Device capable of improving online heating adaptability of roller

An adaptable and rolling technology, applied in the field of rolling, can solve the problems of high heating rod temperature, low processing efficiency, oil sealing pollution, etc., and achieve the effect of high production efficiency, low processing cost and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below by accompanying drawing

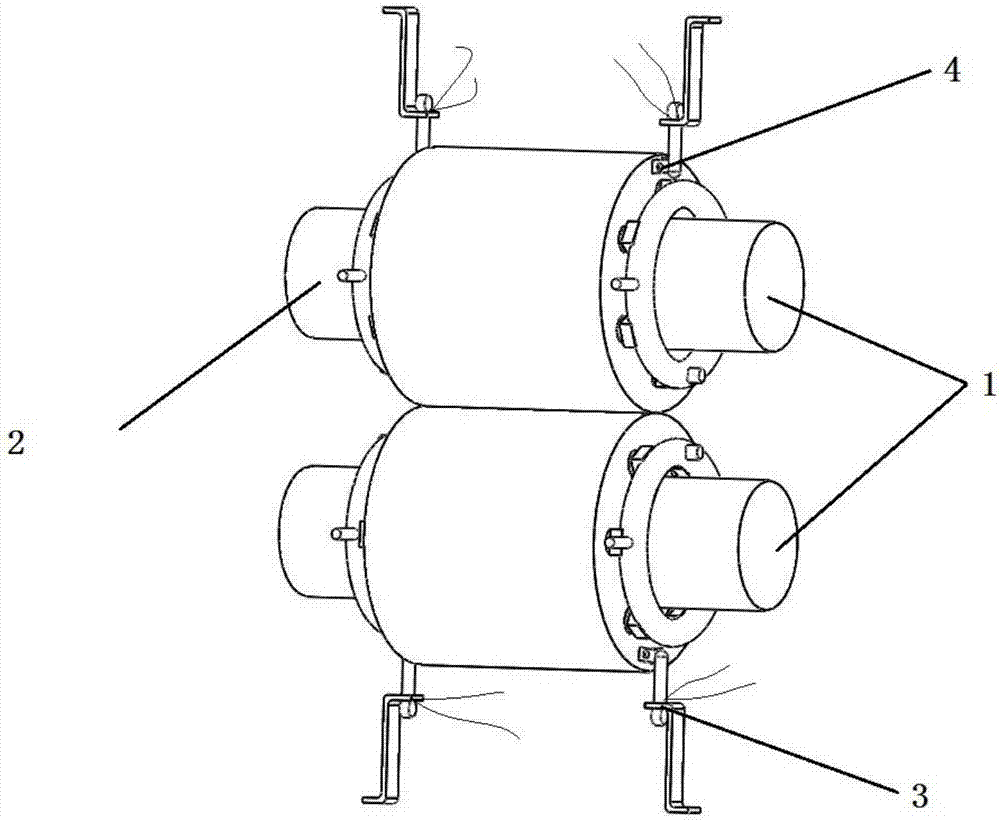

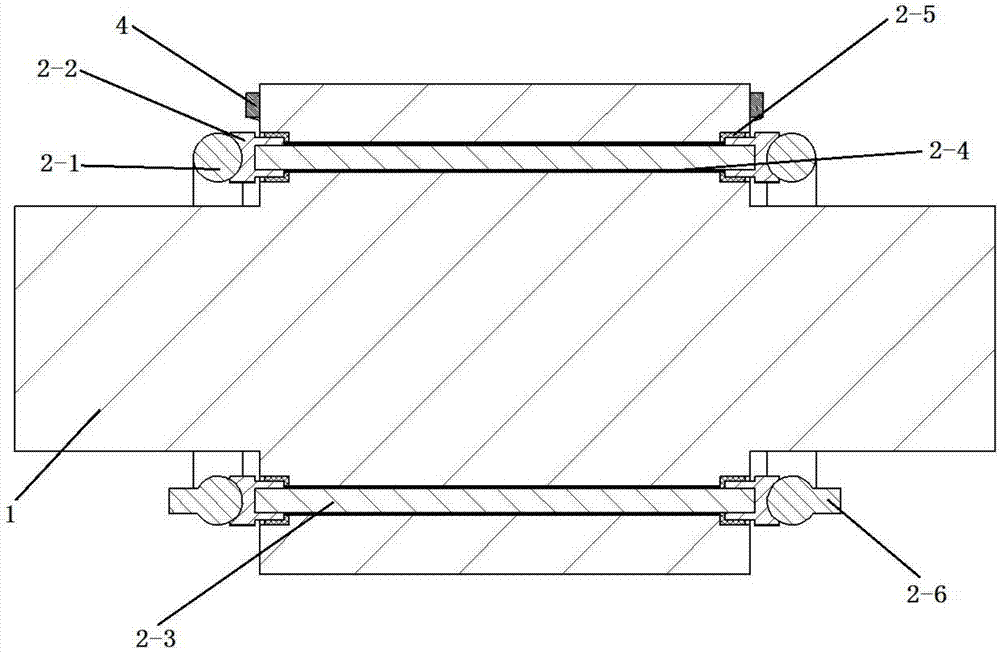

[0015] exist figure 1 with figure 2 In the schematic diagram of a device that can improve the on-line heating adaptability of rolls shown, roll 1 is a common roll, such as Figure 4 As shown, there are 6 axial through-holes that run through the two end faces and are evenly distributed, and the opening of each axial through-hole is provided with the same stepped slot with a diameter larger than the diameter of the axial through-hole. An electric heating element 2 is provided on the roll, such as image 3 shown. A heating rod 2-3 wrapped with an asbestos layer 2-4 is arranged in each axial through hole of the roll, and the parts not covered with asbestos layer at both ends of each heating rod are respectively placed in the hollow cylinder of the conductive block 2-2 Inside, the outer wall of the hollow cylinder is placed in the stepped slot of the axial through hole, and an annular rubber sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com