Method for removing salamander from hearth roller of roller-hearth non-oxidation furnace

A technology without oxidation furnace and furnace bottom roller, applied in furnaces, descaling devices, furnace components, etc., can solve the problems of large number of furnace bottom rollers, serious nodules, labor time and labor, etc., achieving considerable economic benefits and time saving and energy, the effect of ensuring the quality of the table below

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

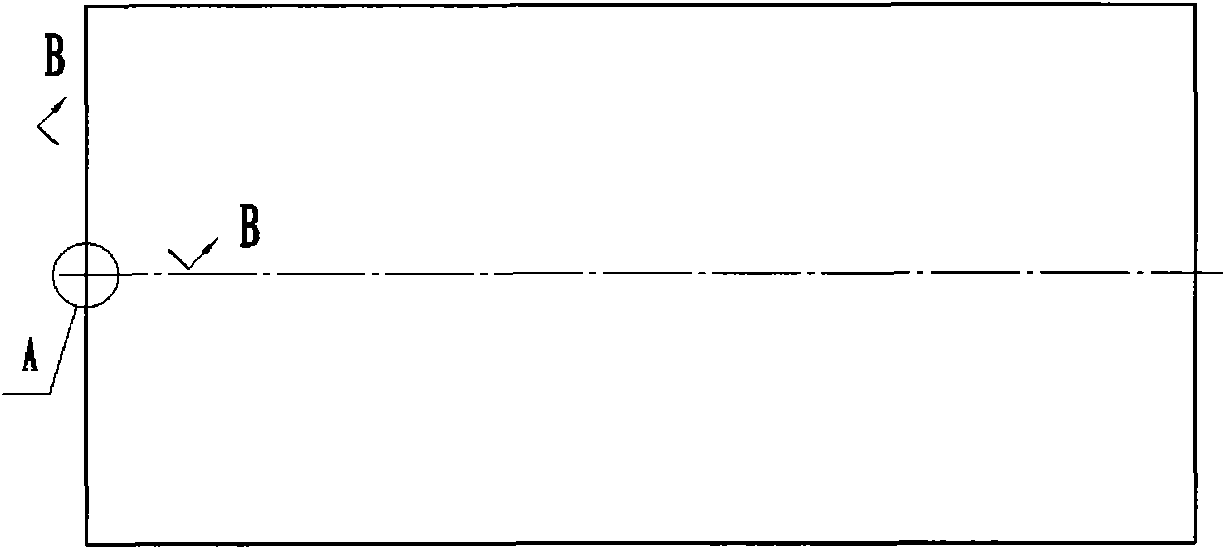

[0021] A method for removing nodules on the bottom rolls of a roller hearth type non-oxidizing furnace according to the present invention, the method lowers the furnace temperature of the roller hearth furnace to 500°C in the non-stop state, and uses a hoist to send the carriage into the furnace Inside, the nodules on the hearth rolls are removed by friction between the lower surface of the furnace plate and the hearth rolls, which specifically includes the following steps:

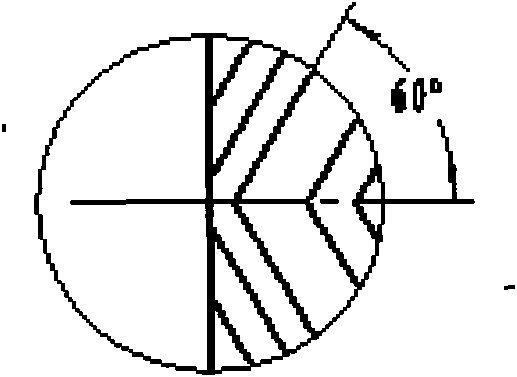

[0022] (1) Make the pallet according to the drawing of the pallet, see the structure of the pallet figure 1 , figure 2 and image 3 . The grooves and ribs at the bottom of the carriage are designed in a unique "herringbone" shape structure, which can effectively solve the disadvantages of the "one" shape structure. Make the friction force between the carriage and the hearth roller uniform to prevent the carriage from running off in the furnace.

[0023] (2) Make two steel plates with a specification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com