Intelligent cleaning method

A technology for cleaning and cleaning heads, applied in the field of laser cleaning, which can solve the problems of inaccurate cleaning, affecting cleaning efficiency, poor cleaning accuracy, etc., and achieve the effects of avoiding residual impurities, improving cleaning effect, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

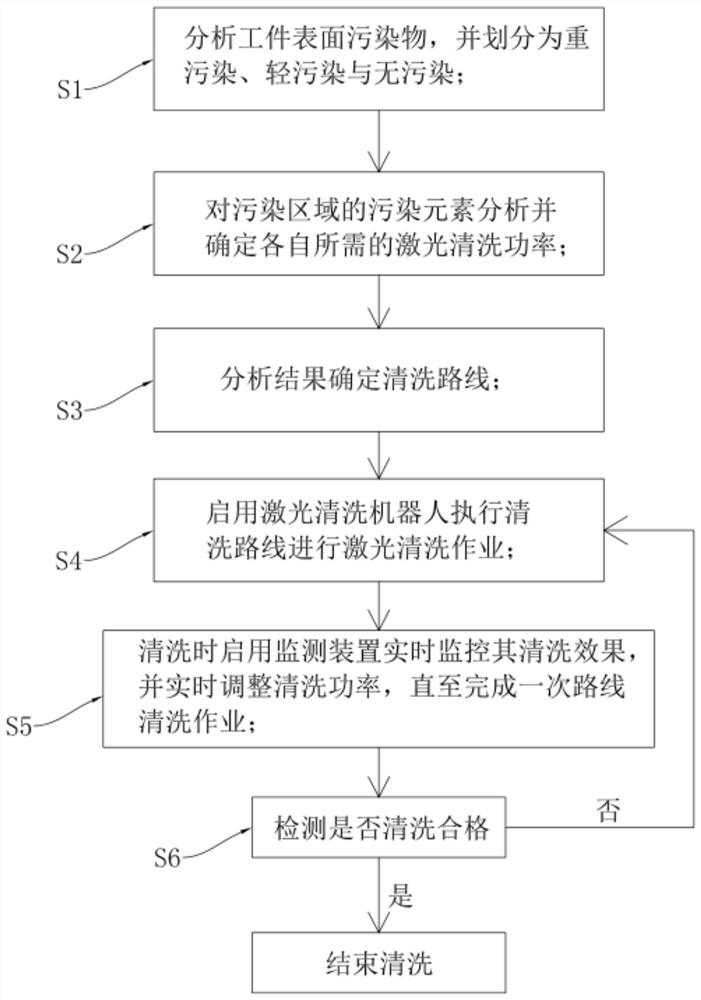

[0032] refer to figure 1 Further explain the intelligent cleaning method.

[0033] An intelligent cleaning method, such as figure 1 shown, including the following steps,

[0034] S1. Prepare the workpiece to be cleaned, use the cooperation of high-pressure blower and dust removal roller brush to preliminarily clean the pollutants that are easy to fall off on the surface, and then send it to the workpiece analysis office, analyze the pollutants on the surface of the workpiece to be cleaned, and use the industrial vision system to record the pollutants to be cleaned. Clean the workpiece surface to feed back to the controller to analyze the pollution area, use the spectrometer to determine the pollution degree of each pollution area, use the elemental analyzer to determine the pollution elements in each pollution area, determine the pollutant distribution area and pollution degree, and divide them into Heavily polluted areas, lightly polluted areas, and non-polluted areas; amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com