Method for manufacturing down draft type cooking fume exhauster and down draft type cooking fume exhauster

The technology of a range hood and its manufacturing method is applied in the manufacture of downdraft range hoods and the field of downdraft range hoods, which can solve the problems of difficulty in controlling the installation height of range hoods, unsatisfactory oil fume suction effect, and easy pollution of range hoods It can reduce the chance of polluting the indoor environment, facilitate the recovery of oil particles, and increase the absorption of oil fume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

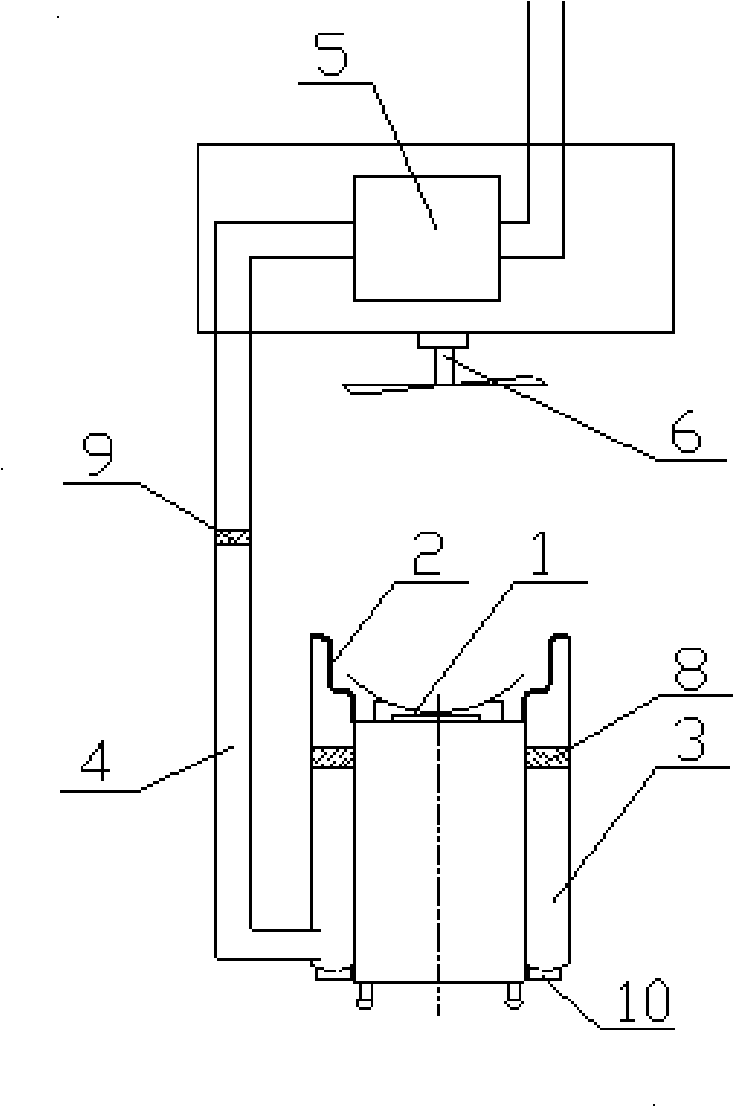

[0016] Embodiment 1: as figure 2 As shown, first use stainless steel to make a Figure 4 The suction mask 2 of the shown shape, the prepared suction mask 2 is placed around the cooking range 1, and the cooking range 1 can be existing common stoves such as fuel oil, gas, induction cooker, resistance furnace, etc., and the lower end of the suction mask 2 is sealed and connected A circular smoke pipe 3, the circular smoke pipe 3 is composed of an inner barrel and an outer barrel, a flue gas pipe 4 is connected to the lower section of the circular smoke pipe 3, and an exhaust fan 5 is connected to the flue gas pipe 4, and the exhaust fan 5 can be Centrifugal fan or axial flow fan, start the present invention when cooking like this, exhaust fan 5 makes circular smoke pipe 3 and flue gas pipe 4 be in negative pressure, and the oil fume that goes out from pot just can be directly absorbed by suction mask 2 and enters circular circuit The smoke pipe 3 is discharged outside the house...

Embodiment 2

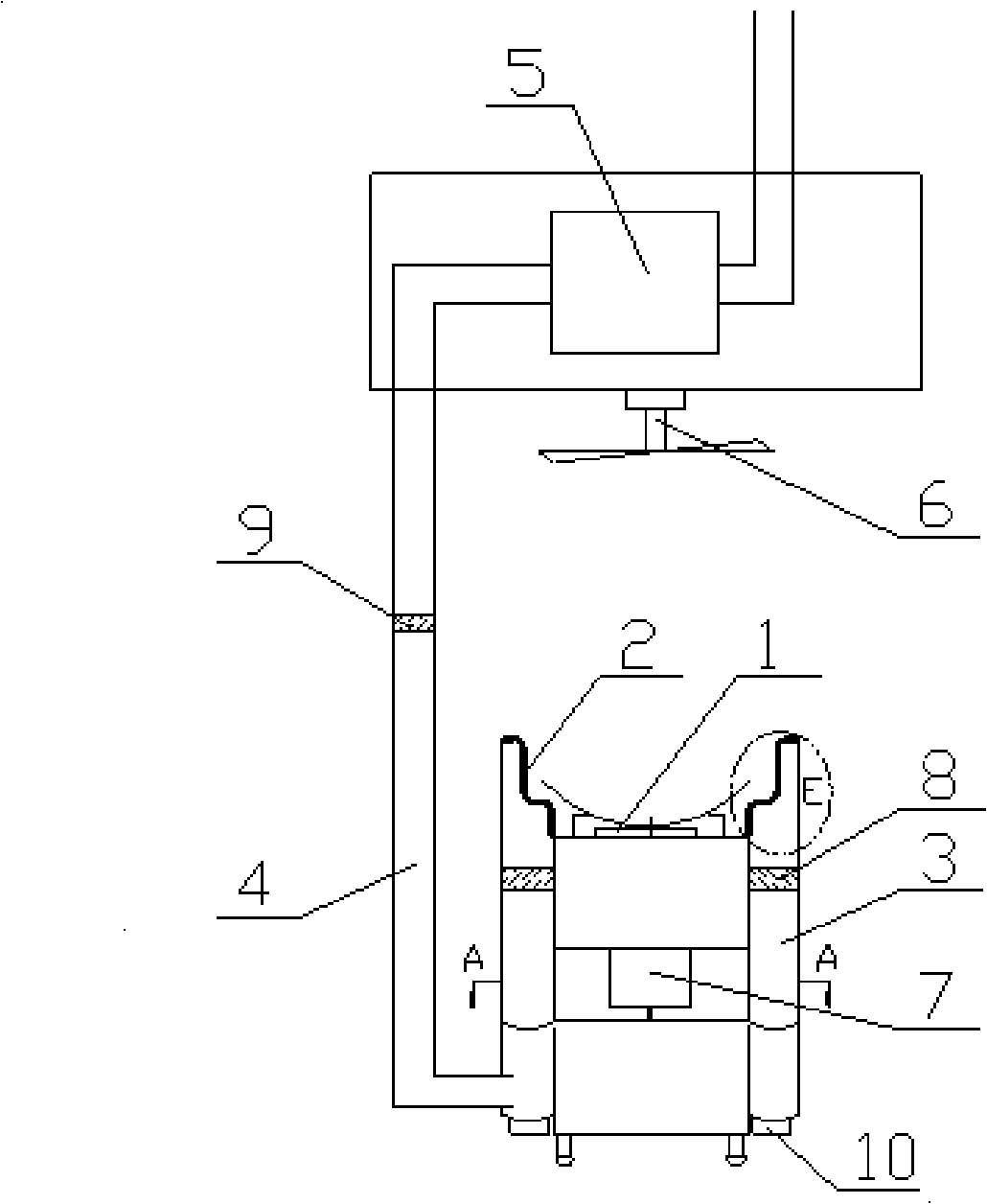

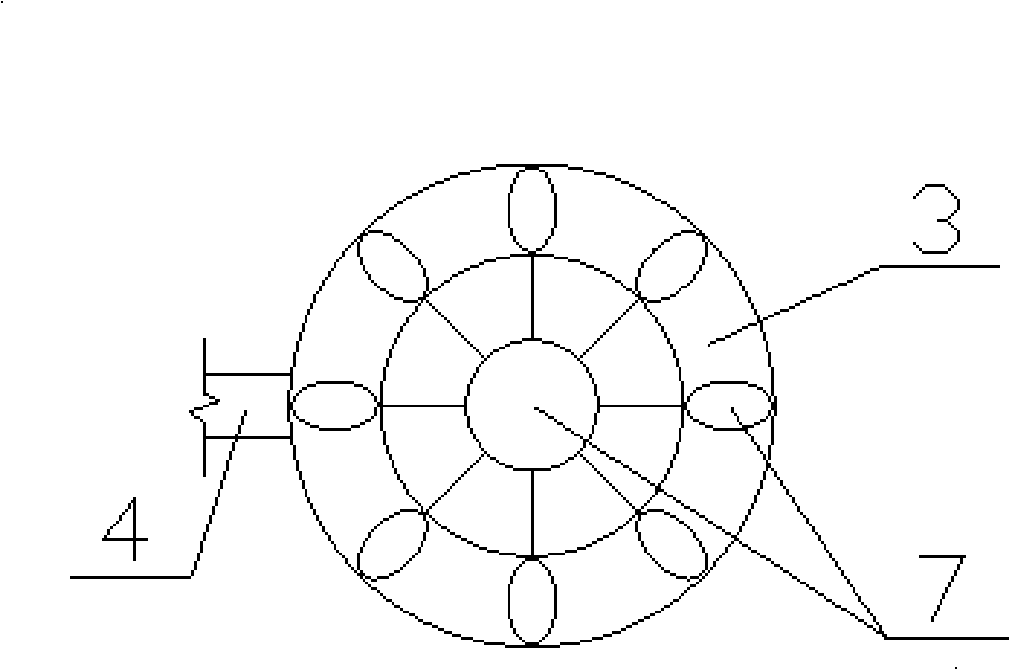

[0017] Embodiment 2: as figure 1 As shown, first use stainless steel to make a Figure 4 The suction mask 2 of the shown shape, the prepared suction mask 2 is placed around the cooking range 1, and the cooking range 1 can be existing common stoves such as fuel oil, gas, induction cooker, resistance furnace, etc., and the lower end of the suction mask 2 is sealed and connected A circular smoke pipe 3, the circular smoke pipe 3 is composed of an inner barrel and an outer barrel, and a gap is opened in the middle of the inner barrel to allow the blades of the axial flow fan 7 to rotate. Inside tube 3, as image 3 As shown (that is, in the jacket produced after the inner barrel and the outer barrel are socketed). A smoke pipe 4 is connected to the lower part of the circular smoke pipe 3, and an exhaust fan 5 is connected on the smoke pipe 4. The exhaust fan 5 can be a centrifugal fan or an axial flow fan, so that the axial flow fan 7 and the exhaust fan are turned on when cookin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com