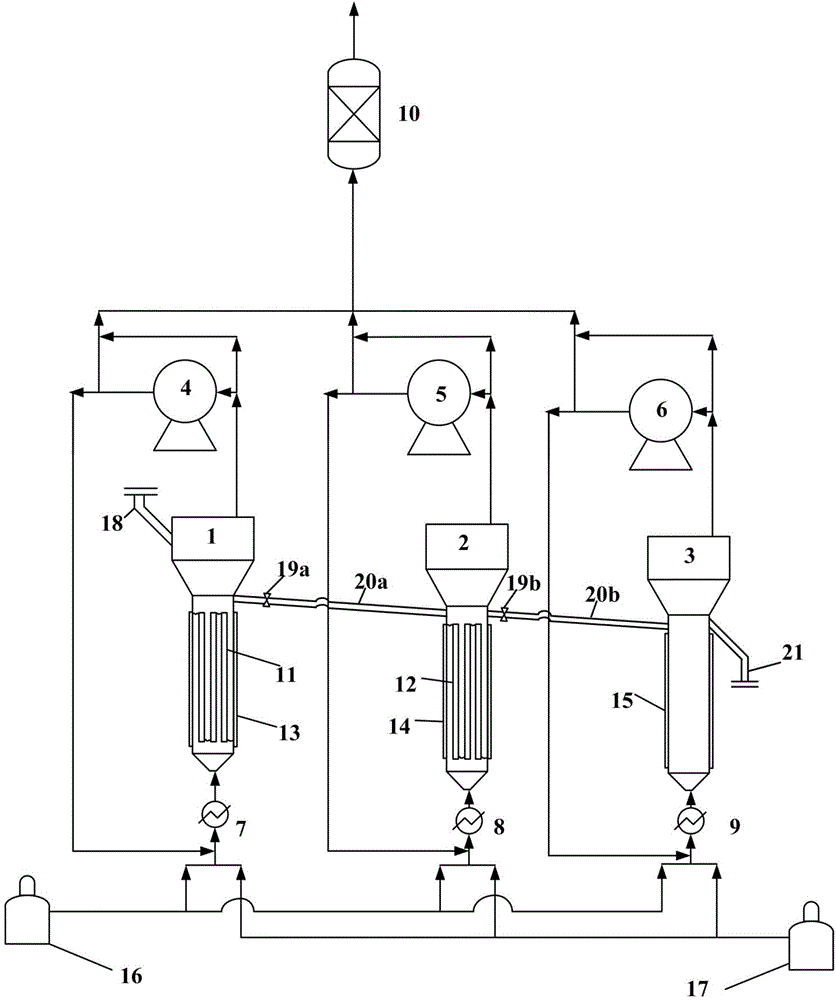

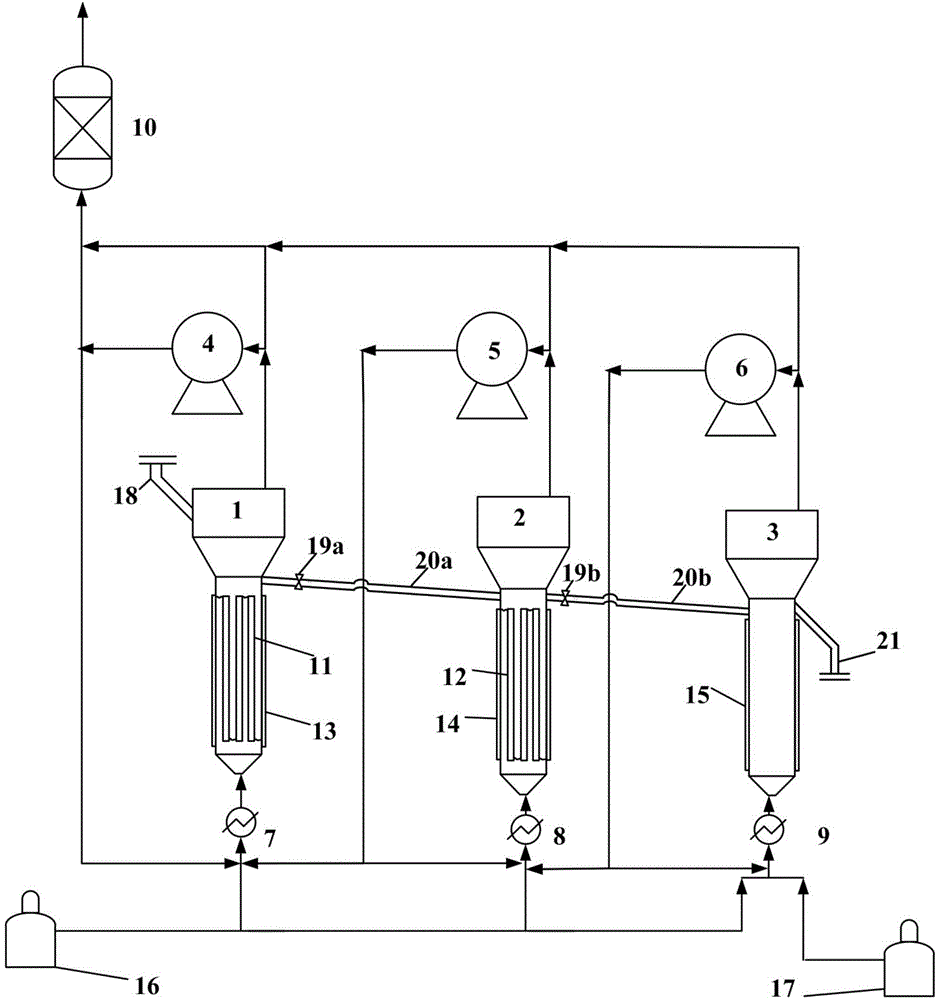

Apparatus and method for preparing chlorinated polyvinyl chloride through continuous gas-solid phase process

A chlorinated polyvinyl chloride, gas-solid phase technology, applied in the direction of chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes that apply energy, etc., can solve the problem of non-continuous production and uncontrollable reactor operation parameters and other issues, to achieve stable equipment operation, save fixed investment costs, and reduce the volume of the reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] a. Add existing CPVC granules in three fluidized beds, chlorine content 67.5%. Close the first valve 19a and the second valve 19b between the first and second fluidized bed reactors and the second and third fluidized bed reactors, and close the PVC feed port and the CPVC discharge ports 18 and 21 . Open nitrogen bottle 16, fluidization certain hour. At this moment, the gas enters the tail gas absorption tower 10 before the first chlorine circulation pump 4, the second chlorine circulation pump 5 and the third chlorine circulation pump 6, and the bed particles are in a fluidized state, and the oxygen is displaced away;

[0039] b. Turn on the gas circulation pump so that nitrogen returns to each reactor inlet through the first chlorine circulation pump 4, the second chlorine circulation pump 5 and the third chlorine circulation pump 6, and slowly turn down the nitrogen cylinder 16 to completely close. At this point, all fluidized bed reactors are in a self-circulating s...

Embodiment 2

[0044] in such as figure 1 In the shown equipment of the present invention, PVC with a particle diameter of 100-200 microns is used as the raw material, the inert gas is nitrogen, and the intake chlorine gas integration rate is 90%. The temperature of the first fluidized bed reactor is controlled at 80°C, the integral rate of chlorine gas is 60%, and the residence time of the raw material is 3h; the controlled temperature of the second fluidized bed reactor is 90°C, the integral rate of chlorine gas is 65%, and the residence time of the raw material is 3h, the temperature of the third fluidized bed reactor was controlled at 120°C, the gas integration rate of chlorine was 80%, and the residence time of the raw material was 4h; the operating pressure of the three fluidized bed reactors was 0.12Mpa, and the wavelength of the ultraviolet lamp was 365nm. The bed superficial gas velocity is 0.4m / s. After the system is stable, the first chlorine circulation pump circulates 70% of th...

Embodiment 3

[0051] a. Add existing CPVC granules in three fluidized beds, chlorine content 67.5%. Close the first valve 19a and the second valve 19b between the first and second fluidized bed reactors and the second and third fluidized bed reactors, and close the PVC feed port and the CPVC discharge ports 18 and 21 . Open the 16 valves of the nitrogen cylinder, and fluidize for a certain period of time. At this time, the gas enters the tail gas absorption tower before the chlorine circulation pump 4. At this time, the bed particles are in a fluidized state, and the oxygen is replaced;

[0052] b. Turn on the gas circulation pump, so that the nitrogen gas circulates through the pump 4 and returns to the air inlet of each reactor, and slowly adjust the valve of the nitrogen cylinder 16 until it is completely closed. At this point, all fluidized bed reactors are in a self-circulating state. Turn on each fluidized bed reactor heating device and gas heating device, and start the tail gas ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com