Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

269results about How to "Less cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

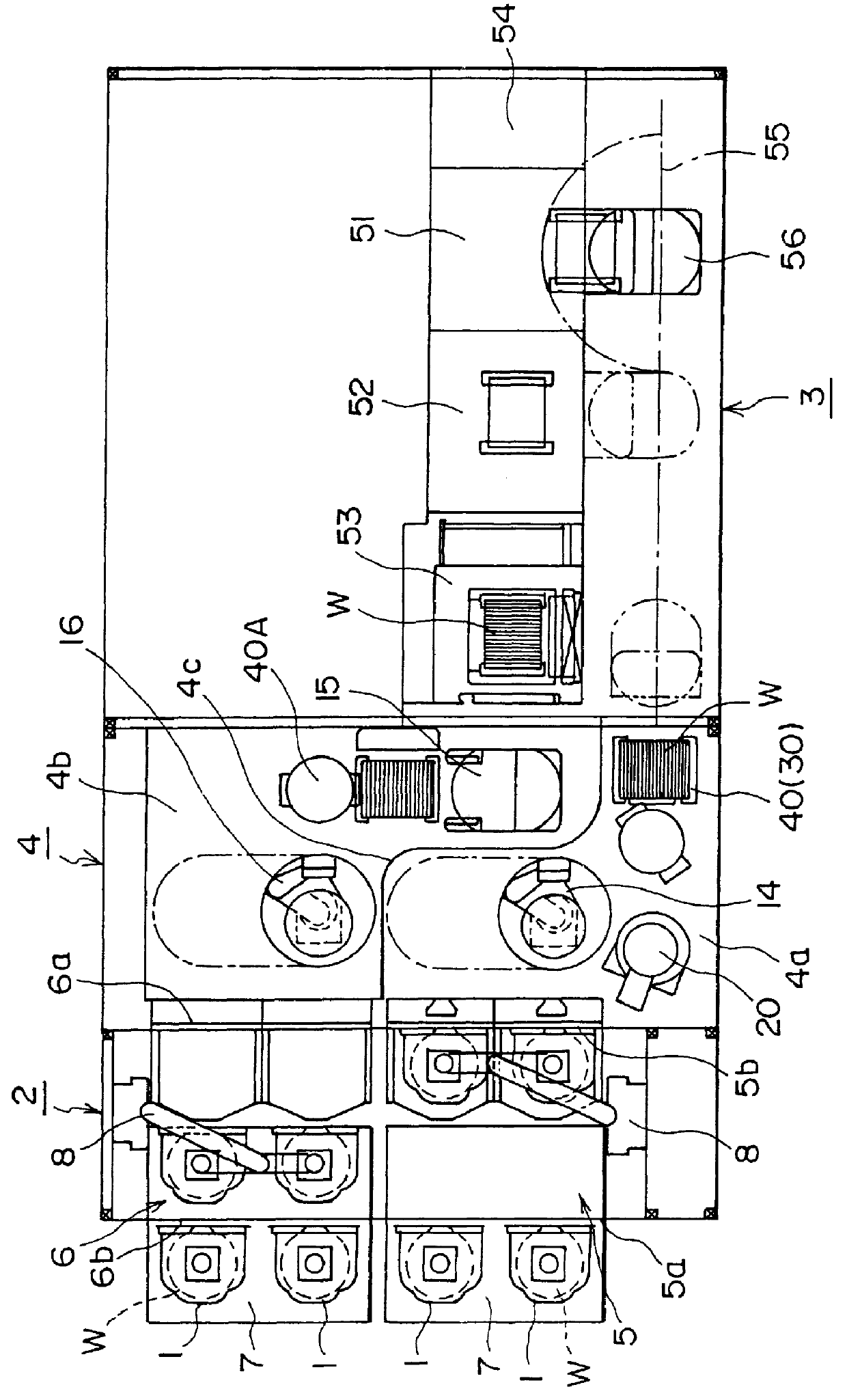

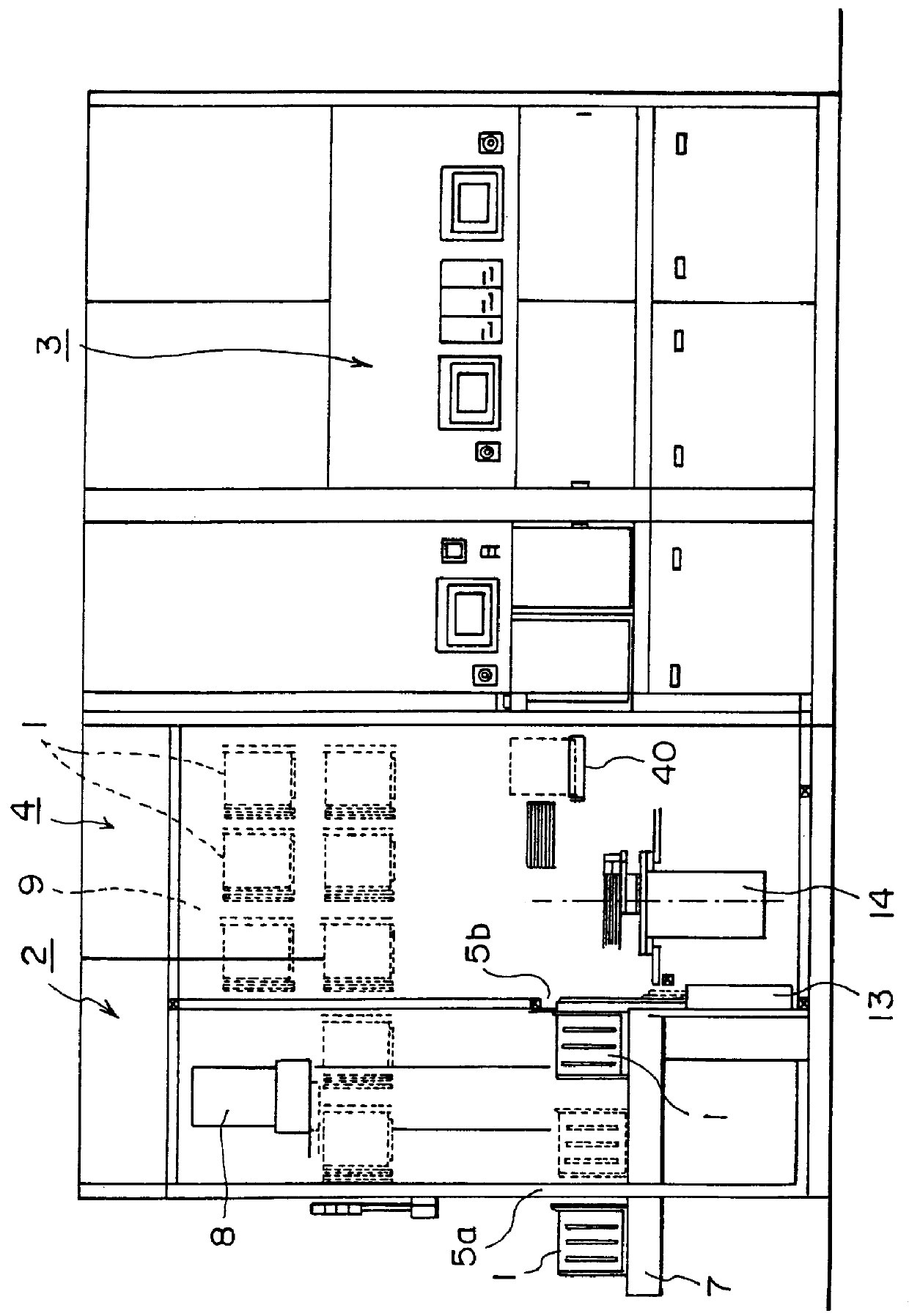

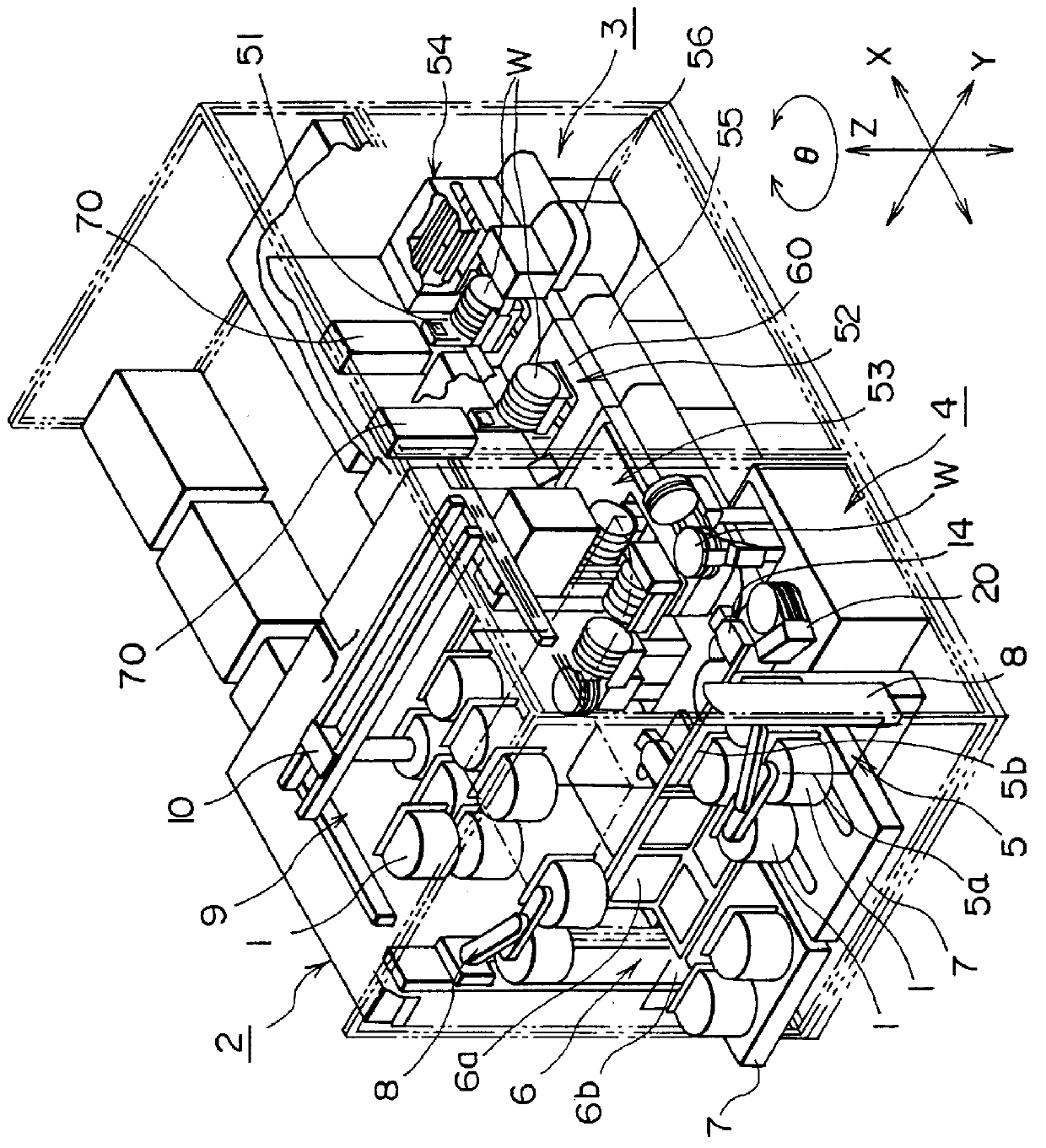

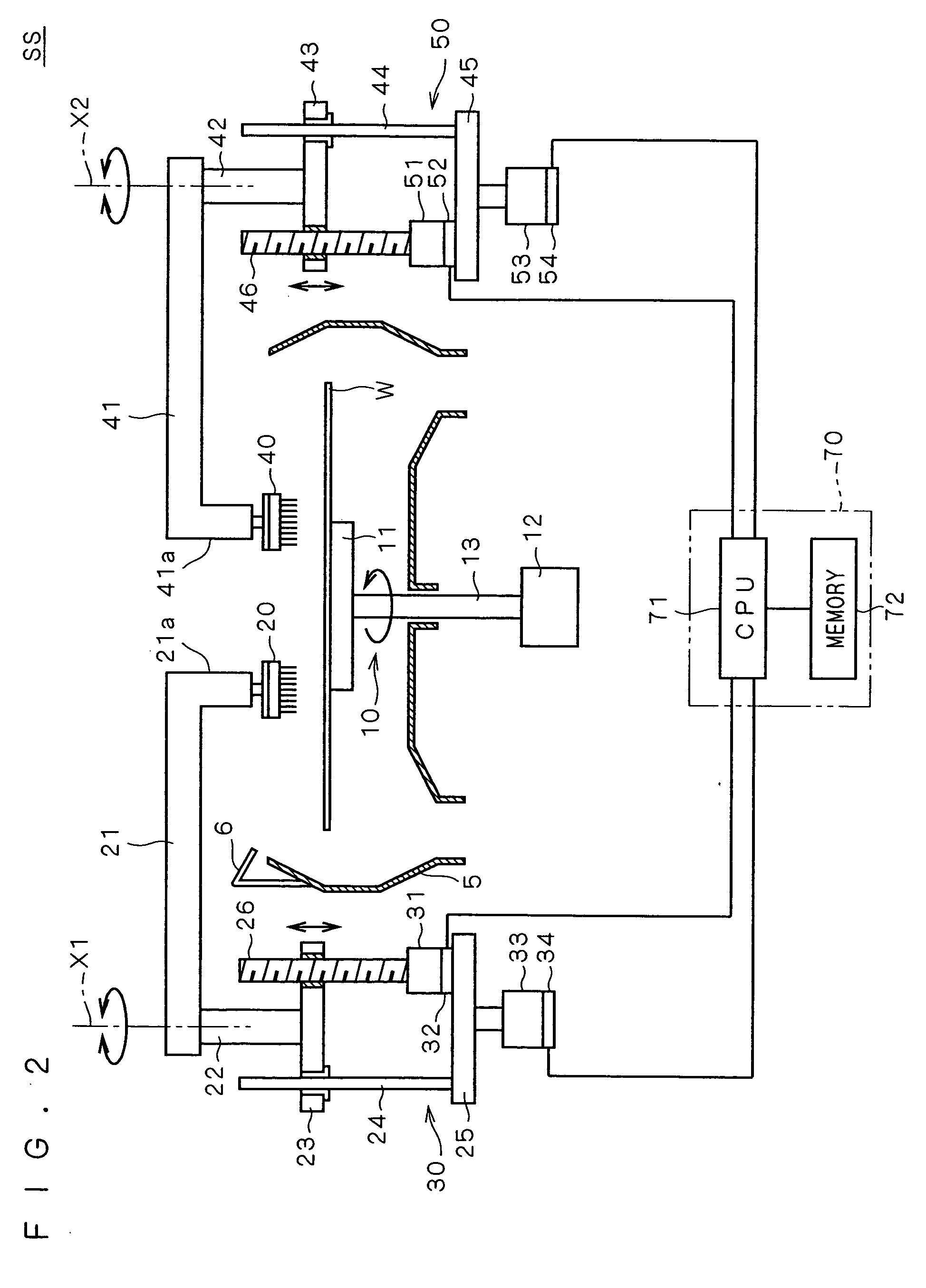

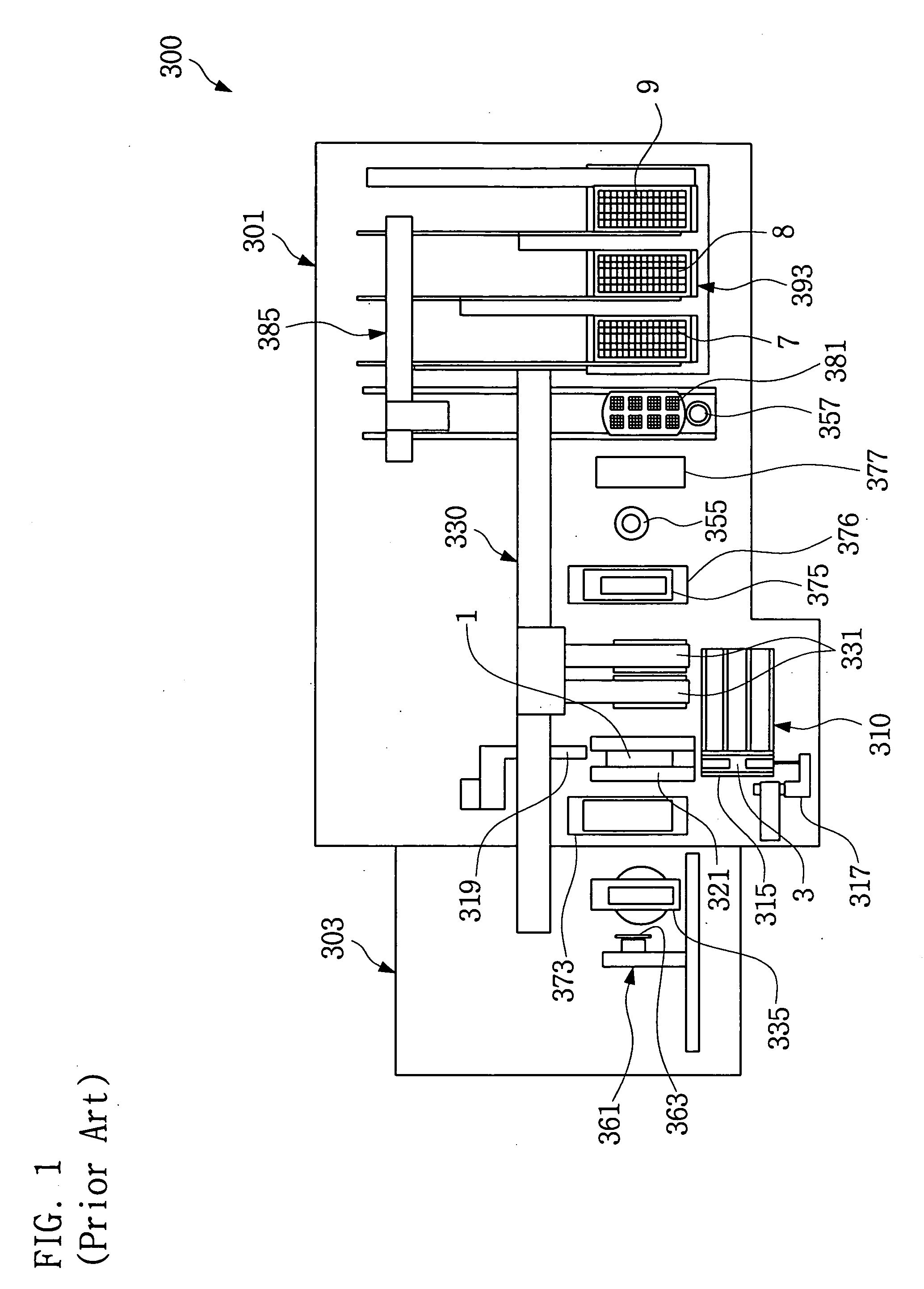

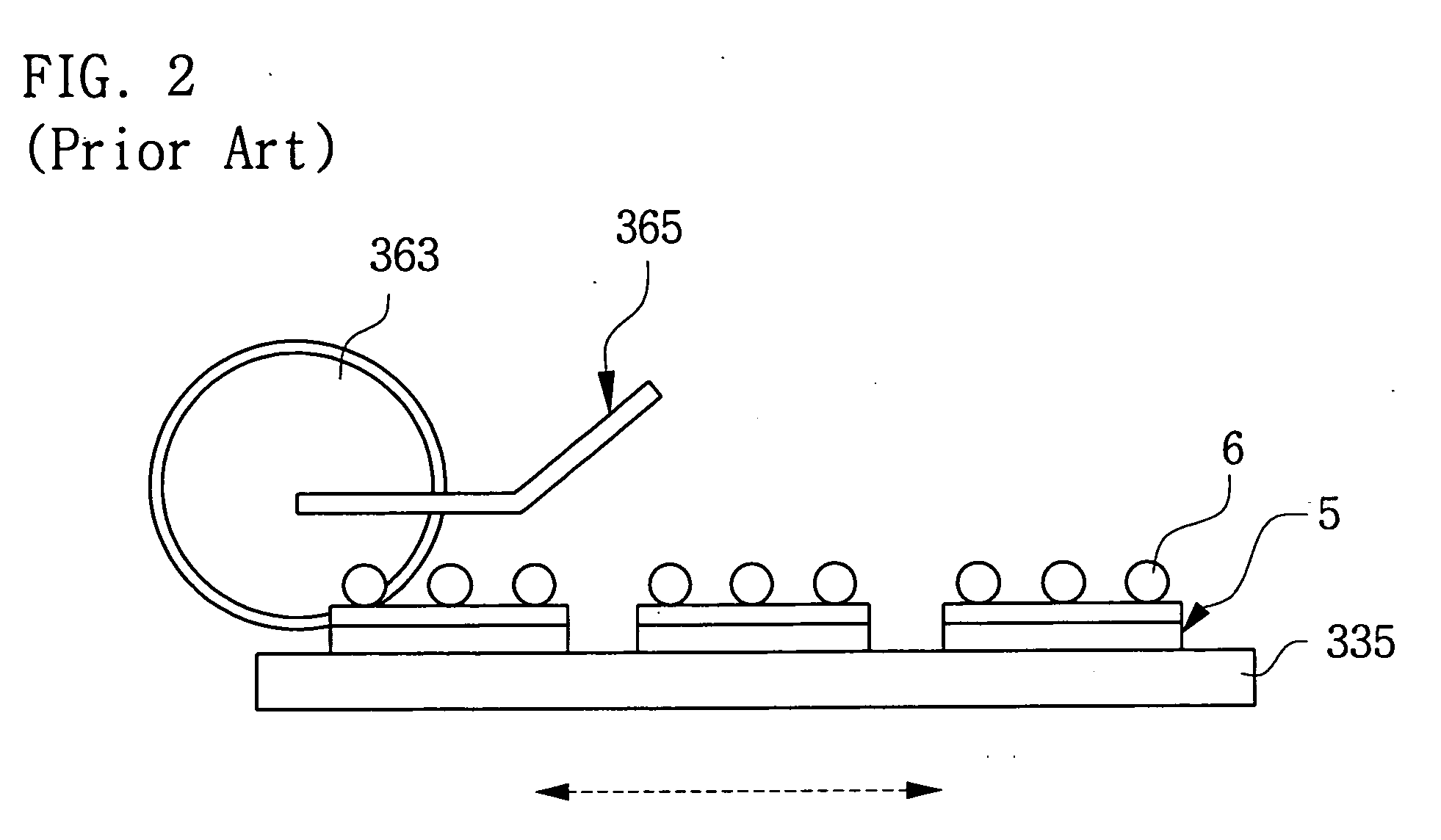

Substrate transporting and processing system

InactiveUS6009890AImprove reliability and operation efficiencyClean evenlySemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringLoading arm

A substrate transporting and processing system generally comprises: a supply section of a carrier 1 for housing therein wafers W to be processed, in a horizontal state; a discharge section of the carrier 1; a wafer unloading arm 14 for unloading the wafers W from said carrier 1; a wafer loading arm 16 for loading the wafers W into the carrier 1; an attitude changing unit 40 for changing the attitude of the wafers W between a horizontal state and a vertical state; a processing section 3 for suitably processing the wafers W; and a wafer transport arm 56 for delivering the wafers W between the attitude changing unit 40 and the processing section 3 and for transporting the wafers W into and from the processing section. Thus, after the wafers W housed in the carrier 1 in the horizontal state are unloaded and the attitude of the wafers W is changed into the vertical state, suitable processes are carried out, and the attitude of the wafers W is changed in the horizontal state after processing, so that the wafers W can be housed in the carrier 1. Thus, it is possible to decrease the size of the whole system to improve the throughput and to improve the yield of products.

Owner:TOKYO ELECTRON LTD

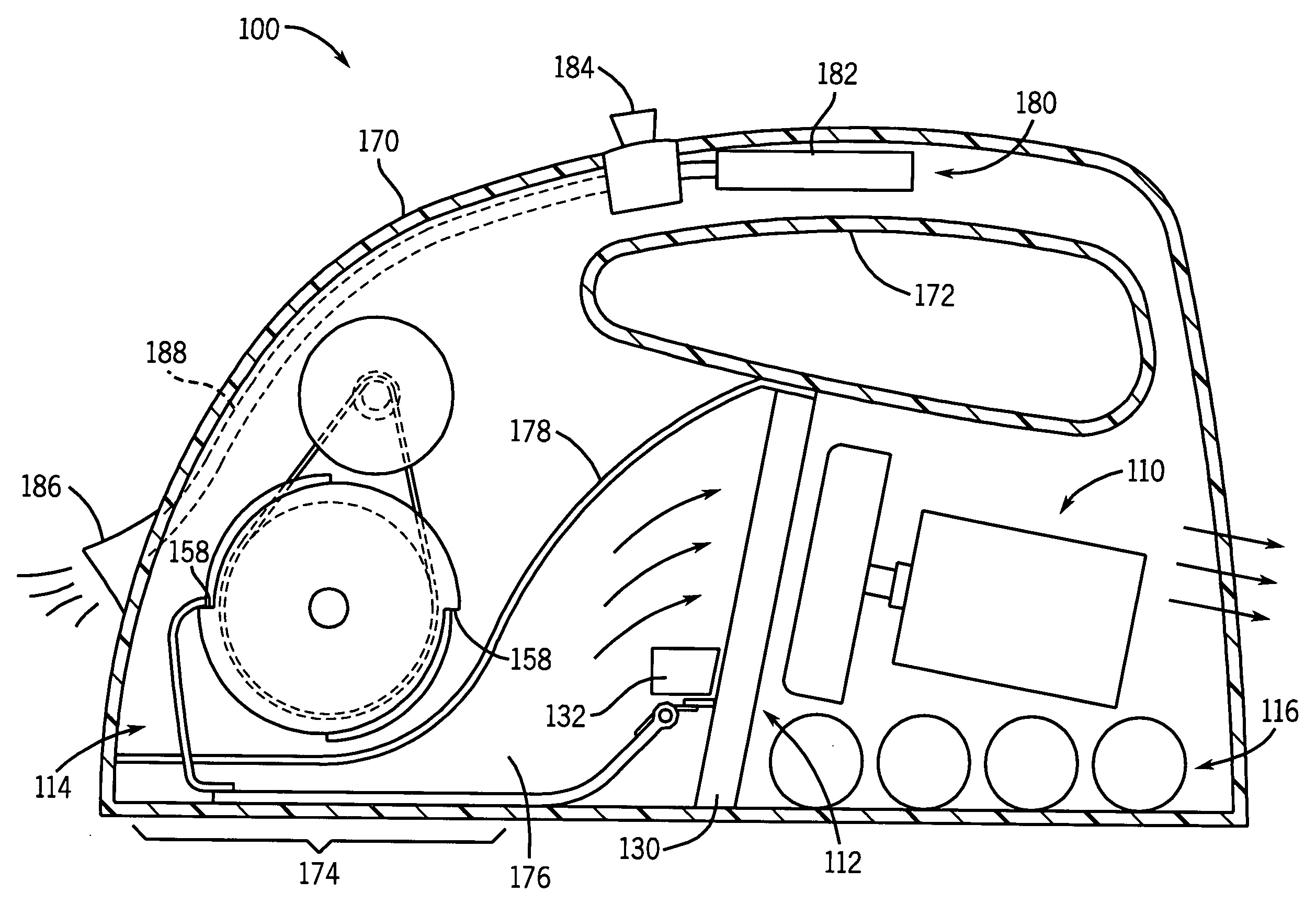

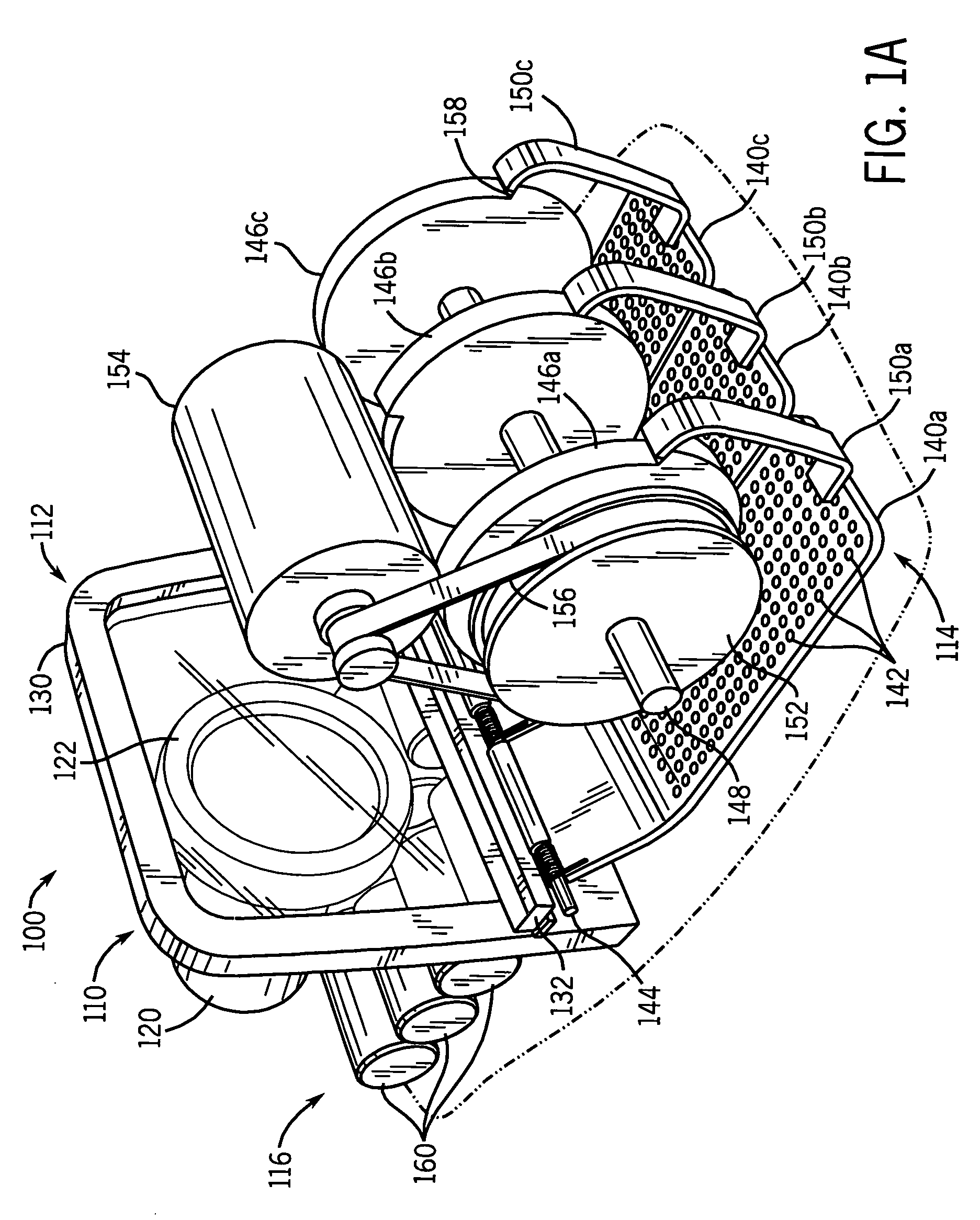

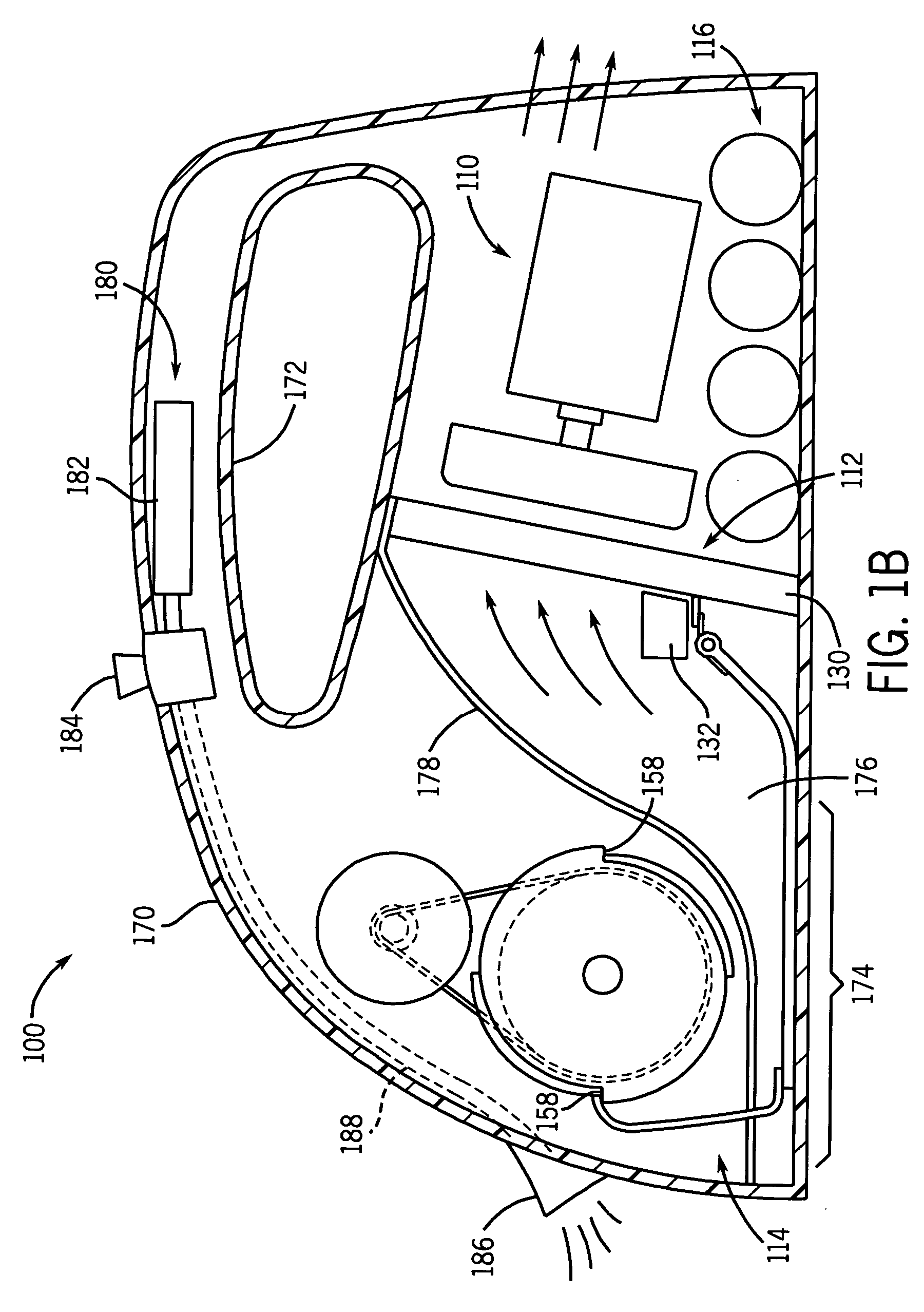

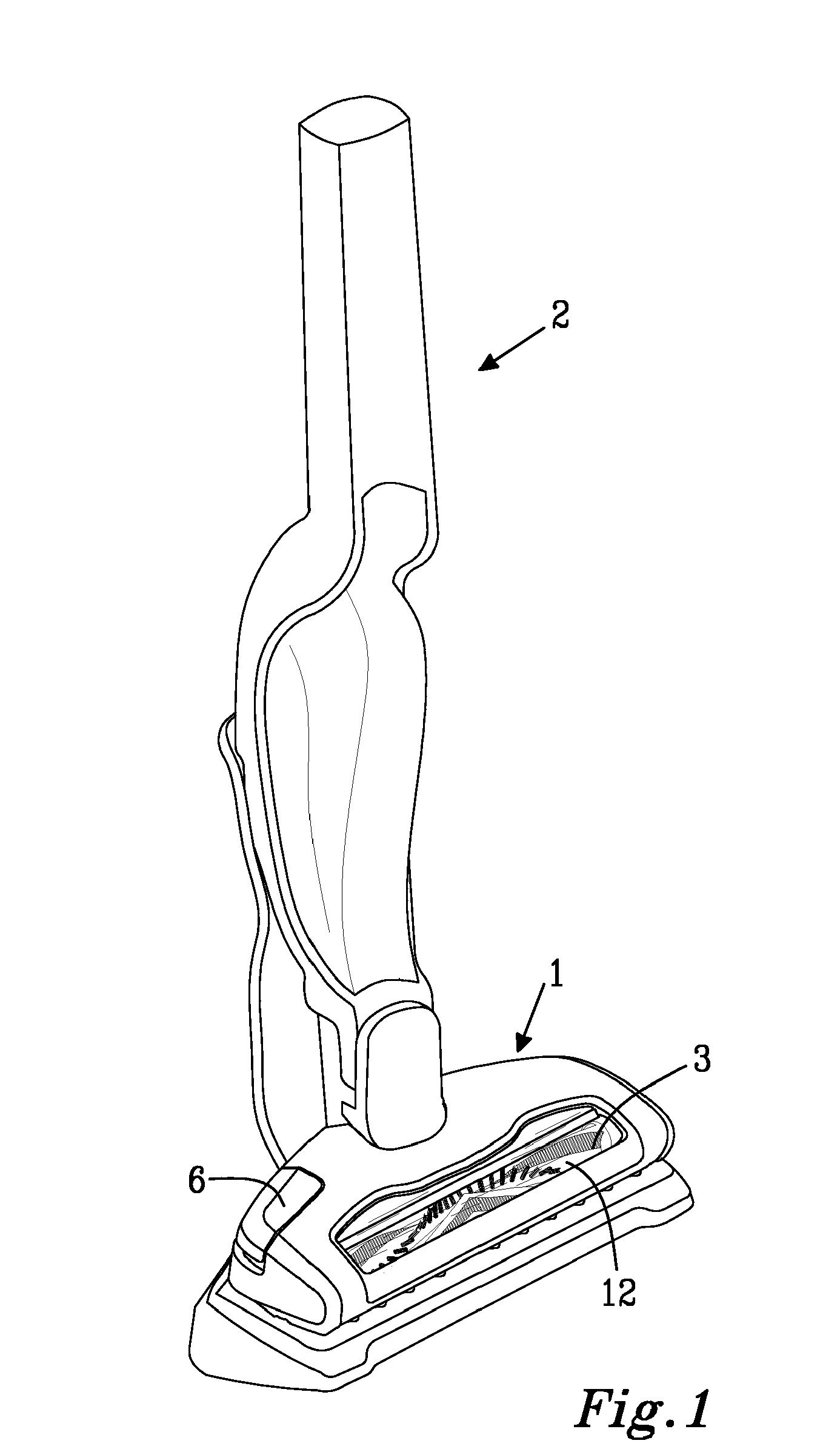

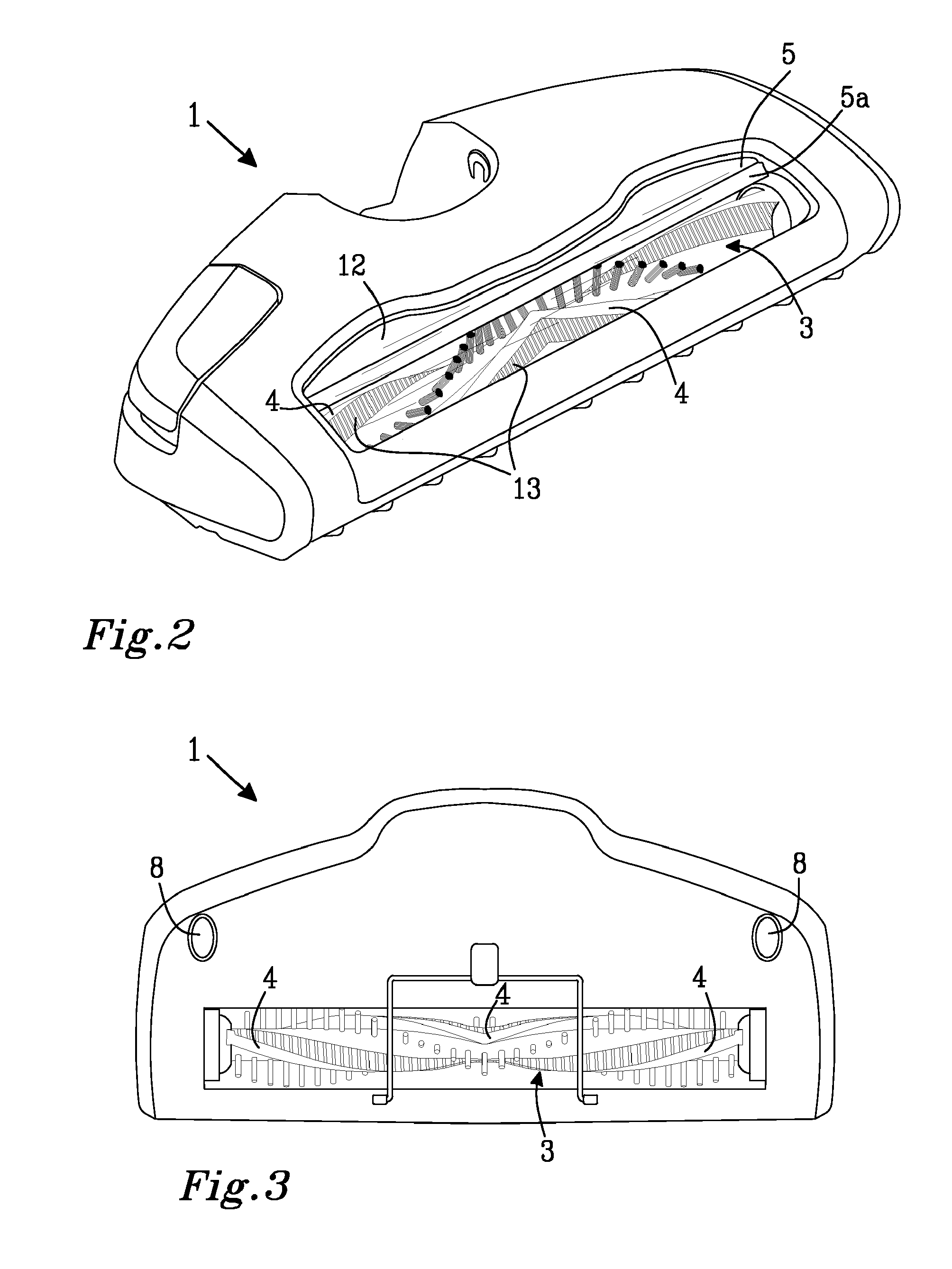

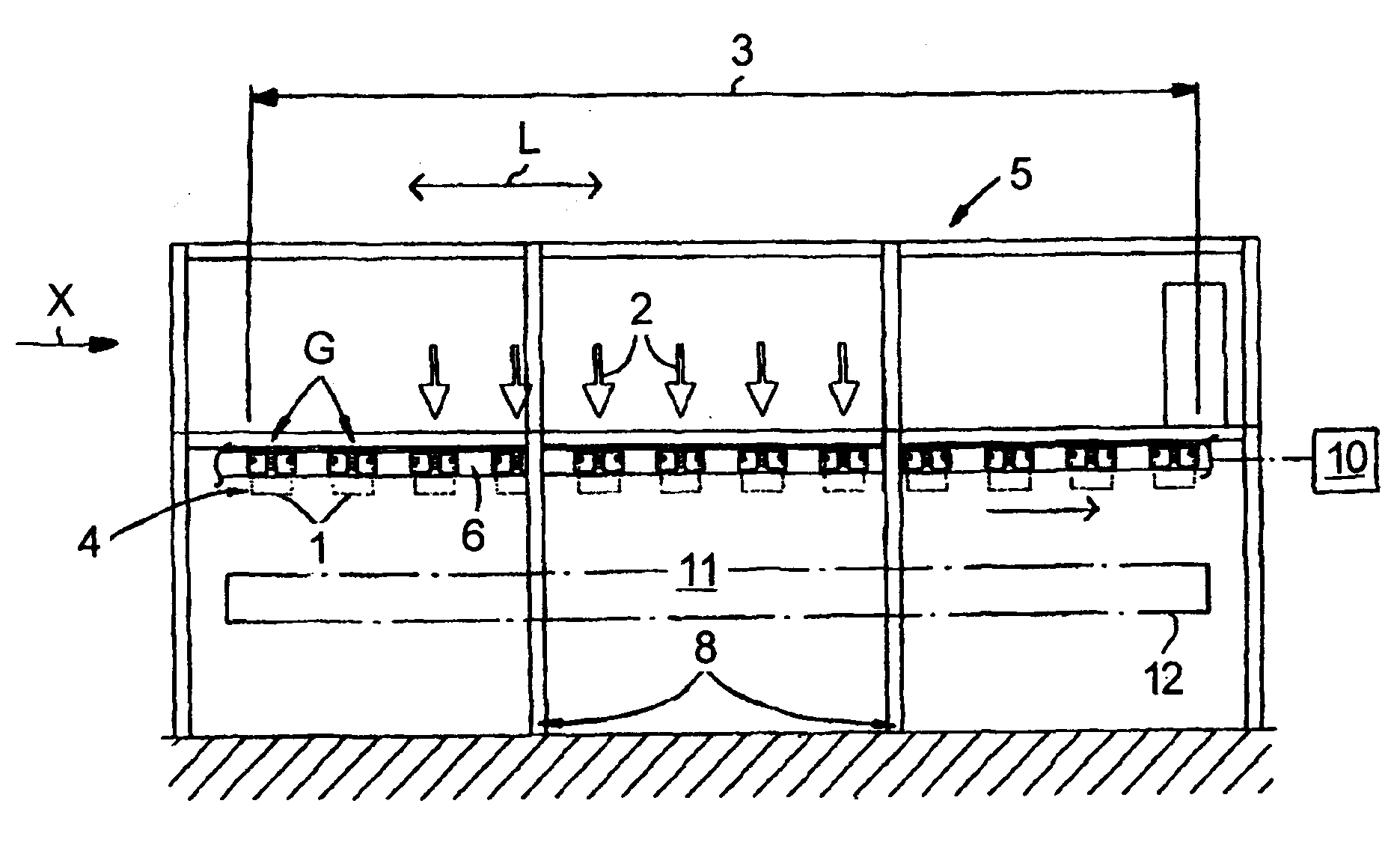

Handheld mechanical soft-surface remediation (SSR) device and method of using same

InactiveUS20060288516A1Efficient executionIncrease the areaCarpet cleanersFloor cleanersParticulatesRestoration device

A handheld mechanical soft-surface remediation (SSR) device and method of dislodging, displacing, and disposing of particulates from surfaces and performing disinfection and / or freshening is disclosed. The device is preferably lightweight, easy-to-use and includes a fan assembly, filter assembly, flapper assembly, battery assembly, and chemical delivery system. Performing soft-surface remediation with the mechanical SSR device includes the steps of retrieving the device from storage, installing the consumables into the device, activating the device, performing the cleaning operation, deactivating the device, removing the consumables from device, preparing the device for the next use, storing the device and, optionally, recharging the batteries.

Owner:SAWALSKI MICHAELM

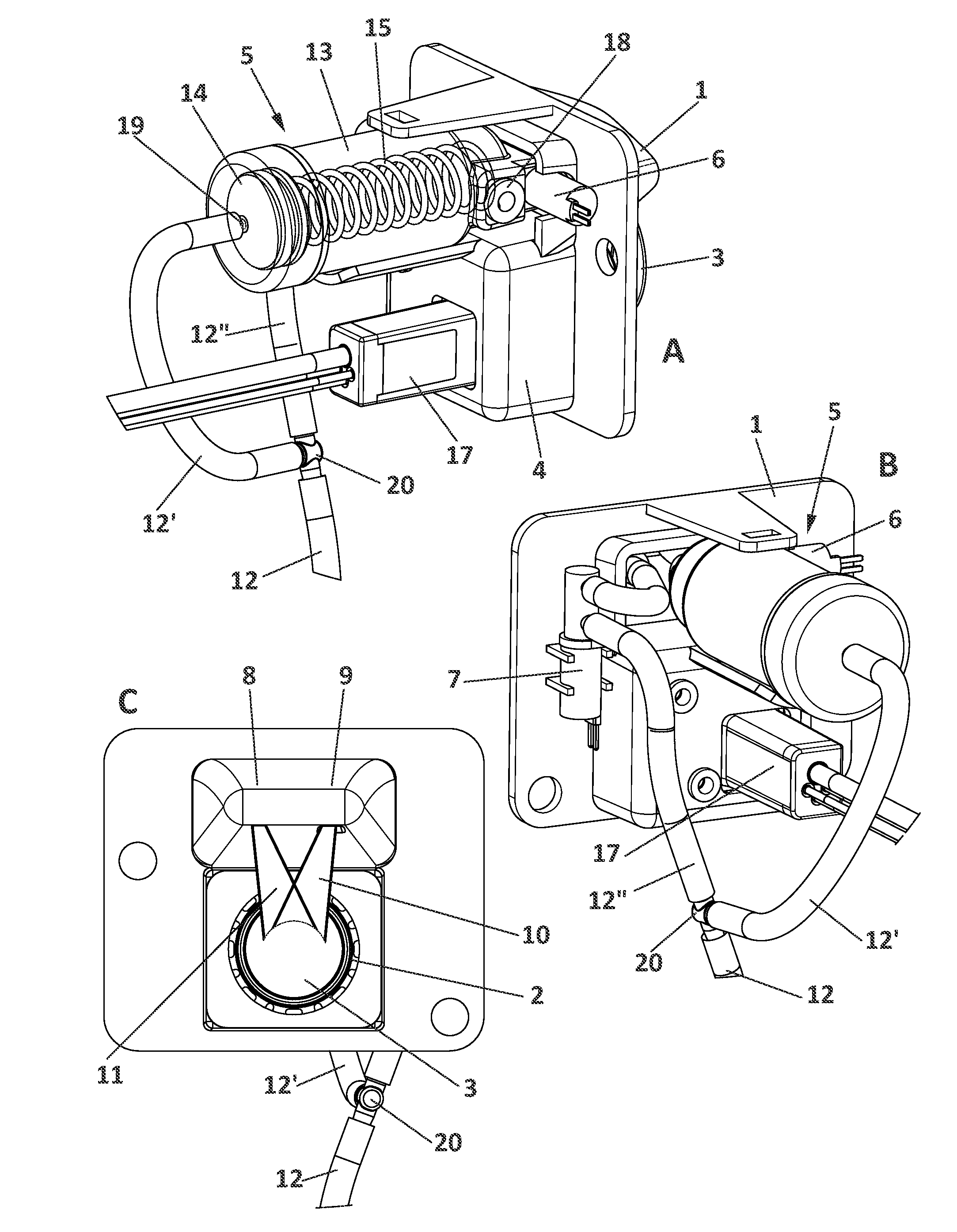

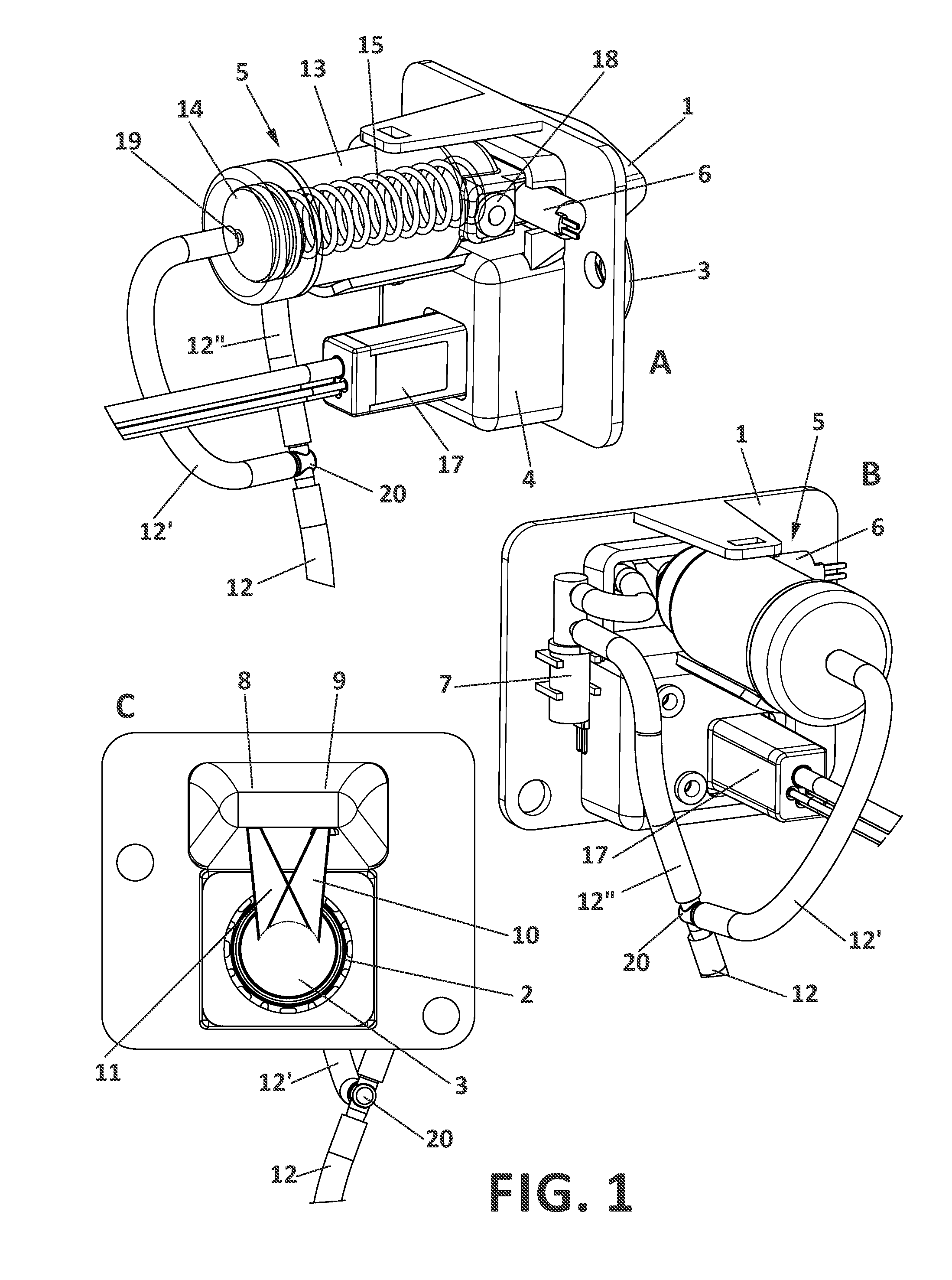

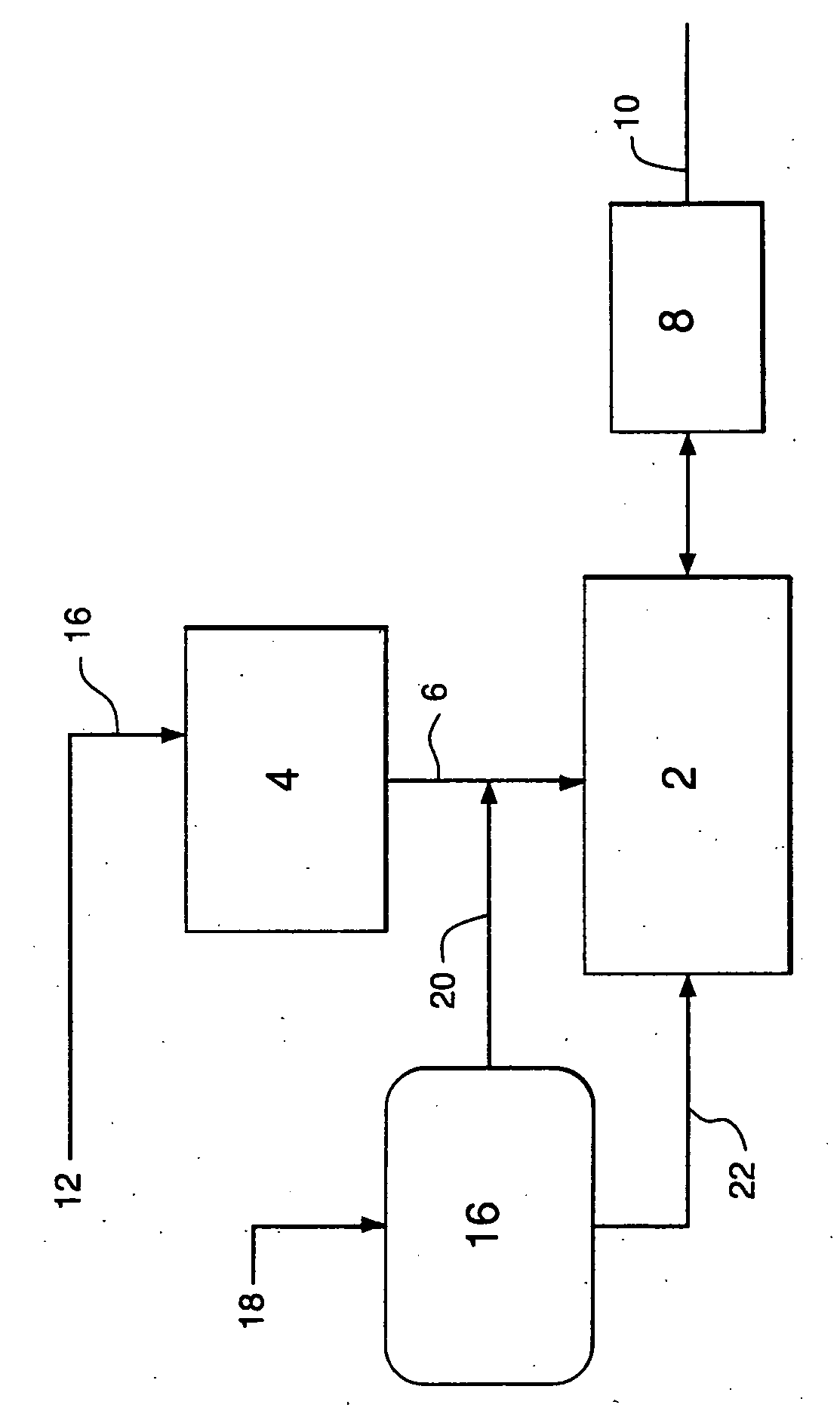

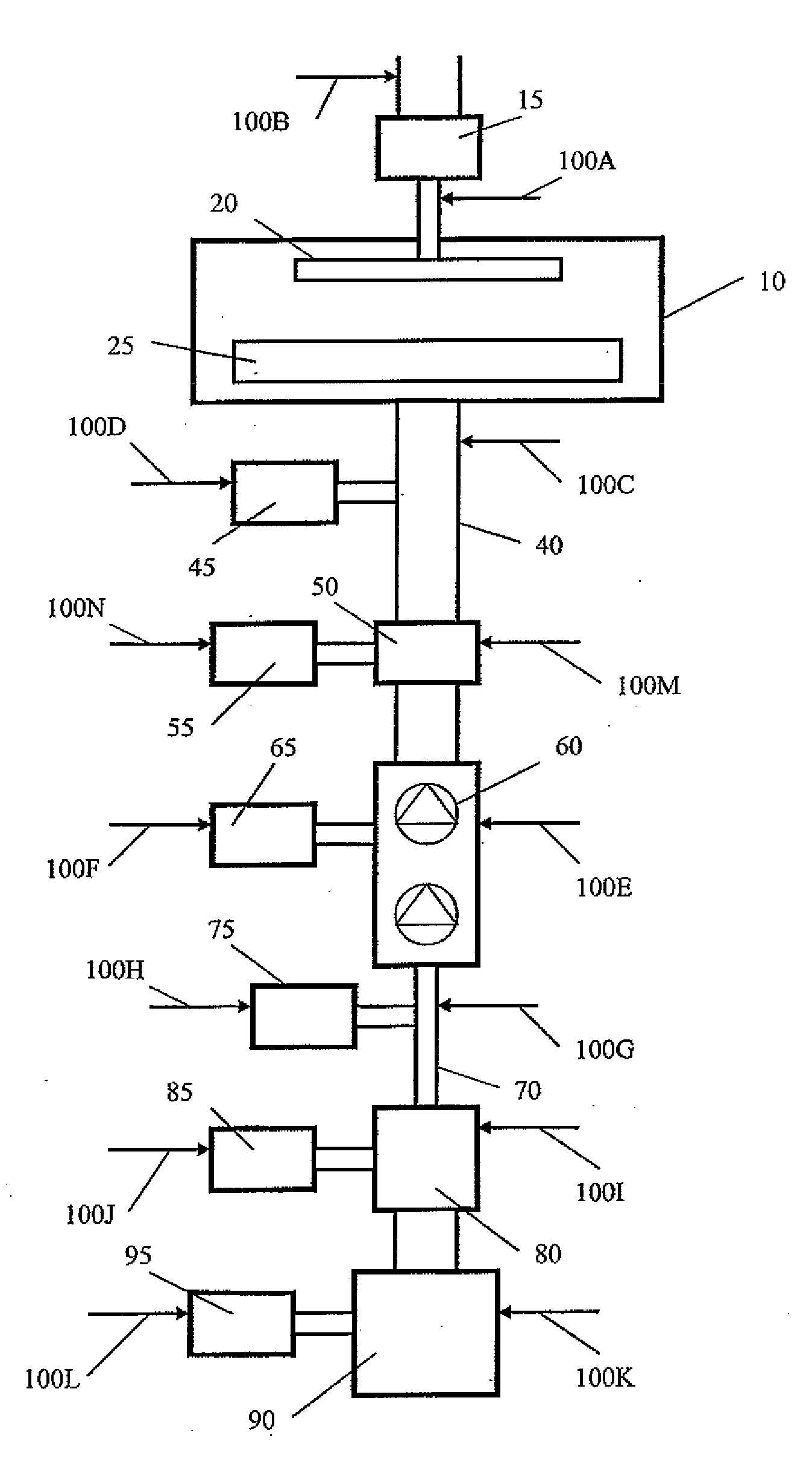

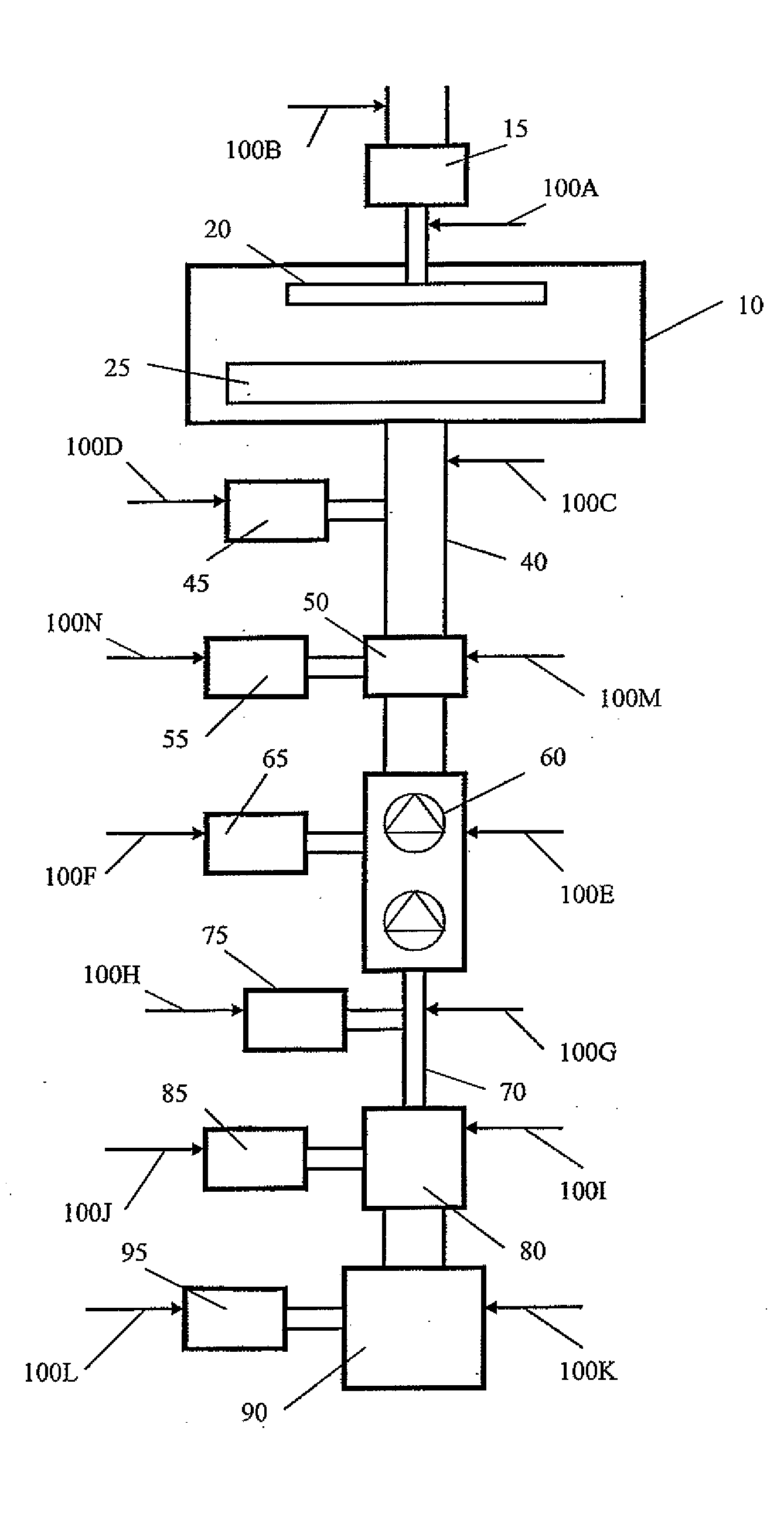

System and method for cleaning a vehicle-mounted optic lens

ActiveUS20150343999A1Reduce in quantityCompletely processedVehicle cleaningCleaning using liquidsCamera lensOptic lens

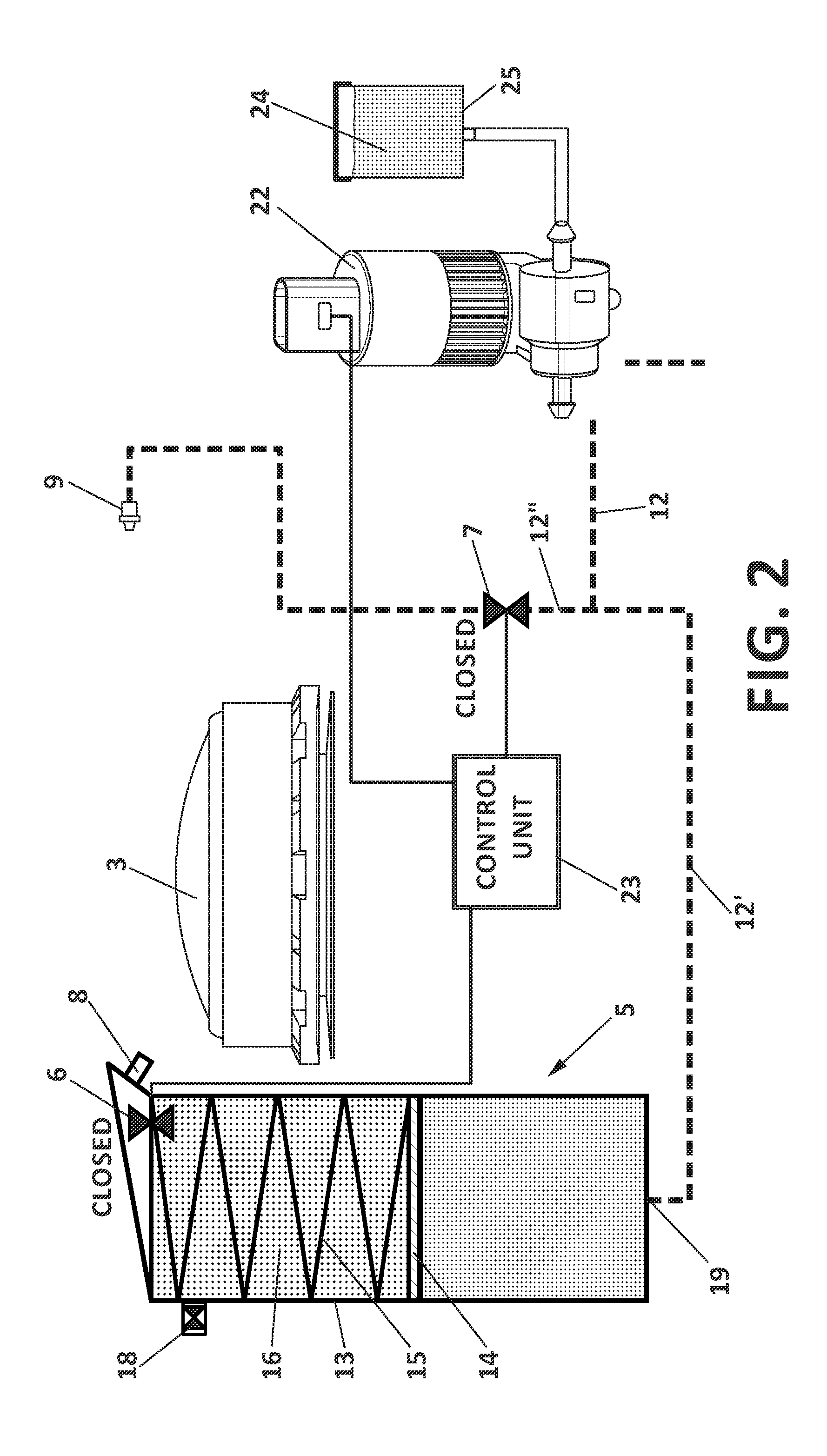

The present invention refers a system and a method for automatically cleaning an optic lens mounted on a vehicle, by spraying a washing liquid to remove any type of dirt from the lens such as a clear image or optic signal can be captured anytime, where an air pump is provided including a variable volume compression chamber to pressurize a volume of air, and a washing liquid conduit is communicated with a liquid nozzle and with the air pump, such as the air pump can be operated by the flow of pressurized washing liquid, such as the same flow of pressurized washing liquid is used to clean the optic surface, and to operate the air pump and generate a blast of air to blow off any liquid drop from the optic lens.

Owner:FICO TRANSPAR

Flow splitter arrangement for series fed product application units

ActiveUS7025010B2Avoid cloggingReduce in quantityPotato plantersFurrow making/coveringVelocity vectorInlet flow

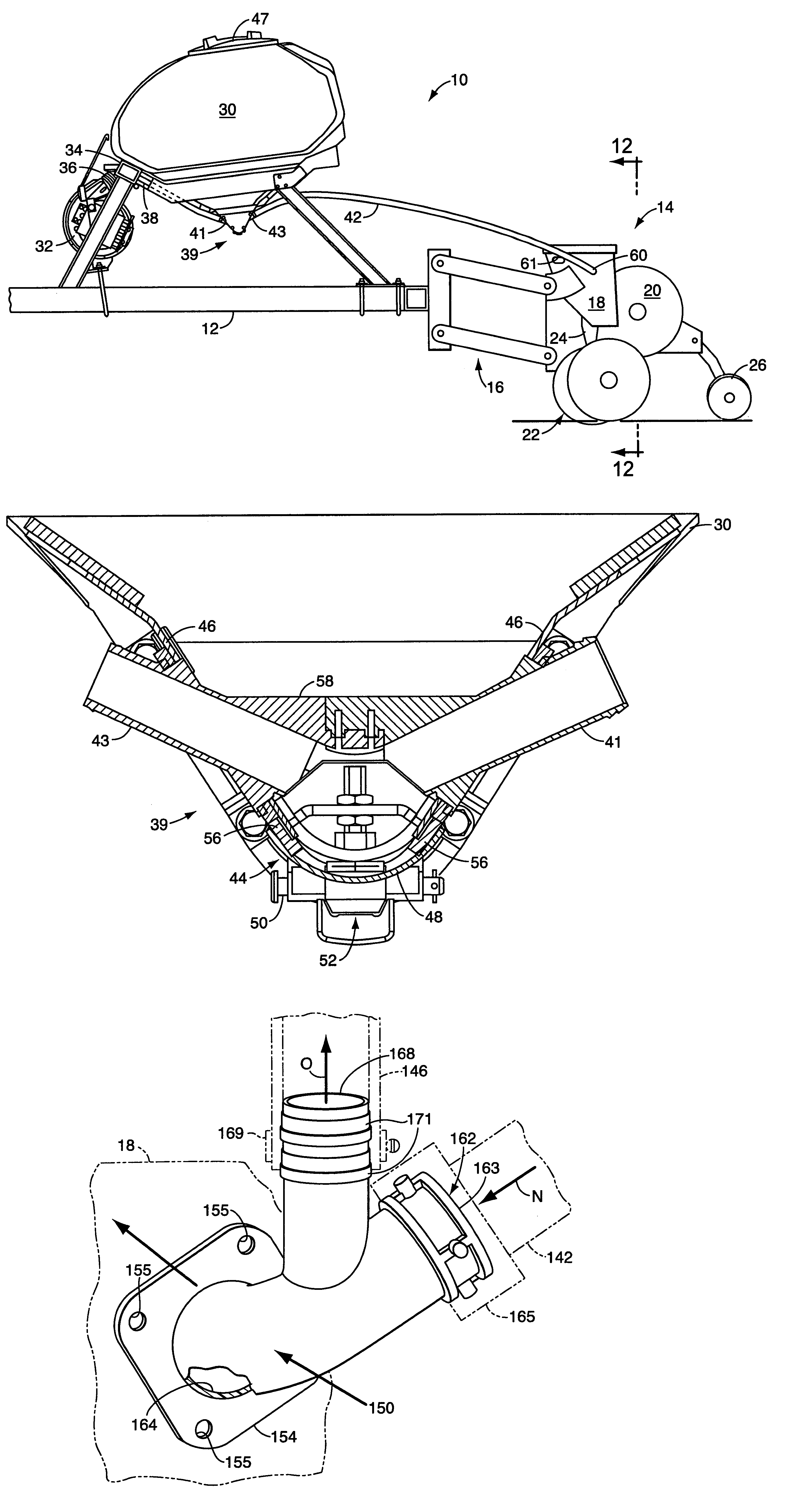

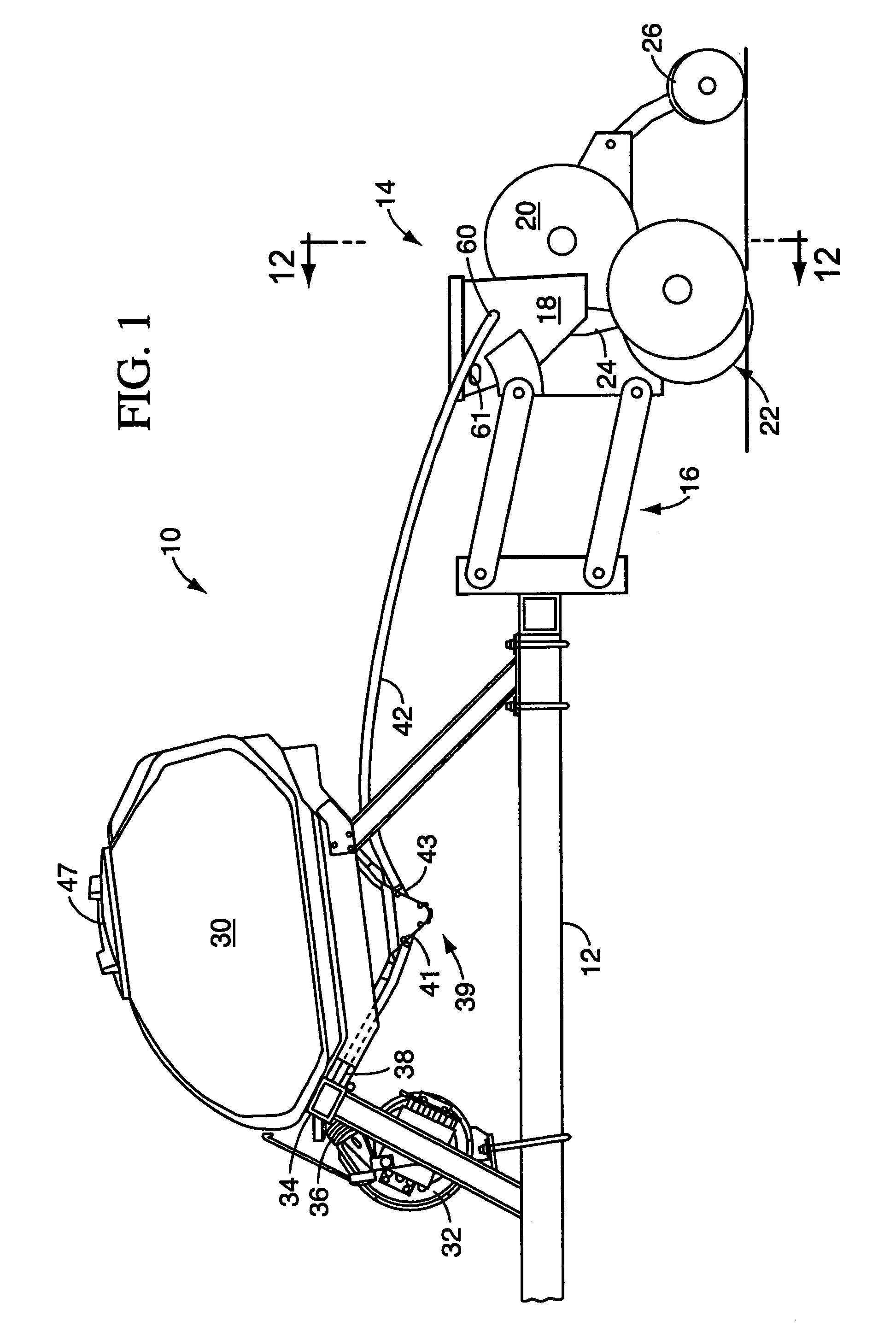

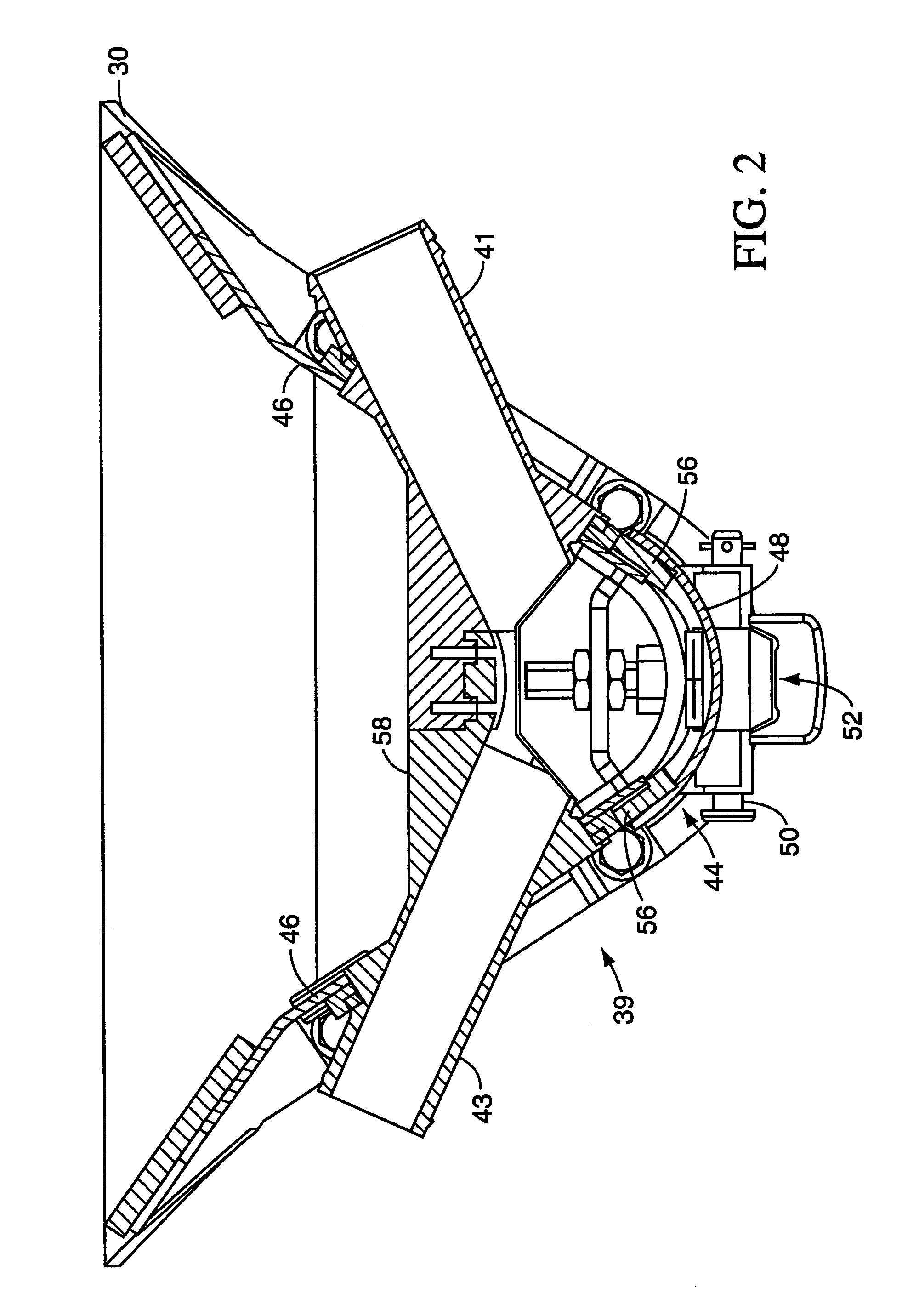

A product-on-demand delivery system applies an agricultural product, such as seed, to a field. The system includes a frame that mounts a main hopper, a splitter fitting, a primary product hose, a secondary product hose, a primary application unit and a secondary application unit. The main hopper has an air nozzle wherein an air stream through the air nozzle entrains product within the air stream and delivers the air / product to the primary outlet hose. The splitter fitting has a splitter inlet flow-connected to the primary product hose and two splitter outlets flow-connected to the application units. The secondary application unit is coupled to the primary product supply hose by the secondary product hose connected at an outlet branch. The outlet branch is connected at an angle such that a product flow velocity vector in the primary product supply hose at the outlet branch is at an obtuse angle to a flow velocity vector of product flowing through the outlet branch. The outlet branch is oriented for a vertical upward flow of air and product.

Owner:DEERE & CO

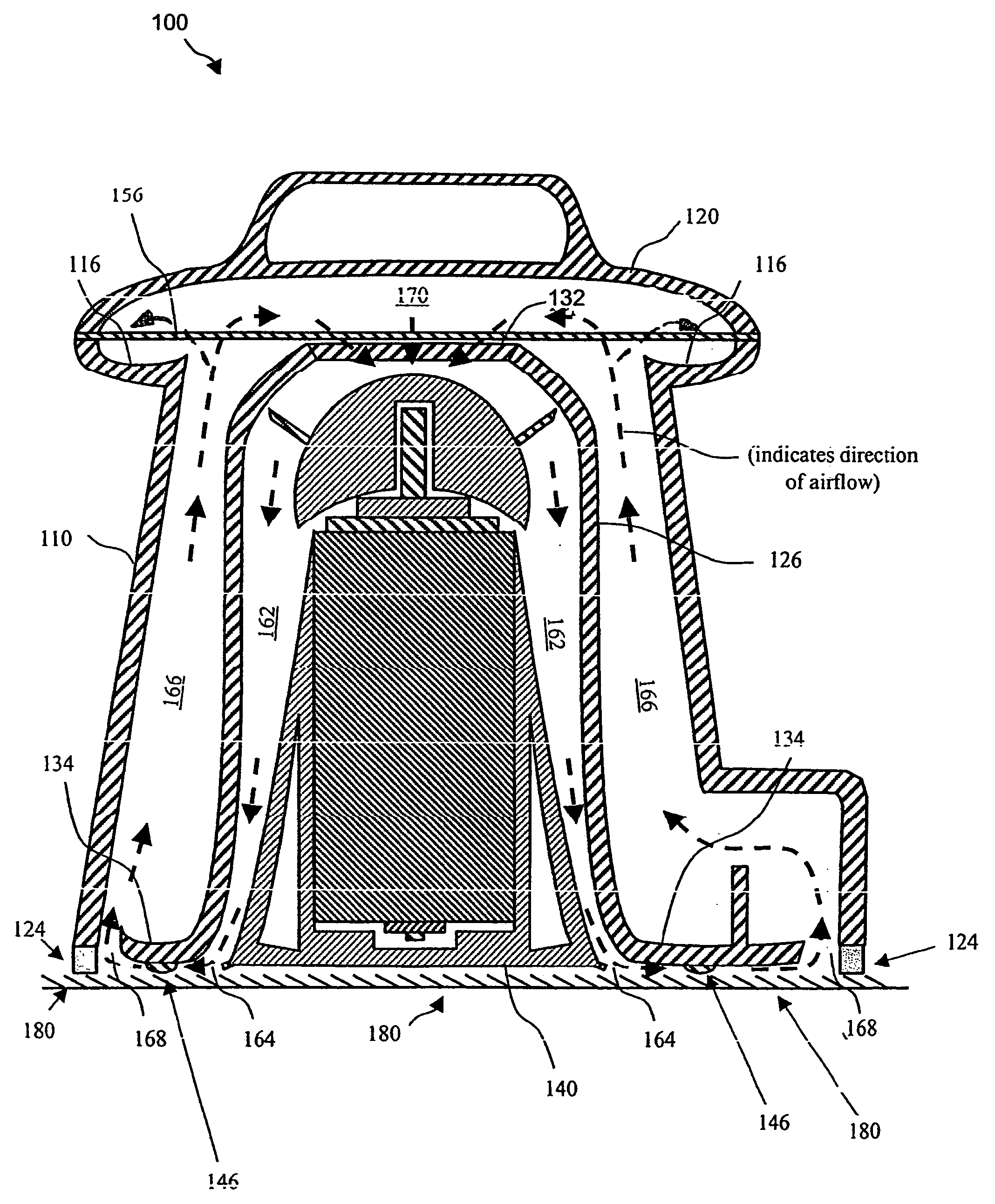

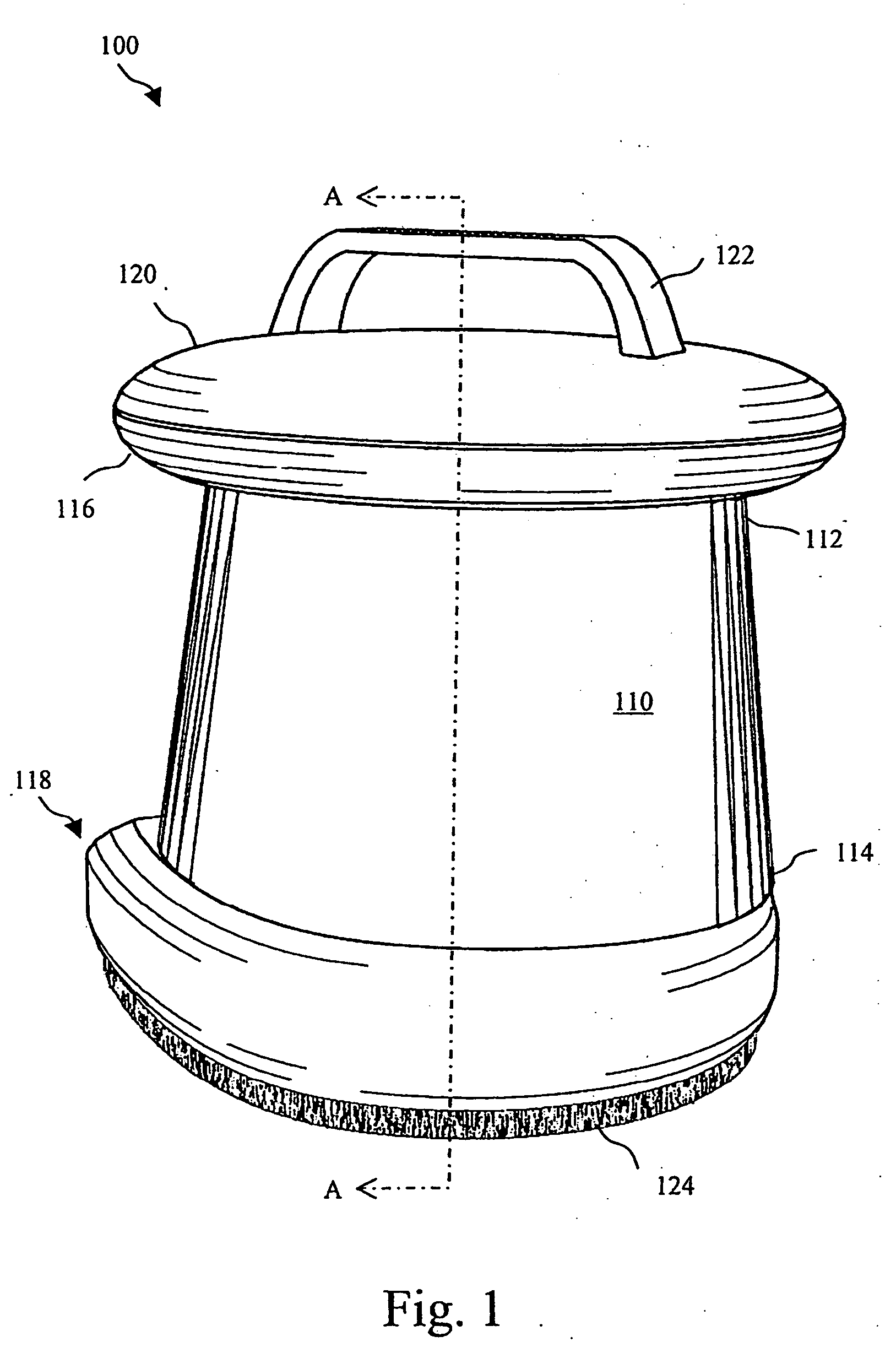

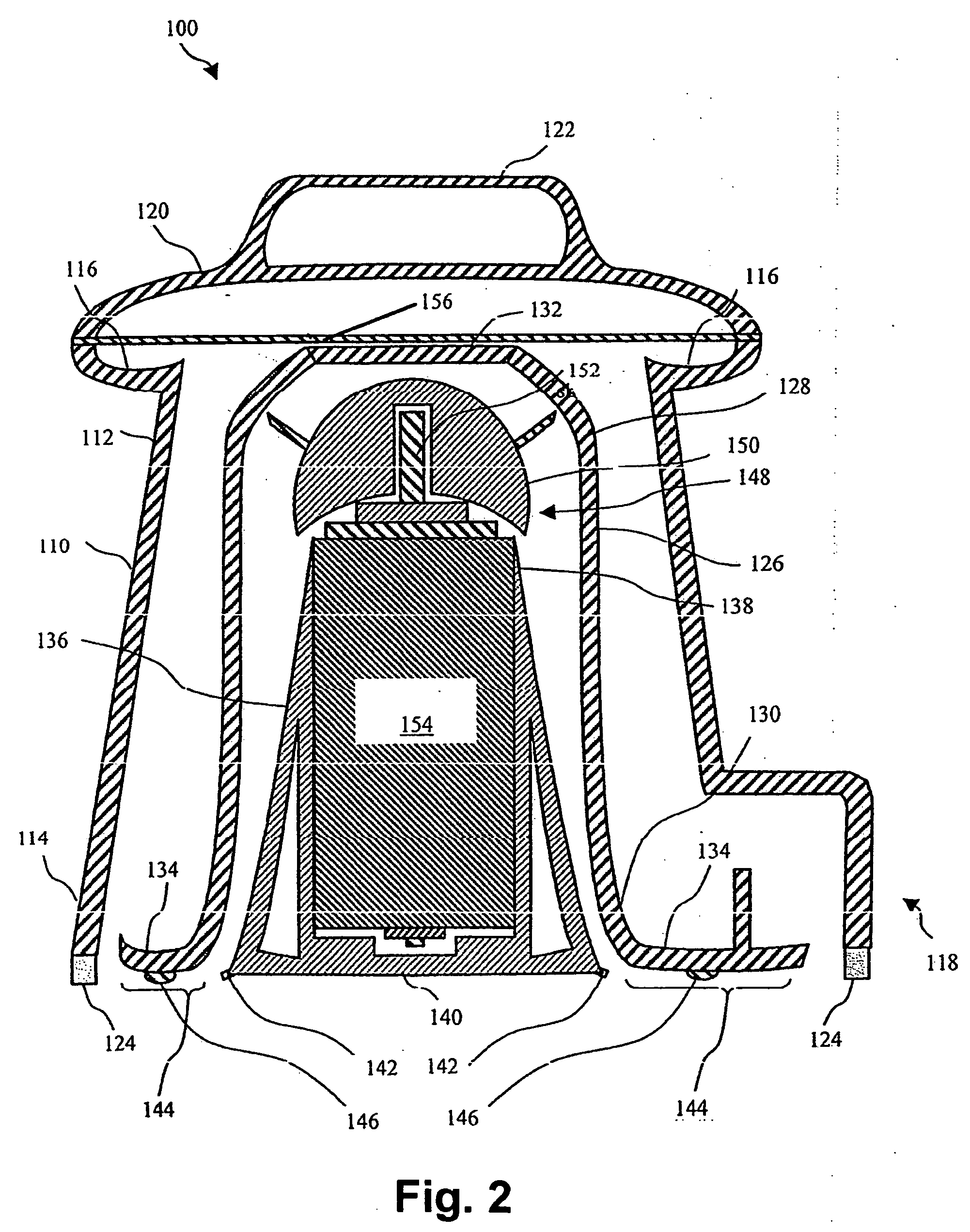

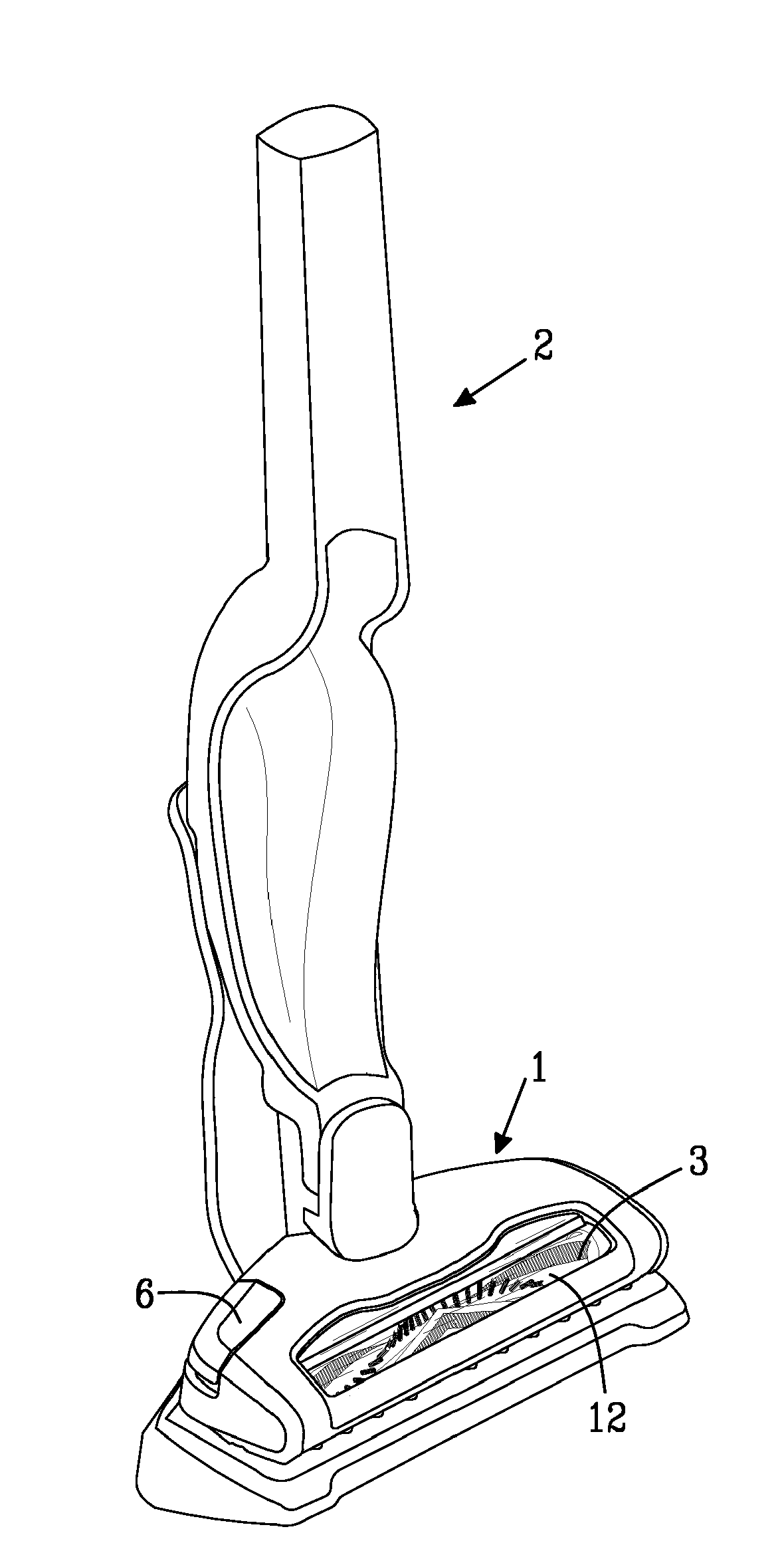

Soft-surface remediation device and method of using same

ActiveUS20060213025A1Efficient executionIncrease the areaCleaning filter meansMechanical cleaningForced-airWaste management

A soft-surface remediation (SSR) device and method of remediating soft surfaces using preferably forced air is disclosed. The device is lightweight, and easy-to-use and preferably includes an outer housing with an optional corner pickup region and a removable cover, an inner housing, a motor housing for housing a fan assembly, an optional disposal catch mechanism, an optional mounted delivery device, a first air channel with an air outlet, a second air channel with an air inlet, and a return air channel in close proximity to the disposal mechanism. The method of performing soft-surface remediation preferably includes use of this SSR device.

Owner:SC JOHNSON & SON INC

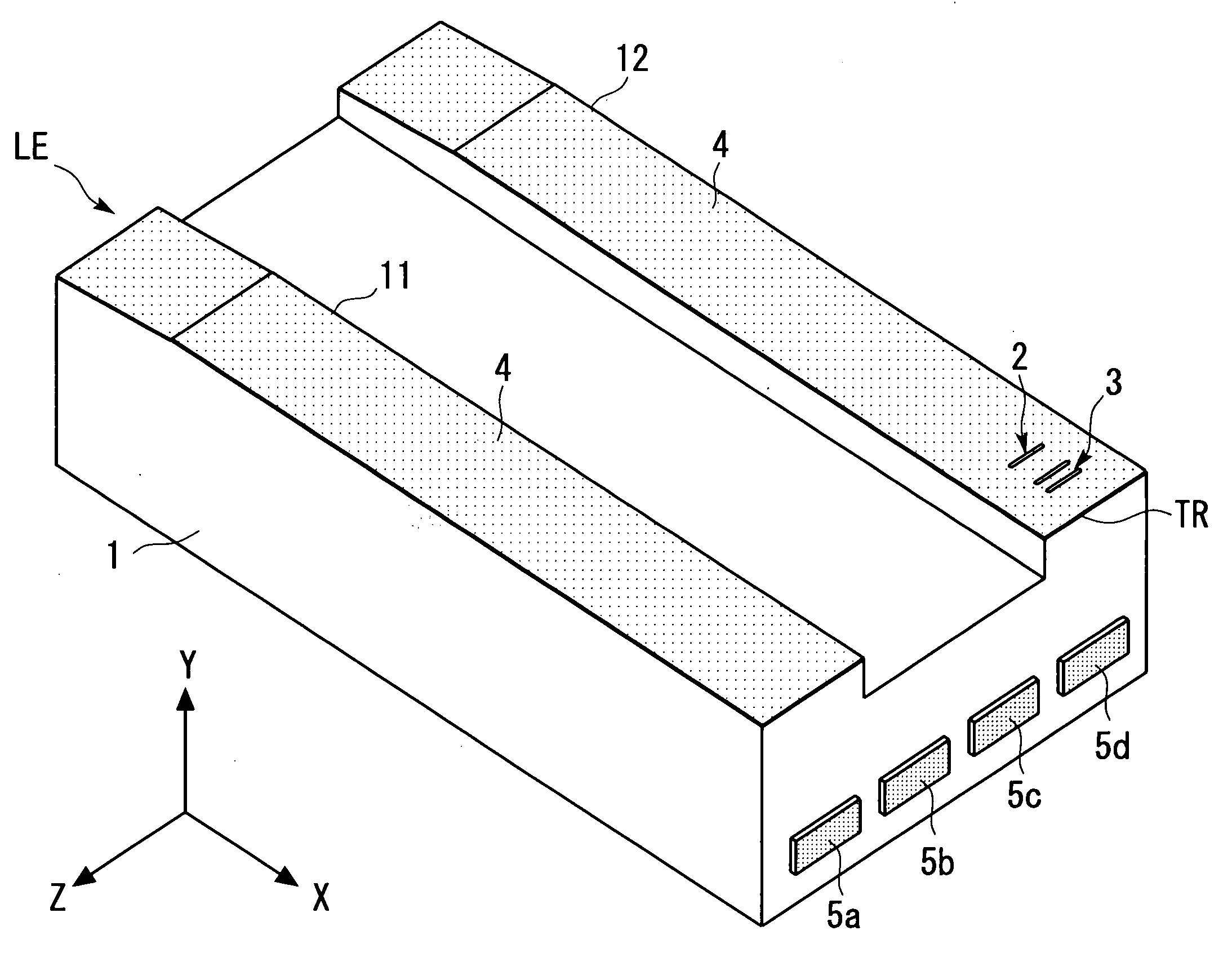

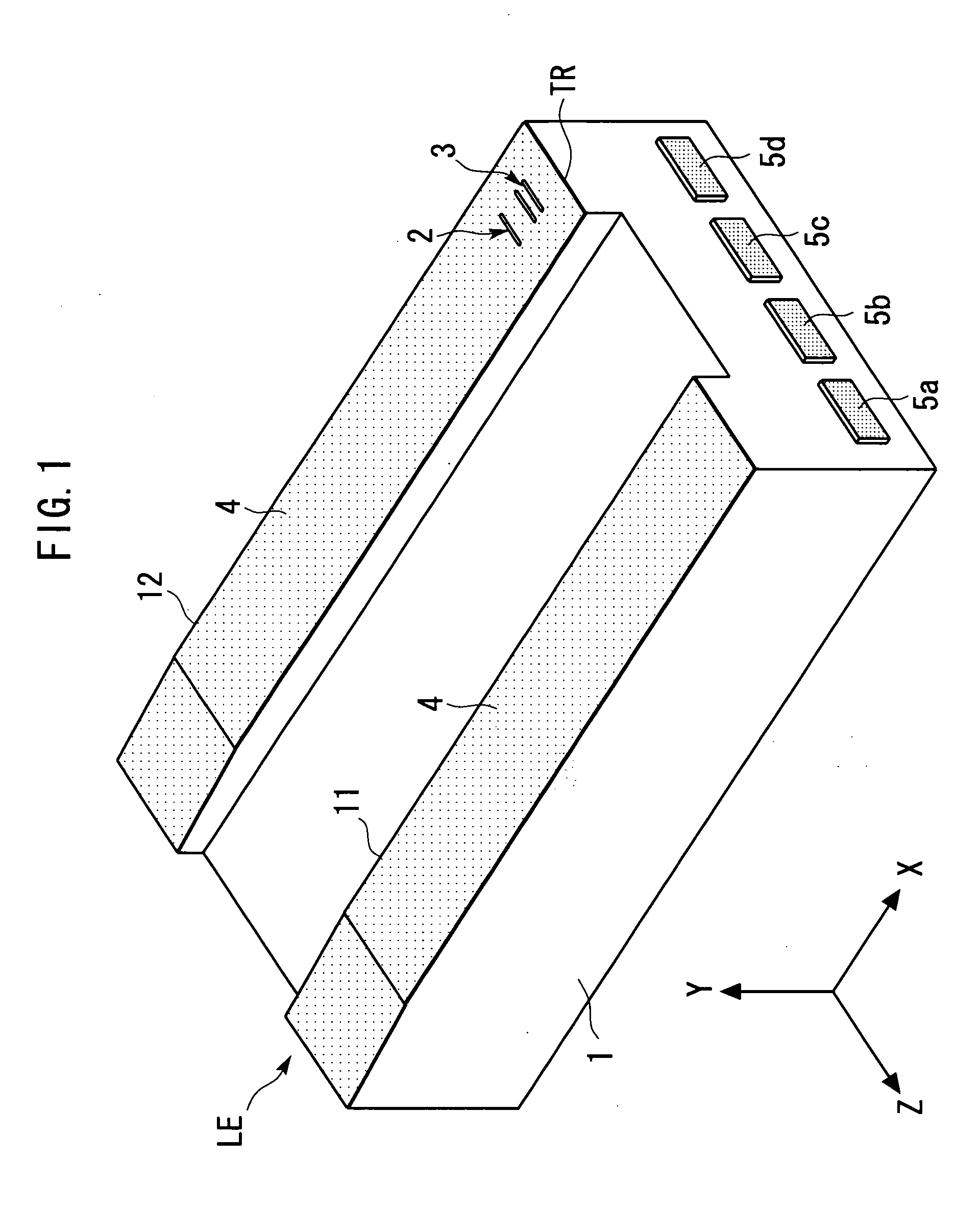

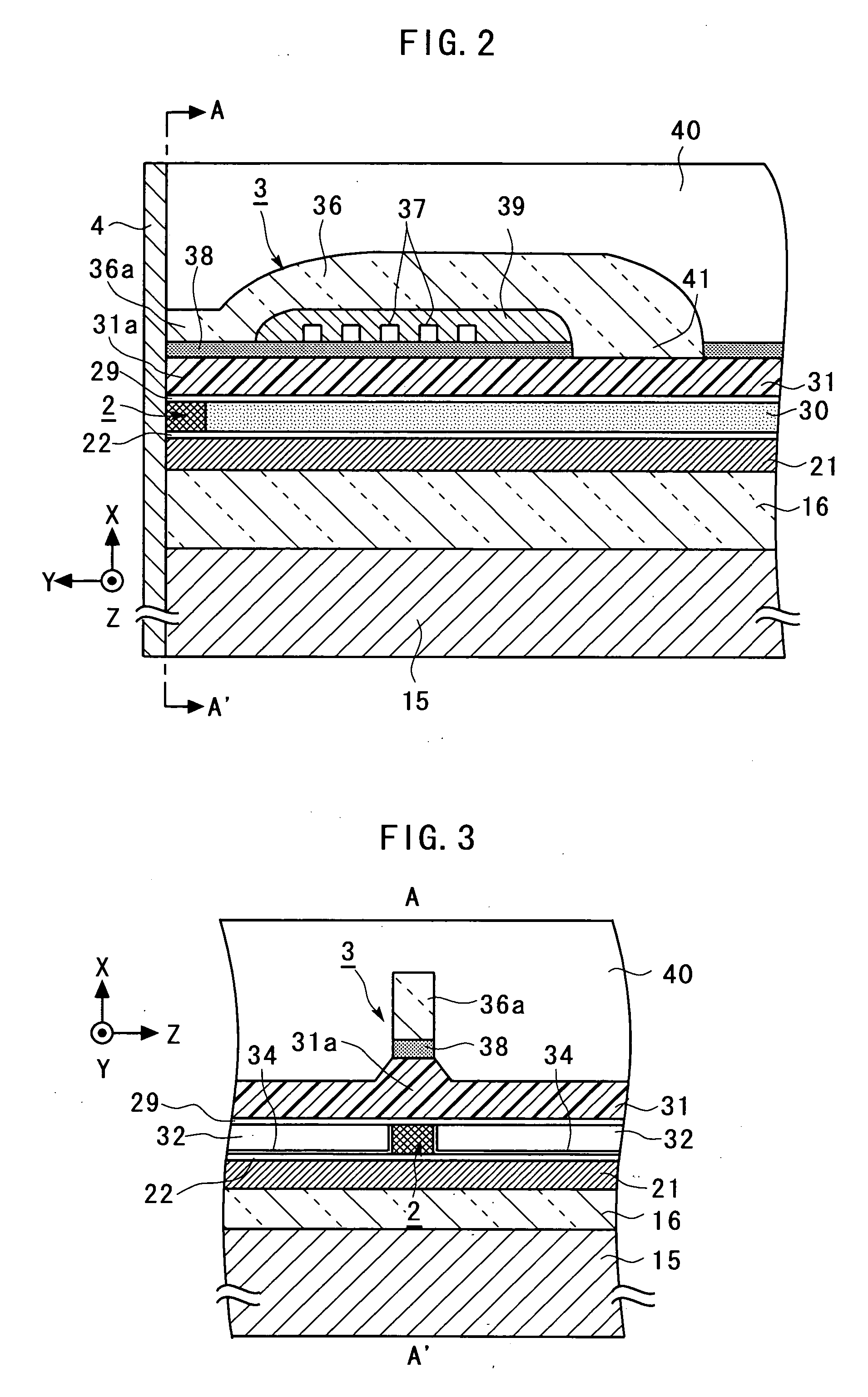

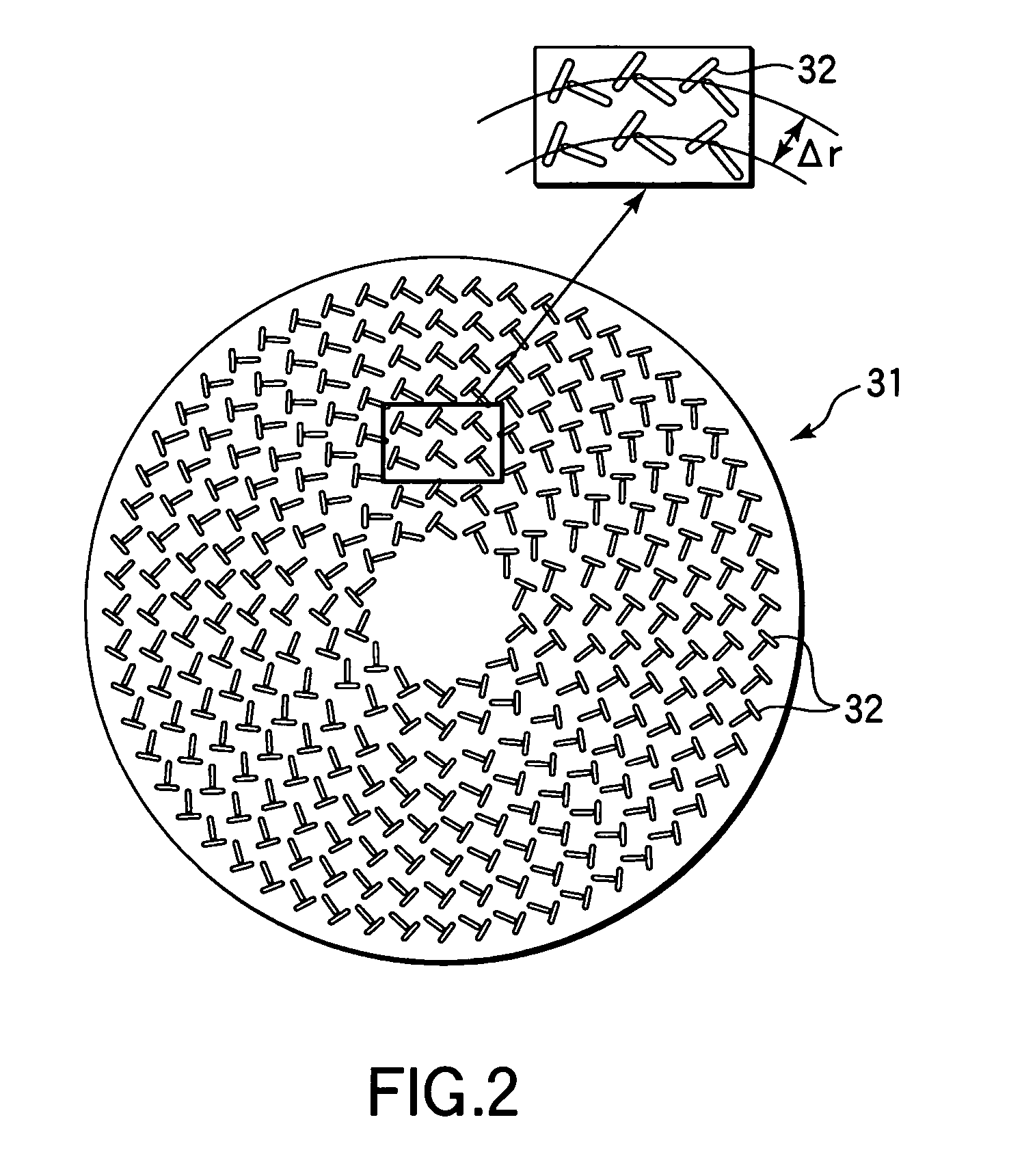

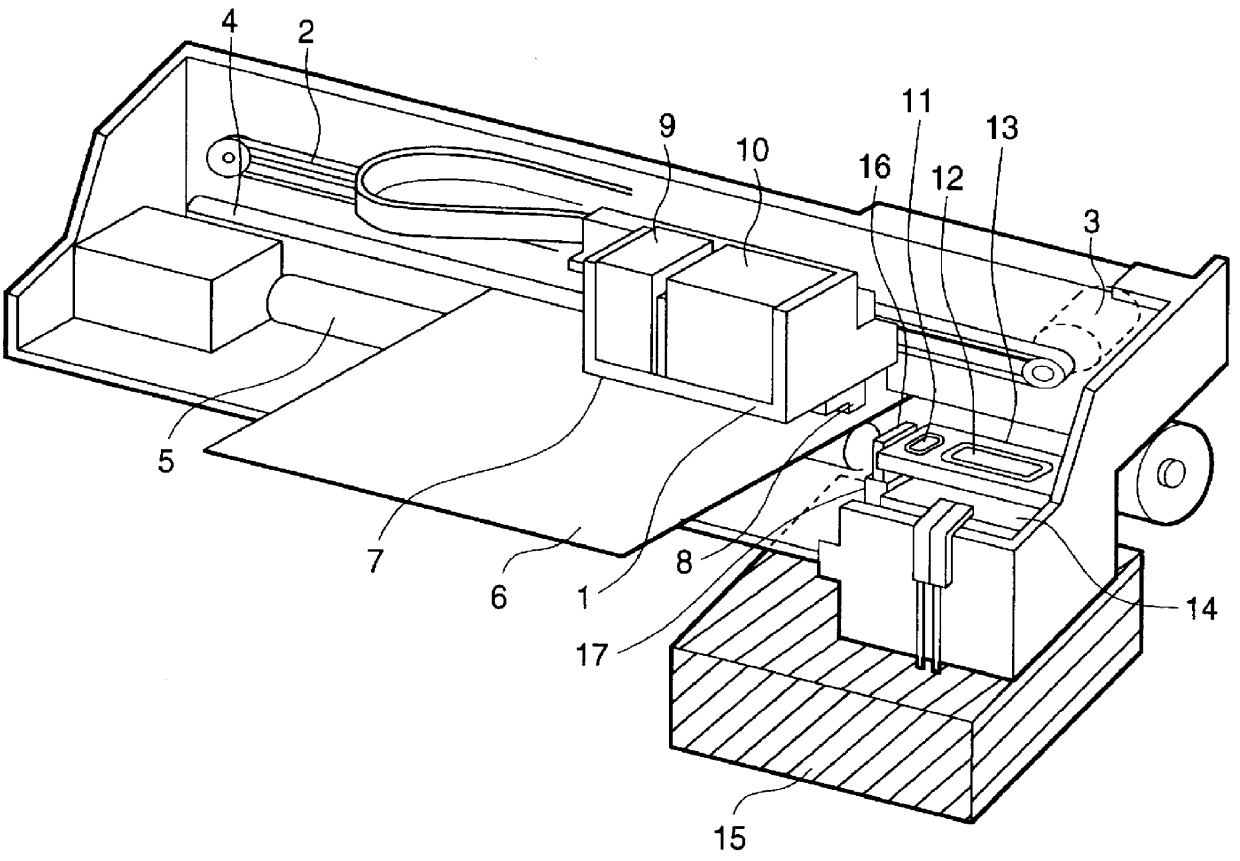

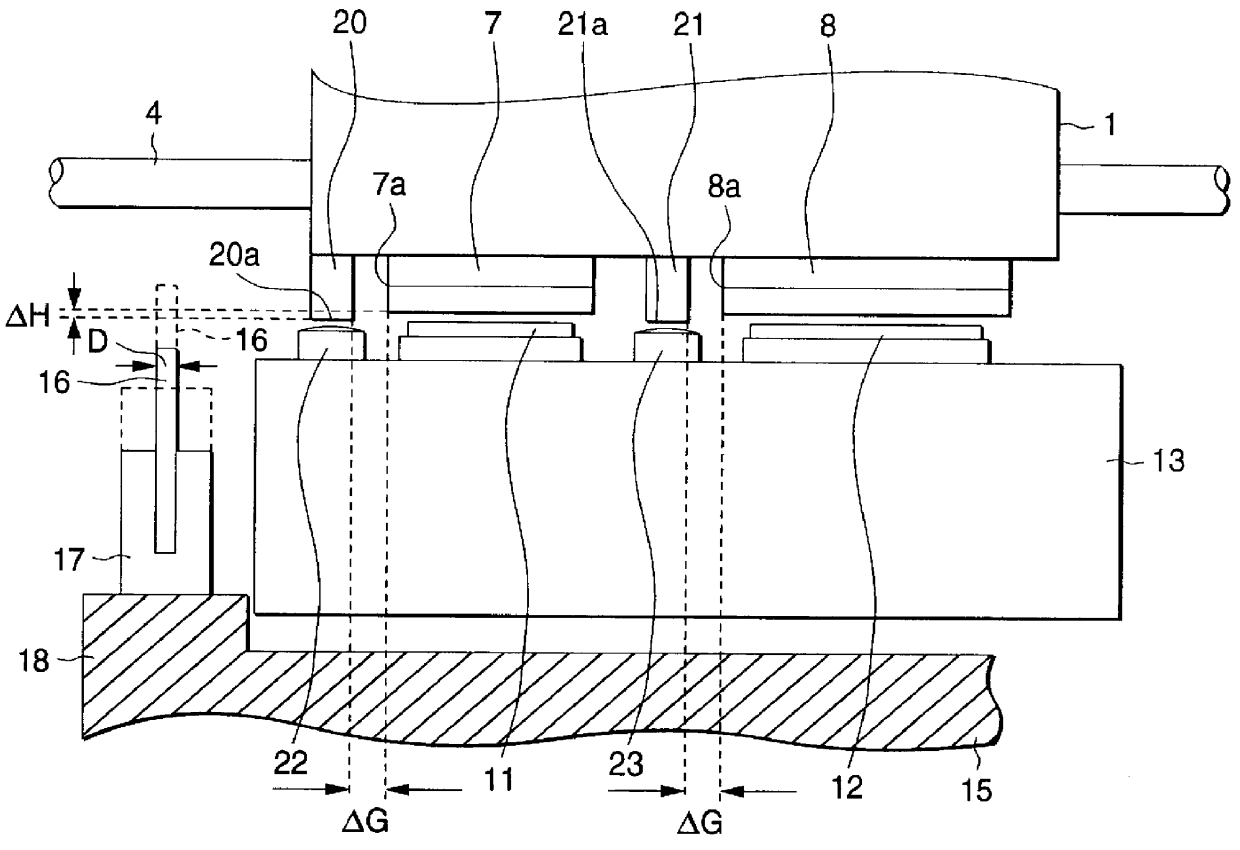

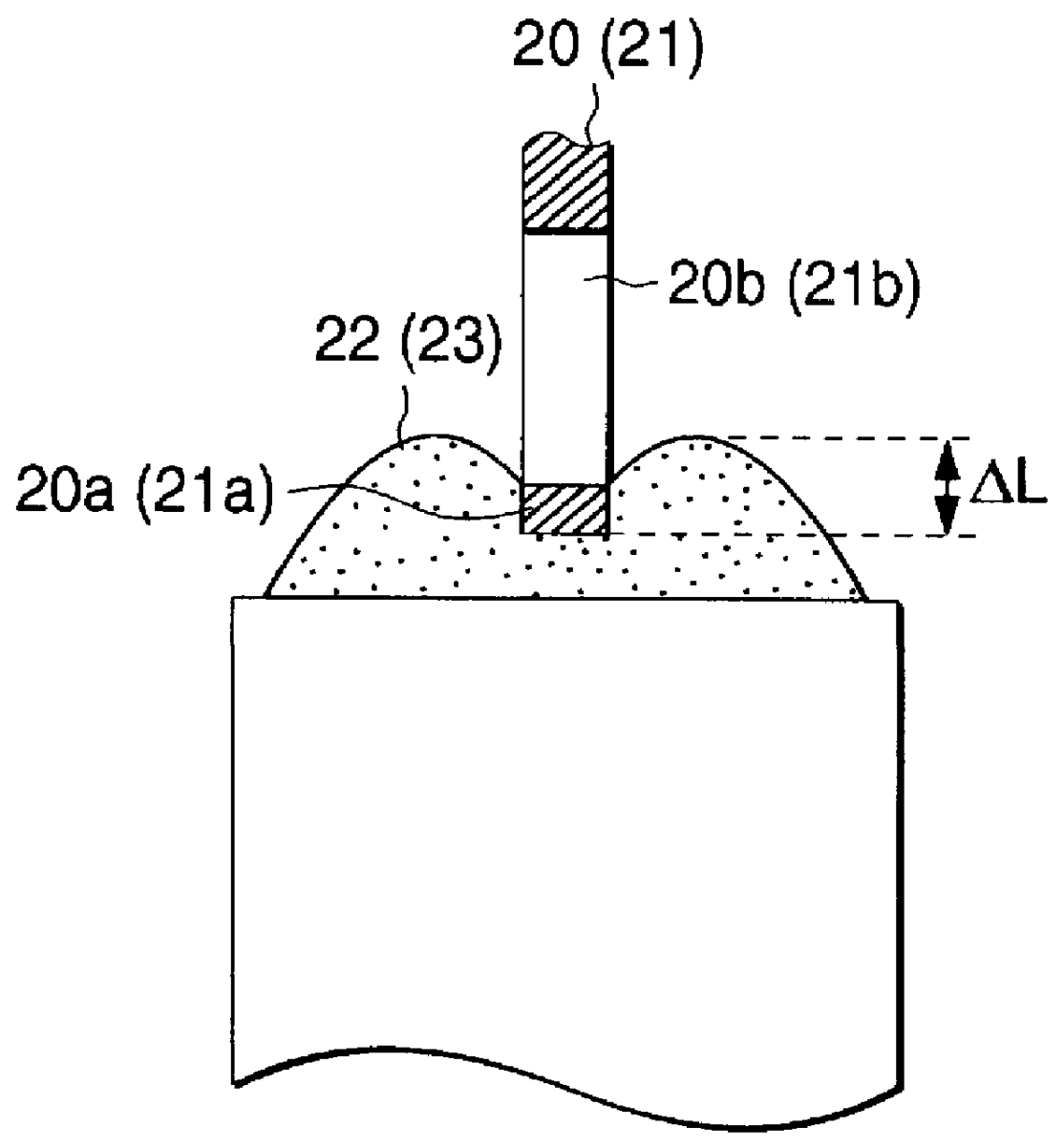

Magneto-resistive device, and magnetic head, head suspension assembly and magnetic disk apparatus using magneto-resistive device

ActiveUS20050008849A1Increase in record densityCost reductionConstruction of head windingsNanomagnetismMagnetic disksHigh oxygen

A magneto-resistive device is provided for contributing to a higher MR ratio and a reduced cleaning time for cleaning the surface of a cap layer. In the magneto-resistive device, a cap layer which serves as a protection layer is formed on a free layer which is the topmost layer of a magneto-resistive layer constituting a TMR devise. An upper electrode which is additionally used as an upper magnetic shield is electrically connected to the free layer through an upper metal layer. The cap layer comprised of a two-layer film made up of a conductive layer closer to the free layer and a topmost conductive layer. The conductive layer closer to the free layer is made of a material having higher oxygen bond energy than Ru, such as Zr, Hf, or the like. The topmost conductive layer is made of a material having lower oxygen bond energy, such as a noble metal or the like.

Owner:TDK CORPARATION

Cleaning solution for cleaning substrate for semiconductor devices and cleaning method using the same

InactiveUS20050020463A1Less cleaningImprove removabilityInorganic/elemental detergent compounding agentsSurface-active detergent compositionsOrganic acidDevice material

A cleaning solution for cleaning a substrate for semiconductor devices and a cleaning method using the said cleaning solution, which comprises at least the following components (A), (B) and (C): (A) an ethyleneoxide-type surfactant containing a hydrocarbon group which may have a substituent group except for phenyl, and a polyoxyethylene group in which a ratio (m / n) of a number (m) of carbon atoms contained in the hydrocarbon group to a number (n) of oxyethylene groups contained in the polyoxyethylene group is in the range of 1 to 1.5, the number (m) of carbon atoms is not less than 9, and the number (n) of oxyethylene groups is not less than 7; (B) water; and (C) alkali or an organic acid. The cleaning solution highly clean the surface of the substrate without occurrence of corrosion by removing fine particles and organic contaminants which are adhered onto the surface of the substrate.

Owner:MITSUBISHI CHEM CORP

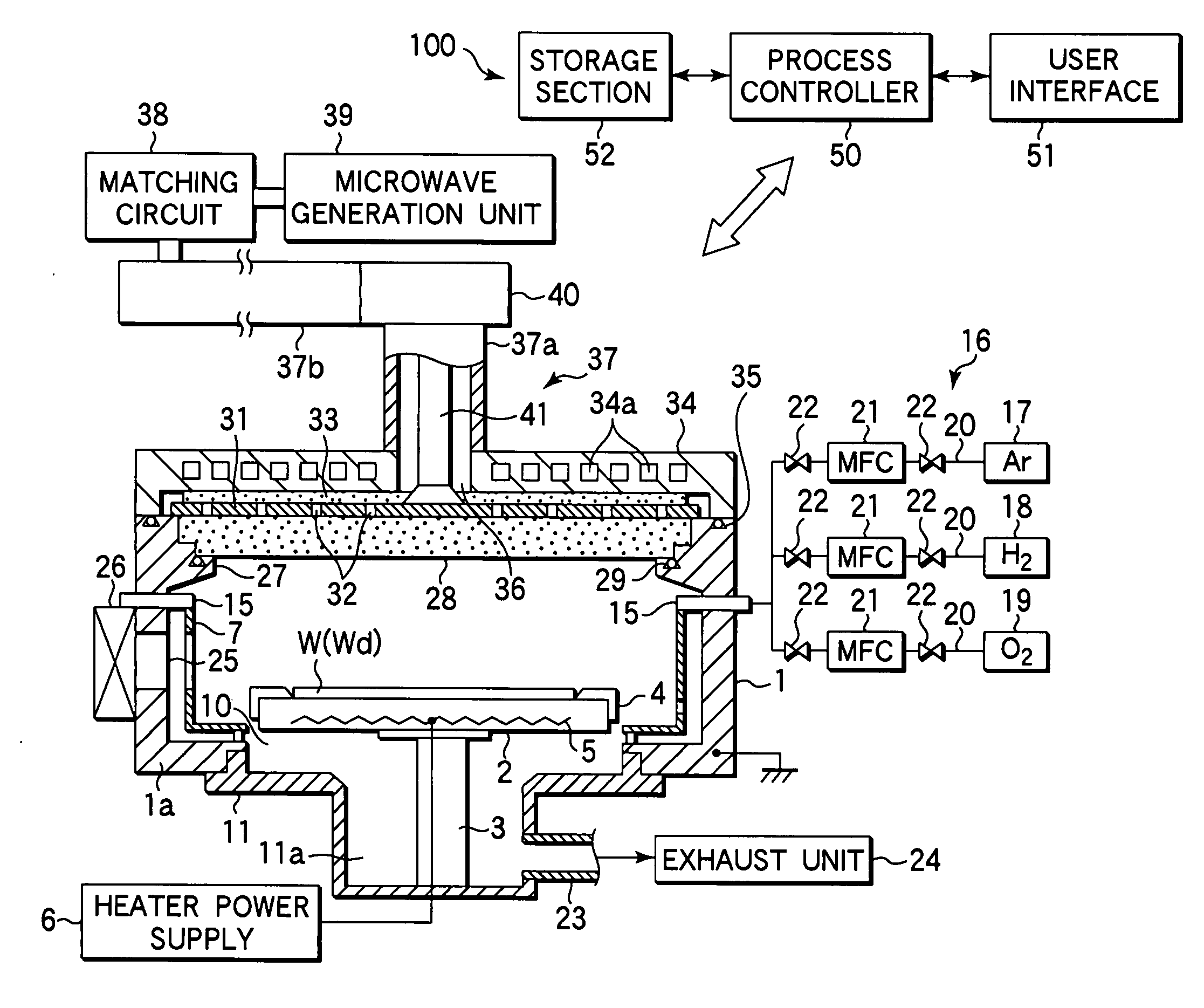

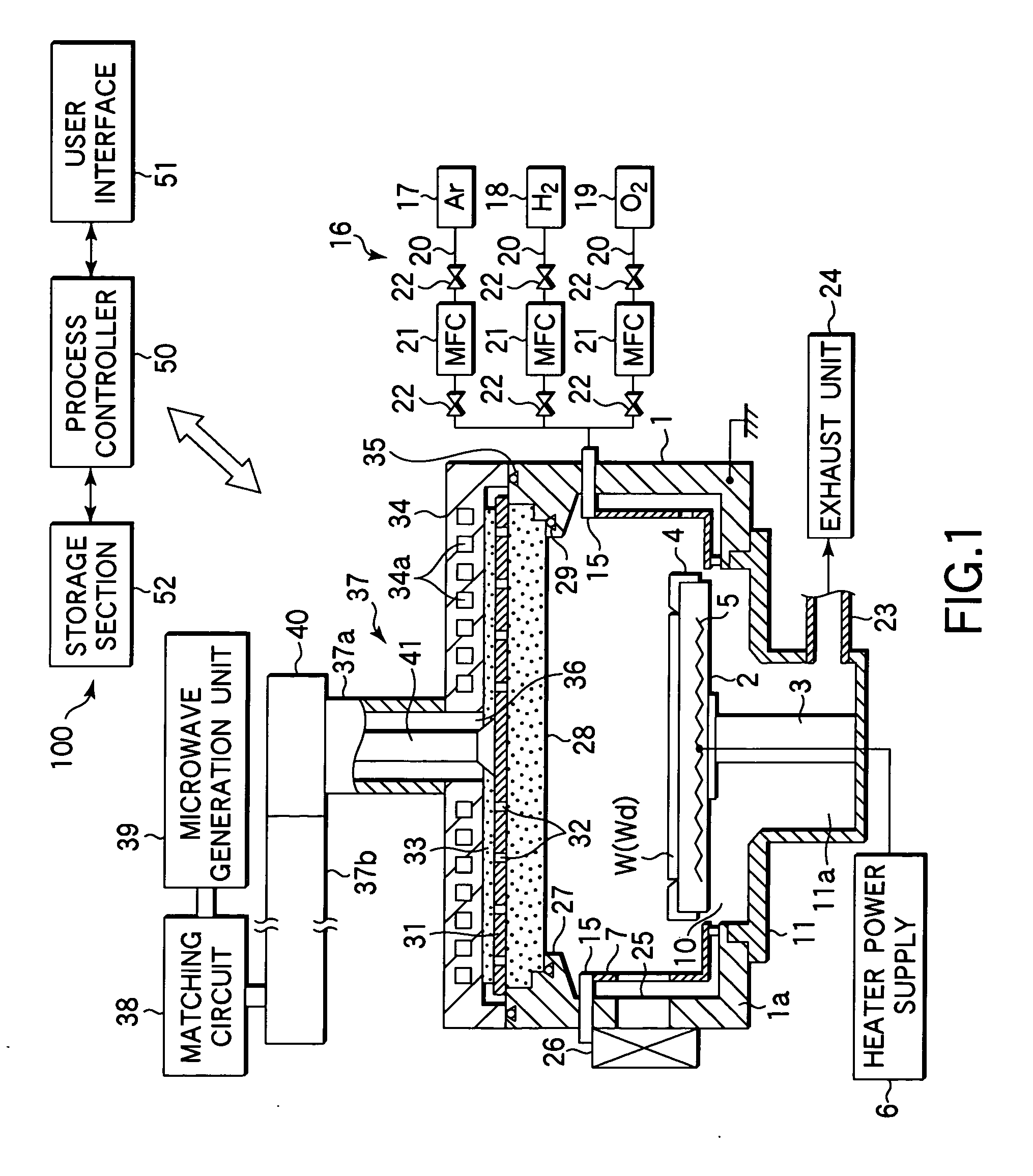

Method for cleaning treatment chamber iIn substrate treating apparatus and method for detecting endpoint of cleaning

InactiveUS20070163617A1Easy to cleanLess cleaningElectric discharge tubesDecorative surface effectsProcess engineeringTungsten

In a substrate processing apparatus for performing a plasma process on a substrate including a tungsten-containing film, cleaning is performed for a process chamber. This cleaning includes, after the plasma process, supplying a gas containing O2 into the process chamber without setting the process chamber opened to the atmosphere, and generating plasma of the gas to clean the process chamber.

Owner:TOKYO ELECTRON LTD

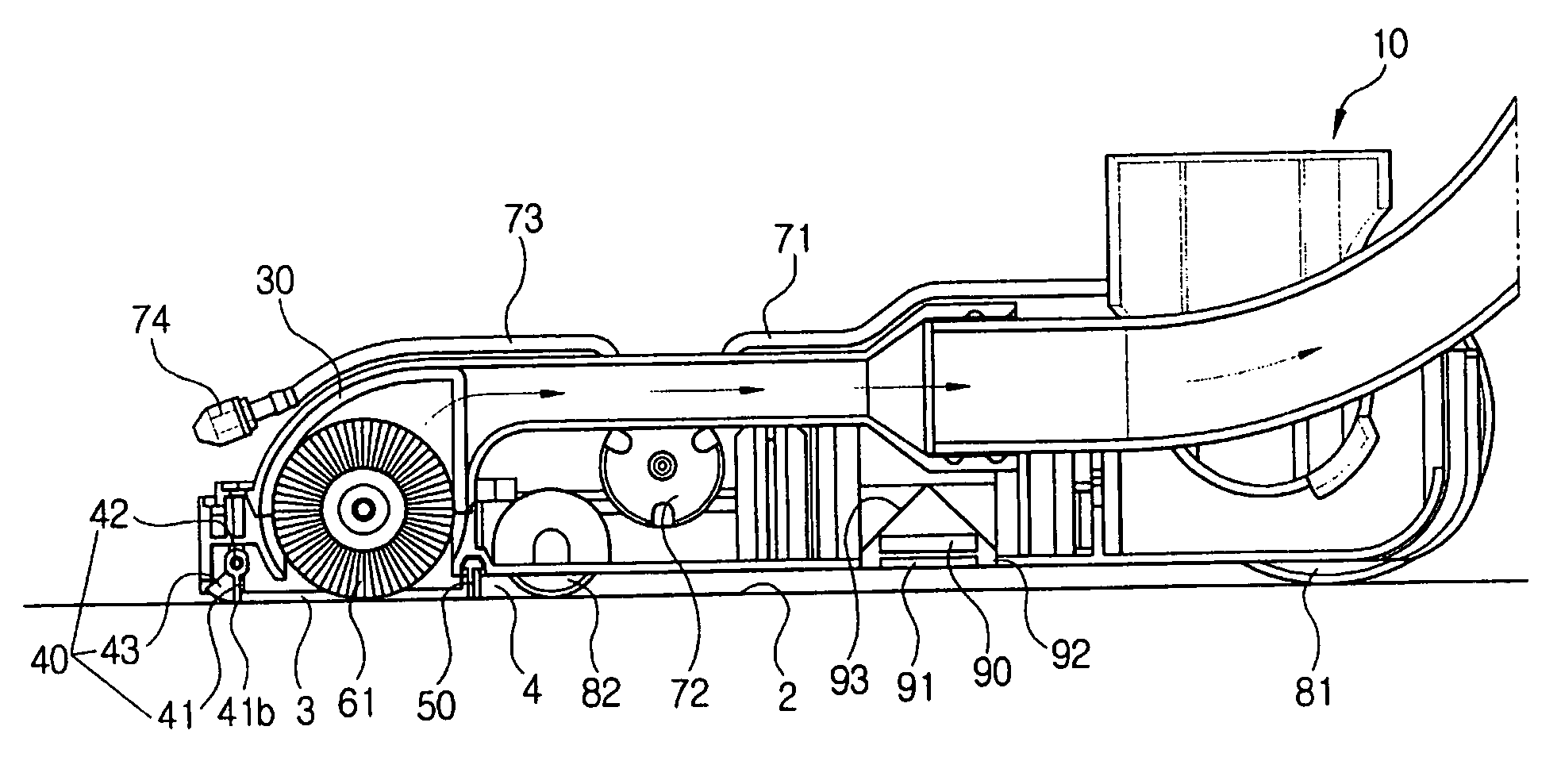

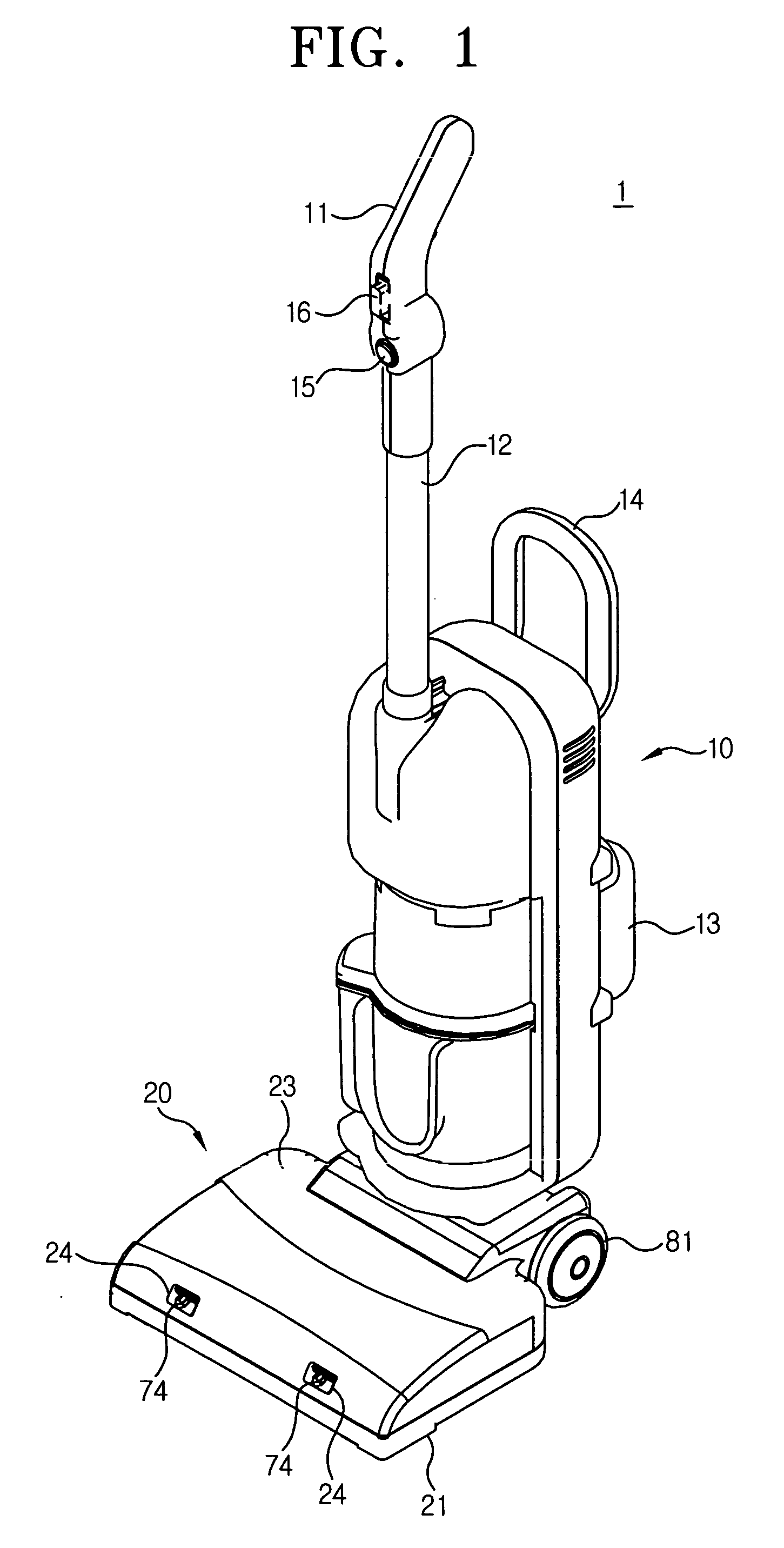

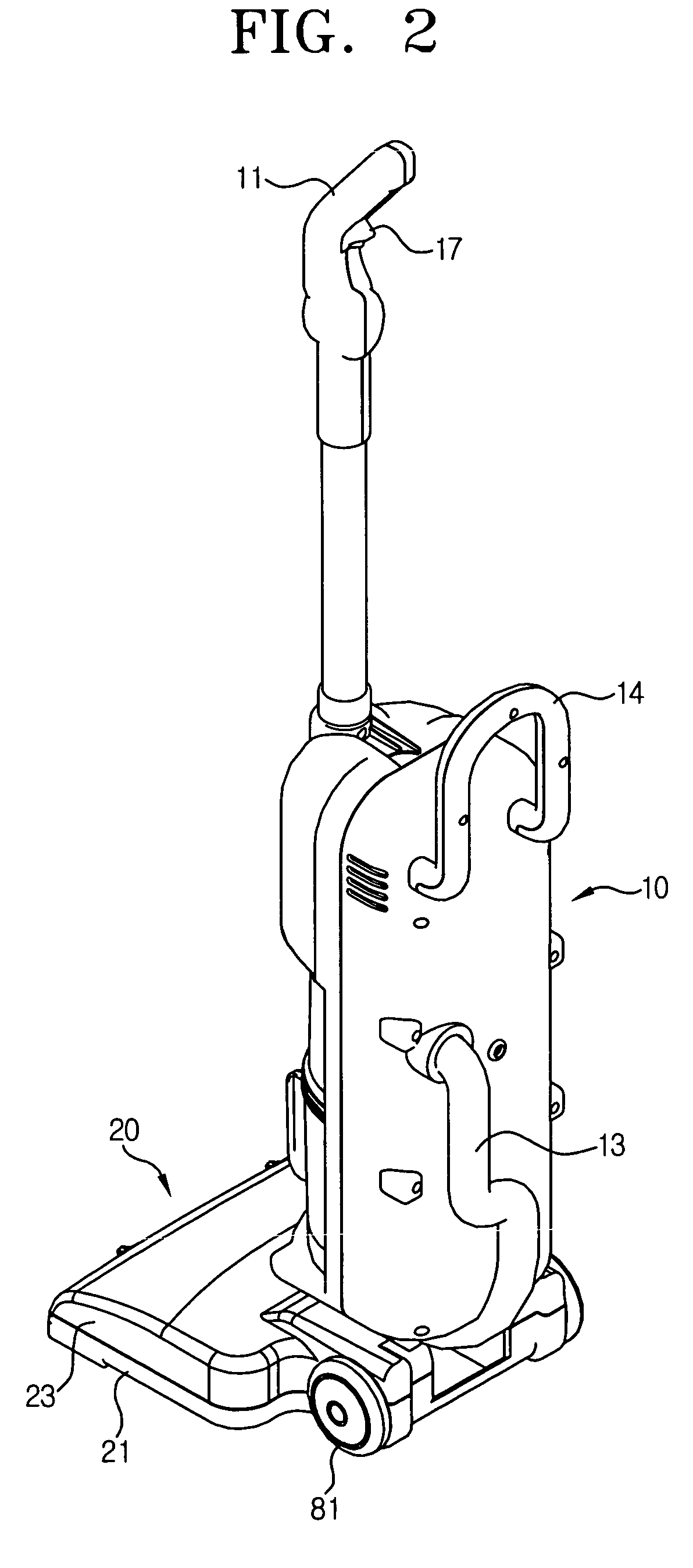

Vacuum cleaner having wet cleaning function

InactiveUS20060288517A1Simple structureReduce cleaningCarpet cleanersFloor cleanersEngineeringFriction force

A vacuum cleaner with a wet cleaning function comprises a main body, a brush assembly having a contaminant suction port facing a cleaning surface, a brush of the contaminant suction port to rotate in contact with the cleaning surface, and a water exhaust nozzle, the contaminants suction port is fluidly communicated with the main body, and a front and a rear block parts formed at a front and a rear of the brush on a bottom surface of the brush assembly to selectively open or block a contaminant suction path by a friction force against the cleaning surface.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

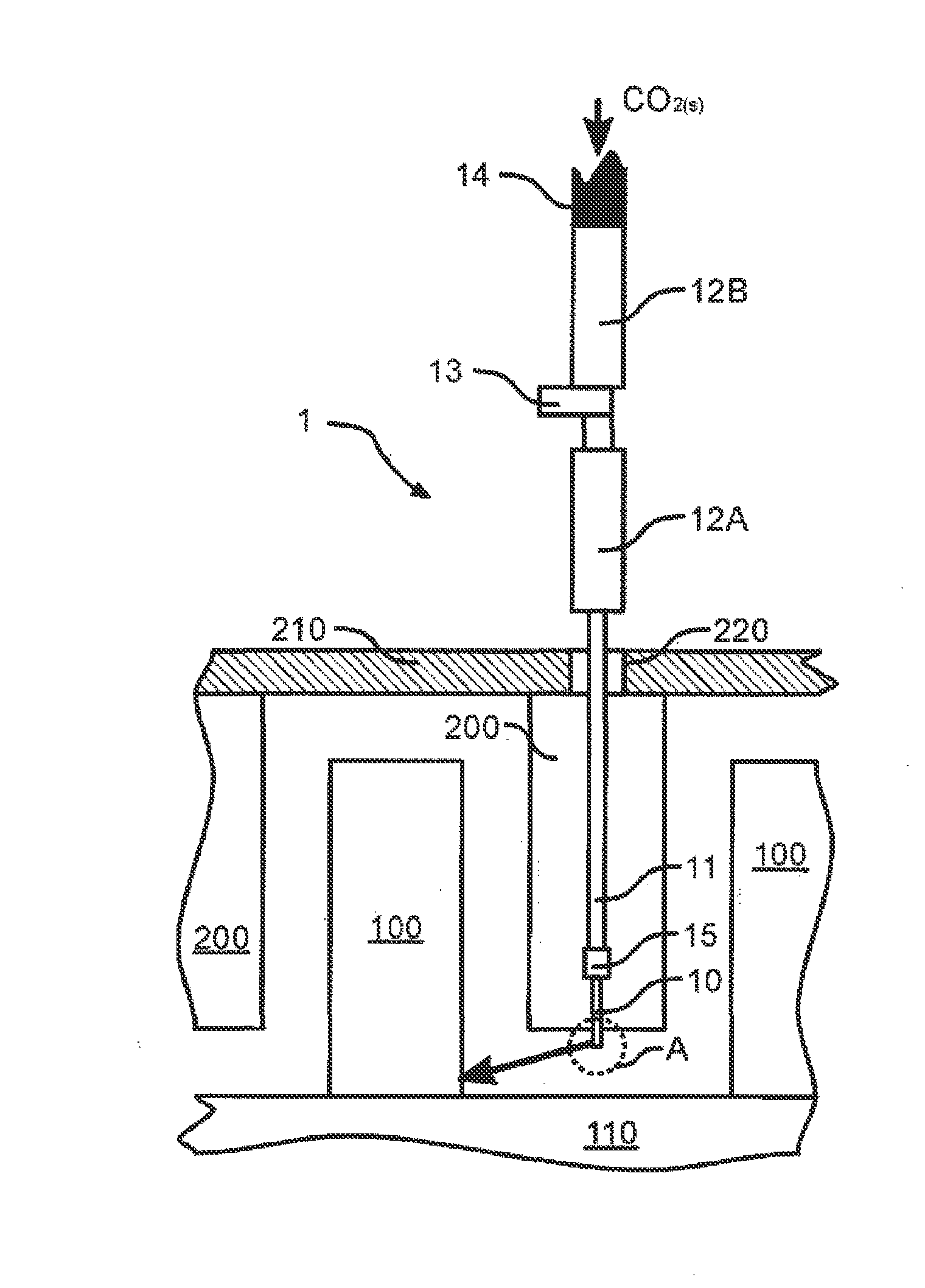

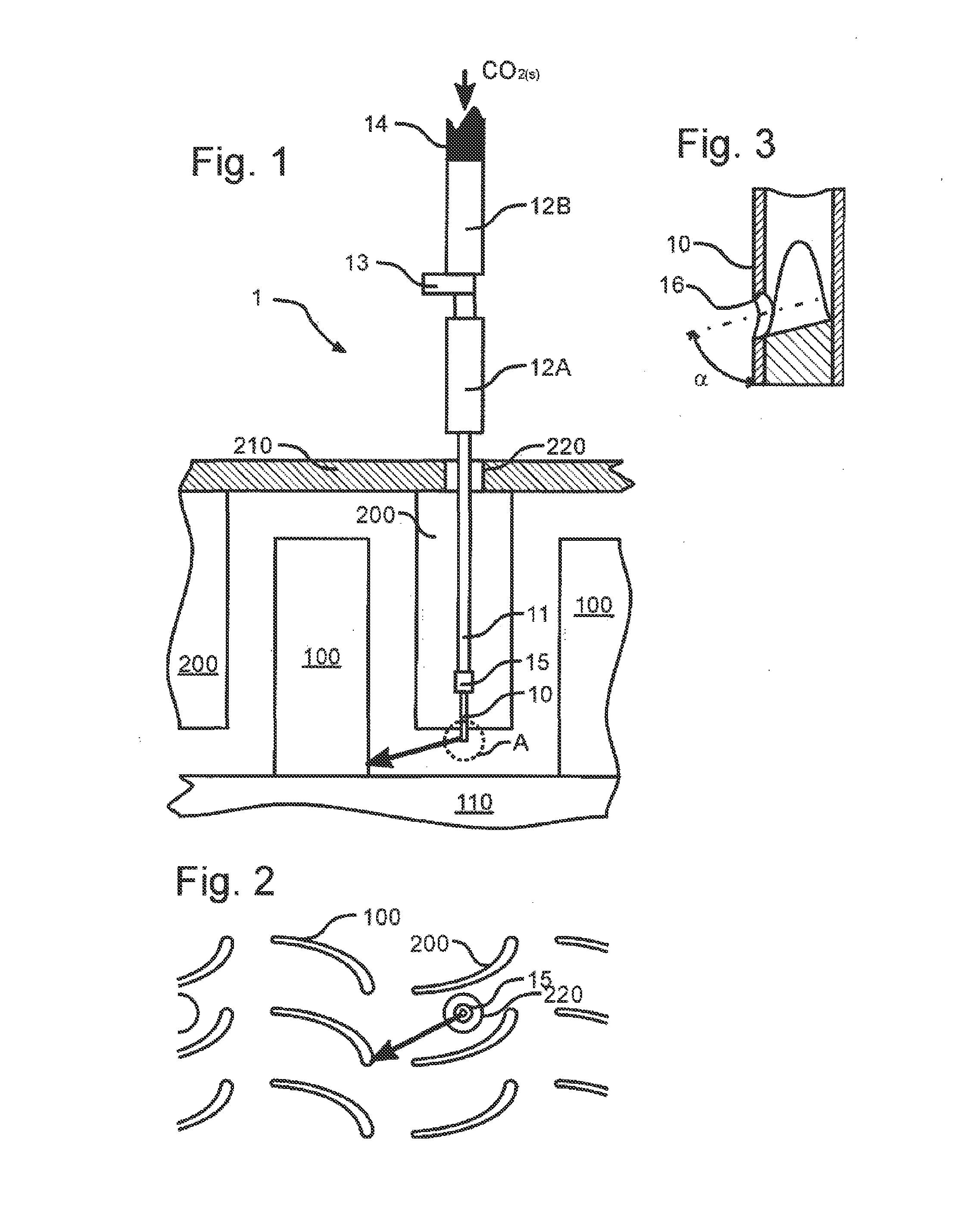

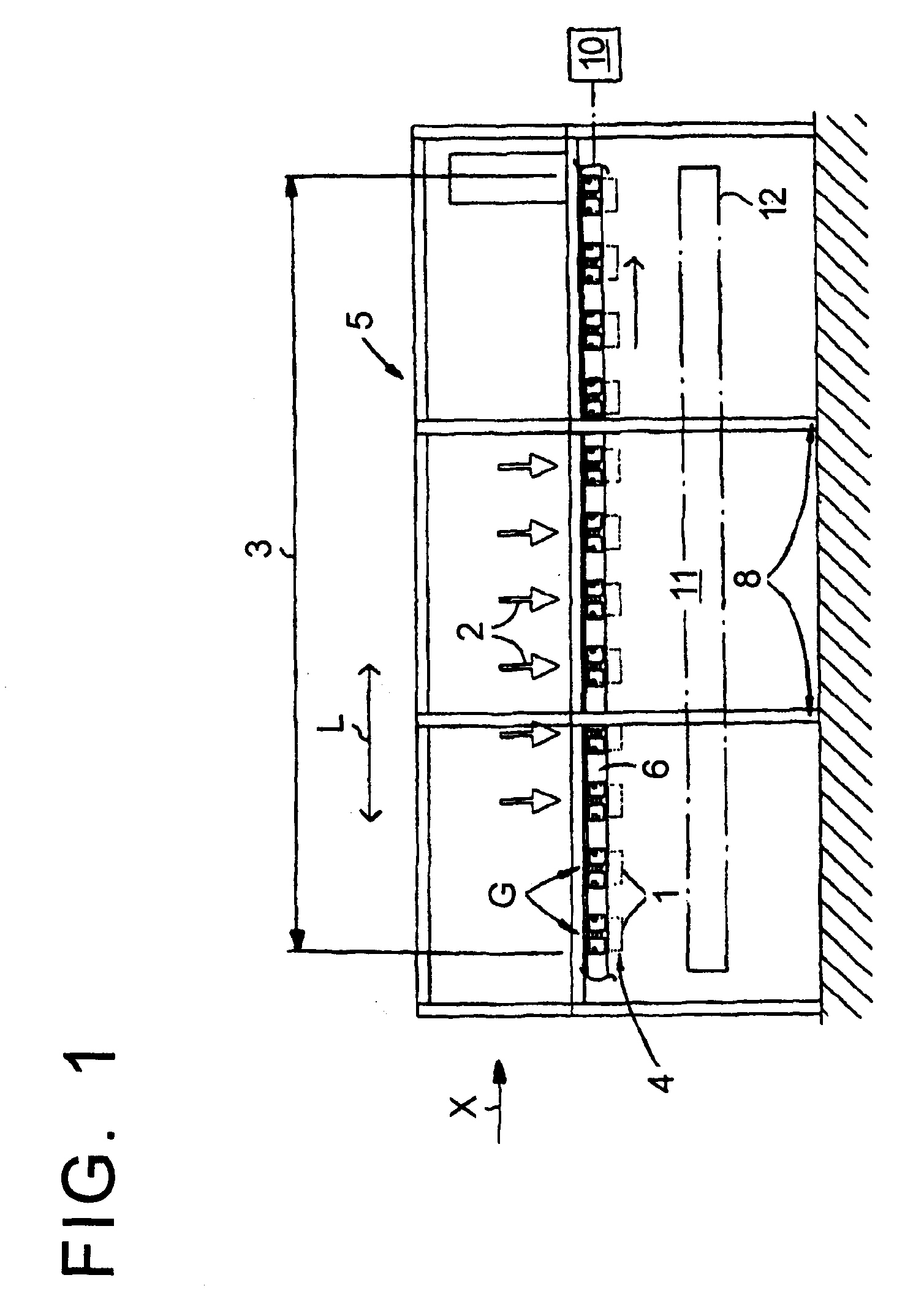

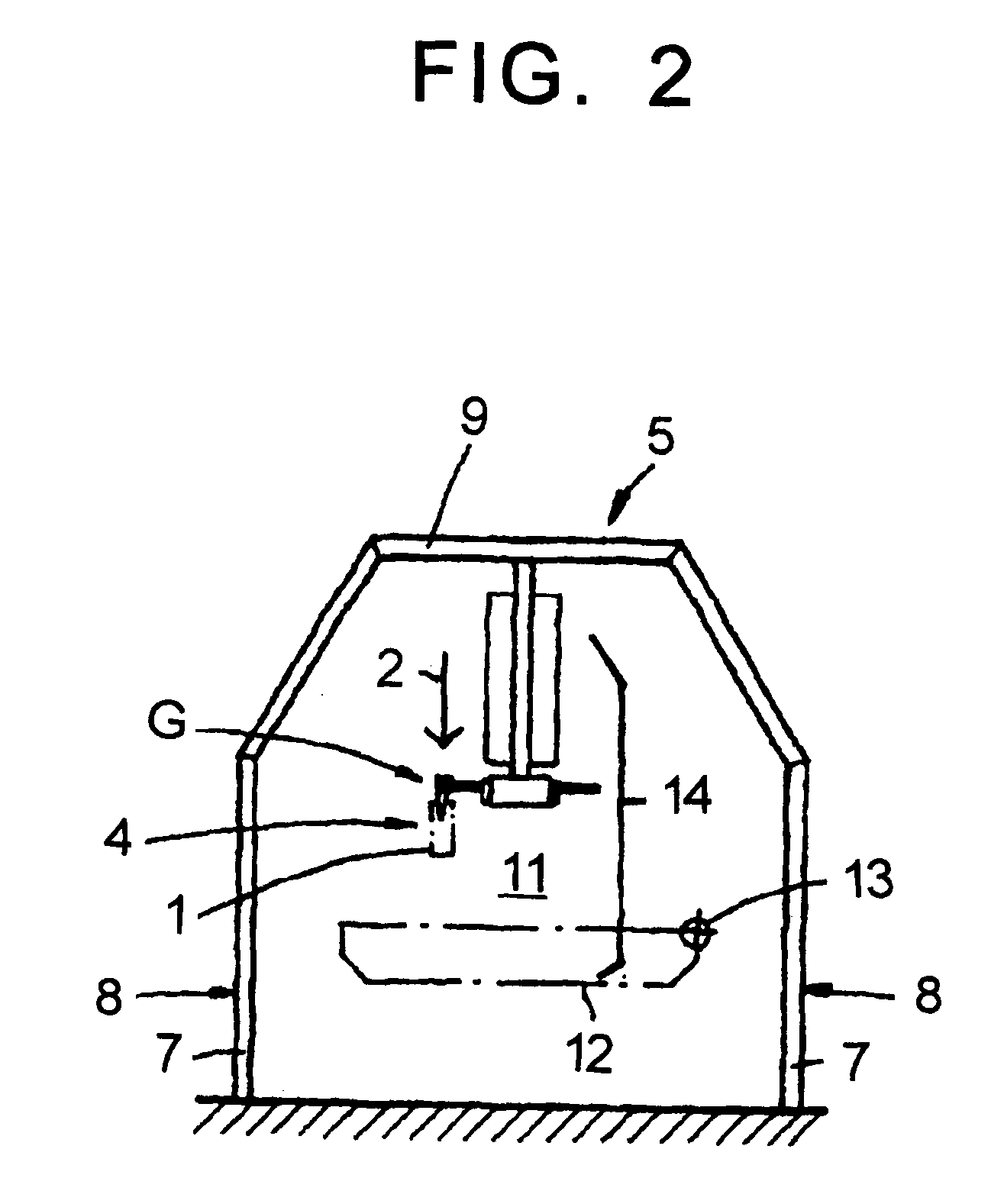

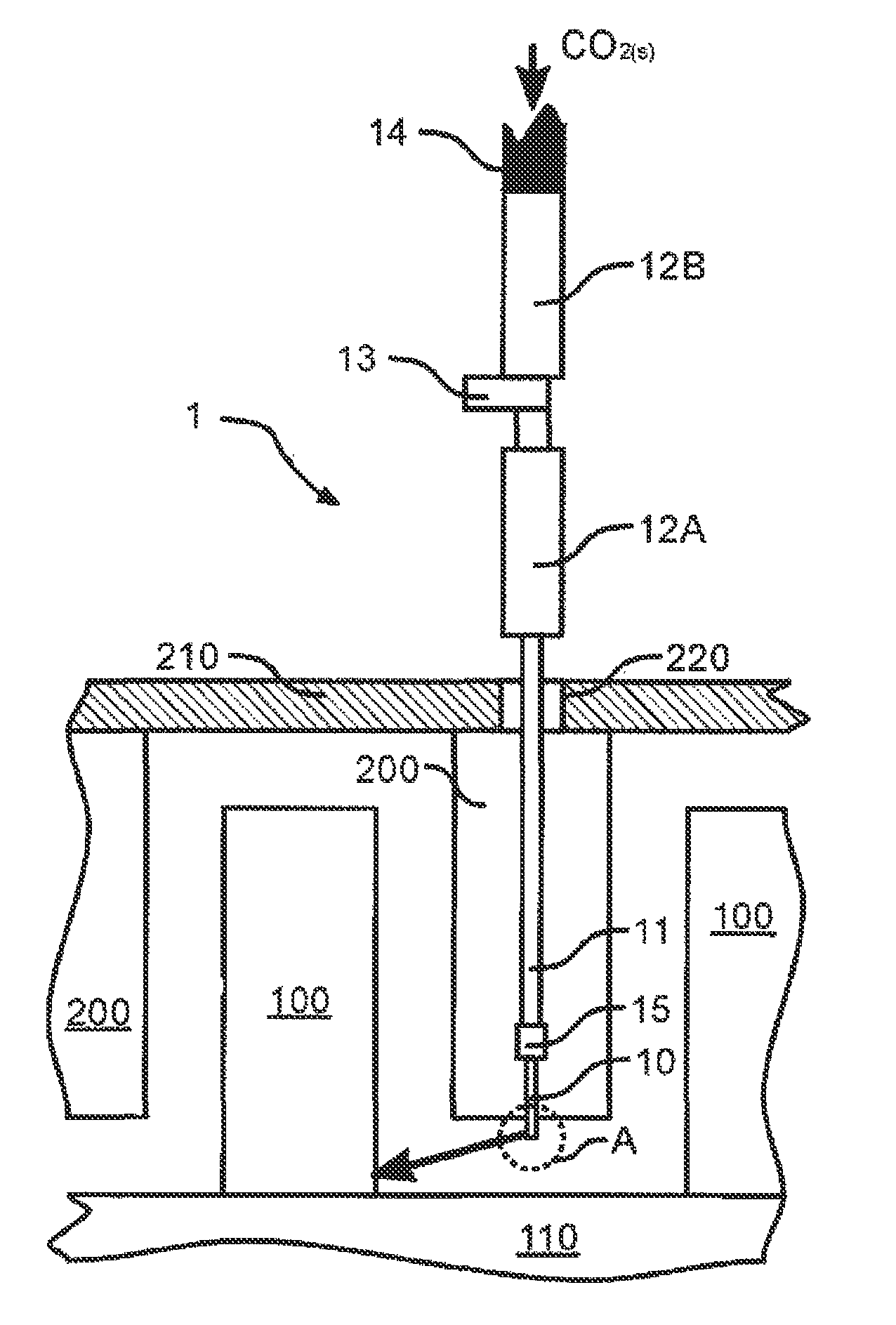

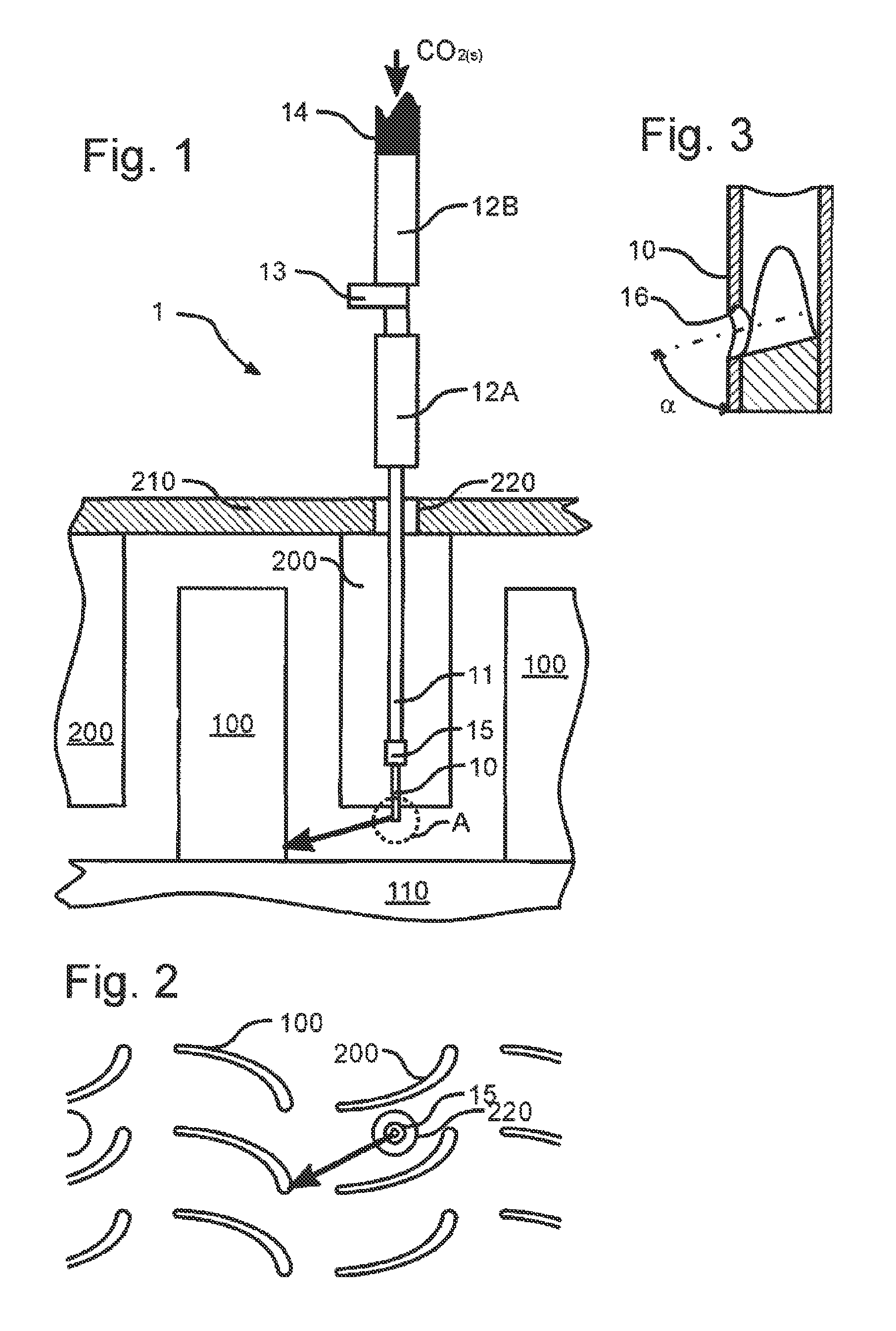

Cleaning of a turbo-machine stage

ActiveUS20130174869A1Easy to useHigh densityHollow article cleaningMachines/enginesDry iceEngineering

The invention relates to a method for cleaning a turbo-machine stage (100) consisting of at least one of the following steps: a cleaning nozzle (1) is introduced into an opening of a turbo-machine, in particular into an inspection opening (220); and the blade (100) of the stage is acted upon by solid particles, said particles subliming at the blade temperature, in particular into dry ice particles.

Owner:MTU AERO ENGINES GMBH

Free radical initiator in remote plasma chamber clean

InactiveUS20070006893A1Less cleaningReduce cleaningElectric discharge tubesElectrostatic cleaningRemote plasmaDeposition process

This invention relates to an improvement in the remote plasma cleaning of CVD process chambers and equipment from unwanted deposition byproducts formed on the walls, surfaces, etc. of such deposition process chambers and equipment. The improvement in the remote cleaning process resides in providing a free radical initiator downstream of the remote plasma generator employed for producing said plasma, said free radical initiator capable of forming free radicals in the presence of said plasma.

Owner:AIR PROD & CHEM INC

Apparatus for and method of cleaning substrate

InactiveUS20050183754A1Improve cleaning efficiencyLess cleaningSemiconductor/solid-state device manufacturingCleaning using toolsEngineering

A substrate cleaning apparatus includes two cleaning brushes driven independently of each other. A first cleaning brush makes a cycling movement including an outward movement progressing in a horizontal direction from a position in contact with the center of the rotation of a substrate to the outside of an edge of the substrate, an upward movement progressing in a vertically upward direction from an end position of the outward movement, an inward movement progressing in a horizontal direction from an end position of the upward movement to a position immediately over the center of the rotation of the substrate, and a downward movement progressing in a vertically downward direction from an end position of the inward movement to a start position of the outward movement. A second cleaning brush makes a similar cycling movement. The first and second cleaning brushes are adapted so that the speed of the inward movement thereof is higher than that of the outward movement thereof and so that the speed of the upward movement is higher than that of the downward movement thereof.

Owner:DAINIPPON SCREEN MTG CO LTD

Cleaning nozzle for a vacuum cleaner

A vacuum cleaner nozzle having a rotatable member arranged around a longitudinal axis for picking up particles from a surface to be cleaned, and a cleaning arrangement for removing articles entangled on the rotatable member. The cleaning arrangement has at least one support surface provided on at least one radially projecting member, and at least one cleaning member movable between a resting position in which the cleaning member is arranged at a distance from the support surface and at least one cleaning position In the vicinity of the rotatable member. In cleaning position, the cleaning member, during rotation of the rotatable member, co-operates with at least one segment of the support surface to remove entangled articles from the rotatable member. The cleaning member includes a resilient sheet member capable of providing resilient contact with a segment of the support surface in the cleaning position during rotation of the rotatable member.

Owner:AB ELECTROLUX

Apparatus for the filling of bags having at least one opening therein and having space to permit decreased accumulation of filling materials

InactiveUS20090320958A1Easy to cleanImproves and promotes cleaning actionConveyorsLiquid fillingFilling materialsTrademark

An apparatus for the filling of bags having at least one opening therein and having space to permit decreased accumulation of filling materials. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:BARTELT PACKAGING LLC

Prevention of post-pecvd vacuum and abatement system fouling using a fluorine containing cleaning gas chamber

InactiveUS20130133697A1Reducing abatement system foulingImprove efficiencyFouling preventionHollow article cleaningEngineeringGas chamber

Methods and apparatus for reducing post PECVD vacuum and abatement system fouling. Chamber cleaning times are reduced leading to increased efficiency and lower cost fabrication processes by introducing F2 or a fluorine containing gas into the PECVD system. When using F2, the cleaning gas may be introduced directly to desired locations of the system where it can interact without activation with unwanted deposits. Alternatively, the cleaning gas may be activated in-situ in the equipment using existing plasma discharge equipment, or the cleaning gas may be activated using an RPS and then introduced to the desired location in its already activated state.

Owner:LINDE AG

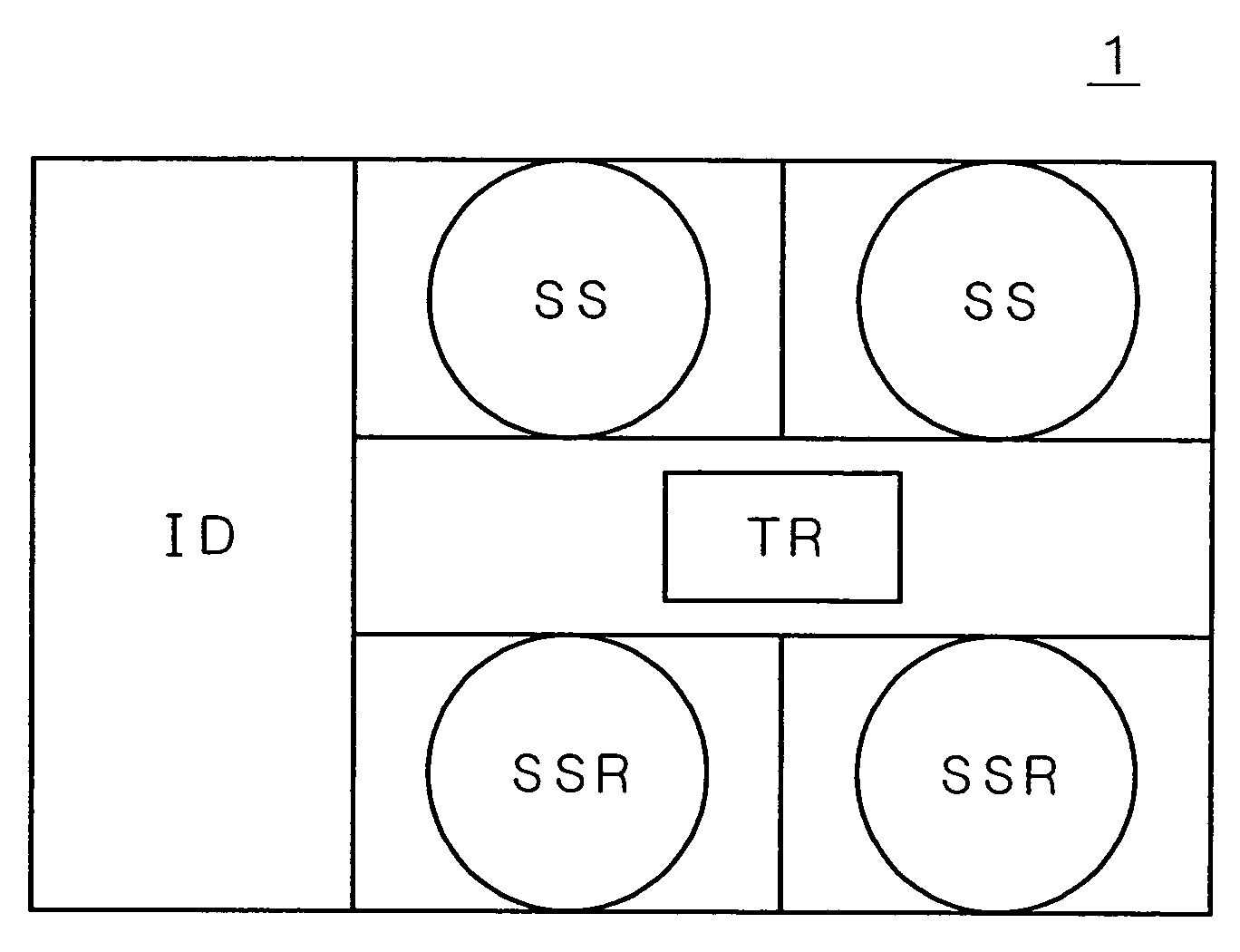

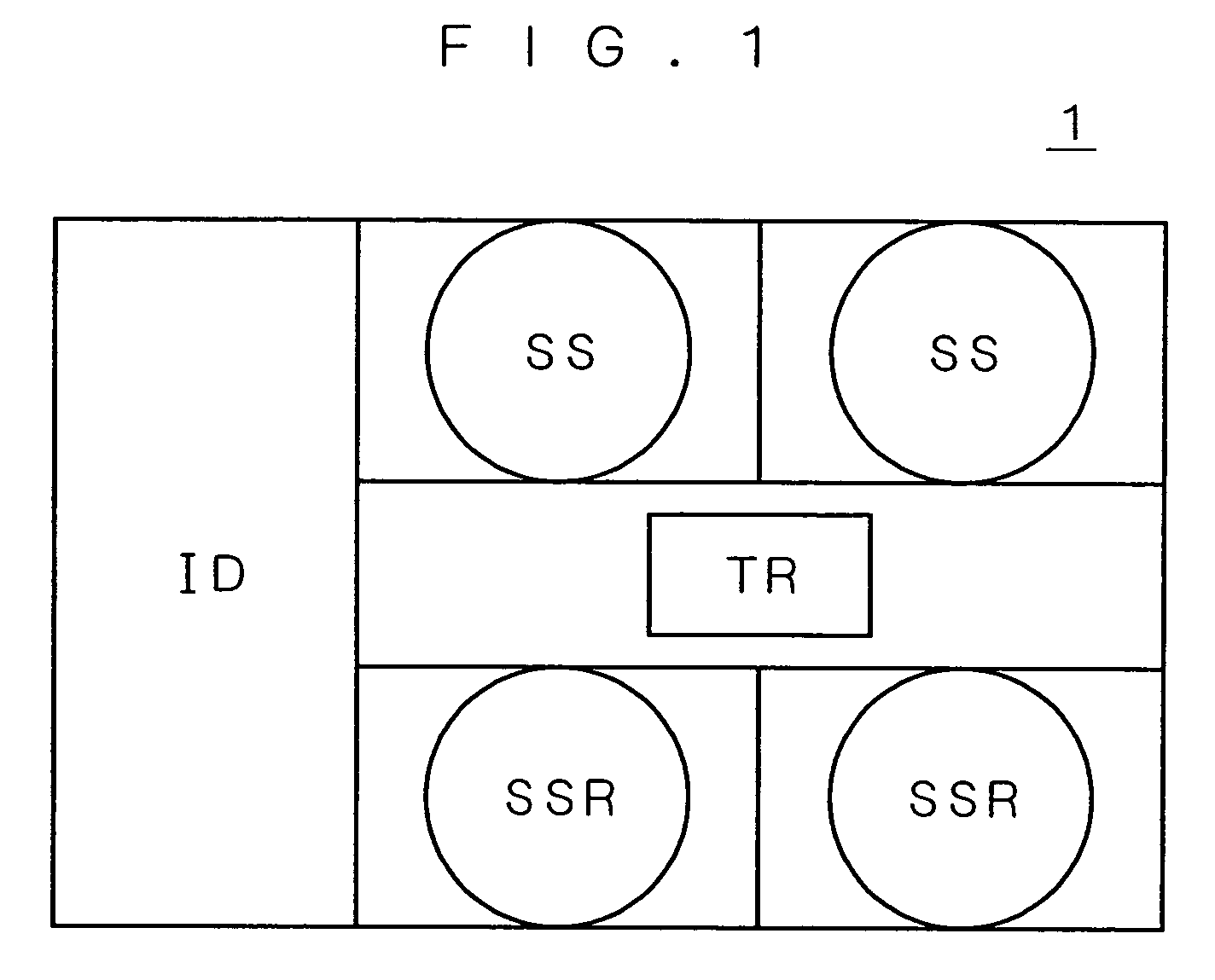

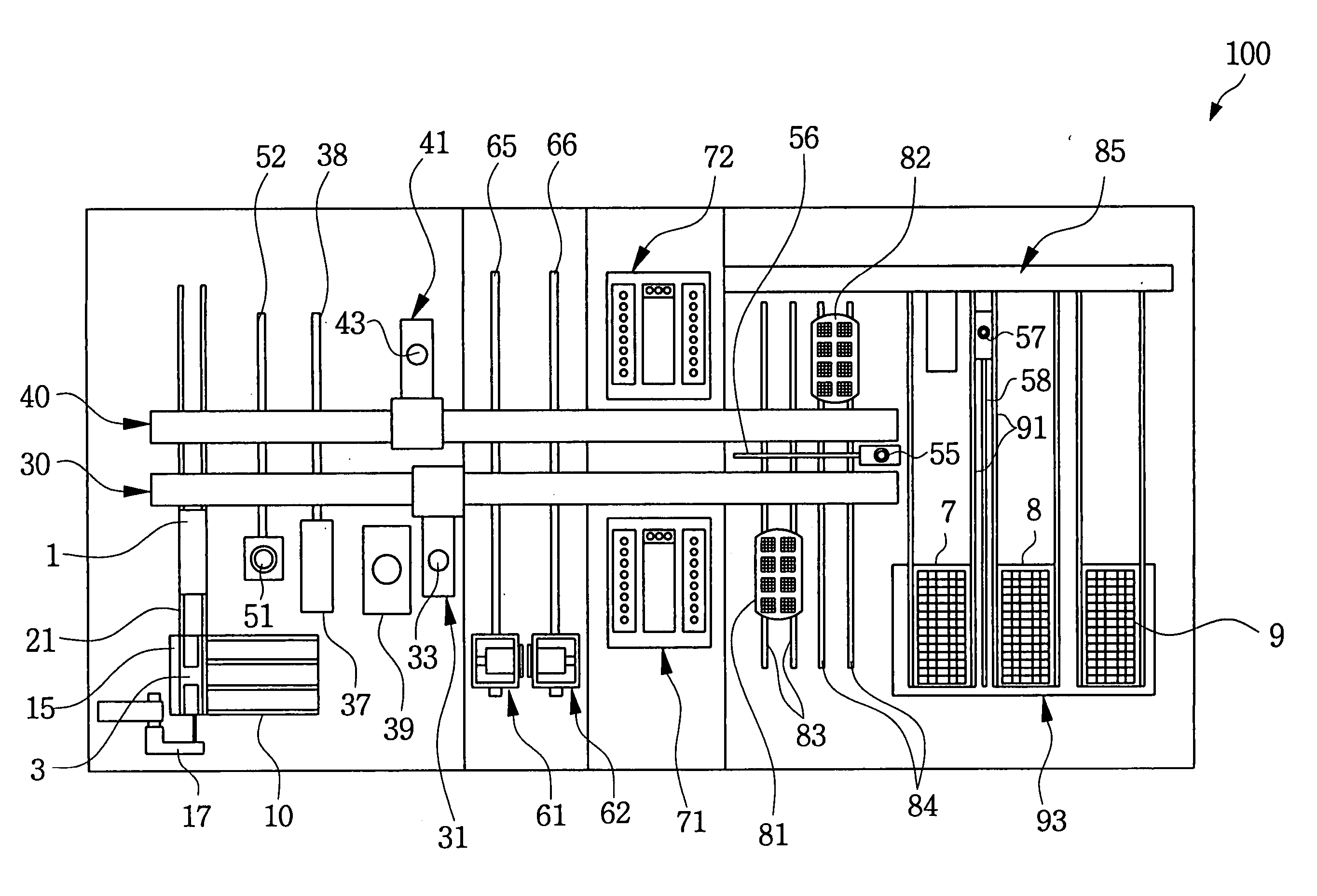

Sawing and sorting system

InactiveUS20060056955A1Easy to changeEasy maintenanceSemiconductor/solid-state device manufacturingFine working devicesEngineeringMechanical engineering

A sawing and sorting system combines a sawing apparatus and a sorting apparatus. The sawing and sorting system comprises a loader. The loader comprises a magazine receiving a plurality of strips. A mounting unit mounts the strip thereon. A plurality of transfer and sawing robots each comprises a picker unit. The picker unit comprises a rotatable chuck table. The transfer and sawing robot transfers the picker unit horizontally and vertically. The rotatable chuck table holds the strip. The picker unit rotates the rotatable chuck table. A plurality of sawing spindle units each comprises a rotary blade. The sawing spindle unit moves the blade horizontally to divide the strip into unit packages. A cleaning unit cleans the unit package. A test means inspects the unit package according to a test criteria. A sorting table mounts the unit package for sorting. An unloader provides trays. A sorting transfer robot sorts the unit packages into the trays.

Owner:SAMSUNG ELECTRONICS CO LTD

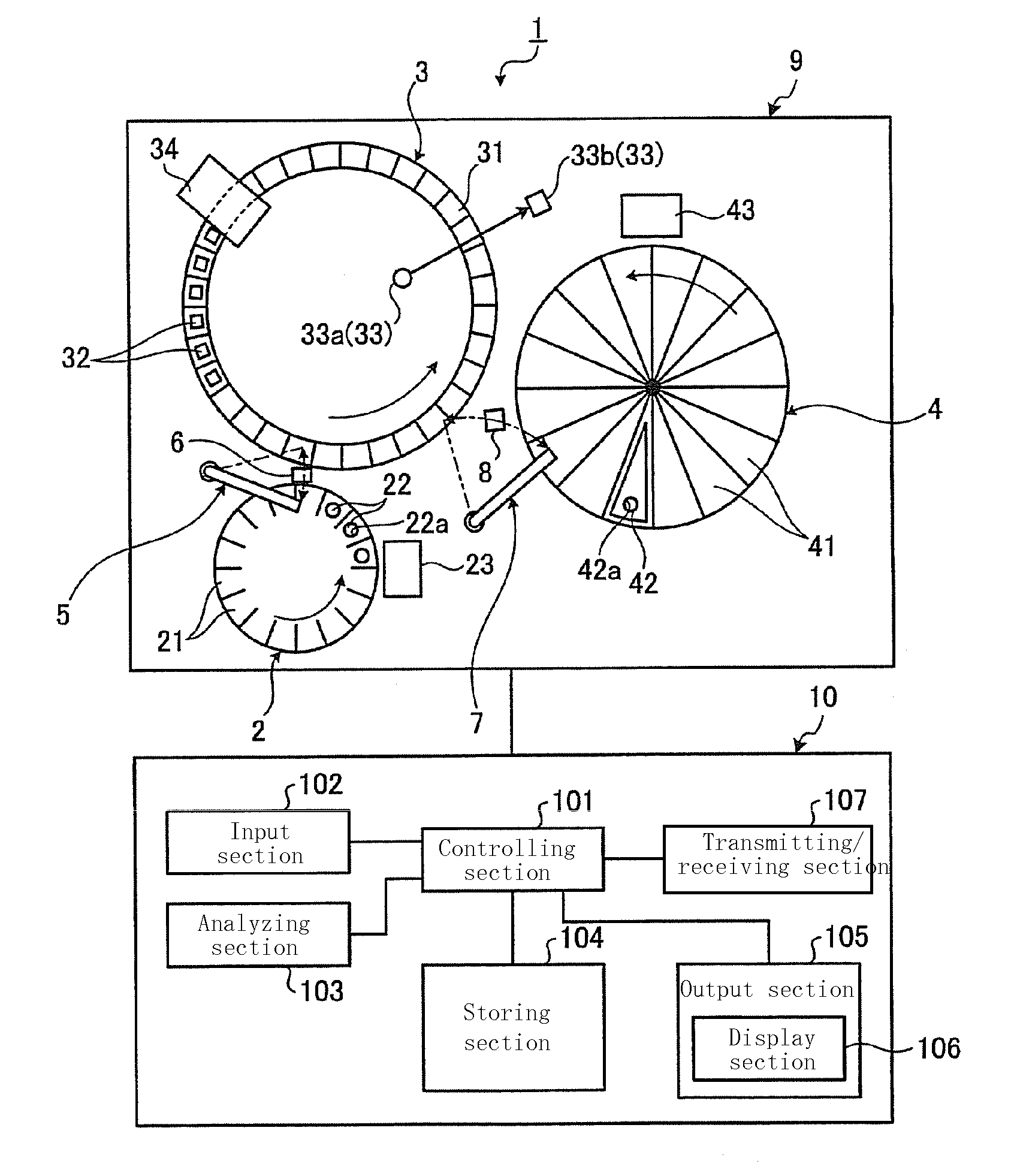

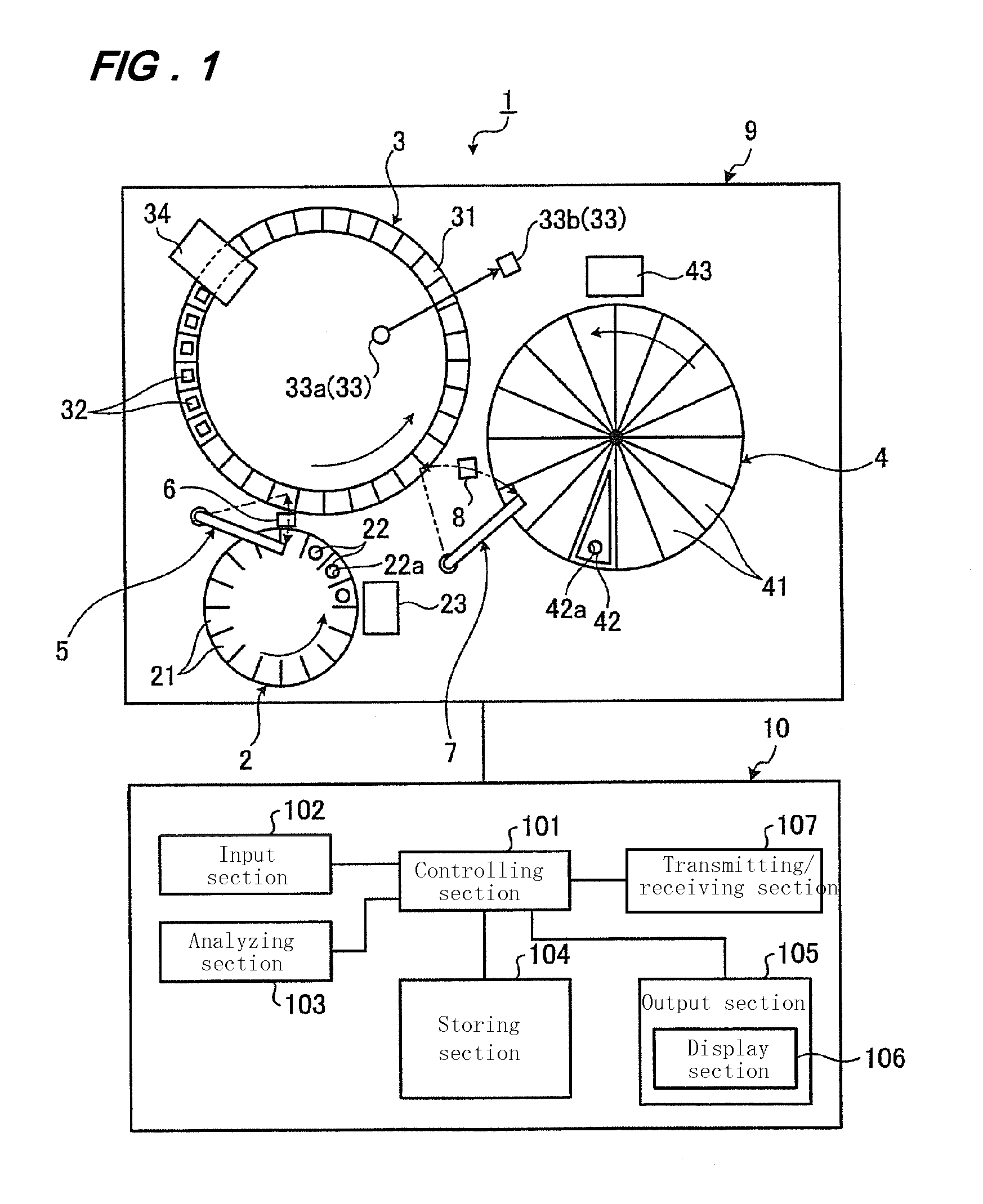

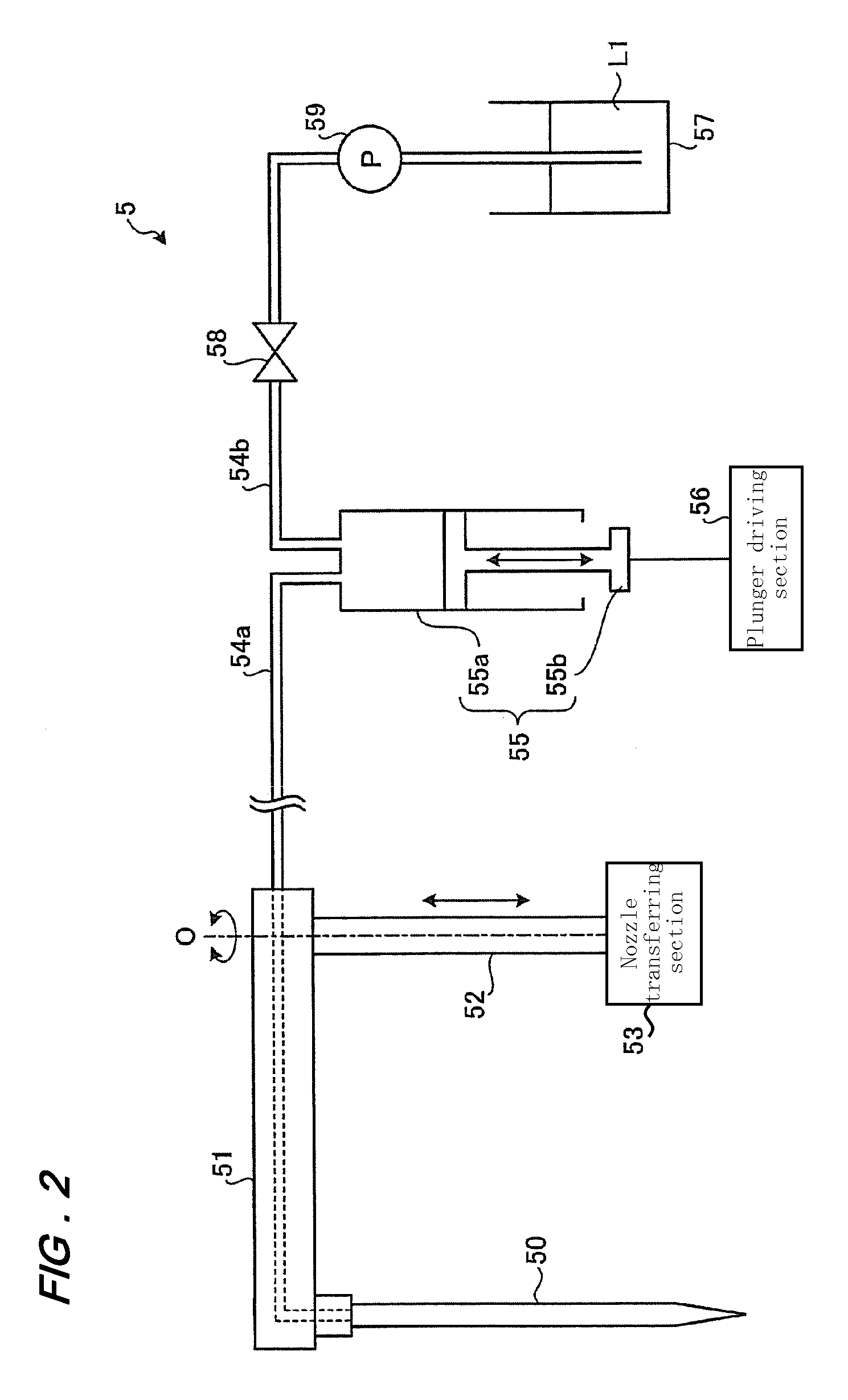

Method of cleaning nozzle and device for cleaning nozzle

ActiveUS20110017238A1Less cleaningEasy to cleanHollow article cleaningSpraying apparatusCleaning methodsEngineering

The present invention provides a nozzle cleaning method and a nozzle cleaning device which allow to surely perform cleaning of a dispensing nozzle and which allow reduction in cleaning time. For this purpose, a nozzle cleaning method for cleaning a dispensing nozzle (50) for suctioning and discharging a liquid includes: a first cleaning step in which, after termination of dispensing, an inner wall surface of the dispensing nozzle (50) is cleaned in an upper portion of a storage tank (62) overflowed with a cleaning liquid (L2) by discharging a liquid for preload (L1); and a second cleaning step in which at least an outer wall surface is cleaned by lowering and immersing the dispensing nozzle (50) into the storage tank (62) overflowed with the cleaning liquid (L2).

Owner:BECKMAN COULTER INC

Molten metal anti-oxidation reducing agent, preparation method and application thereof

InactiveCN101532130AReduce scumSpeed up the flowMetallic material coating processesO-Phosphoric AcidPhytic acid

The invention relates to a molten metal anti-oxidation reducing agent and a preparation method and application thereof. The molten metal anti-oxidation reducing agent comprises the following main compositions in portion by weight: 51.19 to 91.19 portions of nonylphenol polyoxyethylene ether, 3 to 15 portions of organic amine, 0.3 to 5 portions of phosphoric acid and 0.5 to 8 portions of phytic acid; the anti-oxidation reducing agent can further comprise essence in proper amount; and the molten metal anti-oxidation reducing agent is water-soluble oily liquid. The reducing agent has no flash point, does not splash when being added into molten metal and can automatically and rapidly diffuse; the molten metal anti-oxidation reducing agent is lighter than molten metal liquid and can overspread the whole flowing liquid level to isolate air and effectively prevent oxidation; contained active substances and organic or inorganic acid can disperse the inner gravitation of oxidized metal scruff, and actively scatter an inner structure of the oxidized metal scruff to reduce useful metal out; the reduction efficiency is 95 percent or so; cost performance is high; the residual scruff is little, soluble in water and convenient to clean; and the molten metal anti-oxidation reducing agent is convenient to maintain equipment.

Cleaning solution for cleaning substrate for semiconductor devices and cleaning method using the same

InactiveUS20080011321A1Low water solubilityEasy to cleanInorganic/elemental detergent compounding agentsSurface-active detergent compositionsOrganic acidDevice material

A cleaning solution for cleaning a substrate for semiconductor devices and a cleaning method using the said cleaning solution, which comprises at least the following components (A), (B) and (C): (A) an ethyleneoxide-type surfactant containing a hydrocarbon group which may have a substituent group except for phenyl, and a polyoxyethylene group in which a ratio (m / n) of a number (m) of carbon atoms contained in the hydrocarbon group to a number (n) of oxyethylene groups contained in the polyoxyethylene group is in the range of 1 to 1.5, the number (m) of carbon atoms is not less than 9, and the number (n) of oxyethylene groups is not less than 7; (B) water; and (C) alkali or an organic acid. The cleaning solution highly clean the surface of the substrate without occurrence of corrosion by removing fine particles and organic contaminants which are adhered onto the surface of the substrate.

Owner:MITSUBISHI CHEM CORP

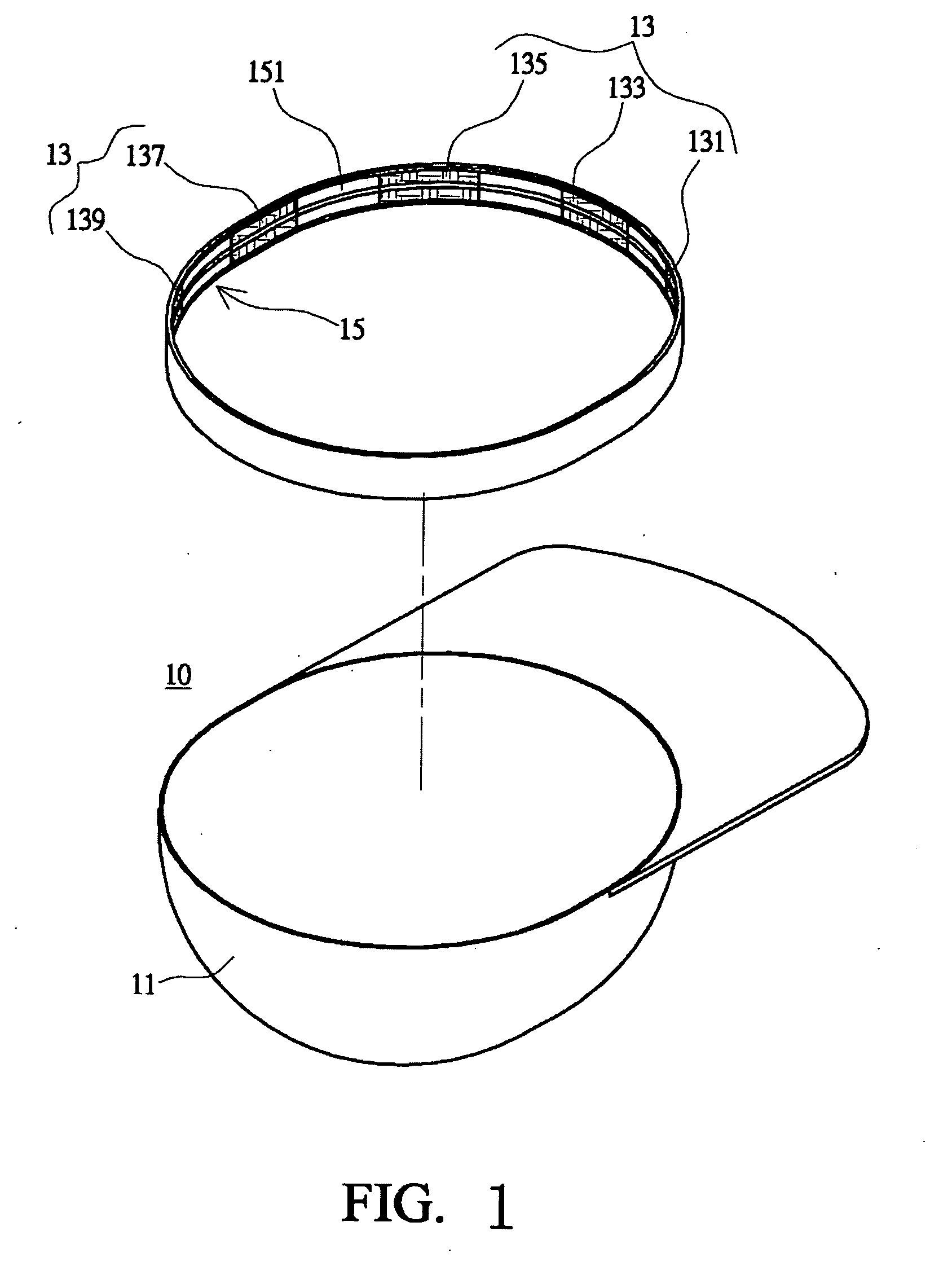

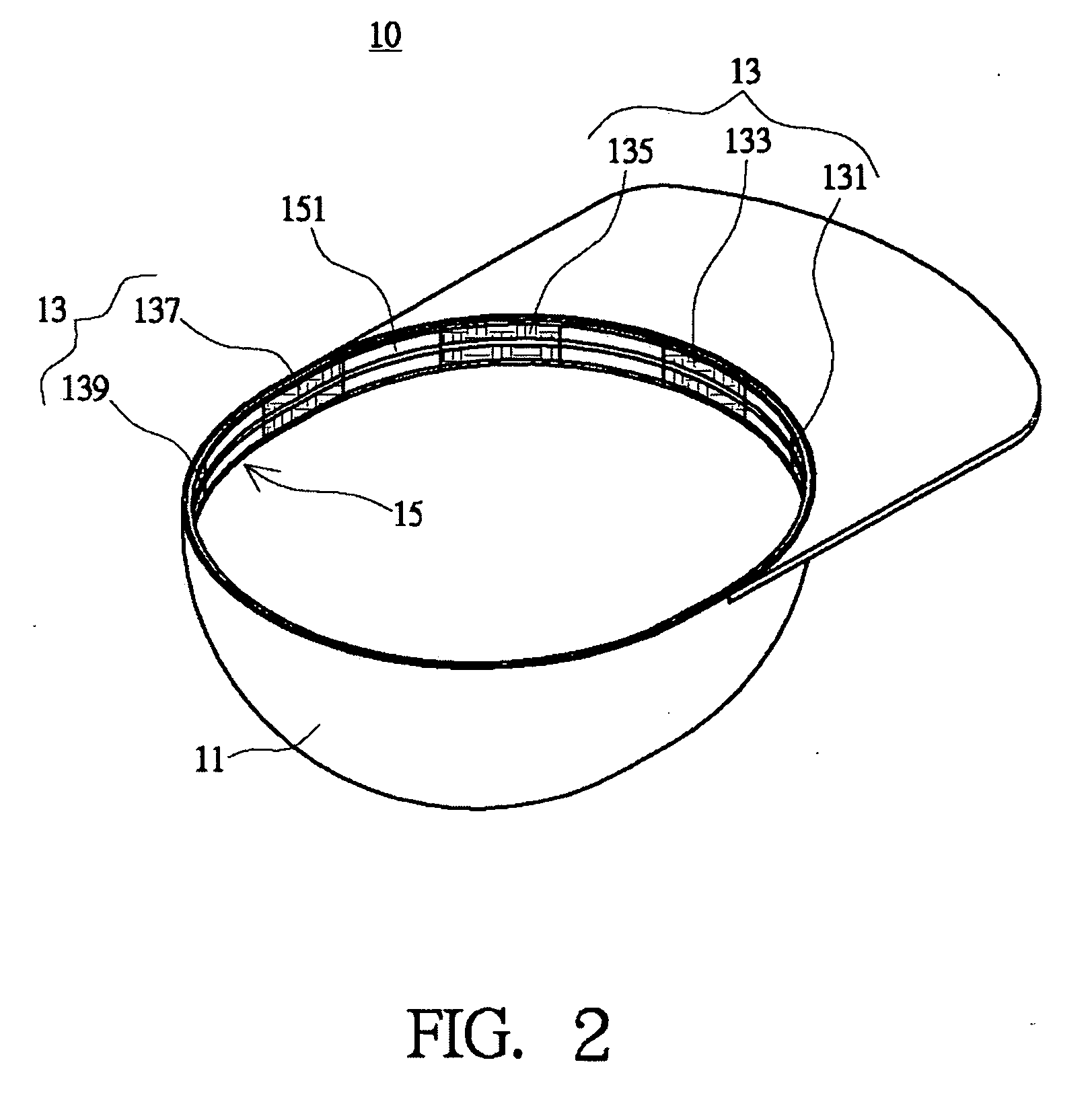

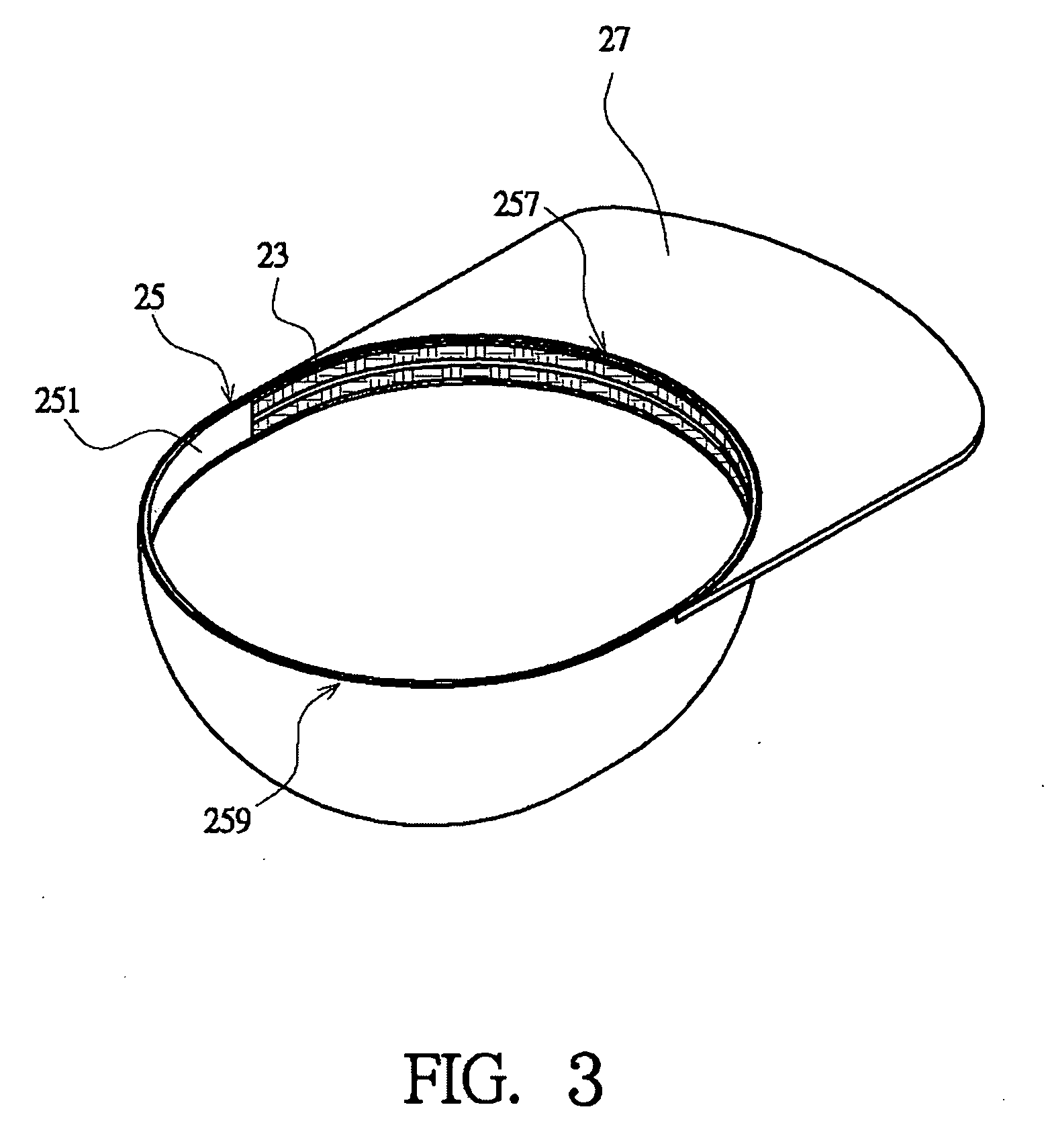

Headwear with deodorizatnt function

InactiveUS20070077223A1Less cleaningExtended service lifeBiocideCosmetic preparationsSpecific functionDeodorant

A headwear with specific functions, including anti-bacteria, odor proofed, deodorant, warm-keeping, and so on, comprises a sweat band made by the fabric material, wherein at least one functional fiber is within a proper section of the sweat band, such as bamboo charcoal based fiber with deodorant anti-bacterial functions, or added with aromatic hydrocarbon to release aroma, and so on, thus, the sweat band can be as a functional sweat band, which can be used to keep fresh and clean within the headwear according to the functional fiber with anti-bacteria and deodorant.

Owner:TAI TUNG HUA

Method and apparatus for determining the stability of an electroless plating bath

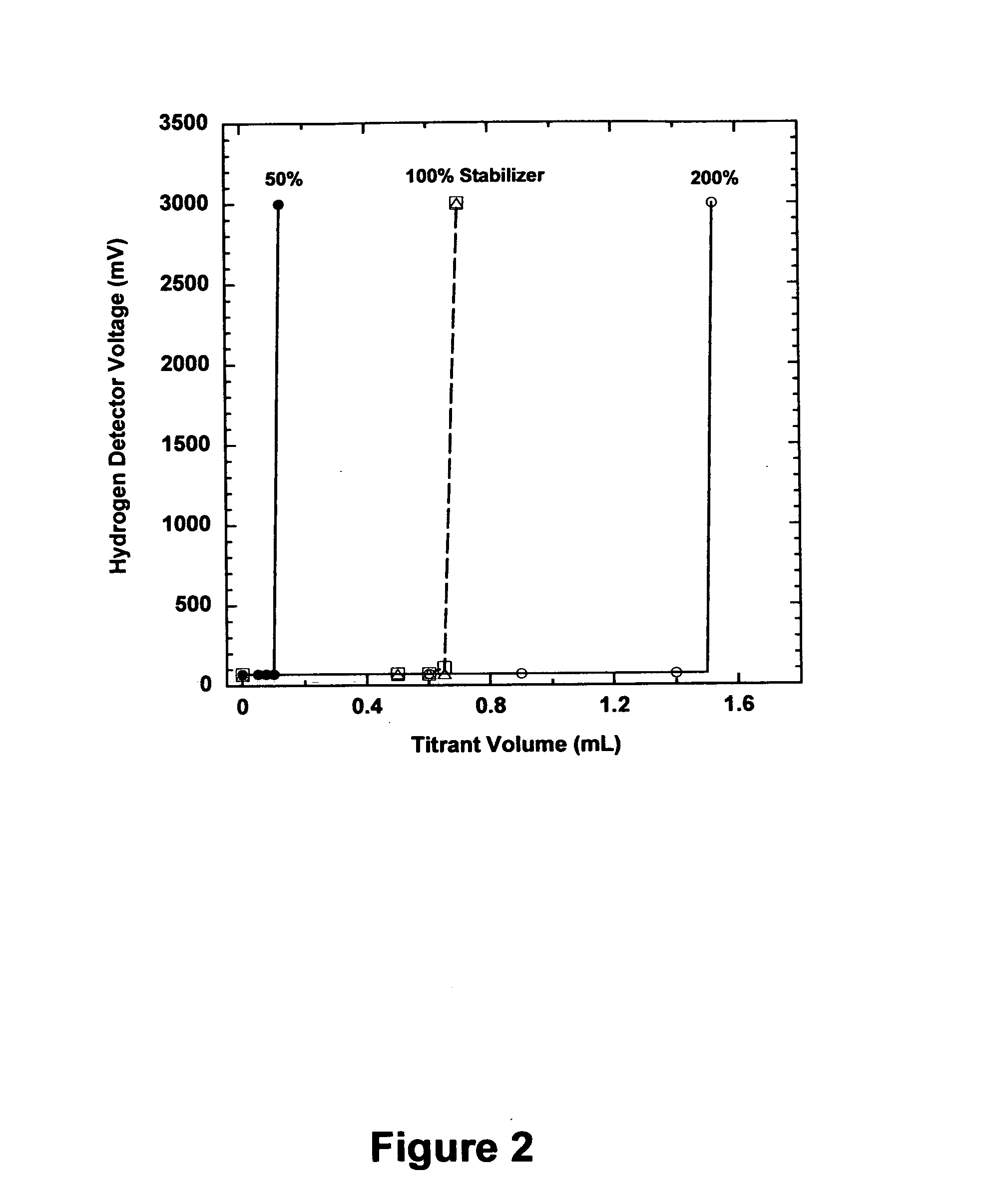

ActiveUS20100035356A1Accurate measurementQuantity minimizationAnalysis using chemical indicatorsChemical analysis using titrationHydrogenCatalytic metal

The stability of an electroless plating bath for depositing a metal (e.g., nickel) is determined by titrating a sample of the plating bath with a titrant comprising ions of a catalytic metal (e.g., palladium) and detecting hydrogen released at the titration endpoint. The quantity of titrant required to attain the endpoint provides a measure of the stability of the electroless plating bath.

Owner:ECI TECH

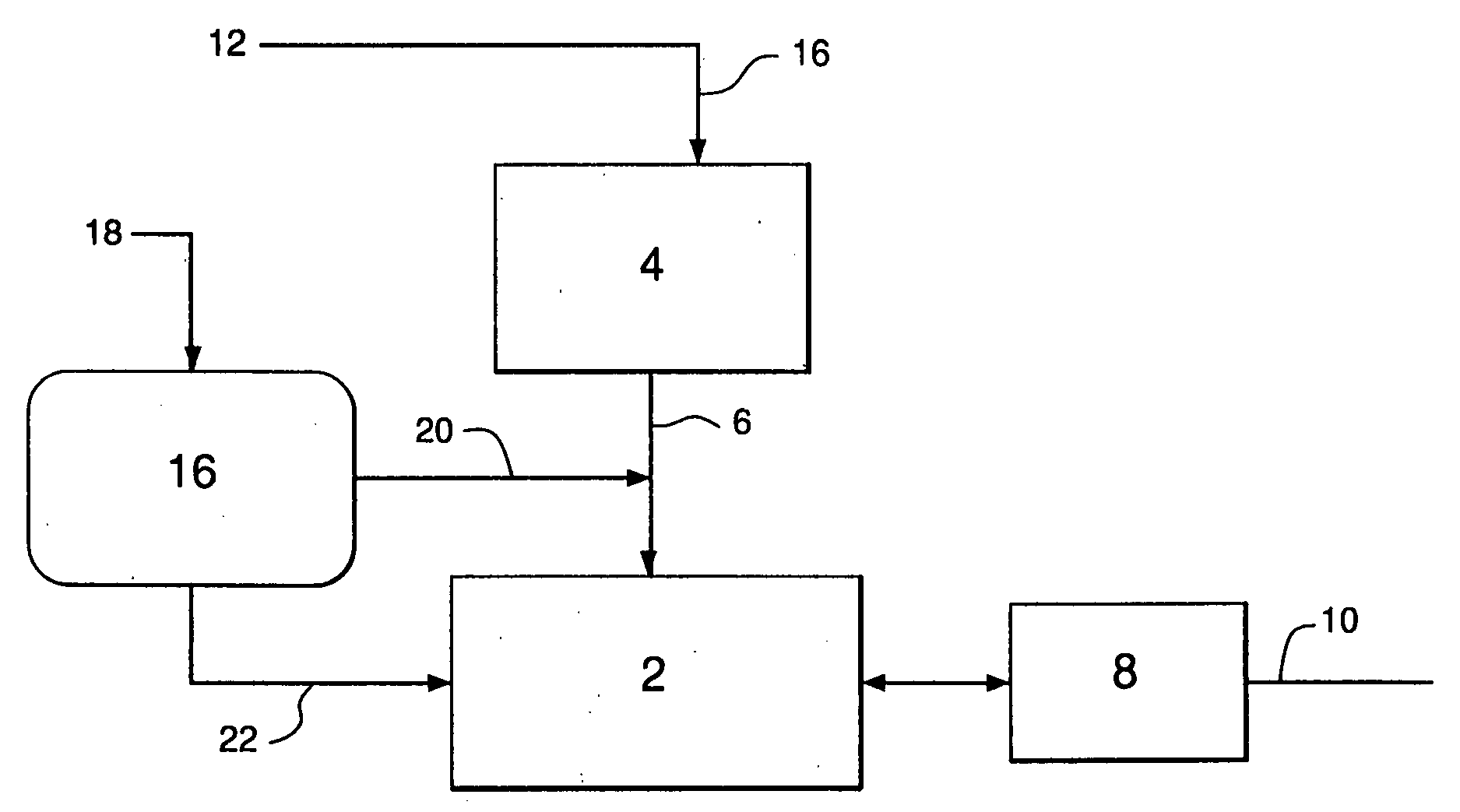

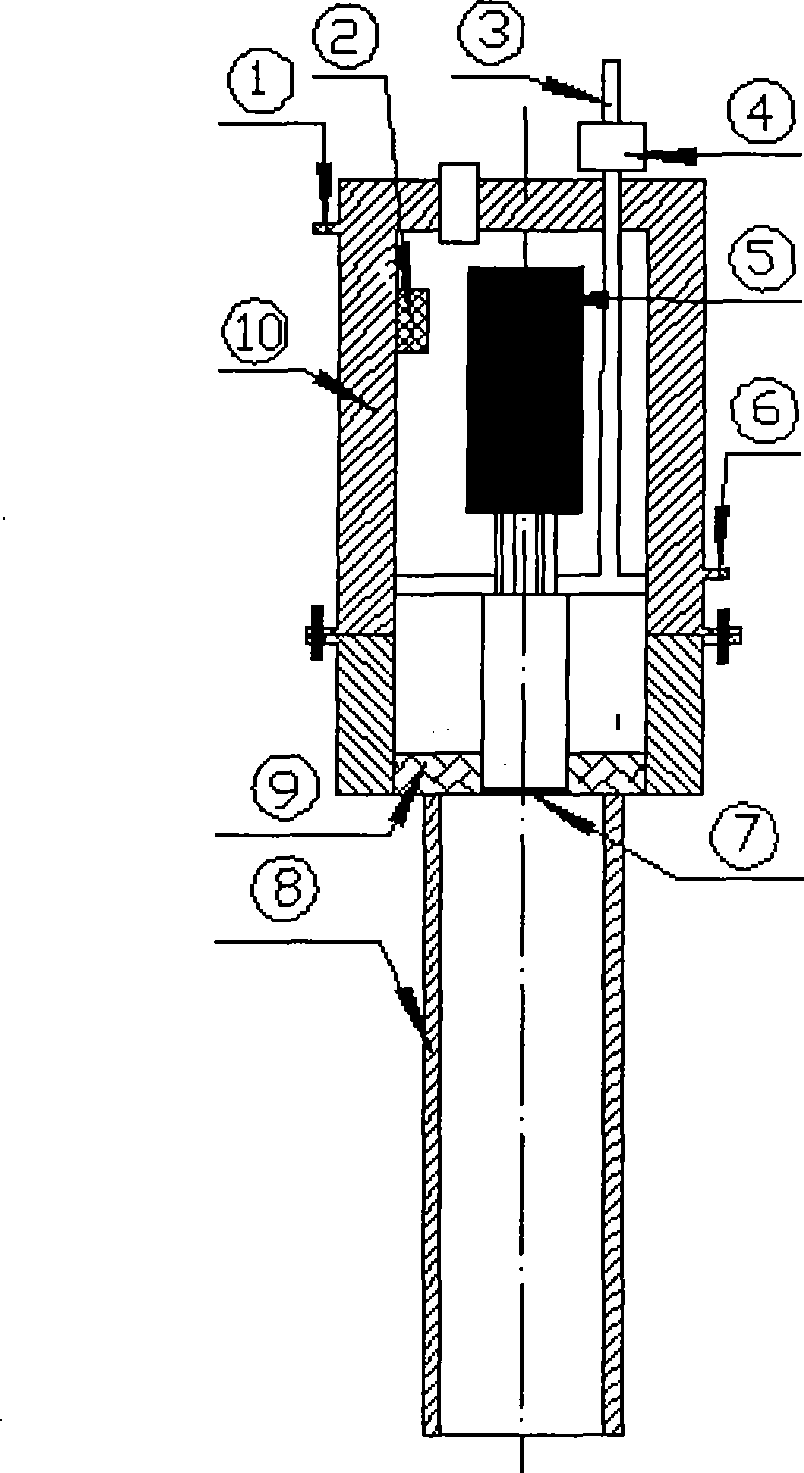

System and method for cleaning a vehicle-mounted optic lens

ActiveUS10286877B2Reduce in quantityCompletely processedVehicle cleaningCleaning using liquidsCamera lensAir pump

The present invention refers a system and a method for automatically cleaning an optic lens mounted on a vehicle, by spraying a washing liquid to remove any type of dirt from the lens such as a clear image or optic signal can be captured anytime, where an air pump is provided including a variable volume compression chamber to pressurize a volume of air, and a washing liquid conduit is communicated with a liquid nozzle and with the air pump, such as the air pump can be operated by the flow of pressurized washing liquid, such as the same flow of pressurized washing liquid is used to clean the optic surface, and to operate the air pump and generate a blast of air to blow off any liquid drop from the optic lens.

Owner:FICO TRANSPAR

Ink jet recording apparatus

A cleaning blade which comes in elastic contact with a nozzle plate to clean a recording head is subjected to ink-receptive treatment on the surface thereof which comes in contact with the nozzle plate, such as formation of grooves or the like which can retain an ink by a capillary force. In this arrangement, an ink can be retained on the blade regardless of the rebounding of the blade shortly after the termination of cleaning operation, making it possible to prevent the ink from flying toward the recording head when the blade rebounds.

Owner:SEIKO EPSON CORP

Cleaning of a turbo-machine stage

The invention relates to a method for cleaning a turbo-machine stage (100) consisting of at least one of the following steps: a cleaning nozzle (1) is introduced into an opening of a turbo-machine, in particular into an inspection opening (220); and the blade (100) of the stage is acted upon by solid particles, said particles subliming at the blade temperature, in particular into dry ice particles.

Owner:MTU AERO ENGINES GMBH

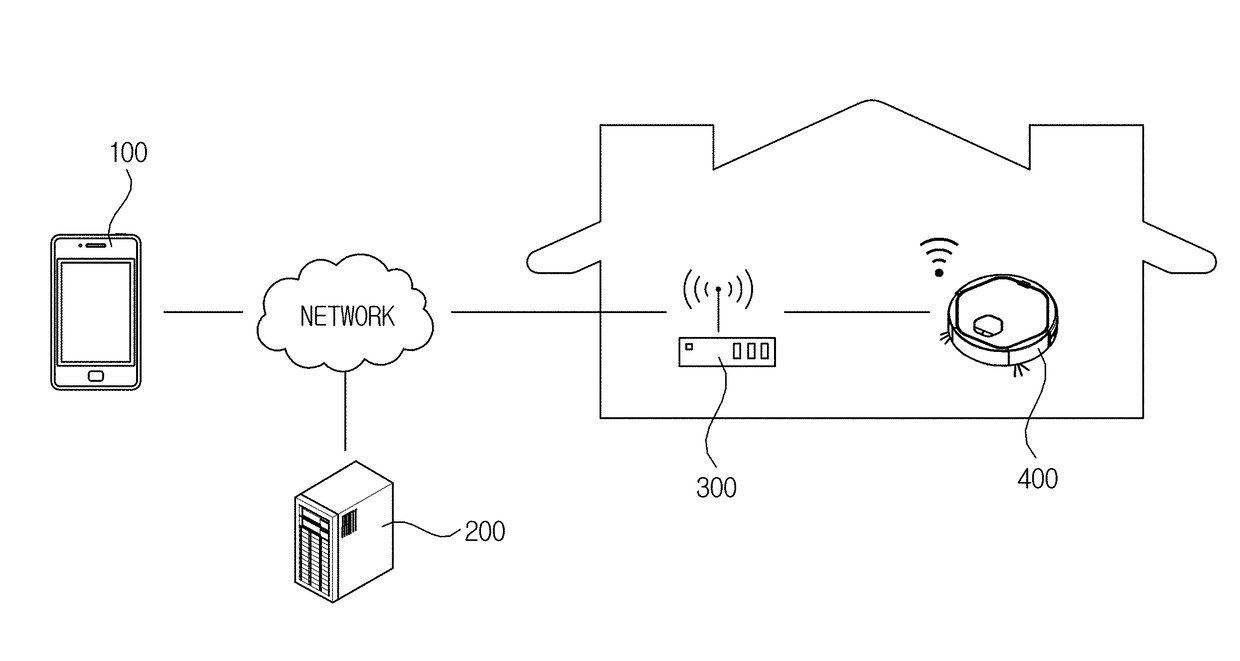

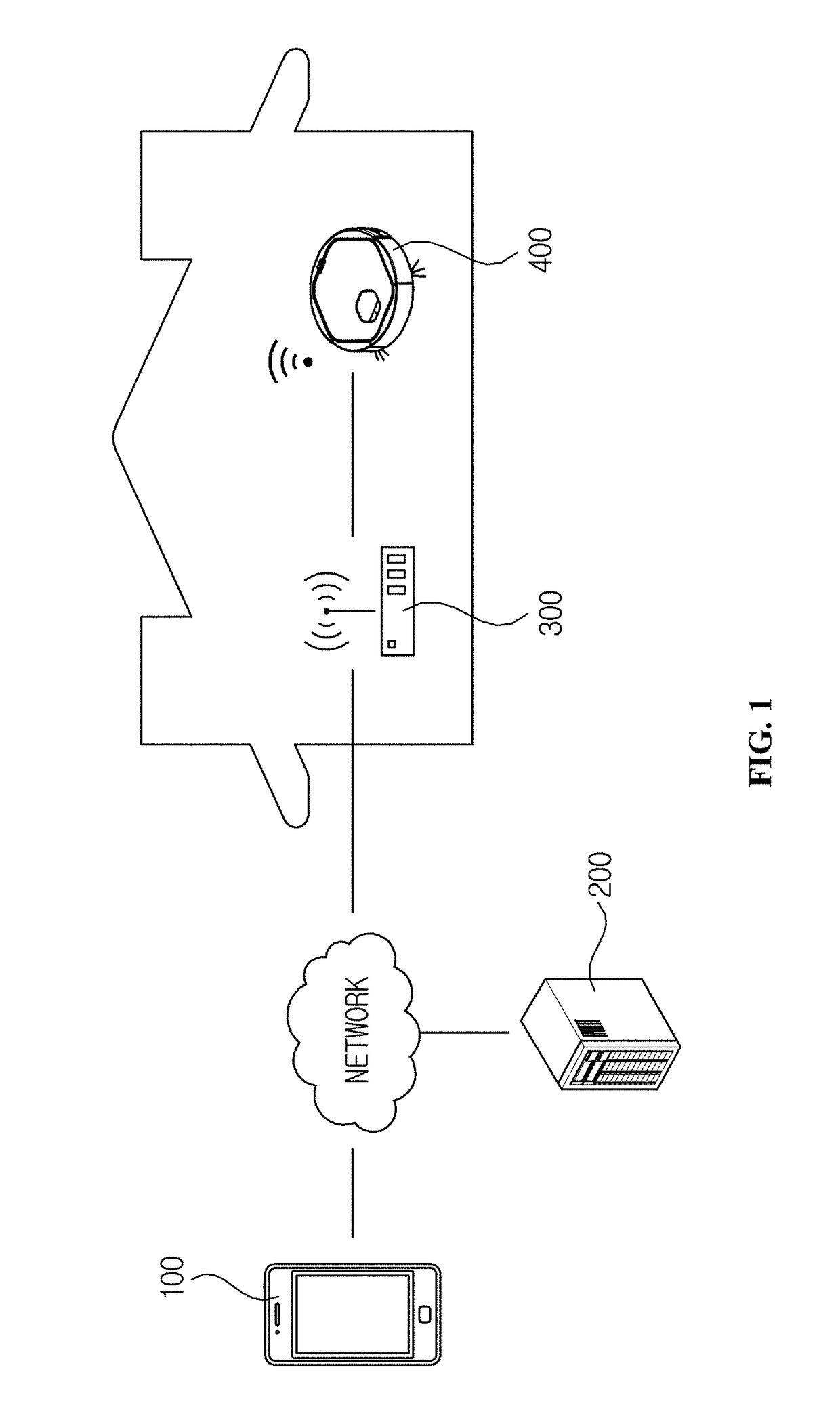

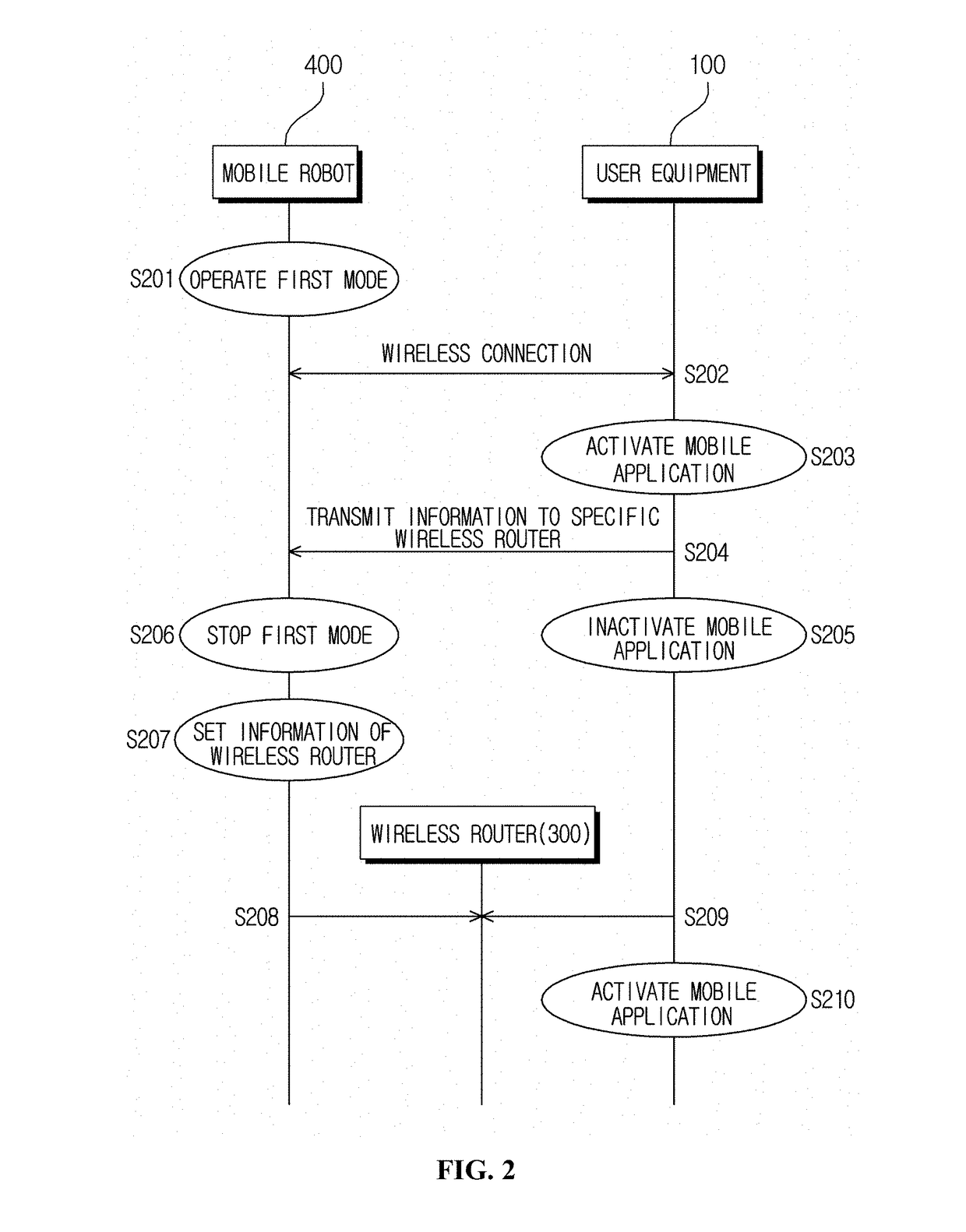

System for operating mobile robot based on complex map information and operating method thereof

ActiveUS20170203439A1Minimize user interventionMinimize the differenceProgramme controlProgramme-controlled manipulatorTransport engineeringMobile robot

Disclosed are a system for operating a mobile robot based on cleaning area information and a method thereof. A mobile robot based on cleaning area information according to an exemplary embodiment of the present invention includes a memory which stores a plurality of cleaning area information in which at least a part of a cleaning available area is changed; and a controller which controls to select one cleaning area information among the plurality of stored cleaning area information, recognize a position on a cleaning area map which configures the selected cleaning area information and perform cleaning on the cleaning available area from the recognized position.

Owner:YUJIN ROBOT

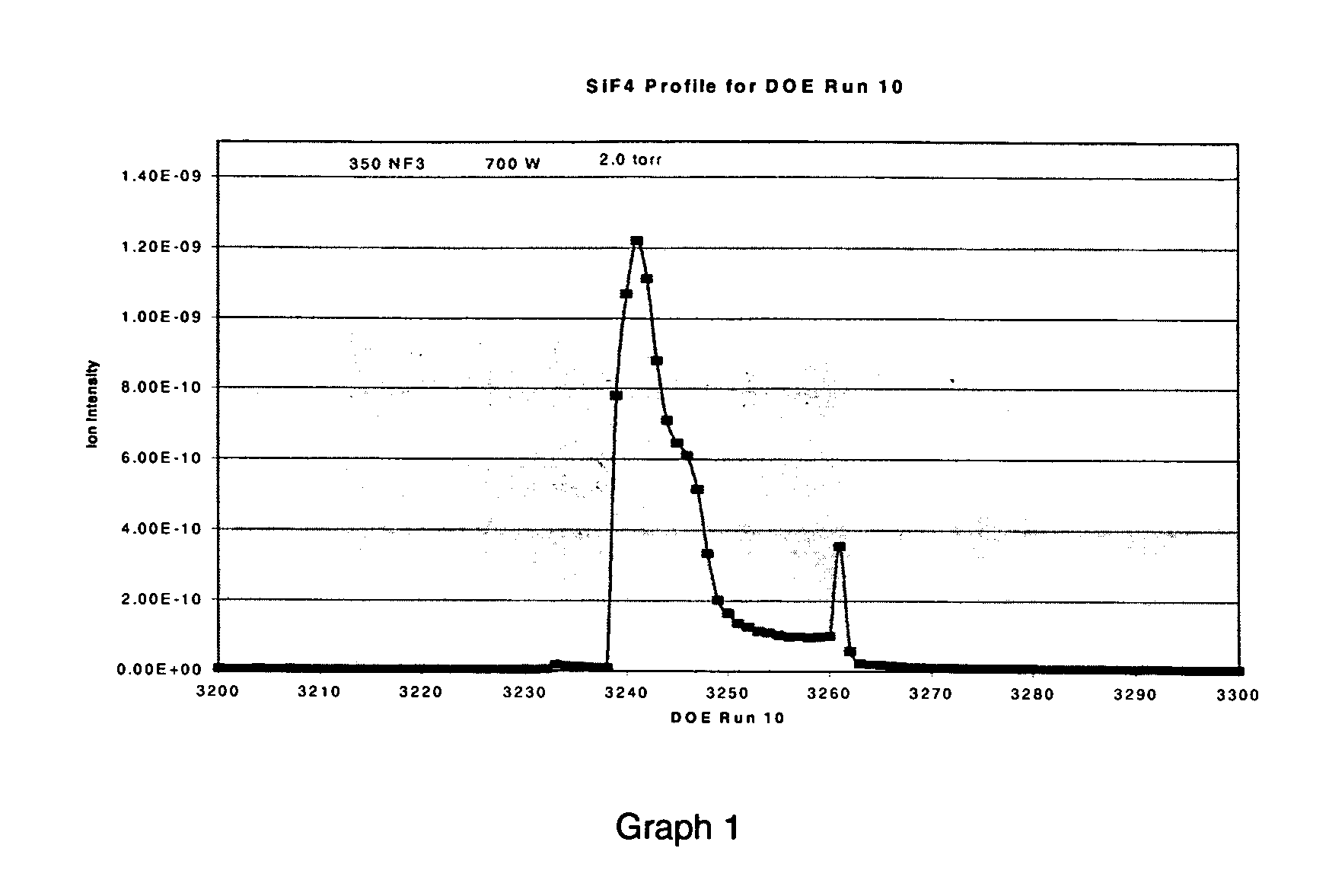

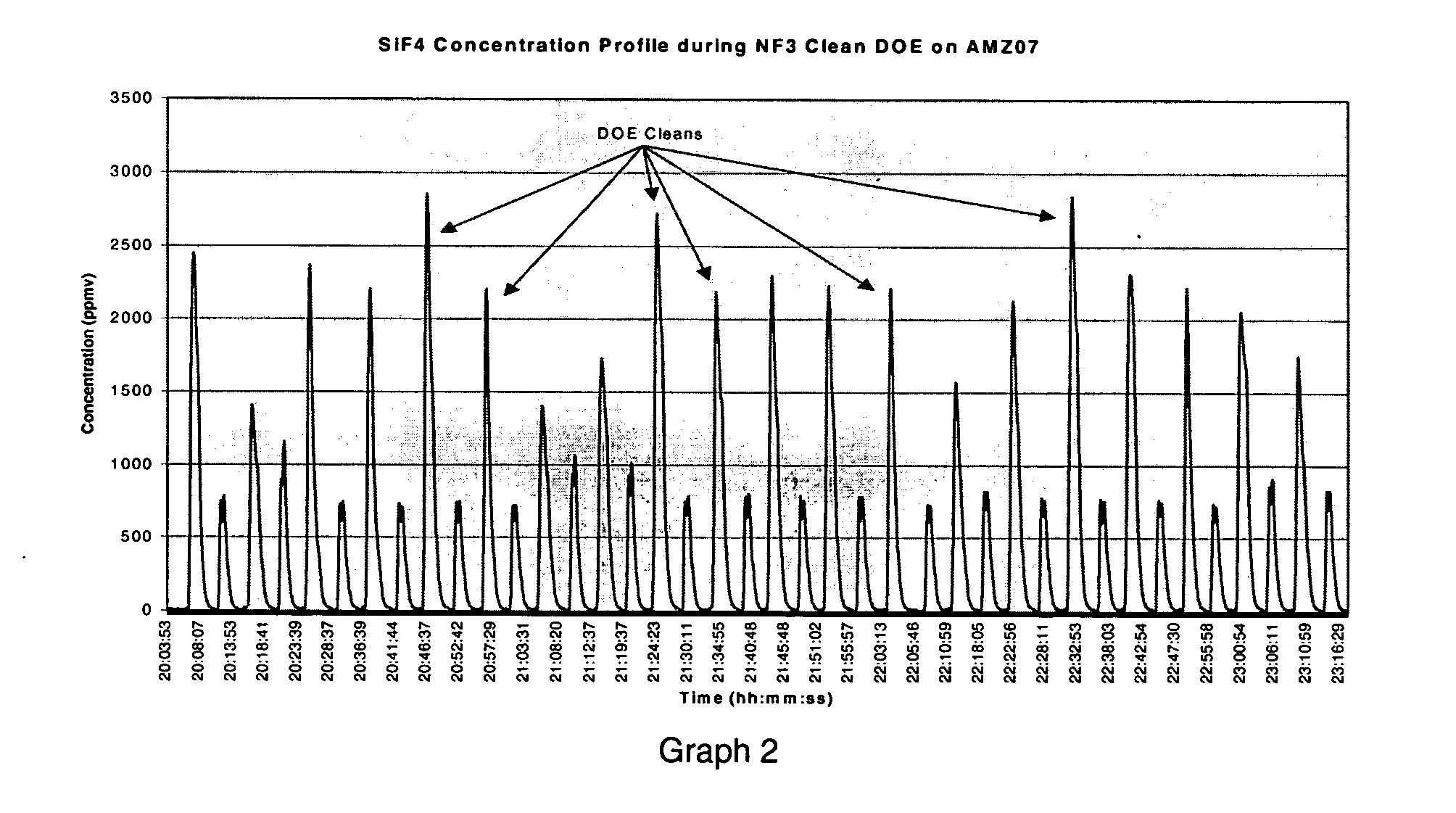

Low temperature CVD chamber cleaning using dilute NF3

InactiveUS20050252529A1Reduce susceptor cool down periodLow plasma energyElectric discharge tubesHollow article cleaningSusceptorPhysical chemistry

This invention relates to an improvement in in-situ cleaning of deposition byproducts in low temperature Plasma Enhanced Chemical Vapor Deposition (PECVD) chambers and hardware therein where process thermal budgets require minimization of the susceptor temperature rise. In the basic in situ PECVD process, a cleaning gas is introduced to the chamber for a time and temperature sufficient to remove films of the deposition byproducts and then the cleaning gas containing deposition byproducts removed from said PECVD chamber. The improvement for minimizing the susceptor temperature rise in a low temperature PECVD chamber during cleaning comprises: employing a cleaning gas consisting essentially of NF3 for cleaning and diluted with a sufficient amount of helium to carry away the heat developed during cleaning of the Plasma Enhanced Low Temperature Chemical Vapor Deposition chamber. The susceptor is maintained at 150° C. or below.

Owner:AIR PROD & CHEM INC

Molten metal oxidation resistance reducing agent

InactiveCN101215712AReduce scumSpeed up the flowWelding/cutting media/materialsSoldering mediaPhosphoric acidPhytic acid

The invention relates to metal melting antioxidative reducing agent, wherein the main component and the content of weight by parts comprises nonyl phenol polyoxyethylene thioether 51.19-91.19 parts, cyclohexylamine hydrobromate 5-20 parts, diphenyl guanidine hydrobromate 3-15 parts, phosphoric acid 0.3-5 parts, and phytic acid 0.5-8 parts, and further contains right amount of perfume compounds. The invention is oil liquid, since the invention is added with surface-active substance, when two liquids contact, relative / infrequent two-way molecular linkage can be generated, the surface tension of high-melting metal can be reduced, and simultaneously antioxidative reducing liquid is promoted to automatically diffuse rapidly. The invention is lighter than metal melting liquid, which can bespread whole flowing liquid and isolate air, and effectively prevent oxidation, while active substance and organic or inorganic acid which are contained in the invention can disperse inner gravity of oxygenized metal dross, take the initiative to break the inner structure of oxygenized metal dross, deacidize available metal, and deacidizing efficiency is about 95%, and the invention has high performance price ratio, less residual dross, cleanness and convenience, which is convenient for equipment maintenance.

Owner:SHENZHEN KUNQI XINHUA

High temperature solid surface long term accurate temperature measuring system in complicated environment

InactiveCN101441119ALong-term temperature measurementStable temperature measurementTemperature measurement of moving solidsPositive pressureWorking environment

The invention provides a mid-high temperature solid surface long-term accurate temperature measurement system of a complex environment, comprising a non-contact type temperature measurement instrument, an incubator, a dustproof sleeve, and a swirl generator, wherein the incubator is divided into a front cavity and a rear cavity through a baffle, the temperature measurement instrument is arranged in the rear cavity, the dustproof sleeve is arranged in the front cavity; the front end of the dustproof sleeve is provided with a lens and the swirl generator, while the front end of the swirl generator is provided with a sighting tube. A probe aims at the temperature measurement surface through the dustproof sleeve, the lens and the sighting tube. The swirl generator generates a certain positive pressure at the front of the dustproof sleeve, so that the outside pollutant is prevented from approaching the dustproof sleeve and the lens, and heat ray from the surface of the measured object is directly introduced into a temperature measurement probe without being absorbed by the participatory media. The sighting tube prevents the difficulty brought by the correction of other heat radiation to the temperature of the temperature measurement instrument. The incubator and the dustproof sleeve provide a favorable working environment, so the invention can perform long-term, stable, continuous, and accurate temperature measurement in the complex environment.

Owner:CHONGQING UNIV

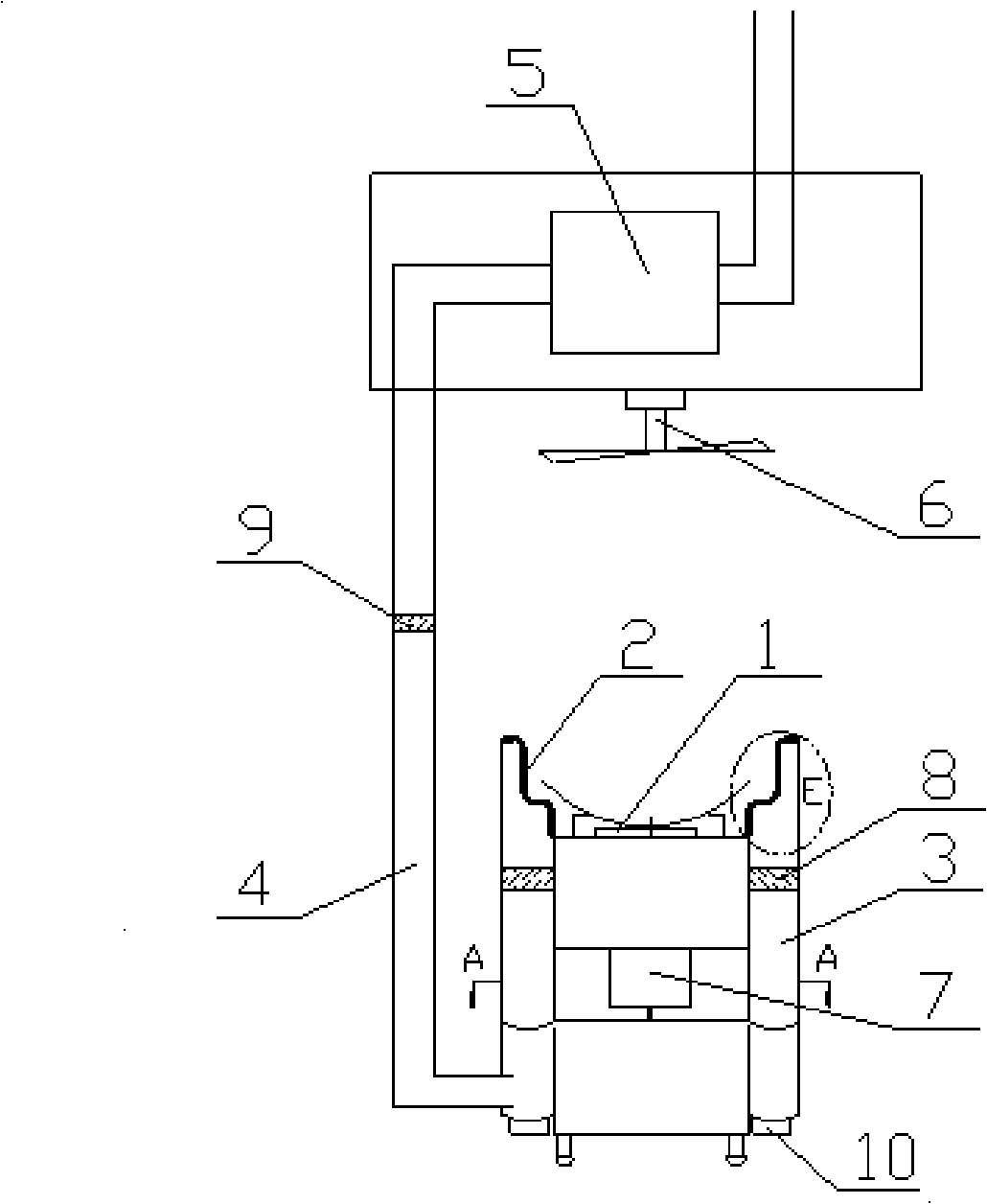

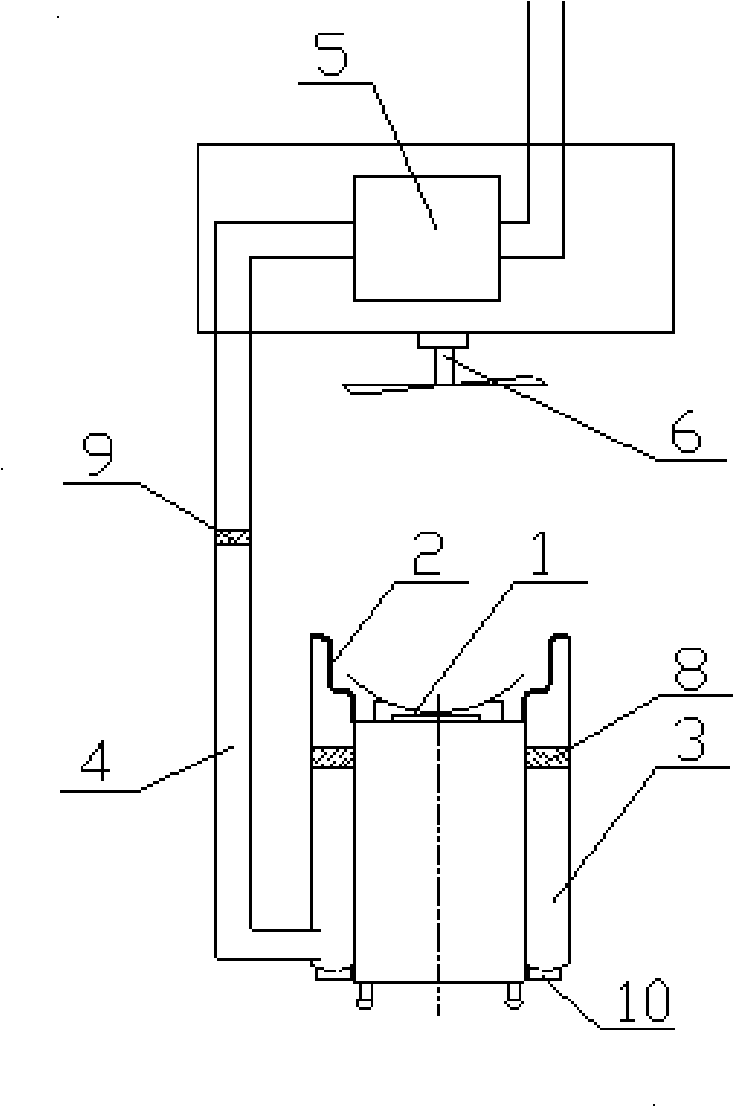

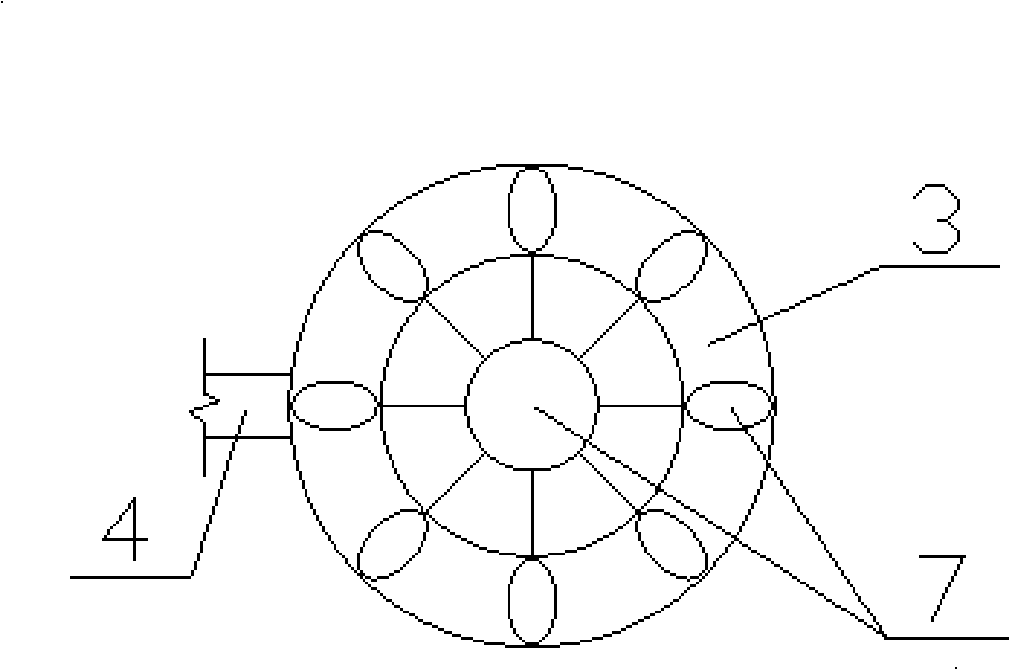

Method for manufacturing down draft type cooking fume exhauster and down draft type cooking fume exhauster

InactiveCN101329080AReduce spreadFacilitated DiffusionDomestic stoves or rangesLighting and heating apparatusShortest distanceEngineering

The invention discloses a manufacturing method of a lower-absorbing range hood and the lower-absorbing range hood. A gas-absorbing face shield connected with a subpressure tube is arranged around a stove to absorb the generated oil-smoke in a short distance. By the gas-absorbing shied which is arranged around the stove and is connected with the subpressure tube, the oil-smoke coming from the frying pan during dishes-frying can be directly absorbed by the invention so as to reduce the chance of oil-smoke diffusion and contamination to the indoor environment; a fan is arranged at the upper end of the stove to generate downward air so as to lead the straight-upward oil-smoke to float to the pan side for being conveniently absorbed by the gas-absorbing face shield, thus further reinforcing the oil-smoke absorption effect; an axial fan is connected with a circular smoke tube, thus further enlarging the subpressure in the circular smoke tube and increasing the oil-smoke absorbing force.

Owner:肖克贤

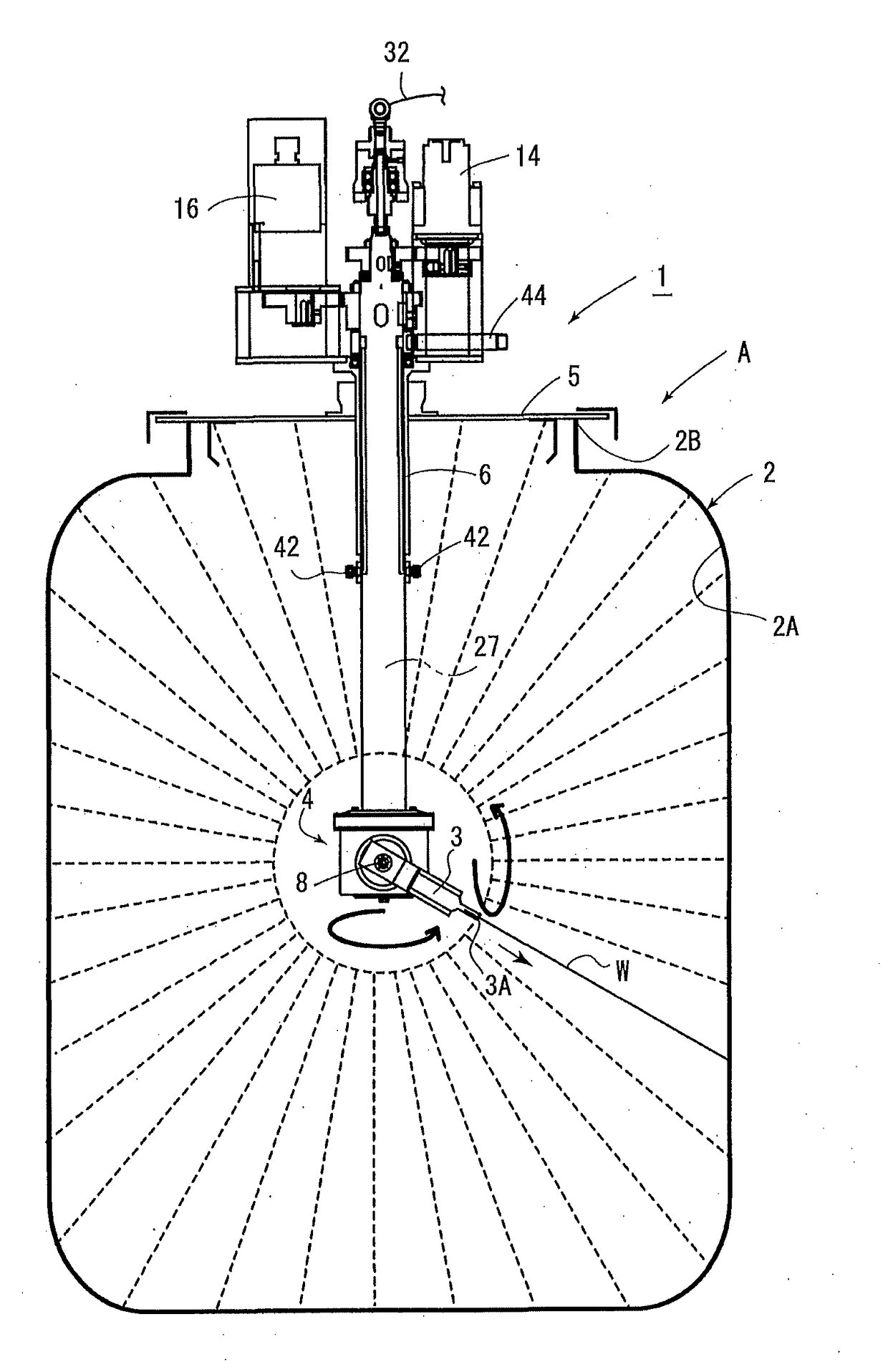

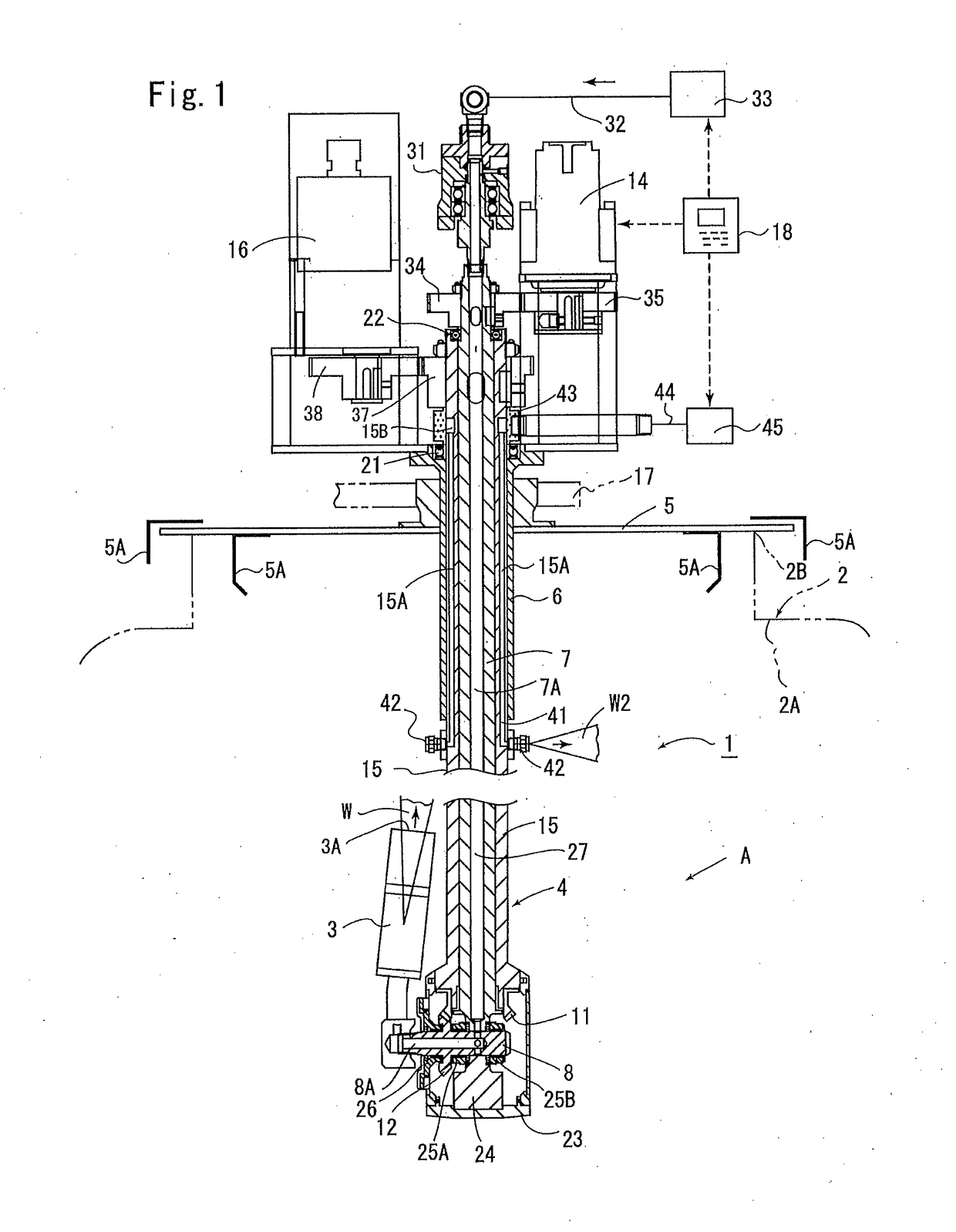

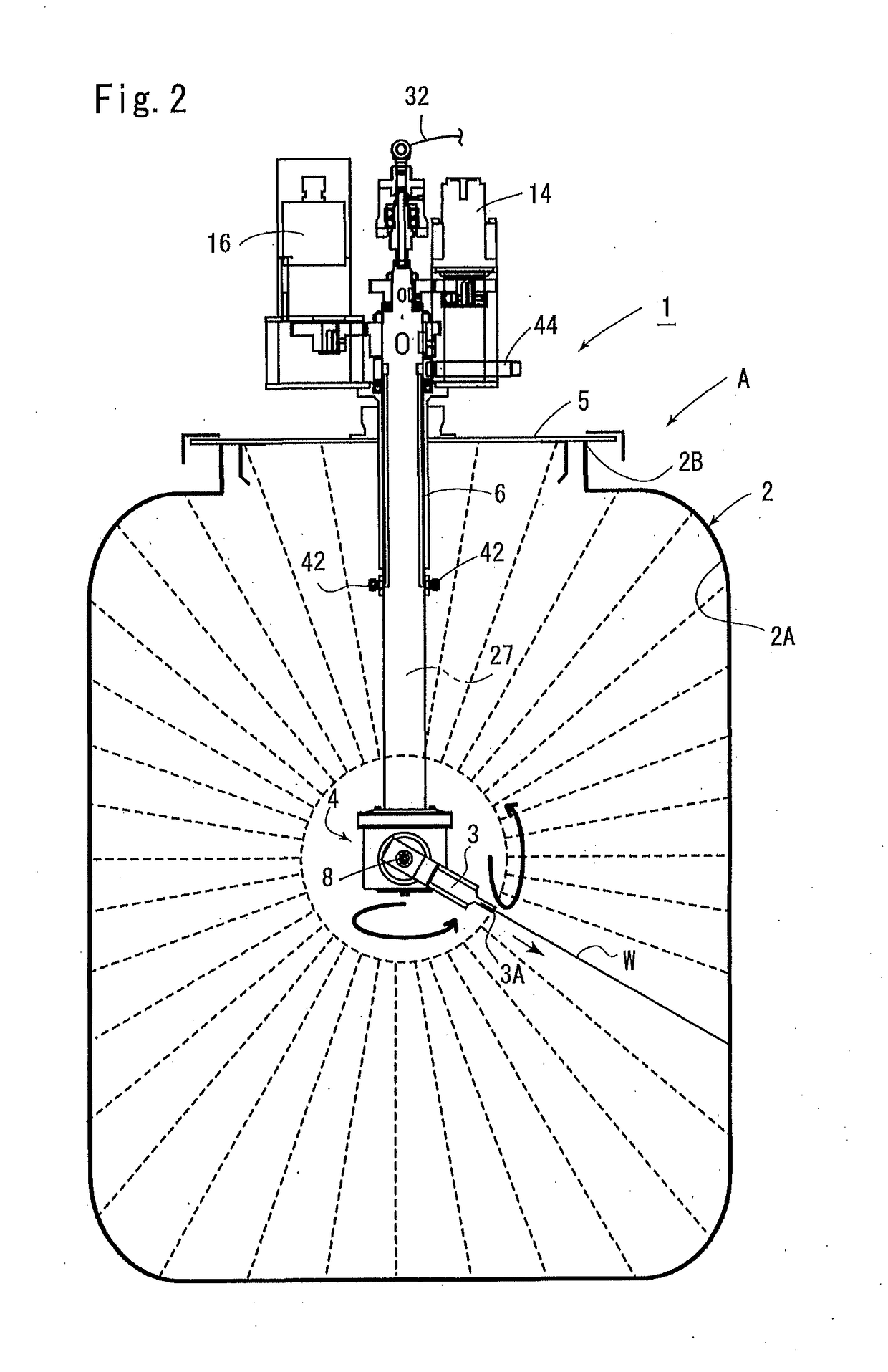

Cleaning apparatus

ActiveUS20180281032A1Curb consumptionEasy to cleanHollow article cleaningSpraying apparatusEngineeringElectric power

A cleaning apparatus 1 includes: a pivot rotary shaft 8 attached with a nozzle 3; a first motor 14 for revolving and rotating the pivot rotary shaft 8 via an inner tube 7 and bevel gears 11 and 12; a second motor 16 for solely rotating an outer tube 15; and a control device 18 for controlling the operation of both the motors 14 and 16. The outer tube 15, and the pivot rotary shaft 8 and the nozzle 3 are operated together via the bevel gears 11 and 12. The first motor 14 is operated with the cleaning fluid W being sprayed from the nozzle 3 to rotate the nozzle 3 and the pivot rotary shaft 8, and the second motor 16 is operated at a required rotational frequency. Then, as a result of the outer tube 15 being rotated, the nozzle 3 is revolved while being inclined in a required direction without being rotated. This makes it possible to preferentially spray the cleaning fluid W onto required areas of the inner surface 2A of the tank 2. It is possible to suppress consumption of the cleaning fluid W and electric power, and efficiently clean the inner surface 2A of the tank 2.

Owner:SHIBUYA MASHINARII

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com