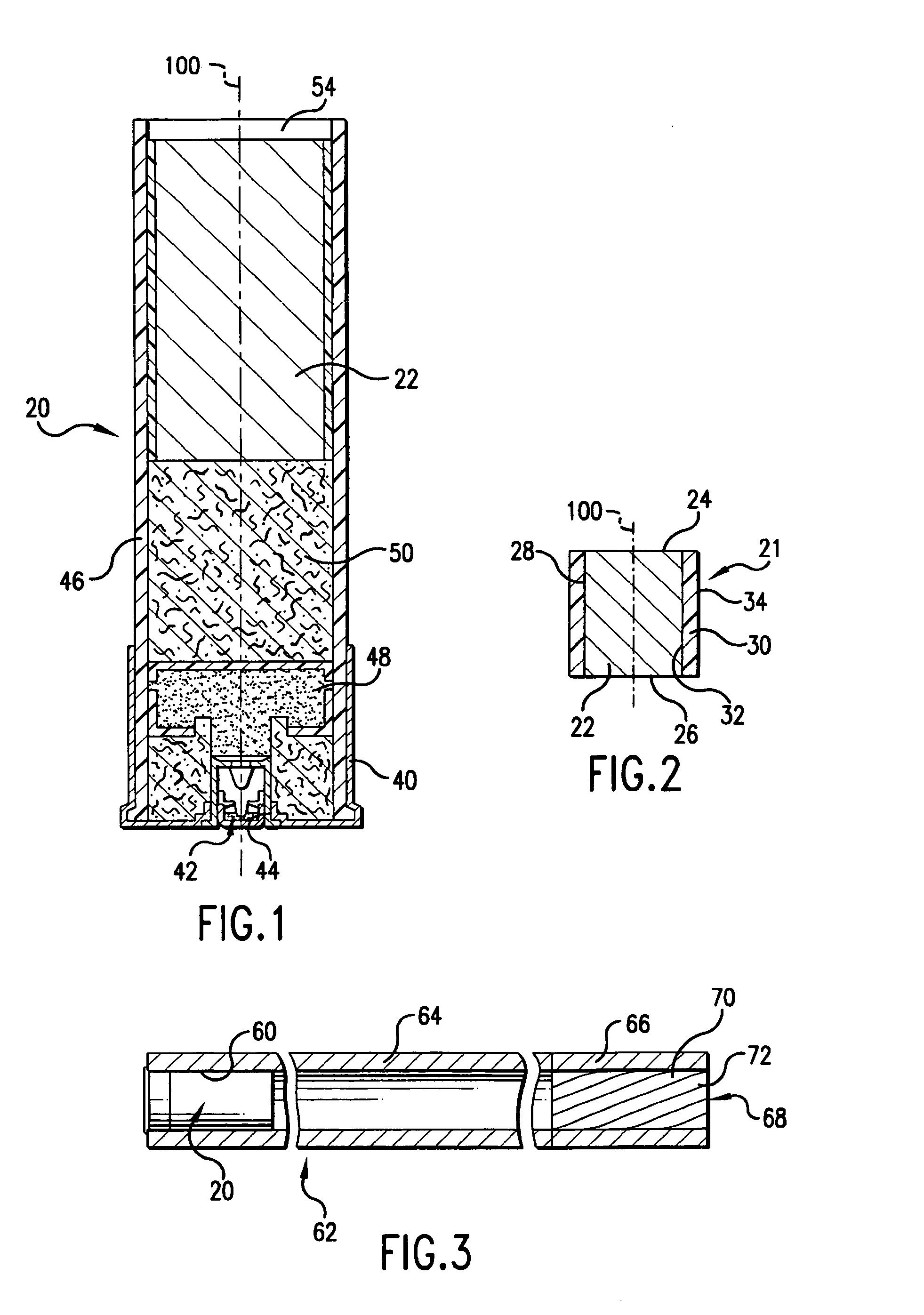

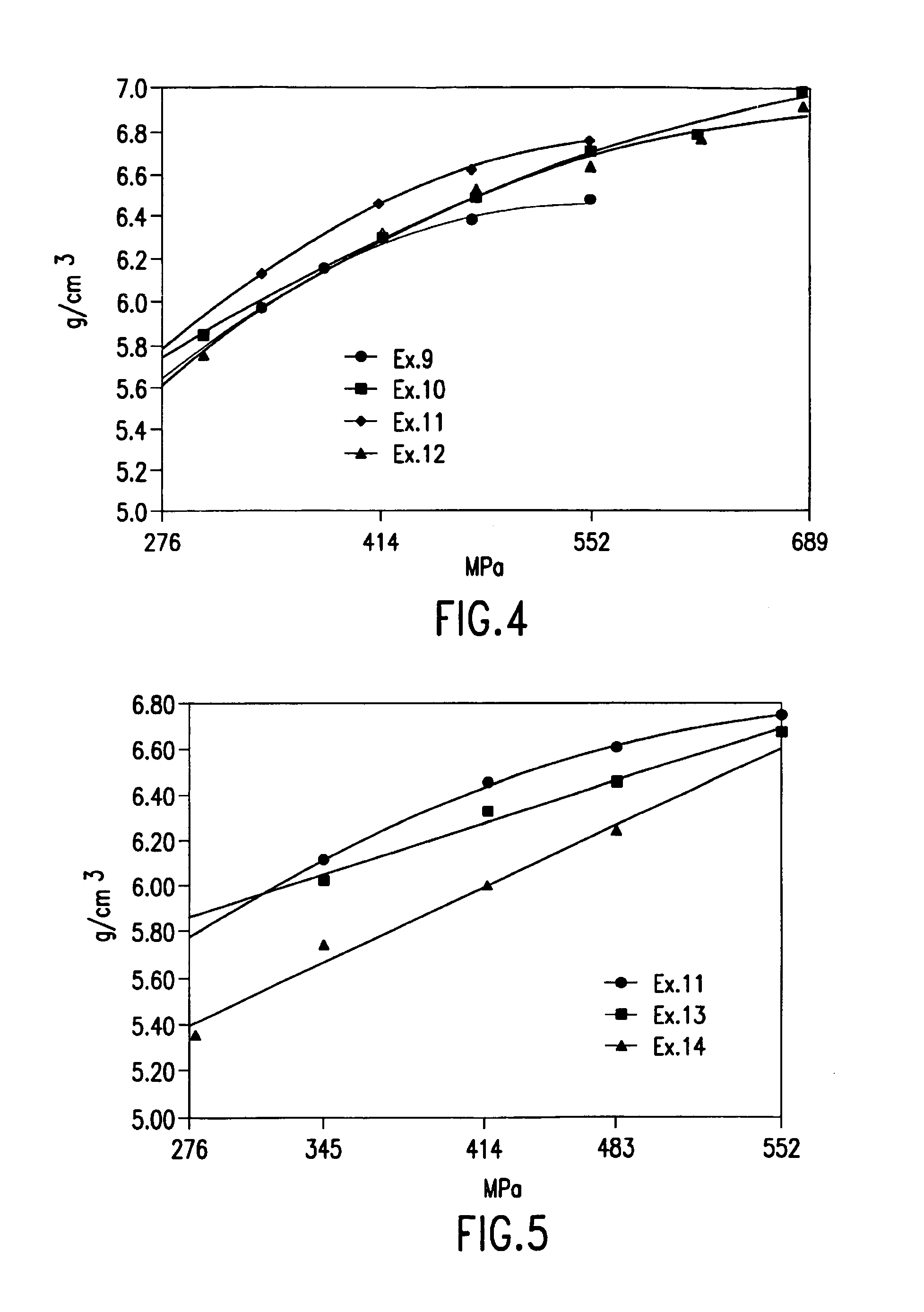

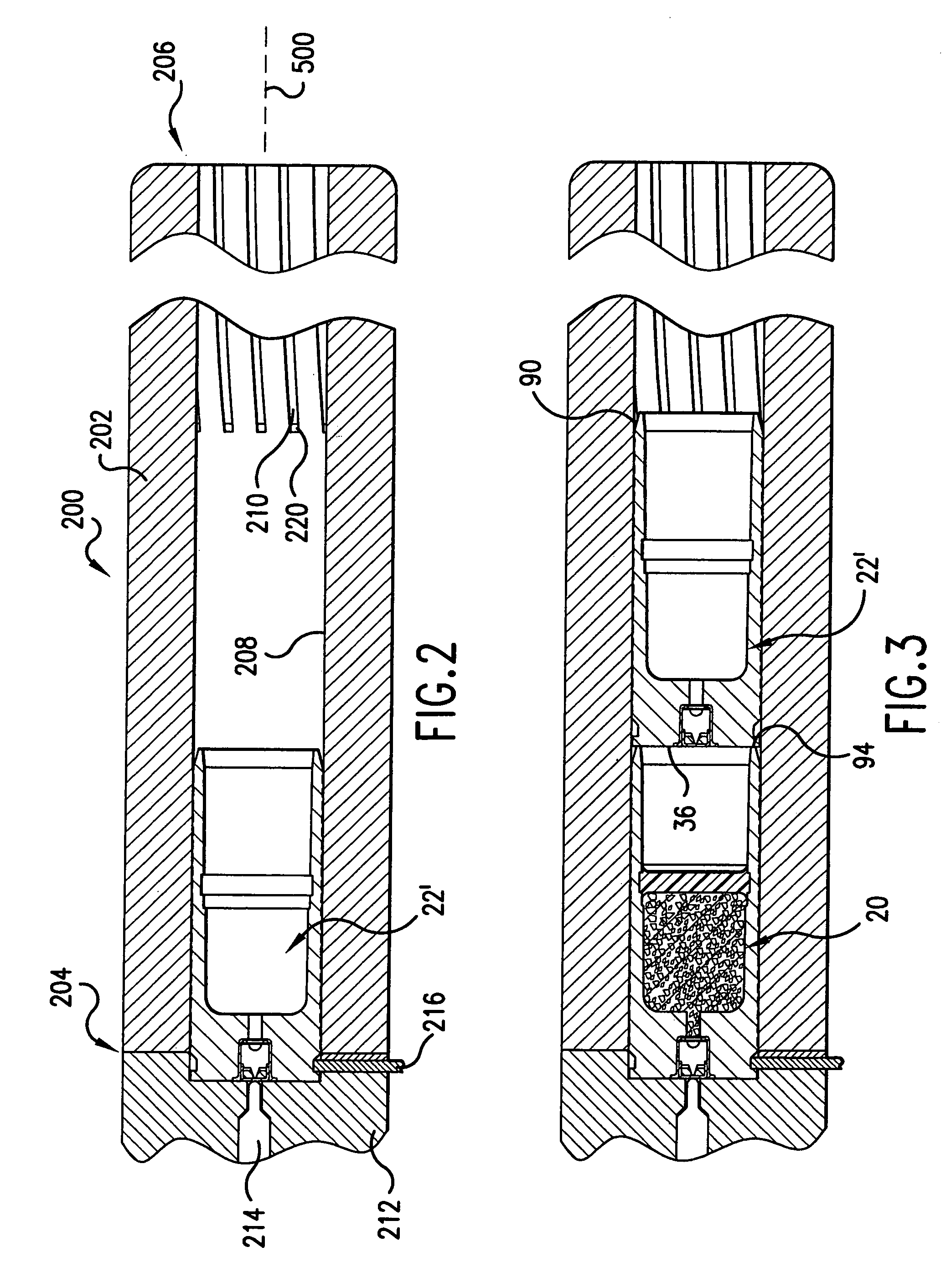

Slug for industrial ballistic tool

InactiveUS7159519B2Reduces and eliminates introductionTo offer comfortAmmunition projectilesShotgun ammunitionParticulatesImpurity

A frangible projectile for expelling from an industrial ballistic tool may be formed by a powder metallurgy process. A preferred embodiment of slug consists essentially of compacted and optionally sintered material and comprises up to 35% ferrotungsten in particulate form, up to 3% lubricant, and the balance iron in particulate form with inevitable impurities.

Owner:OLIN CORP

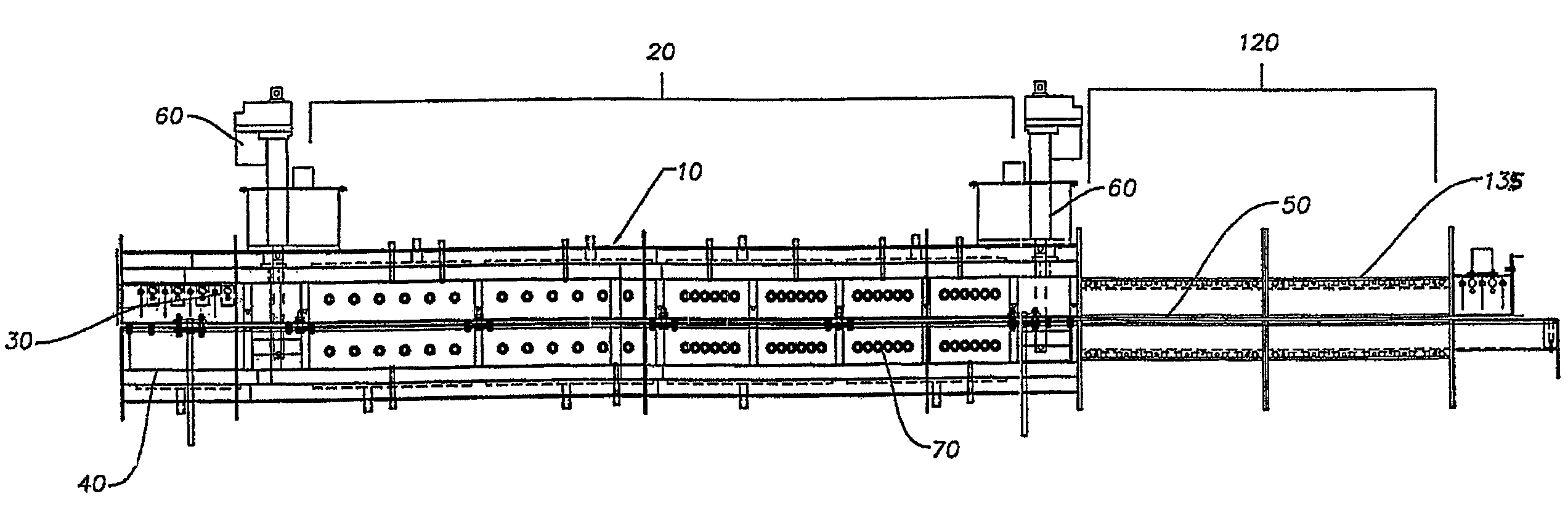

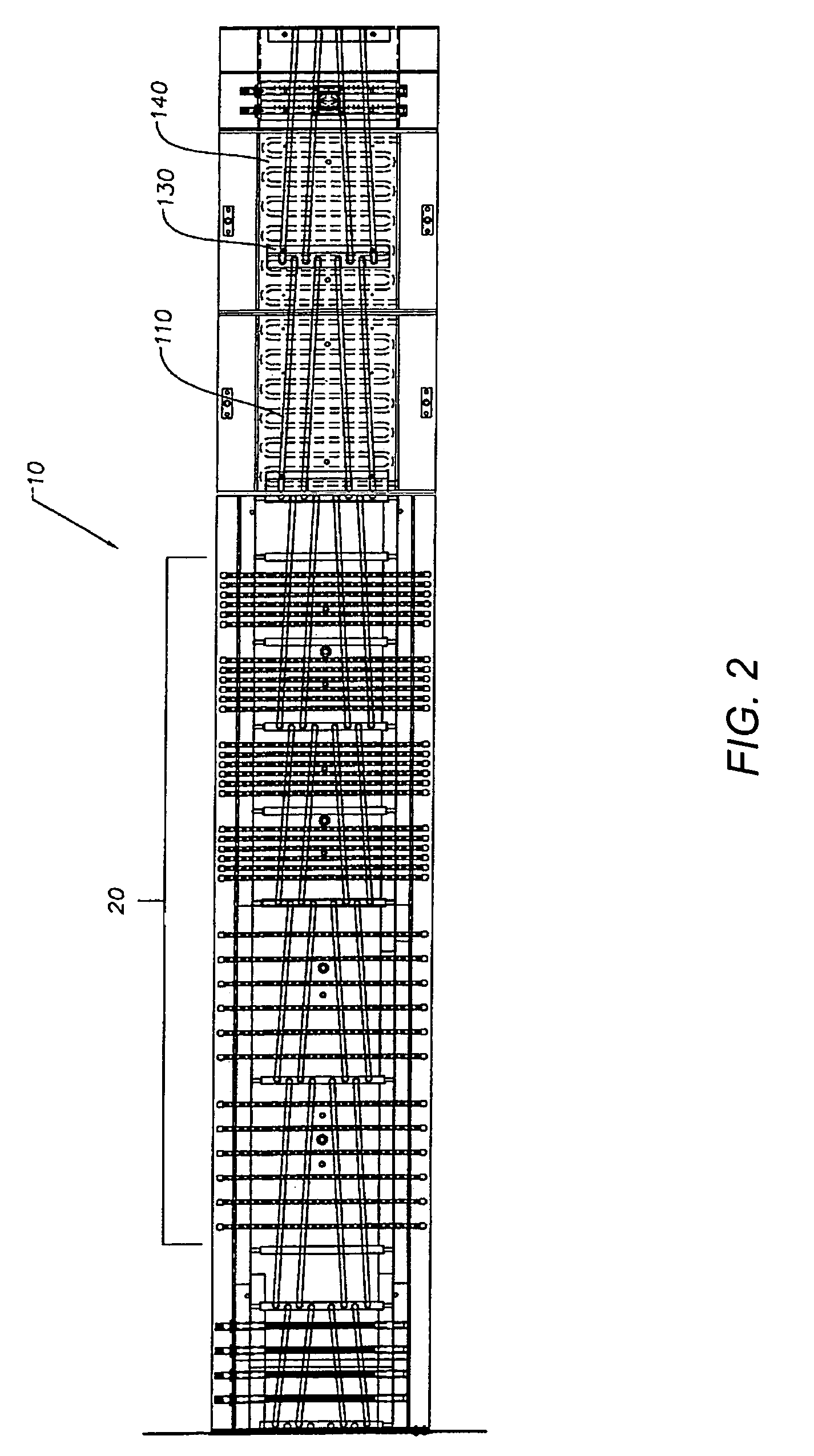

Continuous infrared furnace

A furnace of controlled heating and treatment of material using infrared radiation. The furnace is capable of continuous infrared treating of material with consistent radiation being applied to the material, ease of access to the furnace for maintenance cleaning and repair, excellent control of radiant cooling of the material to be treated, and ease of maintenance of a volatile component condenser.

Owner:ILLINOIS TOOL WORKS INC

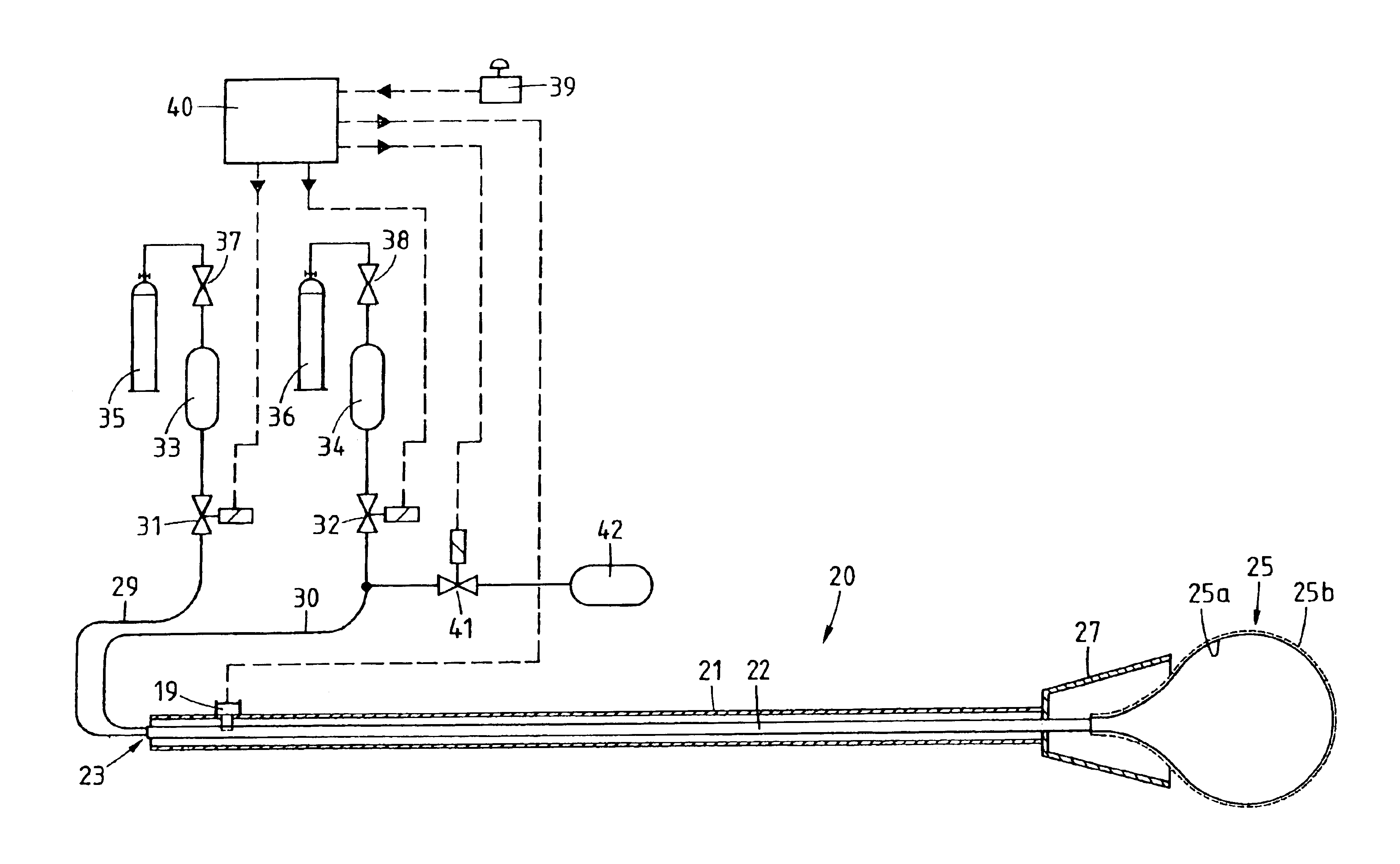

Method for cleaning combustion devices

InactiveUS6935281B2Short timeProcess can be minimizedLinings repairBoiler cleaning apparatusCombustionSlag

An on-line method and a device for cleaning of contamination such as caking or slag deposits from surfaces in vessels and combustion installations by means of blasting technology. An explosive gas mixture is made to detonate in the proximity of the deposits and thereby clean the deposits from the surfaces.

Owner:BANG & CLEAN

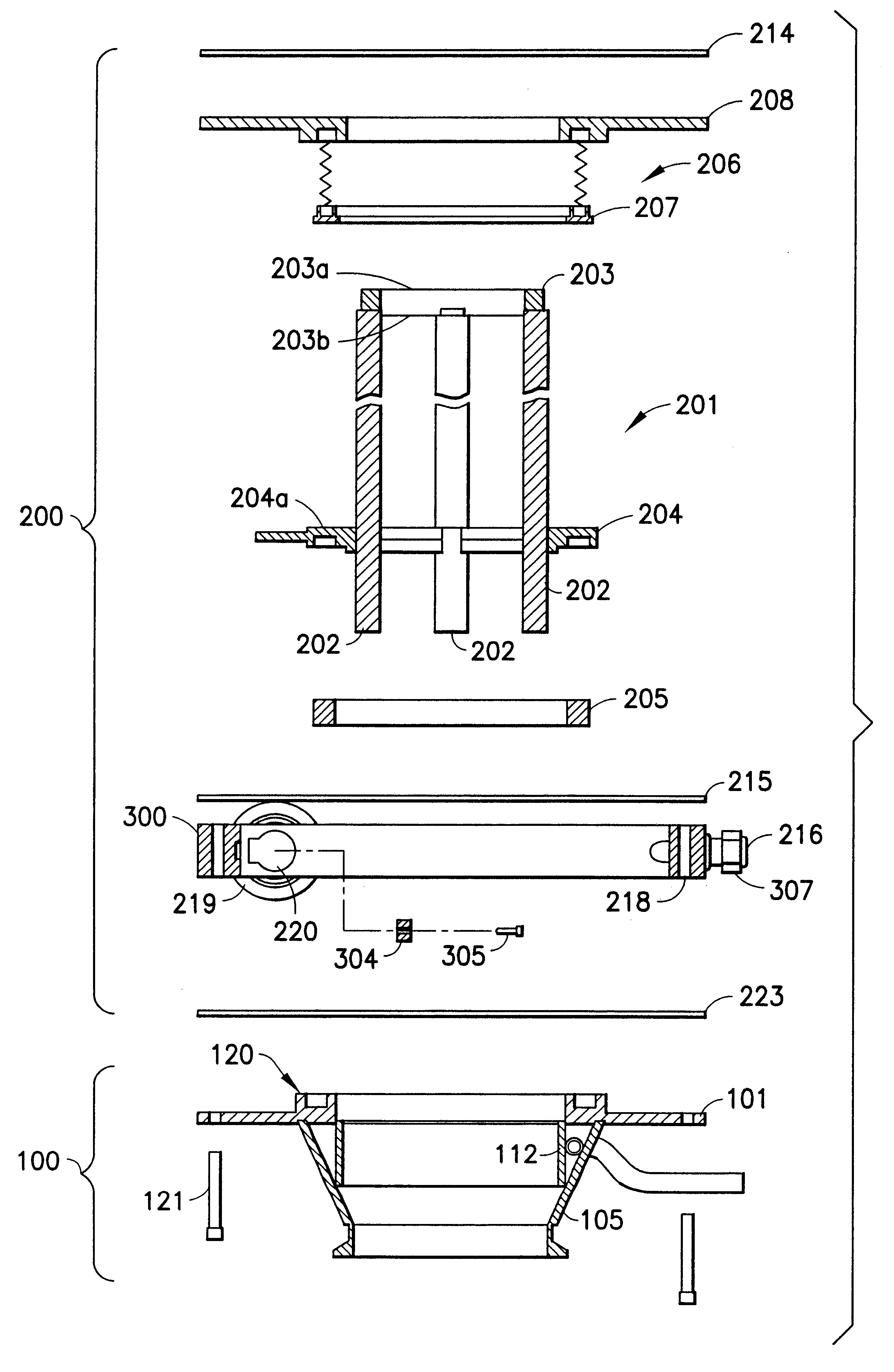

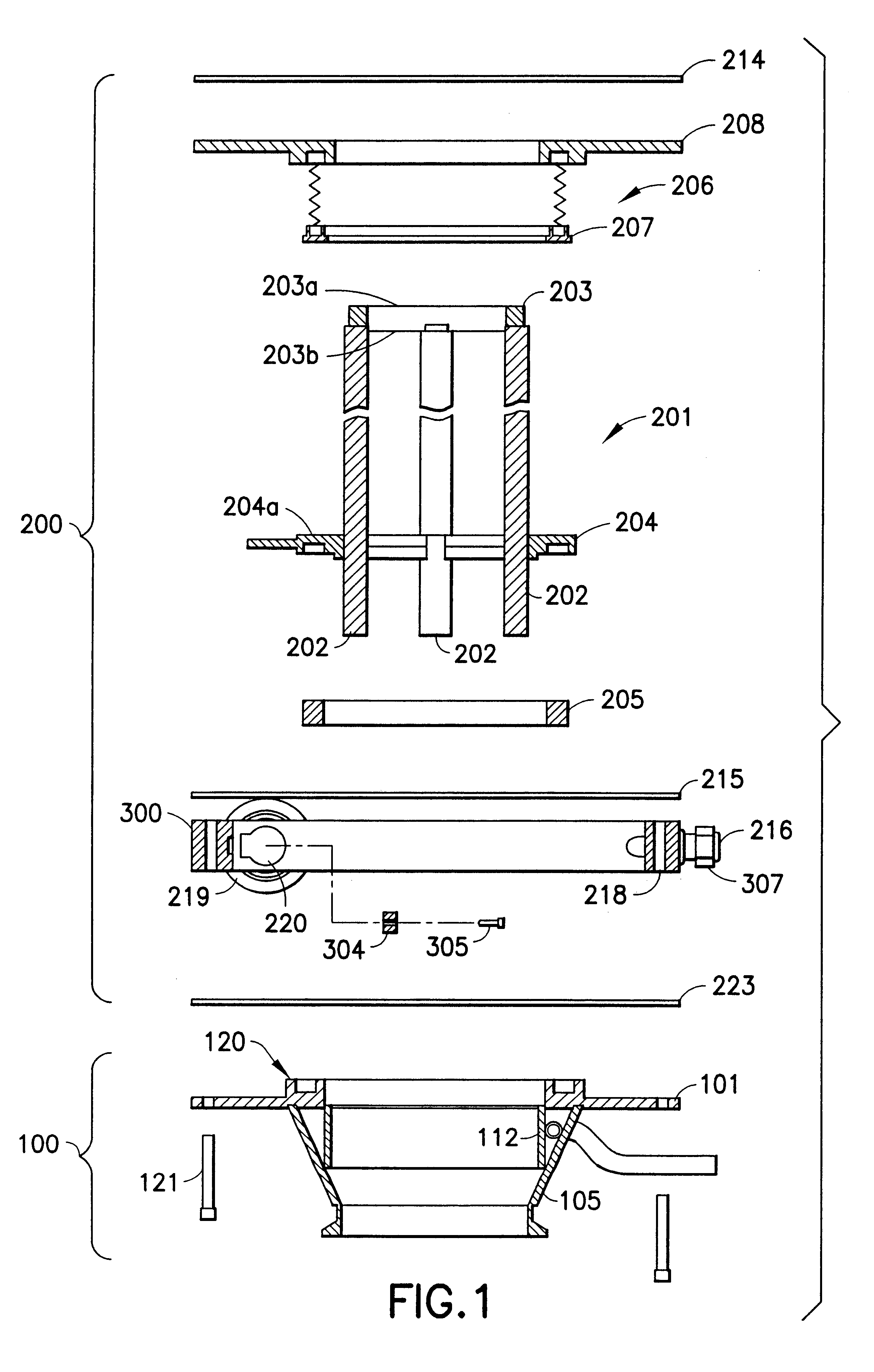

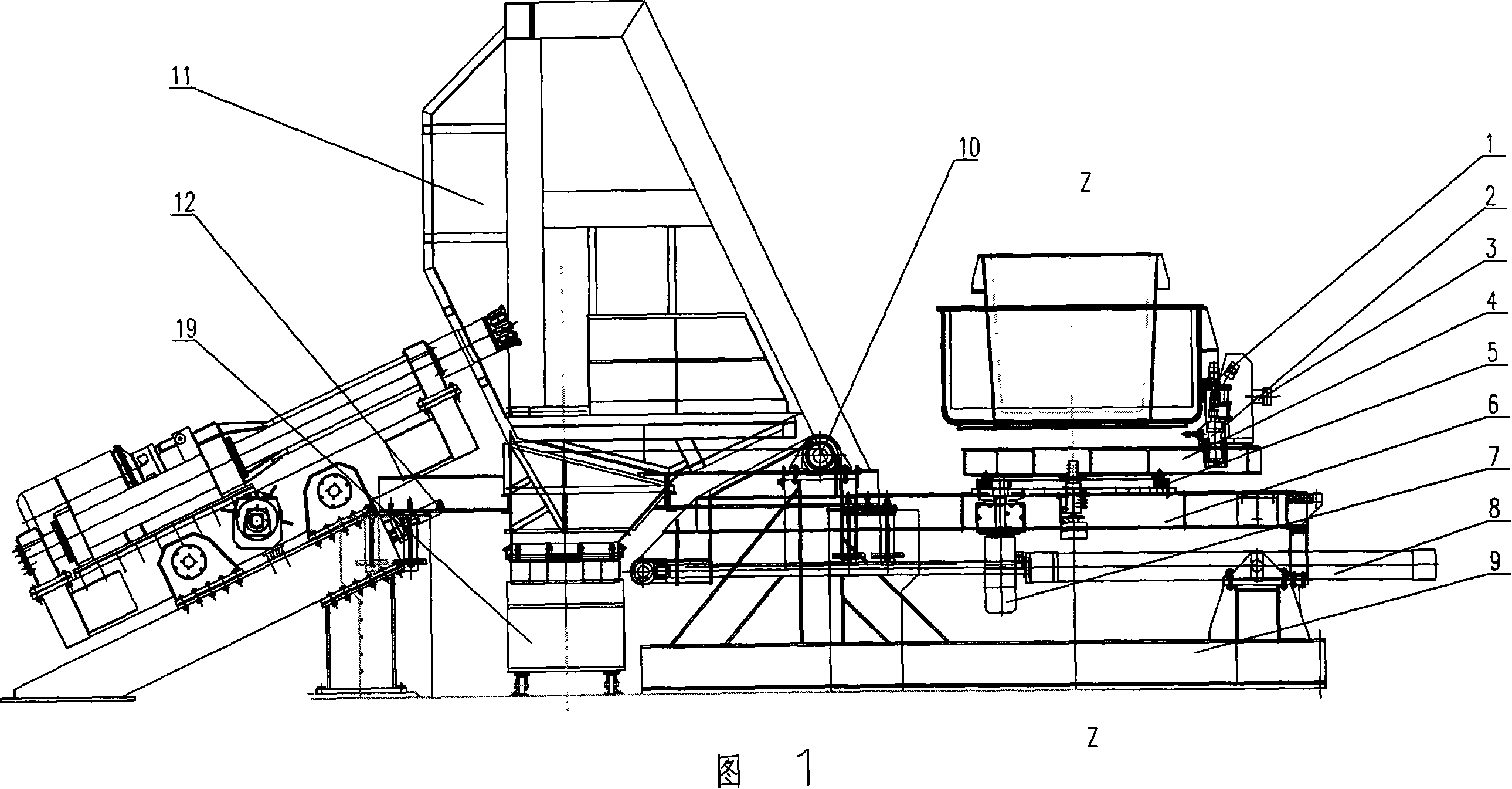

Apparatus and method of use for casting system with independent melting and solidification

InactiveUS20110158887A1High purityLess capital investmentRotary drum furnacesBy pulling from meltThree stageTransfer mechanism

This invention relates to a two or three-stage apparatus and method of use to produce high purity silicon, such as for use in solar panels and / or photovoltaics. The device of this invention includes a melting apparatus with a delivery device, a holding apparatus with a tipping or transfer mechanism, and at least one solidification apparatus for receiving a molten feedstock. The optimized designs of individual apparatuses function efficiently in combination to produce high purity silicon.

Owner:AMG IDEAL CAST SOLAR

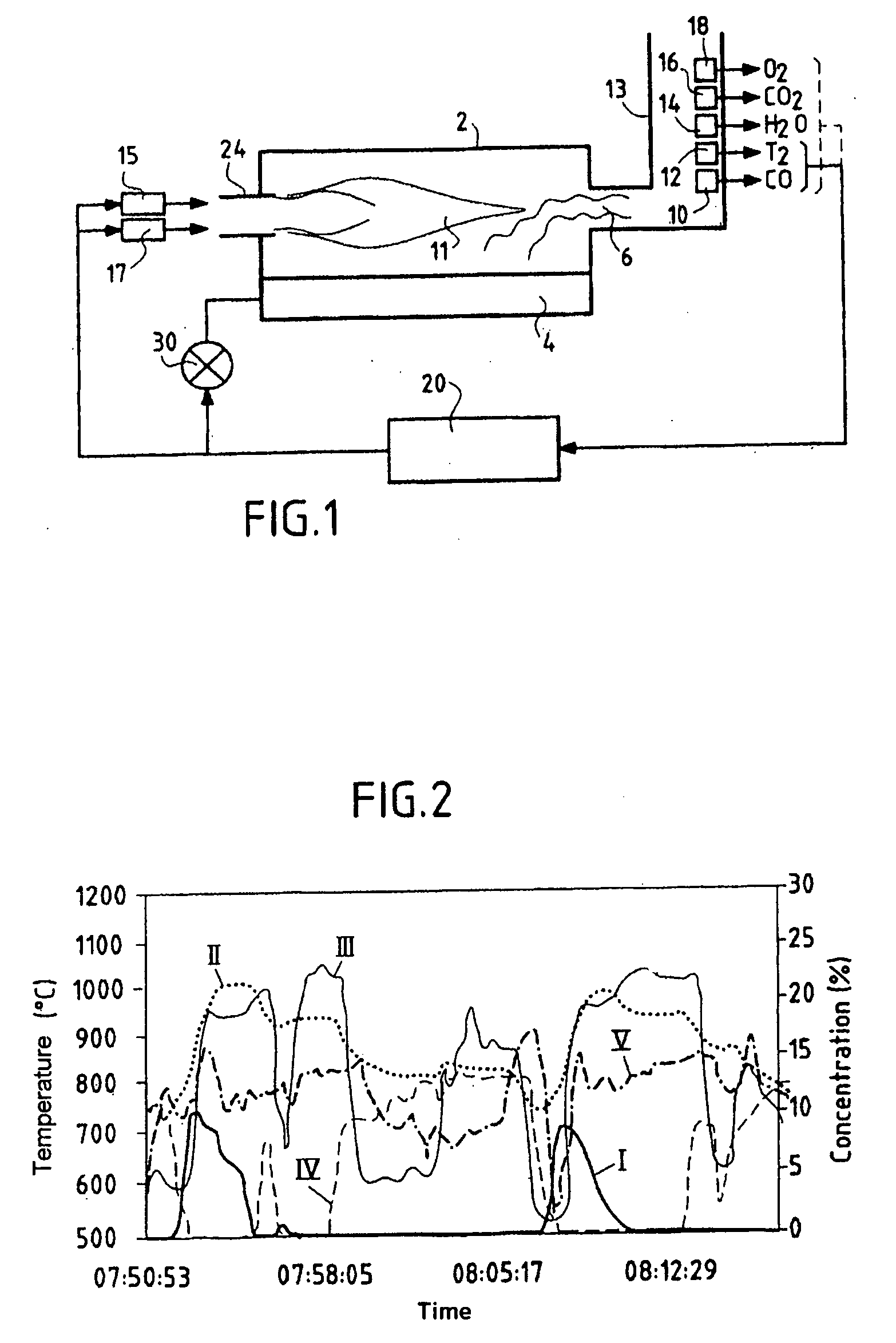

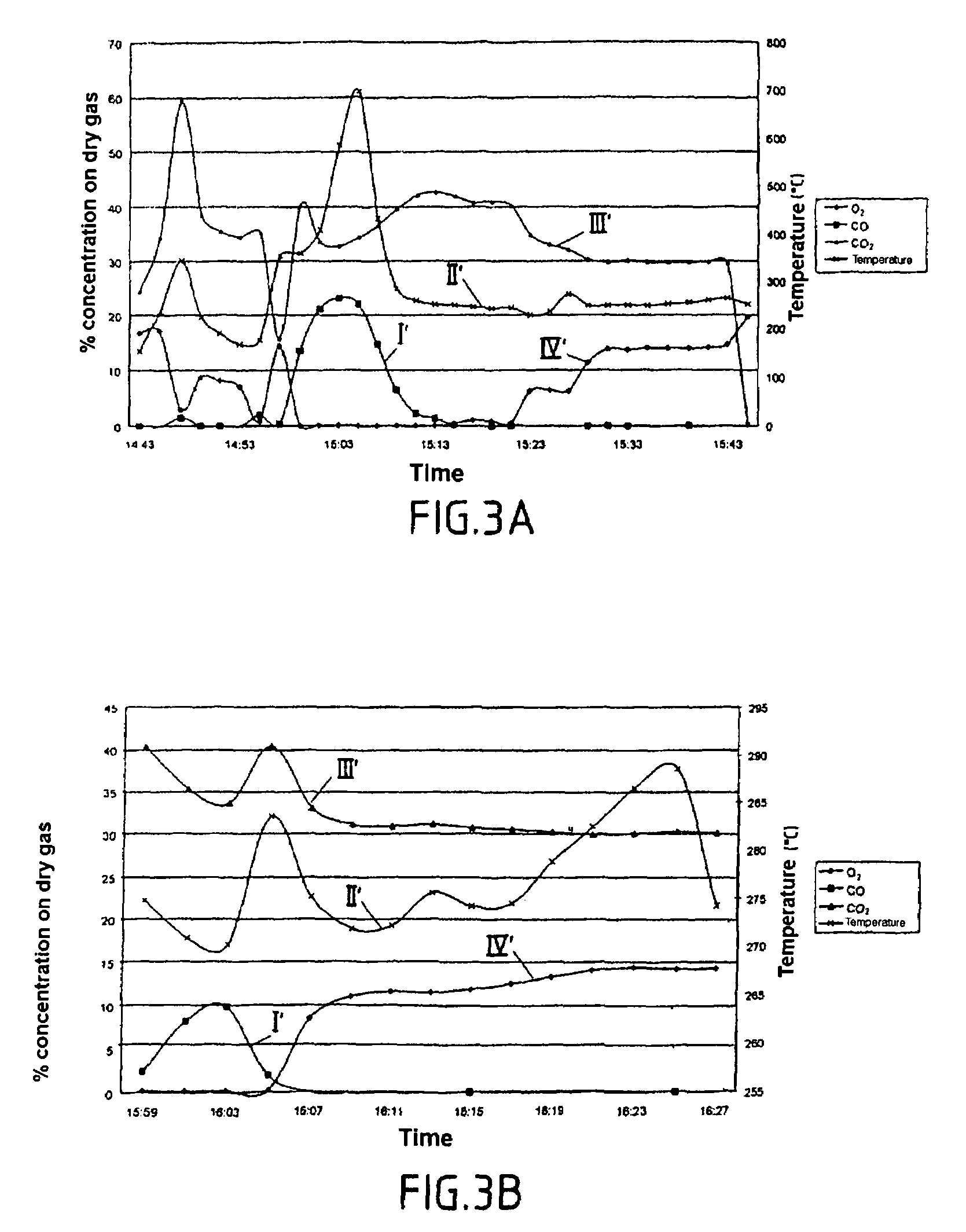

Aluminum melting method using analysis of fumes coming from the furnace

The invention concerns an alumnium melting method, which consists in introducing solid aluminium into a furnace (2), melting the aluminium to form an aluminium bath (4), detecting variations in carbon monoxide (CO) and / or hydrogen (H2) concentration and the temperature in the fumes (6) exiting from the furnace, deducing therefrom the formation of aluminium oxide at the surface of the alumnium bath (4), regulating the melting process on the basis of aluminium oxide formation. The invention also concerns a device for detecting and analyzing fumes exiting from the furnace and an aluminium melting furnace comprising said detecting device.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method for removing salamander from hearth roller of roller-hearth non-oxidation furnace

InactiveCN101968320AGuarantee the quality of the following tableAvoid consumptionIncrustation removal devicesFurnace temperatureEnergy analysis

The invention discloses a method for removing salamander from a hearth roller of a roller-hearth non-oxidation furnace. In the method, the furnace temperature of the roller-hearth furnace is reduced to 500 DEG C in a non-blowout state, and the salamander on the hearth roller is removed by mutual friction between the lower surface of a furnace dragging plate and the hearth roller. The method comprises the following specific steps of: making a bottom groove and edges of the dragging plate into a herringbone structure; manufacturing two steel plates for connecting the dragging plate with a chain and ensuring that the chain is positioned on the central line of the dragging plate; putting the dragging plate on a centering platform for centering, connecting the dragging plate with the chain, putting into the furnace, and connecting a hoisting machine with the chain through a steel wire rope for dragging the furnace; and changing the connecting position of the steel wire rope and the chain after dragging for a certain distance to carry out a next-section furnace dragging process until the salamander is completely removed from the hearth roller of the roller-hearth non-oxidation furnace. The method is high-efficiency and convenient; the salamander on the hearth roller is removed under the non-blowout condition; the lower surface quality of the discharged steel plates is ensured; and energy and production cost are saved.

Owner:NANJING IRON & STEEL CO LTD

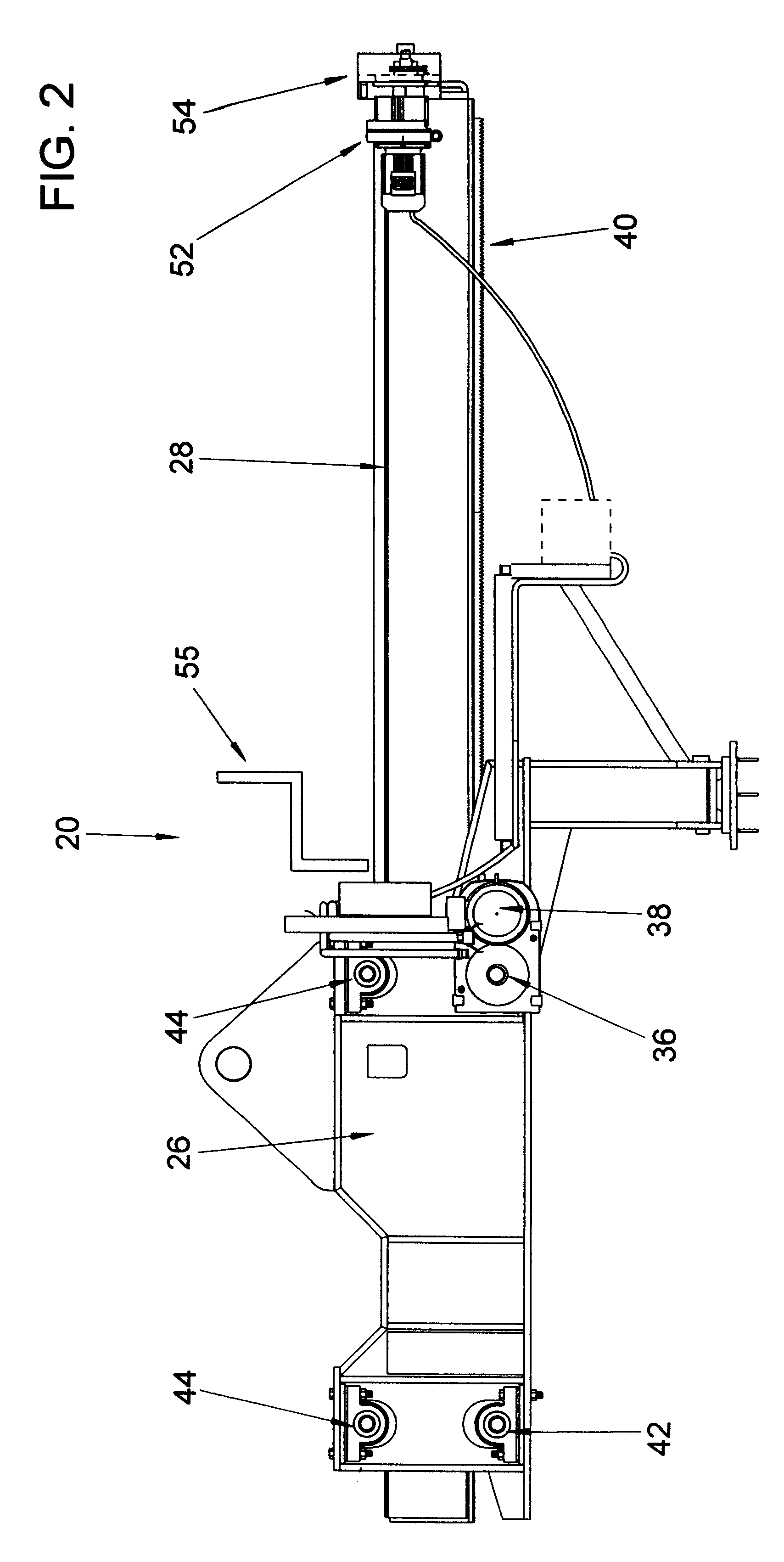

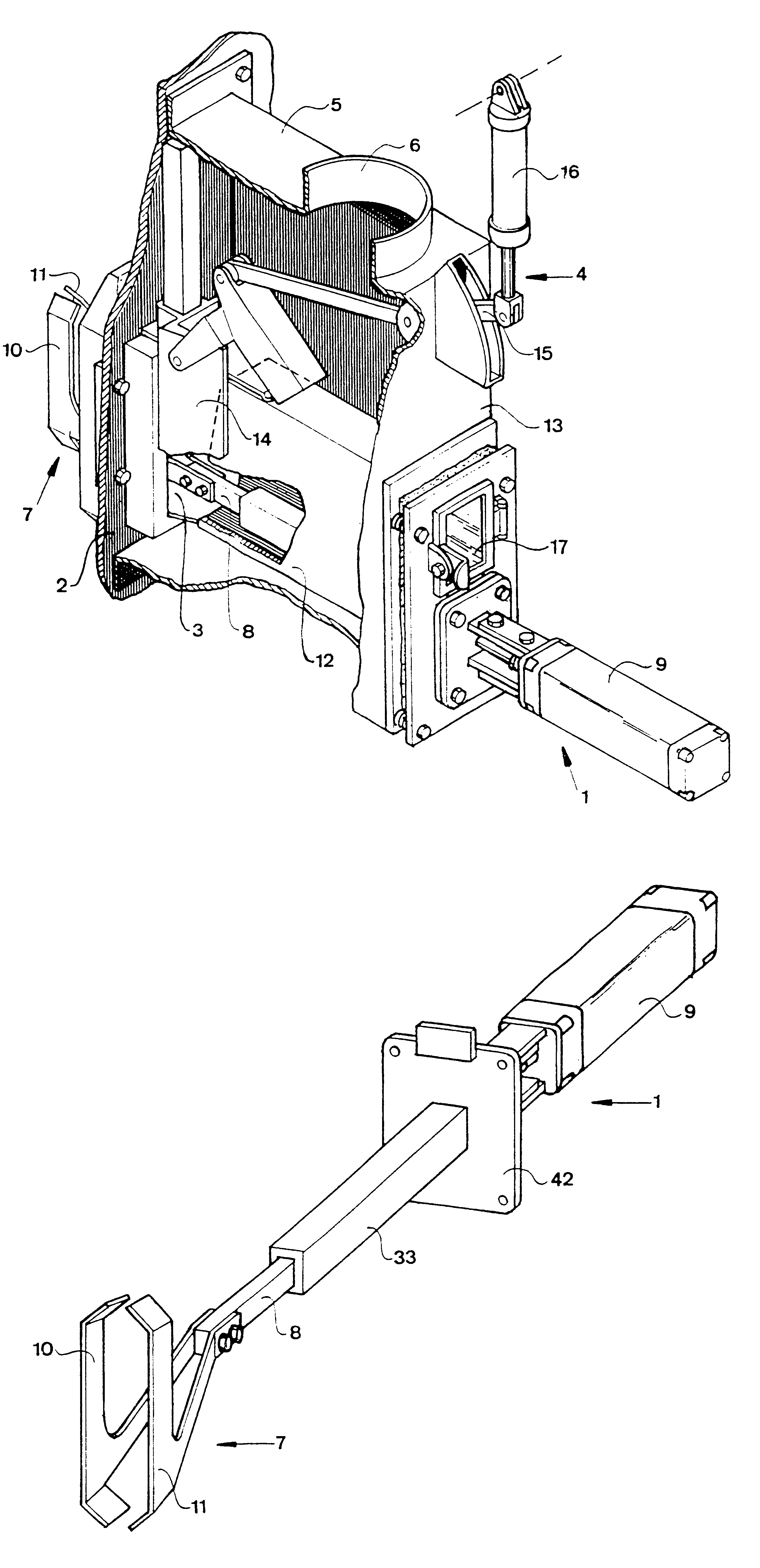

Apparatus for cleaning a coiler furnace drum

A coiler drum cleaner for cleaning the drum of a coiler furnace (typically associated with a reversing rolling mill or Steckel mill) is disclosed. The coiler drum cleaner includes a cleaning element rotatably mounted at one end of a longitudinally extending tubular member, the tubular member being movably installed in association with a coiler furnace such that the cleaning element may be inserted into the coiler furnace and moved across the surface of the coiler drum, by moving the tubular member substantially parallel to the axis of rotation of the coiler furnace drum. The tubular member also includes means for moving the cleaning element roughly perpendicular to the longitudinal axis of the tubular member so as to bring the cleaning element into contact with the drum. In use, the cleaning element is inserted into the coiler furnace, brought into contact with the coiler drum and rotated so as to clean the coiler drum. Preferably, the cleaning element is a cylindrical brush having a plurality of resiliently-flexible carbide-tipped steel tines arrayed about its circumference. The tubular member may also include cooling means.

Owner:IPSCO ENTERPRISES

Aluminum melting method using analysis of fumes coming from the furnace

A process and a device for melting aluminum where solid aluminum is melted in a furnace to form aluminum melt pool. The temperature and carbon monoxide (CO) concentration of the flue gas generated in the melting process is detected and examined for variations. Using this variation information, it is determined if aluminum oxides have formed on the surface of the aluminum melt pool and if they have, the melting process is regulated accordingly.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Automatic crucible dumping and cleaning system for electronic kilns

InactiveCN103017540AReduce work intensityWill not polluteCharge manipulationIncrustation removal devicesPower transmissionTop cap

An automatic crucible dumping and cleaning system for electronic kilns belongs to the technical field of accessory facilities for electronic kilns. The automatic crucible dumping and cleaning system comprises a box underframe, a receiving box, a material discharge mechanism, a pair of door opening and closing mechanisms, a crucible-holding mechanism, a power transmission mechanism and a top cover; the receiving box is fixed on the box underframe, one side of the upper part of the receiving box is provided with a crucible inlet, and the other side of the upper part of the receiving box is provided with a crucible outlet; the material discharge mechanism is connected with the bottom of the receiving box; the door opening and closing mechanisms are arranged on the box underframe, one of the door opening and closing mechanisms corresponds to the crucible inlet, and the other door opening and closing mechanism corresponds to the crucible outlet; the crucible-holding mechanism is supported on the wall of the receiving box; the power transmission mechanism is fixed on the box underframe, and is connected with the crucible-holding mechanism; the top cover is fixed on the box underframe and corresponds to the open part of the top of the cavity of the receiving box, and a group of blowing tube connectors are arranged on the top cover, and are connected with an air source device. The automatic crucible dumping and cleaning system has the advantages that: the working intensity of workers can be decreased, and moreover, the dumping and cleaning efficiency can be increased; the cleaning quality can be guaranteed; and the environment of a working site cannot be polluted.

Owner:唐山盛梅陶瓷有限公司

Fuming furnace

The invention relates to a fuming furnace. The fuming furnace comprises a furnace cylinder, a smoke flue and a dust collection device. One end of the smoke flue is communicated with the upper portion of the furnace cylinder, and the other end of the smoke flue is communicated with the dust collection device. Compared with the prior art, under the condition that the smoke flue is blocked, an automatic warning can be achieved, a collection hopper of the smoke flue is heated, so that blocking objects are softened and flow downwards, the smoke flue is smooth, the production efficiency is improved, and the danger that a worker enters the smoke flue for dredging, industrial accidents happen, and the worker suffers from occupational diseases is avoided.

Owner:覃聪

Chamber cleaning mechanism

InactiveUS6544482B1Precision cleaningCombination devicesExhaust apparatusReciprocating motionEngineering

The present invention provides a reaction chamber cleaning apparatus comprising a chamber, a blade apparatus comprising at least one annular mounting member, at least four scraping blades attached peripherally about the annular mounting member, and a reciprocal movement unit for rotating said scraping blade(s) circumferentially back and forth along the interior surface of said chamber to scrape the interior surface of said chamber; said reaction chamber cleaning apparatus also comprising a vortex unit comprising a generally conical outer shell attached to and extending downwardly from the top plate top plate, and a liquid inlet arranged in relation to the outer shell to tangentially introduce liquid into the outer shell, thereby forming a laminar sheet of fluid on the inner surface of the outer shell; said vortex unit further comprising a baffle and a concentric chamber bounded by the outer surface of the baffle, the inner surface of the outer shell, and the bottom surface of the top plate. The invention also includes methods for using the reaction chamber for effluent abatement.

Owner:APPLIED MATERIALS INC

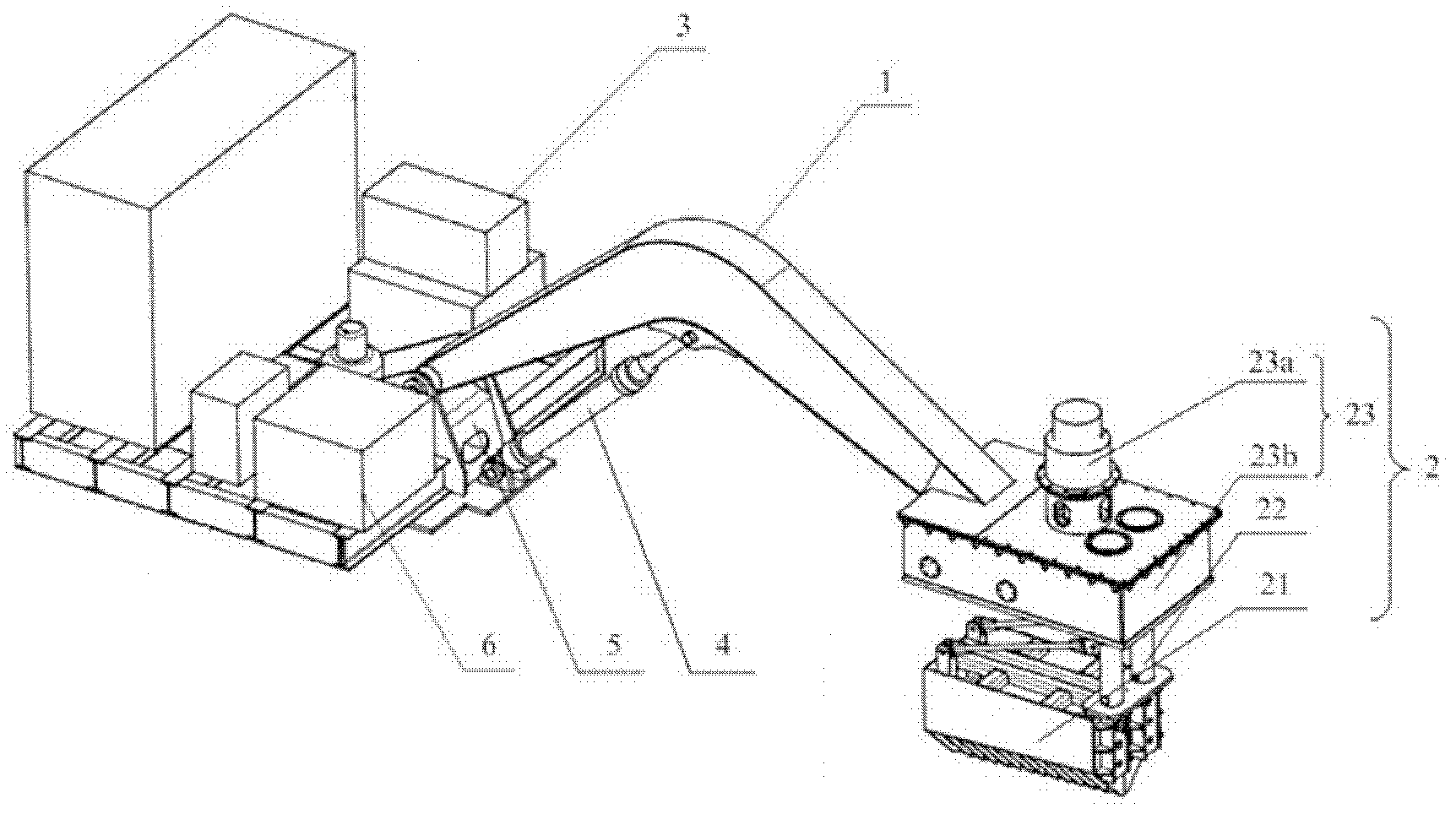

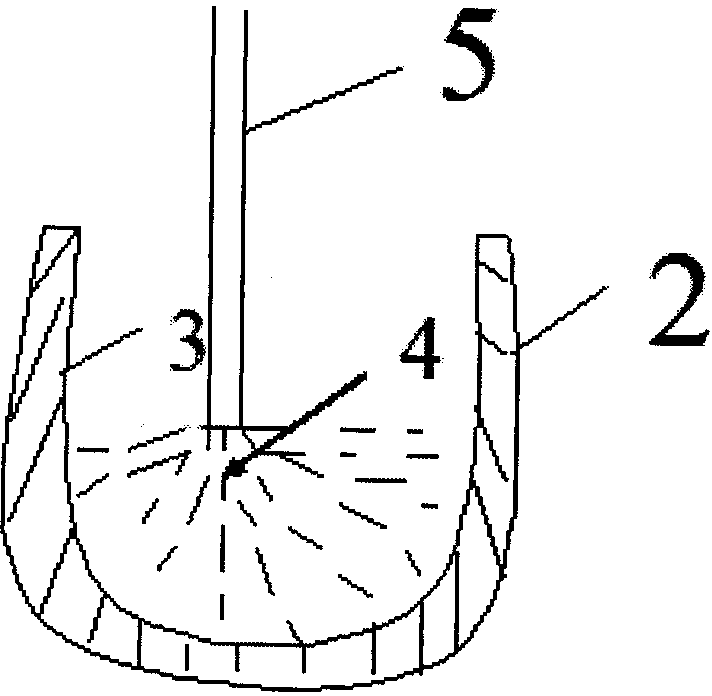

Scum dredger

InactiveCN102494544AAvoid bodily harmReduce the labor intensity of slag removalIncrustation removal devicesEngineeringMechanical equipment

The invention discloses a scum dredger, which comprises a machine frame, a power system and an execution system, wherein the power system and the execution system are arranged on the machine frame, and the machine frame is used for supporting the power system and the execution system; the execution system comprises a support arm and a scum dredging part for cleaning scum; the support arm is arranged on the machine frame in a mode of swinging up and down, is connected with the scum dredging part and is used for supporting the scum dredging part to drive the scum dredging part to move; the power system comprises an energy device for providing energy and a power device for driving the support arm to swing; the power device is connected with the energy device and the execution system; and the energy device provides energy for the power device, so that the support arm can swing up and down. By the structural design of the scum dredger, the scum can be dredged mechanically, so that the bodily injury of operators due to direct scum dredging is avoided. In addition, the scum is dredged by using the mechanical equipment, so that the labor intensity of the scum dredging of the operators is reduced, and the scum dredging efficiency is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

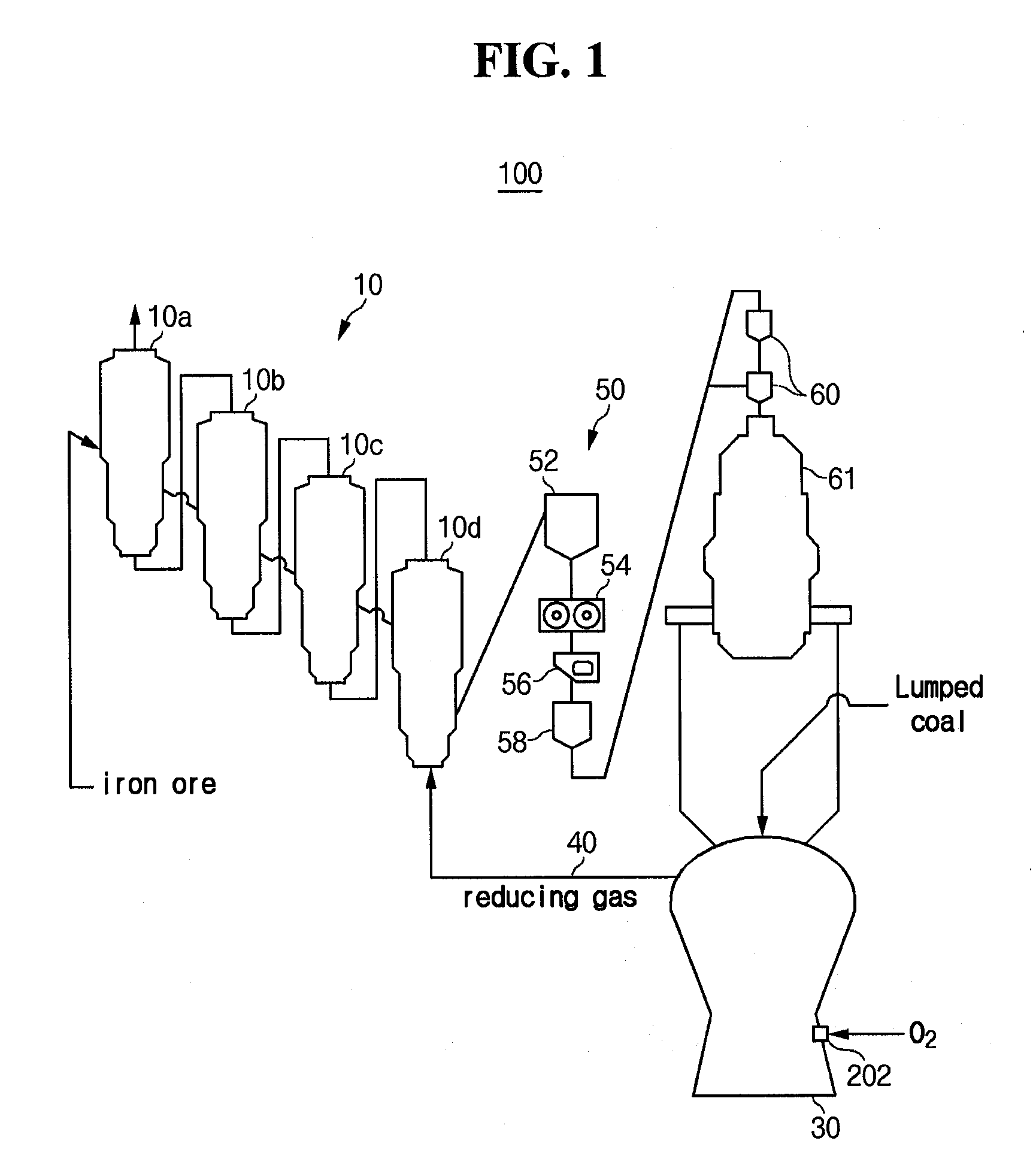

Apparatus for Manufacturing Molten Irons

ActiveUS20080277842A1Easy to operateTime is not consumedDispersed particle separationBlast furnace detailsCycloneFluidized bed

An apparatus for manufacturing molten iron includes i) at least one fluidized-bed reduction reactor that reduces and plasticizes iron ore and converts the iron ore into reduced materials, ii) a melter-gasifier into which the reduced ore is charged and oxygen is injected, the melter-gasifier manufacturing molten iron, and iii) a reducing gas supply line that supplies a reducing gas discharged from the melter-gasifier to the fluidized-bed reduction reactor. The fluidized-bed reduction reactor includes a cyclone that is installed in the fluidized-bed reduction reactor to collect fine iron ore. A gas injector, which prevents the fine ore from adhering by injecting gas containing carbon, is connected to the cyclone.

Owner:POSCO HLDG INC +1

Process for digesting bonded steel of steelmaking casting slag ladle

InactiveCN103033066AIncrease profitResolve interoperability issuesIncrustation removal devicesSteelmakingMolten steel

The invention provides a process for digesting bonded steel of a steelmaking casting slag ladle. The process comprises the steps of: with a 120-Ton converter device as an example, for a slag ladle of a converter, by adopting a gas atomizing spraying device, coating an anti-bonded-slag agent, wherein the consumption is 0.03-0.08kg per ton slag, the spraying time is 3-10min, the spraying thickness is 5-15mm, and slag is to be loaded; for the slag ladle filled with molten steel slag, thermally spilling or treating roller slag, wherein the automatic operation is adopted in roller slag and manual operation is adopted in thermal spilling, and the time is 5-45min; when the thickness of a bonded slag film on the inner wall of the slag ladle is 5-50mm and the thickness of a bonded slag film on the bottom of the slag ladle is 30-50mm, ending the treatment; and directly loading refining casting slag in the slag ladle with the film on the inner wall to prevent molten steel from bonding the slag ladle, so as to play a role in blocking the erosion effect of the refining casting molten steel and steel slag to the ladle wall. Meanwhile, the utilization rate of the slag ladle is increased.

Owner:XINJIANG BAYI IRON & STEEL

Method for alleviation of nodulation degree of furnace roller and aftertreatment of nodules of furnace roller

ActiveCN107630135AEase nodulationIncrease production capacityFurnace typesHeat treatment process controlNodulationsSilicon

The invention relates to a method for alleviation of the nodulation degree of a furnace roller and aftertreatment of nodules of the furnace roller. The method is applicable to production of cold-rolled silicon steel and comprises the following steps: 1) strictly controlling the scale of a steel plate used as a hot rolling raw material; 2) controlling the heating temperature of a normalizing furnace; 3) controlling an oxidizing atmosphere; 4) controlling the temperature of a tapped steel plate; 5) controlling the sequence of production operations; 6) grinding the roller regularly; and 7) measuring the diameter of the furnace roller regularly and adjusting the number of revolution of the furnace roller which is changed in diameter after wearing. The method provided by the invention is optimized in process flow and process parameters, and different treatment measures are adopted according to the nodulation situation of the furnace roller, so the nodulation degree of the furnace roller canbe effectively alleviated, the rhythm of production is accelerated, the yield of cold rolled silicon steel is improved, and production cost is lowered.

Owner:ANGANG STEEL CO LTD

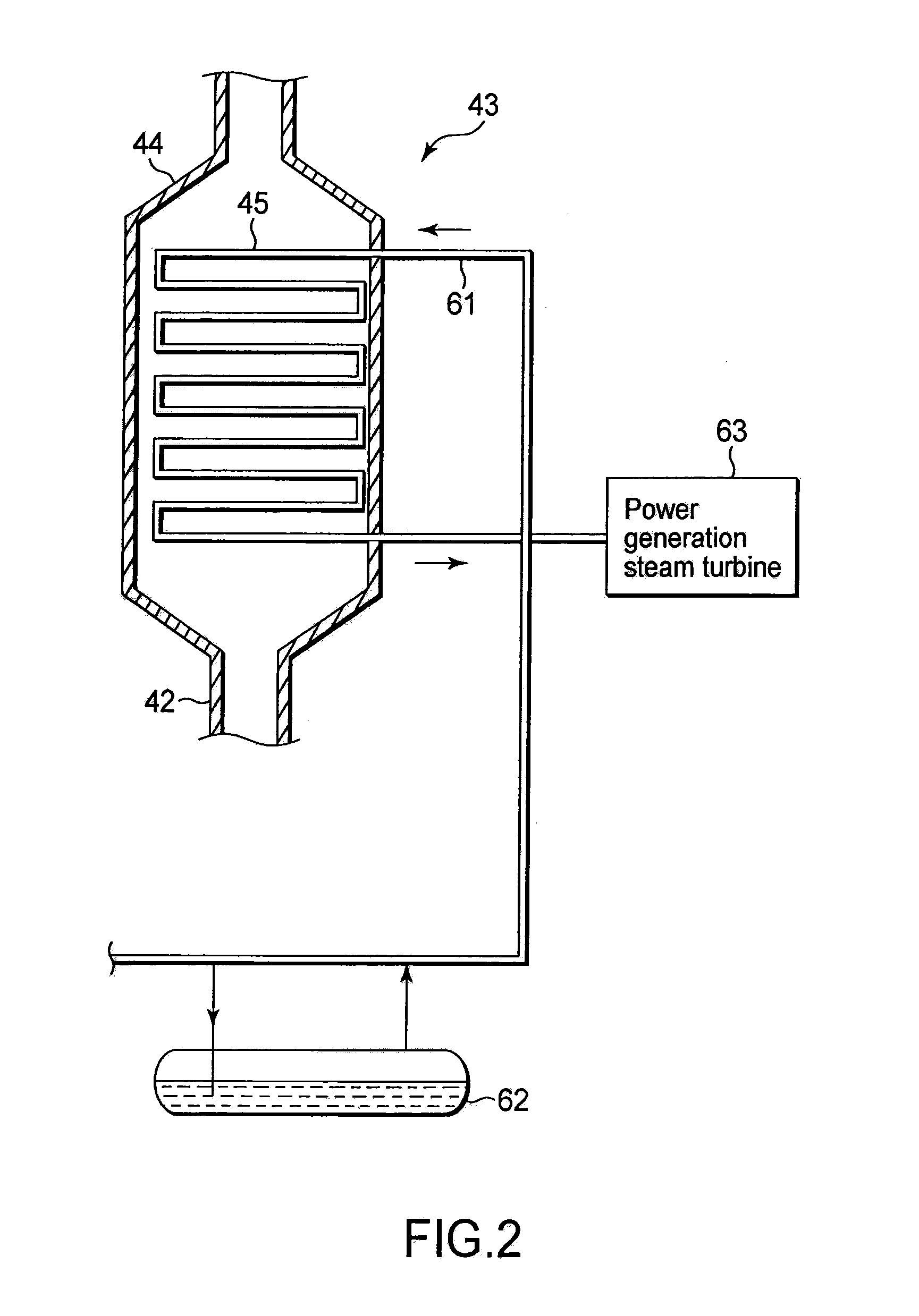

Waste heat recovery structure for steel making electric arc furnaces, steel making electric arc furnace facility, and waste heat recovery method for steel making electric arc furnaces

ActiveUS20120320941A1Minimize changesEffective recoverySteam generation heating methodsRecovering materialsWaste heat recovery unitRecovery method

A waste heat recovery structure includes a first exhaust gas flow path provided to each of steel making electric arc furnaces to discharge exhaust gas thereinto; a waste heat boiler disposed on the first exhaust gas flow path to recover waste heat as saturated steam from exhaust gas; a steam accumulator configured to store steam formed by confluence of saturated steam parts, each generated by the waste heat boiler; a steam super heater configured to turn steam into superheated steam by heating; a second exhaust gas flow path configured to lead exhaust gas from the waste heat boiler to the steam super heater to use it for superheating; a third exhaust gas flow path configured to discharge exhaust gas from the waste heat boiler not through the steam super heater; and a switching device configured to switch flow paths between the second and third exhaust gas flow paths.

Owner:JP STEEL PLANTECH CO

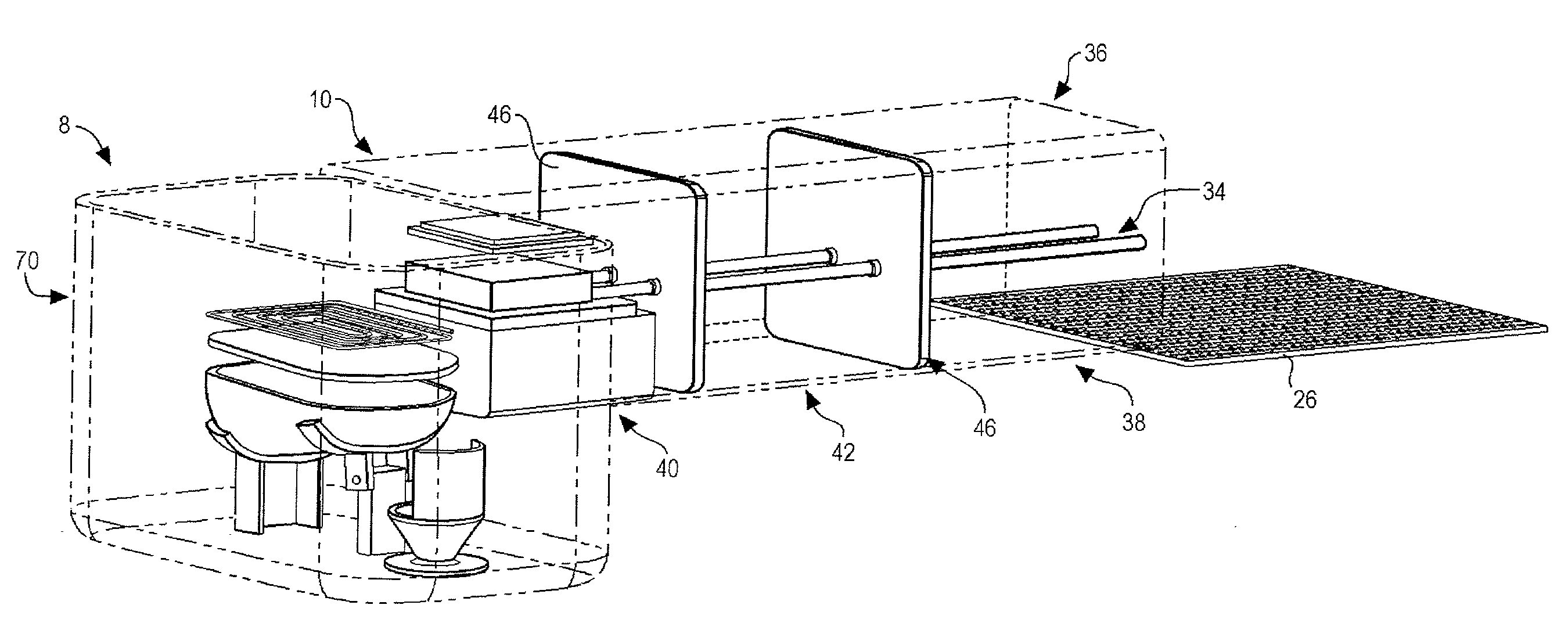

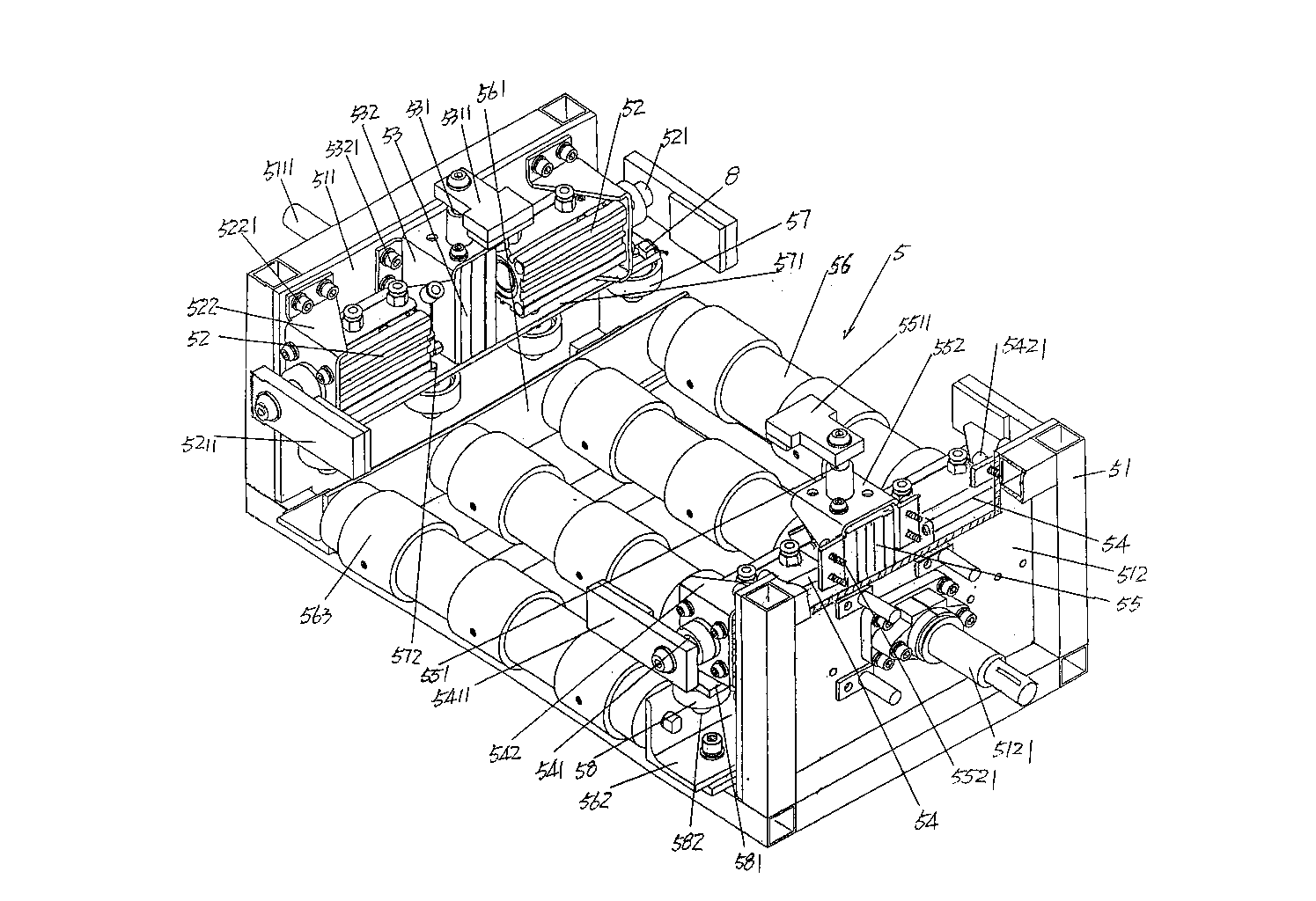

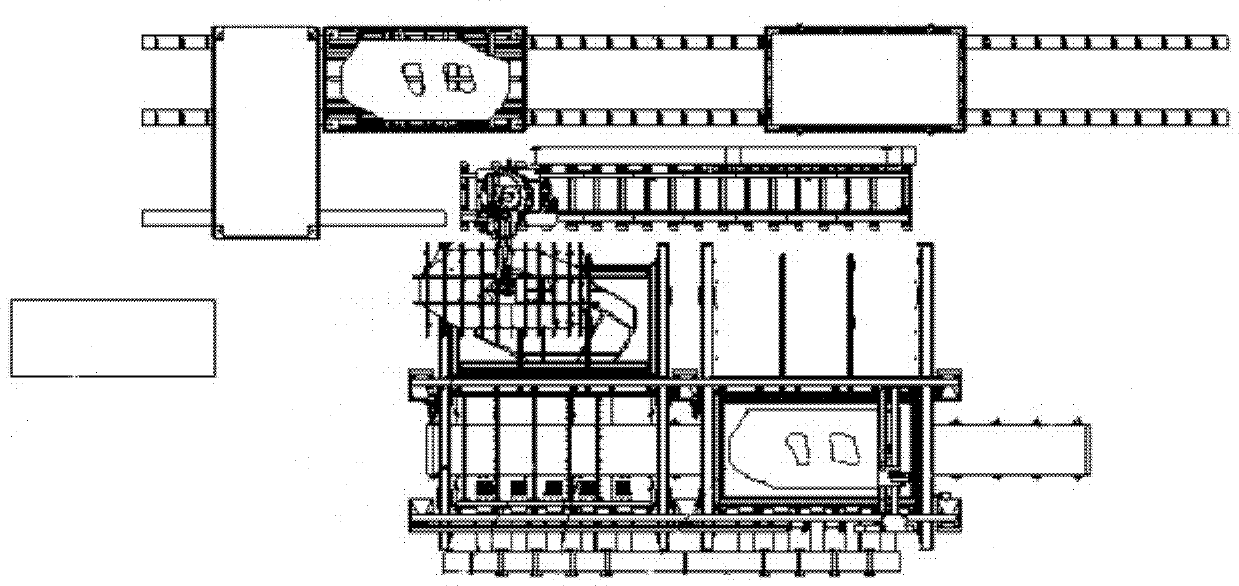

Sagger automatic sweeping device for electronic kiln automatic production line

ActiveCN103528389BReflect all-round cleaningReduce labor intensityCharge supportsIncrustation removal devicesEngineeringUltimate tensile strength

The invention discloses a sagger automatic sweeping device for an electronic kiln automatic production line and belongs to the field of electronic kiln auxiliary facilities. The electronic kiln automatic production line comprises a pair of sagger conveying roller supporting beams and a pair of sagger conveying mechanisms. The sagger automatic sweeping device comprises a machine frame, a disc brush left-right moving mechanism, a disc brush up-down moving mechanism, a guiding track fixing box, a brush disc front-back moving mechanism, a sagger rotating brush dust removing mechanism, a disc brush rotating driving mechanism and a pair of sagger seizing mechanism. The machine frame is fixed with the sagger conveying roller supporting beams. The disc brush left-right moving mechanism is placed on one side of the upper portion of the machine frame. The disc brush up-down moving mechanism is matched with the disc brush left-right moving mechanism. The guiding track fixing box is connected with the disc brush up-down moving mechanism. A bearing base fixing plate is arranged in a guiding track fixing box cavity of the guiding track fixing box. The brush disc front-back moving mechanism is arranged on the guiding track fixing box. The sagger rotating brush dust removing mechanism is arranged on the bearing base fixing plate. The disc brush rotating driving mechanism is connected with the sagger rotating brush dust removing mechanism. The pair of sagger seizing mechanism is arranged on the pair of sagger conveying roller supporting beams. Labor intensity is lowered, cleaning efficiency is high, cleaning effect is ideal, all-direction sweeping without any dead angle is achieved, and the automatic effect of the whole is guaranteed.

Owner:SUZHOU HUIKE EQUIP CO LTD

Treating method of furnace roller nodule

ActiveCN103322824AStable productionGuarantee product qualityIncrustation removal devicesElectrical steelSlow speed

A treating method of a furnace roller nodule comprises the following steps: (1), after a machine shuts down, a mark is made on band steel in the outlet position of a furnace, a furnace roller is rotated, and according to a furnace roller nodule marking ground on the band steel, the number of the furnace roller where the furnace roller nodule is generated and the transverse width position on the furnace roller are determined; (2), a new band steel transition roll is prepared and is an electrical steel band roll made of the same material, holes are formed in the new band steel transition roll, the hole diameter is in a range from 1.5 mm to 2.5 mm, and the hole edges are flush with the band steel, so that the holes are uniformly distributed in the overall width direction of a whole plate; (3), according to the nodule width position reflected on the band steel, the band steel provided with hole groups in corresponding widths is placed in the furnace roller position; (4), the band steel tension is removed, so that the band steel droops and forms a wrap angle with the furnace roller; and (5), the furnace roller rotates independently at a slow speed, so that the furnace roller rotates relative to the band steel, the furnace roller nodule is bulged out of the surface of the band steel when abraded on the holes in the surface of the band steel, and the furnace roller nodule is removed by the hole edges during rotating.

Owner:BAOSHAN IRON & STEEL CO LTD

Heat Treatment Furnace and Heat Treatment Facility Comprising It

ActiveUS20080003534A1Uniform product qualityImprove life expectancyRotary drum furnacesCharge supportsEngineeringHeat treated

With regard to a heat treatment furnace (a solution furnace 1 and an ageing furnace 3), a furnace chamber 15 comprises a furnace body 12 opening downward and a floor body 14 closing the lower opening of the furnace body 12 and rotatably driven, and one or plural stages of mounting shelves 16 on which work pieces 8 are mounted are provided in the furnace chamber 15. Hot-air circulation equipments 20A and 20B circulating hot air in the furnace chamber 15 along the peripheral direction when viewed in plan are provided in the furnace body 12. The mounting shelves 16 are fixed to a prop 17 standingly provided on the floor body 14 and are rotated integrally with the floor body 14.

Owner:TOYOTA JIDOSHA KK +1

Stoking machine of electric resistance furnace

A stoking machine of an electric resistance furnace consists of a travelling mechanism, a panel (7), a turntable (8), a stoking mechanism, a hydraulic system and an operation system, wherein the stoking mechanism, the hydraulic system and the operation system are arranged on the panel (7), and the panel (7) is arranged on a turntable bracket (2) by the turntable (8). The stoking machine of the electric resistance furnace has the advantages that: firstly, the stoking machine can travel freely on a platform of the electric resistance furnace without any railways, and one stoking machine can be used on a plurality of furnace mouths; secondly, due to chain pins and a chain wheel, the stoking speed of a hollow stoking rod is increased by one time, and the force of impact is increased; and thirdly, as the complete machine is insulated, the stoking action can be carried out with the electric resistance furnace powered on.

Owner:HUBEI JINHENG MACHINERY

Robot system and method for copper concentrate injector cleaning in the flash furnace

At present, the flash furnace due to an increase in fusion forms accretions in the burner which causes that the “air umbrella” does not develop and in order to clean it manually the load must be lowered for safety reasons. One of the major disadvantages of all the tasks associated to the cleaning process is the exposure of the personnel to harsh environmental conditions. This in the medium and long term could generate serious occupational diseases to the operators in charge of carrying out such activity. Due to the above, a robot system and method have been developed for the automated cleaning of the burner thus minimizing the decrease of the load. The robotic system is composed mainly of an anthropomorphous robotic manipulator of at least 5 degrees of freedom, and a gripping mechanism which allows to take, manipulate and release several tools from a tool holder to carry out the cleaning process of the smelting furnace.

Owner:HOWARD HUGHES MEDICAL INST +1

Slugging cleaning device of silicon steel furnace and application thereof

InactiveCN102944122AMeet the requirements of continuous productionIncrustation removal devicesSlagHeating furnace

The invention discloses a slugging cleaning device of a silicon steel furnace and application thereof. The device is directly used for removing slugging on a beam and guarantees that a heating furnace normally produces. The silicon steel slugging cleaning device comprises a steel plate, a slag removing rod, a locking bolt and a prying rod, and the application of the cleaning device comprises placing the cleaning device of the silicon steel furnace on a roller way on a steel discharge side of the heating furnace, adjusting positions of the slag removing rod of the silicon steel slugging cleaning device, enabling the slag removing rod to align at accumulated slag on a water beam in the heating furnace, ascending the height of a steel drawing rod in the heating furnace to be equal to that of the silicon steel slugging cleaning device, advancing the steel drawing rod, pushing the silicon steel slugging cleaning device to go forward together, and breaking and shedding the accumulated slag on the beam under the effect of the slag removing rod when the slag removing rod is contacted with the accumulated slag on the water beam. The device can serve as matched equipment for producing oriented silicon steel, and greatly meets requirements for steel continuous production of the oriented silicon steel.

Owner:UNIV OF SCI & TECH LIAONING

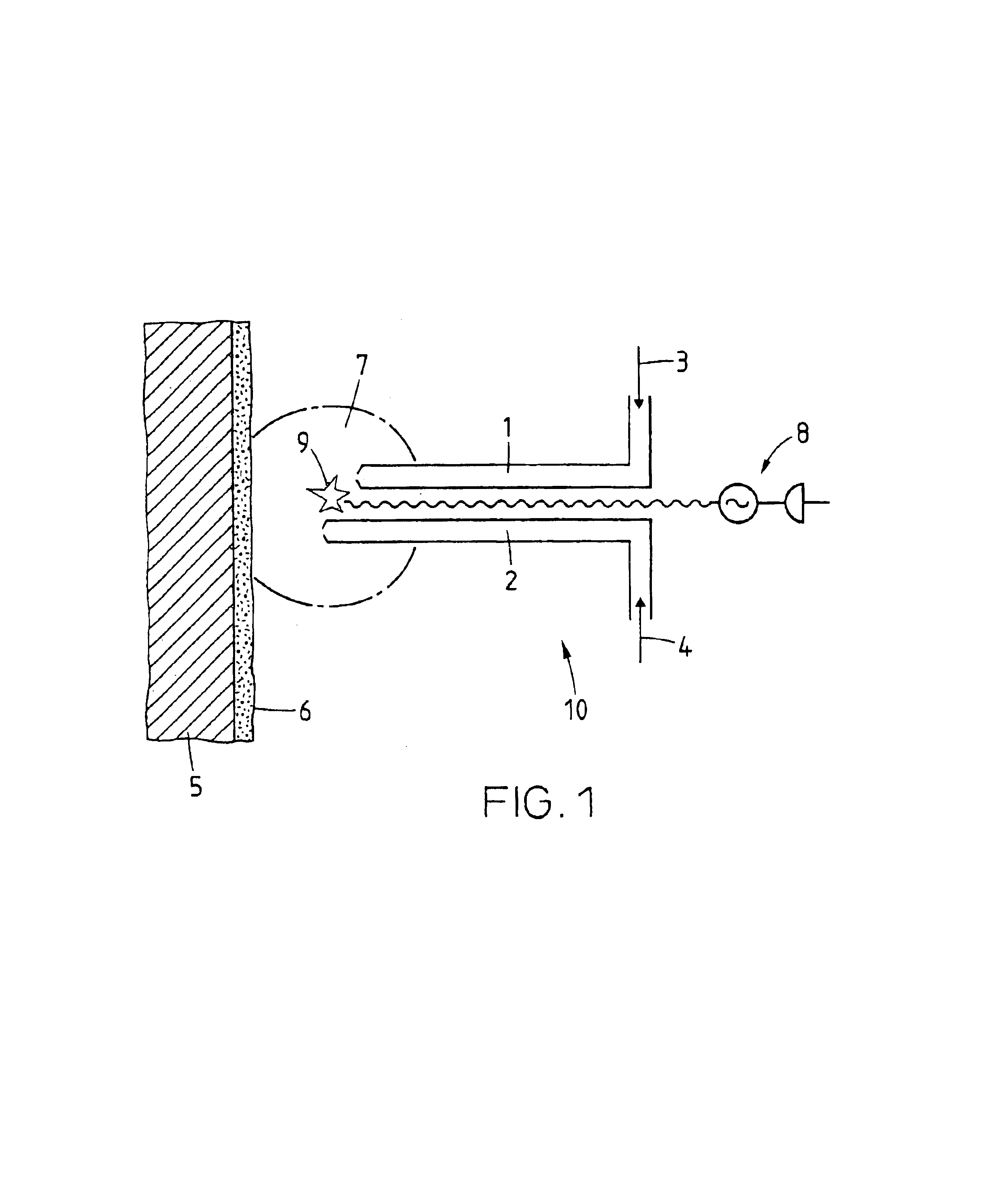

Device for regulating and cleaning an air intake

InactiveUS6431125B1Easy to checkEasy to regulateRotary drum furnacesBoiler cleaning apparatusEnvironmental engineeringMechanical engineering

Owner:LT PROD SKUTSKAR

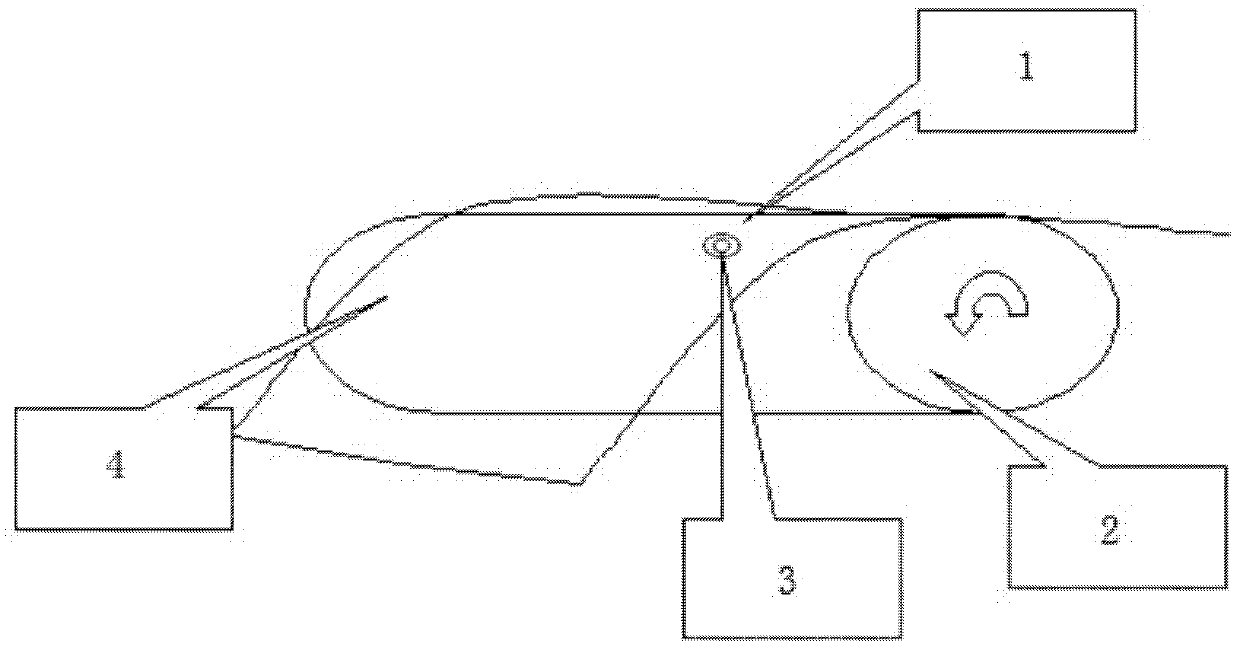

Ladle clearing method and ladle clearing machine group

InactiveCN101069926AImprove uptimeExtended service lifeMelt-holding vesselsCasting cleaning apparatusEngineeringMechanical engineering

The present invention relates to a hand ladle cleaning method and its cleaning machine unit. It is formed from the following several structures: tilting mechanism capable of fixing hand ladle, driving hand ladle and making it be tilted, reset and rotated; cleaning cutting-tool for cleaning hand ladle; and cutting-tool control mechanism for controlling cutting-tool and making it be rotated, forward fed, backwards retracted and horizontally moved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

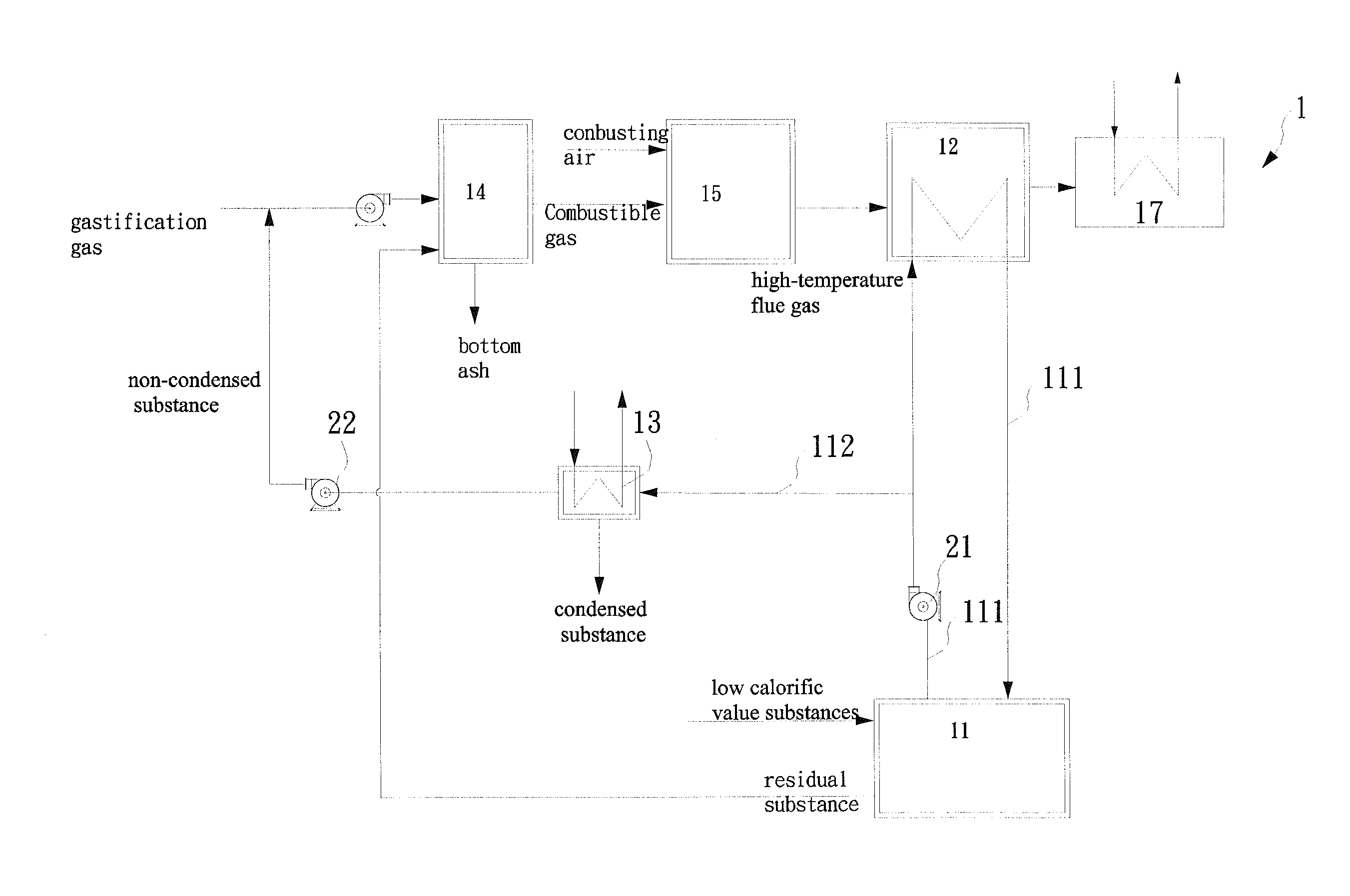

System for substance separation and energy recovery by thermal treatment

ActiveUS20130230815A1Increase temperatureIncrease volumeByproduct vaporizationMaintainance of heating chambersCyclic processCombustion

A system for substance separation and energy recovery by thermal treatment is disclosed. The system includes a thermal treatment reactor, a circulation piping, a heat exchanger, a discharge pipeline, a latent heat recovering device, a gasifier, and a combustion furnace. The substance is fed into the thermal treatment reactor for heating the treated substance so as to produces a gaseous substance by evaporation or pyrolysis. The treated substance is separated into the gaseous substance circulating between the heat exchanger and the thermal treatment reactor and a residual substance being fed into the thermal treatment reactor. The increased gaseous substance, during the circulation process, is fed into a latent heat recovery device, wherein the gaseous substance exchanges heat with a cold fluid and condenses to release latent heat, forming a liquid condensed substance and a non-condensed substance.

Owner:TAIWAN CLEAN ENERGY TECH

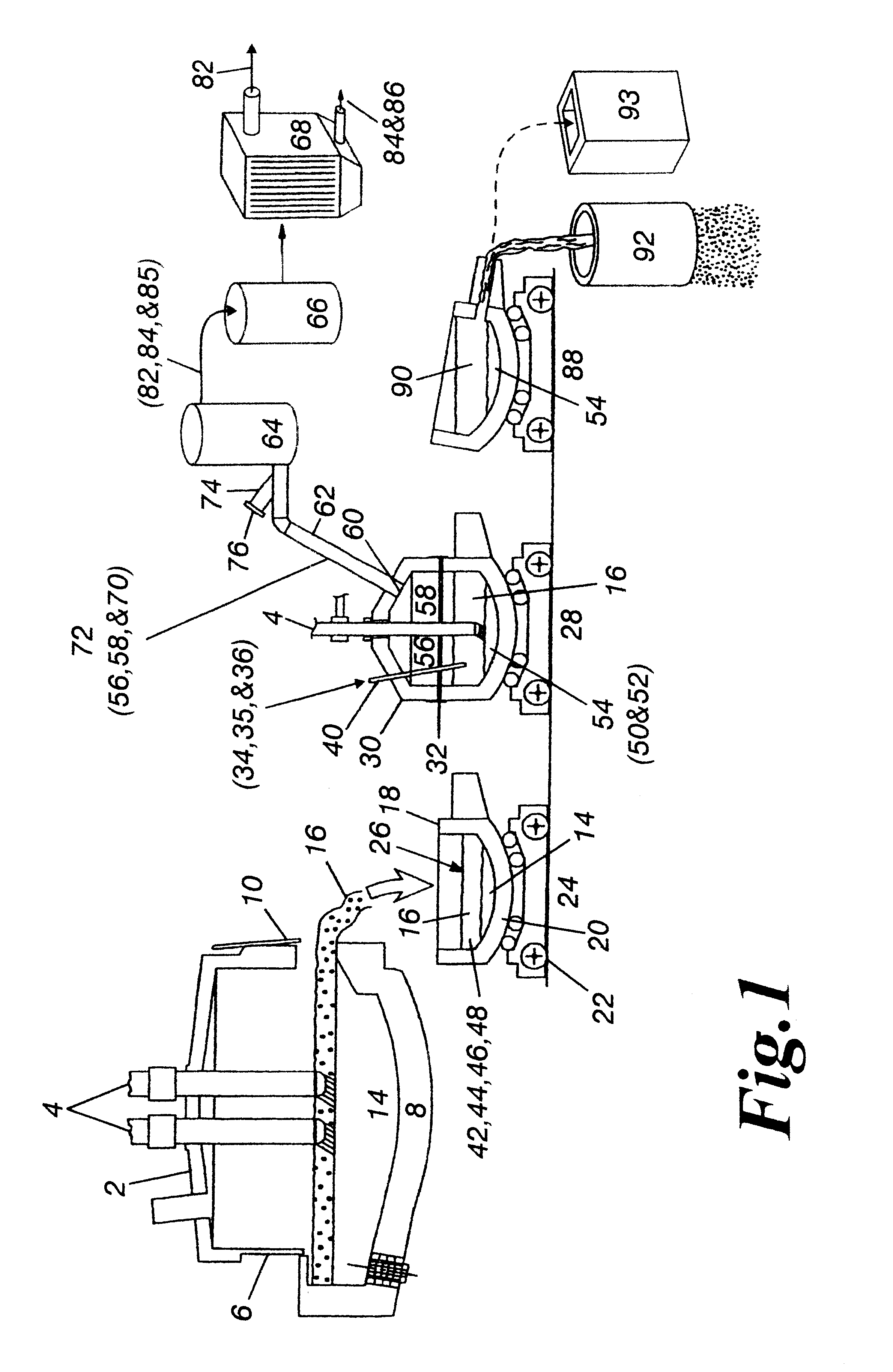

Method and apparatus for recovering metal values from liquid slag an baghouse dust of an electric arc furnace

InactiveUS6438154B1Pollution minimizationEnergy efficiencyMechanical apparatusCharge manipulationSteelmakingElectric arc furnace

An apparatus and method for processing liquid slag and baghouse dust from a steelmaking furnace such as an EAF to recover valuable metals from the slag and dust includes a treatment vessel having a movable lower shell portion for receiving liquid slag and an upper shell portion that couples with the movable lower shell portion during heat activation of the treatment vessel. The slag is combined with silicon dioxide, a reducing agent, baghouse dust, and an inert gas before being heated to between approximately 1400° C. and 3000° C. The heat treatment results in a molten reduced iron and manganese metallic material, a treated slag layer, and an off-gas containing lead, zinc, and carbon monoxide. The off-gas is combusted, cooled, and solidified, resulting in lead oxide and zinc oxide. The slag layer is tapped, cooled, and solidified. The metallic layer is tapped for recycle in the steel making process.

Owner:VALLOMY JOHN A

Method for reducing hearth roll mark defect on steel plate surface

InactiveCN102851477AReduce workloadSuppress generationMaintainance of heating chambersFurnace typesSheet steelHearth

The invention provides a method for reducing hearth roll mark defect on the steel plate surface, which adopts steel plate surface pretreatment, in-furnace atmosphere control and production cycle measurement to effectively suppress the generation of hearth roll nodulation, adopts on-line roll grinding to grind the formed hearth roll nodulation to reduce the hazard extent of the hearth roll nodulation, improves the quality qualified rate of the steel plate from 83.7% to 95%, greatly reduces hearth roll mark defect on the steel plate lower surface, remarkably reduces mass loss, reduces the production cost, and can relatively prolong the service life of the hearth roll, prolong the blowout cycle of the heat treatment furnace and improve the unit yield. The method can also reduce the work load for grinding the defects on the steel plate surface, the labor intensity of grinding workers and spare part consumption and cost.

Owner:ANGANG STEEL CO LTD

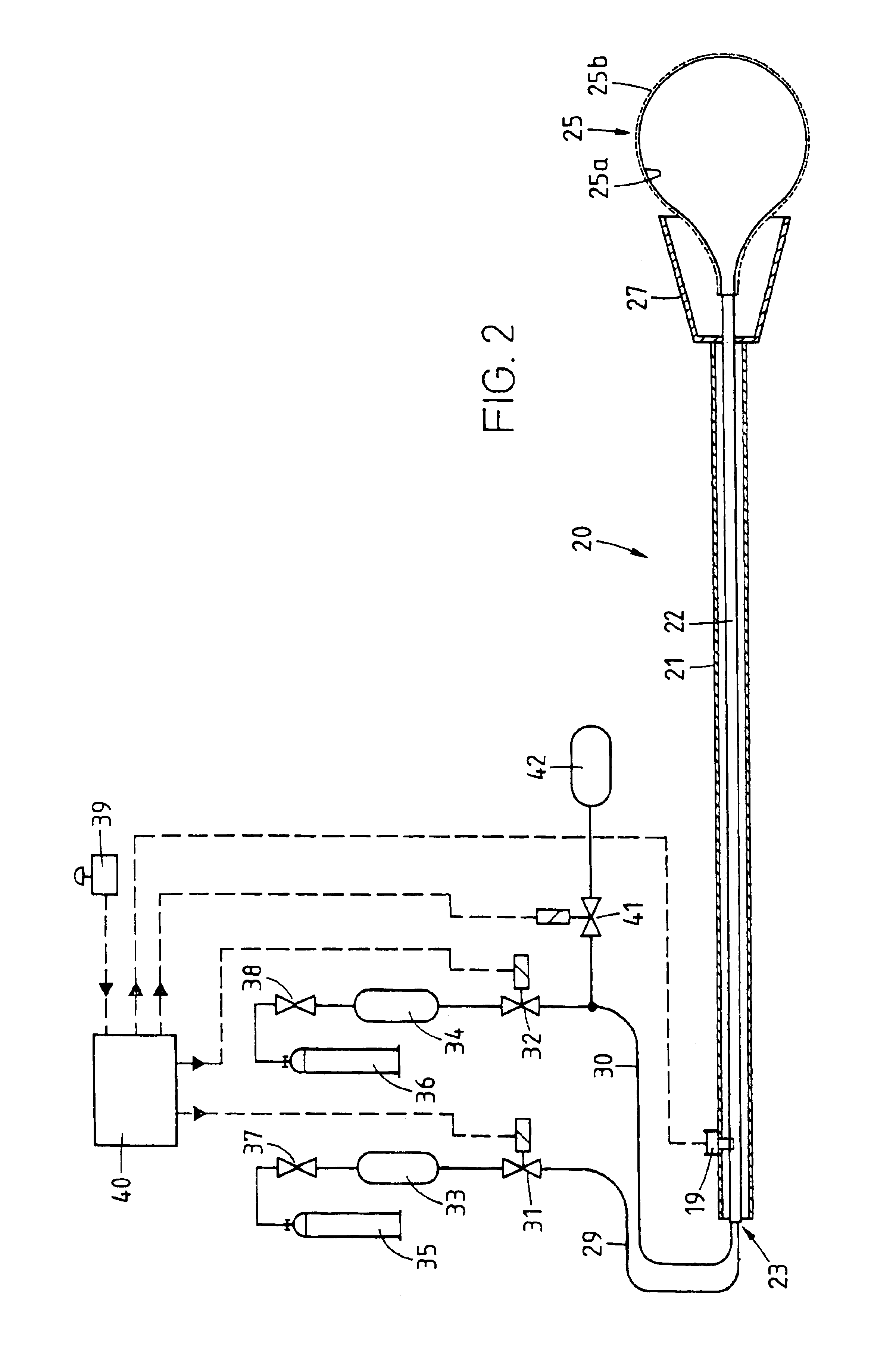

Tuyere cooling system

A tuyere cooling system which includes a coolant circuit for a body section and nose section. A valve is operable to connect the coolant circuits in series or to disconnect flows to the nose section of the tuyere so that if the nose of the tuyere tears during operation, the flow of coolant to the nose section of the tuyere may be cut off without affecting the overall operation of the blast furnace.

Owner:ARCELORMITTAL DOFASCO

Industrial ammunition

InactiveUS7069863B2Low costImprove reliabilityAmmunition projectilesCartridge extractorsMechanical engineeringPhysics

A projectileless ammunition system (20; 320) includes a metallic case (22; 322). A propellant charge (26; 326) is carried by the case and covered by an over-powder member (24; 324) in the absence of a separate projectile. The ammunition is advantageously used with an industrial ballistic tool operating so that each spent case serves as the effective projectile to be propelled by firing of the next round of ammunition.

Owner:OLIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com