Range hood filter net monitoring device and method

A monitoring device and range hood technology, which is applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of inconvenient use of range hoods and inaccurate monitoring methods of oil fume, and achieve the effect of convenient replacement or cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

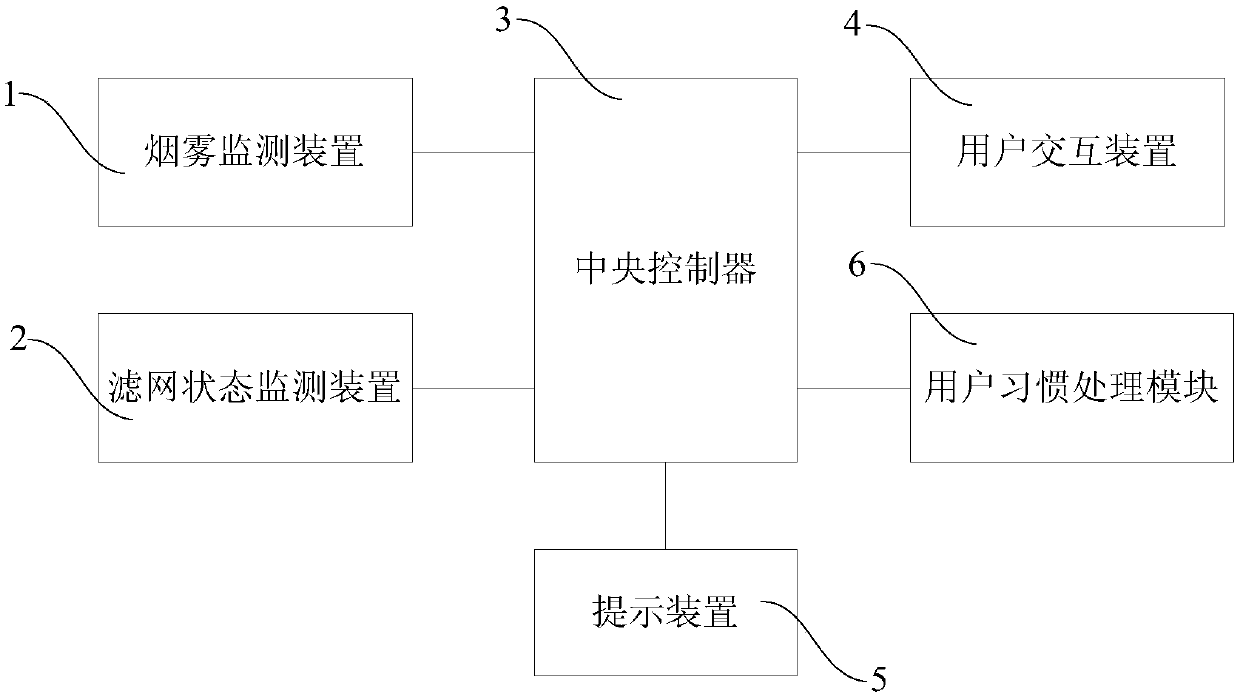

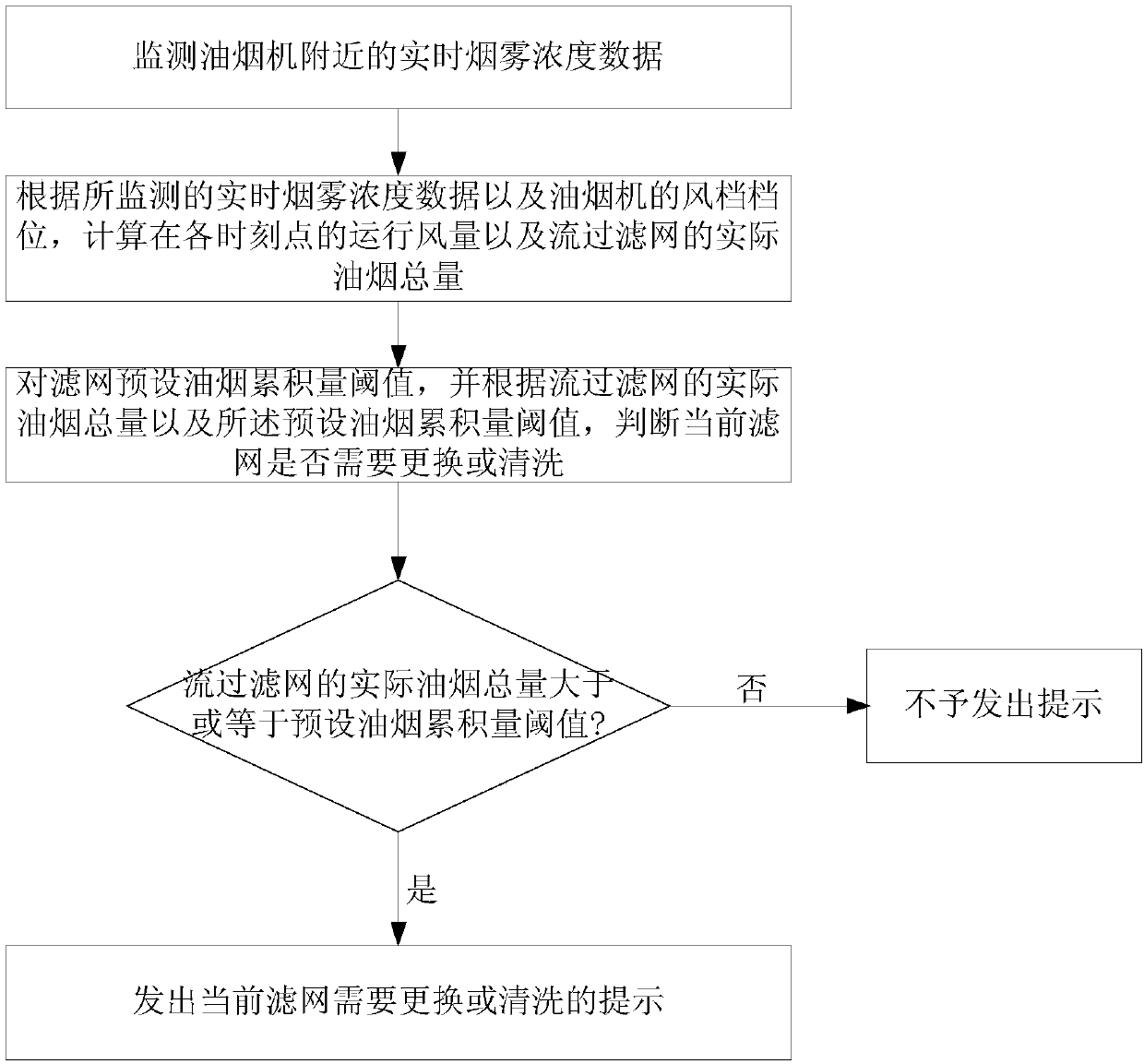

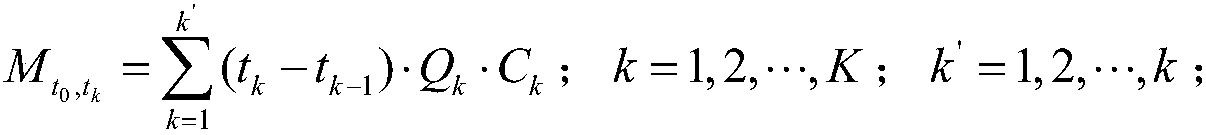

[0041] Such as figure 1 As shown, the filter monitoring device of the range hood in this embodiment includes a smoke monitoring device 1, a filter status monitoring device 2, a central controller 3, and a user interaction device 4. The central controller 3 is respectively connected to the smoke monitoring device 1, the filter Network status monitoring device 2 and user interaction device 4; among them, in this embodiment:

[0042] Smoke monitoring device 1 is used to monitor the real-time smoke concentration data near the range hood, and send the monitored real-time smoke concentration data to the central controller 3;

[0043] The filter status monitoring device 2 is used to monitor the real-time oil smoke volume data of the flow filter, and send the monitored real-time oil smoke volume data to the central controller 1;

[0044] The user interaction device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com