Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

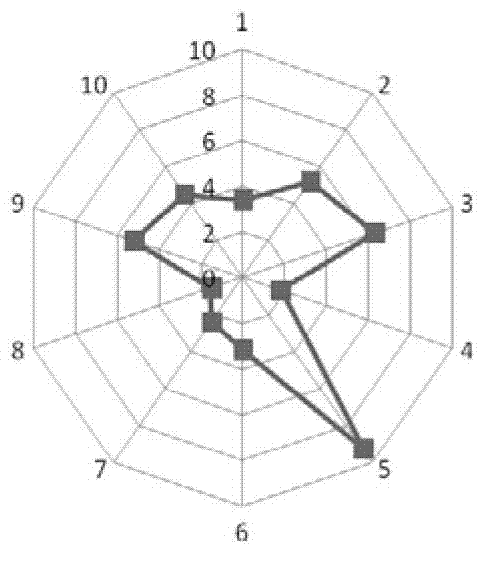

354results about How to "Uniform product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-Absorbing Polysaccharide and Method for Producing the Same

InactiveUS20080009616A1Drying processImprove retentionSugar derivativesBaby linensPolyphosphatePhosphoric acid

The present invention relates to a process for producing a water-absorbent polysaccharide including the process steps of bringing into contact an uncrosslinked polysaccharide with a polyphosphate or a polyphosphoric acid as crosslinking agent in the presence of water to form a polysaccharide gel and crosslinking the polysaccharide gel. The invention further relates to a water-absorbent polysaccharide obtainable by this process, a water-absorbent polysaccharide, a composite, a process for producing a composite, a composite produced by this process, the use of the water-absorbent polysaccharides or of the composites as well as the use of polyphosphates.

Owner:EVONIK DEGUSSA GMBH

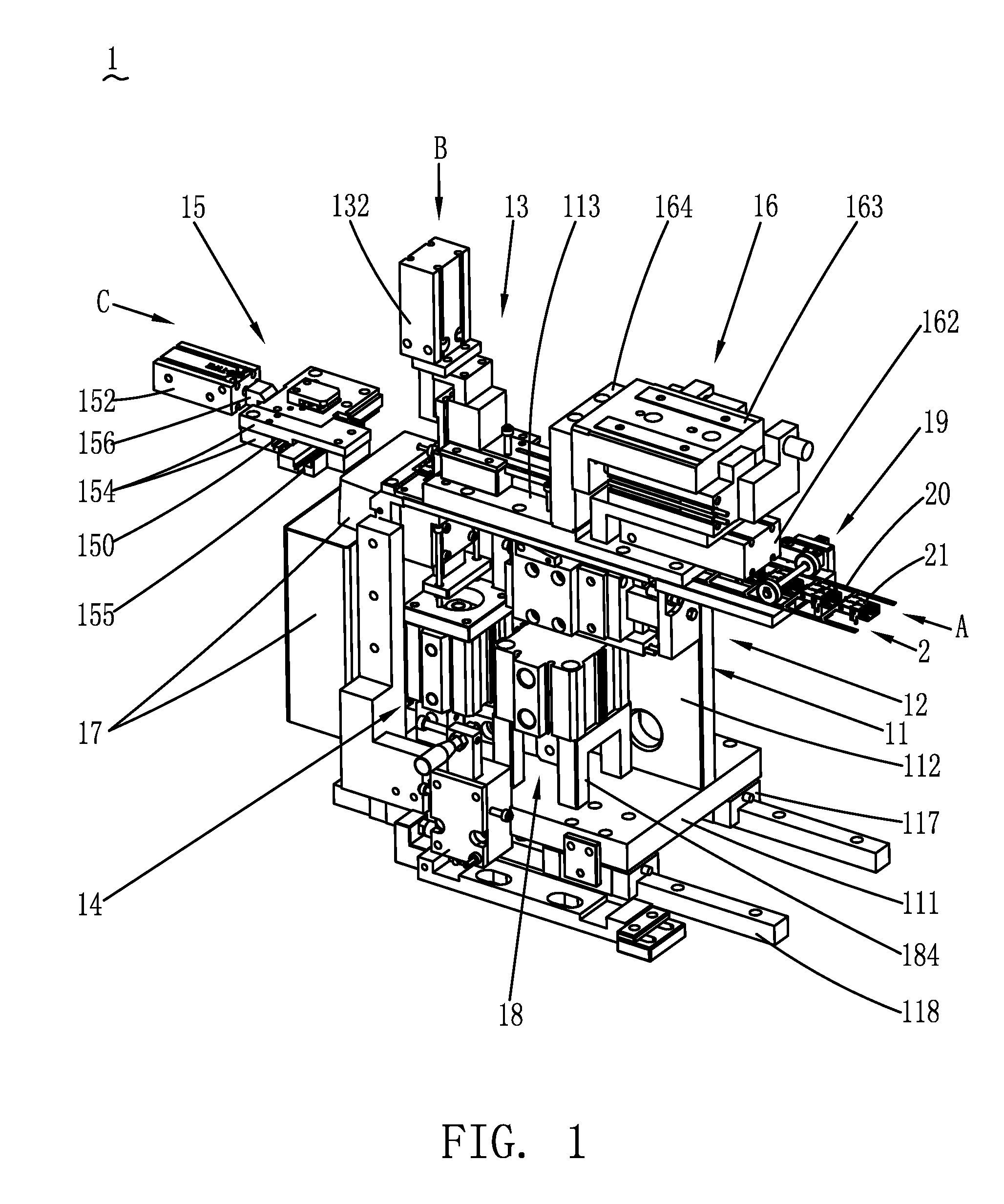

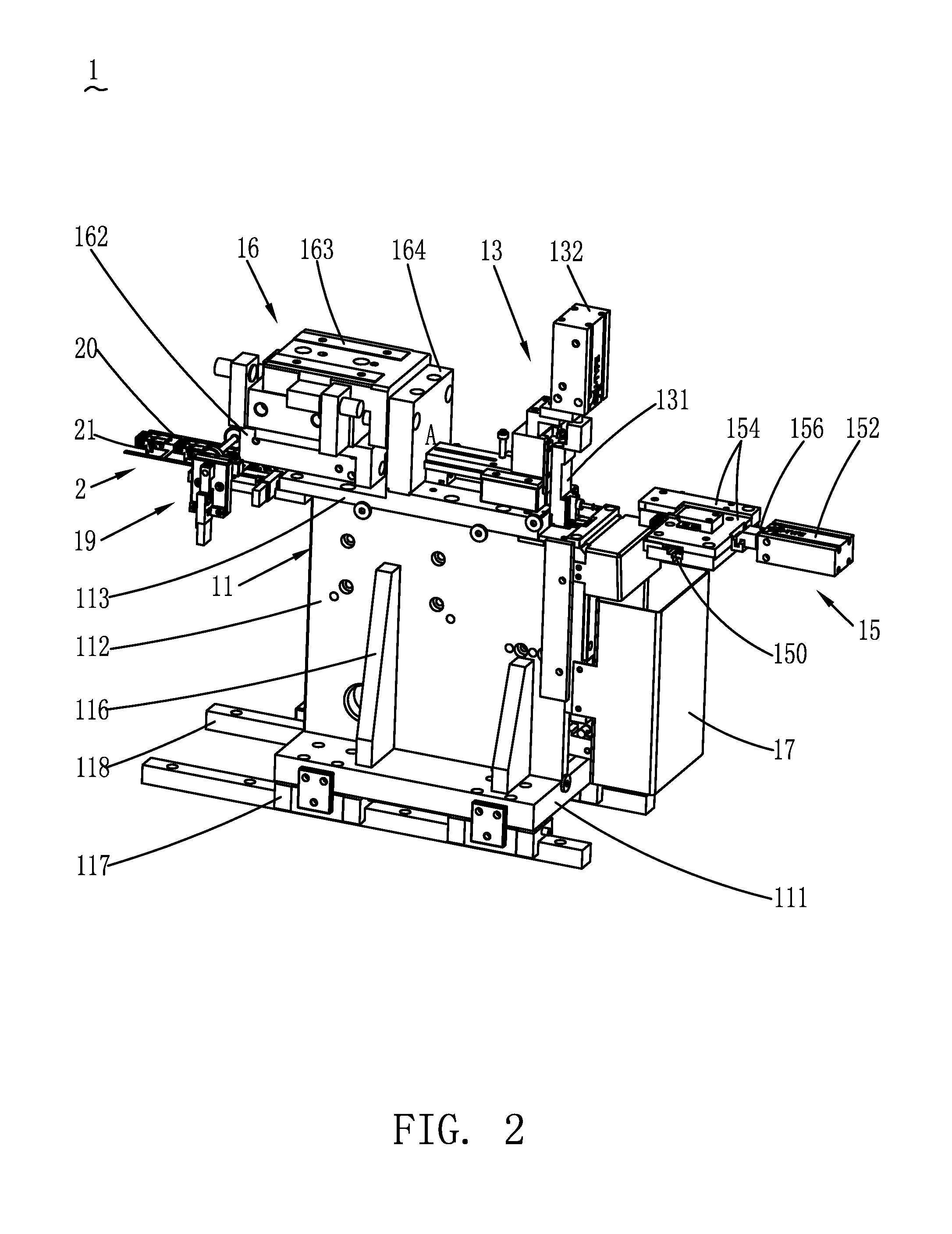

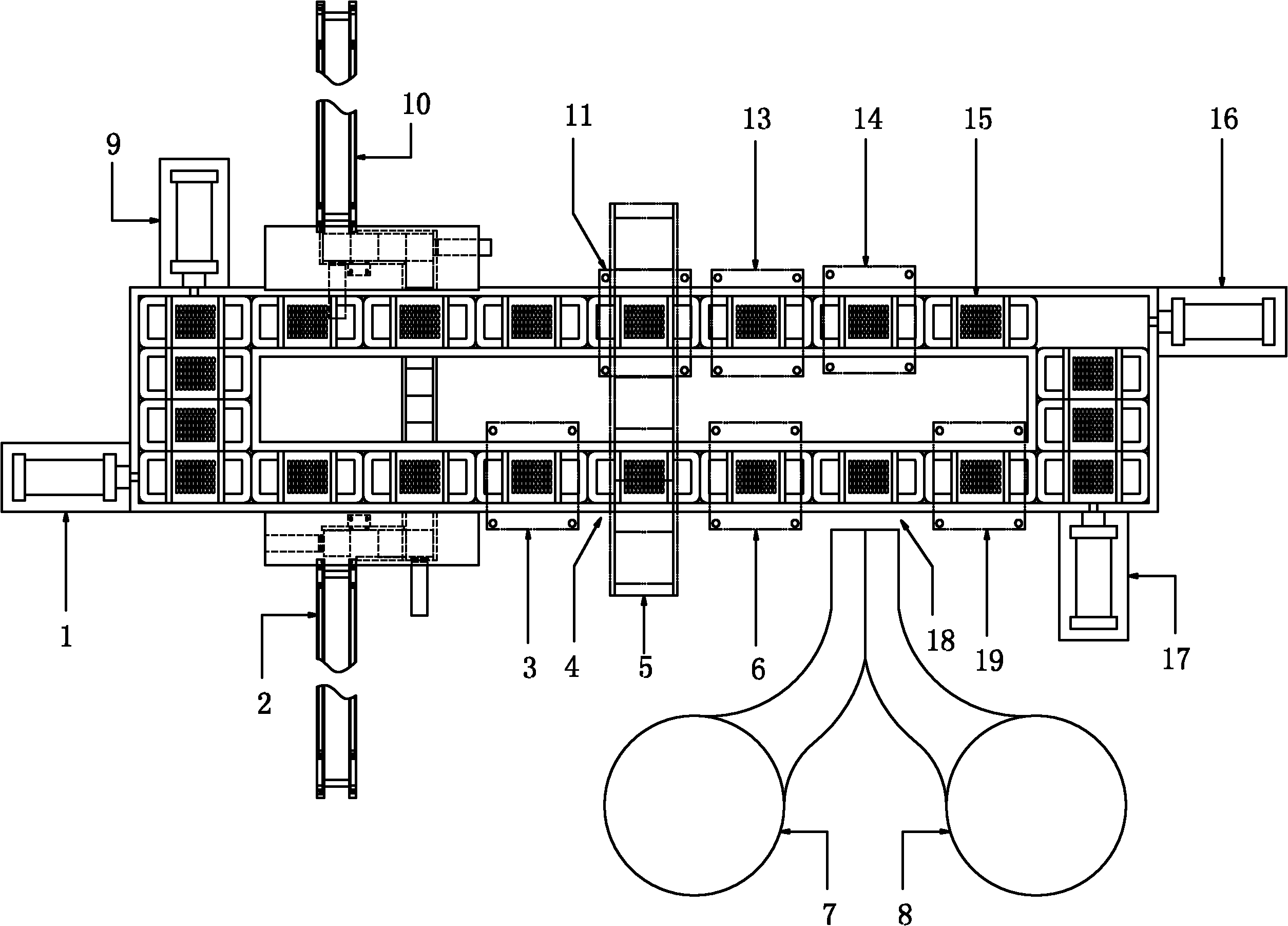

Metal shell cutting and assembling machine

InactiveUS20120066891A1Improve production efficiencyReduce labor costsAutomatic control devicesContact member assembly/disassemblyEngineeringManufacturing efficiency

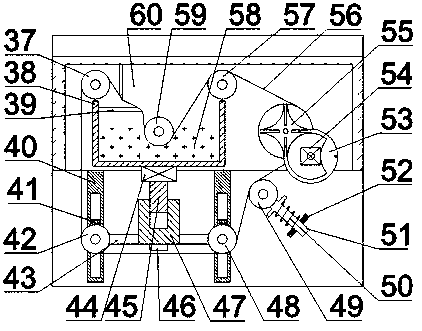

Provided is a metal shell cutting and assembling machine for cutting a material tape with metal shells and assembling the metal shell with a plastic body of a connector. The metal shell cutting and assembling machine includes a frame, a material-feeding mechanism, a pre-press mechanism, a metal shell-cutting mechanism, a plastic body-inserting mechanism, a metal shell-inserting mechanism and a controller. The material-feeding mechanism is used for transferring the material tape. The pre-press mechanism can pre-press the metal shell of the material tape for being cut by the metal shell-cutting mechanism. The metal shell-inserting mechanism can push the metal shell held between the pre-press mechanism and the metal shell-cutting mechanism onto the plastic body-inserting mechanism, and the plastic body-inserting mechanism pushes the plastic body for assembling with the metal shell. Whereby the metal shell cutting and assembling machine can enhance the manufacture efficiency and reduce the labor cost.

Owner:CHENG UEI PRECISION IND CO LTD

Method for refining fasudil hydrochloride

The invention relates to a method for refining fasudil hydrochloride. The method comprises the following steps: 1, discoloring, namely adding active carbon into fasudil after resin adsorption, fully mixing the active carbon and the fasudil, filtering the mixture, removing the active carbon, and collecting the filtered solution for later use; 2, washing, namely adding purified water into the discolored solution, fully mixing the solution, separating the solution to remove water phase, and collecting the oil phase for later use; 3, acidifying and salifying, namely adding the purified water intothe oil phase, adjusting pH value of the solution by hydrochloric acid to fully acidify and salify the oil phase, and collecting the water phase for later use; and 4, crystallization, namely, adding n-butyl alcohol into the water phase, fully mixing the solution, then decompressing and azeotropic-crystallizing the solution, duly replenishing the n-butyl alcohol to keep the consistency of the solution, stopping crystallization till the moisture content in the mother solution is reduced to a certain value, and filtering and drying the crystals to obtain a refined fasudil hydrochloride product.

Owner:TIANJIN CHASE SUN PHARM CO LTD

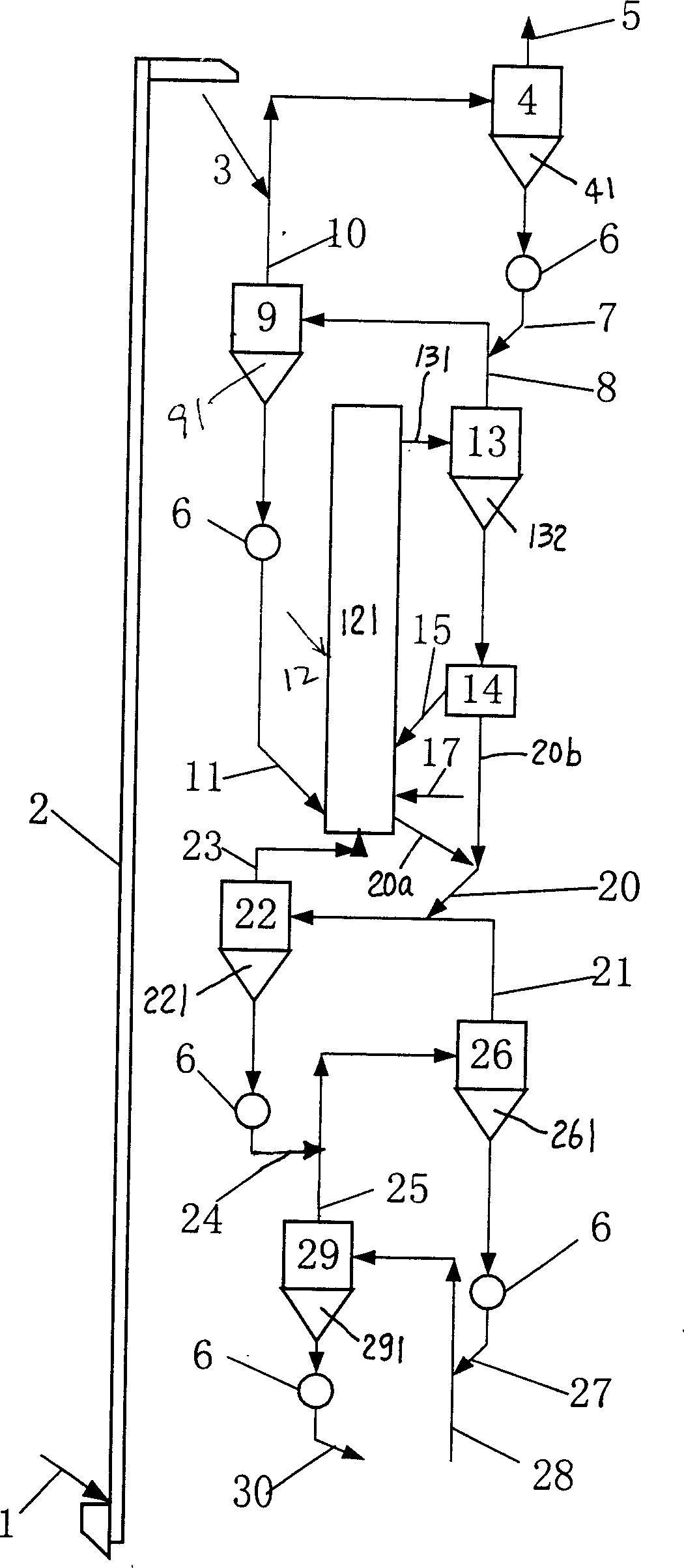

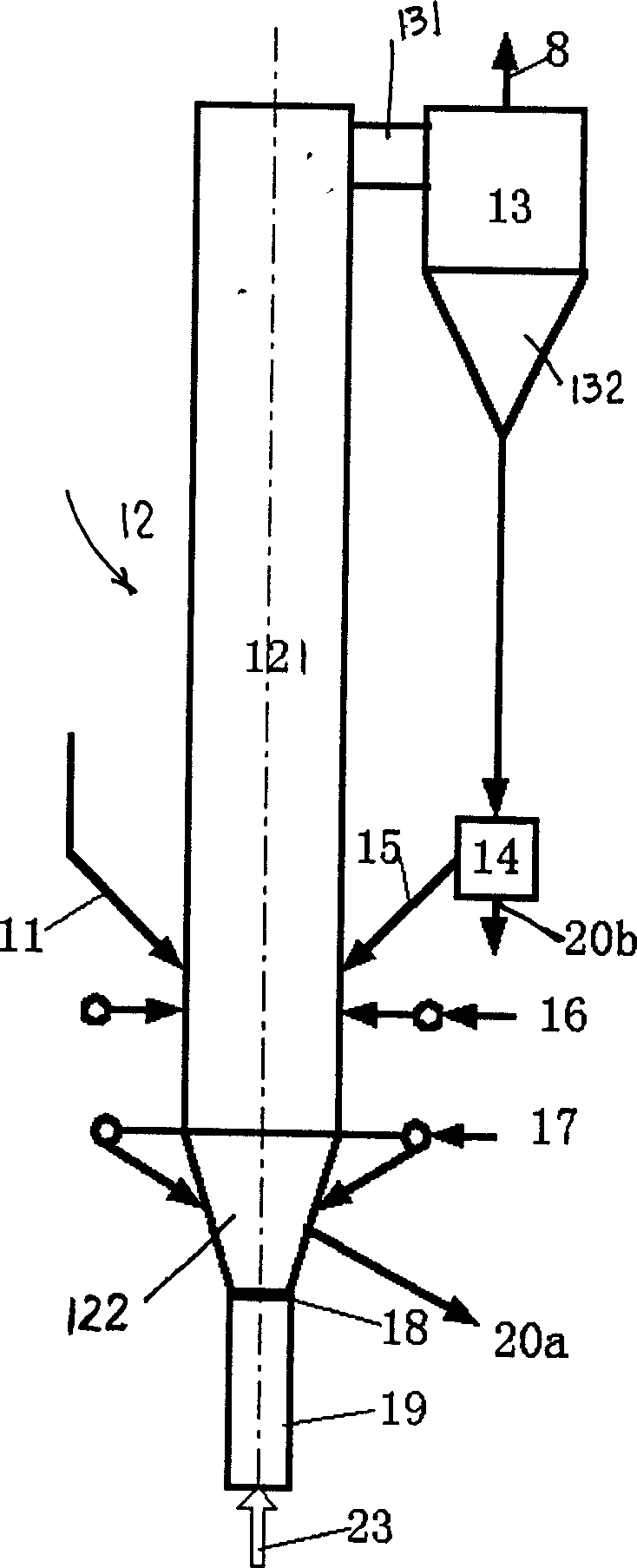

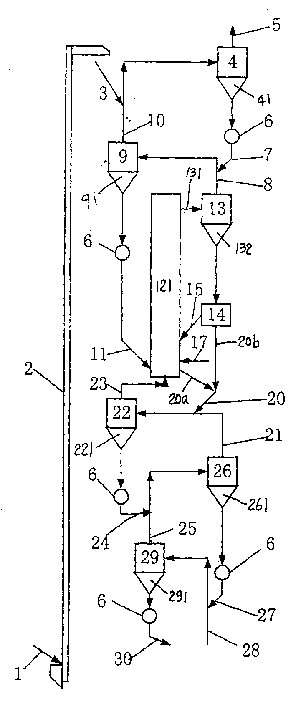

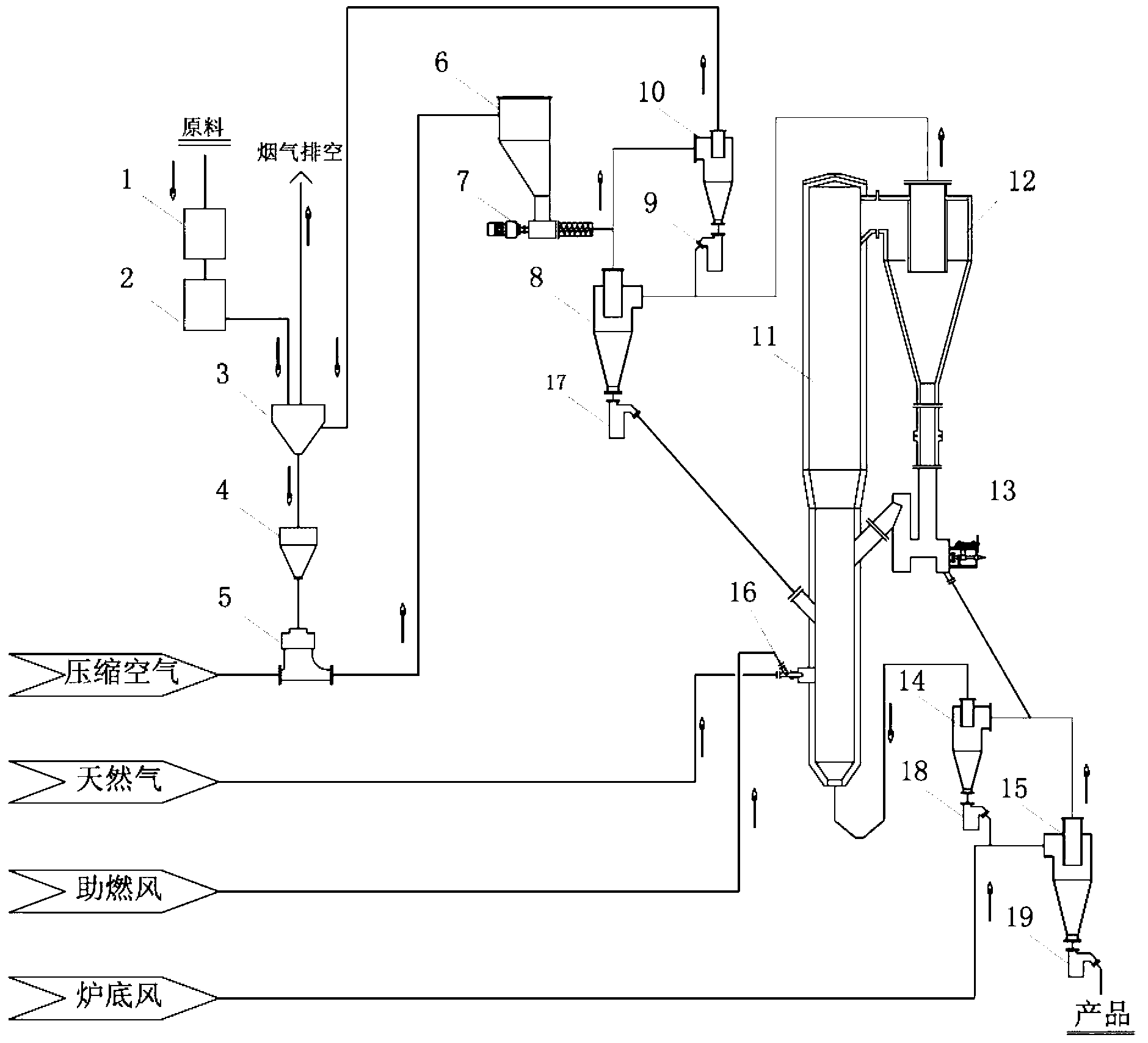

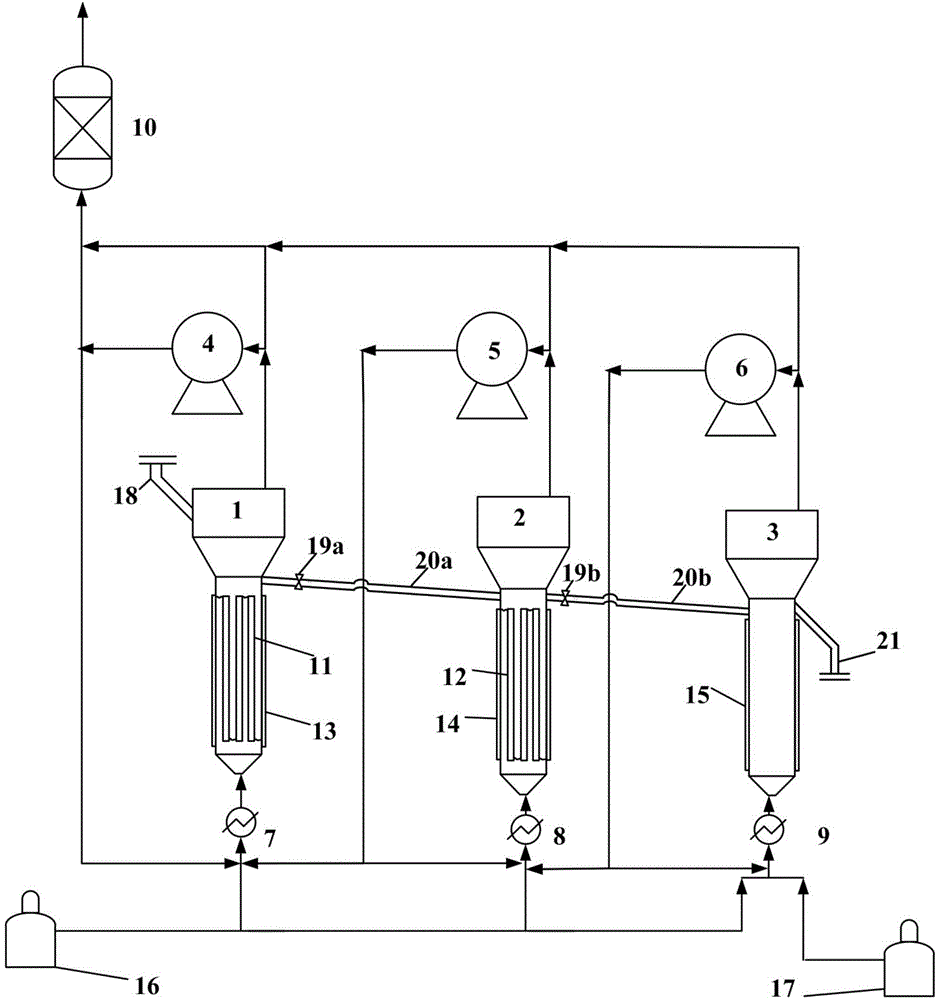

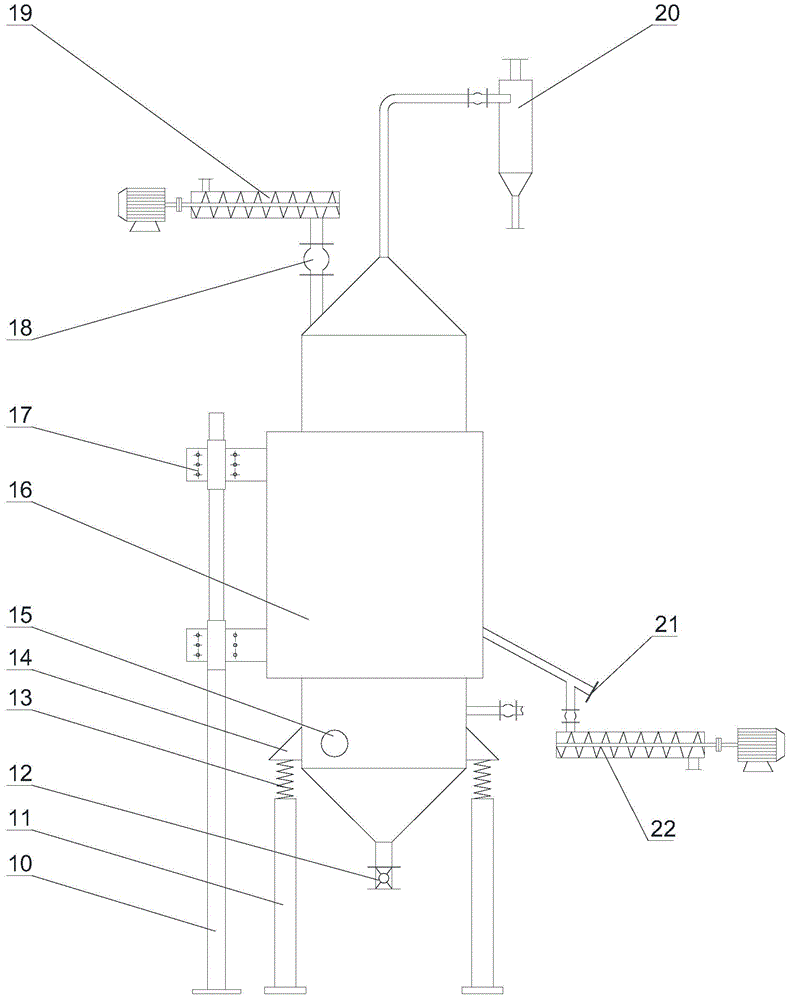

Rapid cycled fluidized calcining procedure for superfine kaolin and equipment

InactiveCN1600687AIncrease productivityImprove thermal efficiencyPigmenting treatmentAluminium silicatesCycloneEngineering

The invention relates to superfine Kaolin calcining process and device, the prodn, method includes; preheating kaolin raw powder material, then putting it in fluidization calcining furnace from the bottom, at same time, sending fuel into the furnace, preheated primary air is sent from plenum under the furnace burns with the fuel and to form a reducibility atmosphere calcining area in the lower section, the volume content of CO+H2 in reduction area is 0-10 percent, secondary air is sent from top of the reduction area to burn residual CO+H2 completely, airflow speed is 1-6m / s in the furnace, raw powder material is in fluidization, kaolin is circularly burned for 0.3-3 hours in temp. 700-1100 deg.C, then is sent into cyclone cooling system to be cooled to obtain superfine kaolin by mixer-grinding and depolymerizing.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Pulverulent, cross-linked polymers capable of absorbing aqueous liquids

InactiveUS7572864B2Simple and economical and safe to carry-outUniform product qualityAdhesive dressingsAbsorbent padsCross-linkPolyol

The invention relates to absorbent, cross-linked polymers based on partially neutralized, monoethylenically unsaturated monomers that bear acidic groups. Said polymers exhibit improved properties with regard to their ability to transport liquids in a swollen state. The surface of the polymers is postreticulated, using a combination of an organic cross-linking compound, excluding polyols, and a cation that is in salt form in an aqueous solution.

Owner:EVONIK DEGUSSA GMBH

Mesona chinensis benth series drinks and preparation method thereof

InactiveCN101703293ANo incompatibilitySimple ingredientsFood preparationHigh volume manufacturingAdditive ingredient

The invention discloses mesona chinensis benth series drinks and a preparation method thereof, wherein the method takes mesona chinensis benth as main material to prepare mesona chinensis benth herbal drink, mesona chinensis benth gelatine powder, hot grass jelly electuary and immortal grass tea with milk through the processes of boiling extraction, concentration and the like. Compared with the existing mesona chinensis benth drinks, the product has the effects of cooling, lowering fire and relieving restlessness, has simple and convenient carrying, convenient drinking, and simple ingredients without incompatibility, reduces precipitation and impurities, and retains the special flavour of vegetable material as much as possible, and also has lower cost, exact efficacy, simple production process and easy operation and control, thus ensuring the product quality and being applicable to large-scale production.

Owner:灵山县宇峰保健食品厂

Process for preparing bamboo-based activated carbon and dedicated device therefor

The invention discloses a preparing method and specific equipment of bamboo activated-carbon, which comprises the following steps: grinding; carbonizing continuously in the multi-pipe retort at 550-750 deg.c for 1-4 h; activating continuously in the retort at 800-950 deg.c for 48-72 h; pickling; bleaching; dehydrating; drying. The retort possesses stove base, furnace, several carbonizing pipes in the furnace vertically, feeder inlet on the top of retort, discharge device on the lower end, which is divided into preheating segment, carbonizing segment and cooling segment, wherein the retorting furnace contains furnace, heat-reserving chamber, chimney with furnace and heat-reserving chamber displaying left and right symmetrical structure; the furnace is separated into left and right half-furnaces by baffle; the heat-reserving chamber is divided into left and right two heat-reserving half-chamber correspondingly; the steam injecting pipe is set on the bottom of heat-reserving half-chamber; the vertical activating band is set in the furnace with several up-to-down carbonizing material channel and transverse gas flux to connect carbonizing material channel.

Owner:浙江恒日炭业有限公司

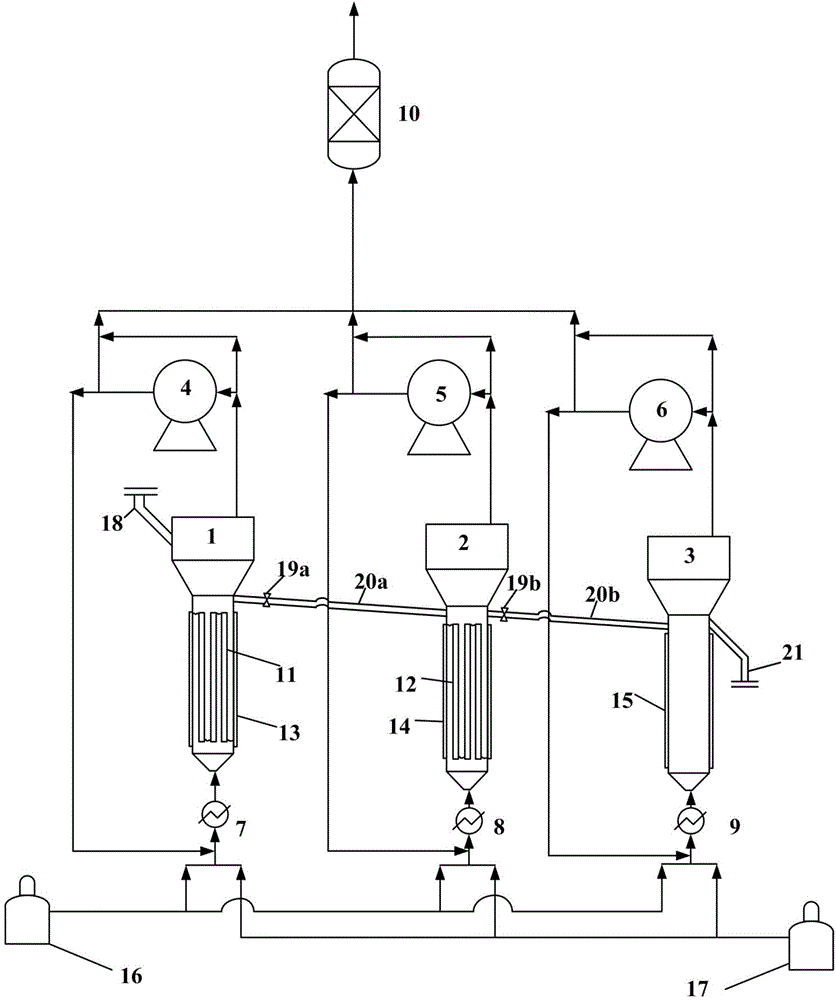

Continuous crystallization process for monopotassium phosphate

InactiveCN103159194AReduce manufacturing costEasy to operatePhosphorus compoundsSmall footprintMonopotassium phosphate

The invention discloses a continuous crystallization process for monopotassium phosphate. The continuous crystallization process comprises the following specific steps of: introducing a feed liquid to be crystallized into a first-stage continuous flash crystallizer so as to be separated into a primary clear liquid, primary crystal mush and secondary steam; discharging the primary crystal mush from the first-stage continuous flash crystallizer and feeding the primary crystal mush into a second-stage continuous cooling crystallizer, wherein the second-stage continuous cooling crystallizer is composed of an Oslo crystallizer and an external cooler; separating the primary crystal mush into secondary crystal mush and a secondary clear liquid in the Oslo crystallizer; discharging the secondary crystal mush from the Oslo crystallizer, feeding the secondary crystal mush into a thickener and separating the secondary crystal mush into triple clear liquid and triple crystal mush; discharging the triple crystal mush from the thickener, feeding the triple crystal mush into a centrifugal machine, and separating the triple crystal mush into solid monopotassium phosphate and a centrifugal liquid; and discharging the solid monopotassium phosphate from the centrifugal machine. The continuous crystallization process is stable in operation, low in energy consumption and low in labor intensity; and by using the continuous crystallization process, the operation stability and the product quality are greatly improved, the on-site operation environment is improved, and the production cost of the monopotassium phosphate is reduced. A mating device for the process is small in floor area and high in capacity.

Owner:HEBEI NUODA CHEM EQUIP

Lithium-rich manganese-based cathode material precursor, cathode material and preparation method thereof

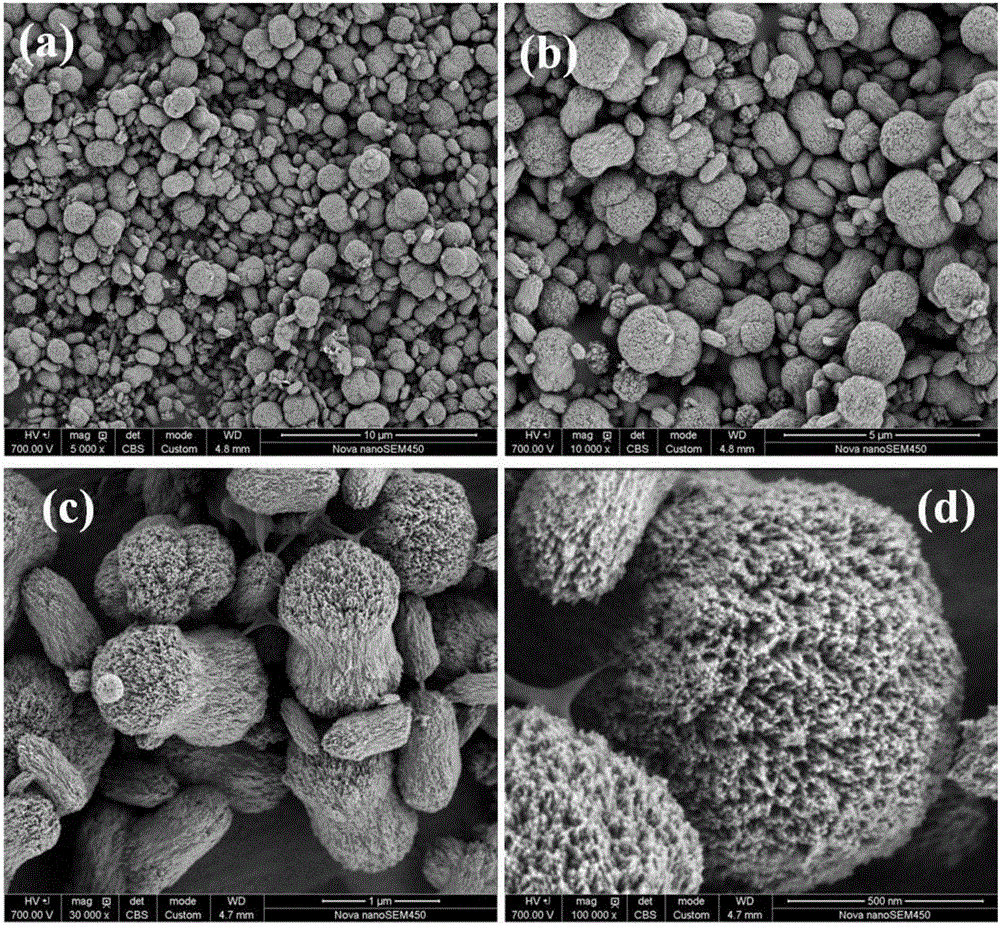

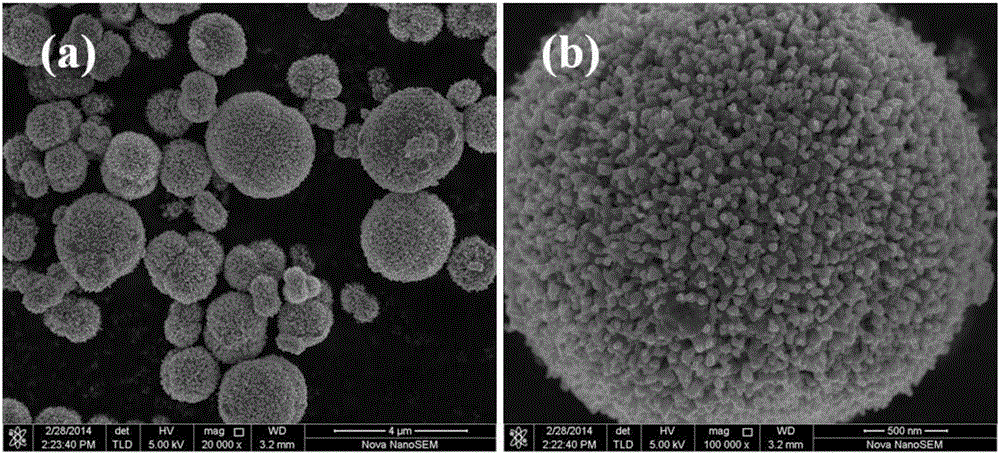

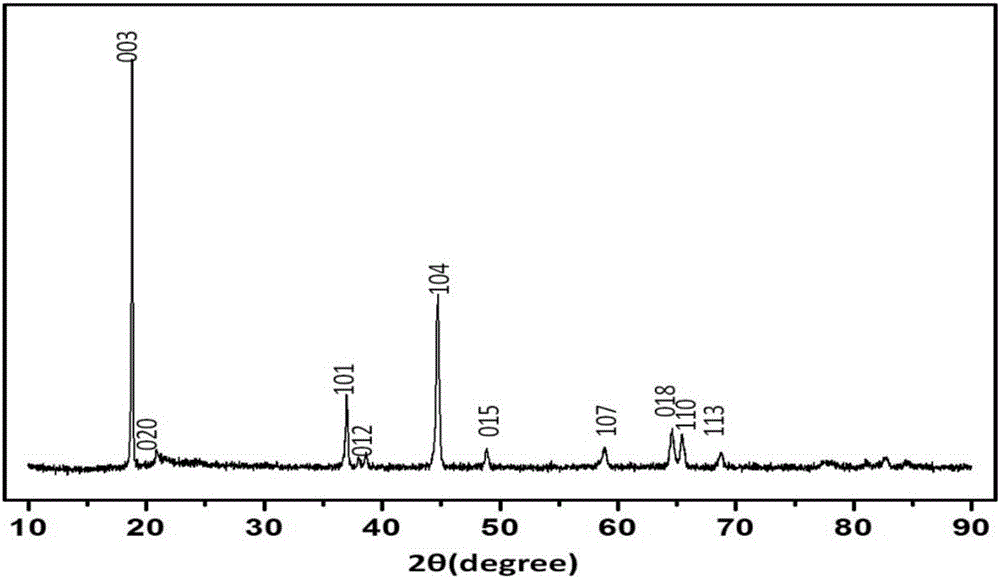

ActiveCN106564967AAccelerates and intensifies the mass transfer processWell mixedMaterial nanotechnologyCell electrodesNickel saltManganese

The invention belongs to the field of electrode material preparation and relates to a lithium-rich manganese-based cathode material precursor, a cathode material and a preparation method thereof. The preparation method comprises the following steps: mixing metal salts (manganese salt, cobalt salt and nickel salt) and a surfactant and water, and dissolving to obtain a metal salt solution; putting a precipitant in water, stirring and dissolving to obtain a precipitant solution; carrying out liquid-liquid coprecipitation reaction on the metal salt solution and the precipitant solution in a hypergravity field reactor, filtering, cleaning, and carrying out vacuum drying so as to obtain a precursor; mixing the precursor and lithium salt and then calcining so as to obtain the lithium-rich manganese-based cathode material. By the coprecipitation method based on the hypergravity technology, the lithium-rich manganese-based cathode material precursor with primary particle being below 100 nm and secondary particle being 1-10 microns is rapidly prepared, and furthermore the prepared cathode material has advantages of uniform component distribution and particle size distribution, small granularity and high activity. Initial irreversible capacity can be reduced, and cycle performance of a lithium ion secondary battery can be enhanced.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

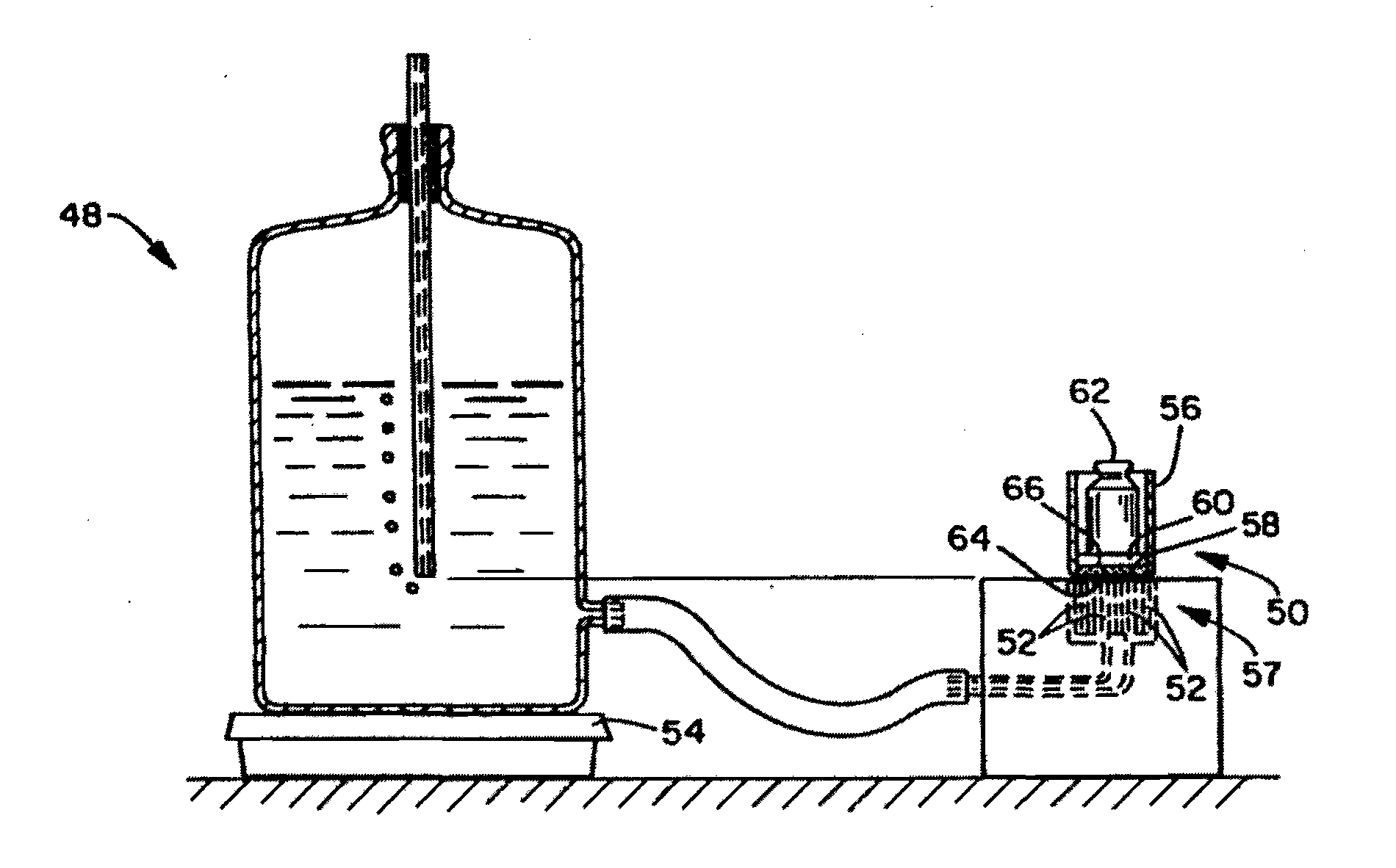

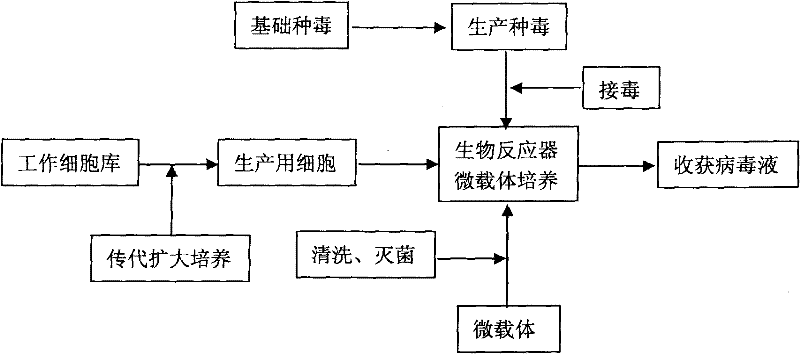

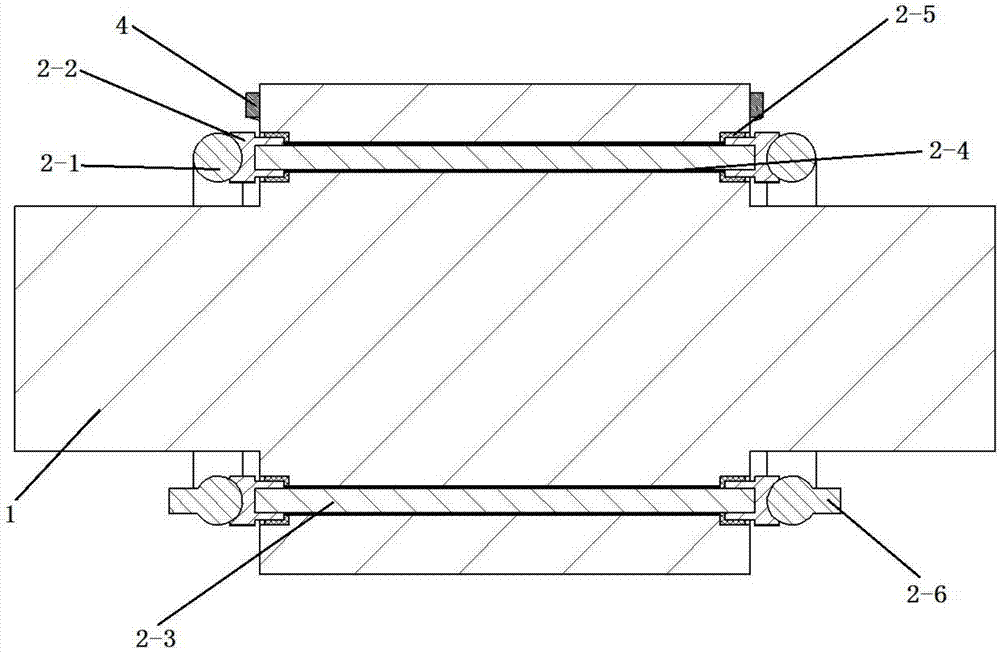

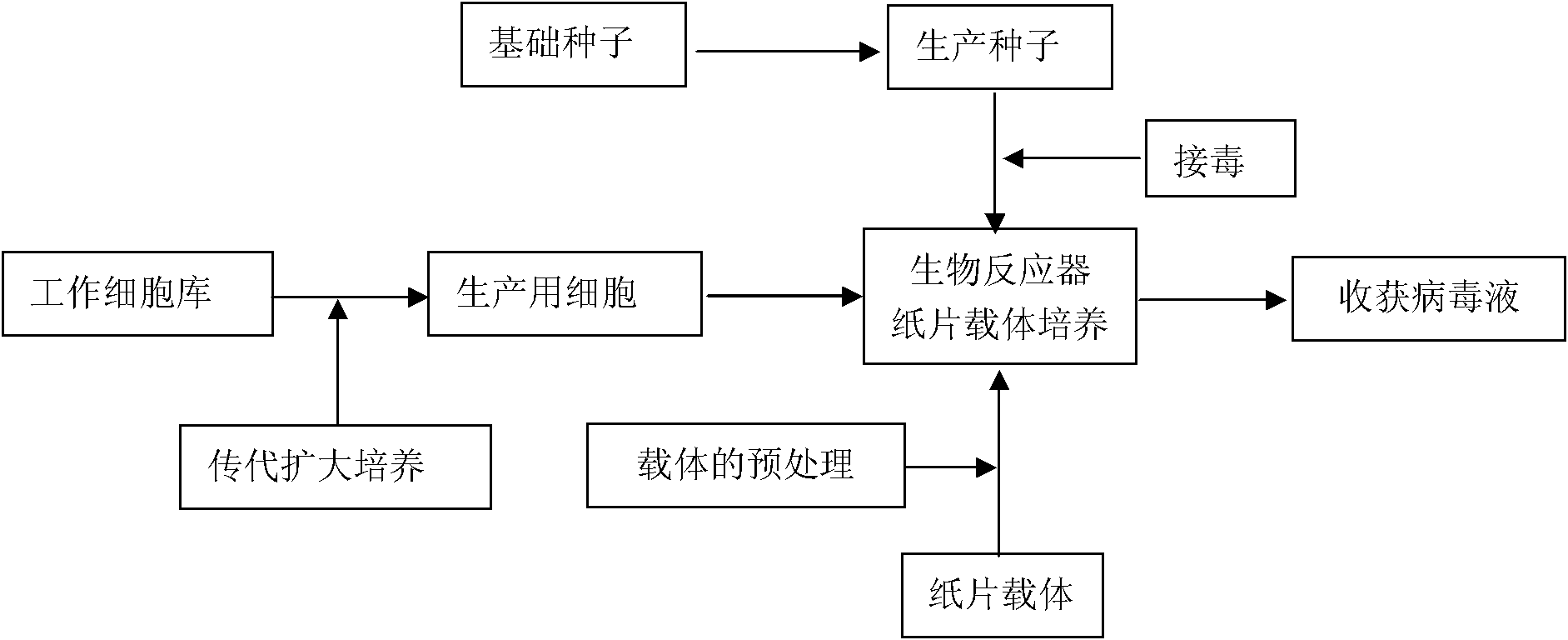

Method for production of porcine epidemic diarrhea virus

The invention discloses a technology for the production of porcine epidemic diarrhea virus by means of the microcarrier culture of VREO cells using a bioreactor, and comprises the technology for the production of different porcine epidemic diarrhea virus strains. The technology comprises the following technical steps: (1) selection of VERO cells as cell line for vaccine; (2) passage and culture of cells for vaccine; (3) propagation of seed culture of the porcine epidemic diarrhea virus; (4) microcarrier suspension culture of the VERO cells in the bioreactor; (5) propagation of porcine epidemic diarrhea virus antigen; and (6) treatment of acquired virus antigen liquid. The production method can remarkably lower production cost and enhance output-input ratio by 5 to 10 times, and has the advantages of short production period, small occupied space, great easiness for enlarging production scale rapidly, little environmental pollution, easy processing, high automation degree, a small number of staff, easy implementation of even and stable quality, obviously lowered production cost and enhanced yield and quality of vaccine.

Owner:成都史纪生物制药有限公司

Industrialized cultivation method of Morchella importuna

The invention provides an industrialized cultivation method of Morchella importuna. The method is characterized by comprising steps as follows: (1) preparation of a culture substrate; (2) preparation of a liquid strain; (3) mycelium culture; (4) fruiting management: mycelia in the step (3) are transferred to a fruiting room for fruiting management, and the fruiting management comprises management in a primordium formation promoting period, management in a mushroom bud formation period, management in a growth period and management in the manure period. According to the method, crop waste is taken as a raw material for preparation of a culture medium, liquid strains are used for sowing, industrialized cultivation of Morchella is completely realized indoor, the method is simple to operate, low in cost, short in cycle, controllable in quality and capable of realizing industrialized production all year round, and one pollution-free, pleasantly scented and delicious green product is obtained.

Owner:东莞东阳光保健品研发有限公司

Automatic welding production line of lighter

InactiveCN102152031AAvoid randomnessIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention discloses an automatic welding production line of a lighter, comprising a rack and a control device, The rack is provided with a transmission line; a fed-material feeding conveying station, a case flattening station, an inner machine head flattening station, an inner machine head directional assembling station, a welding station, a dust removing station, an inner machine head positioning station and a discharged-material conveying station. The automatic welding production line can weld a plurality of lighters simultaneously, therefore the production efficiency is greatly improved, and the product quality is more stable.

Owner:阮俊康

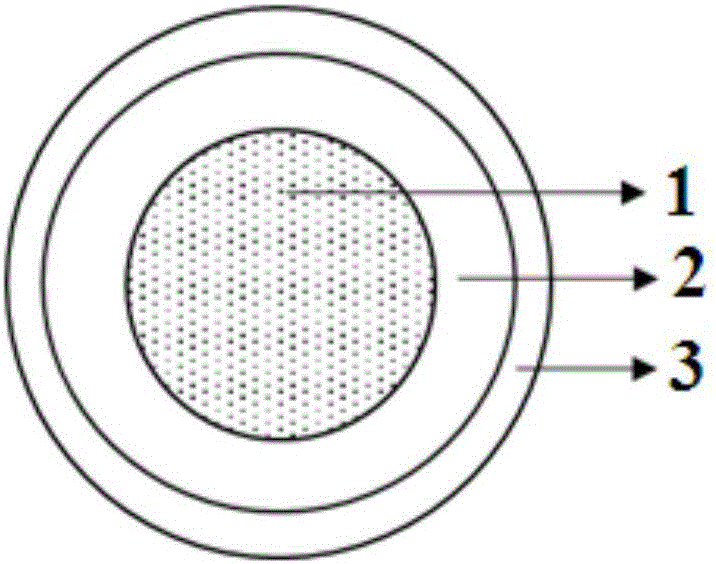

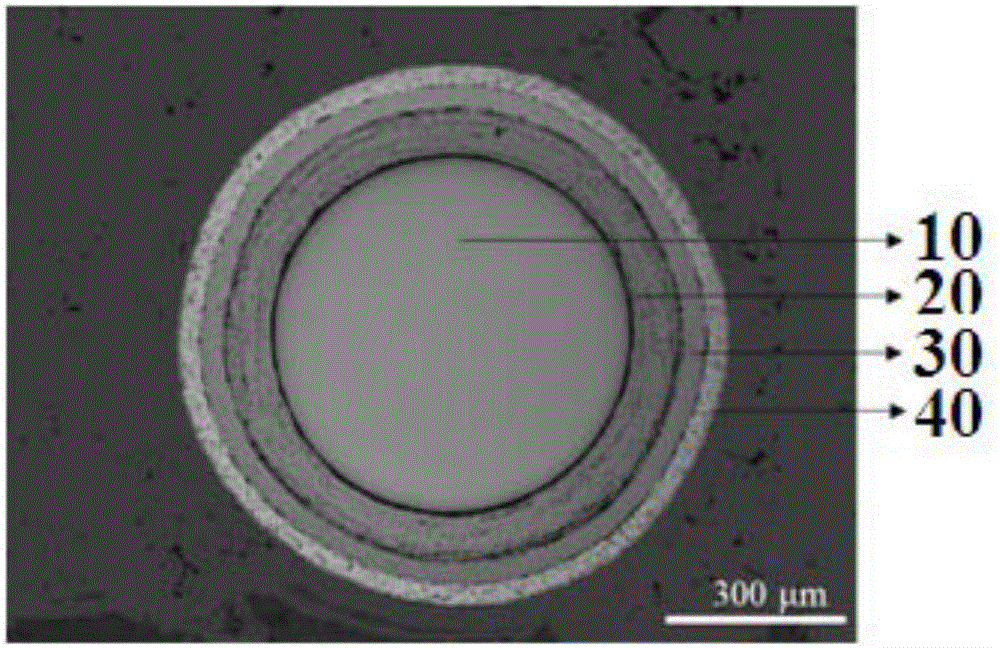

Inorganic nonmetal cladding high-temperature phase change heat storage microcapsule and preparation method thereof

ActiveCN105855537AHigh heat storage densityGood thermal cycle performanceTransportation and packagingMetal-working apparatusMicrospherePyrolytic carbon

The invention relates to an inorganic nonmetal cladding high-temperature phase change heat storage microcapsule. The inorganic nonmetal cladding high-temperature phase change heat storage microcapsule comprises a metal phase change material microsphere, a loose pyrolytic carbon layer and a compact pyrolytic carbon layer. The metal phase change material microsphere is surrounded by the loose pyrolytic carbon layer, and the loose pyrolytic carbon layer is surrounded by the compact pyrolytic carbon layer. The diameter of the metal phase change material microsphere is 500-2000 [mu]m. The density of the loose pyrolytic carbon layer is 0.5-1.5 g / cm<3>. The density of the compact pyrolytic carbon layer is 1.8-2.0 g / cm<3>. The invention further provides a preparation method of the inorganic nonmetal cladding high-temperature phase change heat storage microcapsule. The inorganic nonmetal cladding high-temperature phase change heat storage microcapsule provided by the invention has the advantages of being large in heat storage density, good in heat cycling performance, resistant to high temperature, acid and alkali corrosion and oxidation and the like. According to the provided preparation method of the inorganic nonmetal cladding high-temperature phase change heat storage microcapsule, the product quality is uniform, the yield is high, and the preparation method is suitable for industrial production.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Coal-series kaolin gas suspension calcination method

InactiveCN102795633AEasy to removeImprove thermal efficiencyEnergy inputSilicon compoundsStructural waterDecomposition

The invention discloses a coal-series kaolin gas suspension calcination method comprising the following steps of: firstly, crushing and grinding mineral raw materials of coal-series kaolin, feeding the mineral raw materials into a spray drying tower for dehydration, and feeding the materials subjected to spray drying into a furnace external heat exchange decomposition system for treatment; feeding the treated materials into a gas suspension calciner for rapid calcination in an intensive fluidization condition, wherein the fluidizing velocity is 8-40m / s, and the calcination temperature is controlled within 600-1400 DEG C according to the requirements of products; carrying out gas-solid separation on the rapidly calcined materials under the action of whirlwind, then, controlling the proportions of materials returned to the gas suspension calciner through a loop seal, and adjusting the total standing time of the materials in the gas suspension calciner to control the calcination quality of a product; and further carrying out whitening treatment on the calcined materials through a furnace-external reburning heat exchange system, and then, feeding the materials into a product cabin. The method is simple in process, high in heat efficiency, good gas-solid heat and mass transfer and narrow in calcination temperature fluctuation range; and the product is stable and uniform in quality, smoke waste heat can be sufficiently utilized, high handling capacity is realized, and carbon impurities and structural water in the coal-series kaolin can be rapidly removed.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Biological selenium-rich fertilizer and whole course dynamic gradient method for selenium-rich purple wheat

ActiveCN102795908AAvoid toxic effectsSolve the safety problems caused by inorganic selenium residuesFertilising methodsFertilizer mixturesWheat productCrop cultivation

The invention relates to a method for producing a selenium-rich purple wheat by using a biological selenium-rich fertilizer and a whole course dynamic gradient selenium-rich method, which belongs to the crops cultivation technical field. The method is characterized in that the biological selenium-rich fertilizer is produced, and is used to prepare a selenium-rich fertilizer mother liquor, and then the selenium-rich fertilizer mother liquor is diluted to a selenium-containing fertilizer liquid with different selenium concentrations, and is affected on soil, purple wheat seeds and whole purple wheat at different growth periods. The wheat seeds enable full enrichment on the selenium element, according to the growth characteristics of the purple wheat, the selenium-containing fertilizer liquid with different gradients is used for fitting with the purple wheat growth rules during the whole growth process of the purple wheat, thereby the exogenous inorganic selenium can be conversed to plant endogenous organic selenium with high efficiency. By detecting, the selenium content of the purple wheat product provided in the invention is 0.18-0.28mg / kg, wherein the organic selenium content is 0.16-0.25mg / kg, compared with the purple wheat product which is sprayed by a single selenium-containing fertilizer liquid c in the whole process, the selenium content multiple can reach 5-7 times.

Owner:JIANGSU ACAD OF AGRI SCI

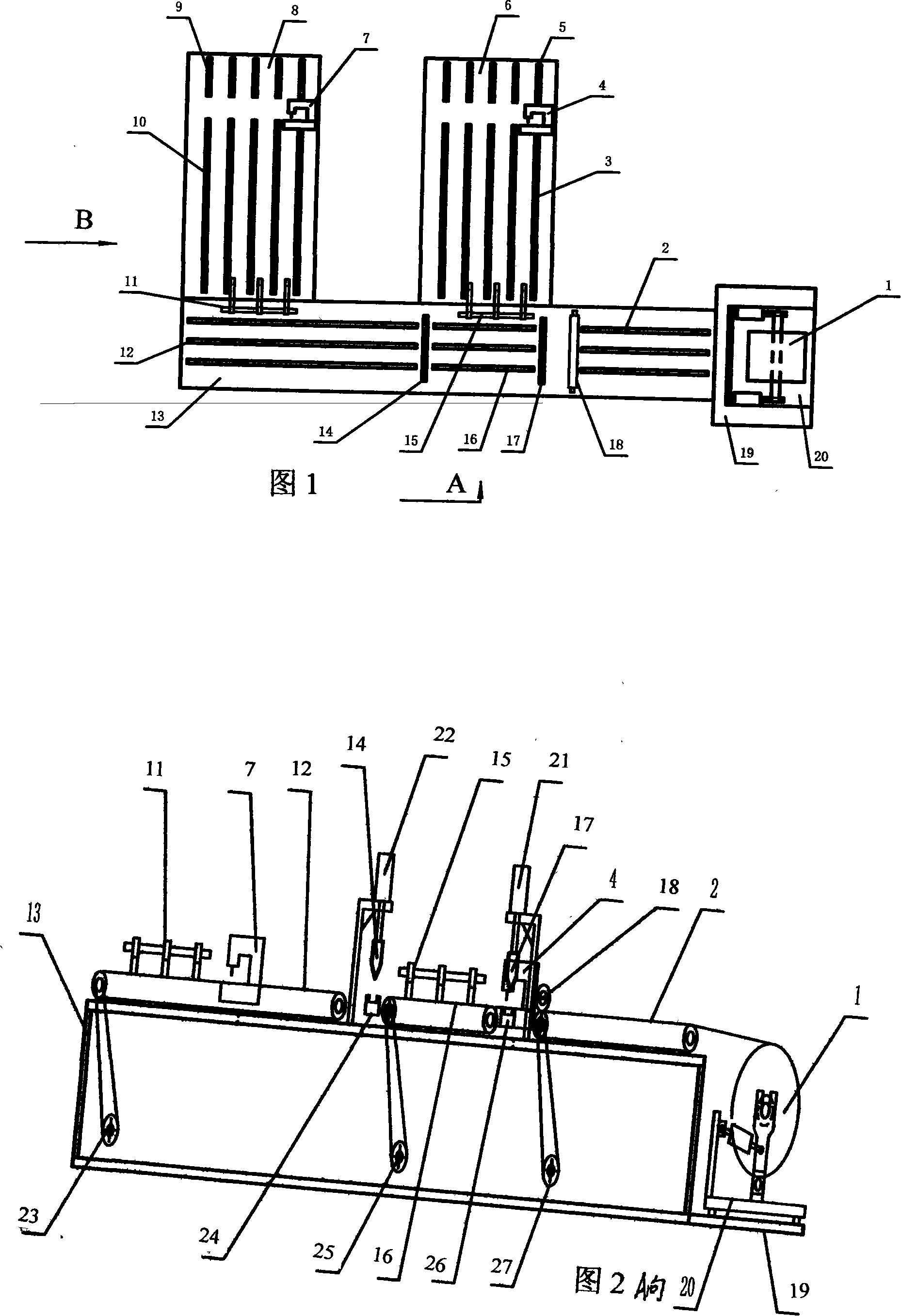

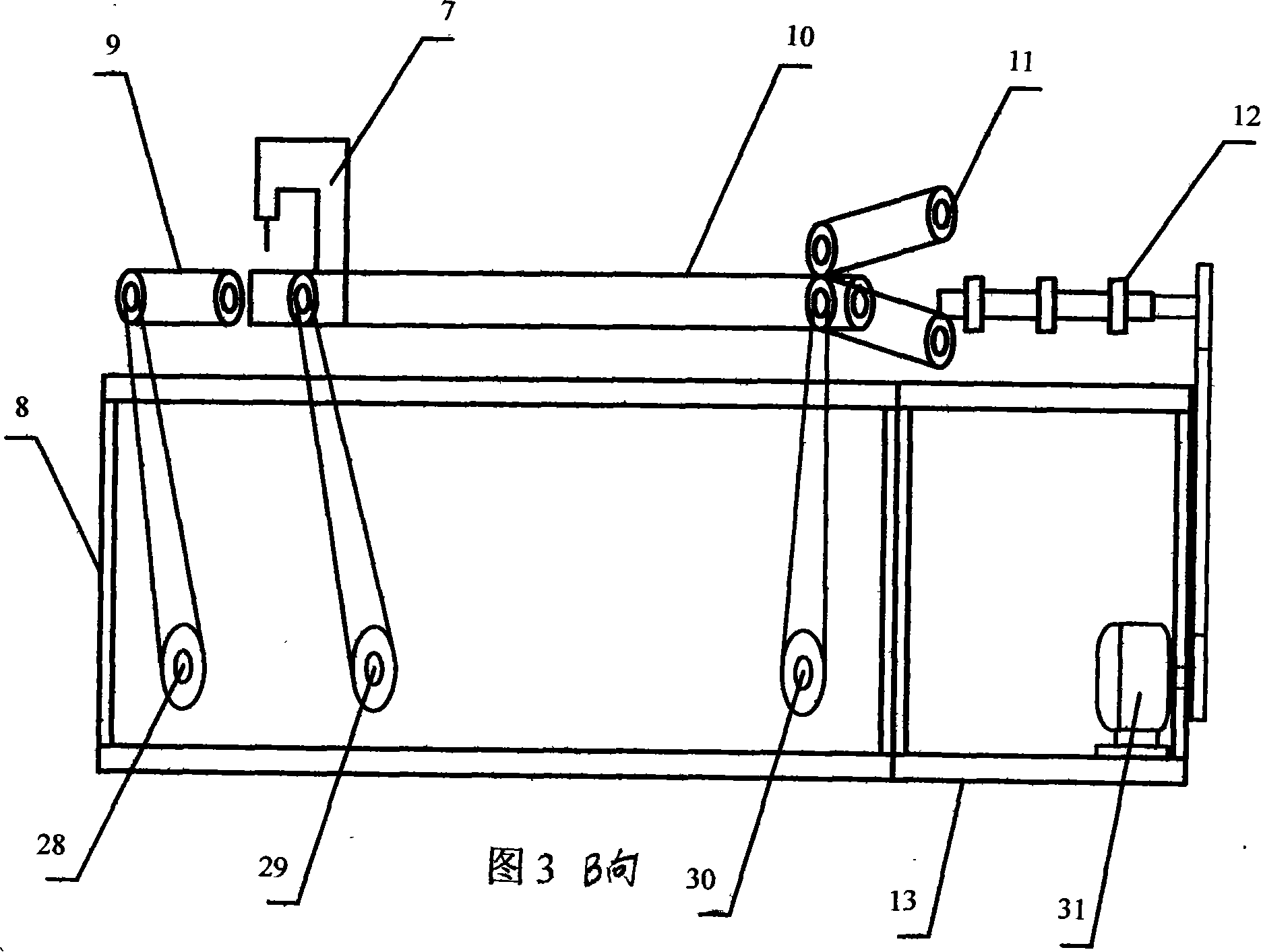

Plastic weaving bag high-speed full-automatic seam cutting machine

InactiveCN101104322AFast productionUniform product qualityEnvelopes/bags making machineryManipulatorEngineering

The invention relates to a woven bag molding machine, particularly to a woven bag quick-acting full-automatic joint cutter to finish the last two steps of cutting and sewing the bottom of the woven bag. The invention is characterized in that: based on the original structure, a plurality of cutting knives on the same plane are mounted on the workbench of the cutting mechanism; the distance between two cutting knives is the same as the length of the woven bag; one or two side faces of the workbench of the cutting mechanism are provided with a plurality of sewing place horizontal moving manipulators which are connected with a bag delivering device; correspondingly sewing place workbench is provided with a plurality of sewers to form a combined linkage acting structure. The invention is efficient with a production speed of 60 to 80 pieces per minute, over one time faster than the original structure, and only work man is needed. The invention can save land and reduce cost with the same efficiency, remarkably improving economic effects.

Owner:丁德光 +1

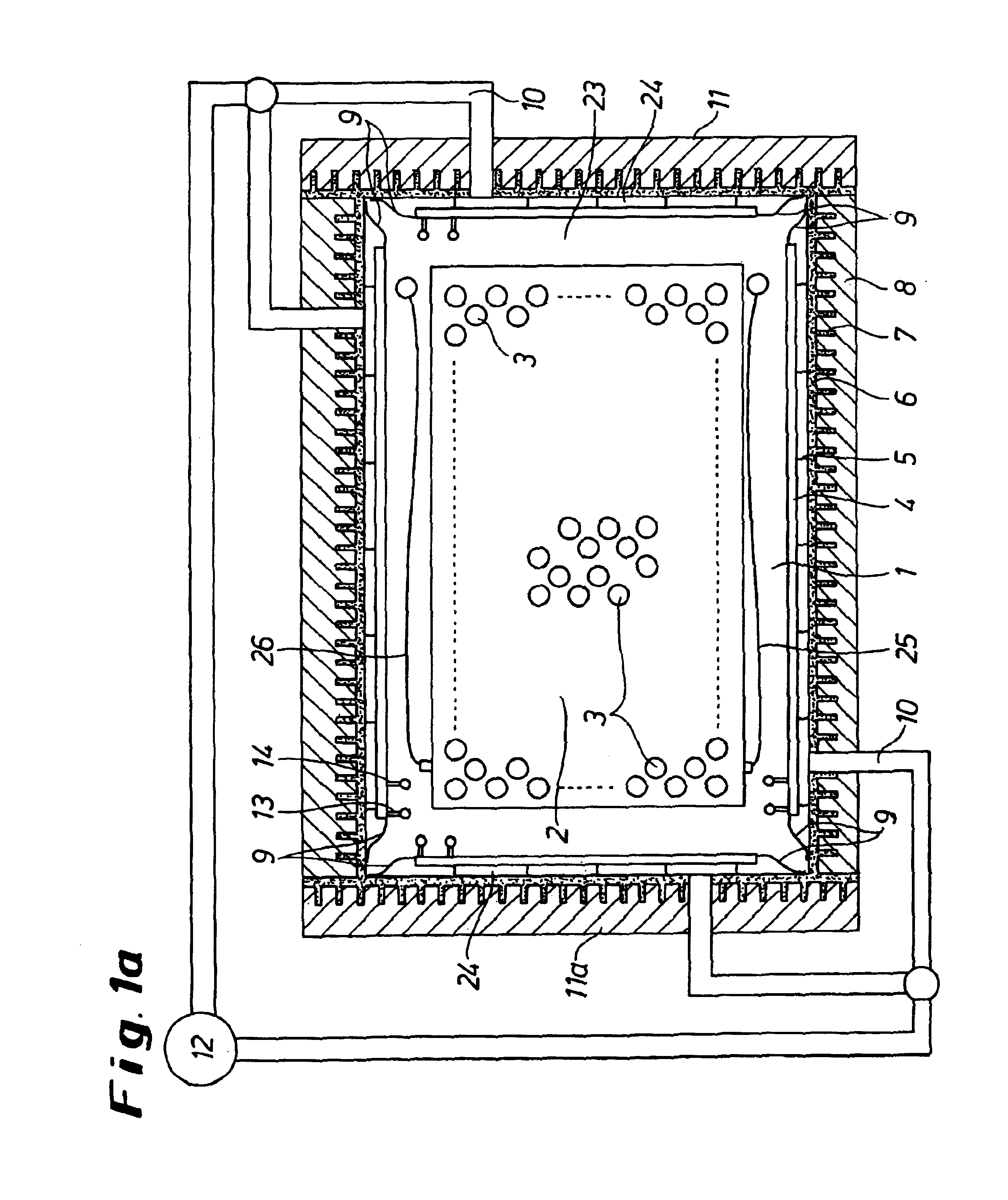

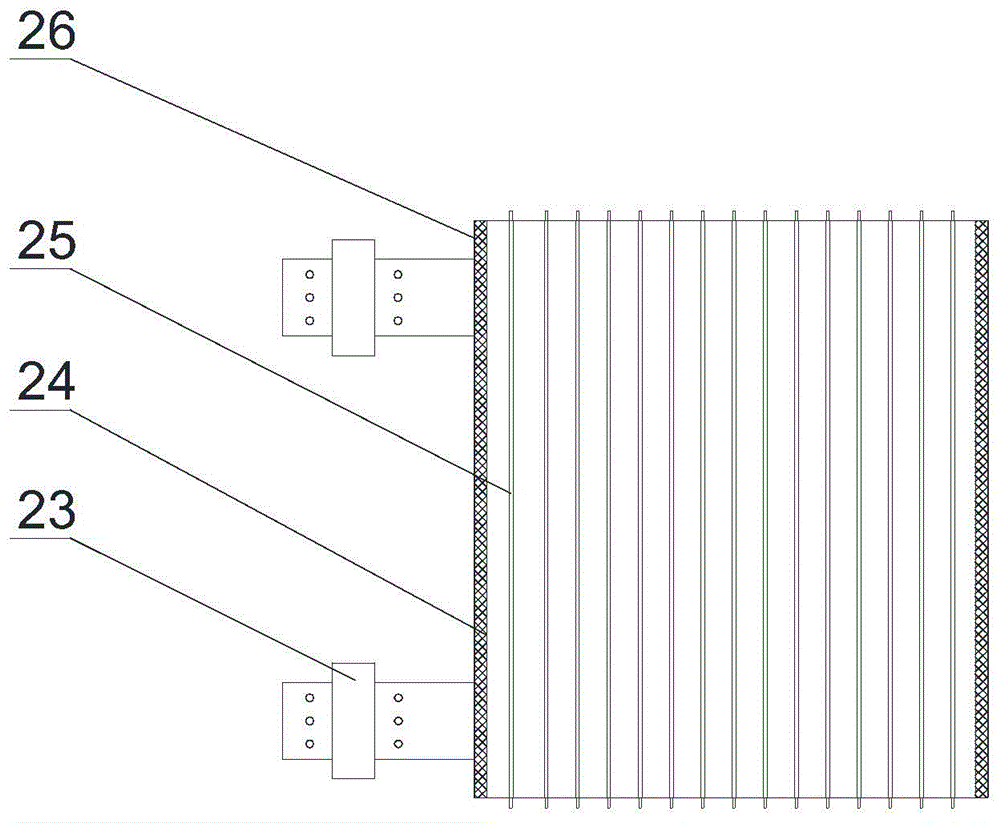

Freeze-drying apparatus

InactiveUS6931754B2Improve uniformityIncrease drying capacityDrying solid materials with heatDrying solid materials without heatSolventFreeze dry

A drying unit for removing solvent from moist material, and a method for drying moist material with the drying unit. The unit comprises at least one drying chamber (23) having at least one stand plate (2) for holding vessels (3), which are filled with moist material, or flat layers of moist material, the drying chamber (23) being connected to a condenser (22) via a vapor passage (15), in which sublimed solvent can be separated out, the stand plates (2) being connected to a temperature-controlled heating / cooling circuit, the chamber (23) having heating / cooling plates (4) or (4′) which are connected to a second heat-transfer circuit, wherein the heating / cooling plates (4) or (4′) are substantially thermally isolated from the chamber wall (6).

Owner:HOF SONDERANLAGENBAU

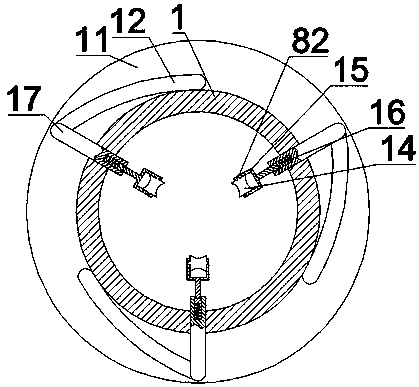

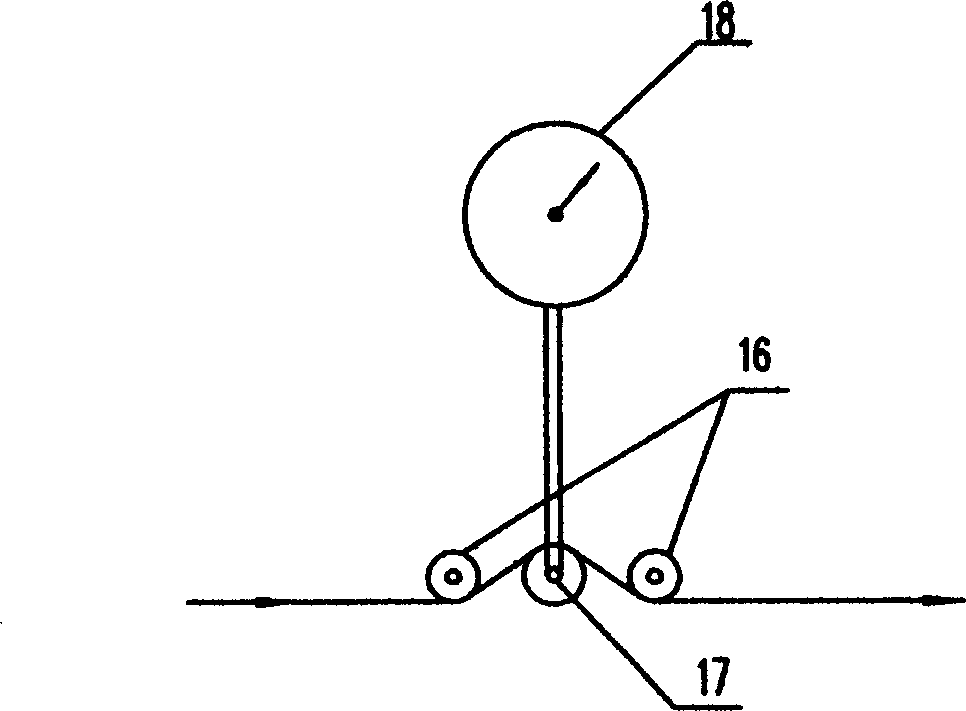

Device capable of improving online heating adaptability of roller

InactiveCN107282639AUniform temperature distributionImprove surface qualityMeasuring devicesRollsControl systemAsbestos

A device that can improve the adaptability of rolling on-line heating, which mainly includes: an axial through hole is arranged on an ordinary roll, and a heating rod wrapped with an asbestos layer is arranged in each axial through hole, and two heating rods of each heating rod The ends are respectively placed in the conductive block, and all the conductive blocks arranged at one end of the roll are in contact with a power-connecting coil, and a binding post and a fixed bracket are arranged on the power-connecting coil. In addition, a contact block with a certain height is arranged on the two end faces of the two rolls. The contact surface of the contact block and the thermocouple is an arc surface with a high middle and low sides, and one end of the thermocouple is set on the end face of the roll. Nearby, the other end of the thermocouple is connected to one end of the elastic piece, and the lead wire on the thermocouple is connected to the control system. The invention not only has a simple structure, but also can continuously heat the rolls on-line during the rolling process, has high production efficiency, low processing cost and convenient operation, and the temperature of the rolls is always in a reasonable temperature range, ensuring better, stable and uniform product quality.

Owner:YANSHAN UNIV

Quantitative marinating method of leisure meat product

InactiveCN102871137AImprove water retentionImprove the uniformity and stability of qualityFood preparationLivestockSmoke

The invention discloses a quantitative marinating method of a leisure meat product. The method comprises the following steps: mixing meat product raw materials and flavorings in proportion, rolling and rubbing, then performing cooking and smoke curing to complete the marinating of the leisure meat product. Compared with traditional marinating methods, the method proportions the raw materials and auxiliary materials quantitatively, has a high spice utilization rate, and has a spice using amount being 10%-30% than that of the traditional methods; the method has no boiling loss; the product yield is improved by 5%-8%; the product quality is consistent; the energy consumption is reduced, and the energy power consumption is only 40%-50% than that of the traditional methods; no waste bittern is discharged, and thus no environmental pollution is caused. The method is suitable for the production of sauce-marinated leisure meat products by cutting raw materials of livestock and poultry fresh (frozen) meat such as duck necks, chicken wings, chicken necks, meat pieces, and the like, and is a novel marinating seasoning method. The method is low in production cost, high in production efficiency, and can realize continuous and industrial production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

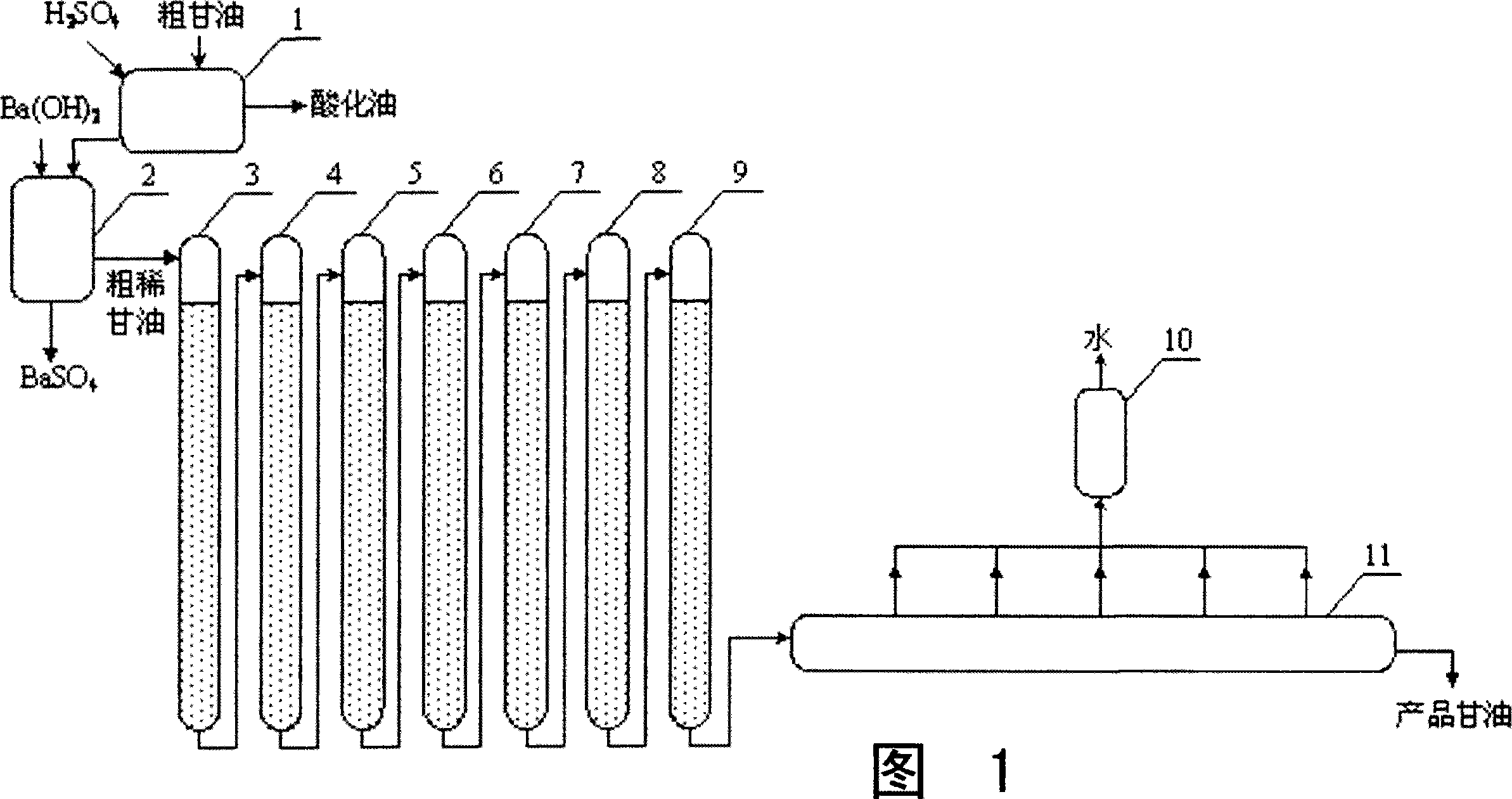

Method for refining biodiesel byproduct glycerin

InactiveCN101182281ASimple processImprove efficiencyHydroxy compound separation/purificationChemical industryBiodiesel

The invention provides a method of refining a biological diesel oil by-product of glycerol. The invention relates to the technical field of the oil and fat chemical industry and more particularly a method of refining the biological diesel oil by-product of the glycerol. The steps of the method are that crude glycerol produced during the production process of the biological diesel oil is added into a acidification reactor for the acidification treatment; acidified oil at the upper layer is returned to a biological diesel oil production system as the production materials of the biological diesel oil, and the glycerol at the lower layer is put into a neutralization reactor for the neutralization reaction; the glycerol layer is put into an ion exchange column for impurity removal to obtain the dilute solution of glycerol which contains water; the dilute solution of glycerol is put into a short-stroke pipeline evaporator for continuous evaporation and concentration to obtain the refined glycerol product. The technical process of the invention is simple; the efficiency is high; the investment is less; the quality of the obtained product is uniform; the invention can reduce the recycle cost of the glycerol and the production cost of the biological diesel oil.

Owner:KUNMING UNIV OF SCI & TECH

Device and method for rapidly forming metal part through induction heating

InactiveCN105903970AHeating evenlyEven and stable heatingAdditive manufacturing apparatusCrucibleMachining

The invention discloses a device and method for rapidly forming a metal part through induction heating. The device comprises a base plate, a front heating unit and an induction smelting unit. The base plate is located below the induction smelting unit and used as a platform for metal part forming. The front heating unit is located between the base plate and the induction smelting unit and used for forming a uniform temperature field. The induction smelting unit comprises a support and a smelting crucible arranged on the support. An induction coil is arranged on the smelting crucible. The outlet end of the smelting crucible is provided with a smelting crucible nozzle opposite to the base plate. The inlet end of the smelting crucible is connected with an air inlet through a rubber plug and used for providing inert gas for the smelting crucible. The method is used for achieving induction heating and rapid forming of the metal part through the device. The device and method have the advantages of being high in machining flexibility, small in subsequent machining amount and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

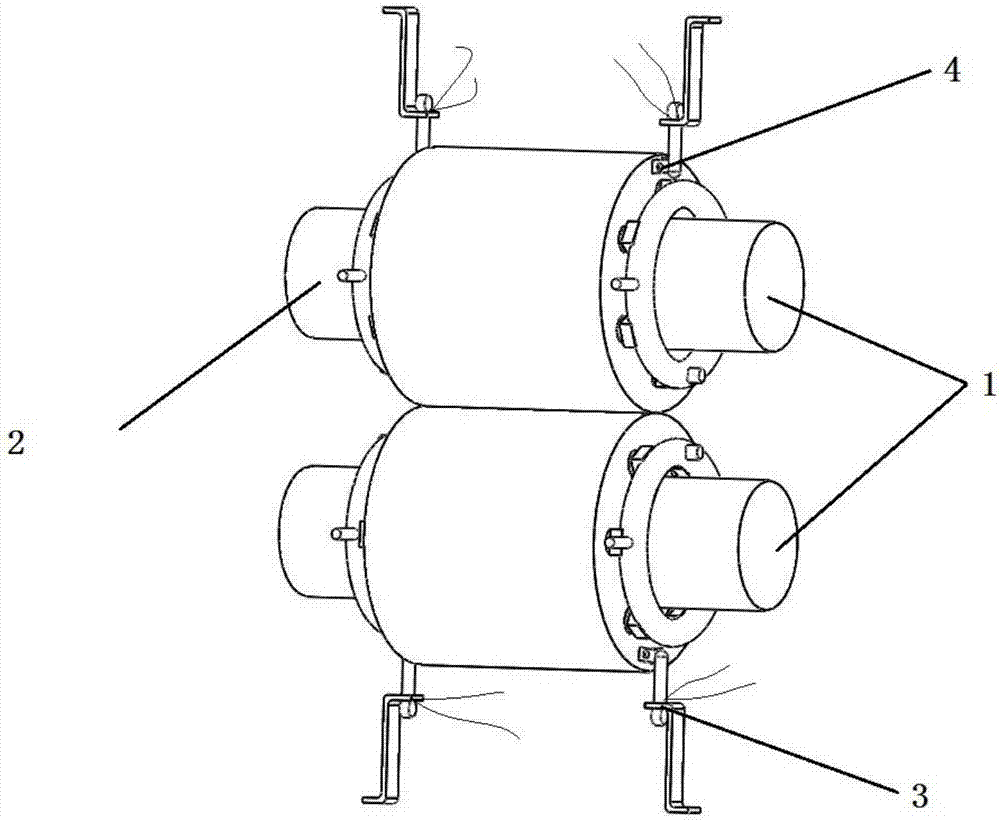

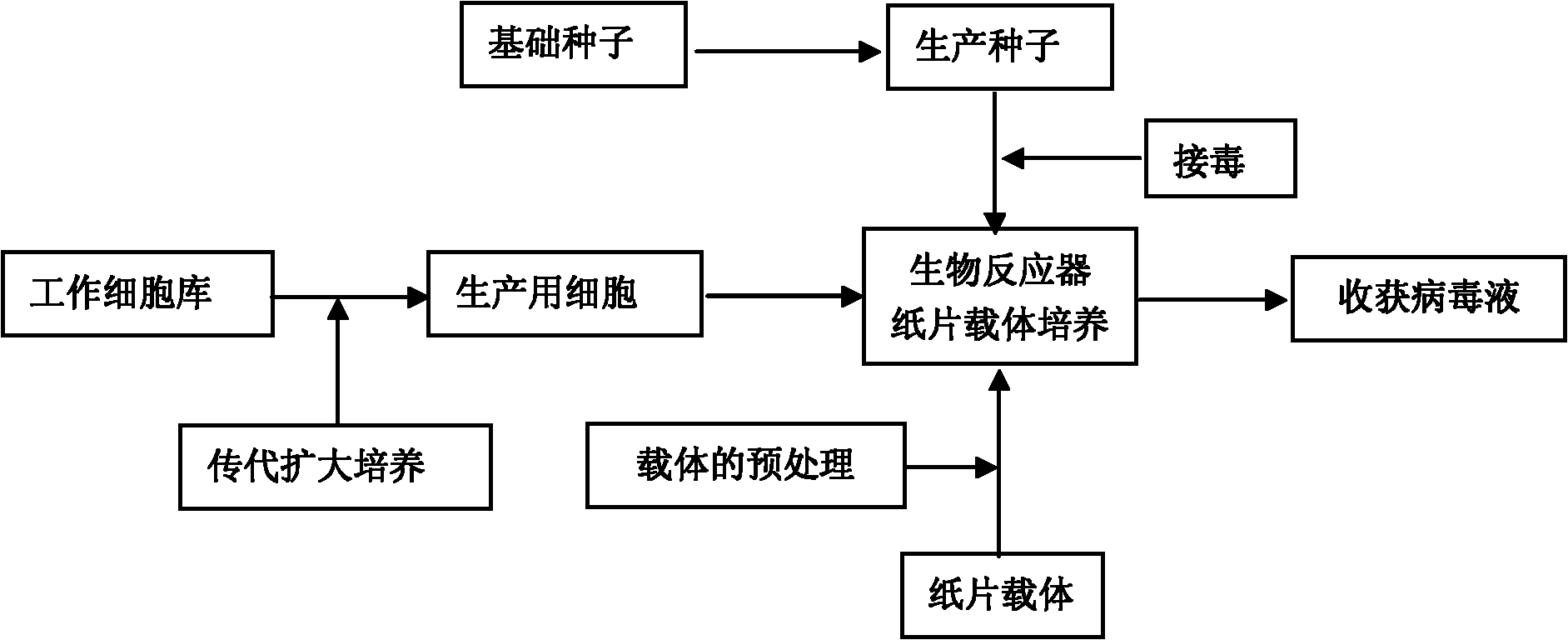

Method for producing PRRS (Porcine Reproductive and Respiratory Syndrome) viruses

ActiveCN102002482AQuality improvementIncrease productionRecovery/purificationPerfusion bioreactorPerfusion Culture

The invention discloses a method for producing PRRS (Porcine Reproductive and Respiratory Syndrome) viruses through culturing Marc-145 cells by applying a torrent-perfusion bioreactor. The method comprises the following steps of: (1) selecting Marc-145 cells as cells for culturing seedlings; (2) subculturing the Marc-145 cells; (3) reproducing virus seeds for production; (4) perfusing and culturing the Marc-145 cells on a paper carrier in the torrent-perfusion bioreactor; (5) producing the PRRS viruses in the torrent-perfusion bioreactor; and (6) treating the obtained virus antigen solution. The invention can greatly decrease the production cost, improve the input-output ratio by more than 10 times and expand the production scale easily and rapidly, has short production preparation cycle and high degree of automation, occupies less area, causes less environmental pollution which is easy to treat, consumes less labor, is easy to realize balanced and stable virus quality and can obviously improve the yield and the quality of the viruses.

Owner:成都史纪生物制药有限公司

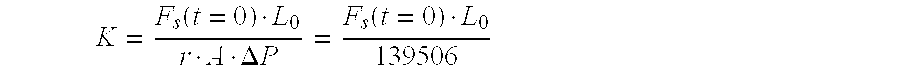

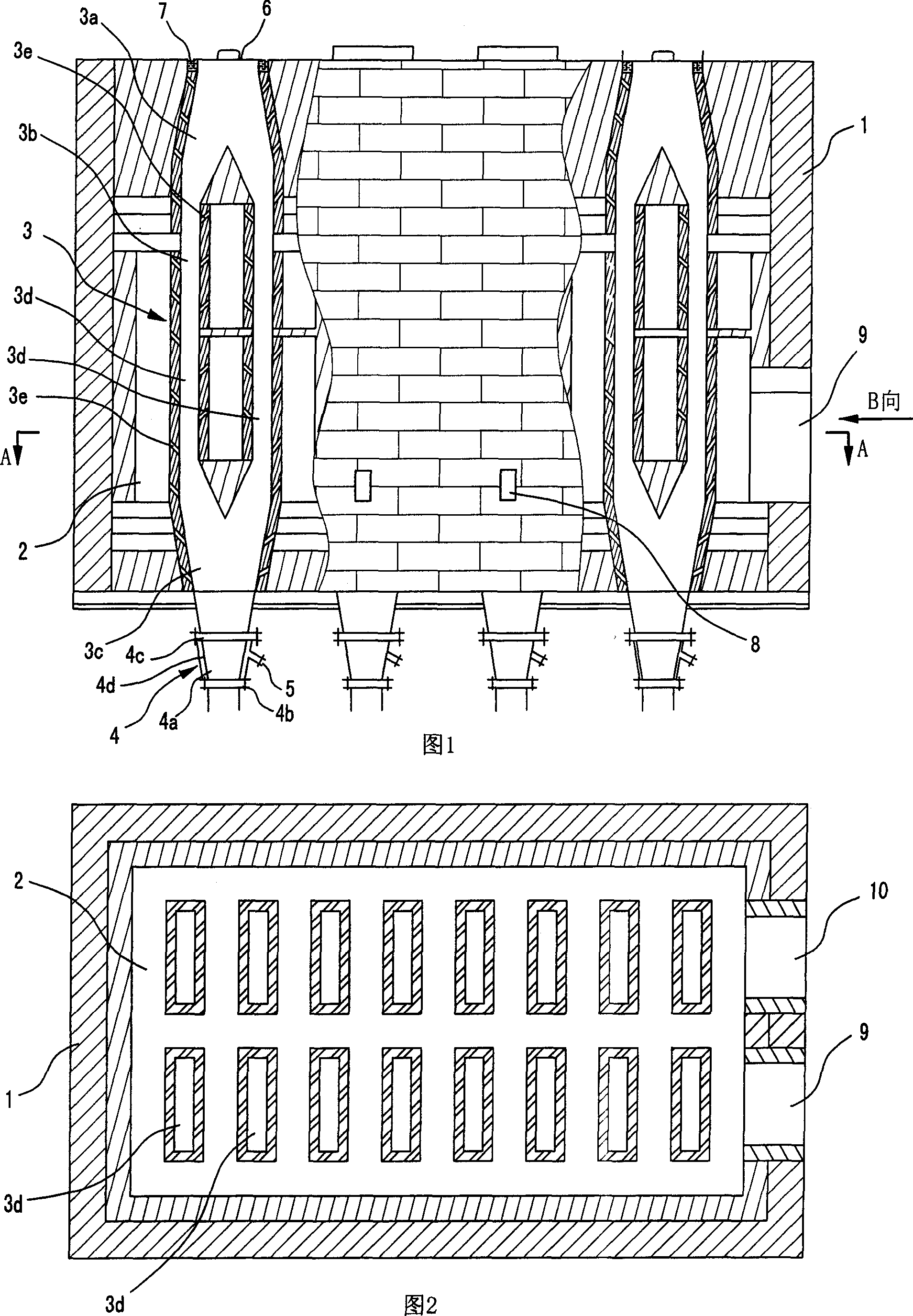

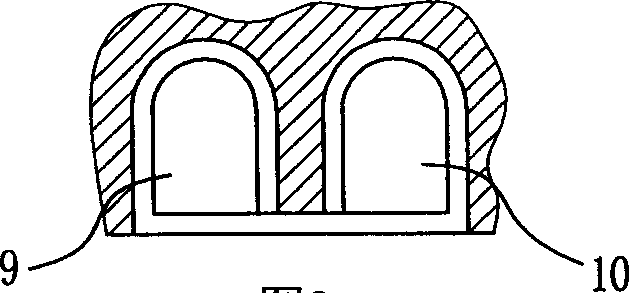

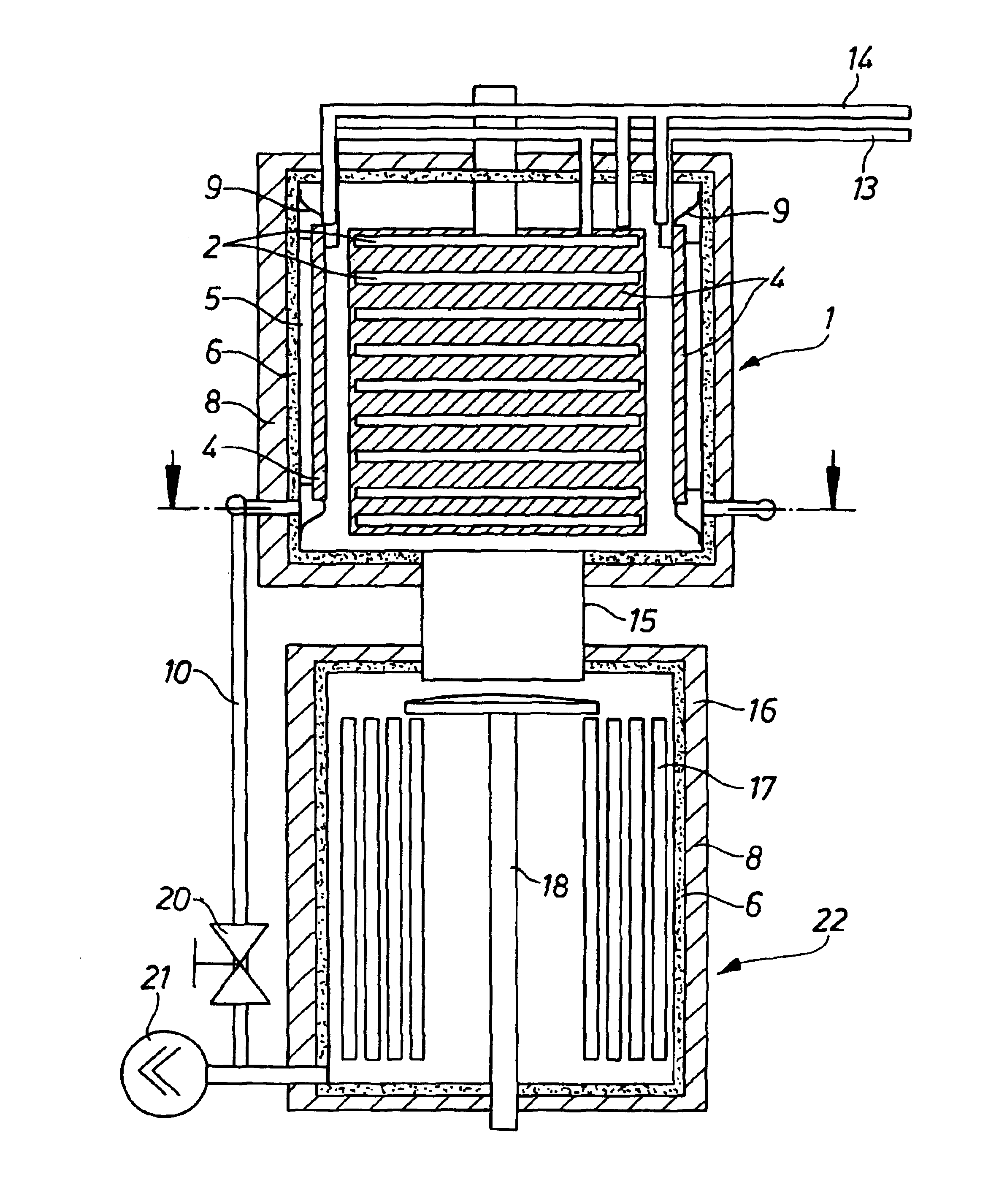

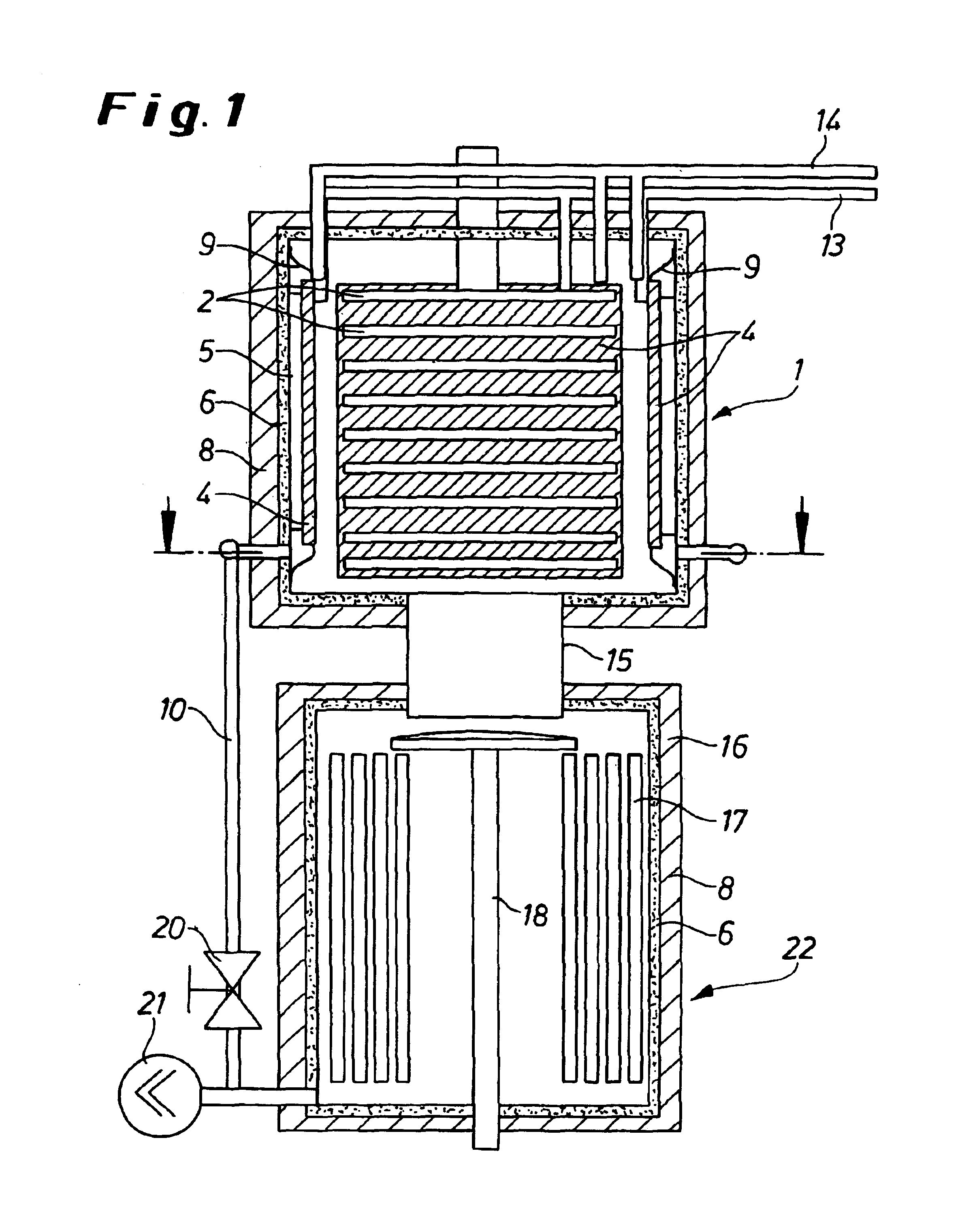

Heat Treatment Furnace and Heat Treatment Facility Comprising It

ActiveUS20080003534A1Uniform product qualityImprove life expectancyRotary drum furnacesCharge supportsEngineeringHeat treated

With regard to a heat treatment furnace (a solution furnace 1 and an ageing furnace 3), a furnace chamber 15 comprises a furnace body 12 opening downward and a floor body 14 closing the lower opening of the furnace body 12 and rotatably driven, and one or plural stages of mounting shelves 16 on which work pieces 8 are mounted are provided in the furnace chamber 15. Hot-air circulation equipments 20A and 20B circulating hot air in the furnace chamber 15 along the peripheral direction when viewed in plan are provided in the furnace body 12. The mounting shelves 16 are fixed to a prop 17 standingly provided on the floor body 14 and are rotated integrally with the floor body 14.

Owner:TOYOTA JIDOSHA KK +1

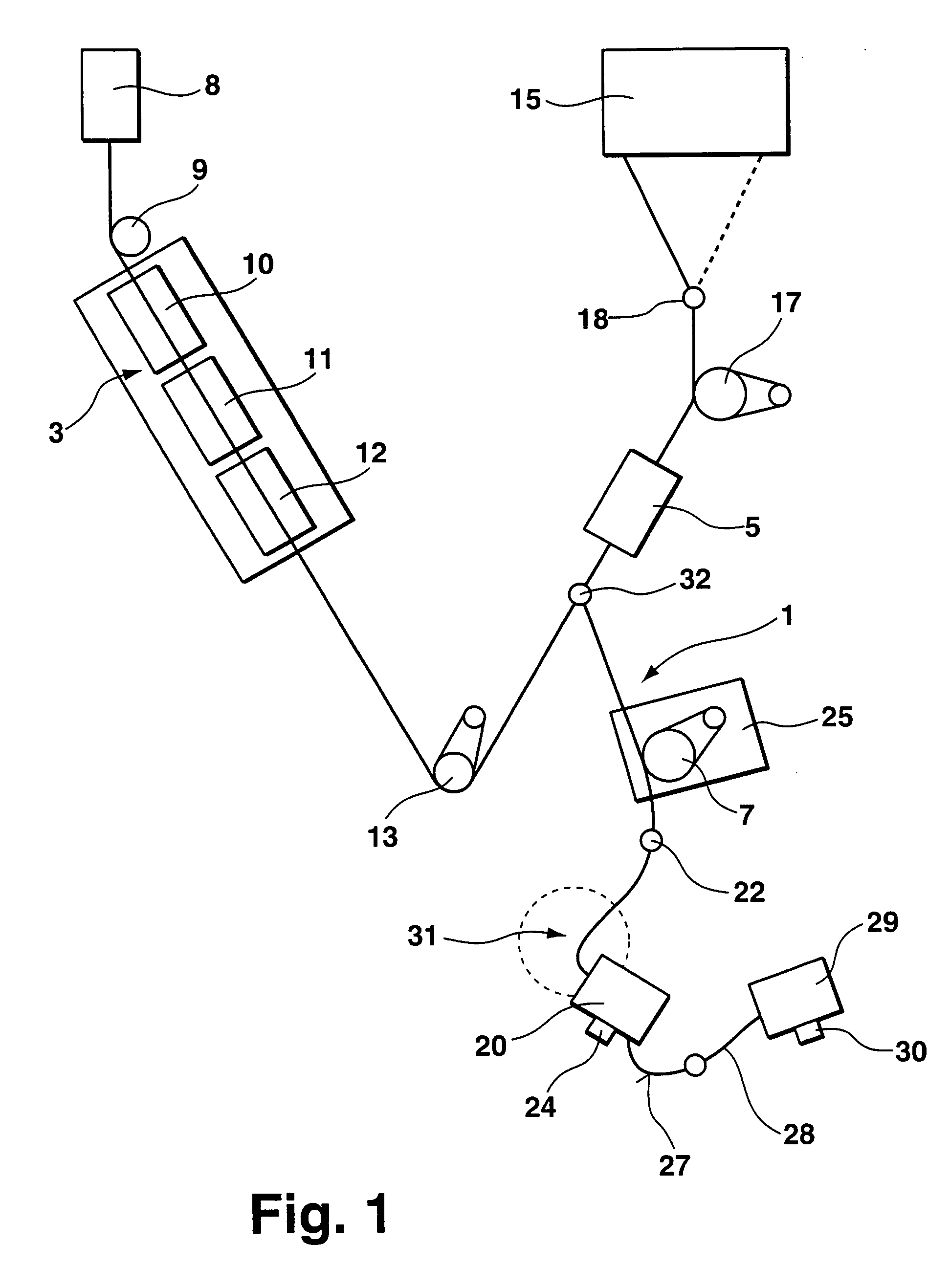

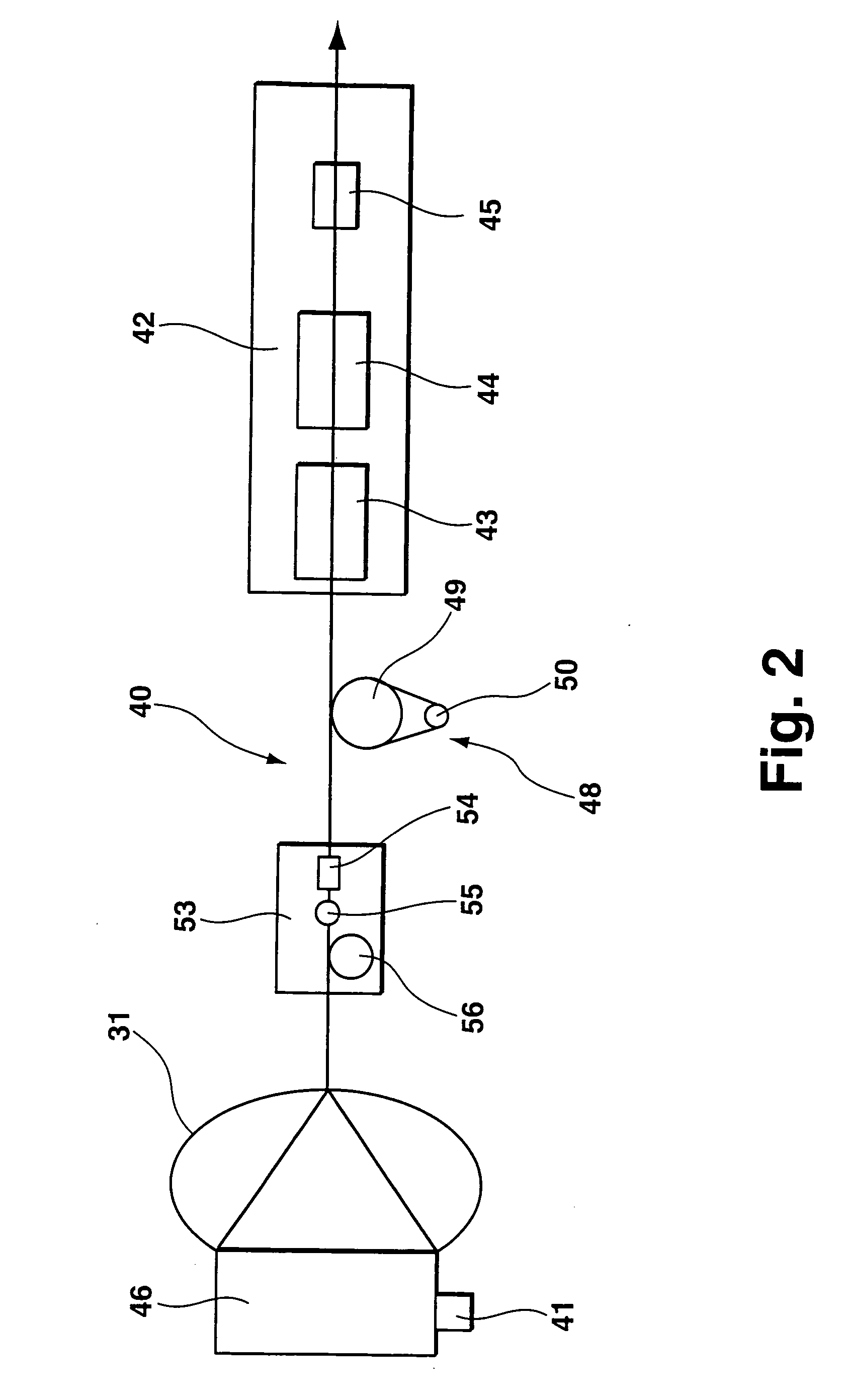

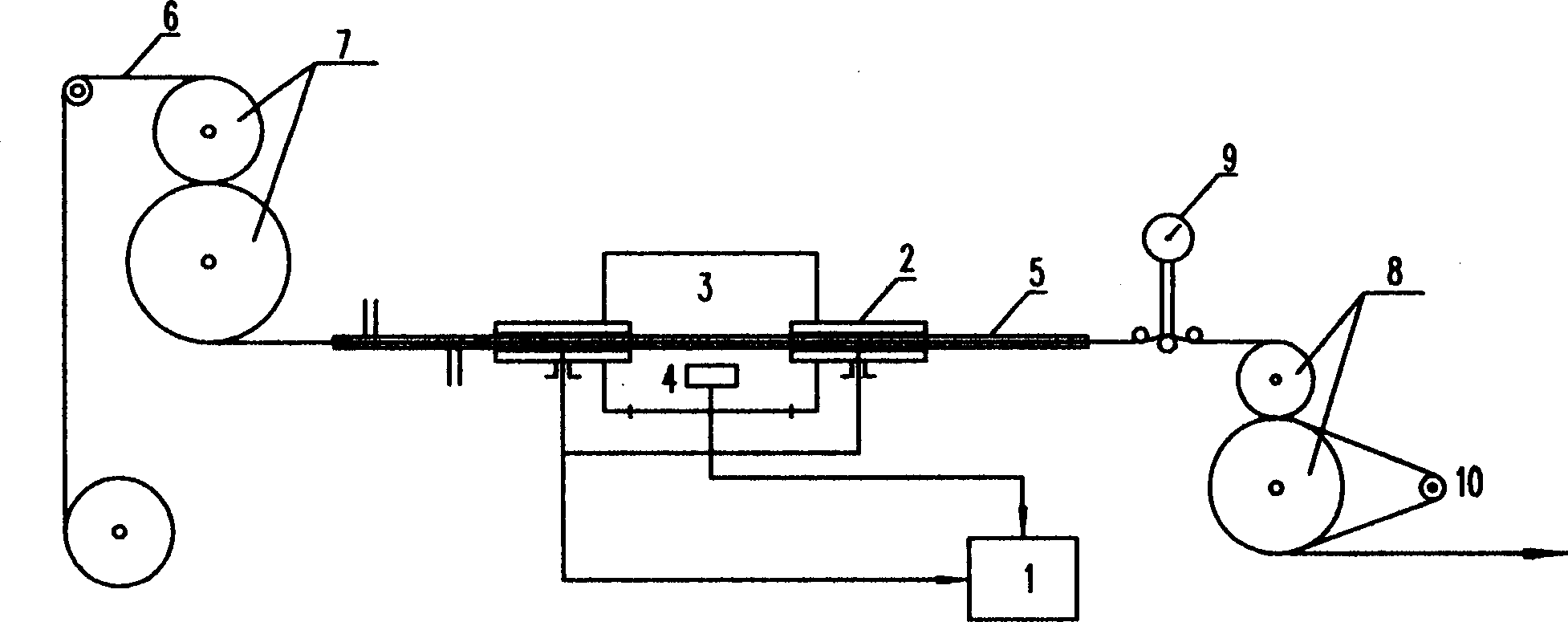

Yarn quality assurance method and yarn processing machine

A yarn quality assurance method and a yarn processing machine set up for implementing the method according to the invention is proposed comprising at least one feeding spool receiver 24, 30 set up to receive respectively at least one feeding spool 20, 29 from which yarns can be taken off, and a multifilament yarn manufacturing unit 5 to which yarns are supplied from the feeding spools 20, 29 via thread runs with respectively one thread tension. According to the invention, a thread tension regulating module 25 with a thread tension sensor is arranged in at least one controlled thread run 1 between the relevant feeding spool receiver 24 and the multifilament yarn manufacturing unit 5, wherein the thread tension regulating module 25 is set up to derive a control value from a thread tension measured by the thread tension sensor and to keep the thread tension constant in a predetermined thread tension range.

Owner:SSM SCHIRER SCHWEITER METTLER AG

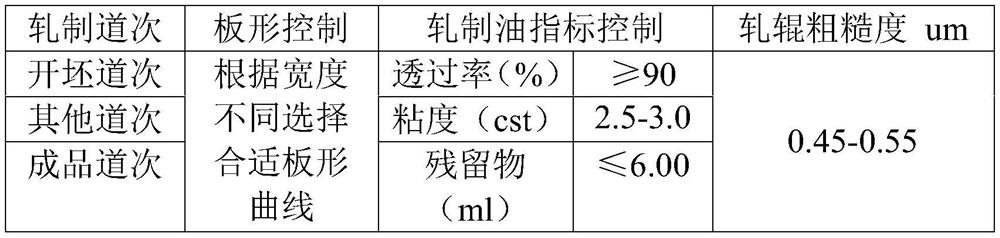

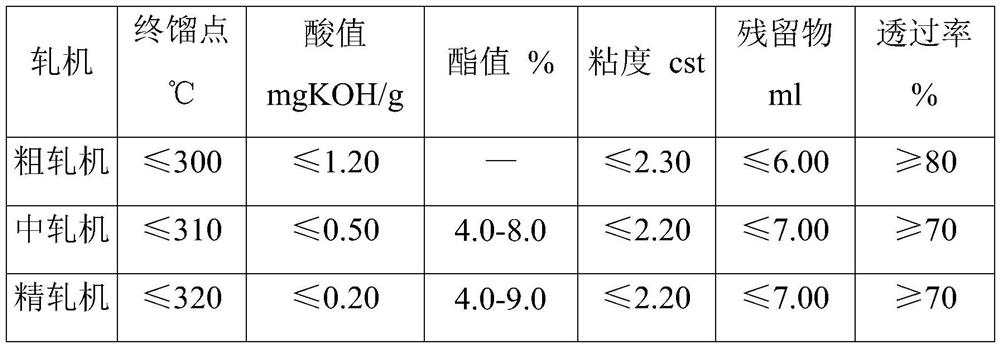

Aluminum foil for 1070 high-performance lithium ion battery and preparation method of aluminum foil

ActiveCN111793759AHigh strengthRaise the recrystallization temperatureElectrode carriers/collectorsSecondary cellsLithium electrodeMetallurgy

The invention discloses an aluminum foil for a 1070 high-performance lithium ion battery, and belongs to the technical field of aluminum foils for lithium ion batteries. The aluminum foil comprises the following components of, in percentage by mass, 0.01%-0.2% of Si, 0.01%-0.25% of Fe, 0.02%-0.05% of Cu, 0.01%-0.03% of Mn, 0.001%-0.03% of Mg, 0.001%-0.05% of Zn, 0.001%-0.05% of V, 0.01%-0.03% of Ti, less than or equal to 0.03% of other single impurity elements and the balance aluminum. The preparation method of the aluminum foil for the 1070 high-performance lithium ion battery comprises the following steps of burdening, smelting, filtering, cast rolling, cold rolling, foil rolling, slitting and packaging. The tensile strength of the 1070 high-performance aluminum foil for the lithium ionbattery prepared by the method is greater than or equal to 210 MPa, and the elongation is greater than or equal to 2.5%, therefore, by adopting the aluminum foil for the 1070 high-performance lithiumion battery and the preparation method of the aluminum foil, the problems of low strength and elongation of the existing 1070 aluminum alloy can be solved.

Owner:NORTH CHINA ALUMINUM

Device for spray printing of characters on surface of pipe

ActiveCN111097619AGuaranteed stabilityEasy to operateSpraying apparatusTypewritersPhysicsEngineering

The invention discloses a device for spray printing of characters on the surface of a pipe. The device comprises a main machine body, a processing cavity runs through the main machine body left and right, a cleaning cavity is formed in the left side of the processing cavity, an annular cleaning device for cleaning the pipe is arranged in the cleaning cavity, a spraying device used for spraying thesurface of the pipe is arranged above the processing cavity, a printing device used for printing the surface of the pipe is arranged below the processing cavity, and a conveying cavity used for clamping and conveying the pipe is formed on the right side of the processing cavity. The pipe is conveyed into the processing cavity and fixed through a conveying arm, the surface of the pipe is cleaned through the surface cleaning device, the spraying device cooperates with the printing device, and meanwhile, due to conveying and rotation of the conveying arm, the characters are sprayed and printed on the surface of the pipe.

Owner:安徽持家汉家居工艺品有限公司

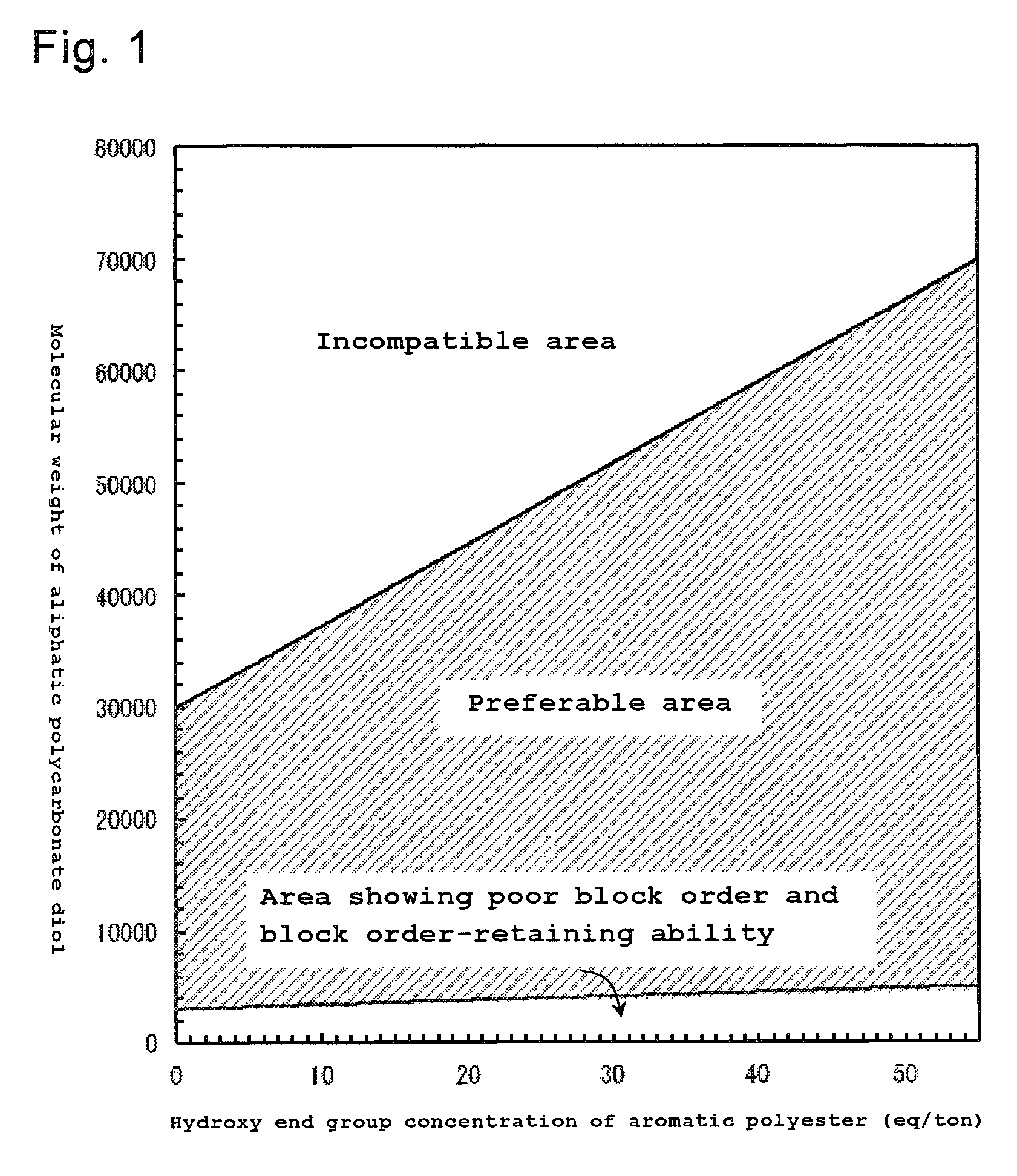

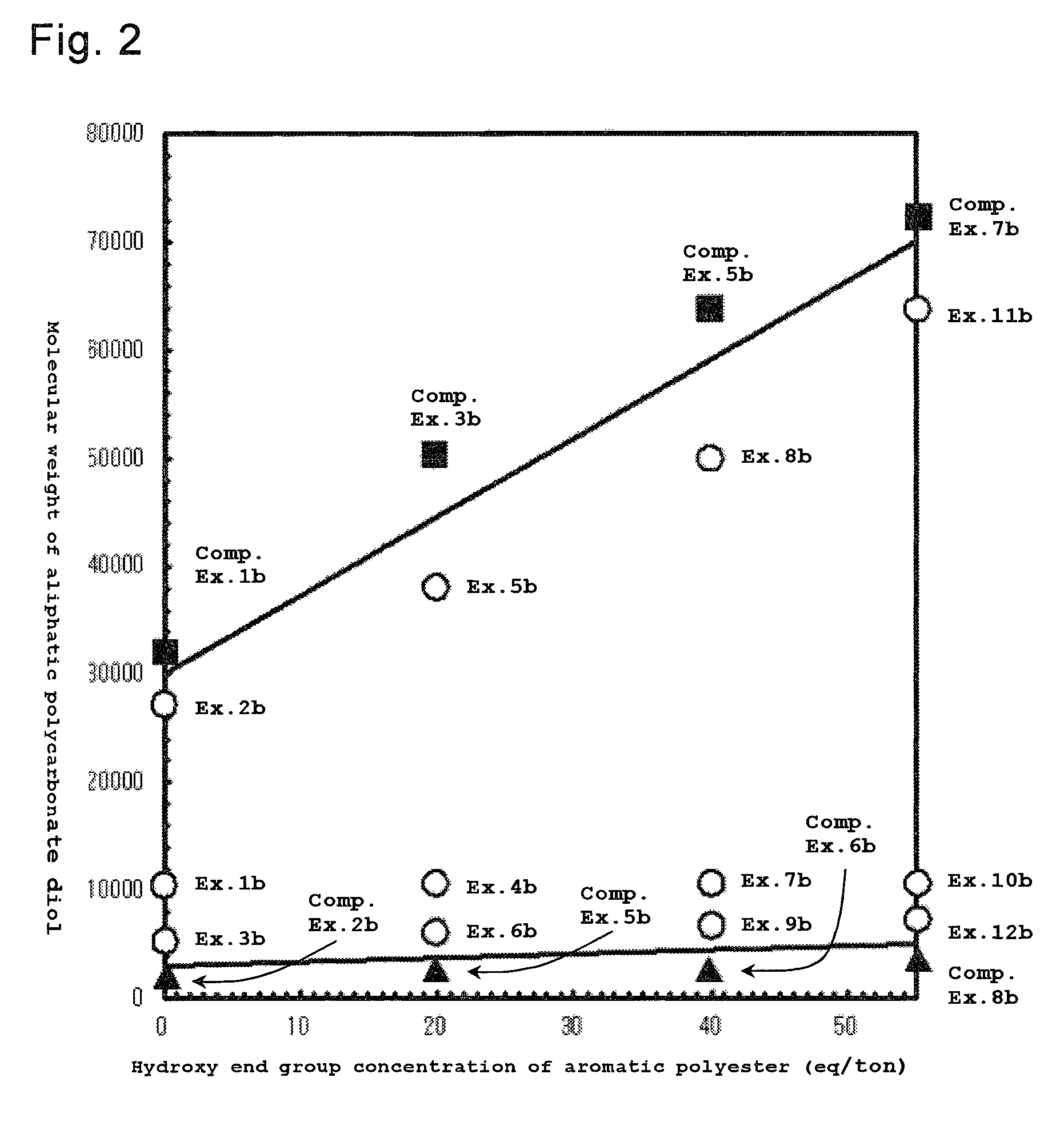

Method for producing thermoplastic polyester elastomer, thermoplastic polyester elastomer composition, and thermoplastic polyester elastomer

The present invention provides a thermoplastic polyester elastomer excellent in heat resistance, heat-aging resistance, water resistance, light resistance, low-temperature property and the like, and further excellent in block order-retaining ability, the thermoplastic polyester elastomer comprising a hard segment which comprises polyester constituted with aromatic dicarboxylic acid and aliphatic or alicyclic diol and a soft segment which comprises mainly aliphatic polycarbonate, wherein the hard segment and the soft segment being connected, and wherein when melting points of the thermoplastic polyester elastomer are obtained by measuring on a differential scanning calorimeter in three cycles in which a temperature is raised from room temperature to 300° C. at a heating rate of 20° C. / min., maintained at 300° C. for 3 minutes and lowered to room temperature at a cooling rate of 100° C. / min., a melting point difference (Tm1−Tm3) between a melting point obtained in the first cycle (Tm1) and a melting point obtained in the third cycle (Tm3) is 0-50° C., and a tensile strength at break is 15-100 MPa.

Owner:TOYOBO CO LTD +1

Apparatus and method for preparing chlorinated polyvinyl chloride through continuous gas-solid phase process

ActiveCN104971668AImprove stabilityReduce volumeEnergy based chemical/physical/physico-chemical processesGas solidTemperature control

The invention provides an apparatus and method for preparing chlorinated polyvinyl chloride through a continuous gas-solid phase process, belonging to the technical field of preparation technology and equipment for chemical materials. The apparatus is composed of three gas-solid fluidized beds and corresponding chlorine circulating pumps, wherein the previous two fluidized beds are provided with ultraviolet lamps, and the third fluidized bed is not provided with ultraviolet lamps. According to the method, a polyvinyl chloride (PVC) raw material successively passes through the three gas-solid fluidized beds; particles stay in each fluidized bed reactor for a period of time; fluidization by using gas mixtures with different chlorine concentrations is respectively carried out in the fluidized bed reactors at different temperatures; and a CPVC (chlorinated polyvinyl chloride) product with chlorine content reaching the standard is eventually obtained. According to the invention, since the fluidized bed reactors capable of continuous feeding and chlorination are adopted, the volume of the reactors are reduced to more than two times of the volume of a conventional gas-solid phase reactor capable of intermittent feeding under the condition of same production power, and the apparatus has the advantages of good temperature control during reaction and a high chlorine conversion rate; and the method is simple, is free of waste water discharge and produces products with stable quality.

Owner:TSINGHUA UNIV +1

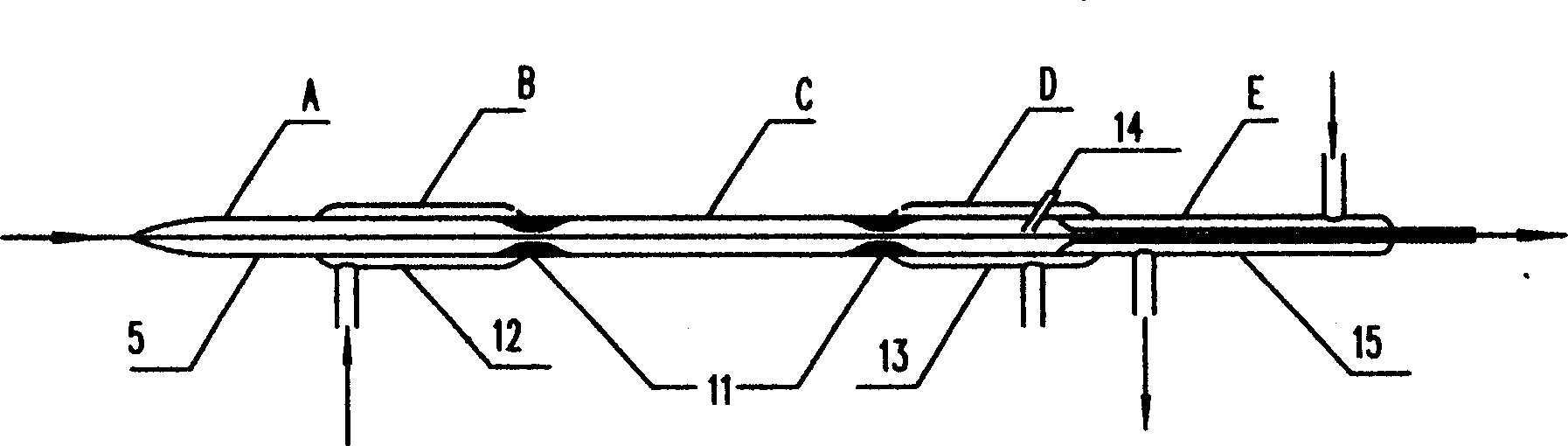

Method for producing high-strength high-modules carbon fibre and special equipment thereof

InactiveCN1385567AStable output powerReaction temperature control sensitiveFibre chemical featuresMicrowave heatingTemperature controlCarbon fibers

The present invention relates to a high-strength high-modules carbon fibre and its special equipment. It is characterized by that its high-frequency heating reaction pipe is formed from deoxygenationsection. cracking section, graphitizing section air-cooling section and water-cooding section. The carbon fibre can be continuously passed through said sectional reactino pipe, the reaction temp. of the graphitizing section is controlled at 2500-2650 deg.C, under the action of catalyst the graphitizing process of carbon fibre is completed. The drafting equipment is equipped with a drafting force display device, the drafting force can be controlled in the optimum state, it also has an optical temp.-measuring device, and the output power is controlled and regulated by computer. The strength of said fibre of greater than 3.5 GPa, and its modules is greater than GPa.

Owner:张蓬洲

Vibratory fluidized bed reactor for continuous production of rare earth fluorides and production method

InactiveCN104084095AImprove fluidization qualityOptimizing the gas-solid fluidization reaction processRare earth metal compoundsChemical/physical processesHydrogen fluorideFluoride products

The invention discloses a vibratory fluidized bed reactor for continuous production of rare earth fluorides. The vibratory fluidized bed reactor comprises a feeding device, a discharging device, a fluidized bed, a vibrator and a heating device, wherein a rare-earth-containing material feeding hole is formed in the upper part of a fluidized bed body; a rare earth fluoride product discharge opening communicated with the discharging device is formed in the lower part of the fluidized bed body; a hydrogen-fluoride-containing gas inlet is formed in the bottom of the fluidized bed body; gas distribution plates through which hydrogen-fluoride-containing gas passes and uniform air distribution is realized are arranged in the cavity of the fluidized bed body; an exhaust pipe is arranged on the top of the fluidized bed body; the heating device is arranged on the outer side of the fluidized bed body and covers the fluidized bed body; the vibrator is arranged on the outer wall of the fluidized bed body; the bottom of the fluidized bed body is connected to supports through elastic supporting pieces. According to the scheme in the invention, the fluidization quality can be improved, the mass transfer and heat transfer effects are improved, the production efficiency is high, and the product is uniform and stable in quality, high in fluorination rate and low in process cost.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com