Plastic weaving bag high-speed full-automatic seam cutting machine

A fully automatic technology for plastic woven bags, applied in envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of high cost, poor economic benefit, difficult management, etc., achieve fast production speed and reduce production sites , The effect of uniform product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

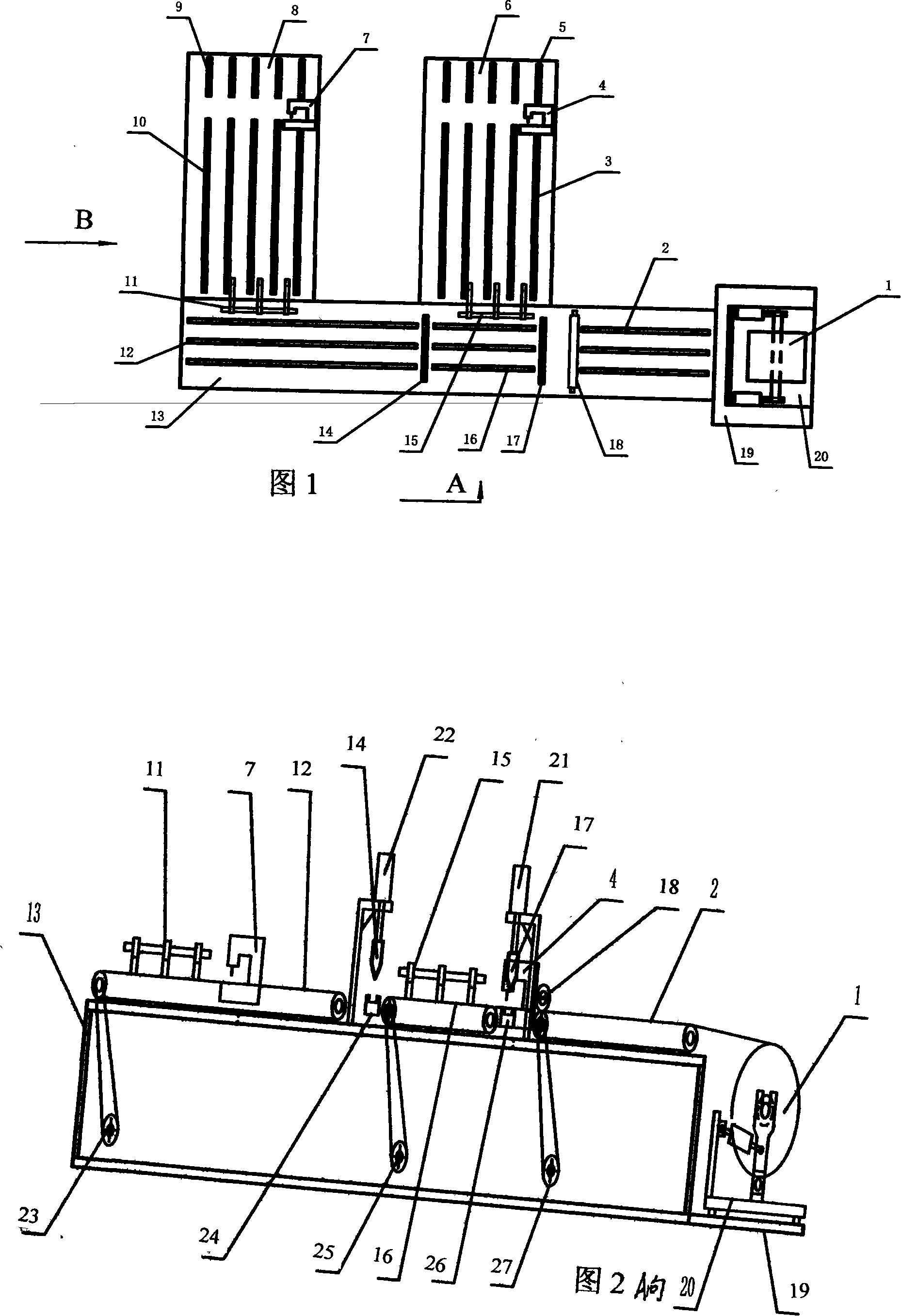

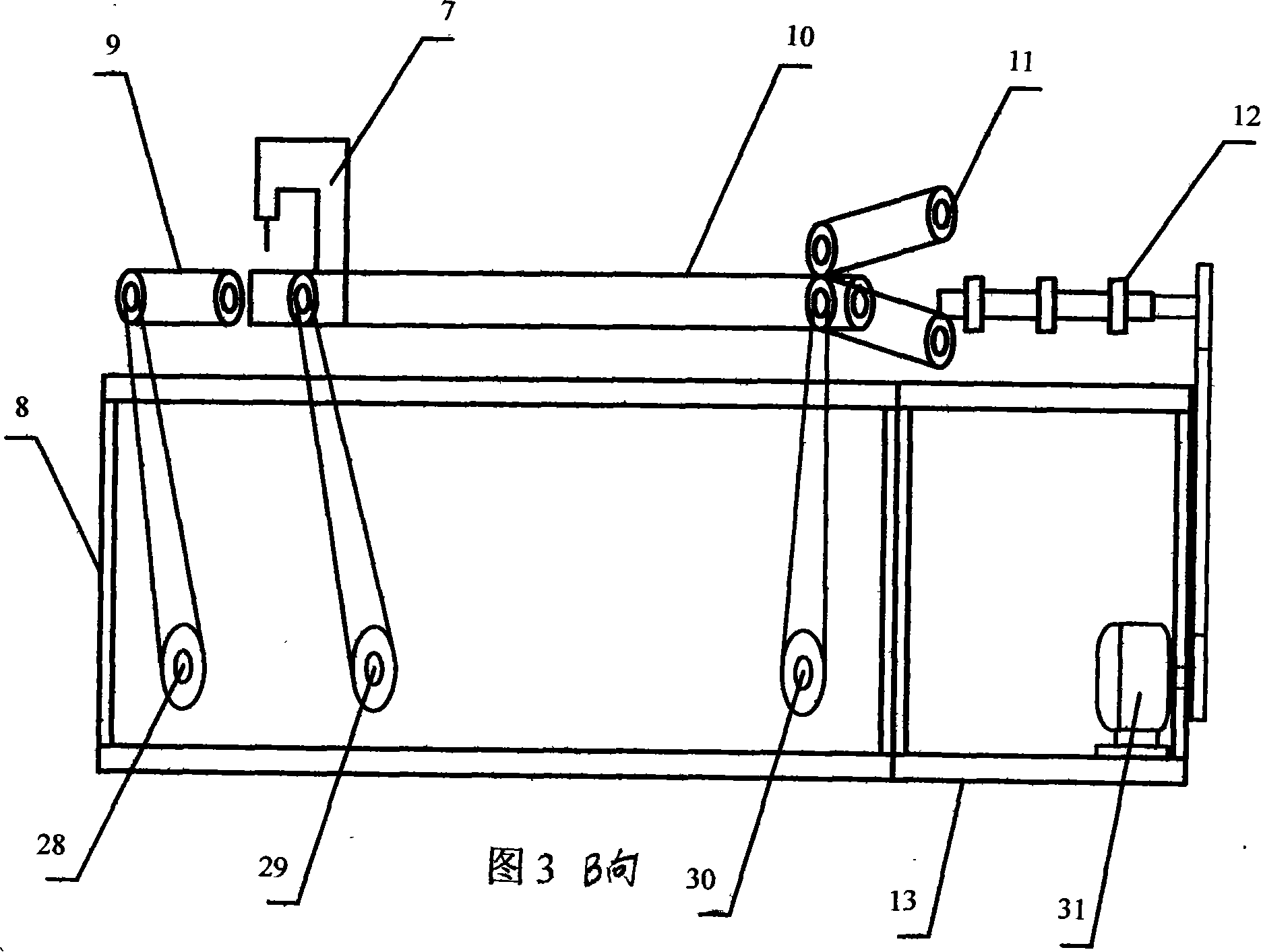

[0013] The embodiments are further described below in conjunction with the accompanying drawings.

[0014] With reference to Fig. 1, be the equipment that two sewing machines and supporting parts are installed. In the figure, 1-plastic woven fabric material, 2-cutting mechanism first-stage bag sheet conveying device, 3-first sewing station front-stage bag sheet conveying device, 4-sewing machine, 5-first sewing station post-stage Bag sheet conveying device, 6-first sewing station worktable, 7-second sewing station sewing machine, 8-second sewing station workbench, 9-second sewing station post-stage bag sheet conveying device, 10th Second sewing station front-stage bag conveying device, 11-second sewing station traverse manipulator, 12-cutting mechanism rear-stage bag conveying device, 13-cutting mechanism workbench, 14-cutting mechanism post-cutting Knife, 15-first sewing station traverse manipulator, 16-intermediate bag conveying device of cutting mechanism, 17-cutting knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com