Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

279results about How to "Precision cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

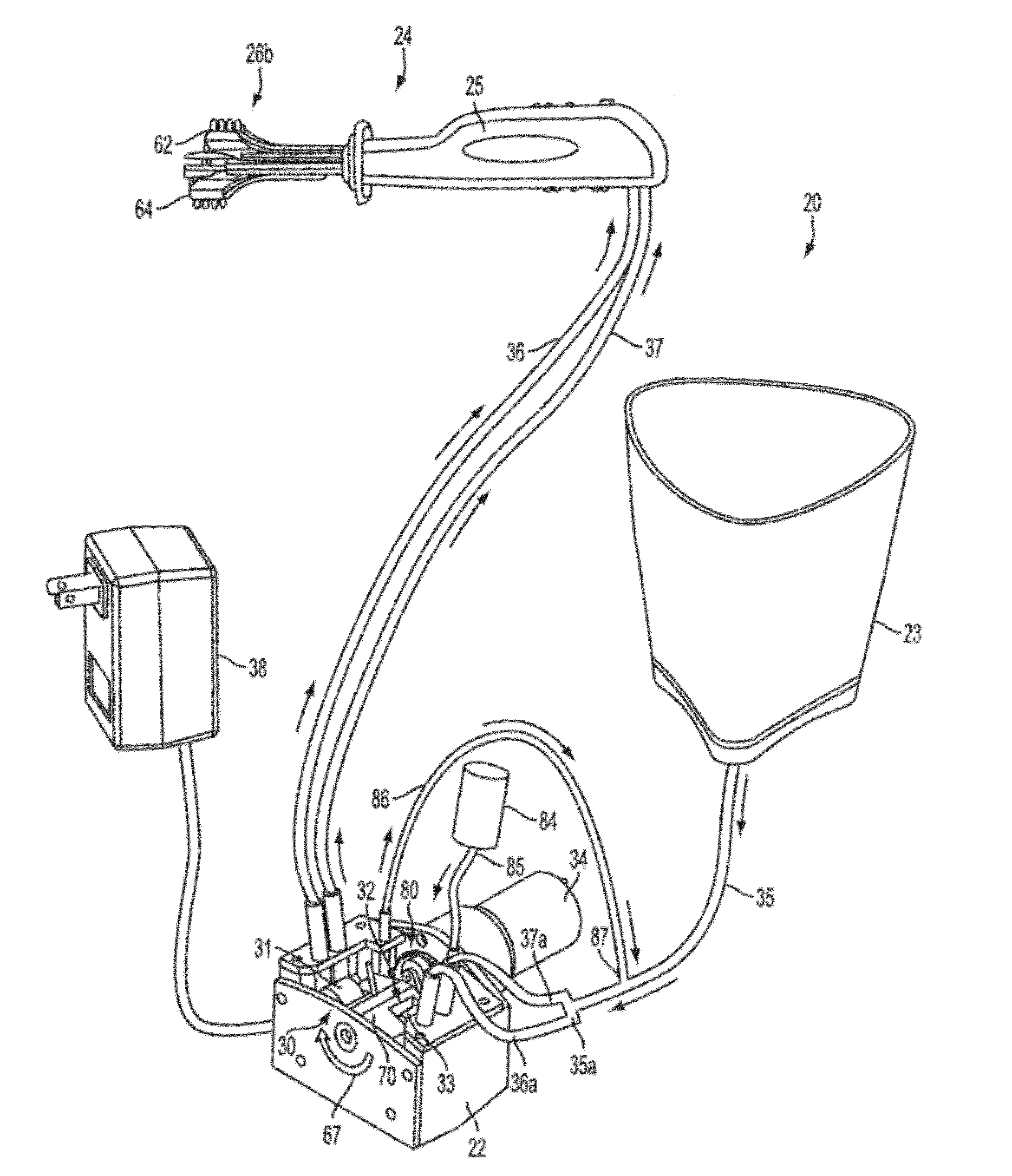

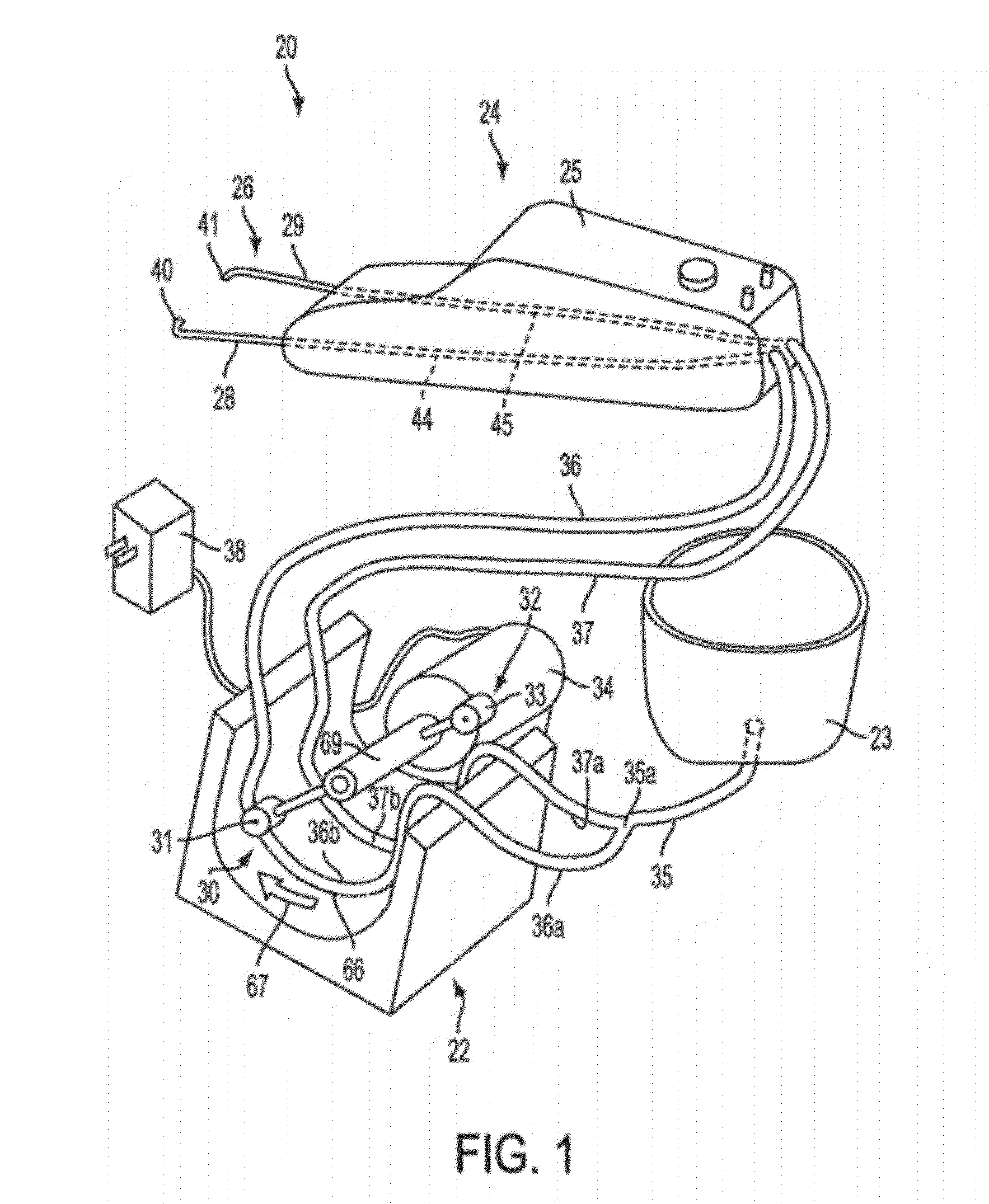

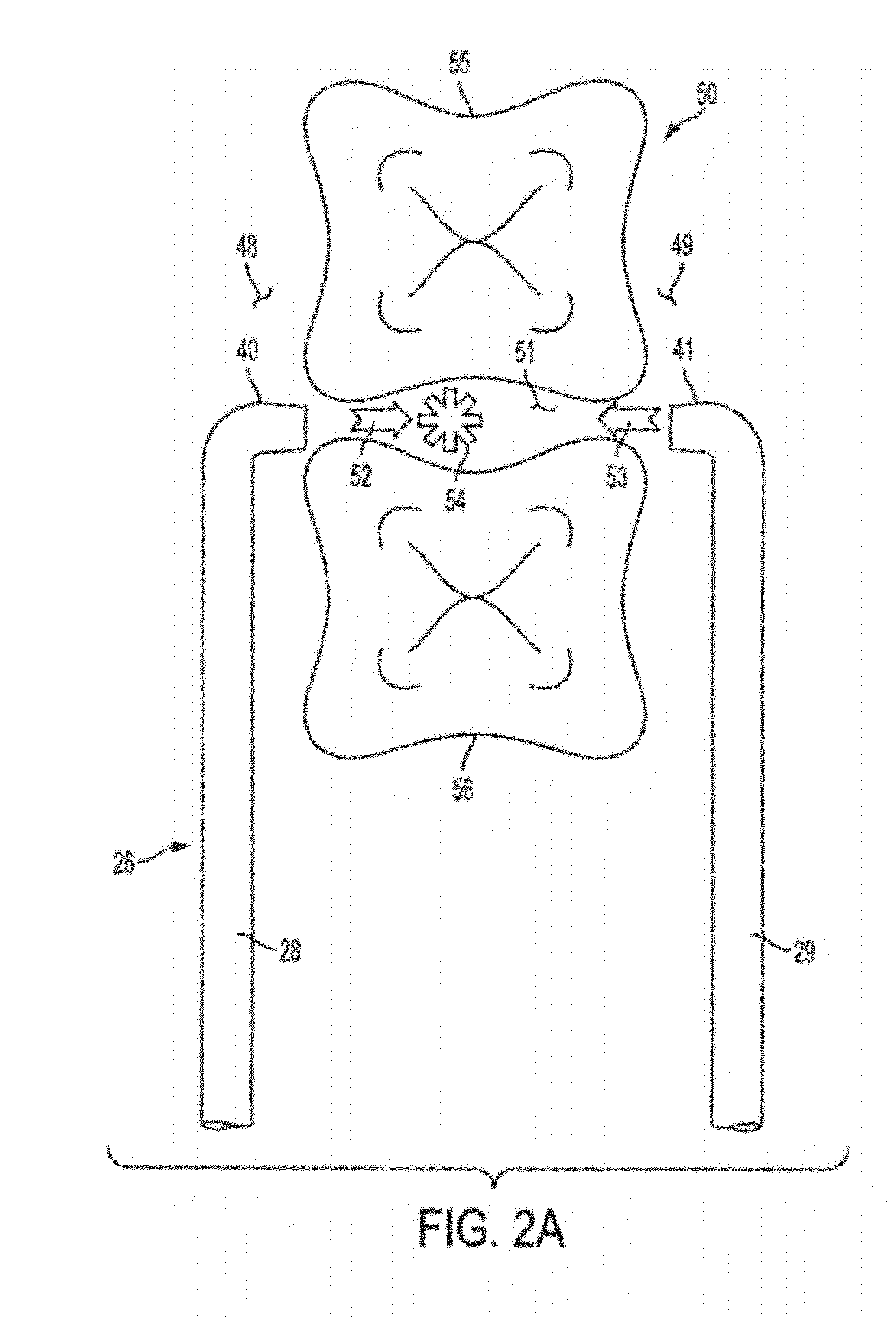

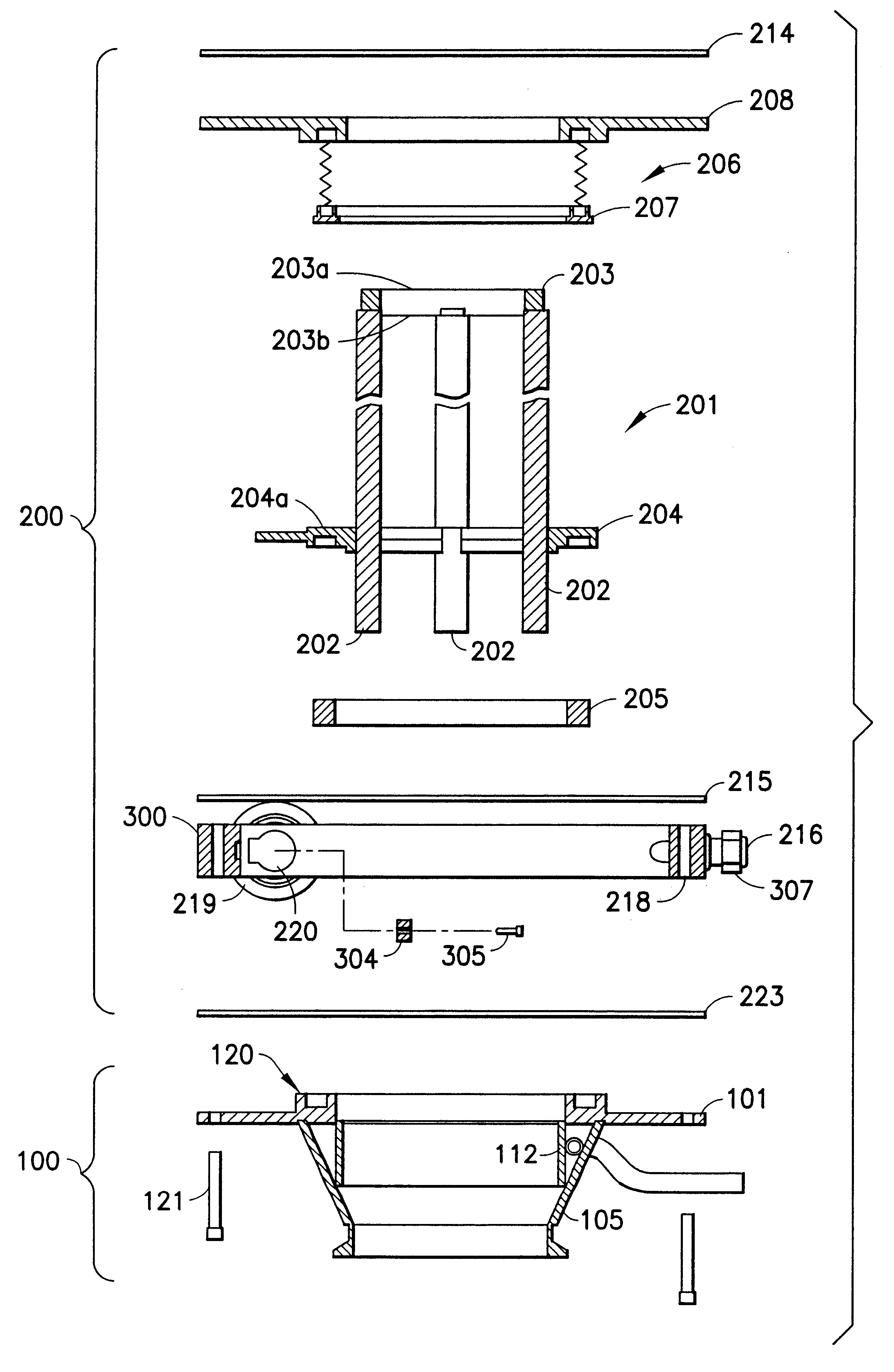

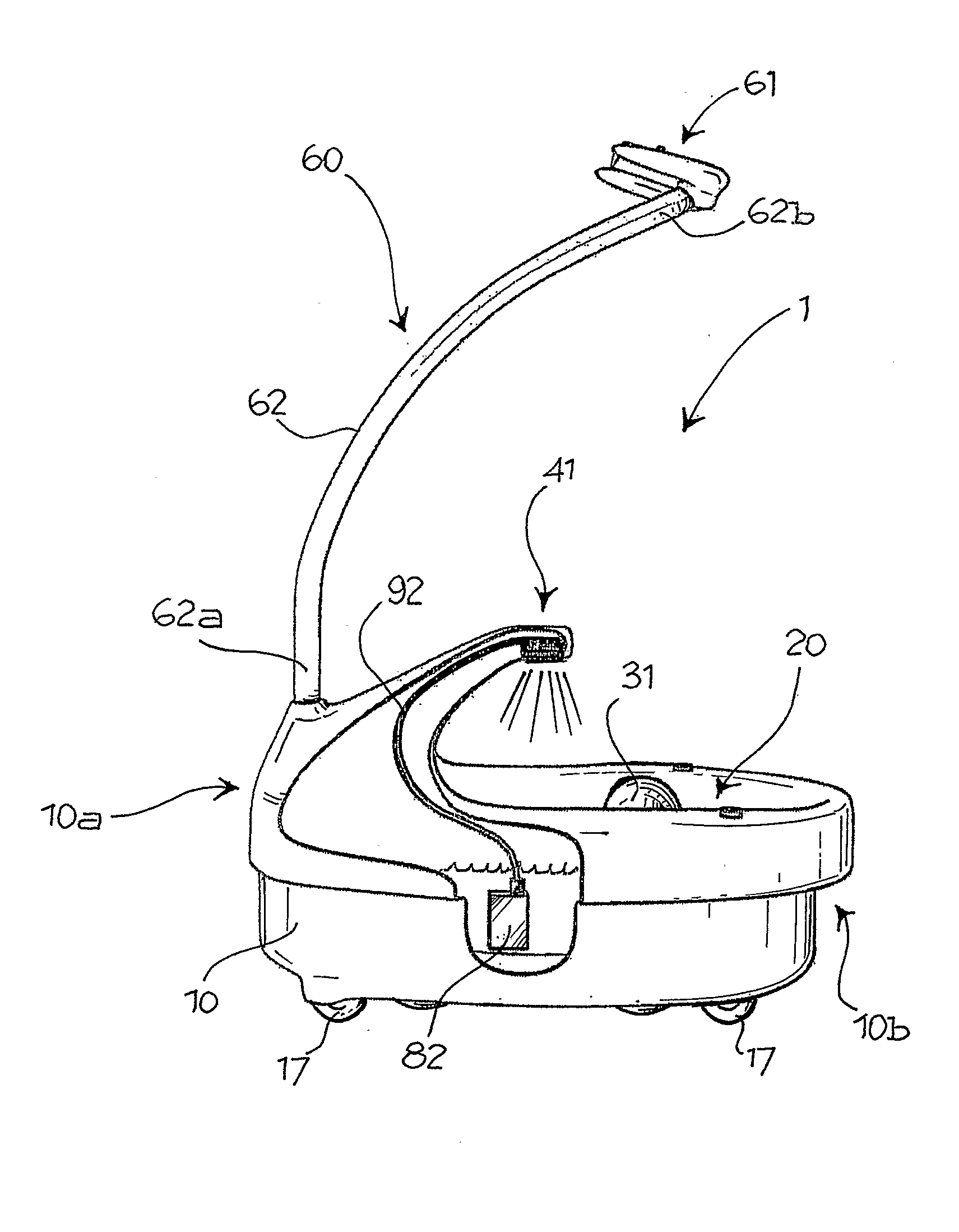

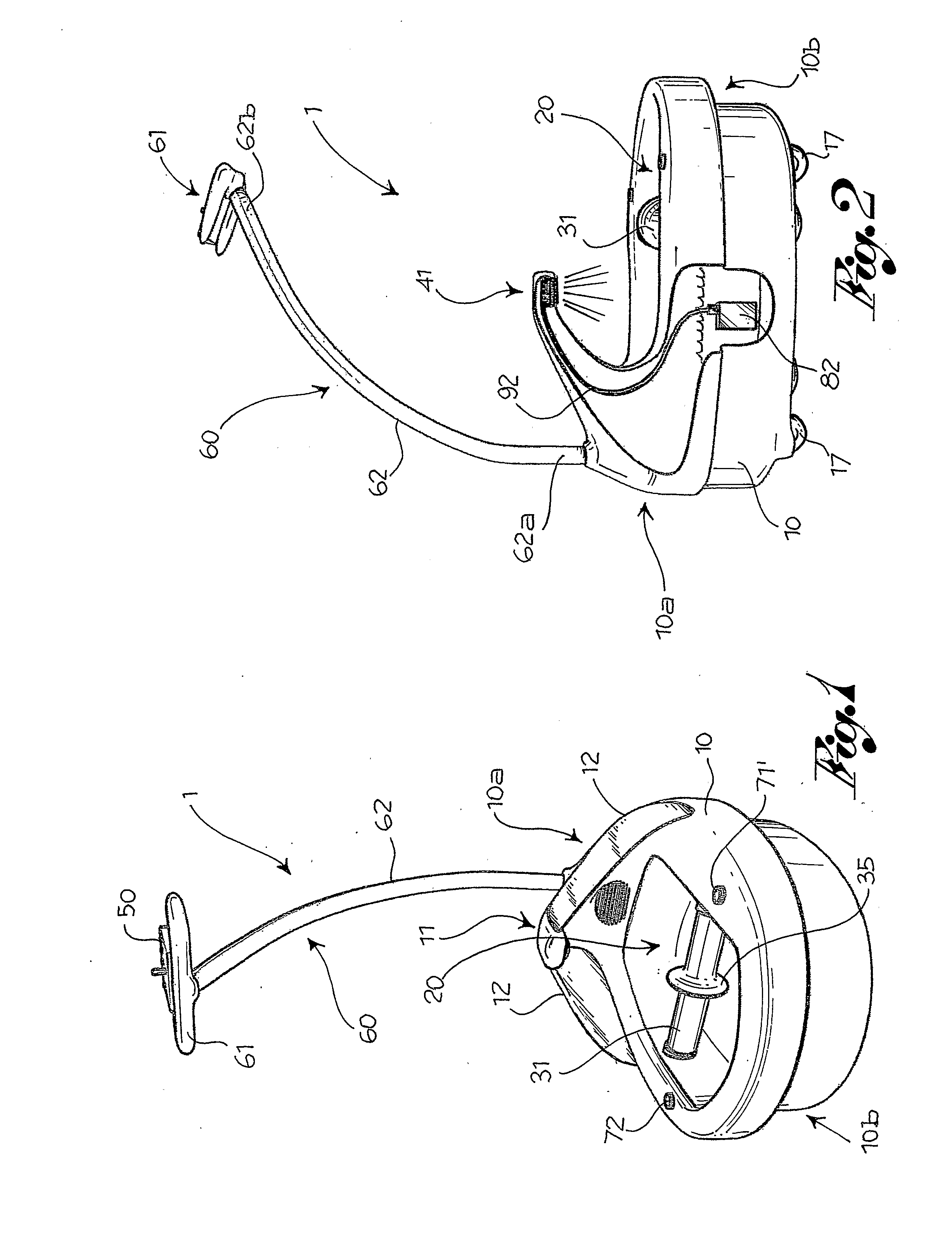

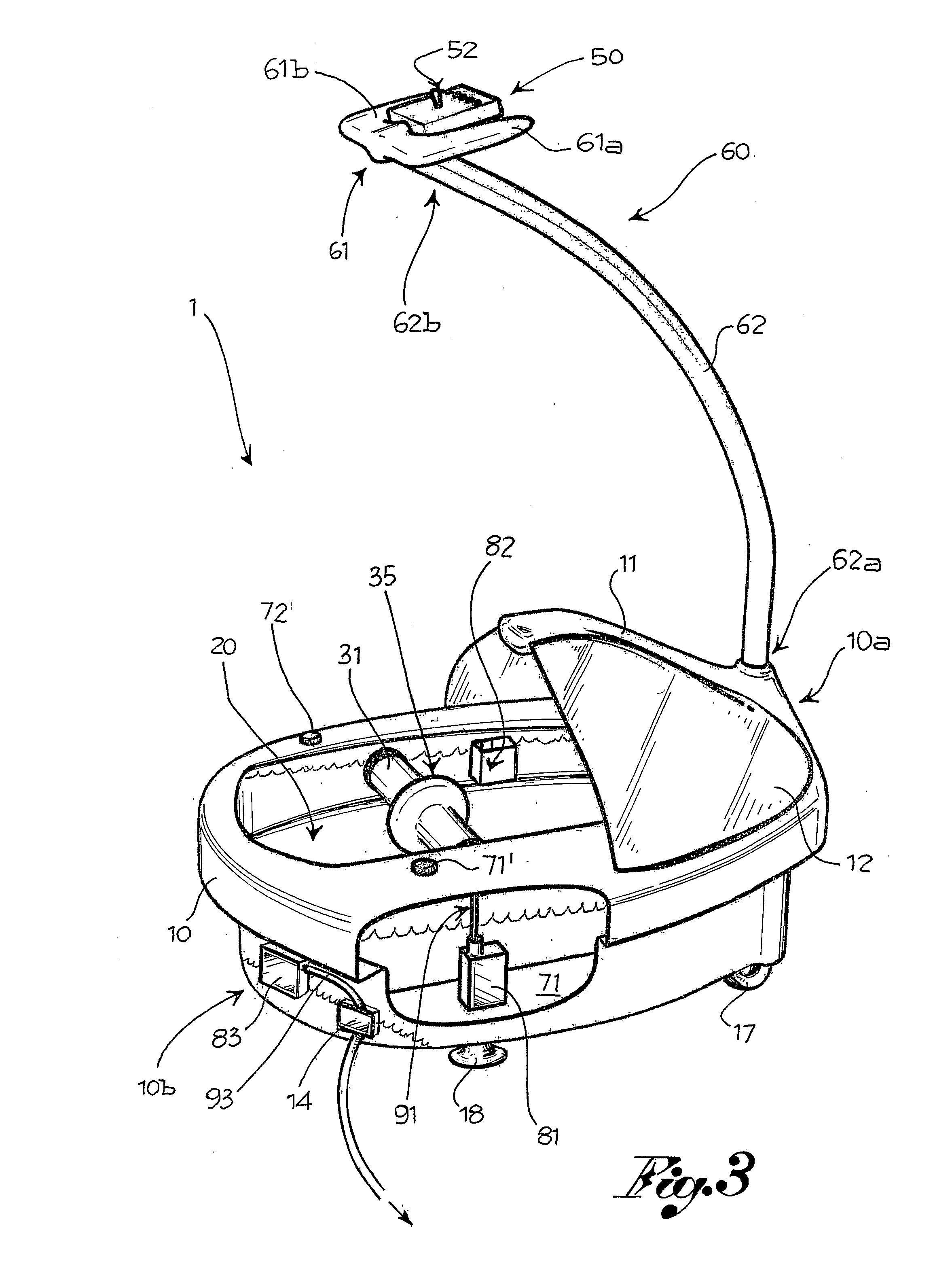

Oral Irrigation and/or Brushing Devices and/or Methods

InactiveUS20120064480A1Promotes Oral HealthPrecise positioningGum massageBristleBrush deviceDentistry

An integrated or combined oral care device having an oral cleaning device including a handle, and one or more cleaning head assemblies and a fluid irrigation assembly attached or attachable to the oral cleaning device.

Owner:CRA LABS

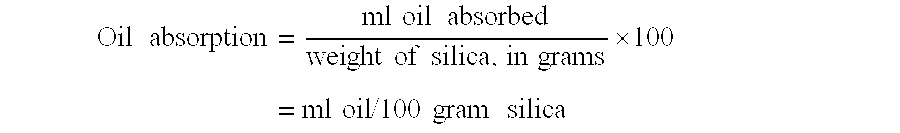

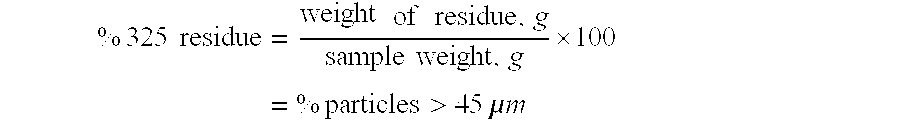

Method for making particulate compositions and products thereof

InactiveUS20070001037A1Easy to produceImprove uniformityCosmetic preparationsOther chemical processesParticulatesSilicon dioxide

A method of making abrasive compositions, and more particularly, it relates to a method of making precipitated silica abrasive compositions having excellent cleaning performance and lower abrasiveness with post-reactor sizing of the abrasive particles being performed directly via wet comminution and centrifugation, optionally followed by hydraulic chamber press filtering combined with vacuum dewatering and de-agglomeration is provided. By targeting a specific particle size range, it has been determined that higher pellicle film cleaning levels may be achieved without also increasing the dentin abrasion properties of the silica products themselves. As a result, dentifrices including such classified abrasive silica products, exhibiting particularly desirable cleaning benefits, can be provided for improved tooth polishing, whitening, and the like, without deleteriously affecting the hard tooth surfaces. Also encompassed within this invention also are products of this selective process scheme and dentifrices containing such particularly manufactured and classified silica products.

Owner:J M HUBER CORP

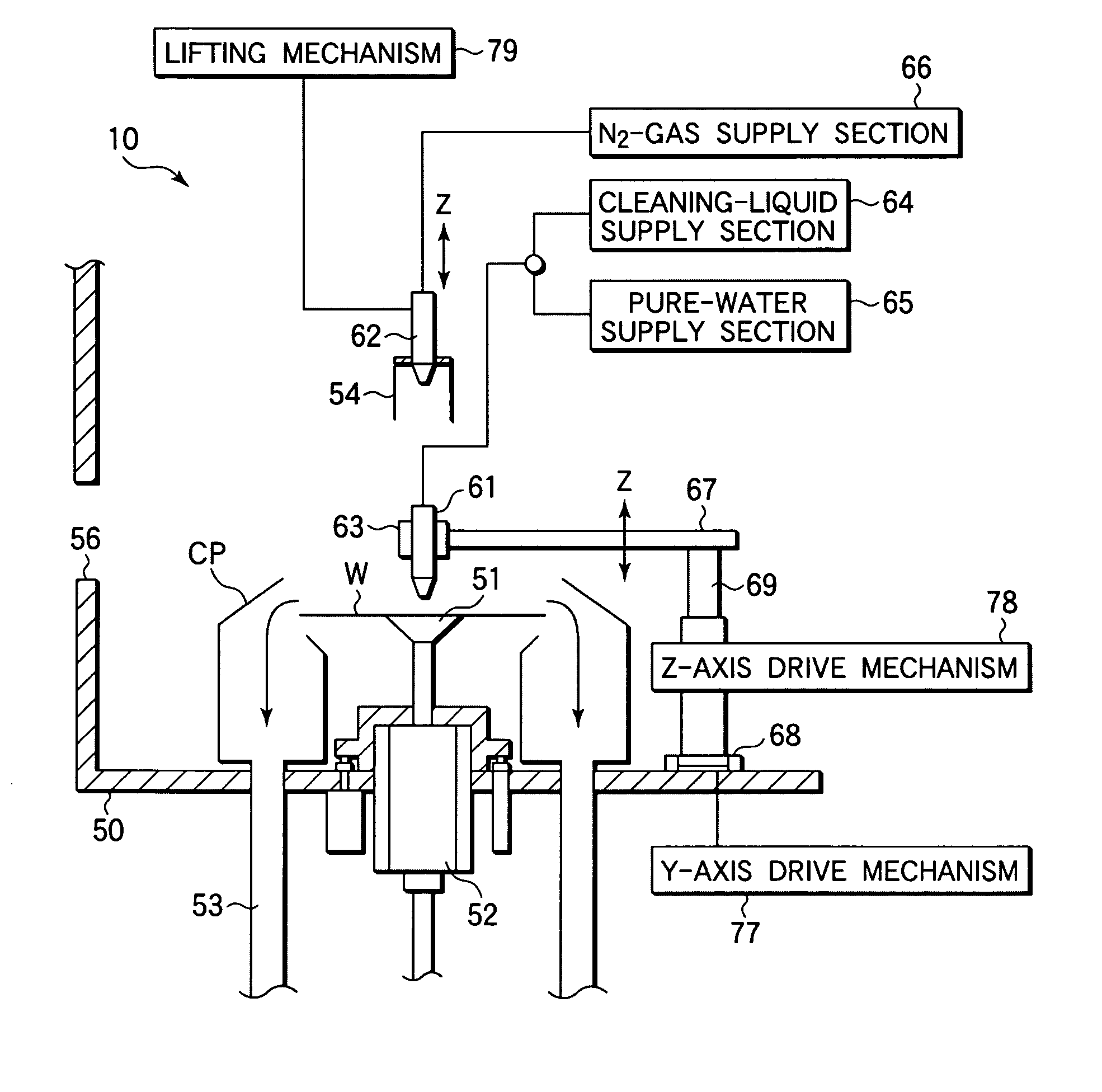

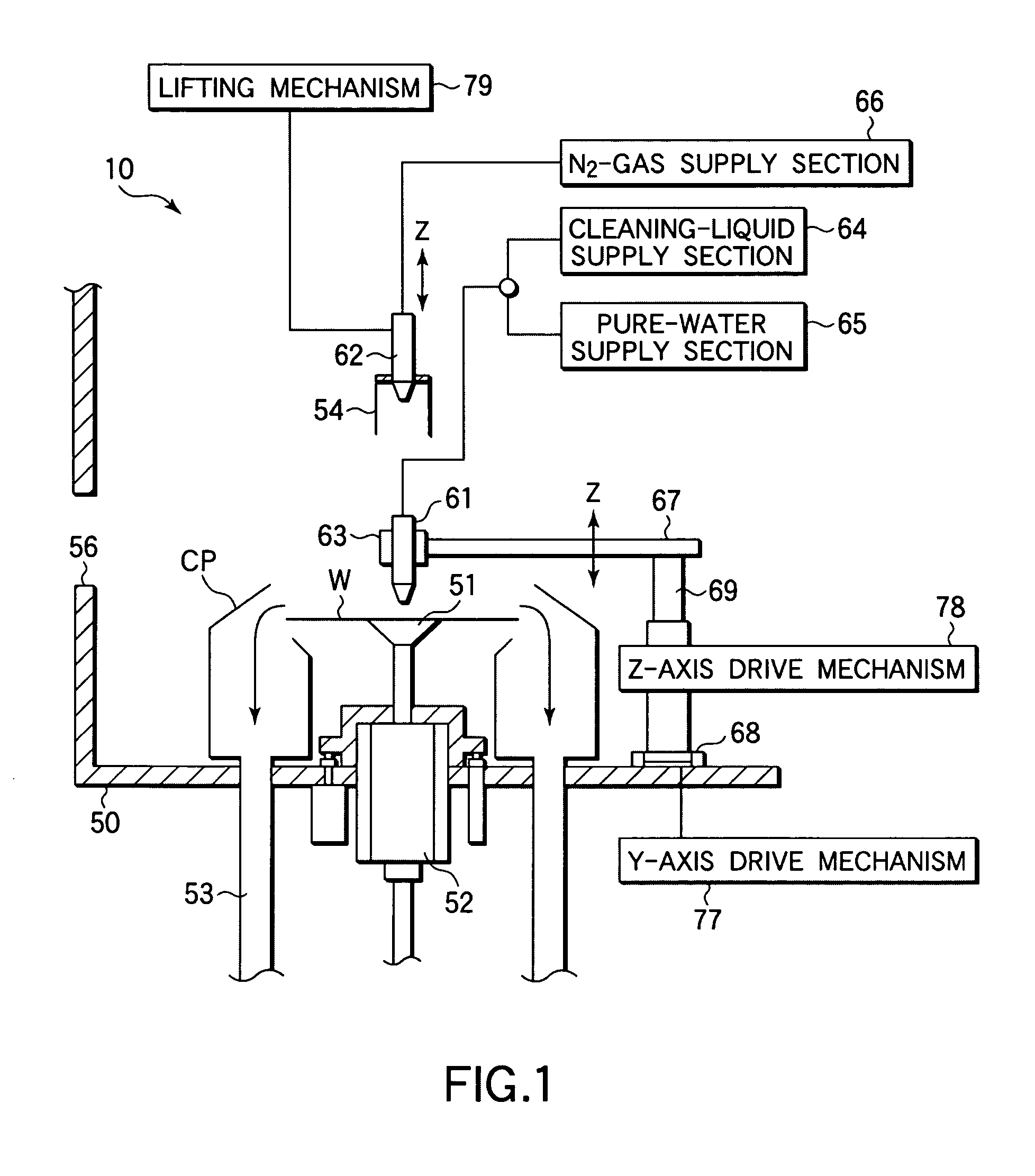

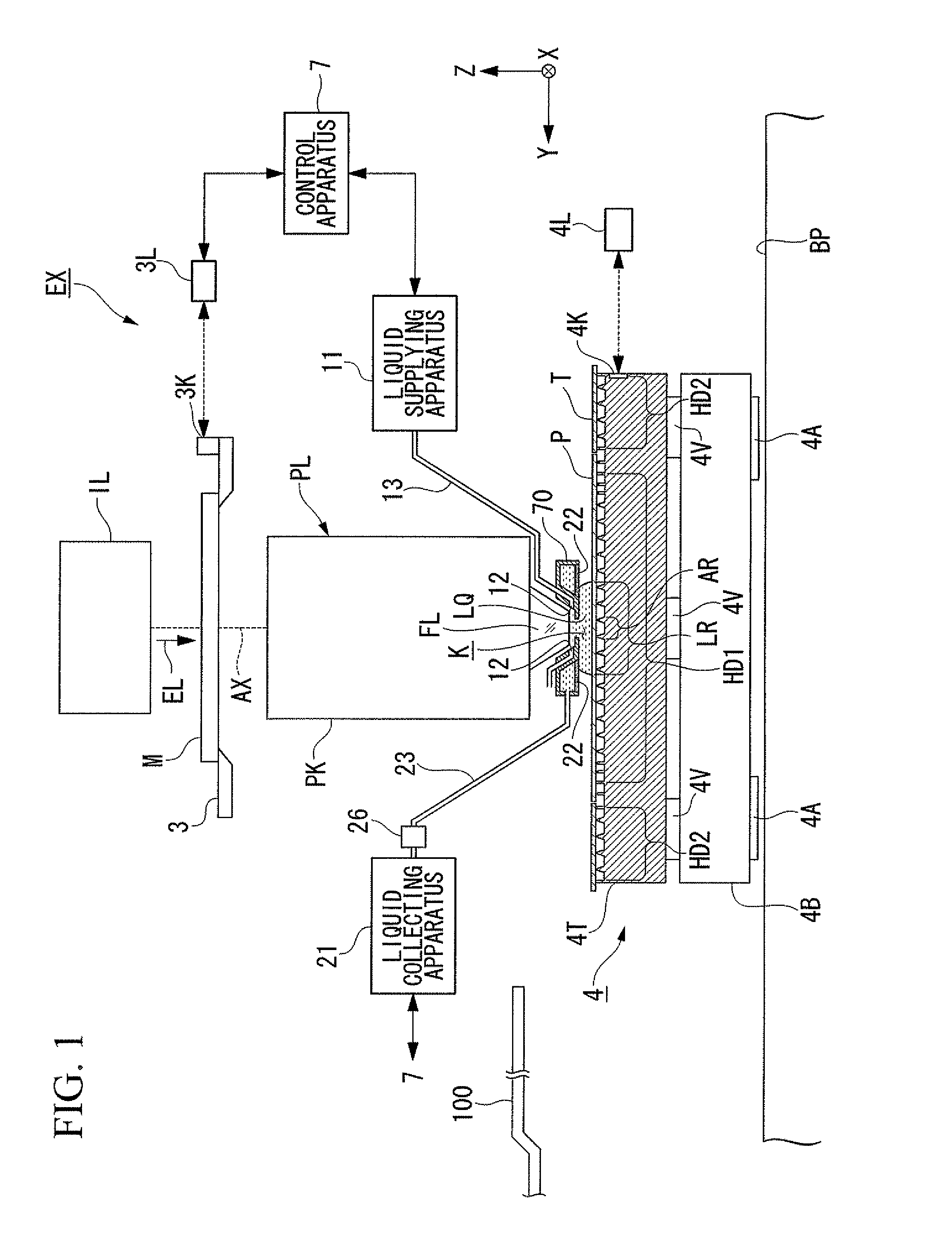

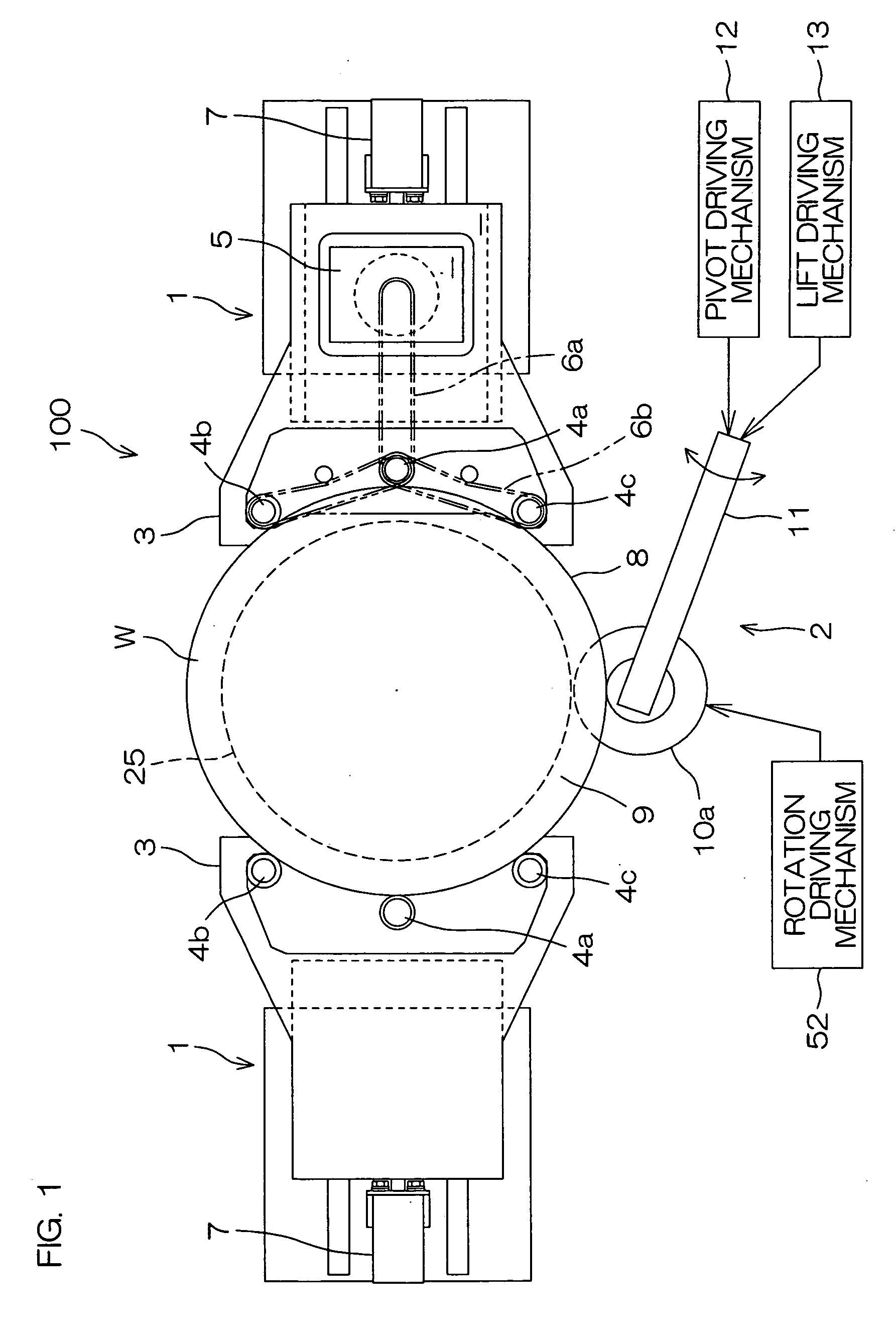

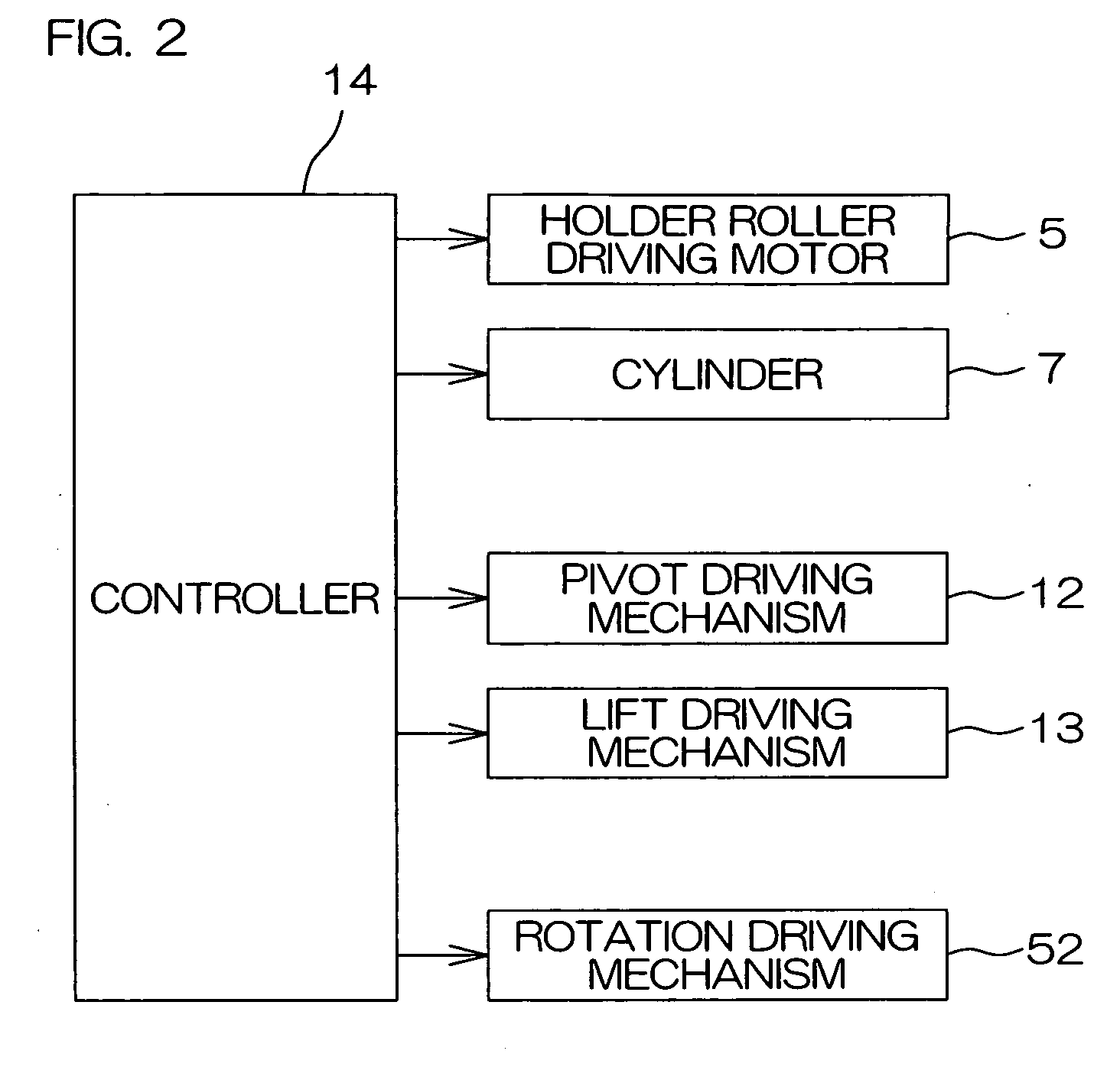

Substrate cleaning method, substrate cleaning apparatus and computer readable recording medium

InactiveUS20070131256A1Suppress generationPrecision cleaningReconditioning/cleaning record carriersSemiconductor/solid-state device manufacturingEngineeringFeed point

After a rinse process on a wafer W is performed by feeding pure water to the surface of the wafer W at a predetermined flow rate while rotating the wafer W in an approximately horizontal state, a feed amount of the pure water to the wafer W is reduced, and a pure-water feed point is moved outward from the center of the wafer W. In this manner, the wafer W is subjected to a spin dry process while forming a liquid film in a substantially outer region of the pure-water feed point.

Owner:TOKYO ELECTRON LTD

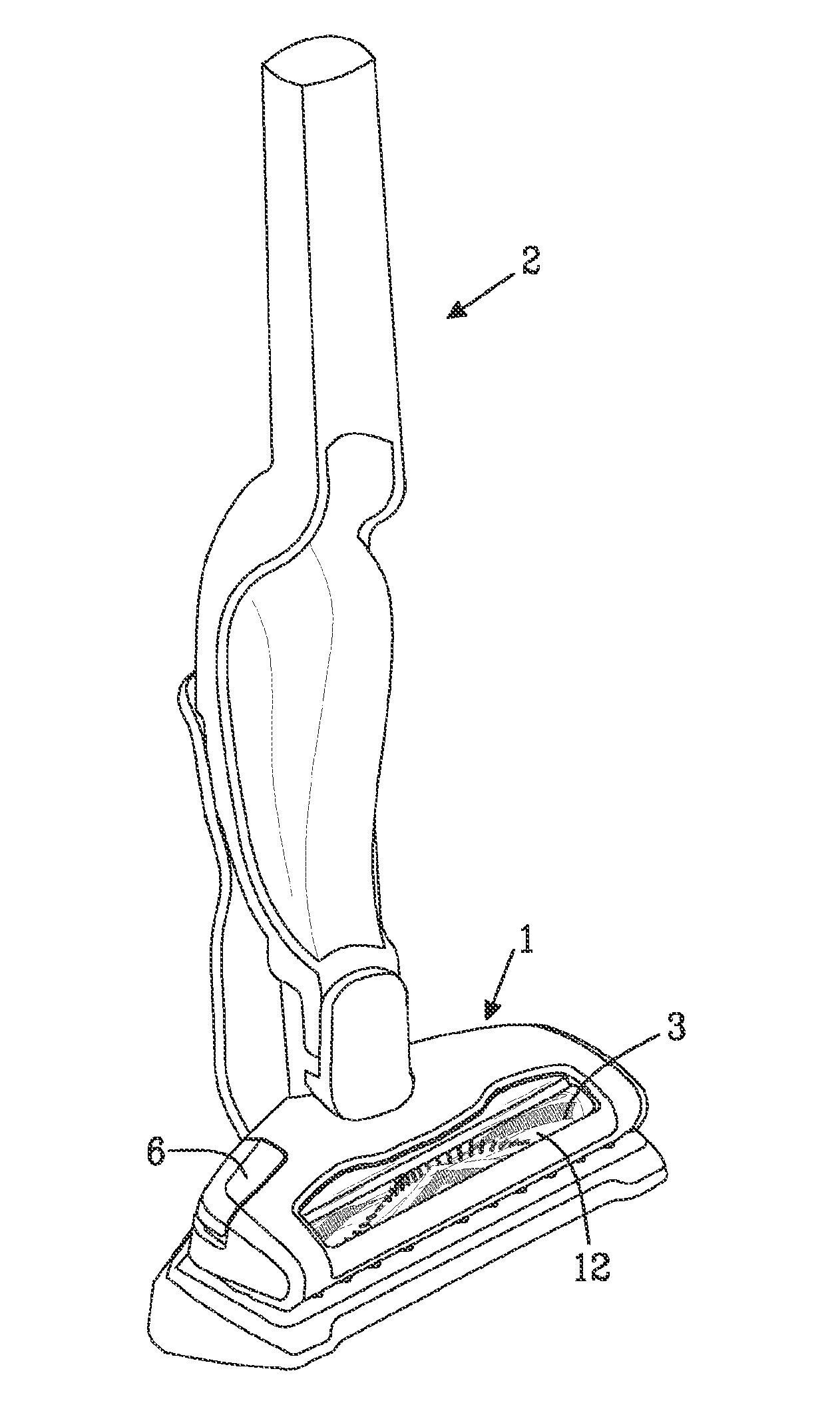

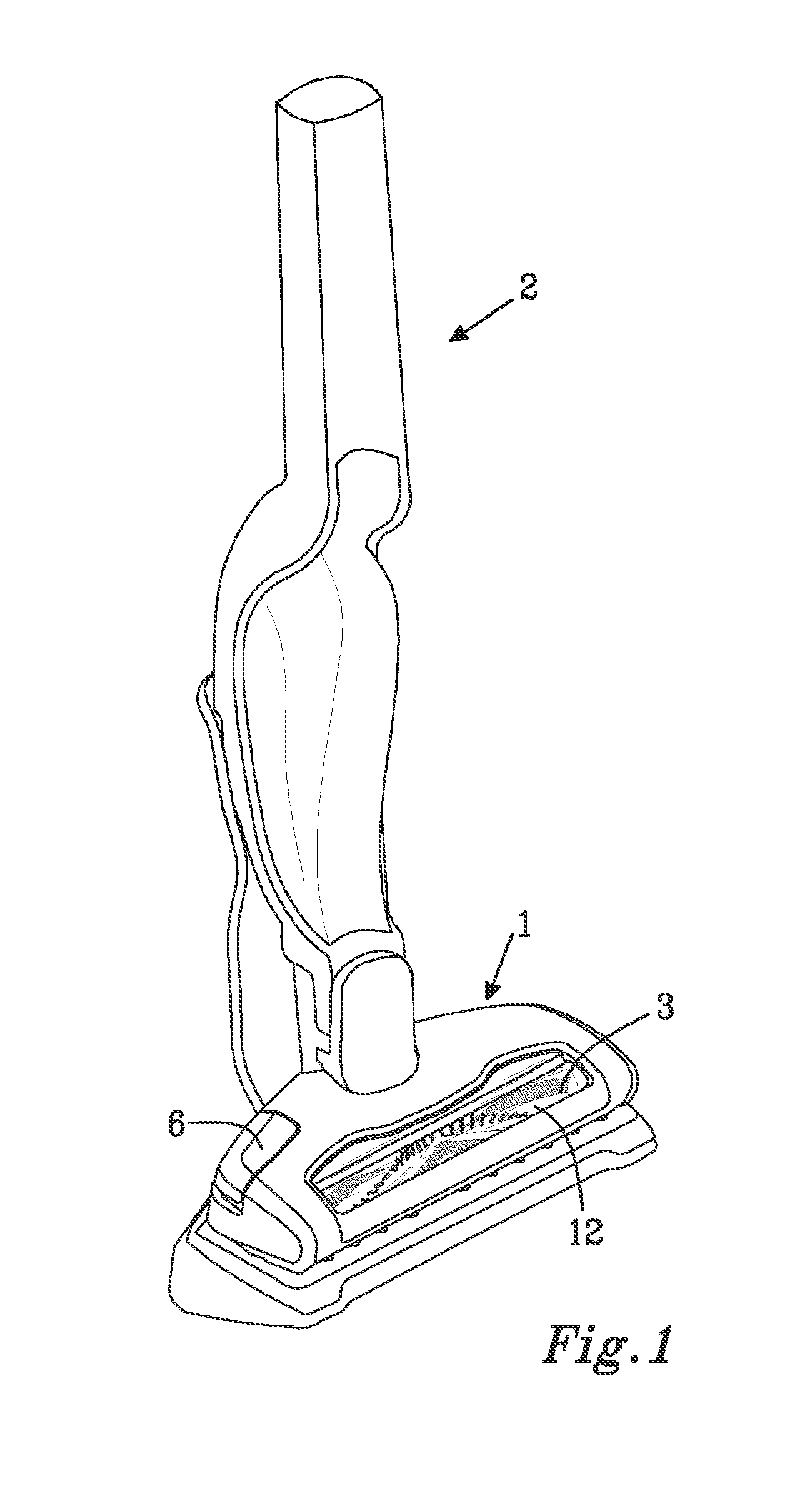

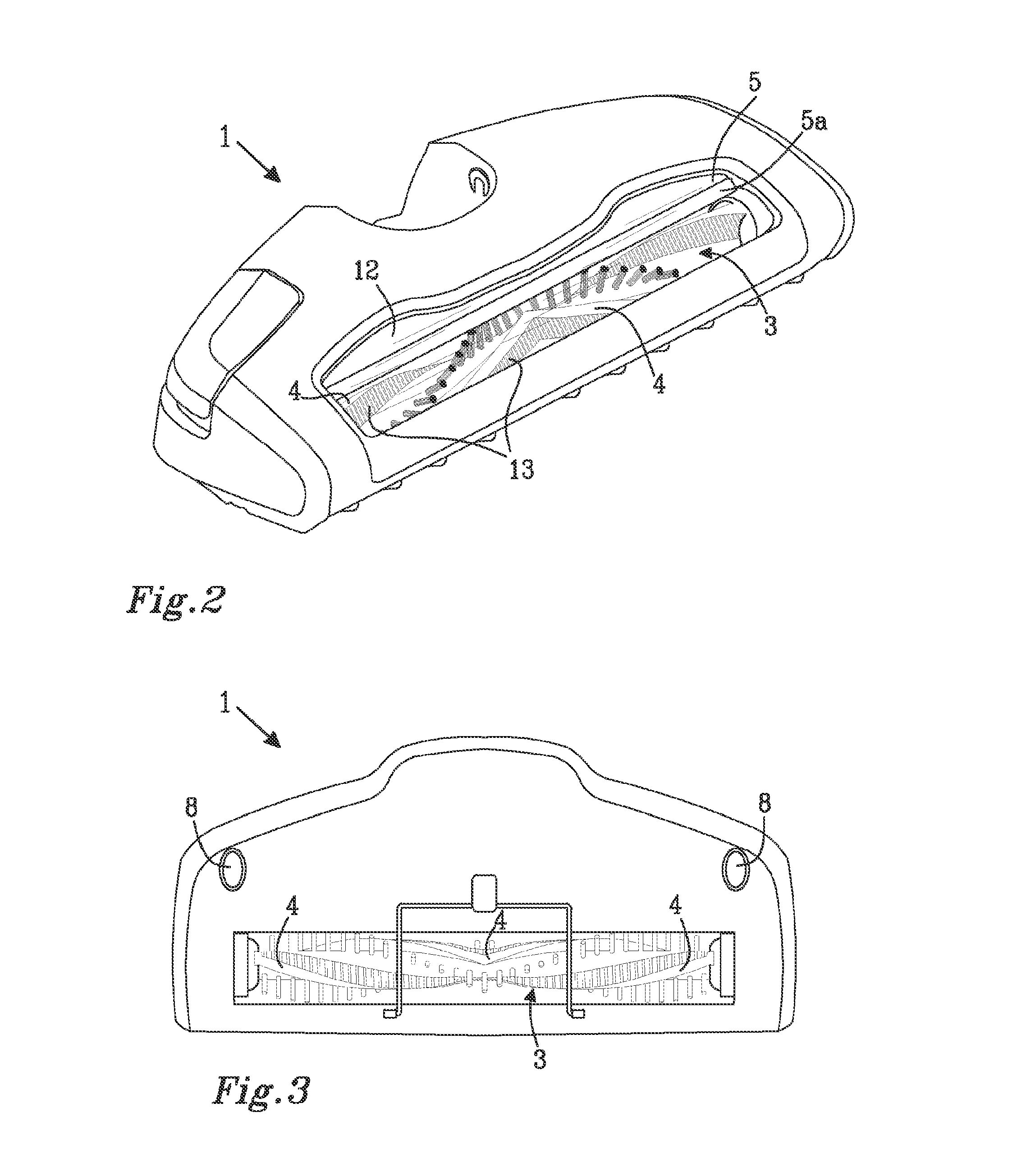

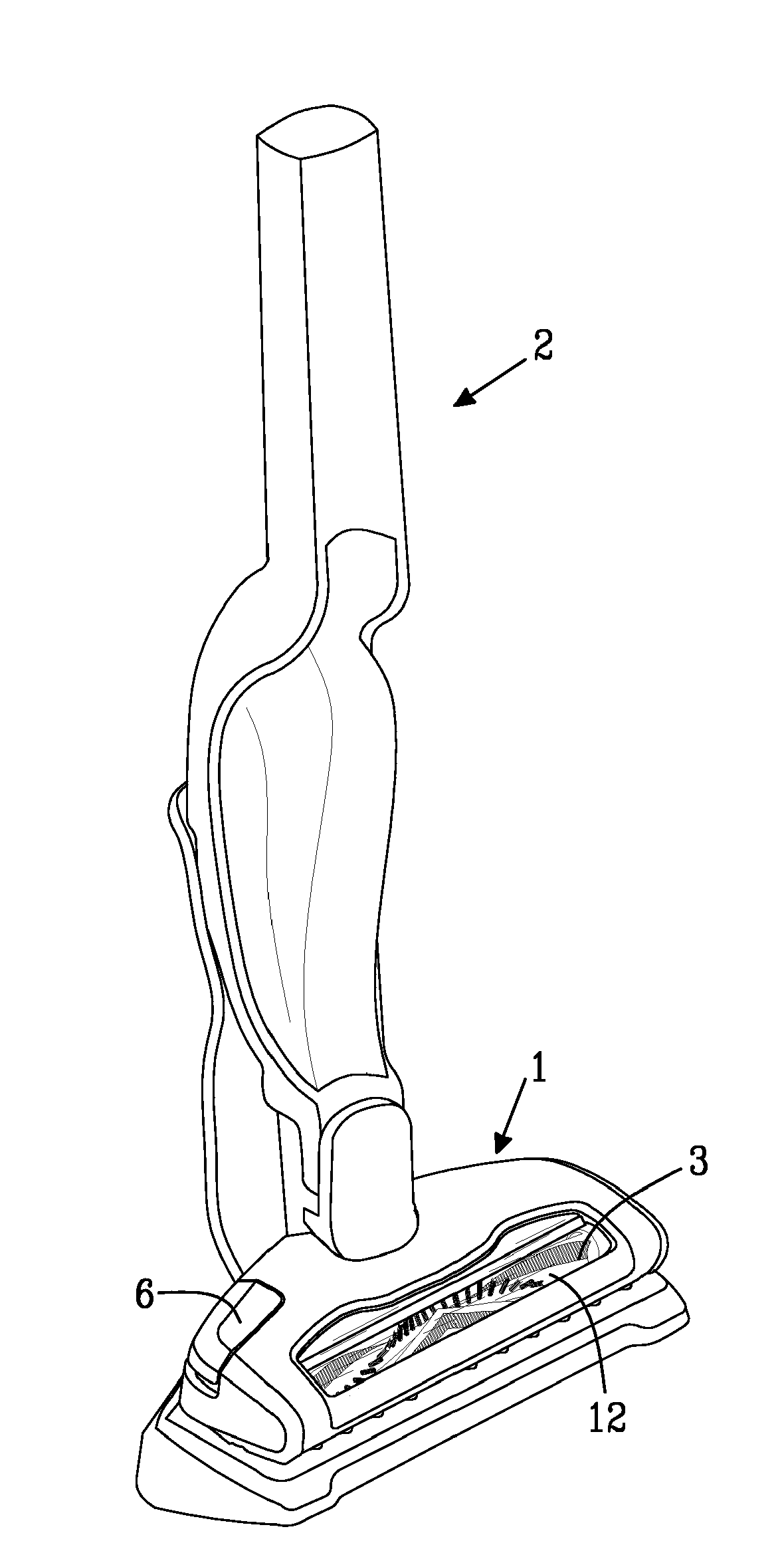

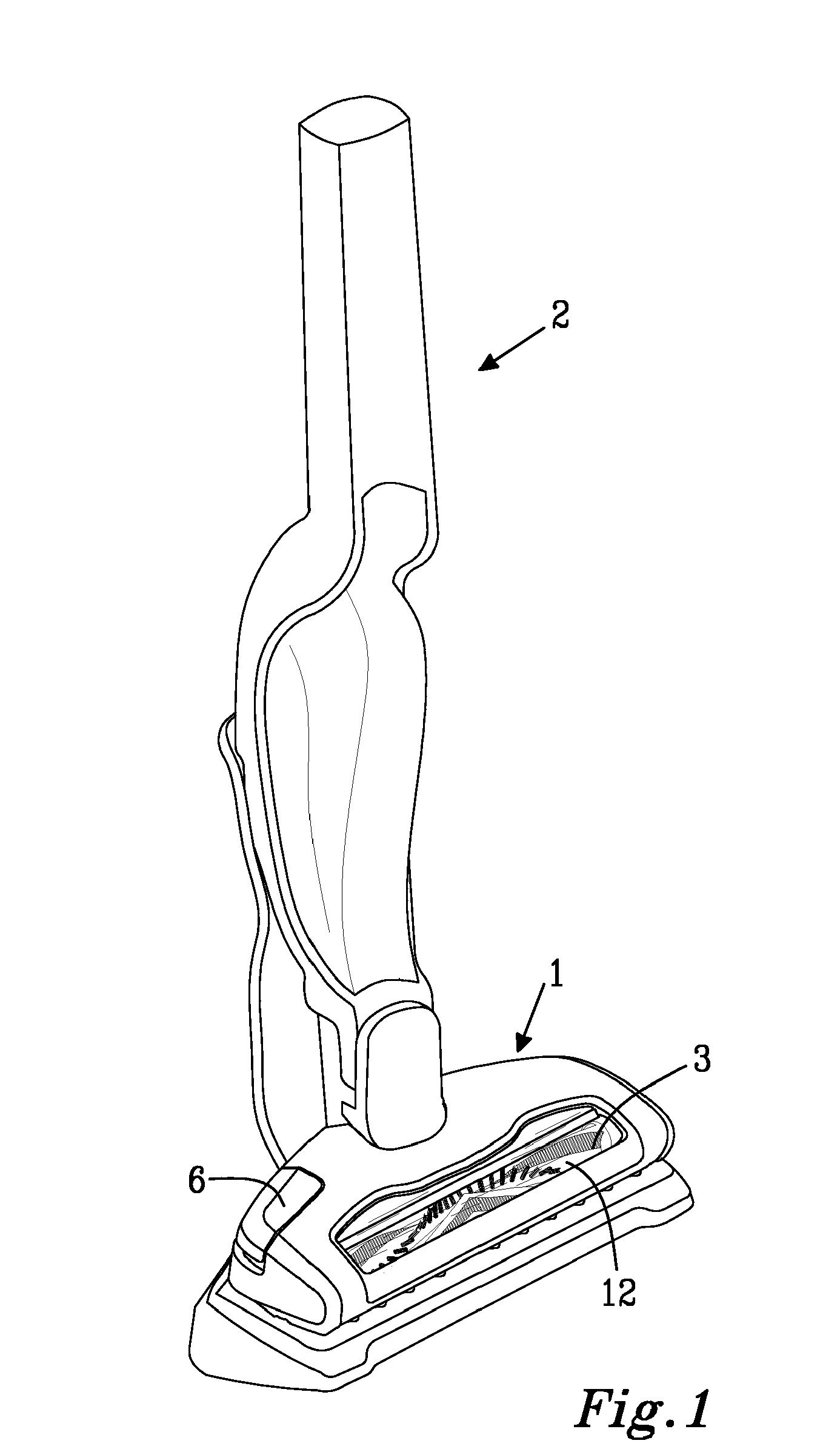

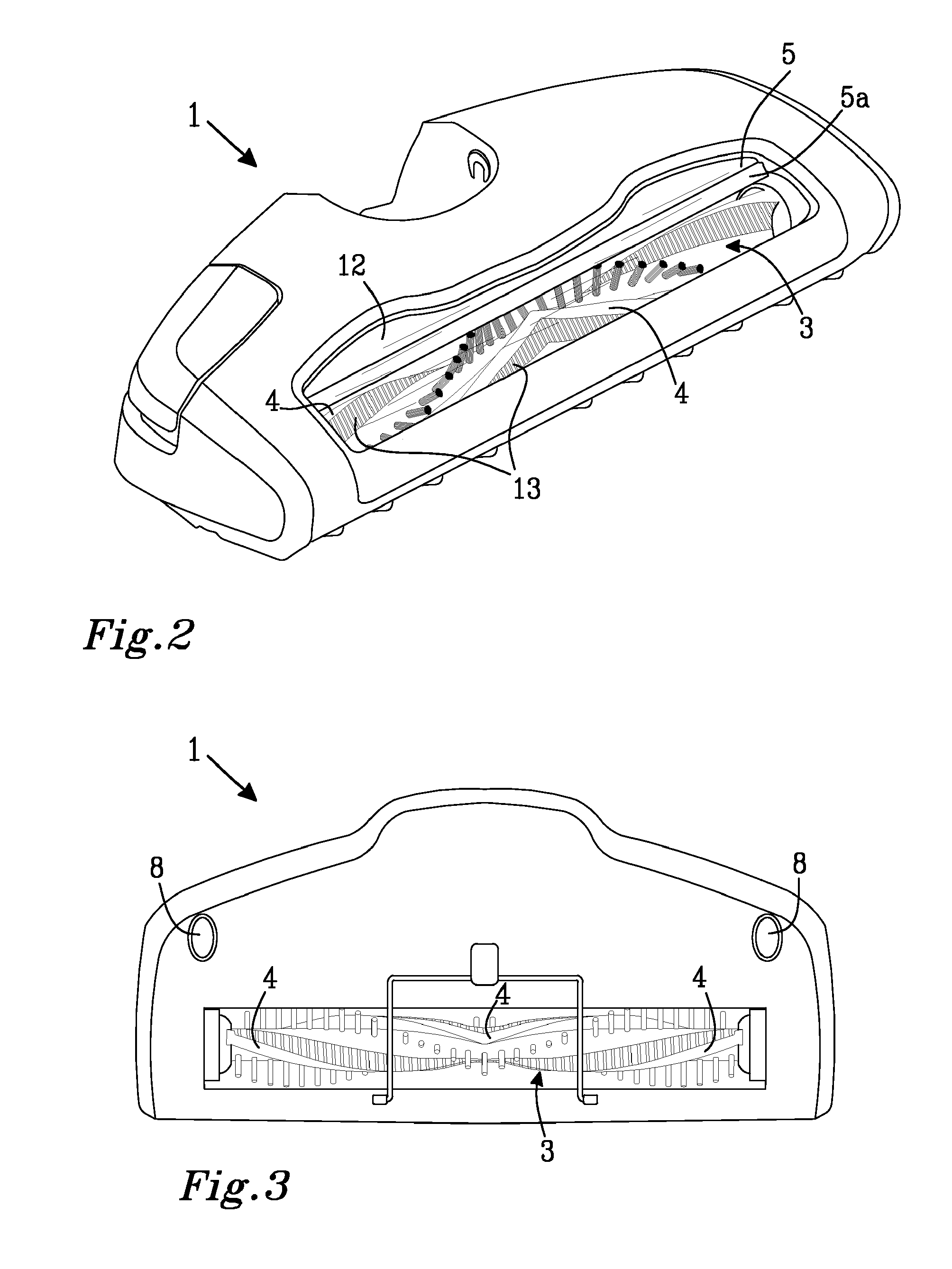

Cleaning nozzle for a vacuum cleaner

A vacuum cleaner nozzle having a rotatable member arranged around a longitudinal axis for picking up particles from a surface to be cleaned, and a cleaning arrangement for removing articles entangled on the rotatable member. The cleaning arrangement has at least one support surface provided on at least one radially projecting member of the rotatable member, and at least one cleaning member movable between a resting position in which the cleaning member is arranged at a distance from the support surface and at least one cleaning position in the vicinity of the rotatable member. In the cleaning position, the cleaning member co-operates with at least one segment of the support surface to remove any entangled articles from the rotatable member as the rotatable member rotates. The at least one support surface comprises a number of segments arranged at an individual respective radius in relation to the longitudinal axis.

Owner:AB ELECTROLUX

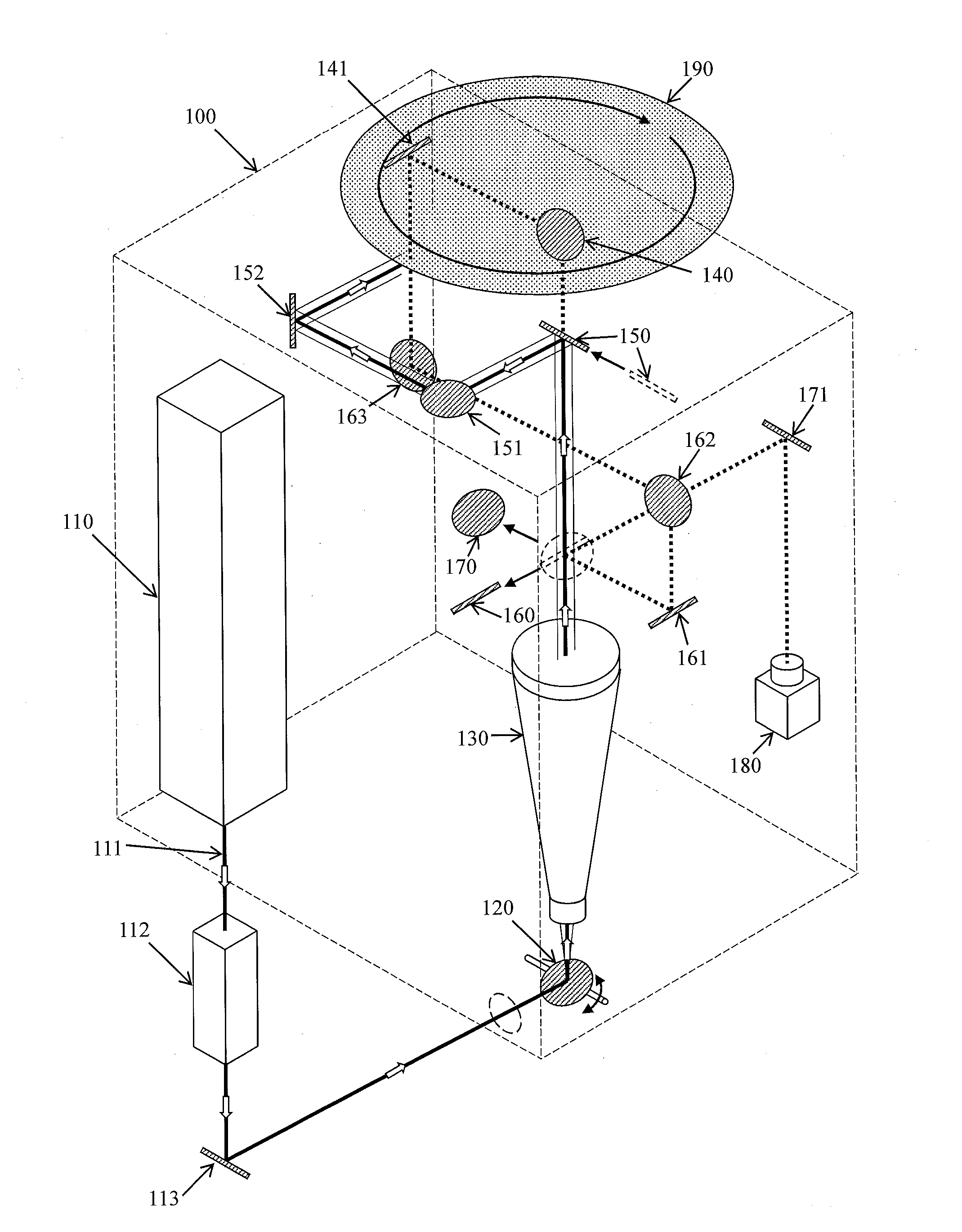

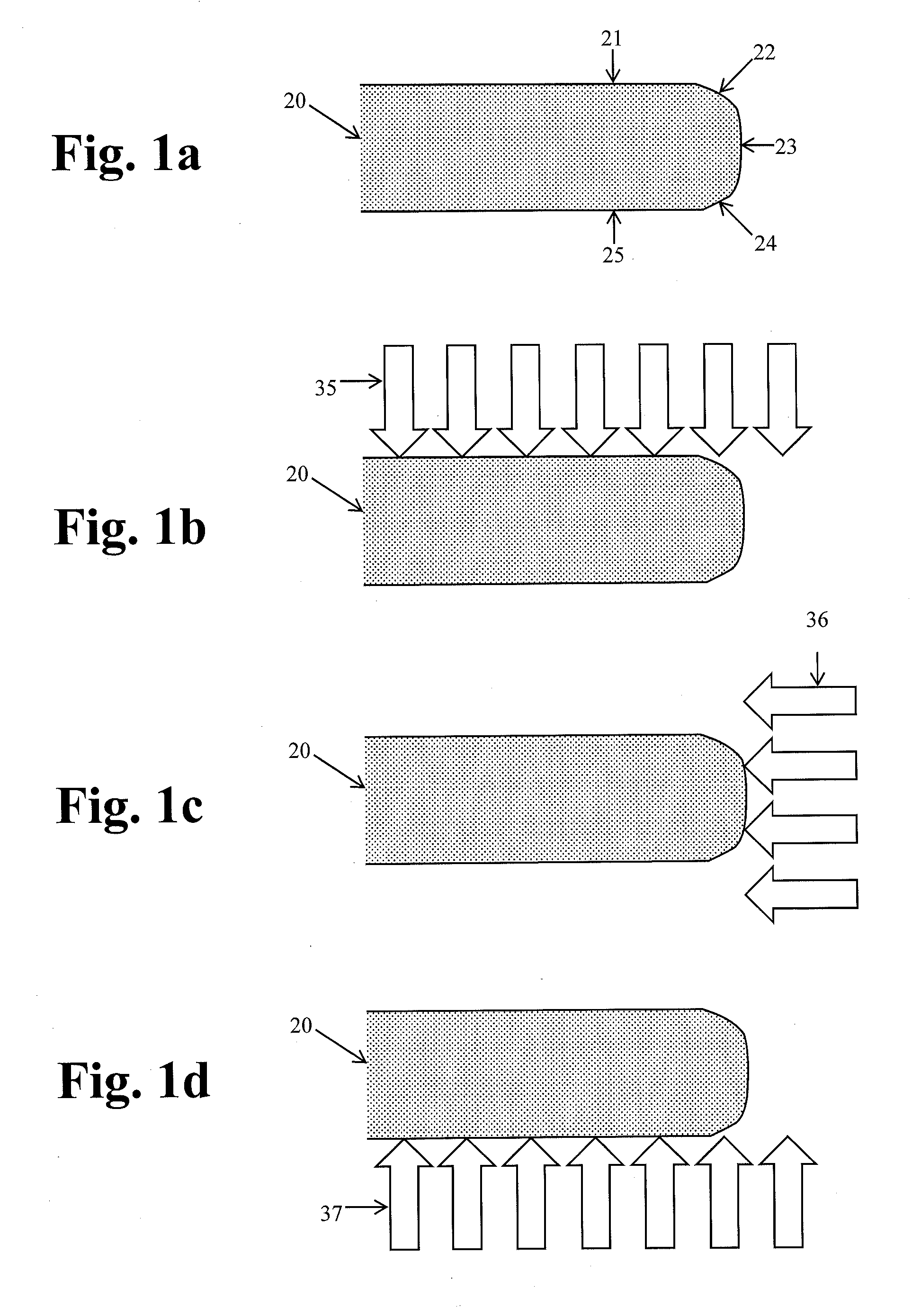

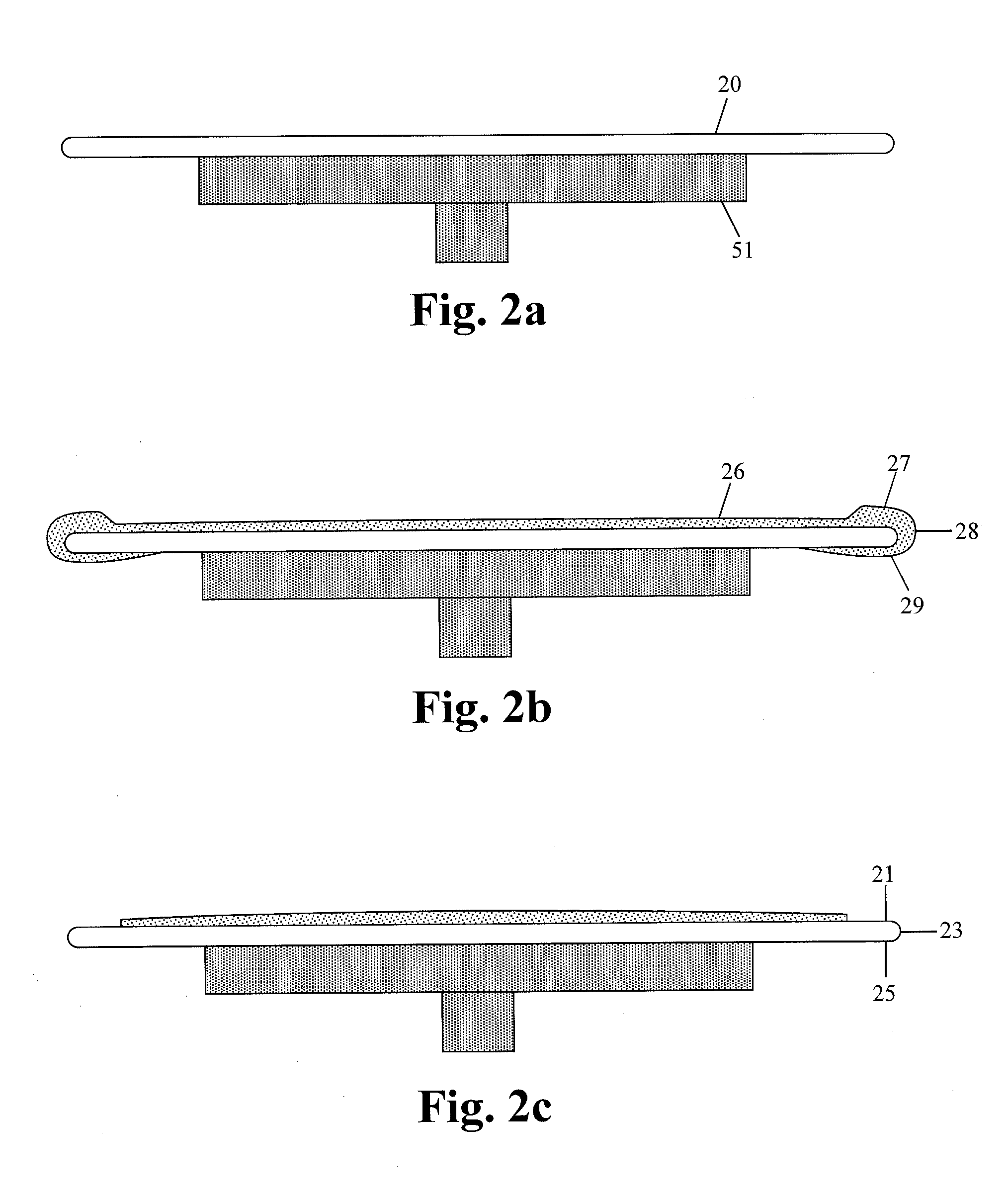

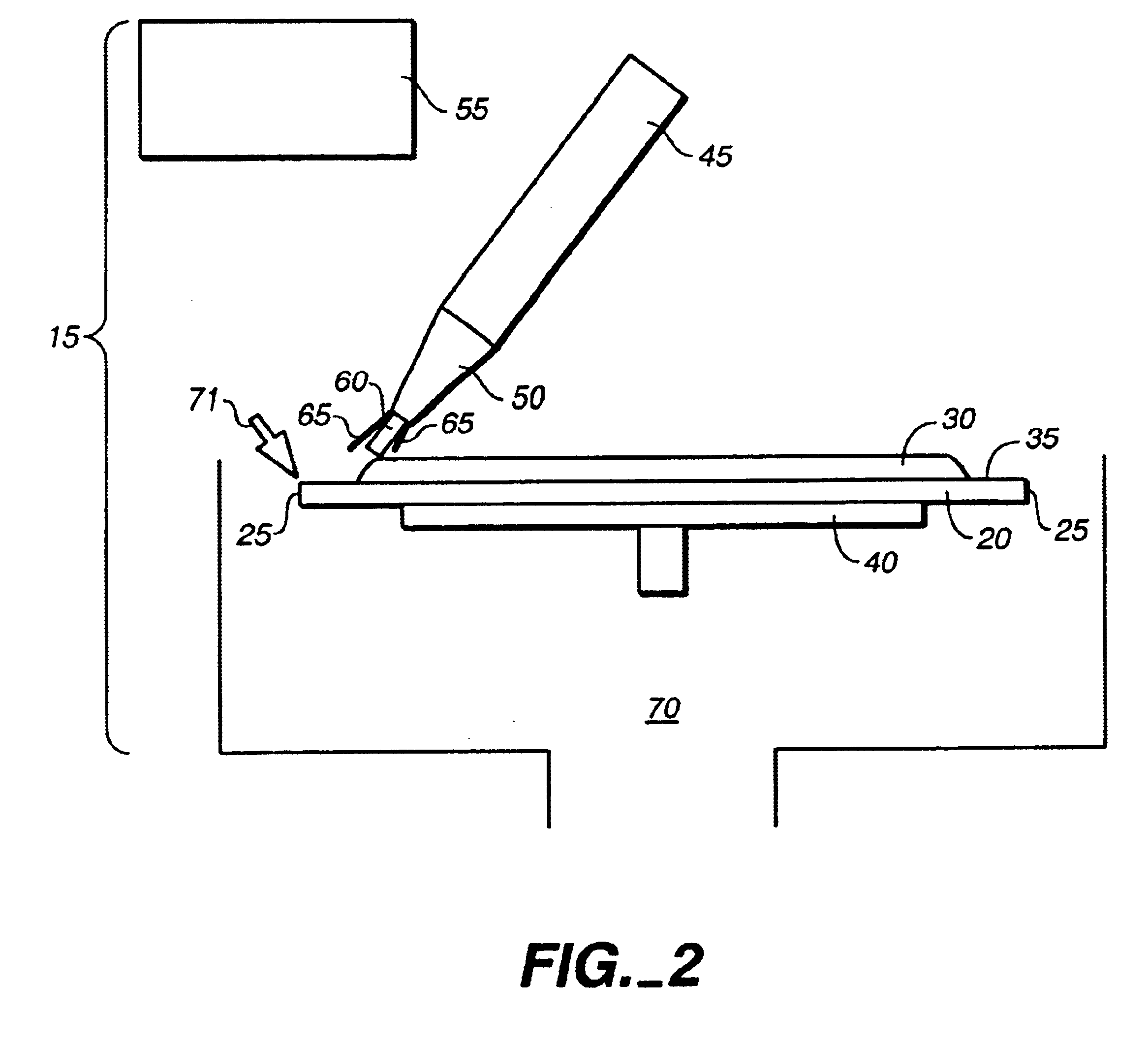

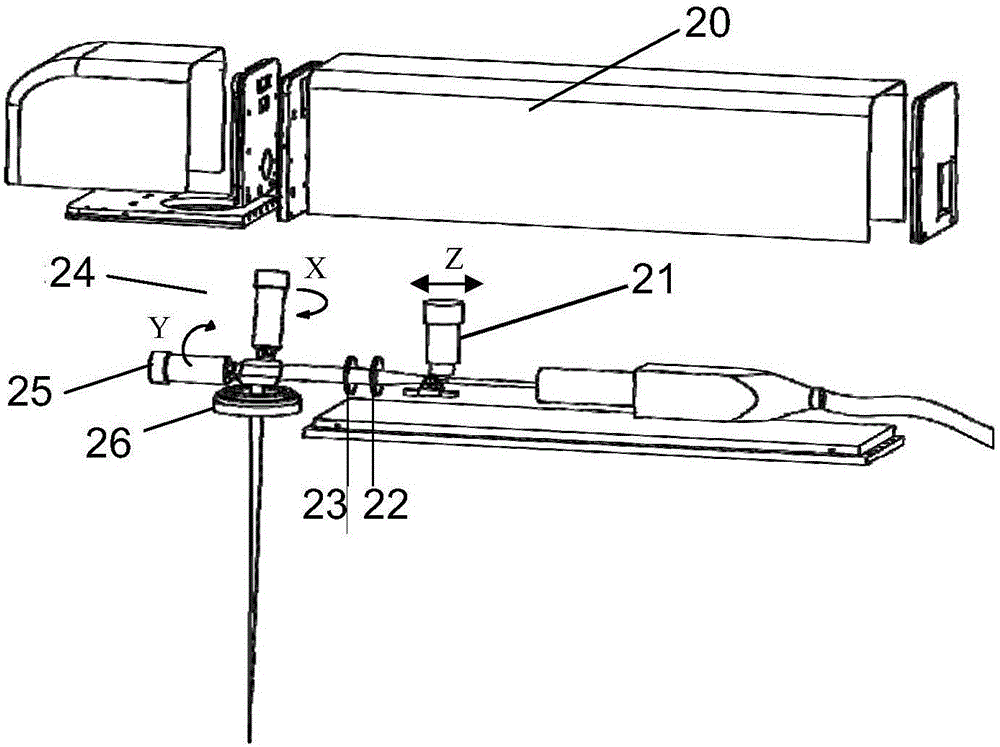

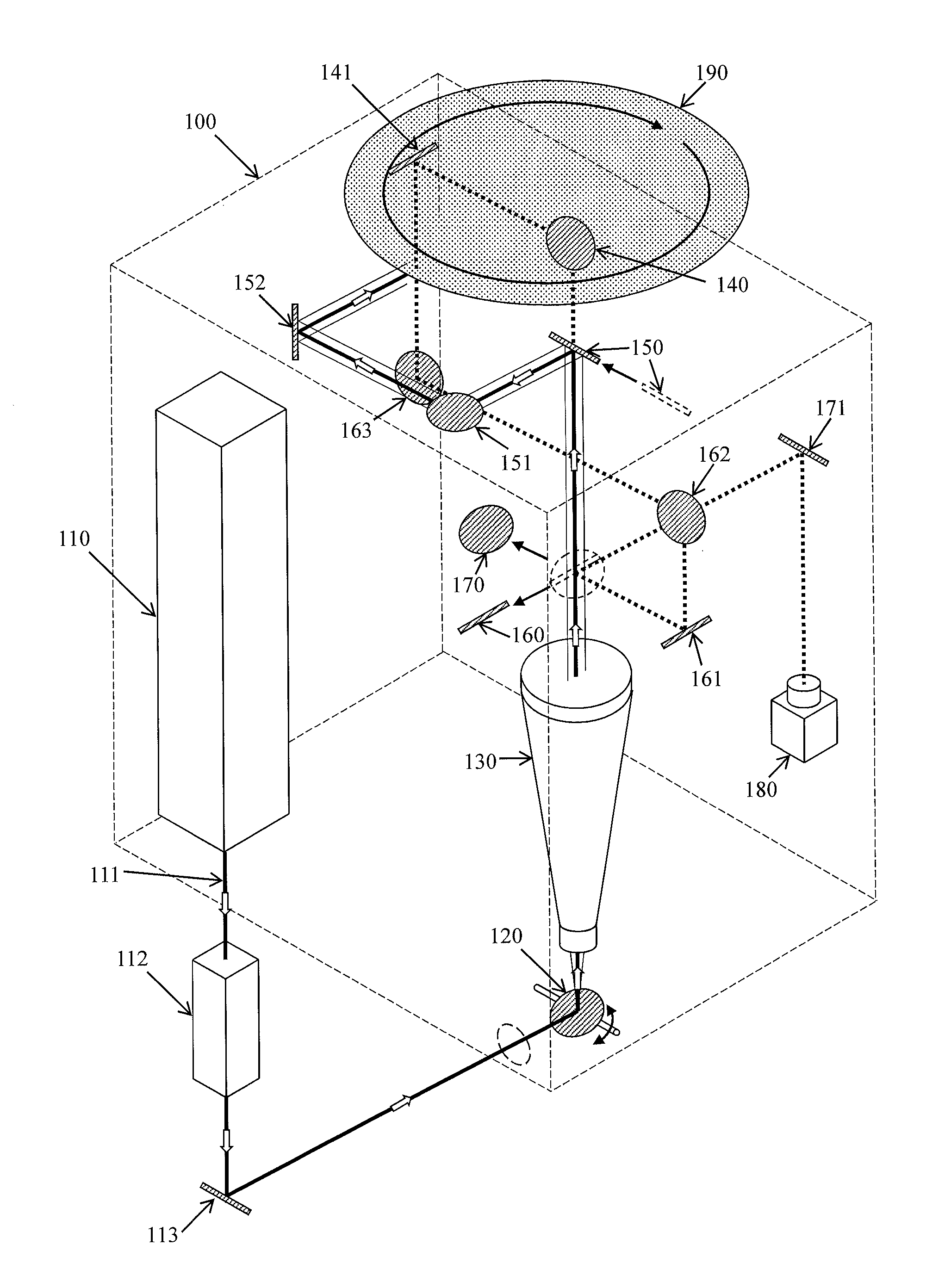

Method and apparatus for processing substrate edges

InactiveUS20110168672A1Process environmental protectionEliminate needDecorative surface effectsPhotomechanical apparatusGas syringeSolvent

A method and apparatus for processing substrate edges is disclosed that overcomes the limitations of conventional edge processing methods and systems used in semiconductor manufacturing. The edge processing method and apparatus of this invention includes a laser and optical system to direct a beam of radiation onto a rotating substrate supported by a chuck, in atmosphere. The optical system accurately and precisely directs the beam to remove or transform organic or inorganic films, film stacks, residues, or particles from the top edge, top bevel, apex, bottom bevel, and bottom edge of the substrate. An optional gas injector system directs gas onto the substrate edge to aid in the reaction. Process by-products are removed via an exhaust tube enveloping the reaction site. This invention permits precise control of an edge exclusion zone, resulting in an increase in the number of usable die on a wafer. Wafer edge processing with this invention replaces existing solvent and / or abrasive methods and thus will improve die yield.

Owner:UVTECH SYST

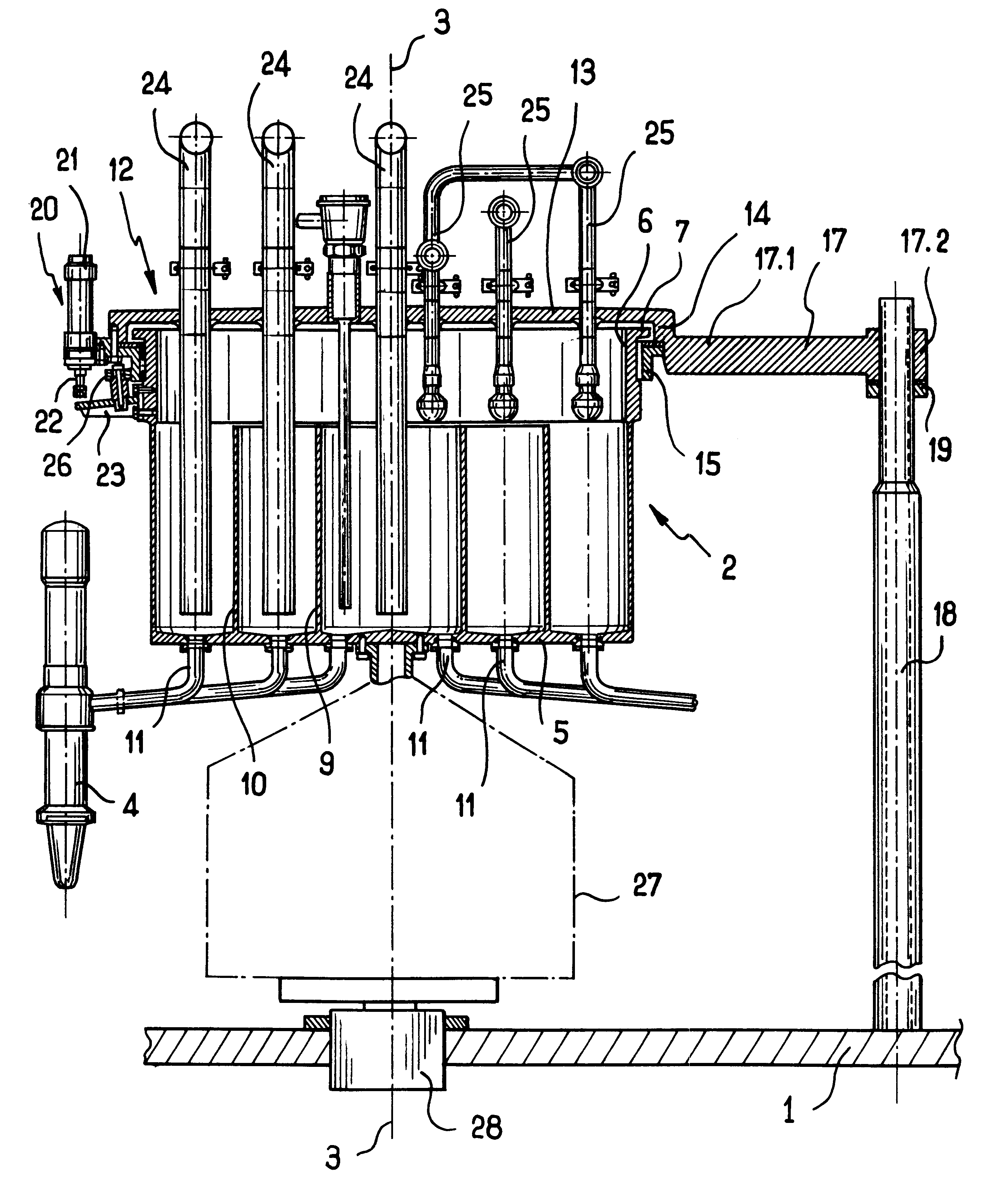

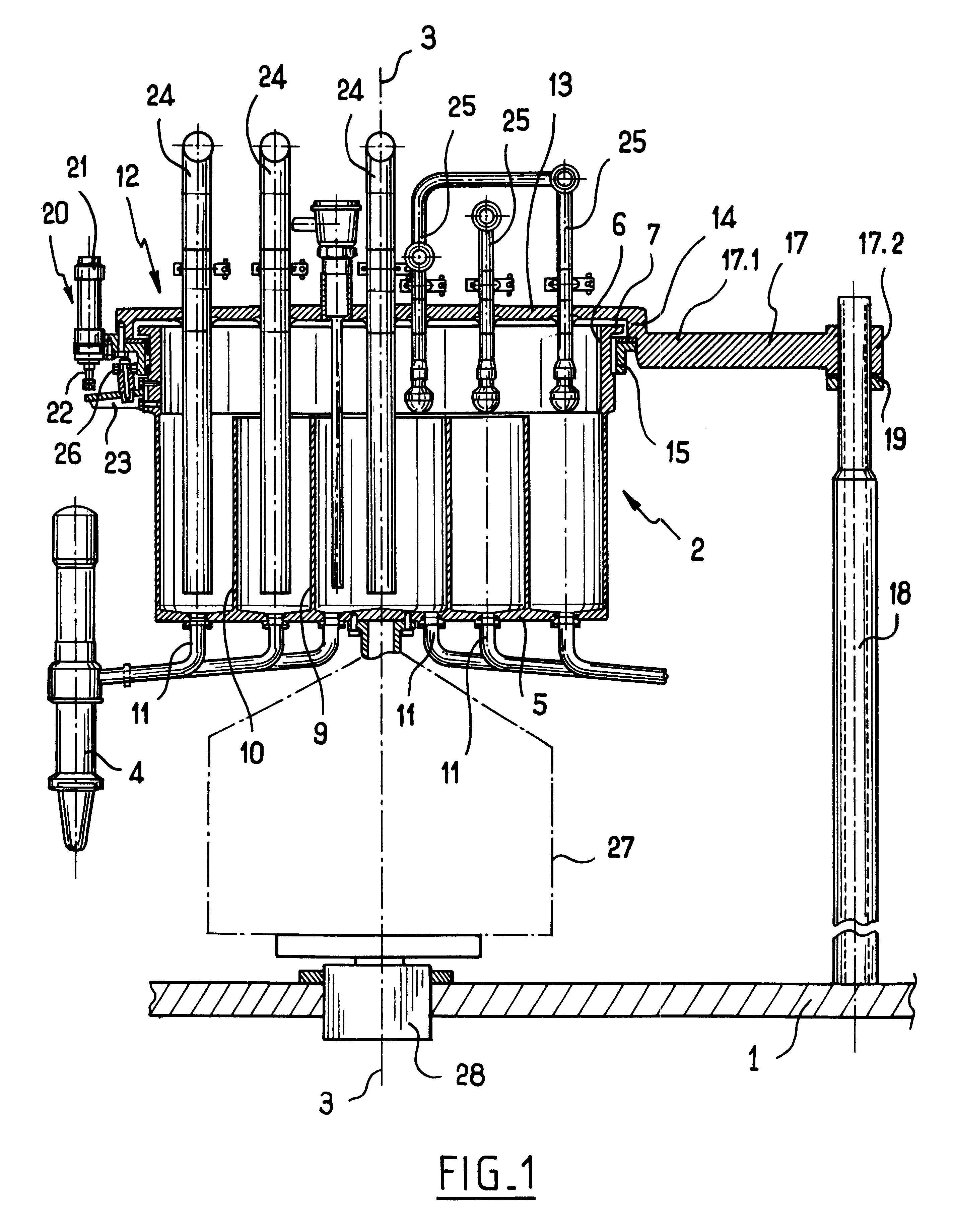

Installation for filling containers

InactiveUS6334473B1Keep the distancePrevent rotationFilling without pressureSolid materialFixed frameEngineering

A filling installation comprising a fixed frame, a tank mounted on the fixed frame so as to rotate about an axis, and a lid associated with the tank and provided with a feed pipe, positioning means being fixed to the lid, and being mounted on the fixed frame to slide parallel to the axis of rotation between a position in which the lid is applied against an edge of the tank so as to close off said tank and a position in which the lid is spaced apart from the edge of the tank.

Owner:SERAC GROUP

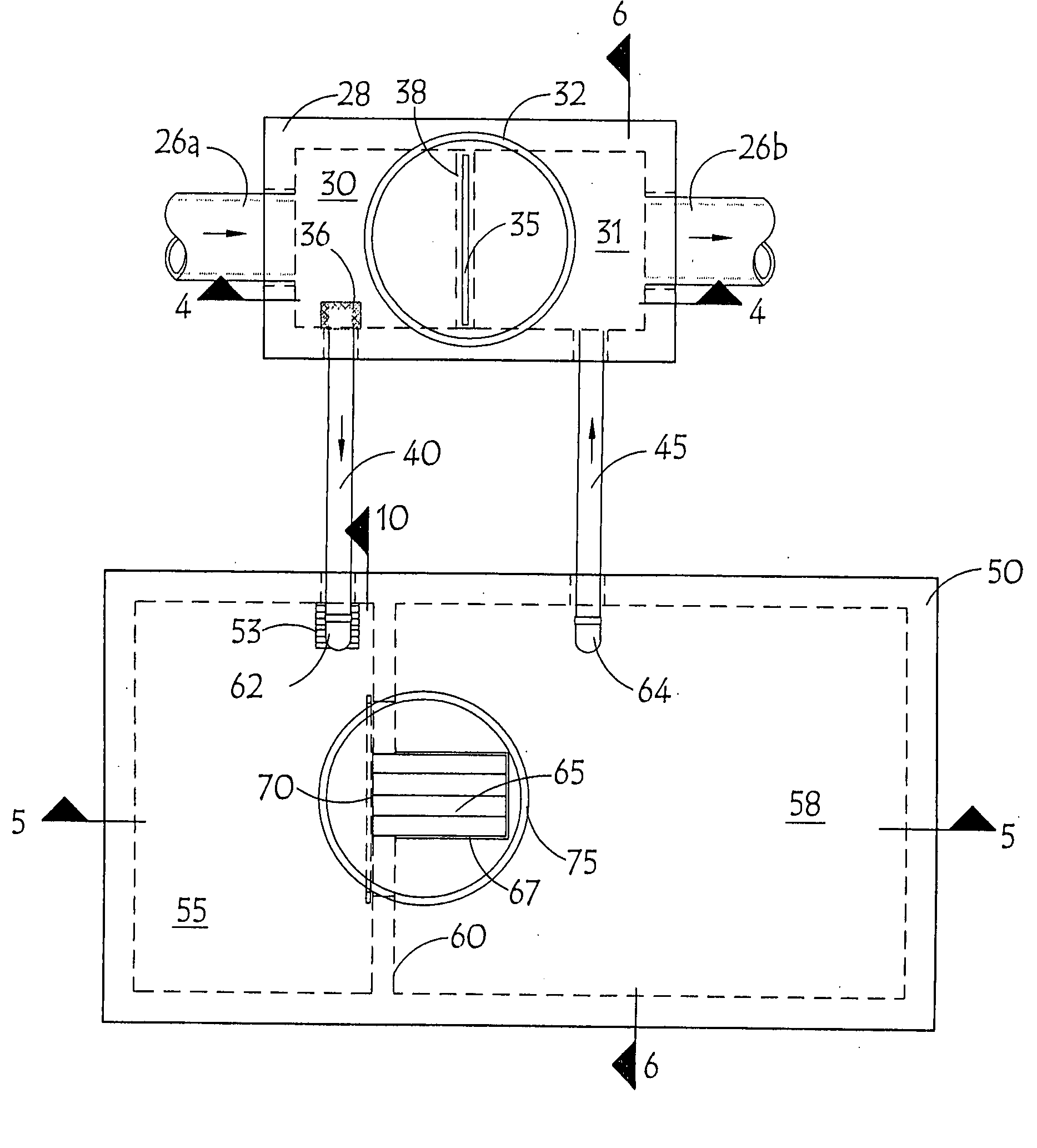

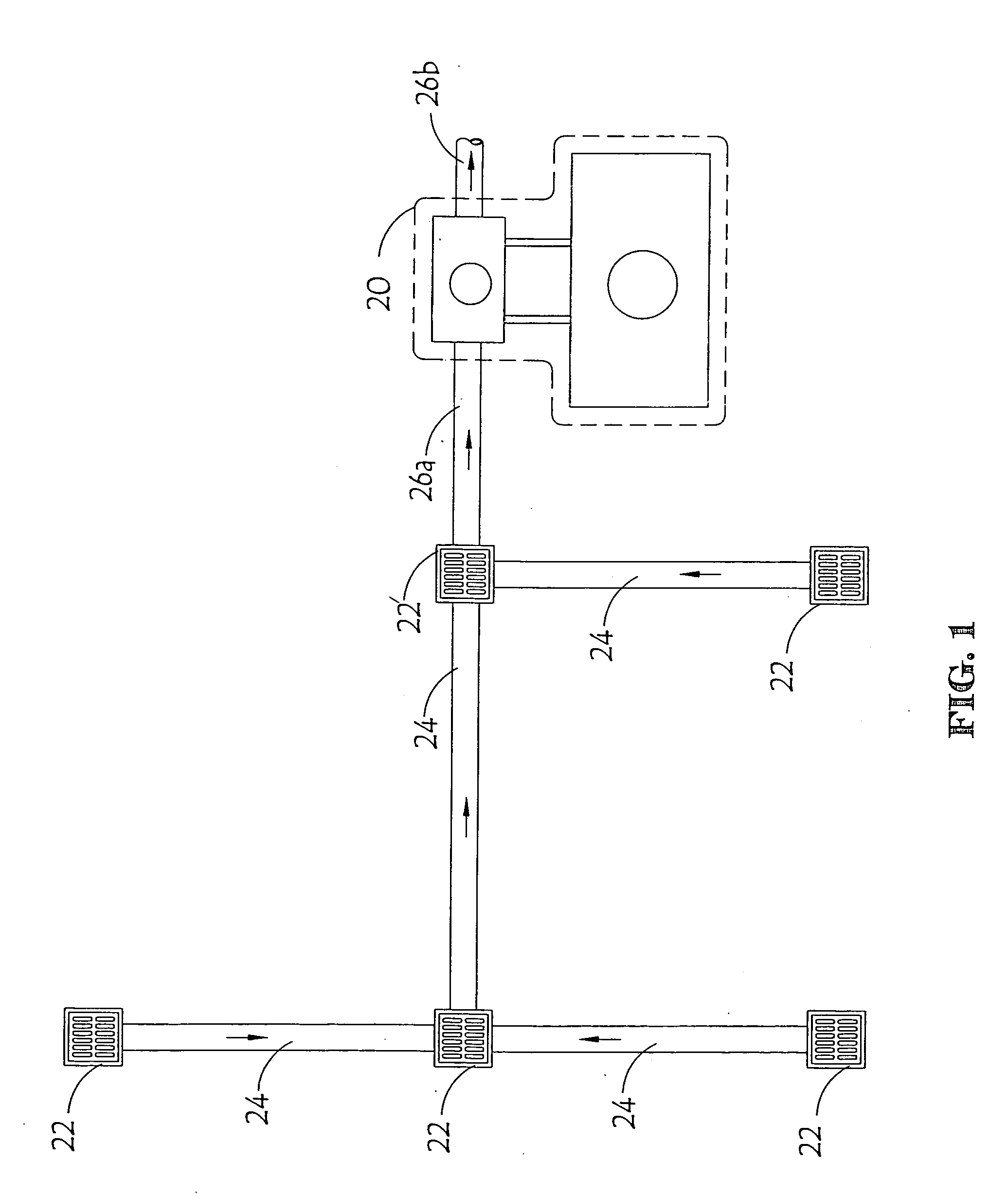

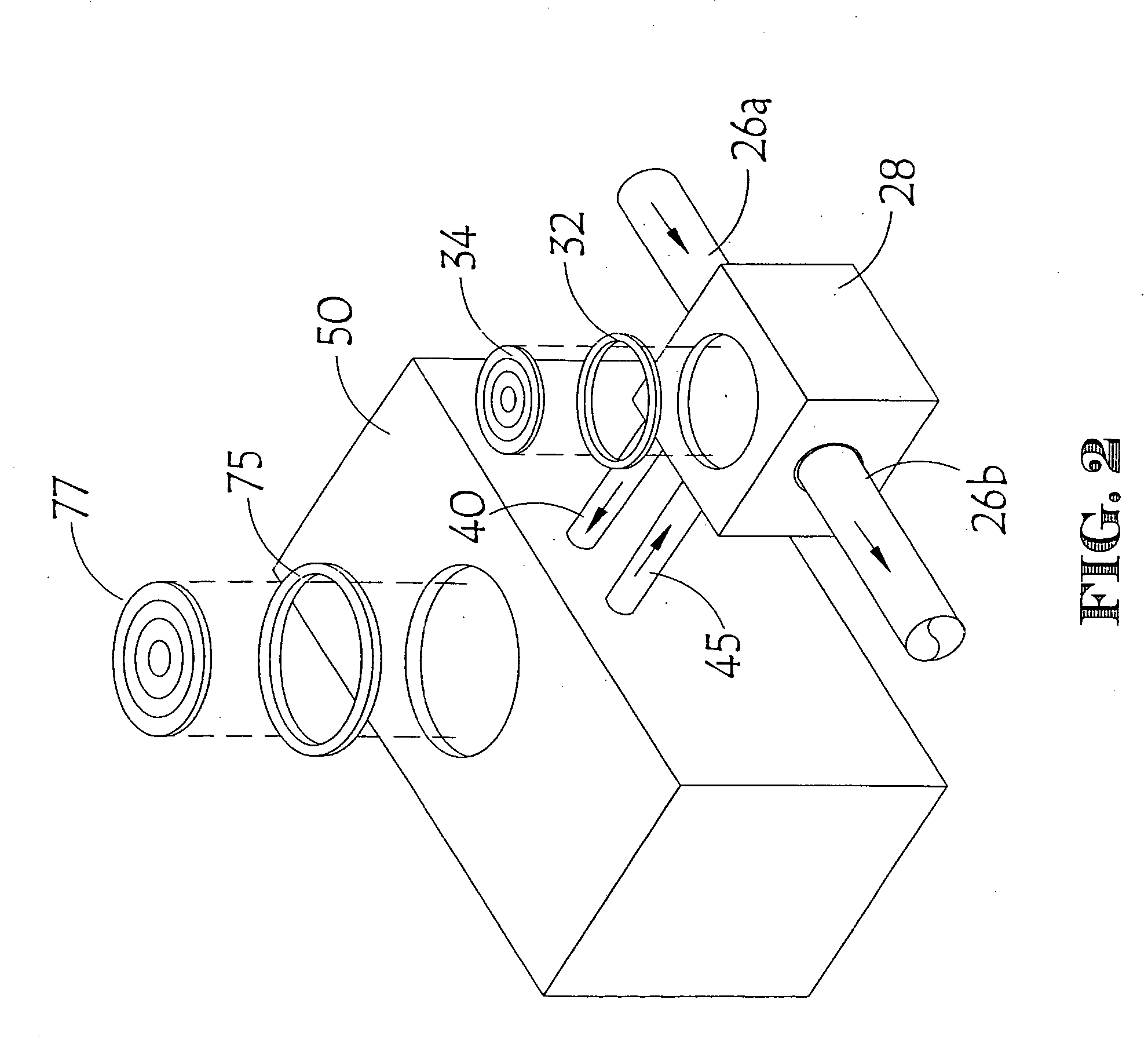

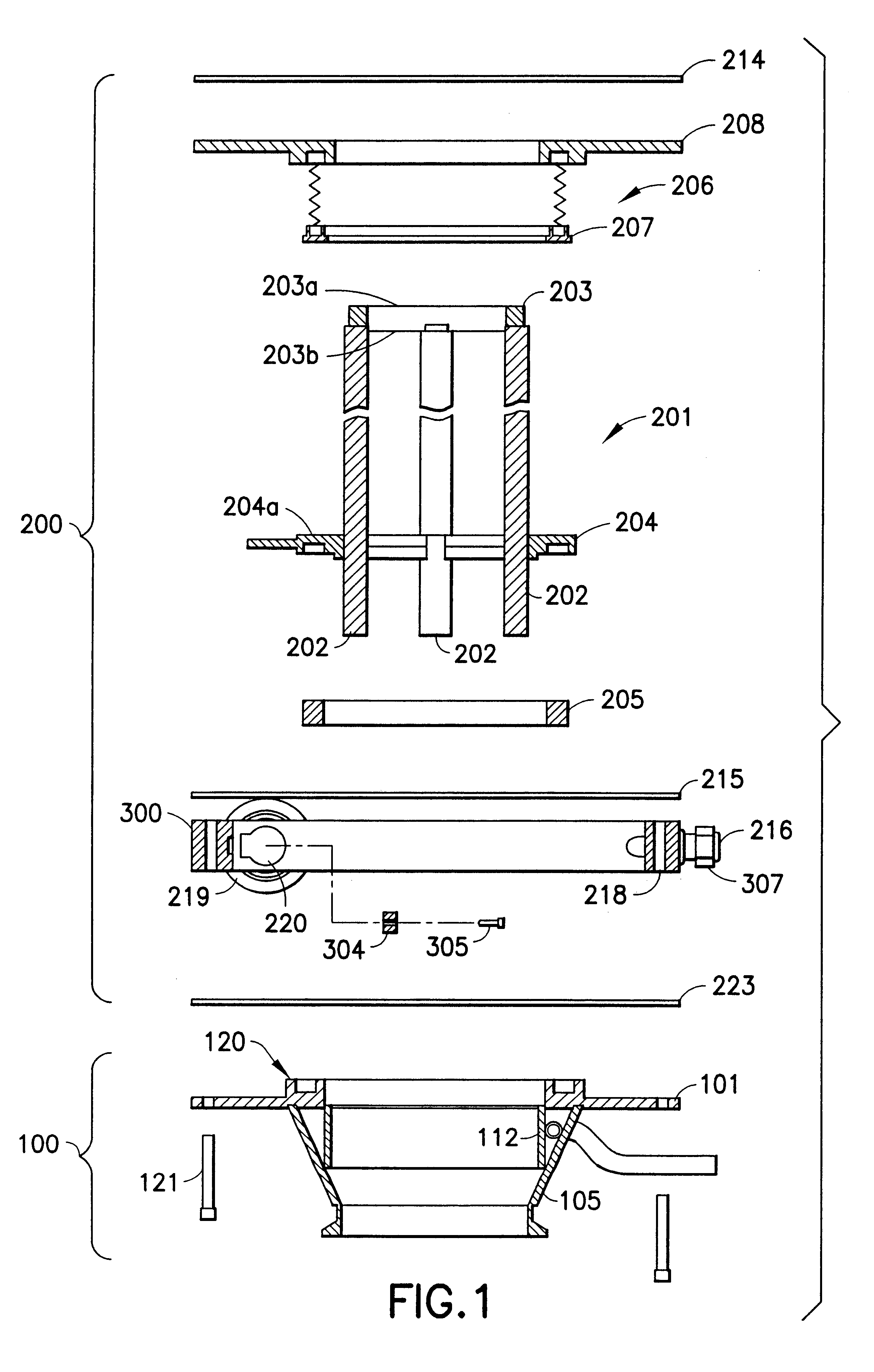

System for stormwater environmental control

ActiveUS20050103698A1Operation moreReadily and effectively cleanedFatty/oily/floating substances removal devicesSewerage structuresControl systemEngineering

The present invention provides a method of installing an environmental control system so as to allow for separate sizing of treatment and bypass capacity while also offering the ability to make or change either treatment or bypass capacities at different times. This is accomplished by containing the treatment and bypass functions in separate chambers, using screen, baffle, or coalescing media pack to further refine effectiveness and capacity of each structure independently. The control structure and interceptor structure may be pre-engineered to a variety of sizes, capacities, or other specifications. This allows simple selection of a specific control structure and a specific interceptor structure from a variety of combinations, eliminating the need for custom engineering for each installation.

Owner:PARK ENVIRONMENTAL EQUIP LLC

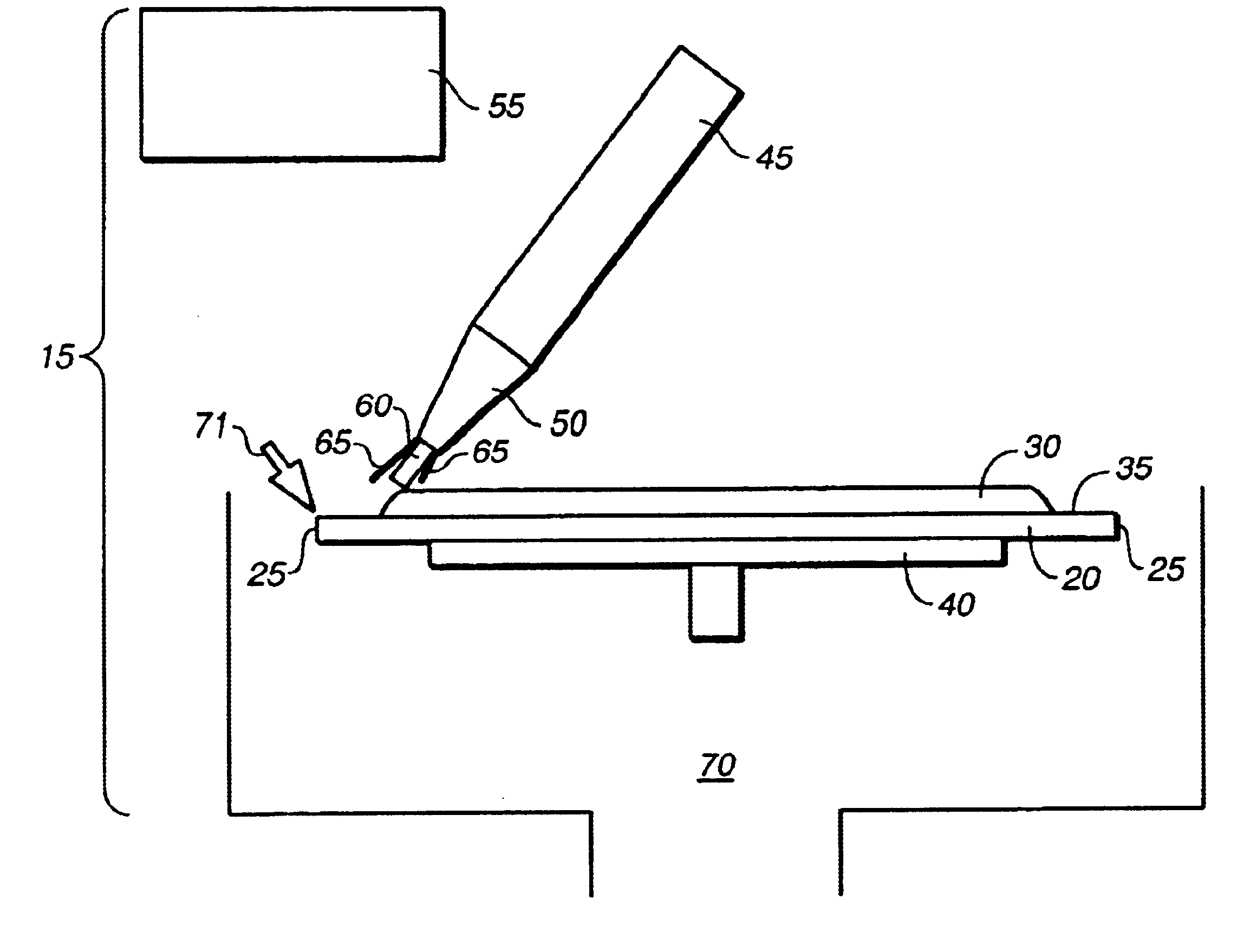

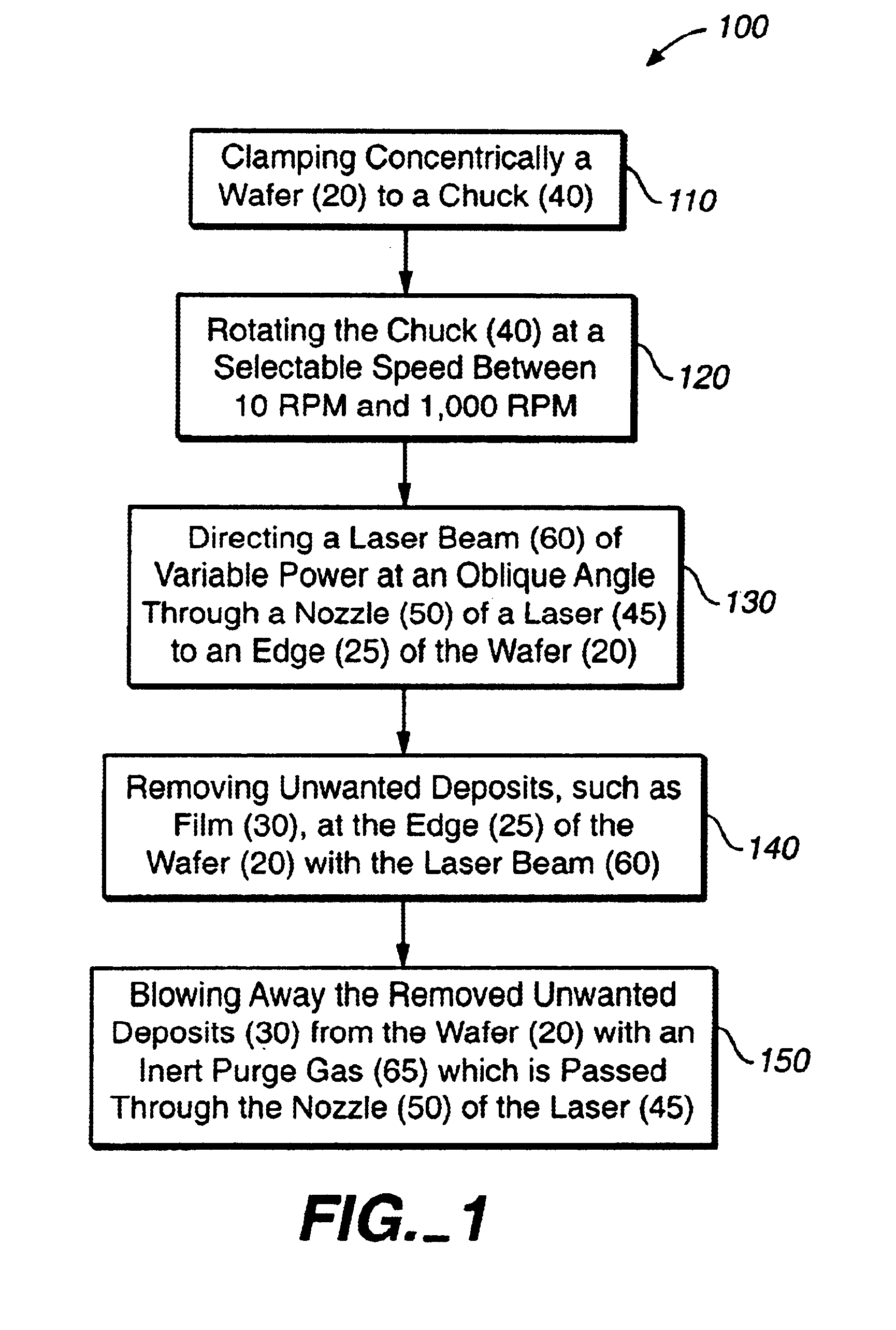

Method to use a laser to perform the edge clean operation on a semiconductor wafer

InactiveUS6874510B2Reduce processing stepsReduce equipmentDecorative surface effectsSemiconductor/solid-state device manufacturingSlagEngineering

A method for performing the edge clean operation on a semiconductor wafer. A laser beam is used to accurately clean the edge of the wafer. The wafer is clamped concentrically to a chuck and rotated at a selectable speed, preferably in the range of 10 rpm to 1,000 rpm. A laser beam of variable power is directed onto toward the edge of the wafer at an oblique angle through a nozzle through which an inert purge gas is simultaneously passed. The laser beam removes unwanted deposits at the edge of the wafer and the gas is used to blow away the residue and prevent slag buildup on other parts of the wafer. The process is preferably carried out in an exhausted chamber.

Owner:BELL SEMICON LLC

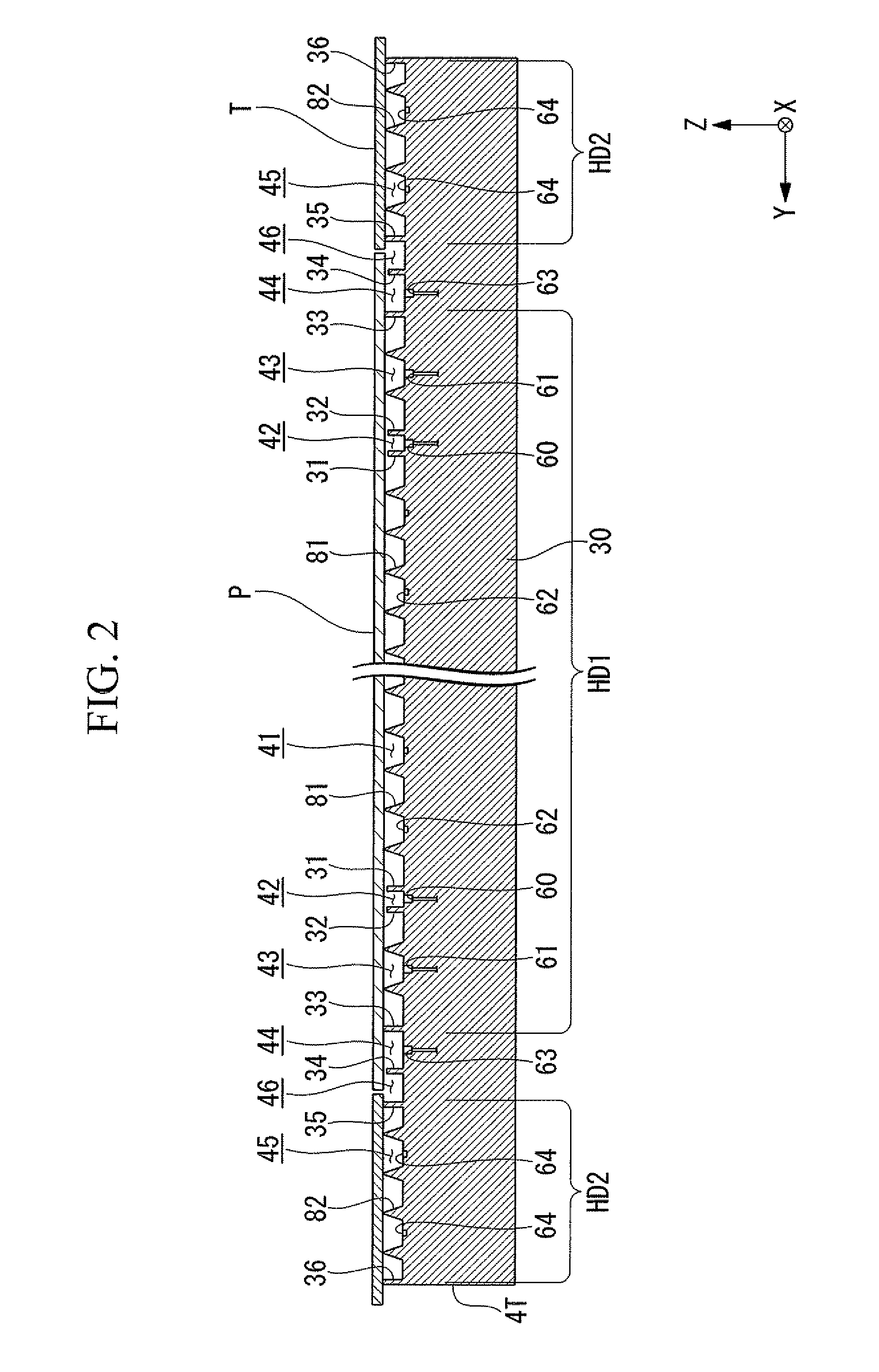

Cleaning member, cleaning method, and device manufacturing method

InactiveUS20080202555A1Desired performancePrecision cleaningCarpet cleanersFloor cleanersEngineeringCleaning methods

Owner:NIKON CORP

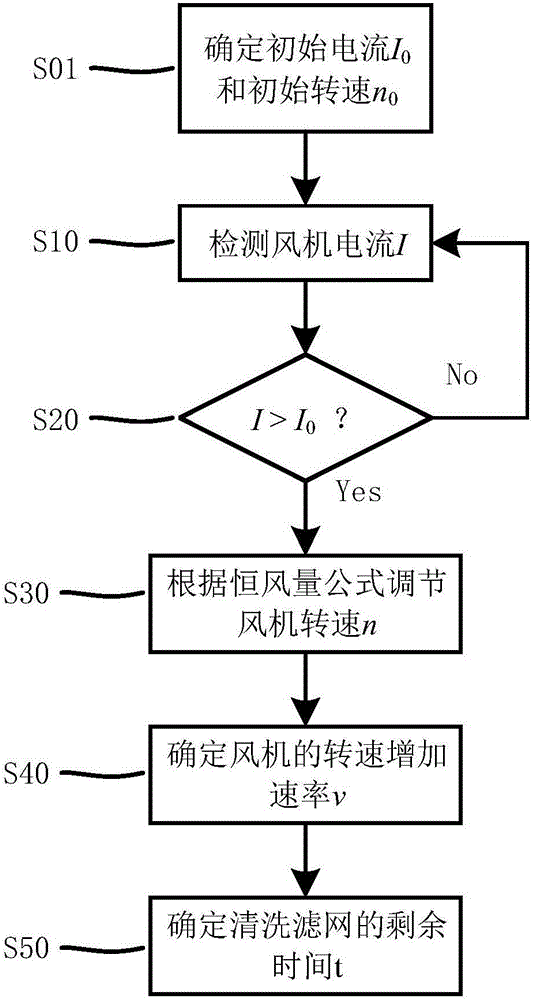

Method for determining remaining time of cleaning filter screen, air feeding equipment and control method for air feeding equipment

ActiveCN106369749AConstant air volumeHigh intelligenceMechanical apparatusSpace heating and ventilation safety systemsControl theoryFlue

The invention provides a method for determining remaining time of cleaning a filter screen in air feeding equipment. The air feeding equipment comprises the filter screen and an air feeding fan; and the filter screen is arranged on an air flue of the air feeding fan. The method comprises the following steps of regulating the rotation speed of the air feeding fan according to a current change condition of the air feeding fan, and enabling air quantity output of the air feeding equipment to be constant; and determining remaining time of cleaning the filter screen according to the rotation speed increase rate of the air feeding fan. The method provided by the invention can be used for detecting filth blockage degree of the filter screen in real time, so that remaining time is determined; and moreover, the rotation speed of the fan can be increased according to the filth blockage degree of the filter screen to ensure constant air quantity output by the system, and therefore, a comfortable environment is provided for a user. The invention further provides a control method for the air feeding equipment and the air feeding equipment.

Owner:GREE ELECTRIC APPLIANCES INC

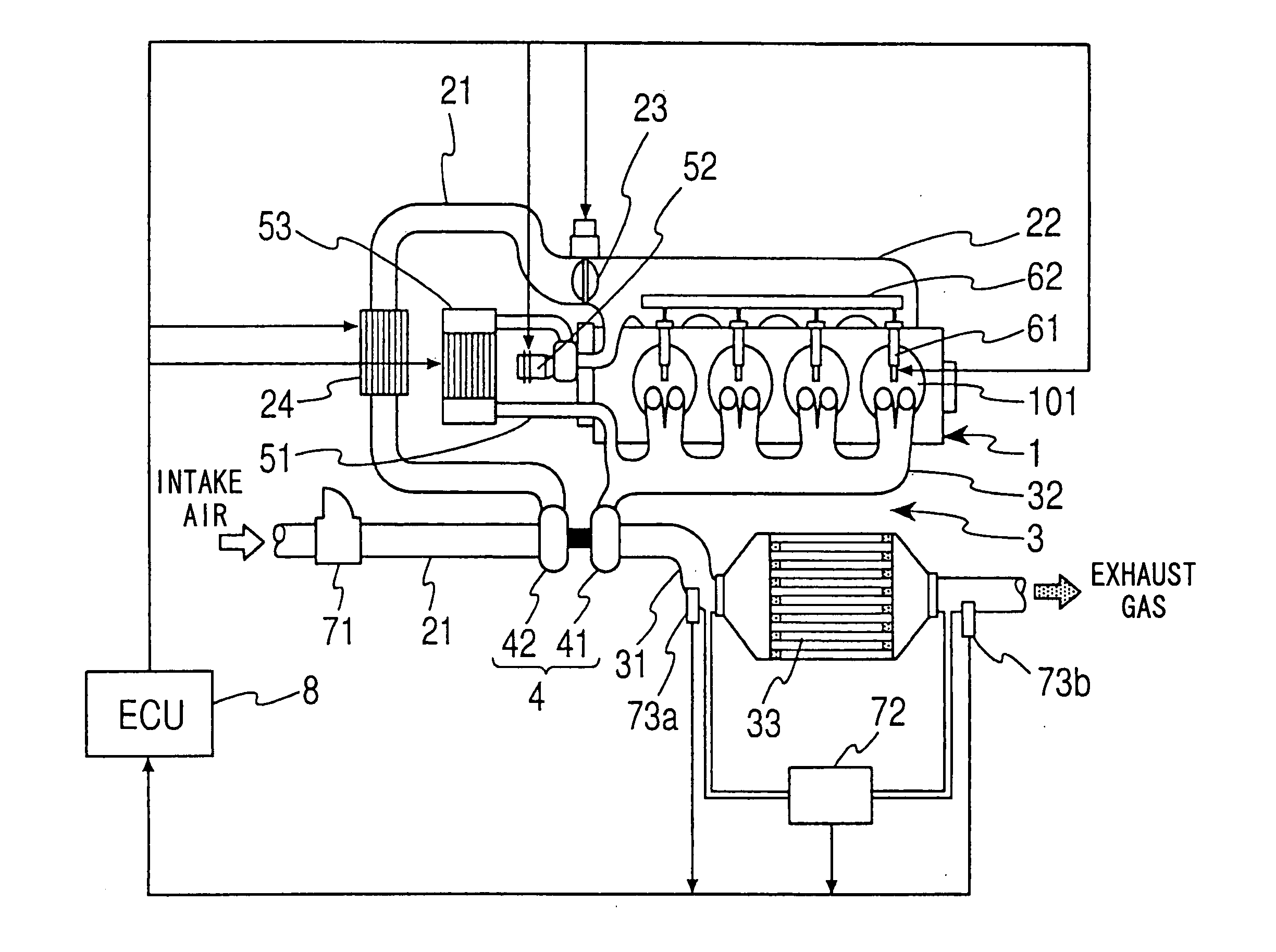

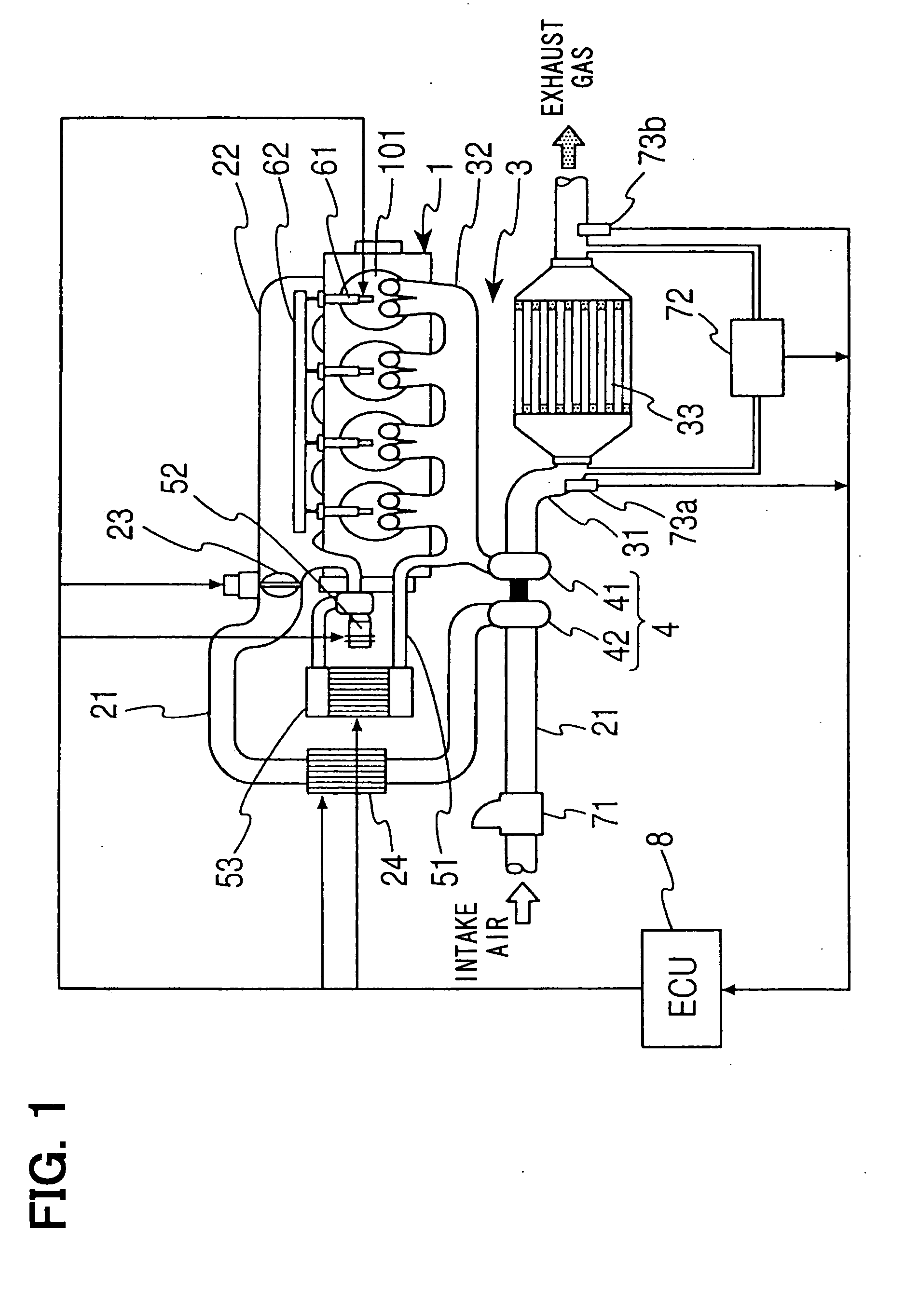

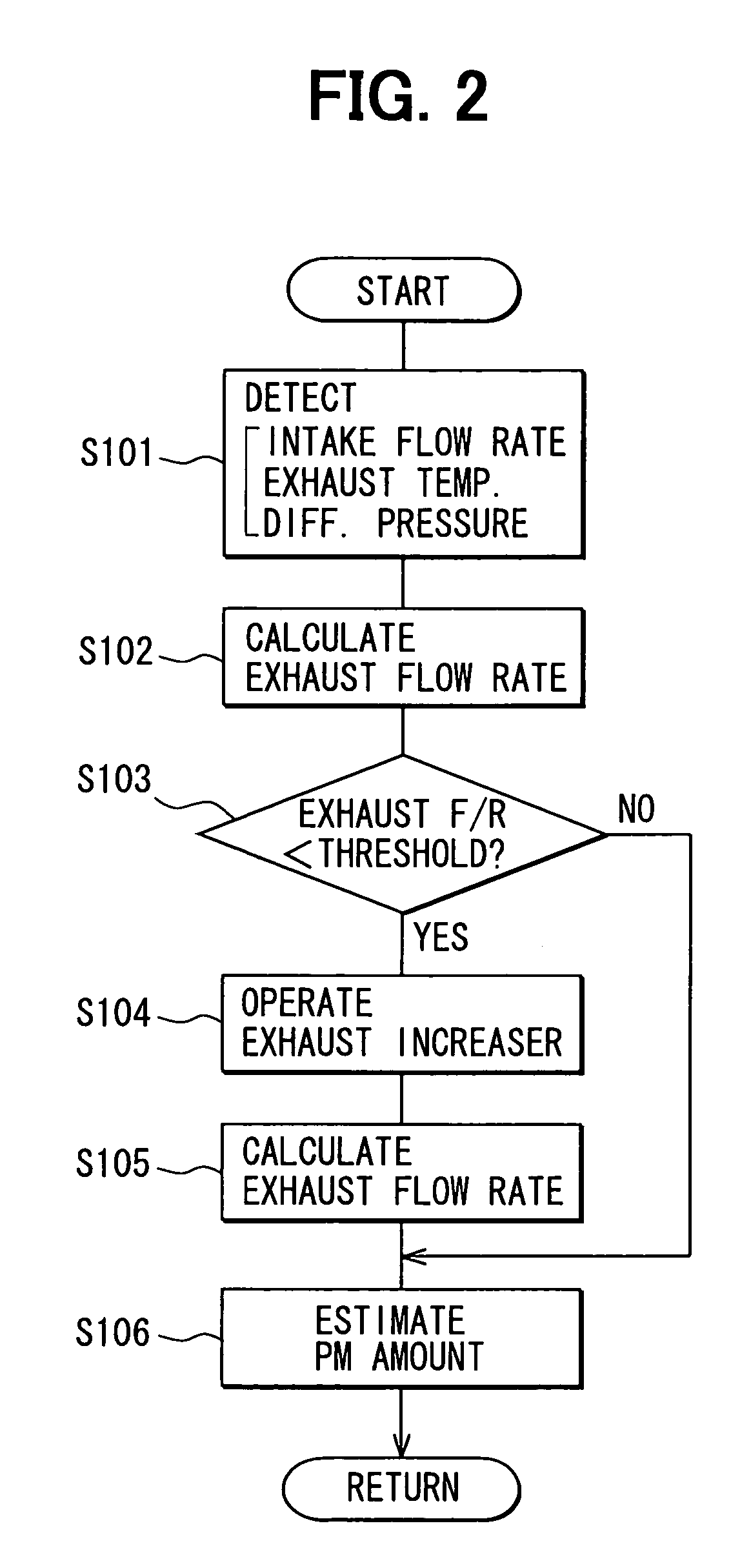

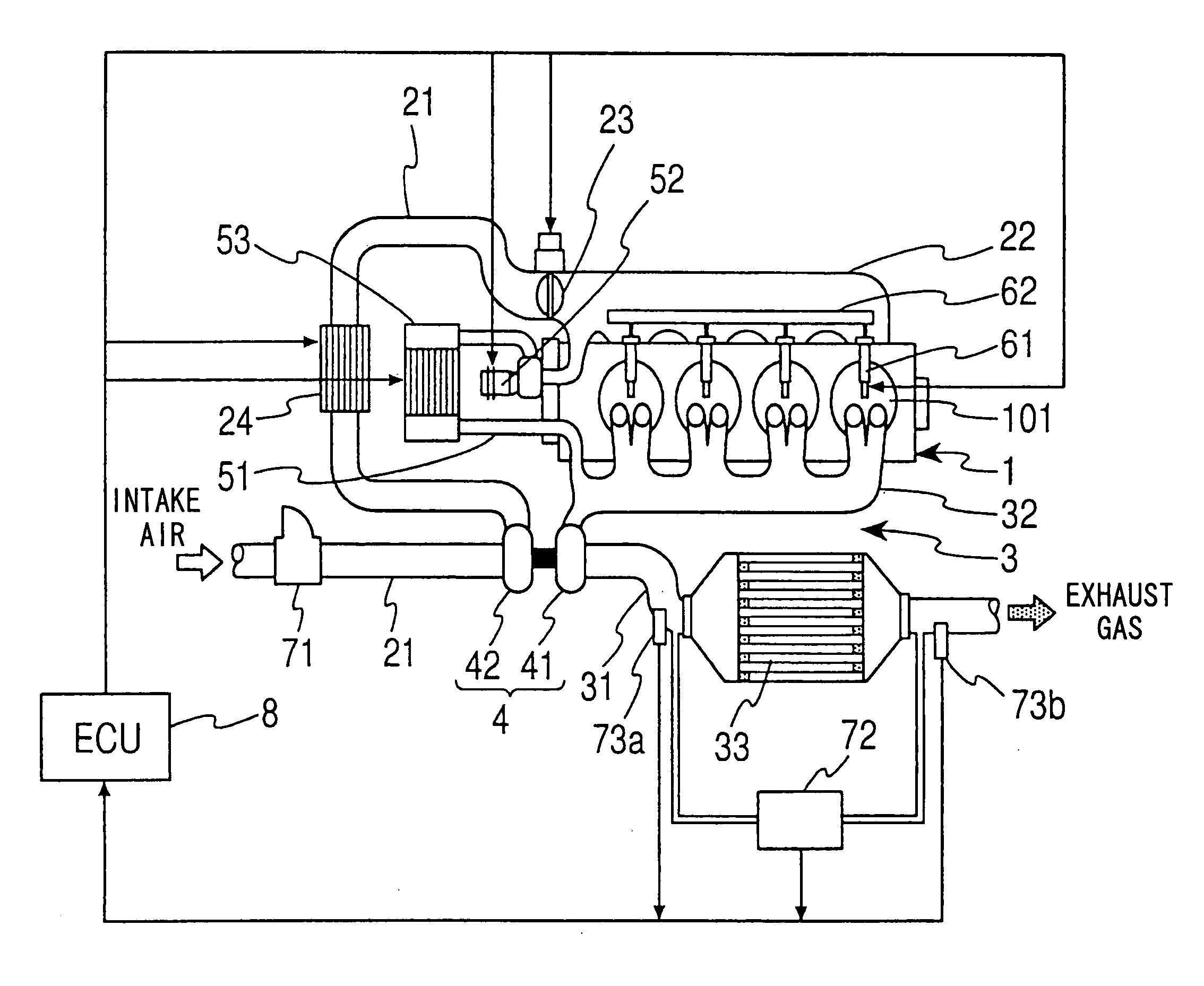

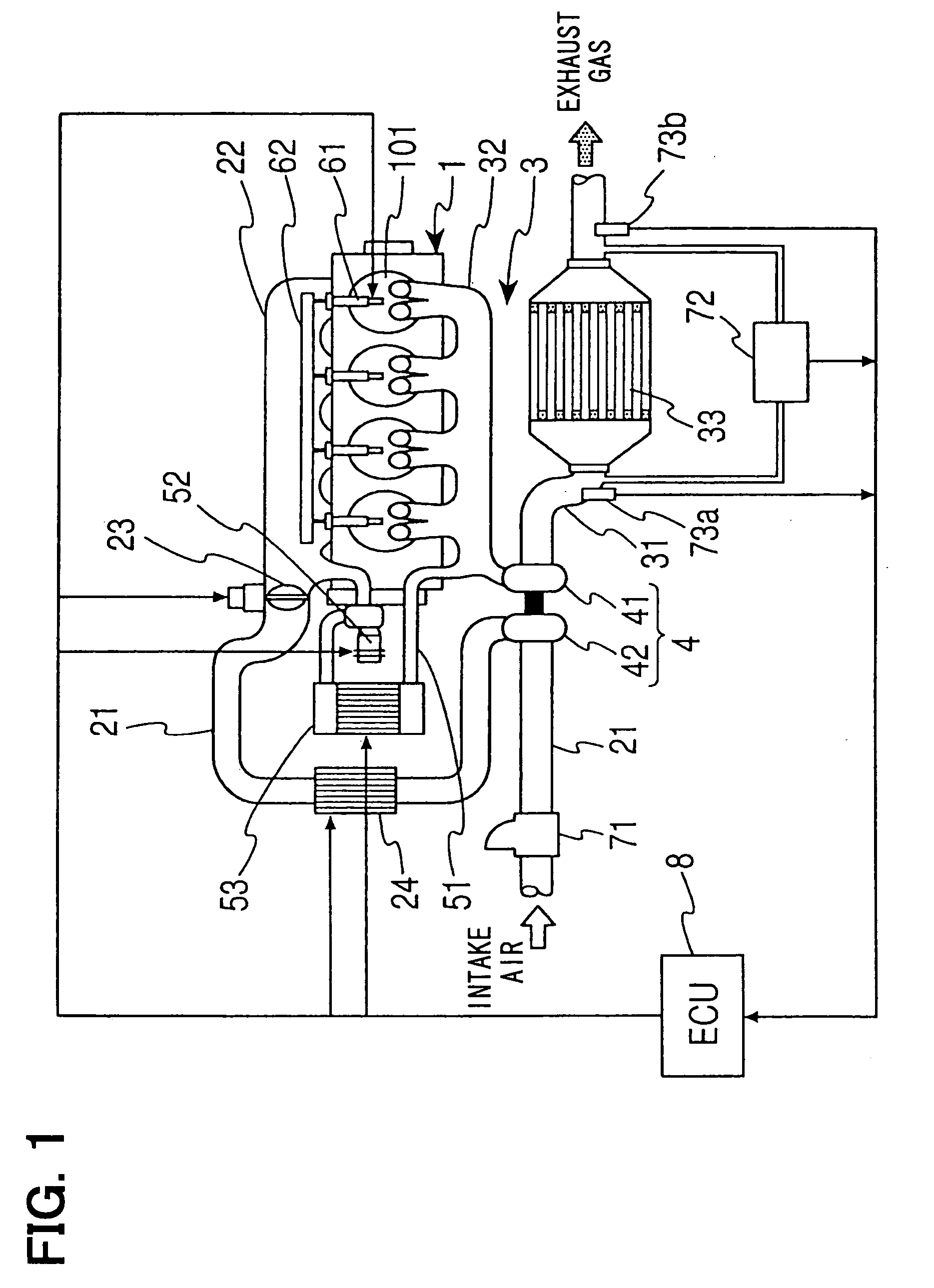

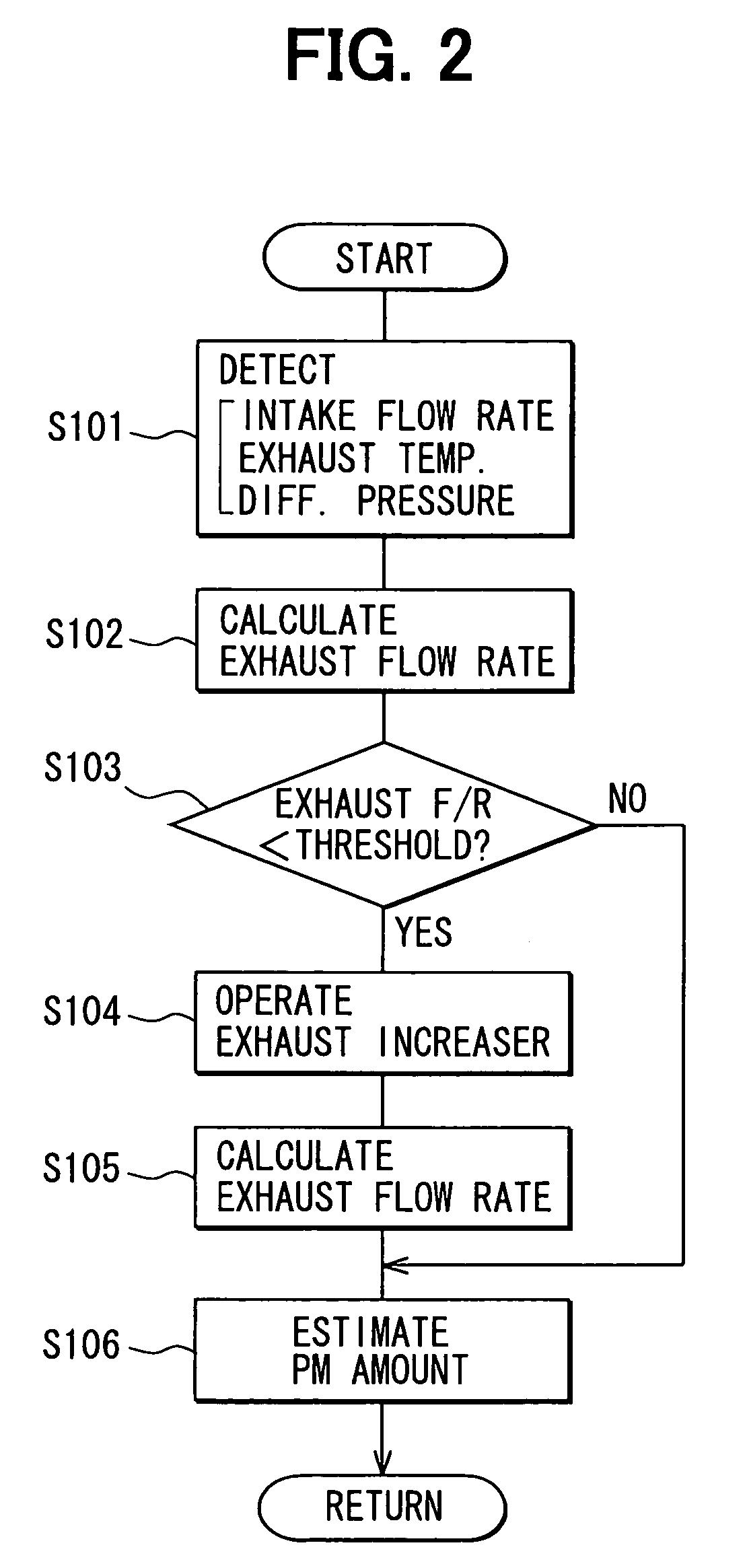

Exhaust emission control system for internal combustion engine

ActiveUS20050217250A1Low costPrecision cleaningElectrical controlInternal combustion piston enginesParticulatesDifferential pressure

An exhaust emission control system for an internal combustion engine is located on a vehicle and provided with a particulate filter to accumulate particulate matters in an exhaust gas of the engine. The system has a pressure difference detector, an exhaust flow rate detector, a regeneration controller and a detection accuracy increaser. The pressure difference detector detects a differential pressure in the particulate filter. The exhaust flow rate detector detects an exhaust flow rate of the engine. The regeneration controller determines to regenerate the particulate filter based on the differential pressure and the exhaust flow rate. The detection accuracy increaser increases a detection accuracy of the differential pressure.

Owner:DENSO CORP

Exhaust emission control system for internal combustion engine

ActiveUS7174706B2Low costPrecision cleaningElectrical controlInternal combustion piston enginesParticulatesDifferential pressure

An exhaust emission control system for an internal combustion engine is located on a vehicle and provided with a particulate filter to accumulate particulate matters in an exhaust gas of the engine. The system has a pressure difference detector, an exhaust flow rate detector, a regeneration controller and a detection accuracy increaser. The pressure difference detector detects a differential pressure in the particulate filter. The exhaust flow rate detector detects an exhaust flow rate of the engine. The regeneration controller determines to regenerate the particulate filter based on the differential pressure and the exhaust flow rate. The detection accuracy increaser increases a detection accuracy of the differential pressure.

Owner:DENSO CORP

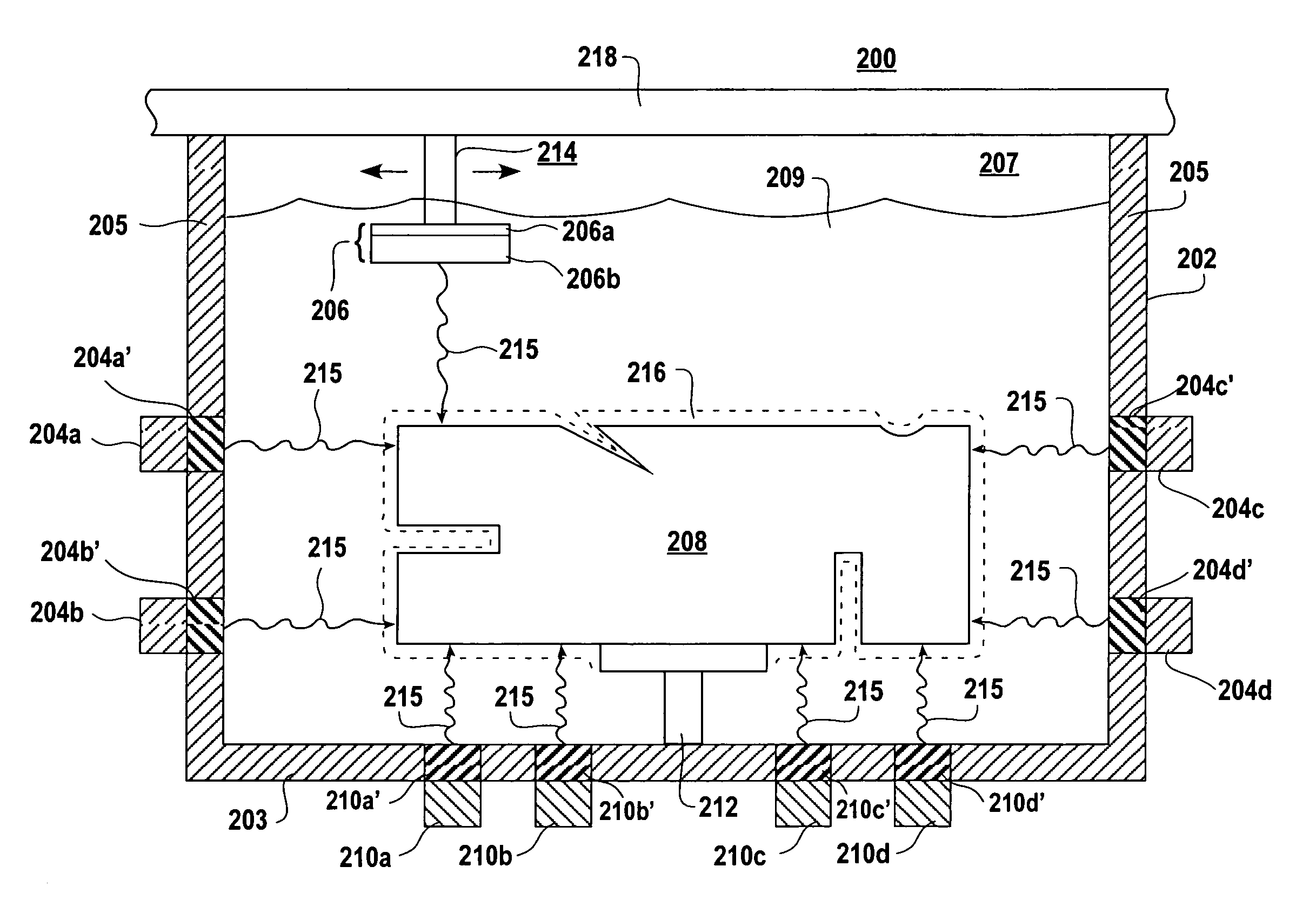

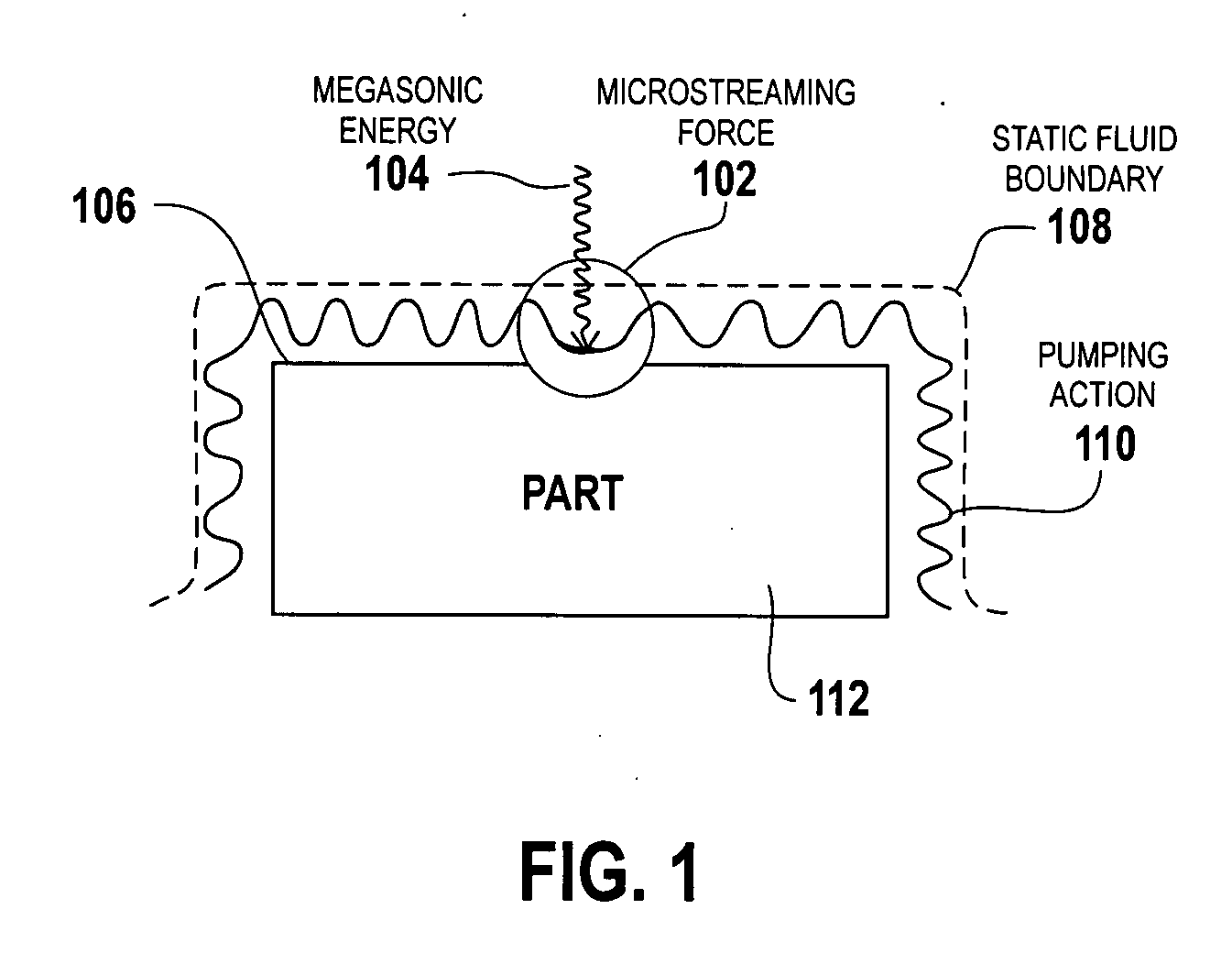

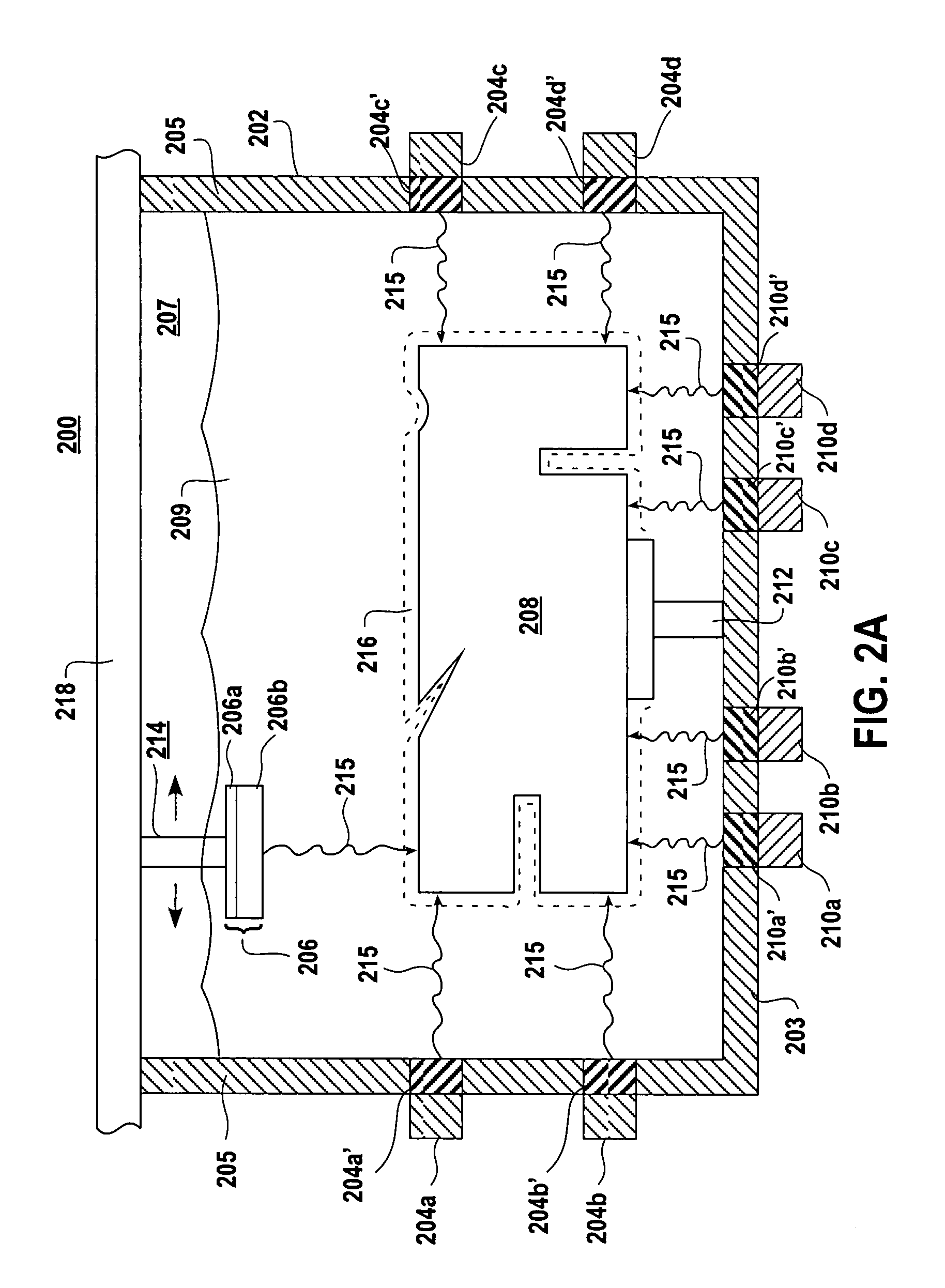

Megasonic precision cleaning of semiconductor process equipment components and parts

ActiveUS20080142055A1Precision cleaningImprove performanceElectrostatic cleaningSemiconductor/solid-state device manufacturingParticulatesProcess equipment

Methods and apparatus are provided for using various megasonic apparatus including megasonic tanks, scanning megasonic plates, megasonic jets, and megasonic sweeping beams etc., in combination with selective chemistries to remove sub-micron particulate contaminants from the surfaces of the processing equipment used in semiconductor, medical, or any other processing environments.

Owner:LAM RES CORP

Cleaning nozzle for a vacuum cleaner

A vacuum cleaner nozzle having a rotatable member arranged around a longitudinal axis for picking up particles from a surface to be cleaned, and a cleaning arrangement for removing articles entangled on the rotatable member. The cleaning arrangement has at least one support surface provided on at least one radially projecting member, and at least one cleaning member movable between a resting position in which the cleaning member is arranged at a distance from the support surface and at least one cleaning position In the vicinity of the rotatable member. In cleaning position, the cleaning member, during rotation of the rotatable member, co-operates with at least one segment of the support surface to remove entangled articles from the rotatable member. The cleaning member includes a resilient sheet member capable of providing resilient contact with a segment of the support surface in the cleaning position during rotation of the rotatable member.

Owner:AB ELECTROLUX

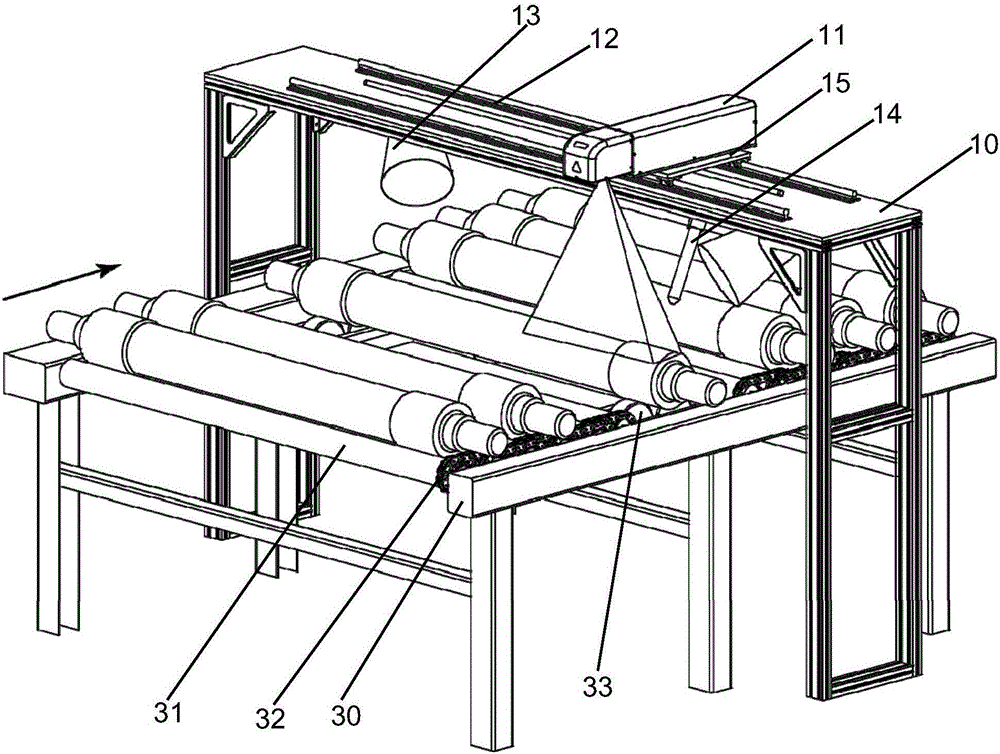

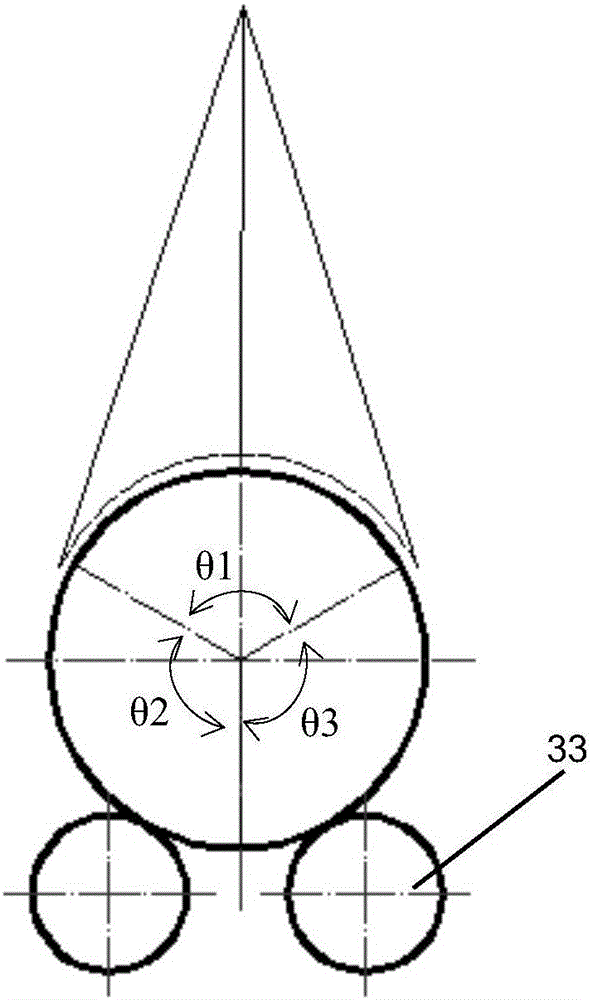

Laser cleaning device and method for axis parts

InactiveCN106513381APrecision cleaningImprove cleaning efficiencyCleaning processes and apparatusComputer control systemFixed frame

The invention discloses a laser cleaning device and method for axis parts. The device comprises a fixed framework and a computer control system as well as a rotating mechanism, wherein at least one laser cleaning head is arranged on the fixed framework; the at least one laser cleaning head is mounted on the fixed framework through a slide rail; the rotating mechanism is used for rotating parts thereon, and corresponds to the at least one laser cleaning head; the computer control system is used for controlling the laser cleaning head to clean partial circumferential surfaces of parts on the rotating mechanism in the axial direction of the parts; after the circumferential surfaces of the parts are cleaned, the rotating mechanism is utilized to rotate the parts by certain angle to clean the un-cleaned circumferential surfaces of the parts in the axial direction of the parts. The laser cleaning device can be used for precisely cleaning axis parts, is high in cleaning efficiency and is good in cleaning effect.

Owner:苏州菲镭泰克激光技术有限公司

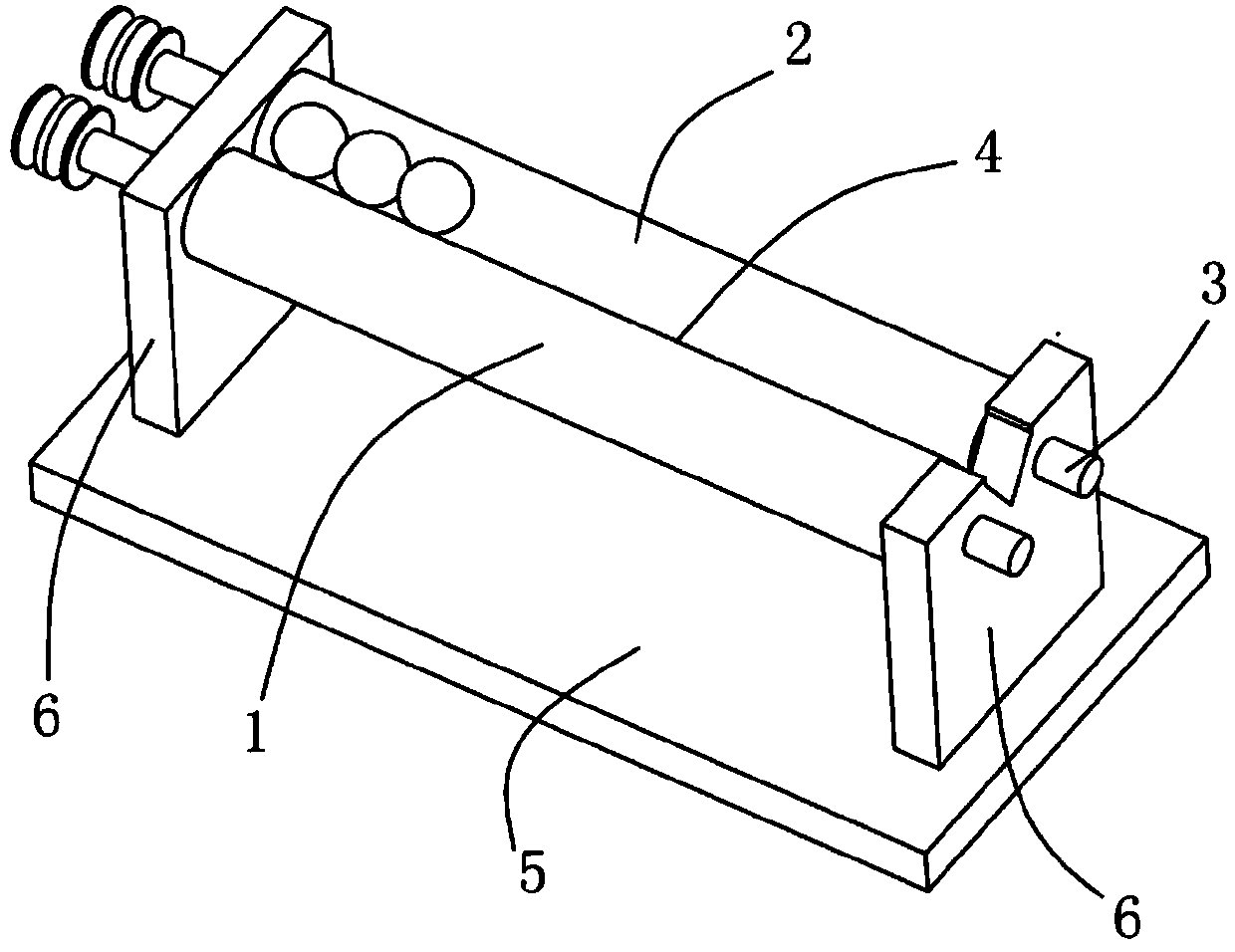

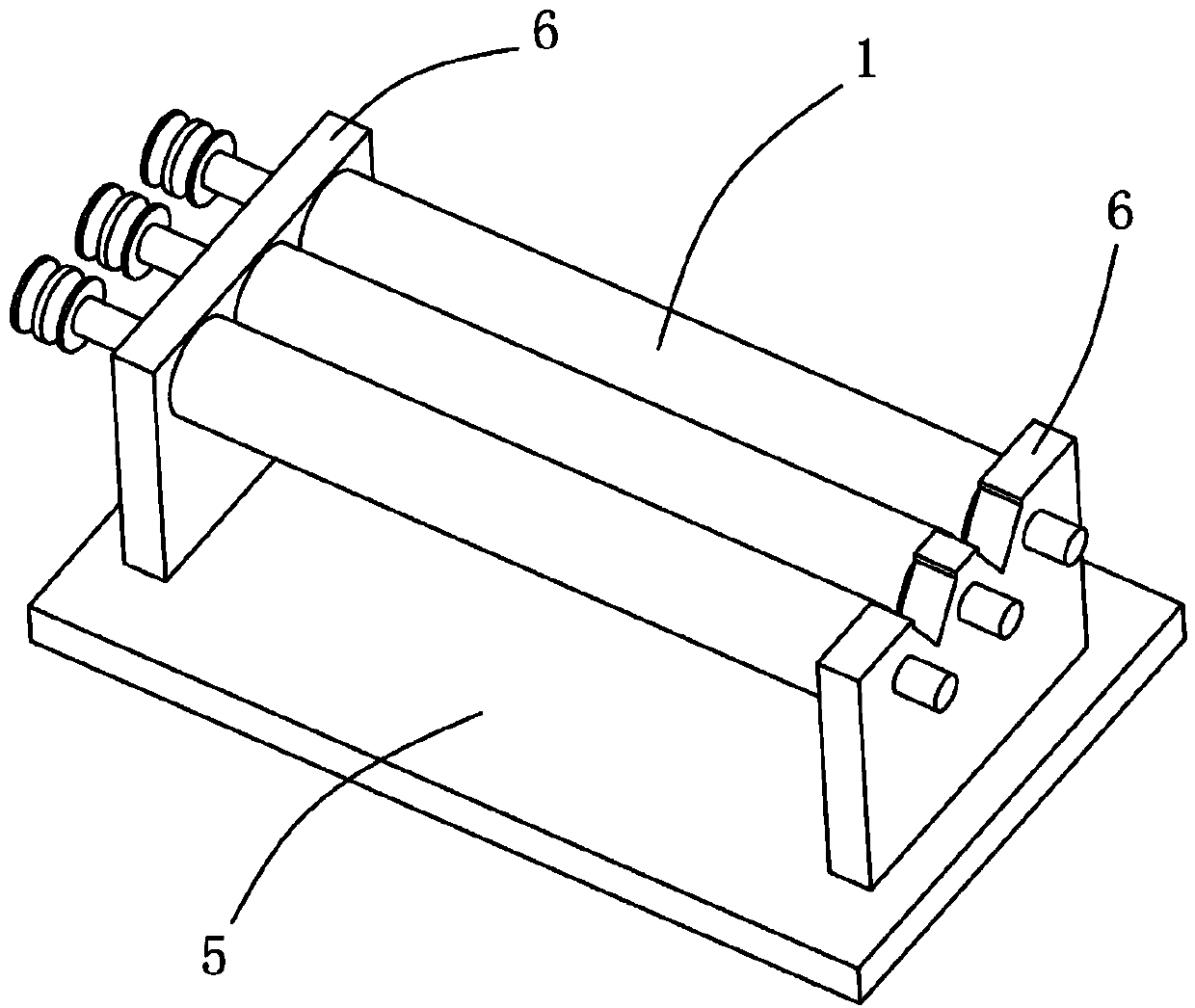

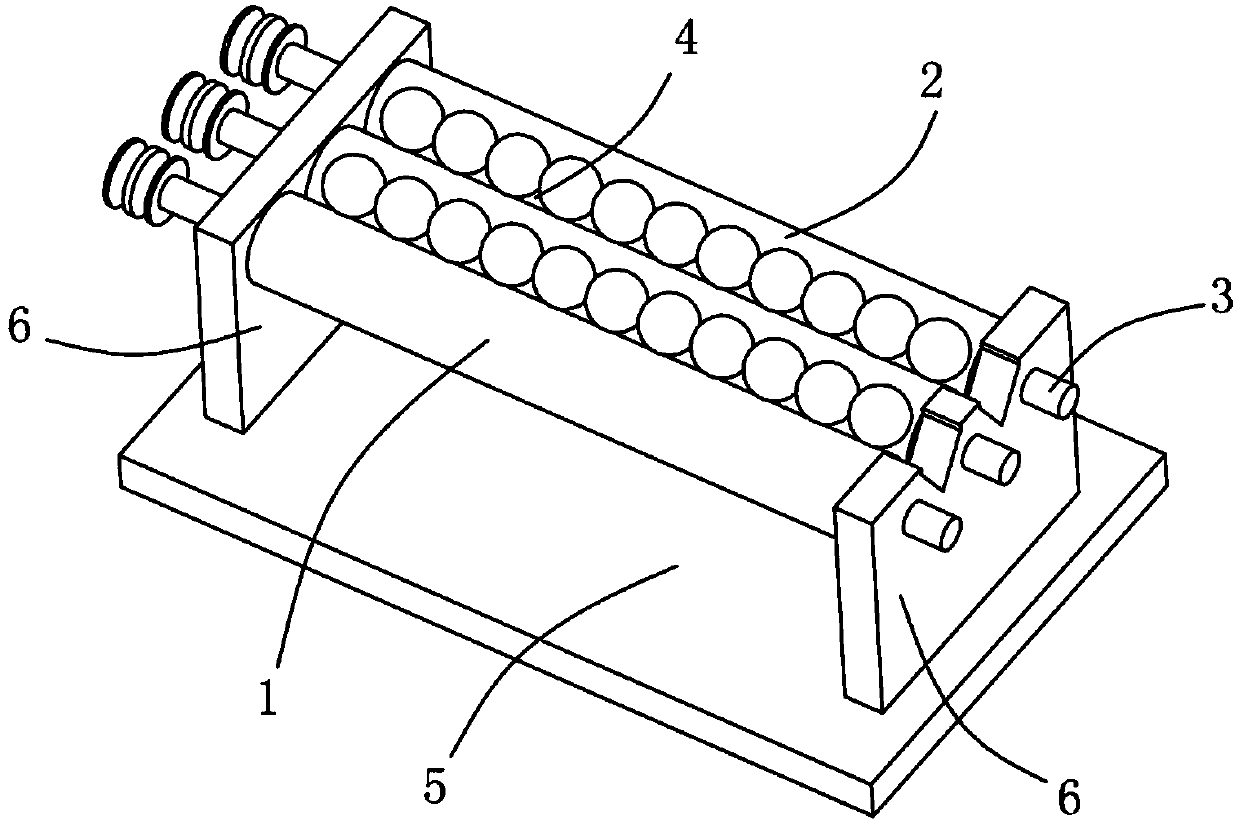

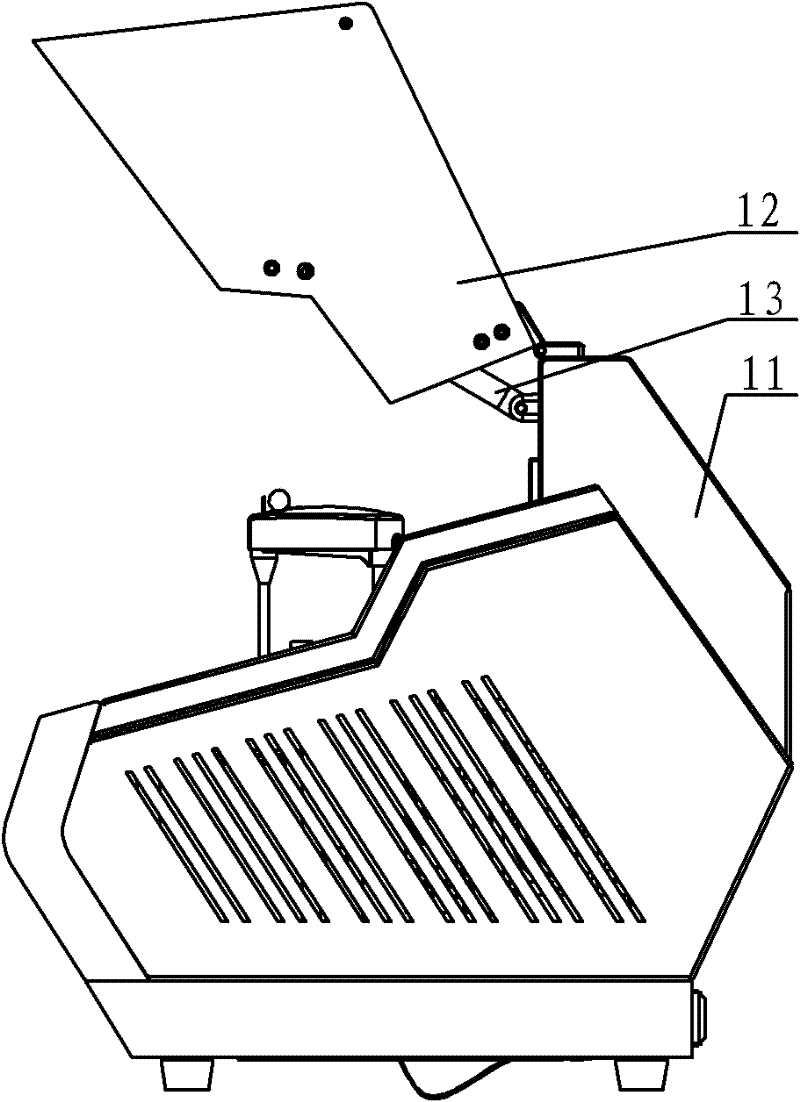

Steel ball surface defect detection sorting equipment

ActiveCN104190634AImprove fullyHigh false positive rateOptically investigating flaws/contaminationCleaning using toolsMetallurgySurface cleaning

The invention discloses steel ball surface defect detection sorting equipment. The steel ball surface defect detection sorting equipment comprises a steel ball size screening device, a steel ball surface cleaning device, a steel ball surface unfolding device, a camera, a sorting device and a control module, wherein the steel ball size screening device comprises two parallel rolling shafts; the steel ball surface cleaning device comprises a trapezoid rotary table and a rotary sleeve covering the rotary table; the steel ball surface unfolding device comprises at least two rolling bars, wherein a containing groove is formed between two adjacent rolling bars, and at least one rotatable rolling bar in the two adjacent rolling bars can be used for driving steel balls to roll in the containing groove in synchronism with the rolling bars. The equipment disclosed by the invention can screen out the out-of-size steel balls and can clean the surfaces of the steel balls so as to prevent the false detection caused by blots on the surfaces of the steel balls; in combination with the specific steel ball surface unfolding device, the steel ball surface defect detection storing equipment can rapidly and accurately sort the steel ball sizes and the steel ball surface defects, and the steel ball sorting efficiency is greatly promoted.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

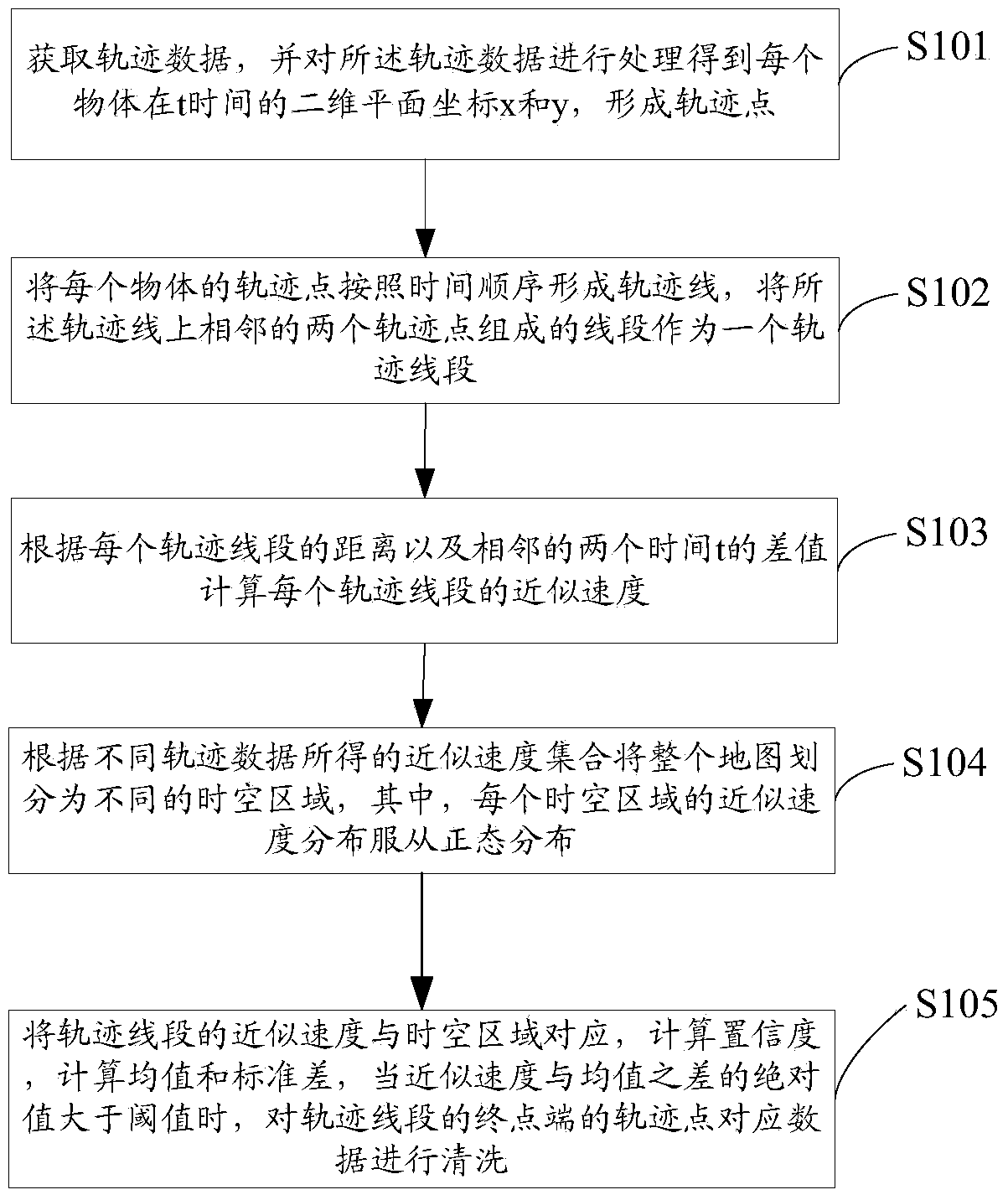

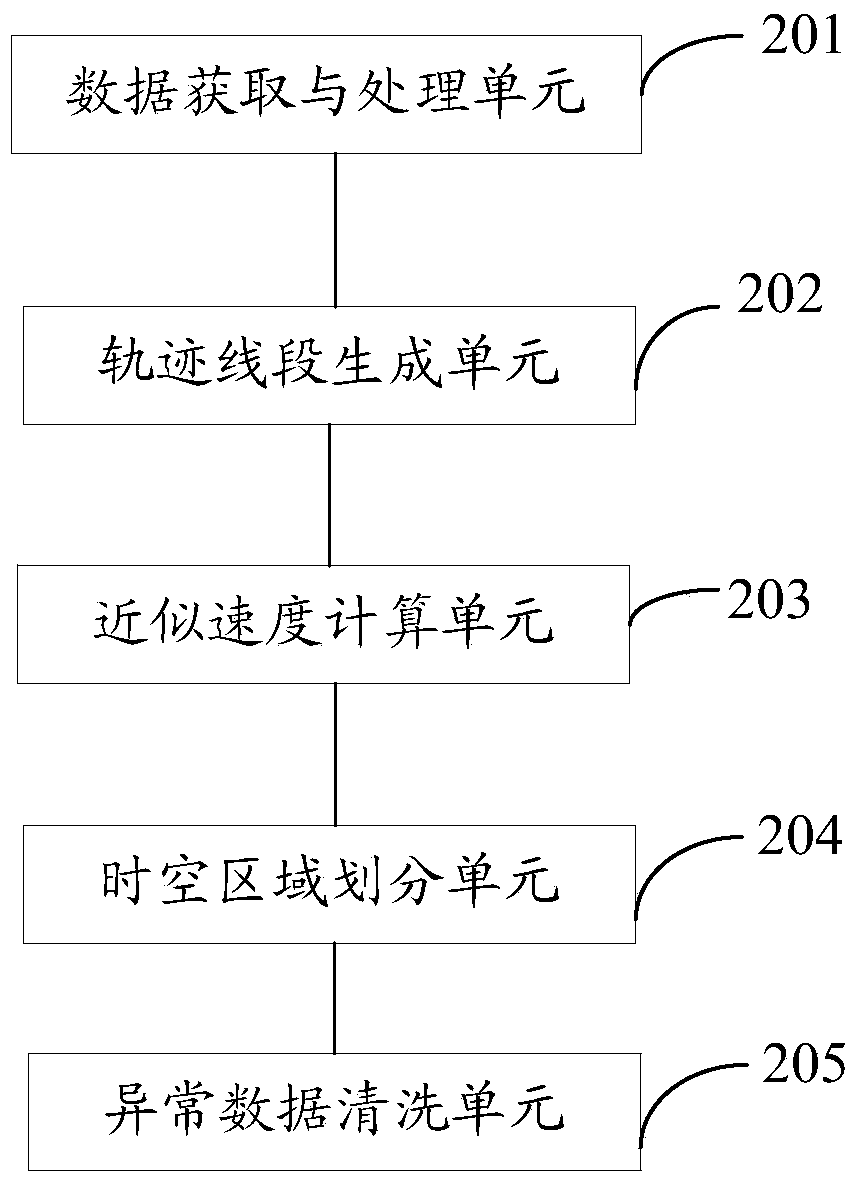

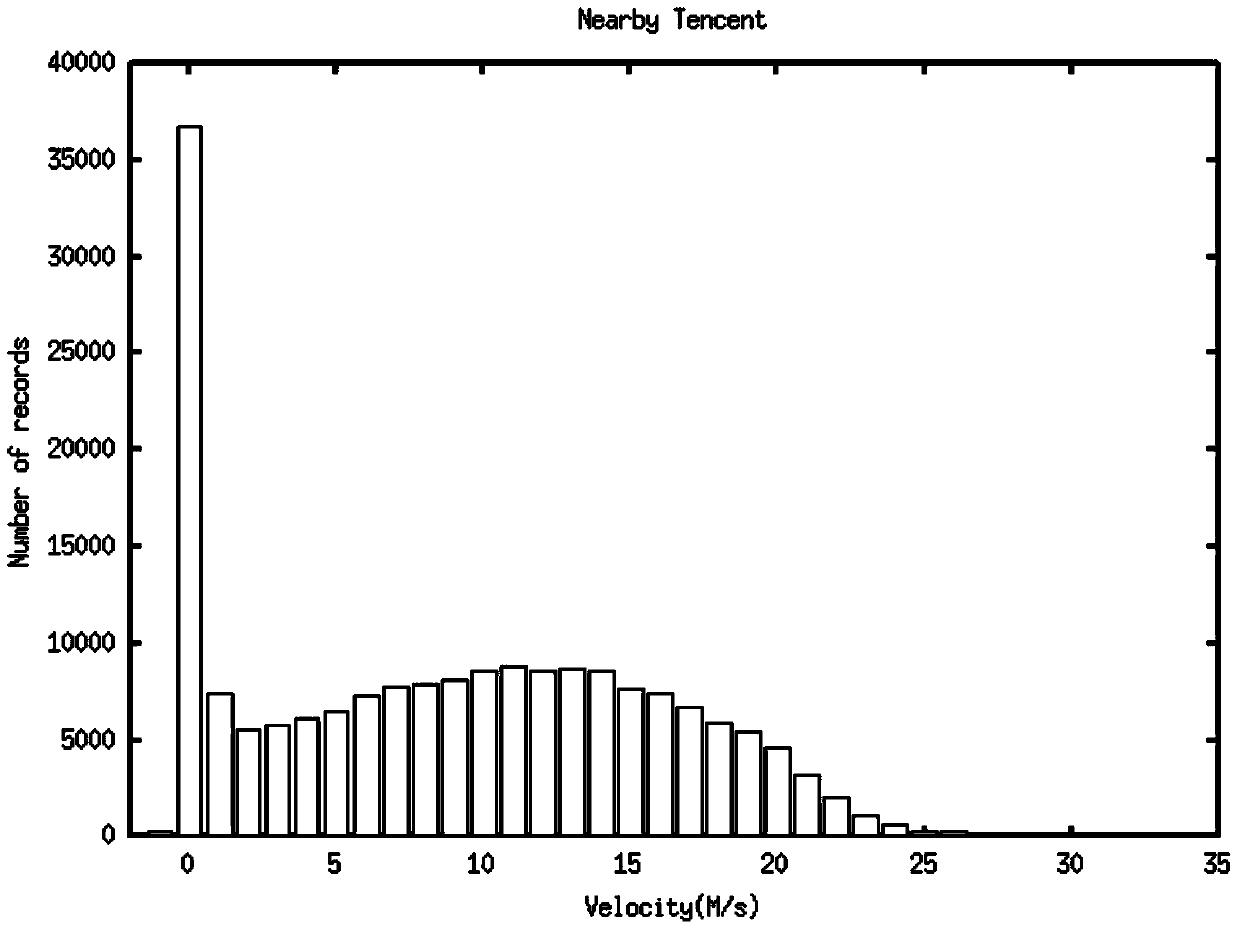

Trajectory data cleaning method and device

ActiveCN103745083AEasy to cleanPrecision cleaningSpecial data processing applicationsTime spaceComputer science

The invention relates to the technical field of information, in particular to a trajectory data cleaning method and device. According to the trajectory data cleaning method and device, time and areas are considered at the same time, space-time area division is carried out, a trajectory line segment formed by every two adjacent track points on each object trajectory line and the speed of the corresponding space-time area are considered comprehensively, the data cleaning effect is good, and abnormal data can be accurately cleaned.

Owner:SHENZHEN INST OF ADVANCED TECH

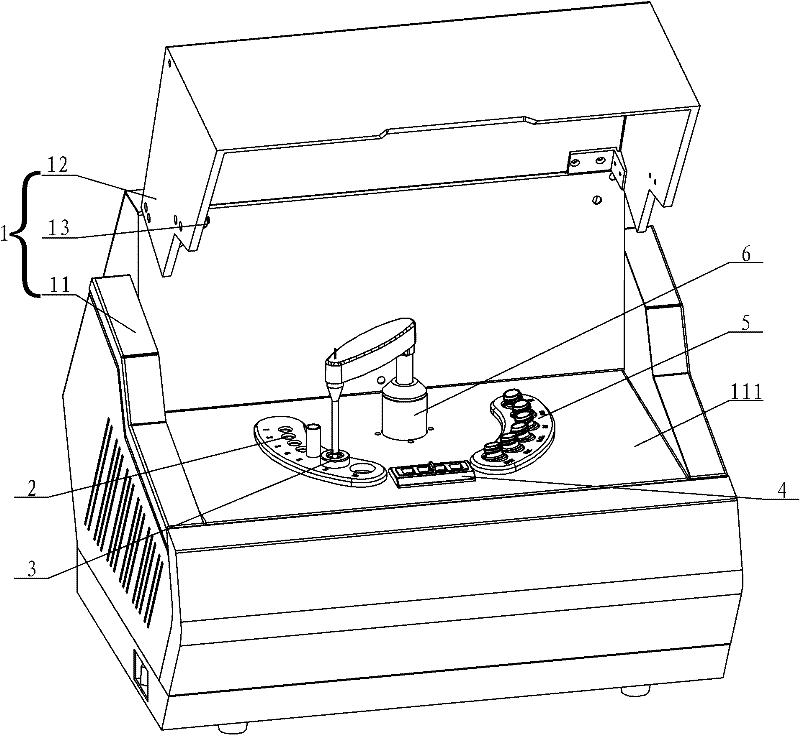

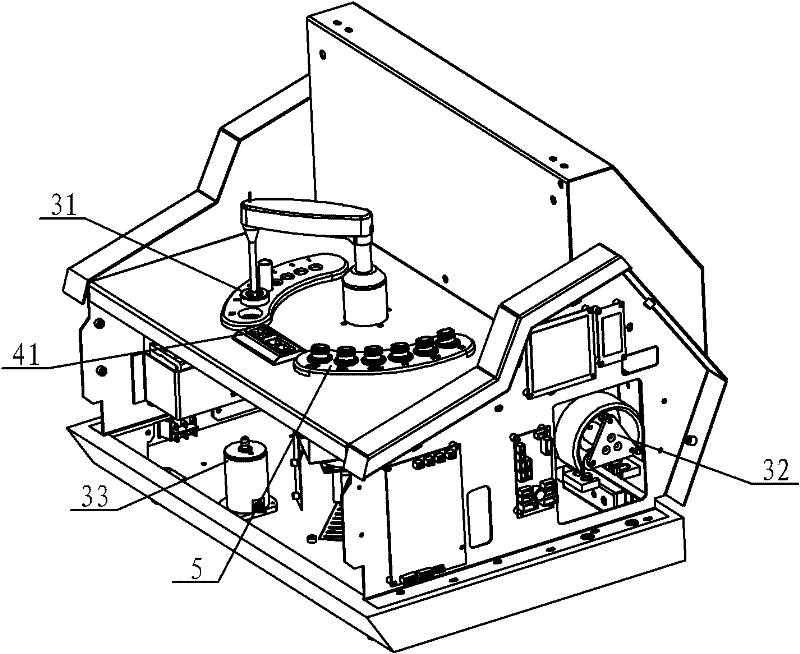

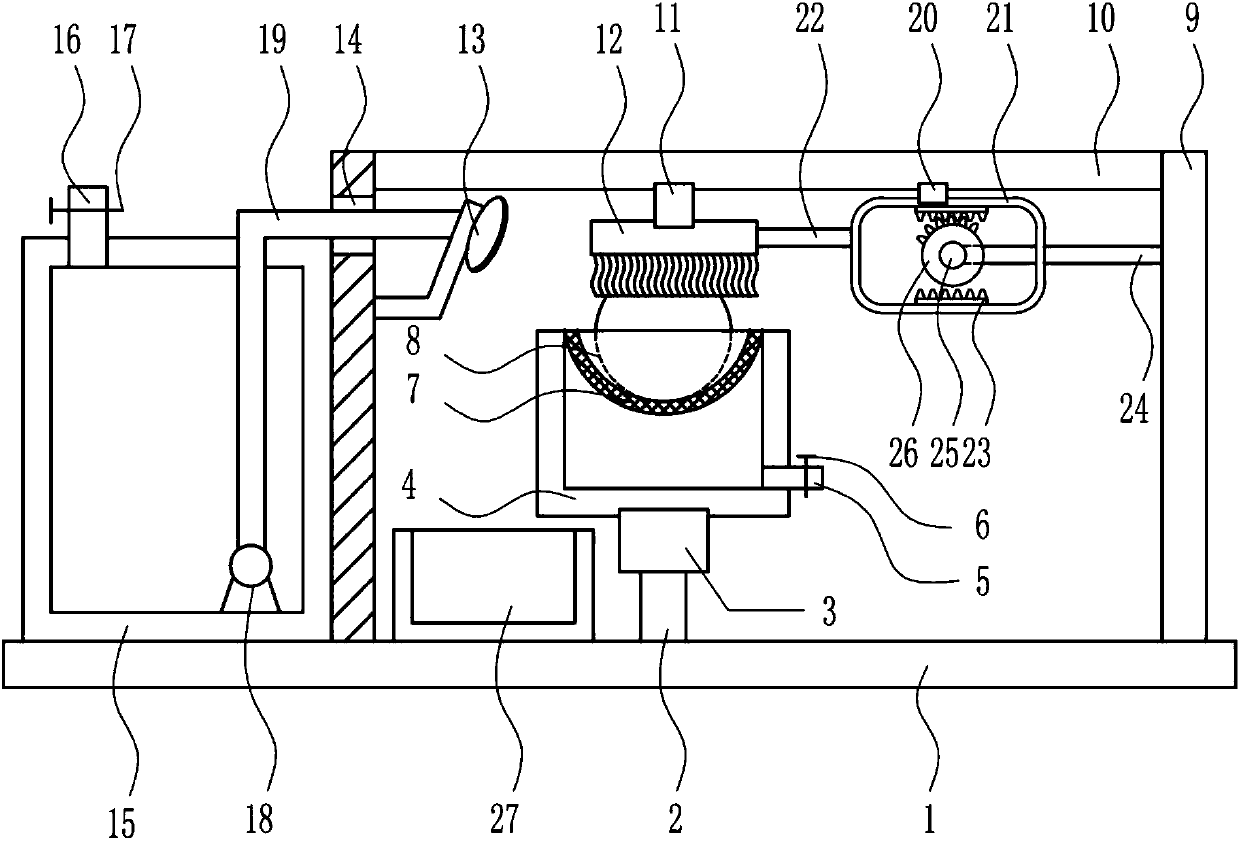

Rotary sample addition type fully-automatic blood coagulation tester

The invention discloses a rotary sample addition type fully-automatic blood coagulation tester. The tester which comprises a test system, a rotary sample addition system, an inclined reagent refrigeration system, a cleaning system and a cabinet is characterized in that the test system assembles four test channels which can simultaneously work; the rotary sample addition system comprises a rotary sample addition arm module, a sample addition probe module with constant temperature heating and liquid level probing functions, and a lead screw linear guide rail sample introduction control system; the inclined reagent refrigeration system which adopts an inclined mode to install a reagent bottle saves the reagent and avoids waste; and the cleaning system comprises an overflow type cleaning module and a double-channel peristaltic liquid charging and discharging system. The tester has the advantages of accurate test, accurate sample addition, reagent saving, long reagent preservation time, constant heating of the test system, high detection efficiency, simple operation, good cleaning effect, safe and efficient liquid discharge, and small noise.

Owner:北京众驰伟业科技发展有限公司

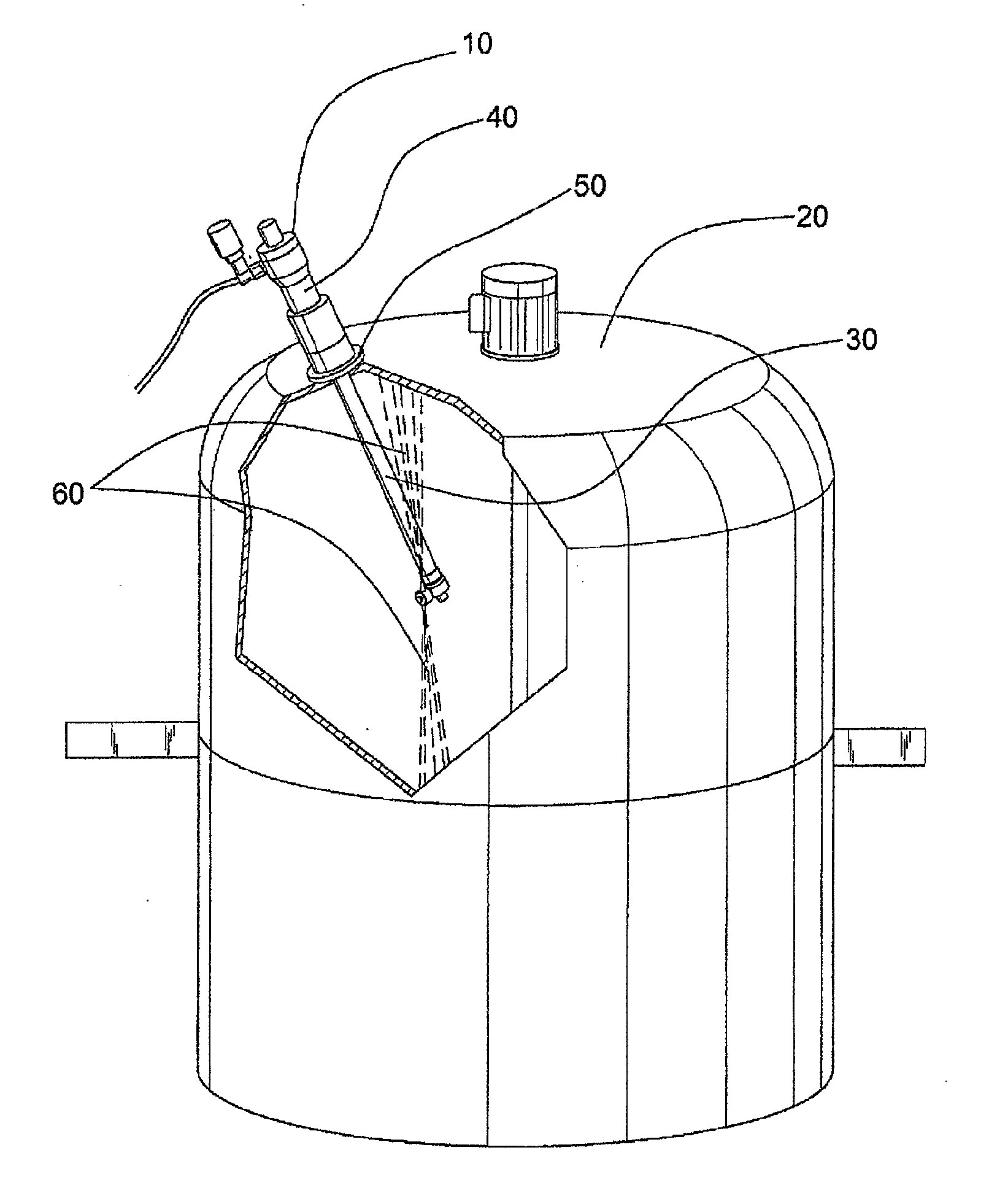

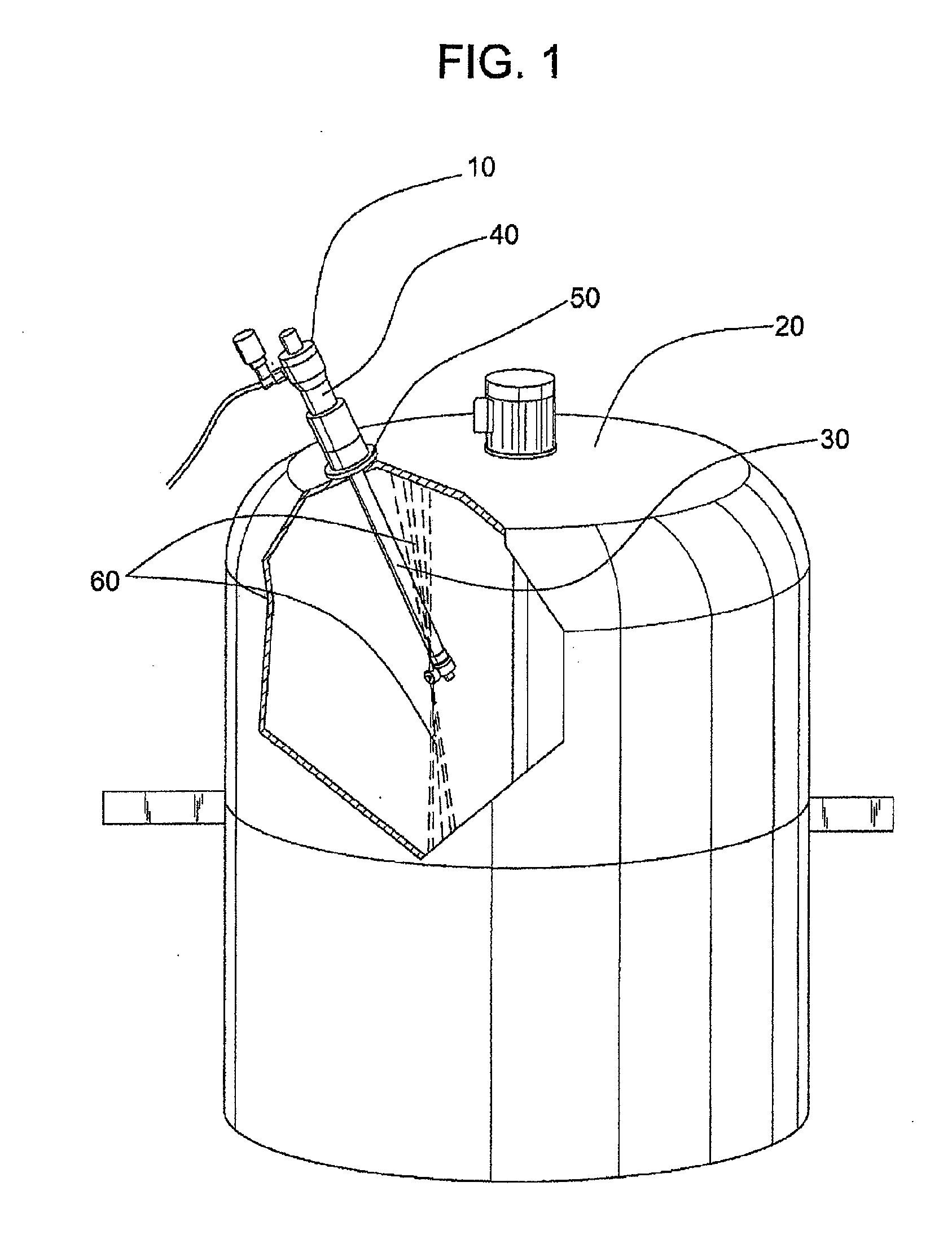

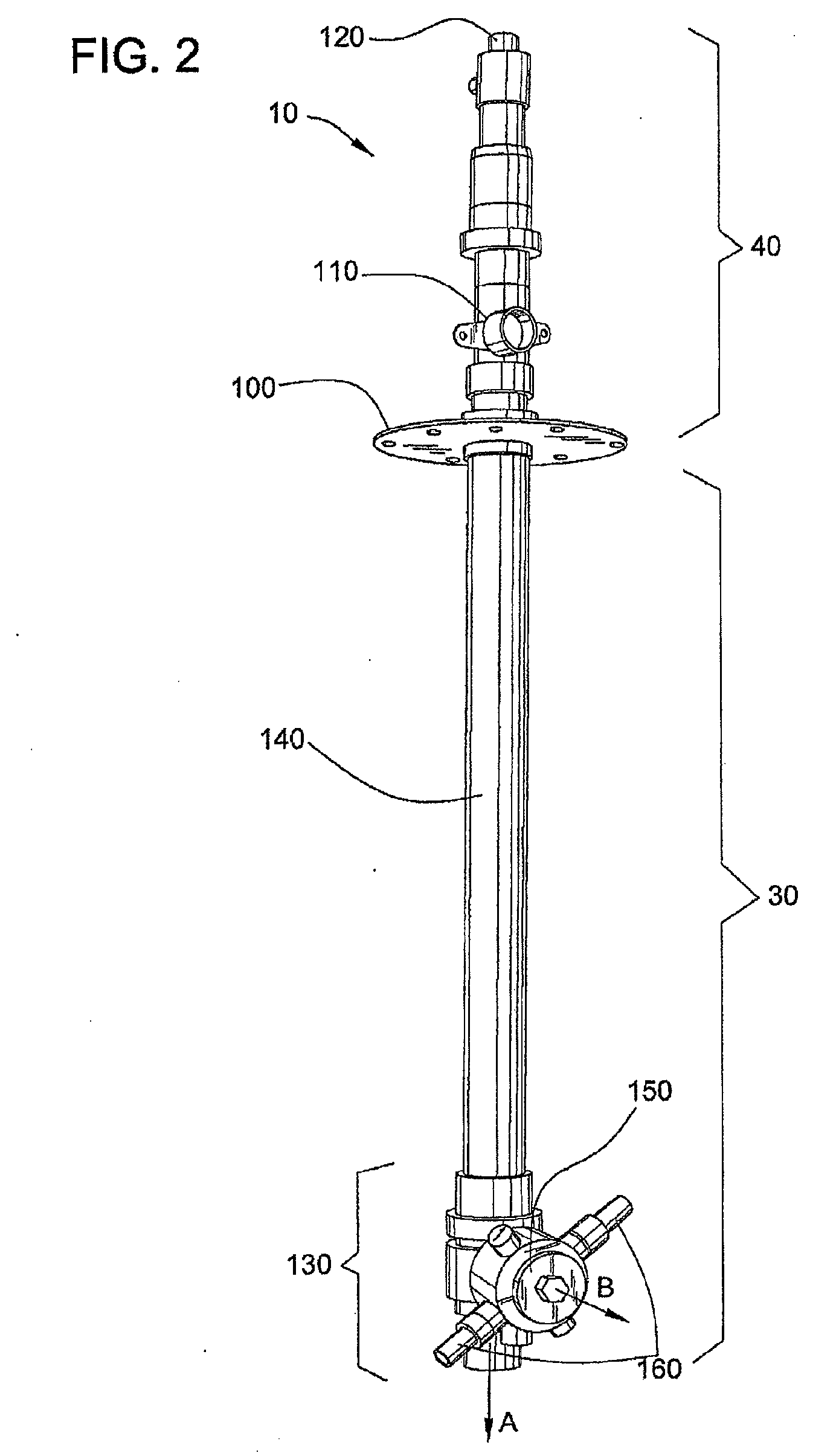

Automated Tank Cleaning Monitoring System

ActiveUS20090173362A1Evaluate cleaning efficacyPrecision cleaningHollow article cleaningCleaning using liquidsCleaning validationMonitoring system

A tank cleaning verification process works in conjunction with a specialized spray head to evaluate cleaning efficacy and to ensure proper cleaning. The system includes an encoder, and one or more pressure sensors to verify proper operation as the tank cleaning system automatically accounts for one or more characteristics of the vessel being cleaned and modifies the cleaning operation accordingly.

Owner:SPRAYING SYST

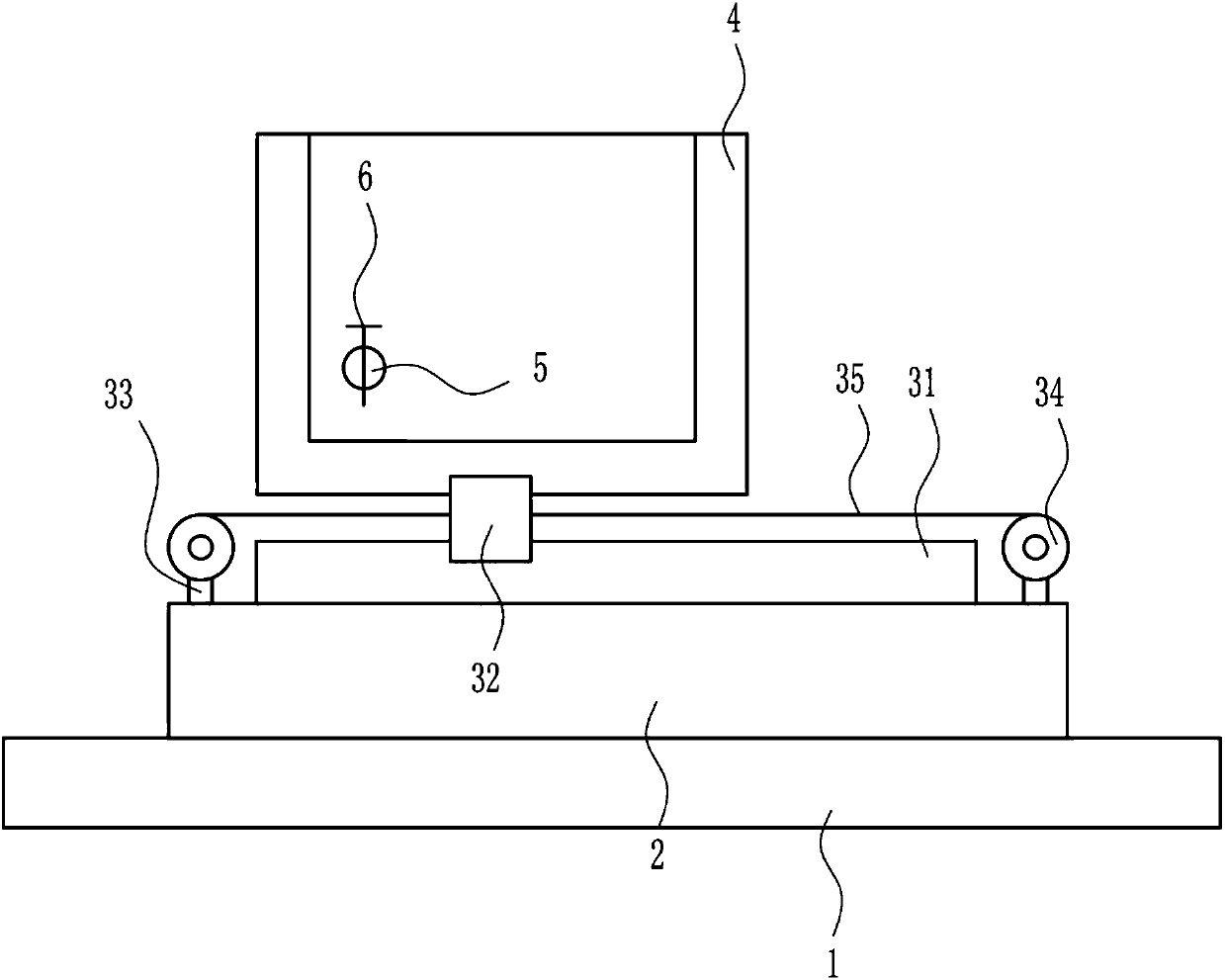

Pet dog toy ball cleaning equipment

InactiveCN107891027ASave human effortImprove work efficiencyCleaning using toolsCleaning using liquidsEngineeringDog toy

The invention relates to ball cleaning equipment, in particular to pet dog toy ball cleaning equipment. The technical problem to be solved by the invention is to provide the pet dog toy ball cleaningequipment which is thorough in cleaning, can accurately clean and cannot enable water to flow outside to pollute a floor during cleaning. In order to solve the technical problem, the invention provides the pet dog toy ball cleaning equipment. The pet dog toy ball cleaning equipment comprises a base, a fixed plate, a moving mechanism, a placing frame, a water outlet pipe, a first valve, a filter screen, a bracket, a second slide rail, a second slide block, a brush, a nozzle and the like; the fixed plate is arranged in middle of the base; the moving mechanism is arranged at the top of the fixedplate; the placing frame is arranged above the moving mechanism; the water outlet pipe is arranged at the lower part of the right wall of the placing frame; and the first valve is arranged at the right part of the water outlet pipe. The pet dog toy ball cleaning equipment achieves the effects of thorough cleaning, capability of accurately cleaning and incapability of enabling the water to flow outside to pollute the floor during cleaning, realizes the ball brushing work through front-back movement of the placing frame, and improves the working efficiency when saving the labor force.

Owner:郑诗青

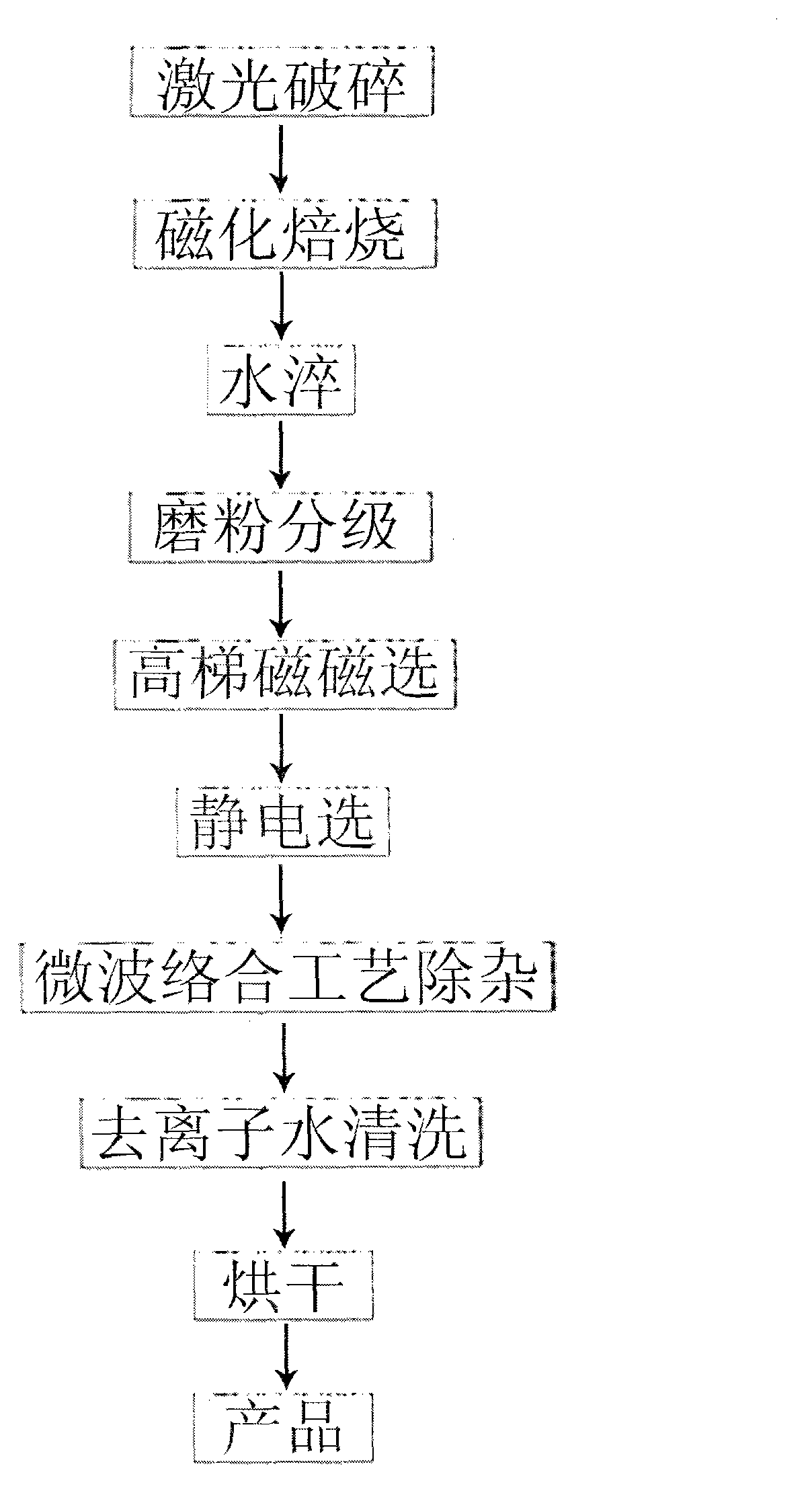

Process for preparing high-purity quartz from vein quartz

The invention discloses a process for preparing high-purity quartz from vein quartz, which comprises the steps of raw vein quartz ore selection, laser fracturing, electromagnetic roasting, water quenching, pulverization and grading, high-gradient magnetic separation, electrostatic separation, impurity removal based on a microwave complexing method, deionized water cleaning and drying. According to the invention, the process flow and structure are reasonable, the technology is advanced, efficient and easy to control, the impurity removal is targeted, high in quality index and favorable in stability; and the high-purity ultrafine quartz material can be used in such high and new technical fields as novel electric light sources, high-insulation sealing, aerospace instruments, war industry technical products, micro electronics, high-grade optical glass, quartz crucible main materials, quartz tubes and quartz rods.

Owner:刘少云

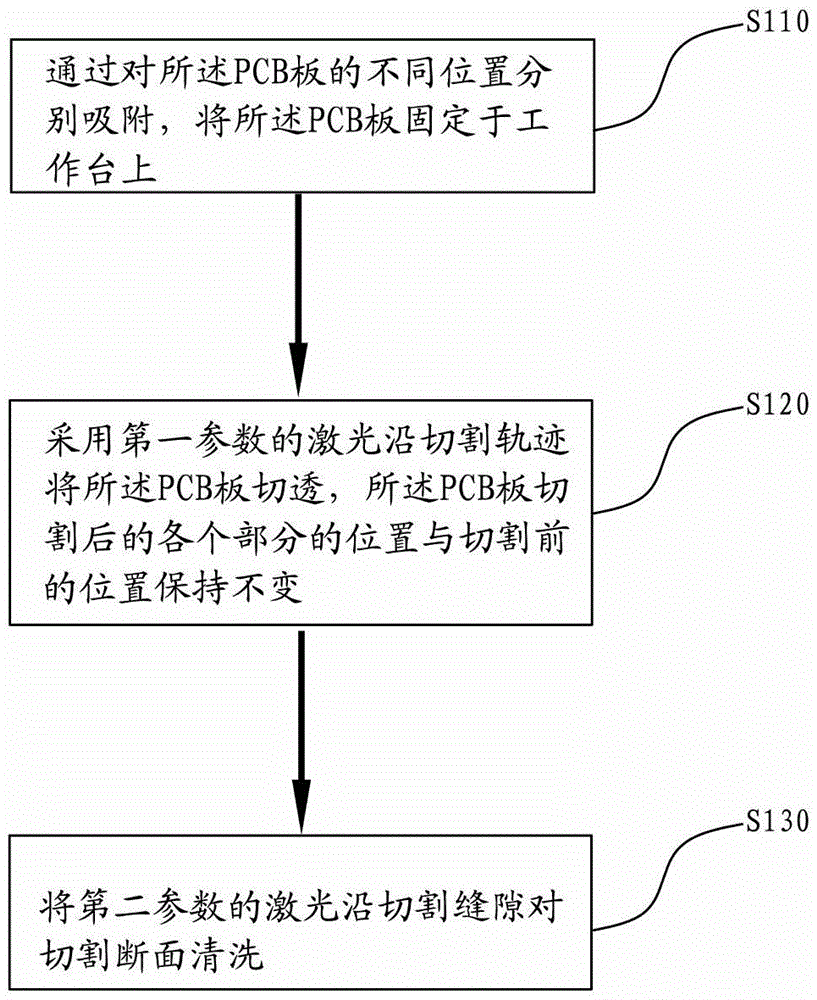

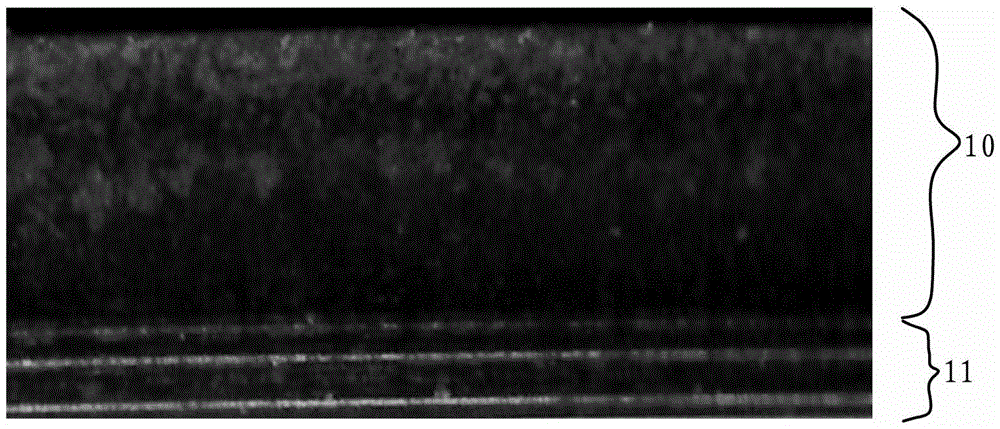

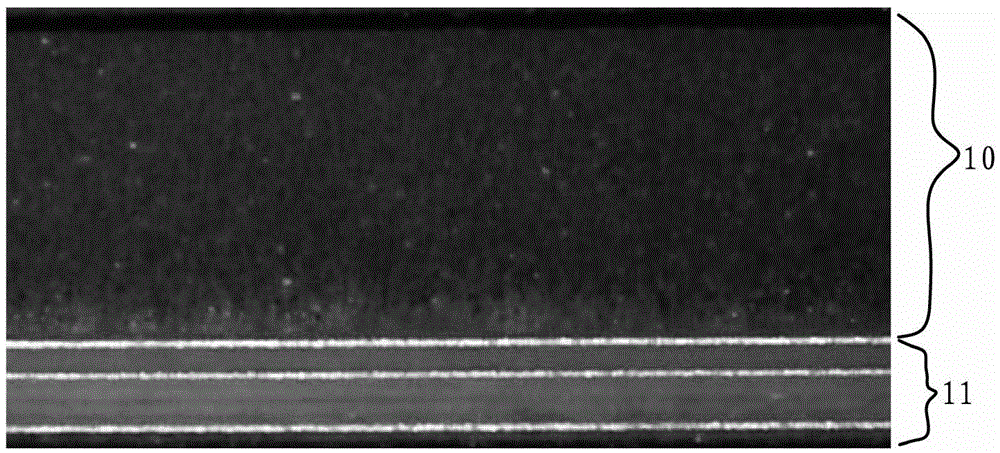

Laser cutting method for PCB containing copper layer

ActiveCN105479016AEasy to cleanPrecision cleaningLaser beam welding apparatusLaser processingEngineering

The invention is applied to the field of laser machining, and provides a laser cutting method for a PCB containing a copper layer. The laser cutting method comprises the steps that different positions of the PCB are attracted, and the PCB is fixed to a working table; laser with first parameters is adopted to cut through the PCB along the cutting trajectory, and positions of all parts of the cut PCB and the positions of all parts of the PCB obtained before cutting keep unchangeable; and laser with second parameters penetrates a cutting gap to clean a cutting section. The position of the PCB obtained before cutting and the position of the PCB obtained after cutting keep unchangeable, the laser is utilized for cleaning the cutting section, and due to the fact that the PCB is not taken away, the laser cleans the cutting section along the edge of the cutting gap, and the laser can completely penetrate the surface of the lower end of the PCB from the upper end of the PCB, so that cleaning is convenient, and the cleaning effect is good; and the position of the PCB obtained before cutting and the position of the PCB obtained after cutting keep unchangeable, and it is ensured that during cleaning, the proper position can be accurately cleaned.

Owner:HANS LASER TECH IND GRP CO LTD

Chamber cleaning mechanism

InactiveUS6544482B1Precision cleaningCombination devicesExhaust apparatusReciprocating motionEngineering

The present invention provides a reaction chamber cleaning apparatus comprising a chamber, a blade apparatus comprising at least one annular mounting member, at least four scraping blades attached peripherally about the annular mounting member, and a reciprocal movement unit for rotating said scraping blade(s) circumferentially back and forth along the interior surface of said chamber to scrape the interior surface of said chamber; said reaction chamber cleaning apparatus also comprising a vortex unit comprising a generally conical outer shell attached to and extending downwardly from the top plate top plate, and a liquid inlet arranged in relation to the outer shell to tangentially introduce liquid into the outer shell, thereby forming a laminar sheet of fluid on the inner surface of the outer shell; said vortex unit further comprising a baffle and a concentric chamber bounded by the outer surface of the baffle, the inner surface of the outer shell, and the bottom surface of the top plate. The invention also includes methods for using the reaction chamber for effluent abatement.

Owner:APPLIED MATERIALS INC

Automatic Apparatus for Washing Feet

InactiveUS20100043137A1Eliminate disadvantagesPrecision cleaningBathsDouchesStanding PositionsBiomedical engineering

Owner:ZAVAN PAOLO

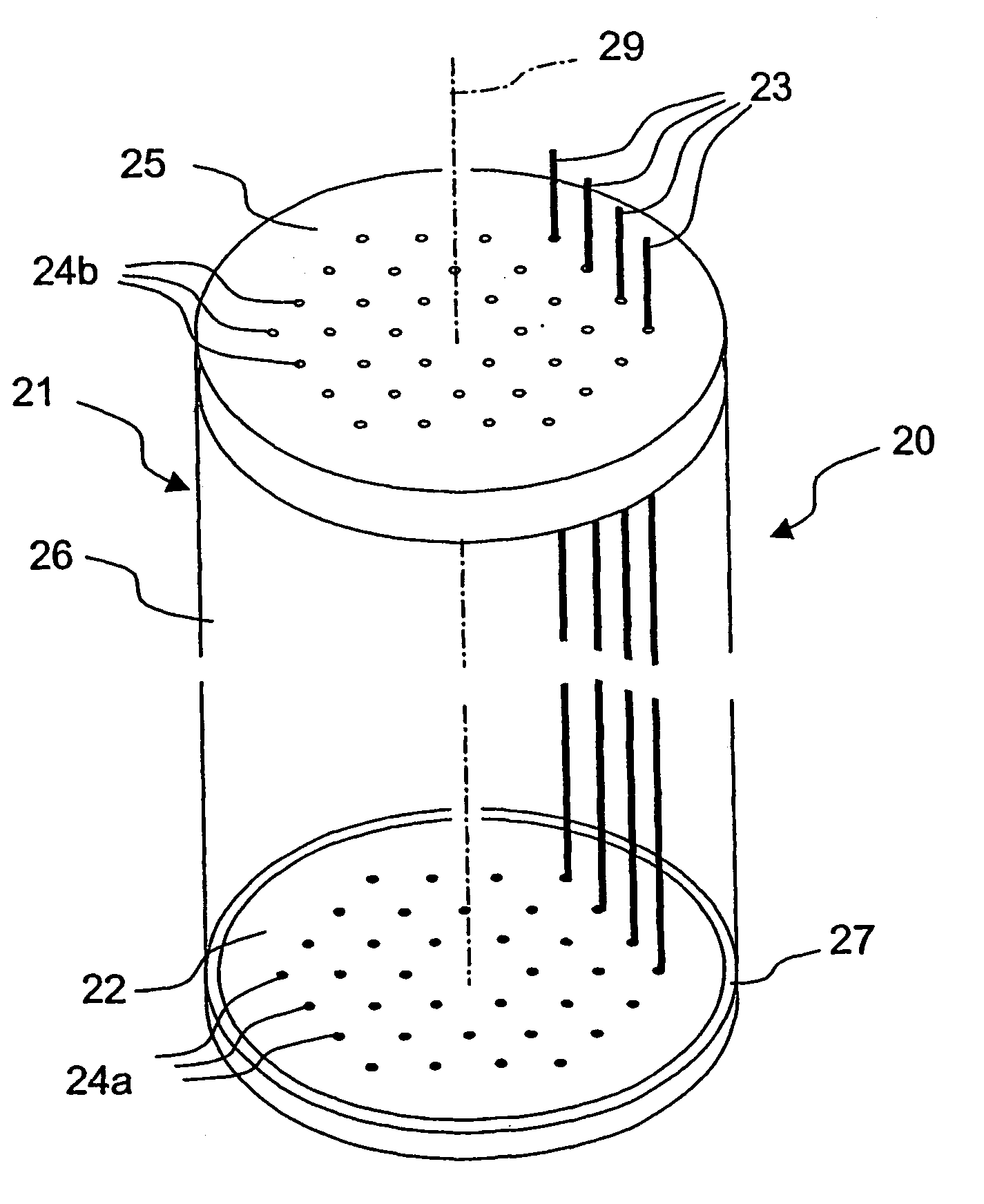

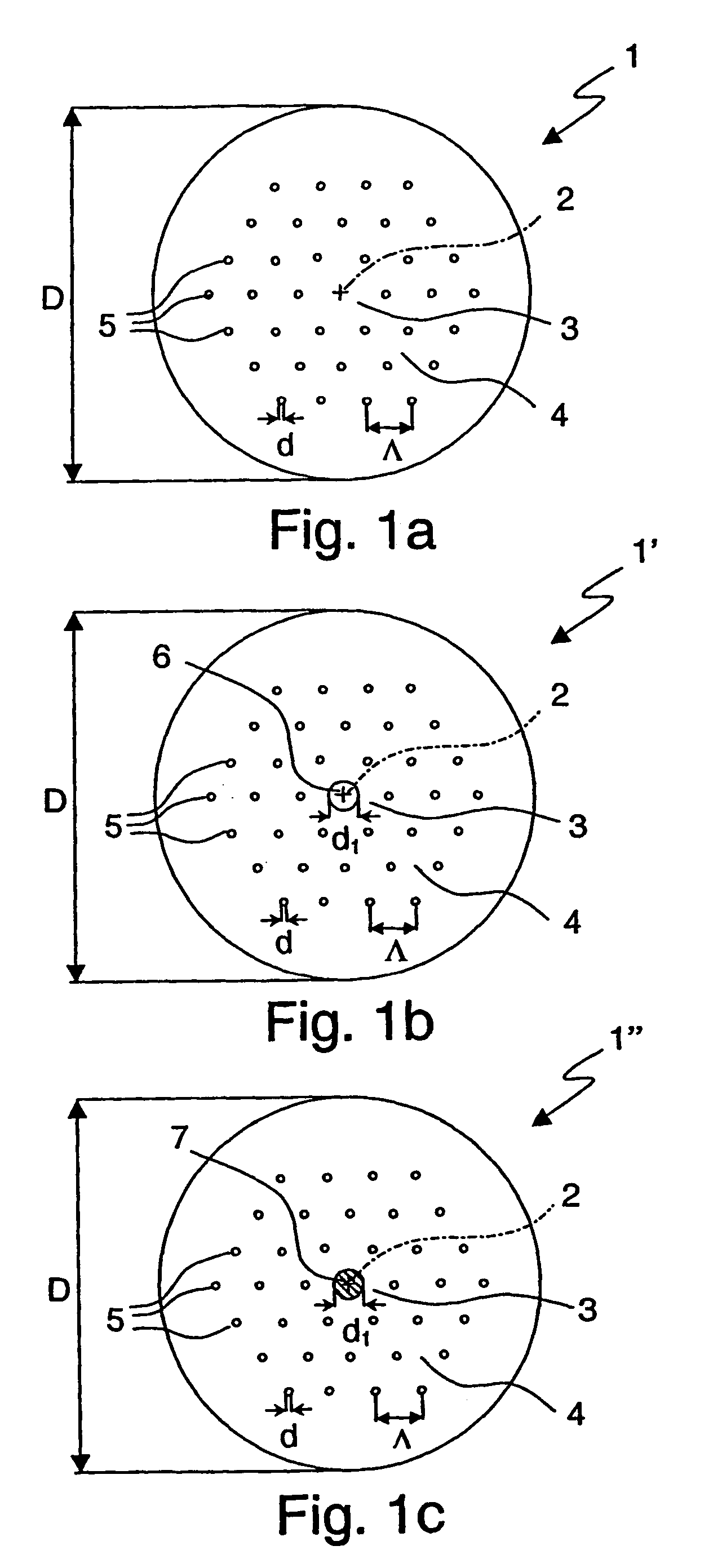

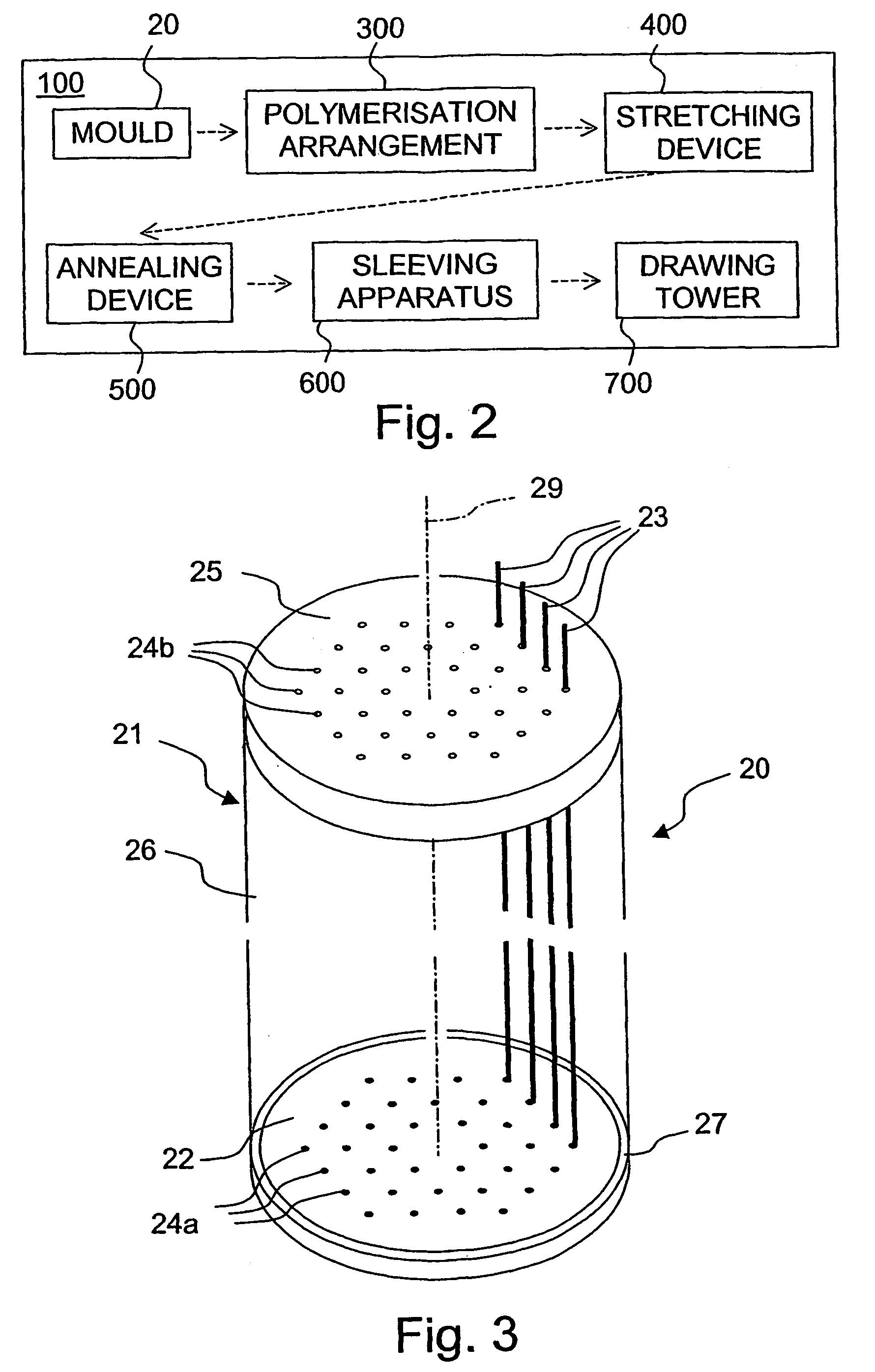

Process for manufacturing a micro-structured optical fibre

InactiveUS7212716B2Small valueQuality improvementOptical fibre with multilayer core/claddingOptical articlesPolymer scienceStress conditions

An intermediate polymer preform of elongated shape for manufacturing a microstructured optical fibre is made from a mould with a tubular par containing a pattern of hole generating elements (wires, rods or tubes) extending along it. The hole generating elements are releasably attached to an upper and to a lower base of the mould. The mould is cleaned by circulating a filtered solvent in it. The mould is filled with a fluid polymer optical material or polymer precursor. The polymer material or precursor is consolidated so that it cannot change its shape under operating stress conditions at ambient temperature. The hole generating elements are released from the upper and lower base. The consolidated core preform is extracted from the mould. The process can further include calibrating the intermediate preform.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

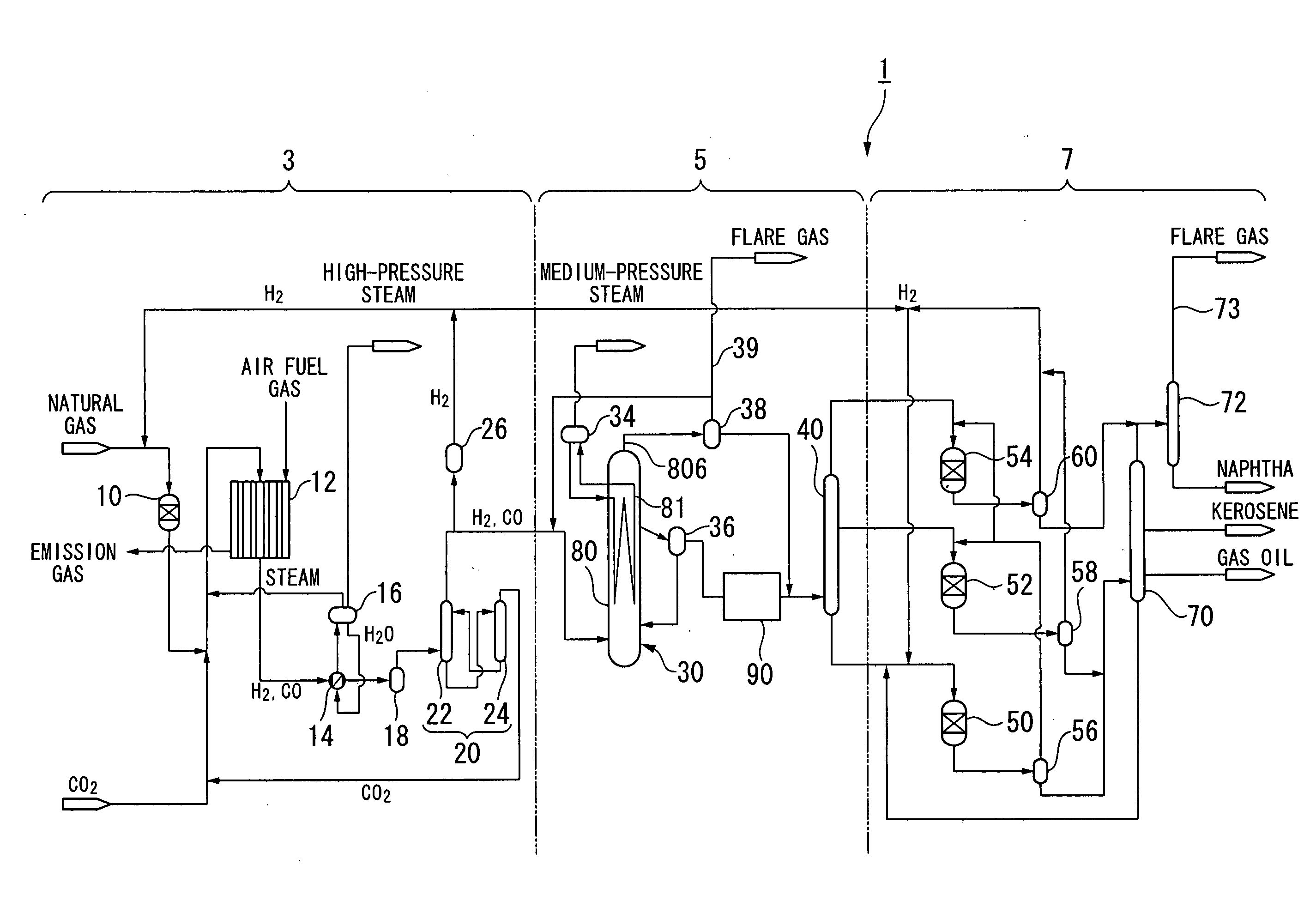

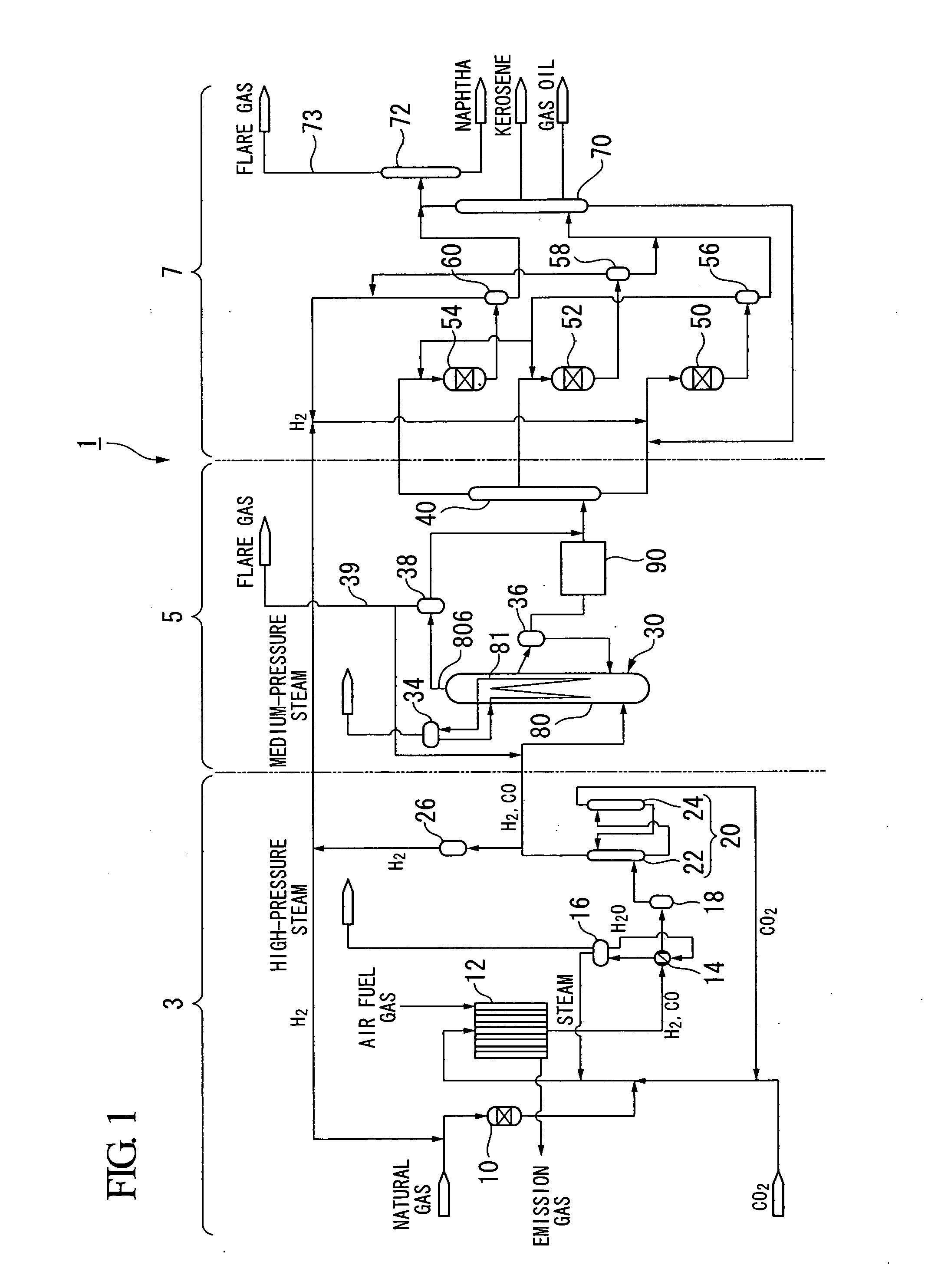

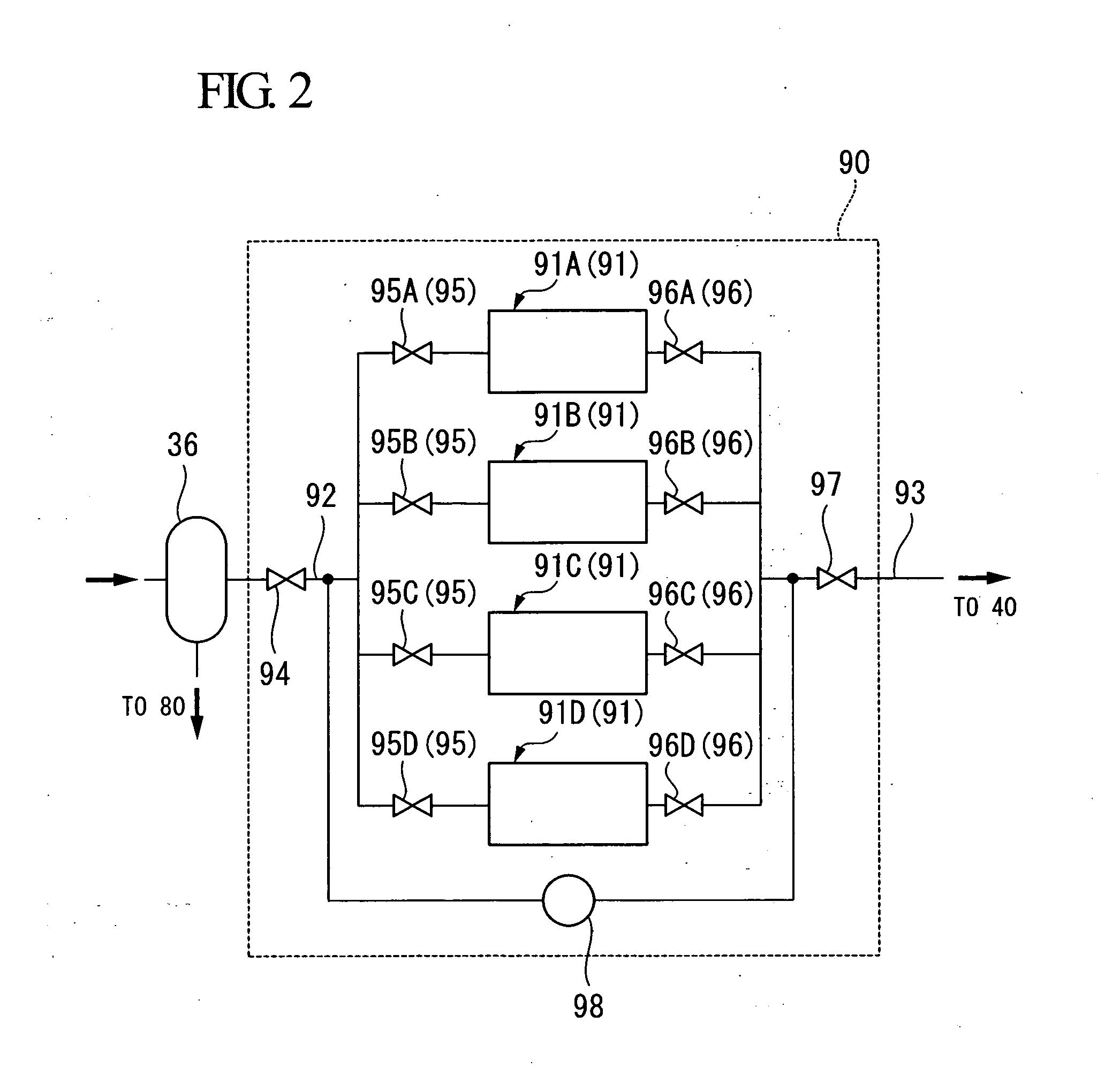

Synthesis reaction system for hydrocarbon compound, and method of removing powdered catalyst particles

ActiveUS20110044859A1Precision cleaningAccurately determineWater/sewage treatmentLiquid hydrocarbon mixture productionChemical reactionHydrogen

A synthesis reaction system is provided with: a reactor which synthesizes a hydrocarbon compound by a chemical reaction of a synthesis gas including hydrogen and carbon monoxide as main components, and a slurry having solid catalyst particles suspended in liquid; a separator which separates the hydrocarbon compound from the slurry; and a filtering device which filters the hydrocarbon compound extracted from the separator to trap powdered catalyst particles.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD +5

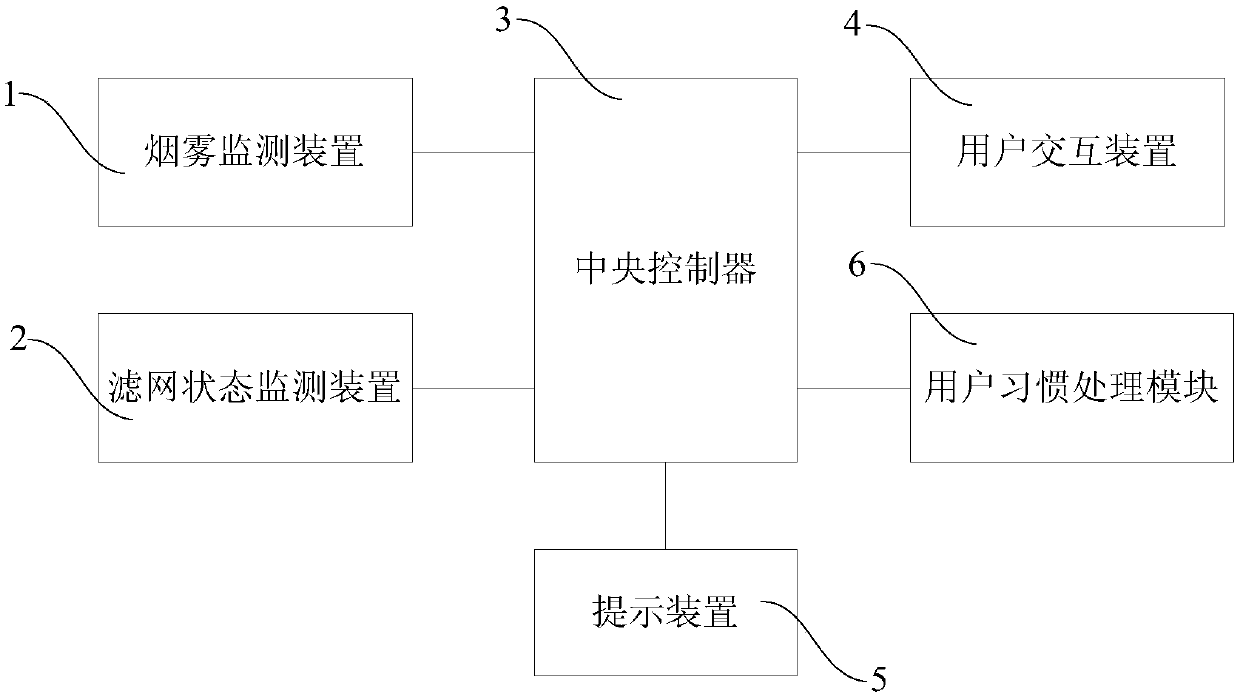

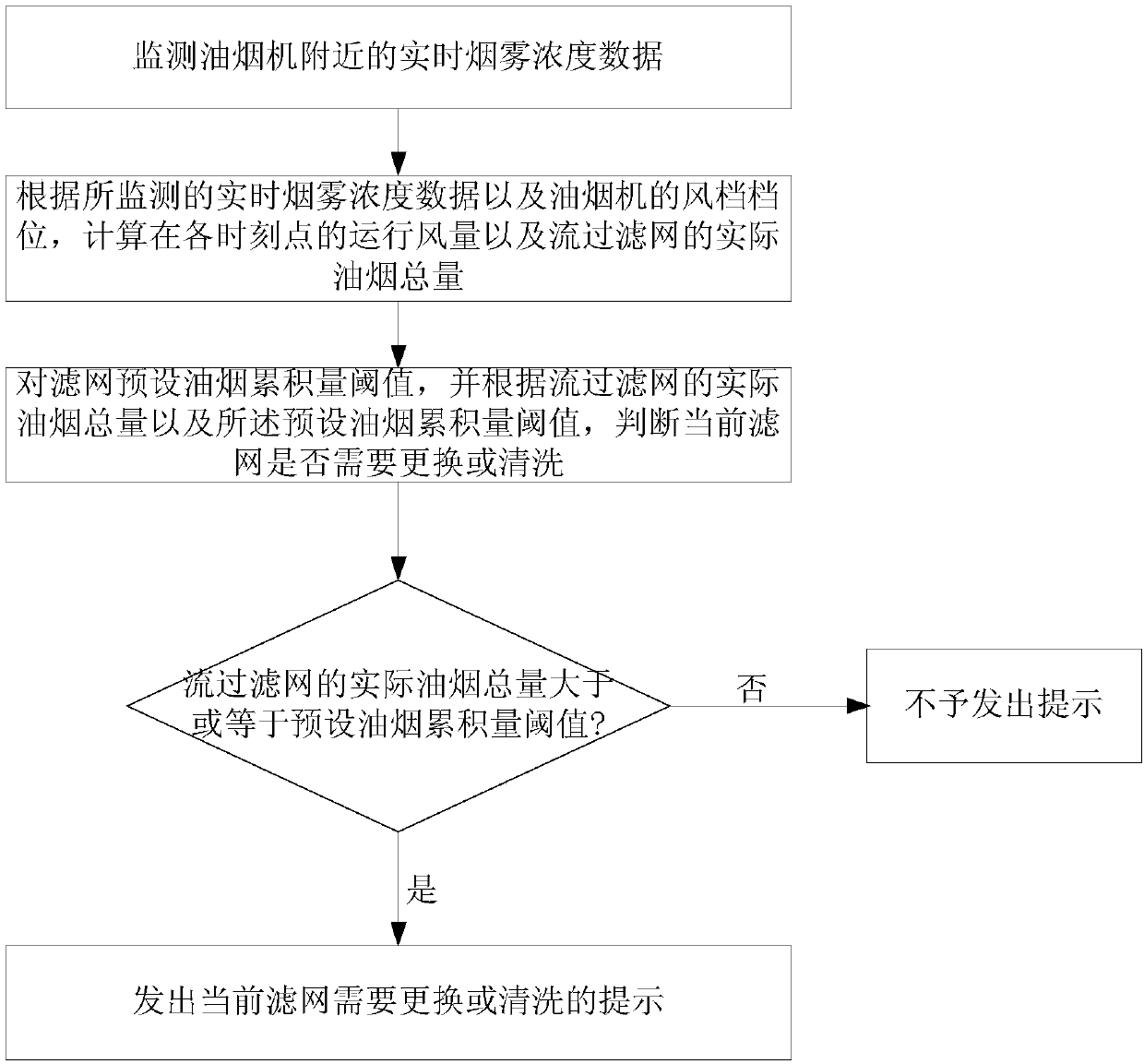

Range hood filter net monitoring device and method

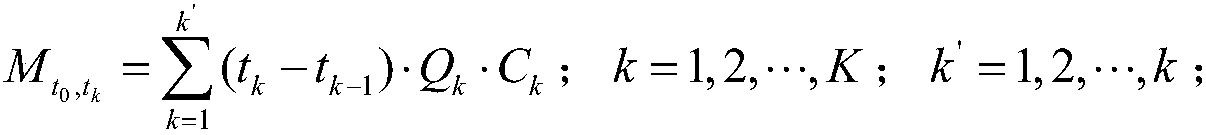

ActiveCN109539341AEasy to clean and replaceAccurate replacementDomestic stoves or rangesLighting and heating apparatusInteraction deviceAir volume

The invention relates to a range hood filter net monitoring device and method. The range hood filter net monitoring device comprises a smoke monitoring device, a filter net state monitoring device, acentral controller and a user interaction device; and the central controller is connected with the smoke monitoring device, the filter net state monitoring device and the user interaction device. By monitoring real-time smoke concentration data nearby a range hood, according to the monitored real-time smoke concentration data and the gear of an air damper of the range hood, operating air volumes and the actual total amount of oil smoke flowing through a filter net at all moment points are calculated; aiming at a preset oil smoke cumulant threshold value of the filter net, according to the actual total amount of the oil smoke flowing through the filter net and the preset oil smoke cumulant threshold value, whether the current filter net needs to be replaced or washed or not is judged; and thus a user can be automatically and accurately reminded to replace or wash the filter net according to the real-time smoke concentration data and real-time oil smoke cumulant data on the filter net, so that the range hood is normally used by the user conveniently.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Method and apparatus for processing substrate edges

InactiveUS8658937B2Eliminate needEfficient removalDecorative surface effectsPhotomechanical apparatusGas syringeSolvent

Owner:UVTECH SYST

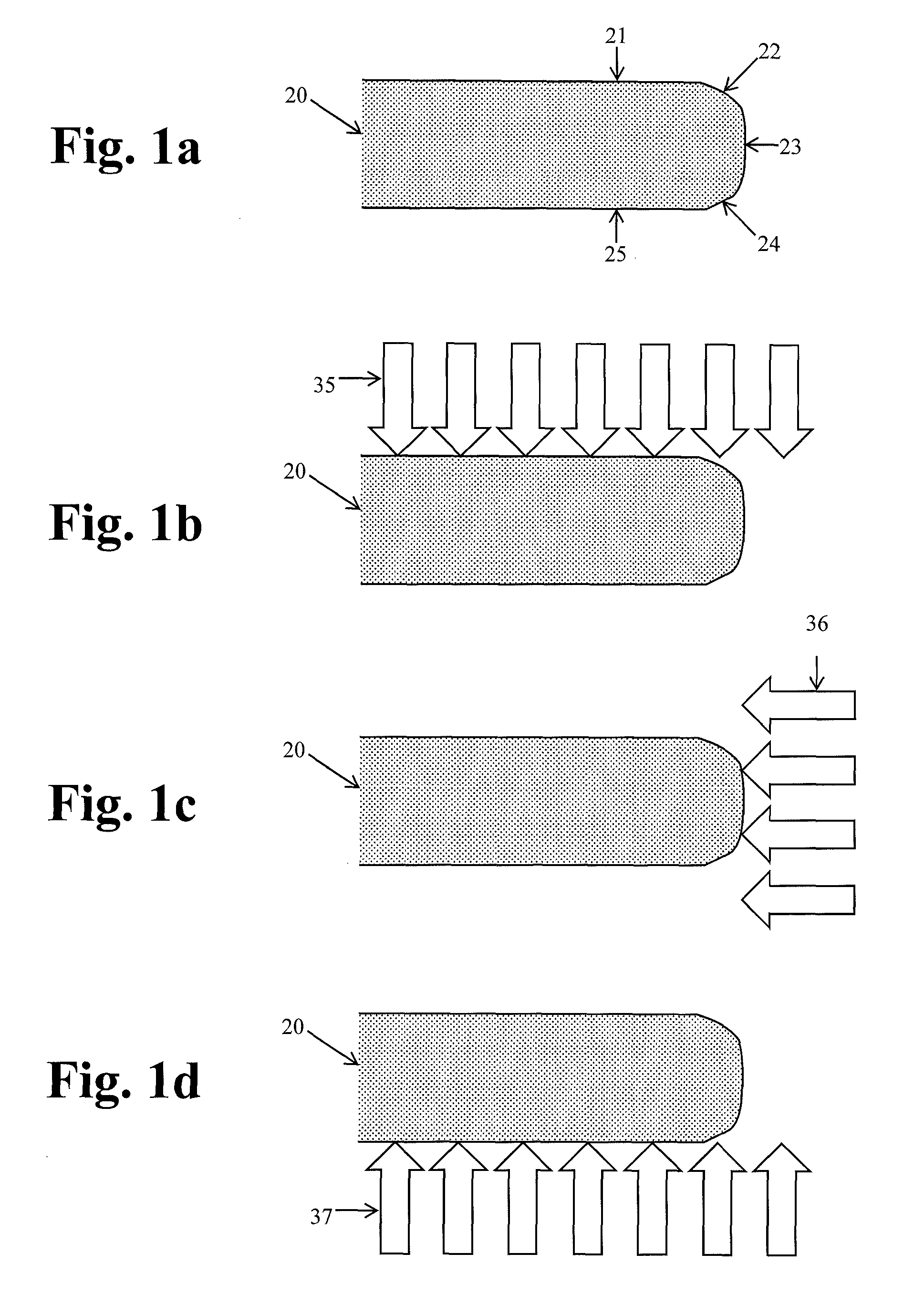

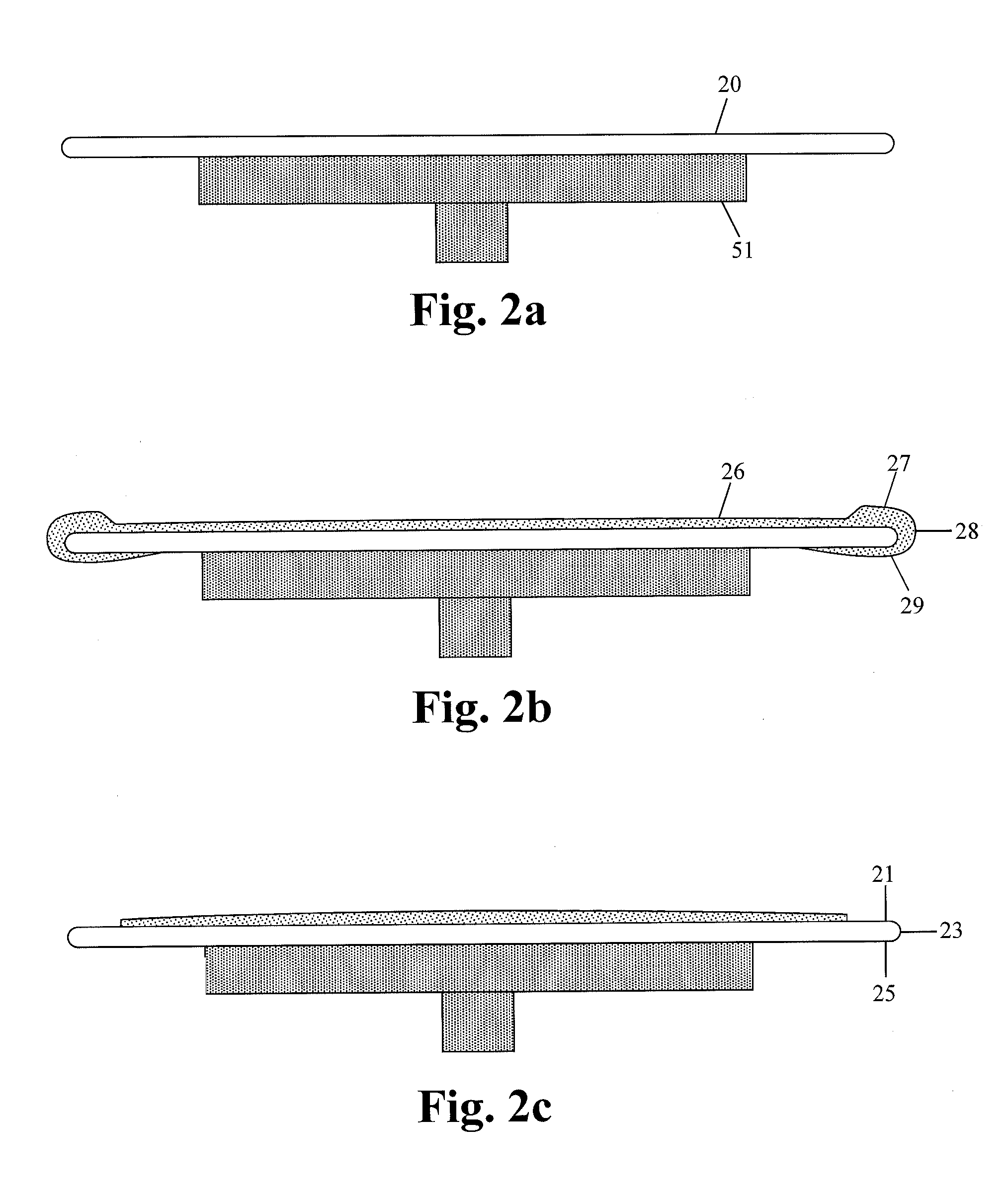

Substrate cleaning brush, and substrate treatment apparatus and substrate treatment method using the same

InactiveUS20070006895A1Easy to adjustPrecision cleaningSemiconductor/solid-state device manufacturingCleaning using toolsEdge regionEngineering

An inventive substrate cleaning brush includes a peripheral surface cleaning portion, and a marginal area cleaning portion connected to the peripheral surface cleaning portion. The peripheral surface cleaning portion has a peripheral surface cleaning surface to be pressed against a peripheral surface of a substrate. The marginal area cleaning portion has a marginal area cleaning surface to be pressed against a marginal area of a major surface of the substrate, and the marginal area cleaning surface projects from the peripheral surface cleaning surface by a variable projection length.

Owner:SCREEN HLDG CO LTD

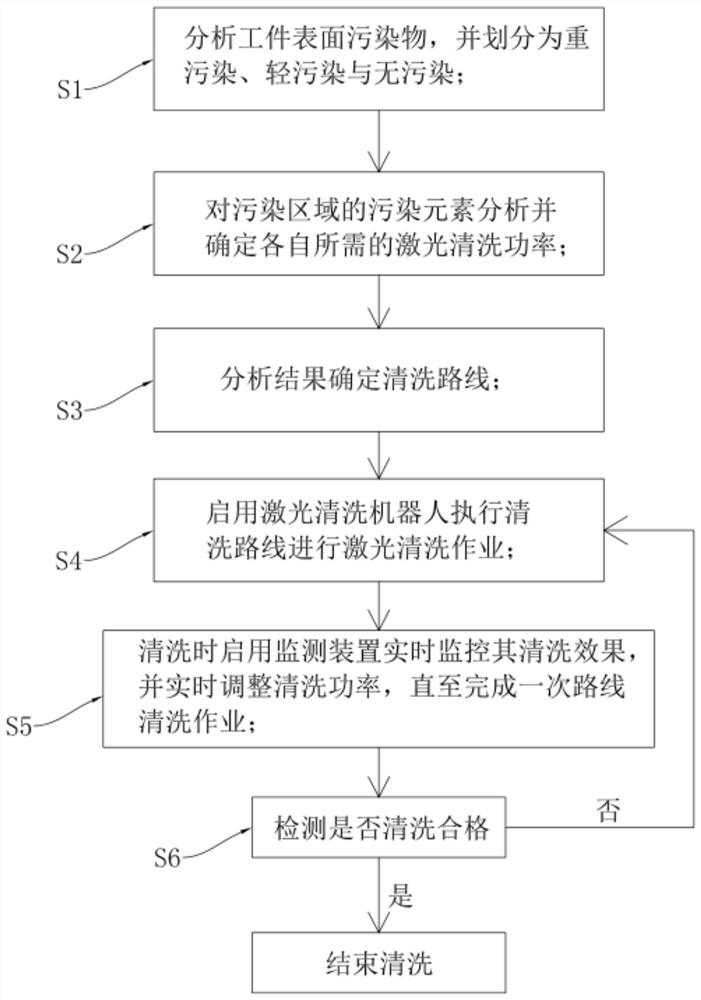

Intelligent cleaning method

ActiveCN112452947AEasy to analyzePrecision cleaningCleaning processes and apparatusReal time analysisControl signal

The invention discloses an intelligent cleaning method, and relates to the technical field of laser cleaning. The intelligent cleaning method is characterized by comprising the following steps of: S1,analyzing pollutants on the surface of a workpiece to be cleaned, and respectively dividing the pollutants into a heavily polluted area, a lightly polluted area and a pollution-free area; S2, analyzing the pollution elements of each polluted area and determining the laser cleaning power required by each polluted area; S3, determining a cleaning route for selective cleaning according to an analysis result; S4, sending a control signal of the cleaning route through a controller to a laser cleaning robot for execution, and monitoring the cleaning effect of the laser cleaning robot in real time through a monitoring device in the cleaning process; S5, analyzing the cleaning effect in real time and adjusting the cleaning power in real time through the controller; and S6, judging whether the cleaning is qualified or not through a cleaning effect detector, and if not, returning to the step S4 until the cleaning is qualified. Accurate cleaning can be achieved according to the cleaning route, the number of repeated cleaning times is reduced, and the effect of improving the cleaning precision and efficiency is achieved.

Owner:XIAMEN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com