Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about How to "Satisfactory adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

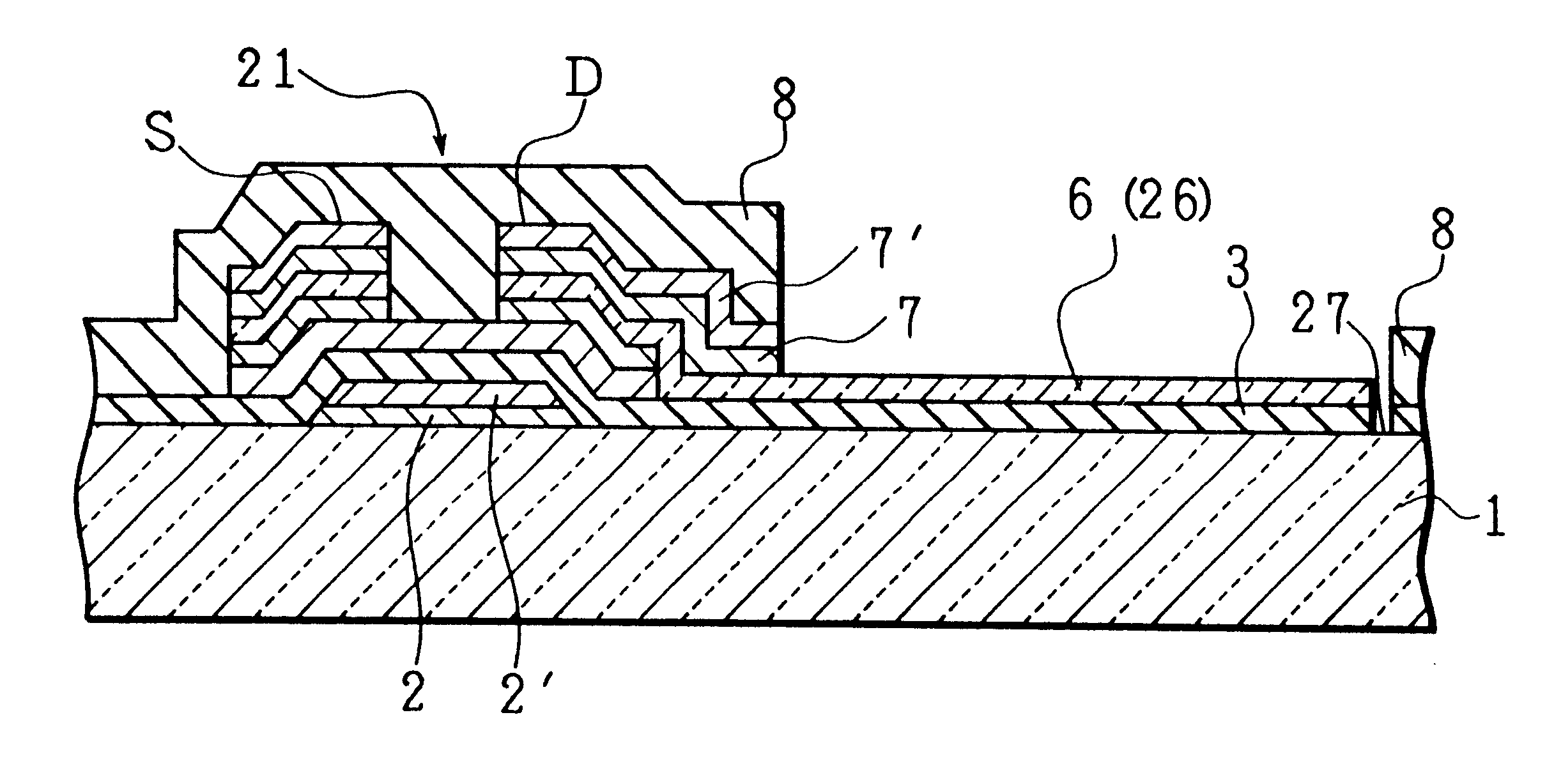

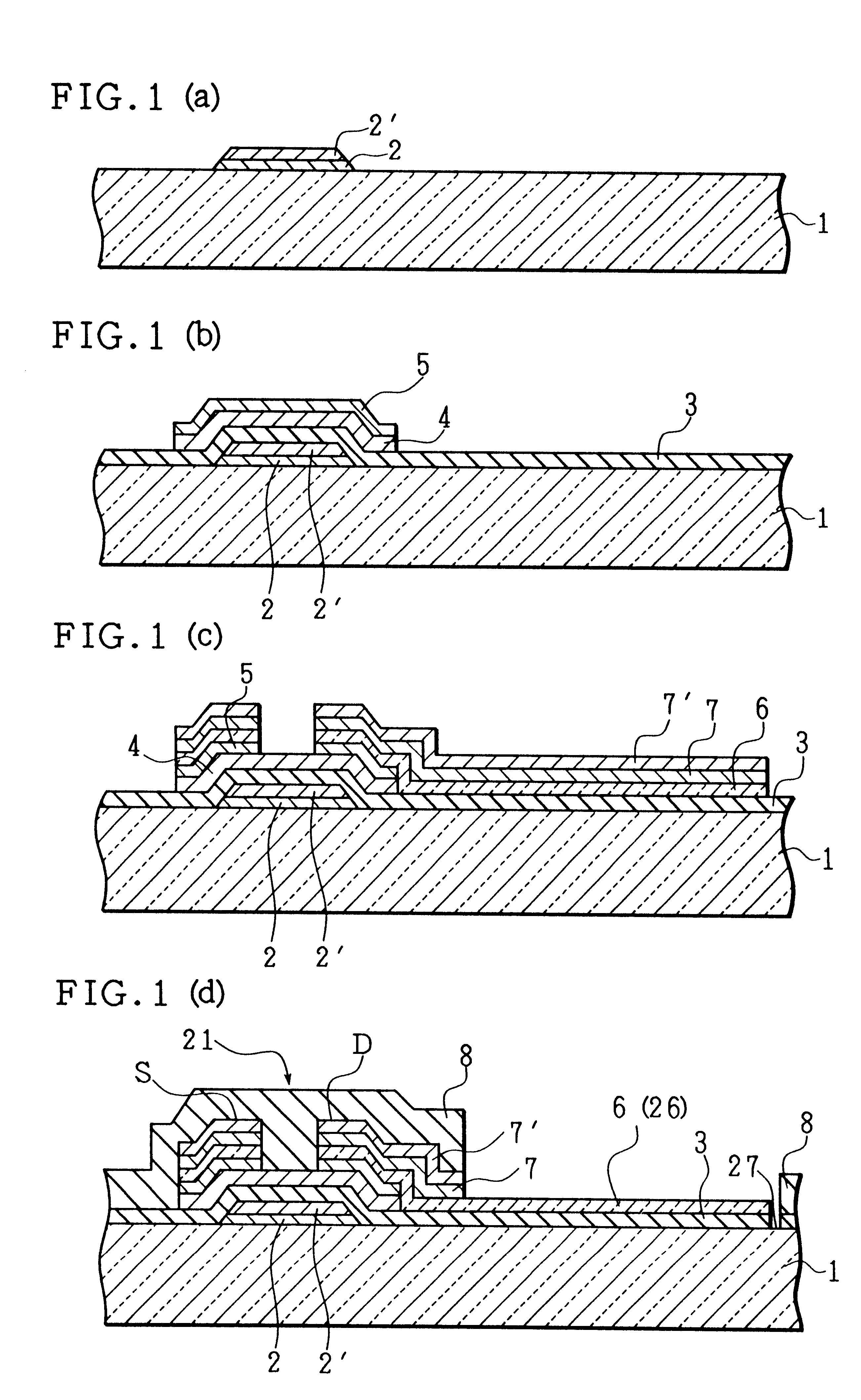

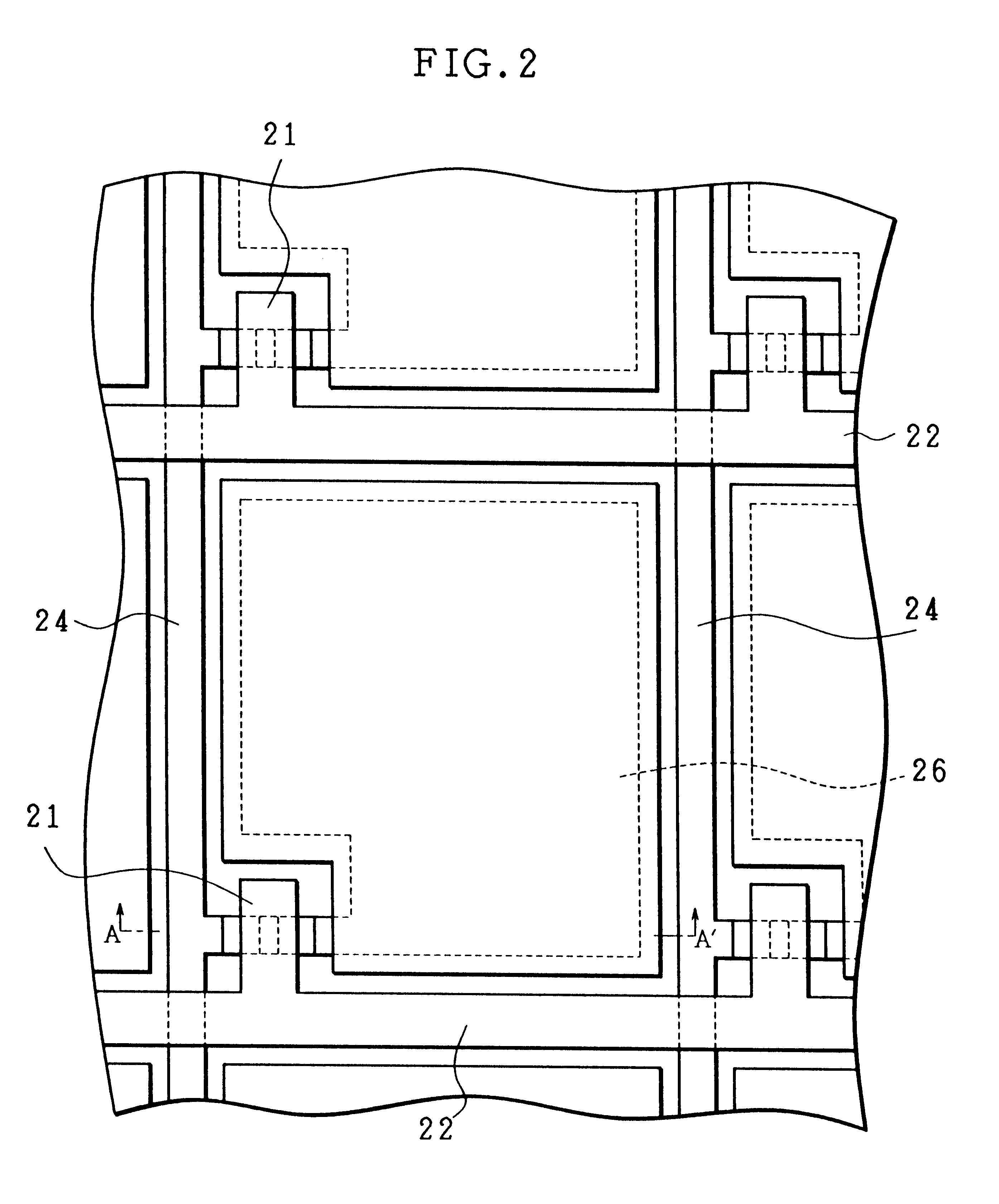

Method of manufacturing liquid crystal display

InactiveUS6323051B1Preventing decrease in yieldAvoid production cutsTransistorSolid-state devicesLiquid-crystal displayCell separation

A manufacturing method of a liquid crystal display of the present invention is a manufacturing method of a liquid crystal display having a glass substrate provided thereon with a matrix of thin film transistors, each having a semiconductor film pattern formed by photo-etching a high-resistance semiconductor film and a low-resistance semiconductor film, and a third metal film serving as a source metal film layer layered on the semiconductor film pattern, in which the semiconductor film pattern is formed on the glass substrate first, and thence the third metal film is layered on the glass substrate. Consequently, a liquid crystal display can be manufactured with a fewer number of manufacturing steps while at the same time the manufacturing costs can be saved by preventing a decrease in the yield caused by film separation.

Owner:SHARP KK

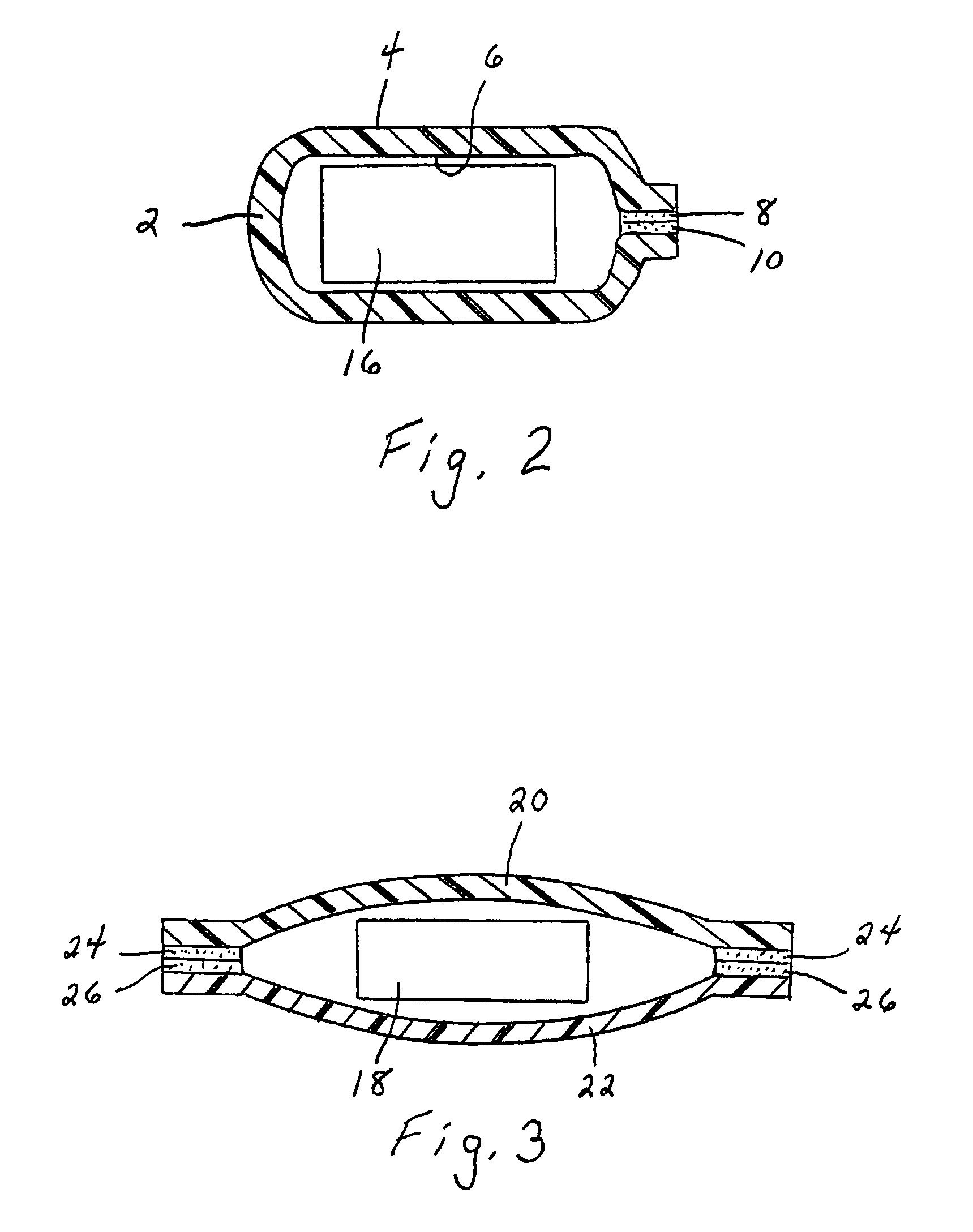

Electromagnetic wave absorber

InactiveUS6869683B2Satisfactory abilitySatisfactory adhesionMagnetic/electric field screeningConductive materialPhysicsPliability

An electromagnetic wave (EM) absorber is constructed by integrally laminating an EM-absorbing layer having an EM-absorbing filler dispersed in a silicone resin on at least one surface of an EM-reflecting layer having an electrically conductive filler dispersed in a silicone resin. It has satisfactory EM-absorbing and shielding abilities and is workable, flexible, weather resistant and heat resistant due to the nature of the silicone resin itself. The use of the silicone resin in both the EM-absorbing and reflecting layers ensures that a firm bond is established between the layers. In a preferred embodiment wherein a heat conductive filler is blended, the absorber has a satisfactory heat transfer ability as well.

Owner:SHIN ETSU CHEM CO LTD

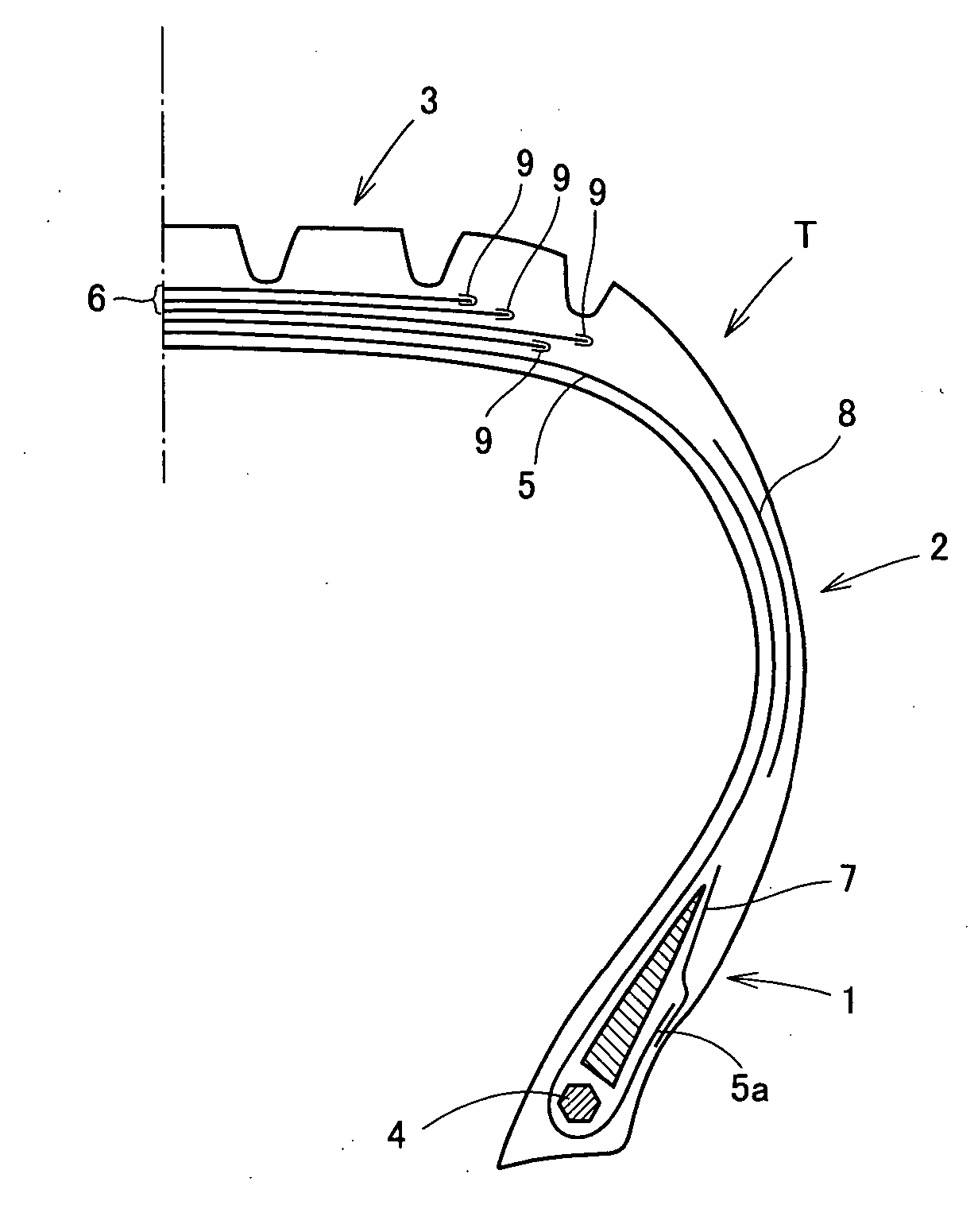

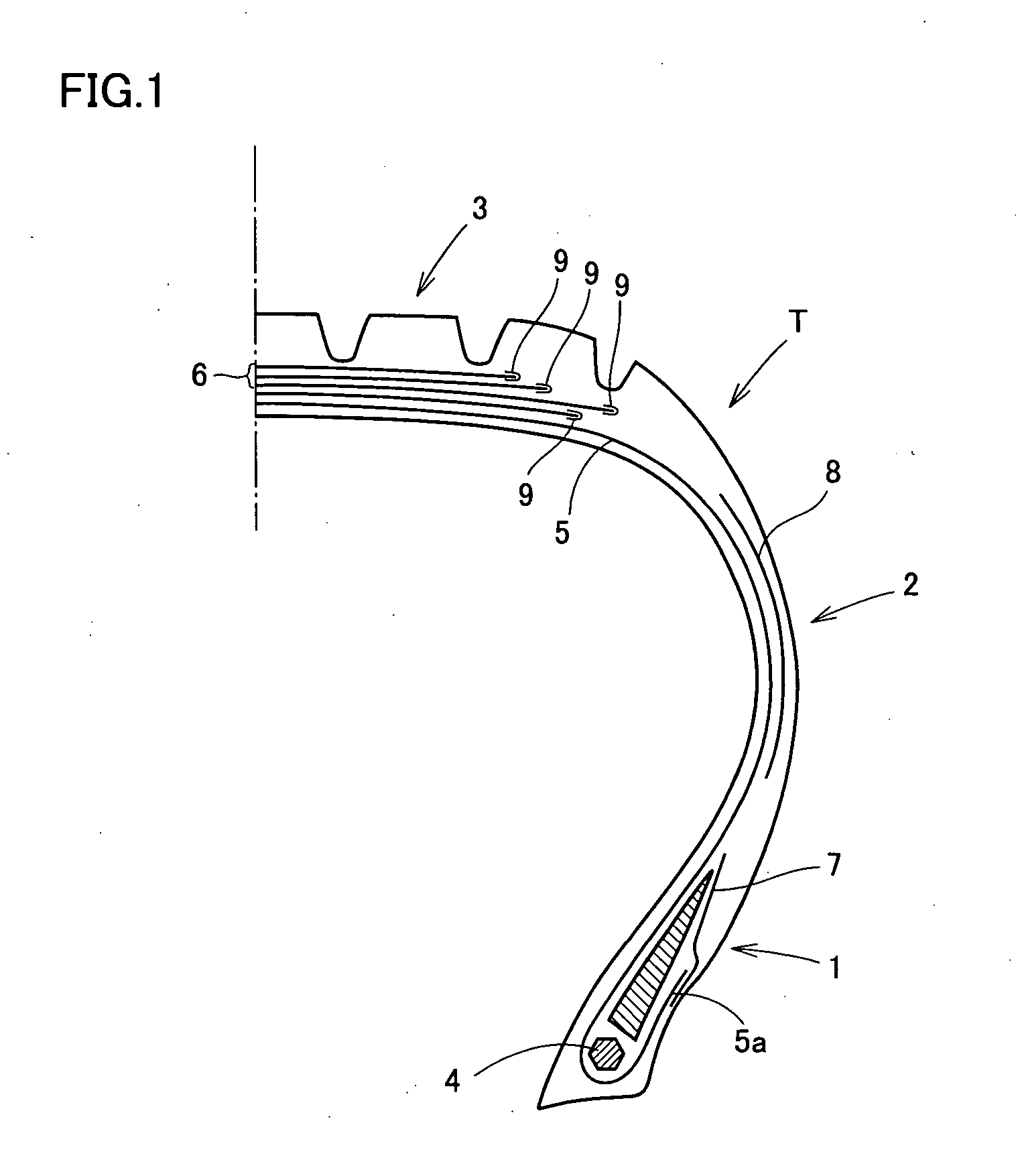

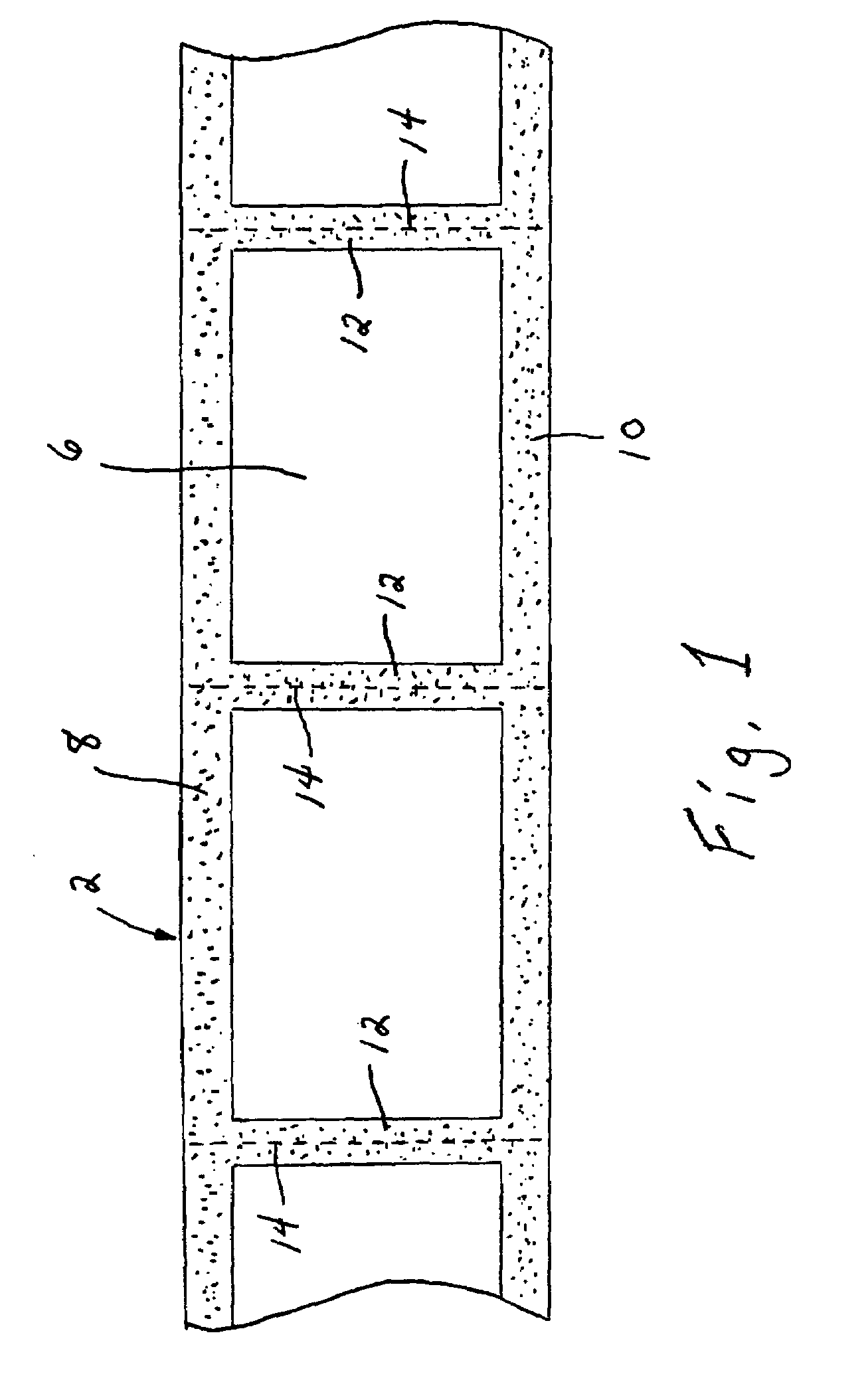

Pneumatic tire and method of producing the same

InactiveUS20060102269A1Increased durabilityReduce rolling resistanceSpecial tyresPneumatic tyre reinforcementsRolling resistanceCobalt salt

There is provided a pneumatic tire capable of achieving both reduced rolling resistance and enhanced durability and a method of producing the same. The pneumatic tire includes a reinforcement layer, formed of a steel cord coated with coating rubber, including at least one of a carcass, a bead reinforcement layer, a side reinforcement layer and a belt, with said coating rubber formed of a rubber compound containing 100 parts by mass of diene rubber, 30 to 80 parts by mass of silica having a nitrogen surface area of at least 70 m2 / g and at most 150 m2 / g, 1 to 15 parts by mass of a silane coupling agent, and organic acid cobalt salt. Preferably the steel cord has a cut edge of a breaker coated with an edge strip of rubber.

Owner:SUMITOMO RUBBER IND LTD

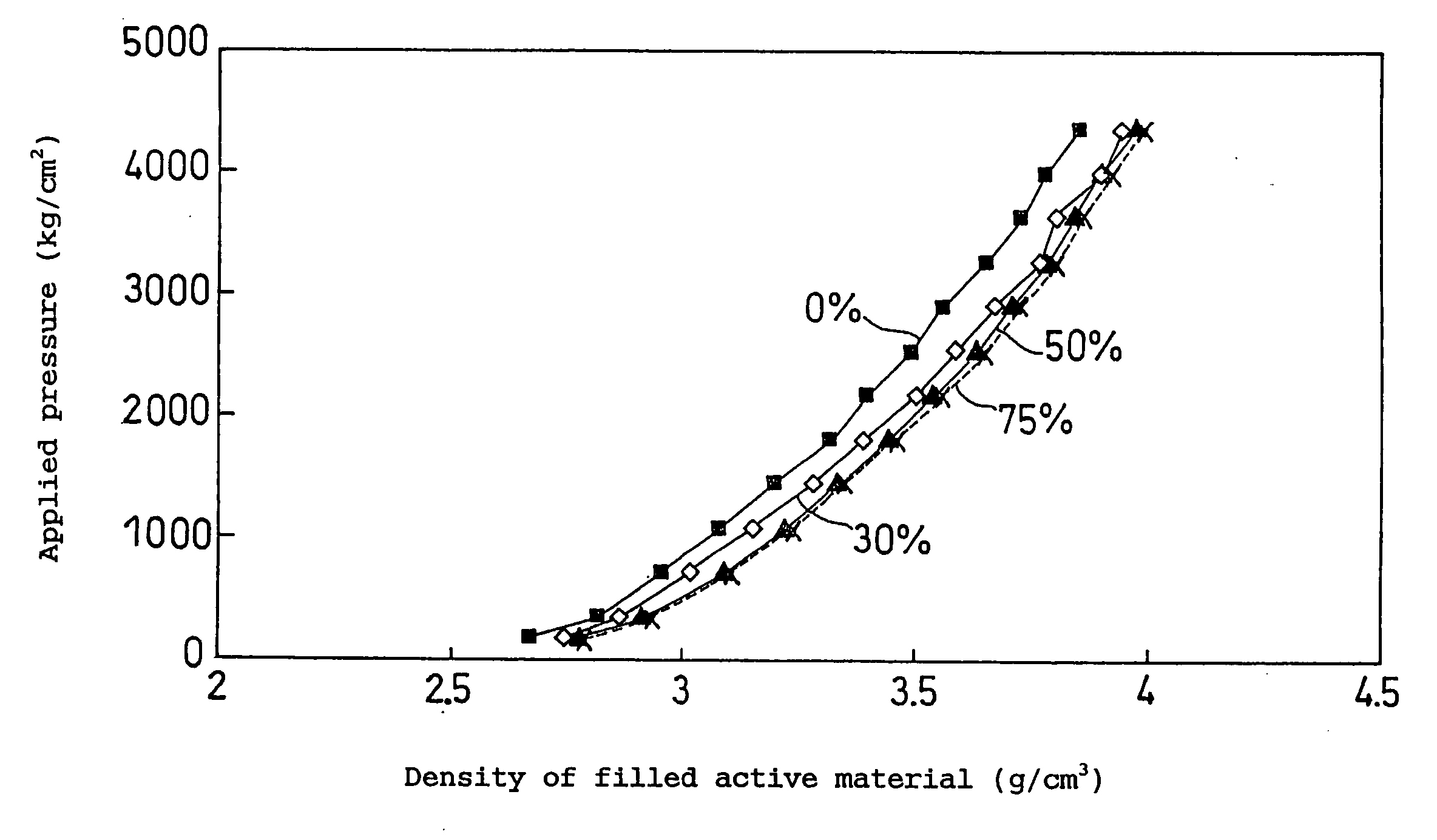

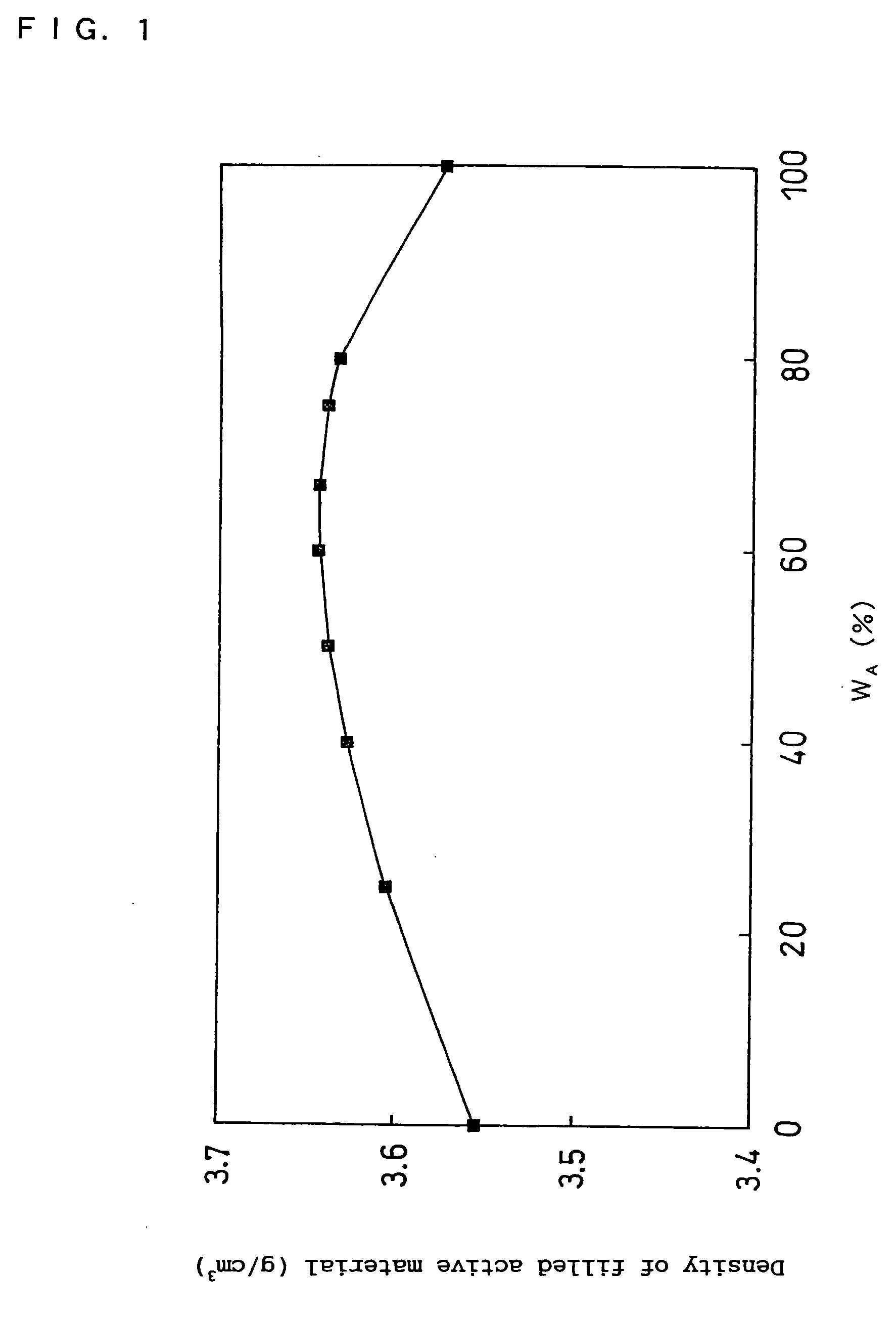

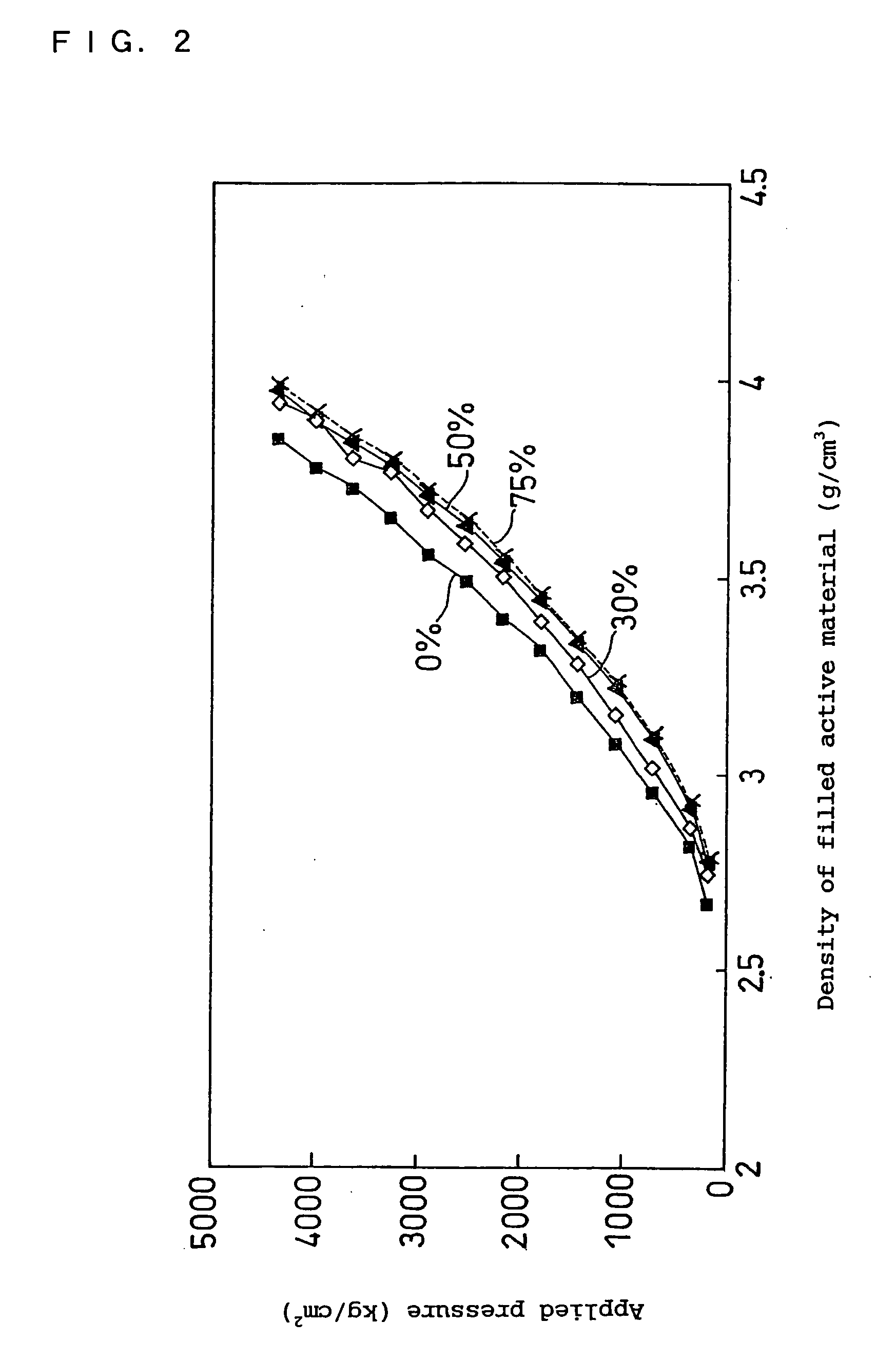

Non-aqueous electrolyte secondary battery

ActiveUS20060115730A1Increase flexibilityPrevent curingFinal product manufactureActive material electrodesParticulatesFluorocarbon

Disclosed is a non-aqueous electrolyte secondary battery having an electrode group in which a positive electrode and a negative electrode are spirally wound with a separator interposed therebetween. The positive electrode contains a positive electrode active material and a binder. The positive electrode active material contains a mixture of two different particulate substances having different average particle sizes. The two different particulate substances are lithium composite metal oxides containing nickel as an essential element. The binder includes fluorocarbon resin and rubber particles. The fluorocarbon resin contains at least a vinylidene fluoride unit. The amount of the rubber particles per 100 parts by weight of the fluorocarbon resin is 1 to 25 parts by weight.

Owner:PANASONIC CORP

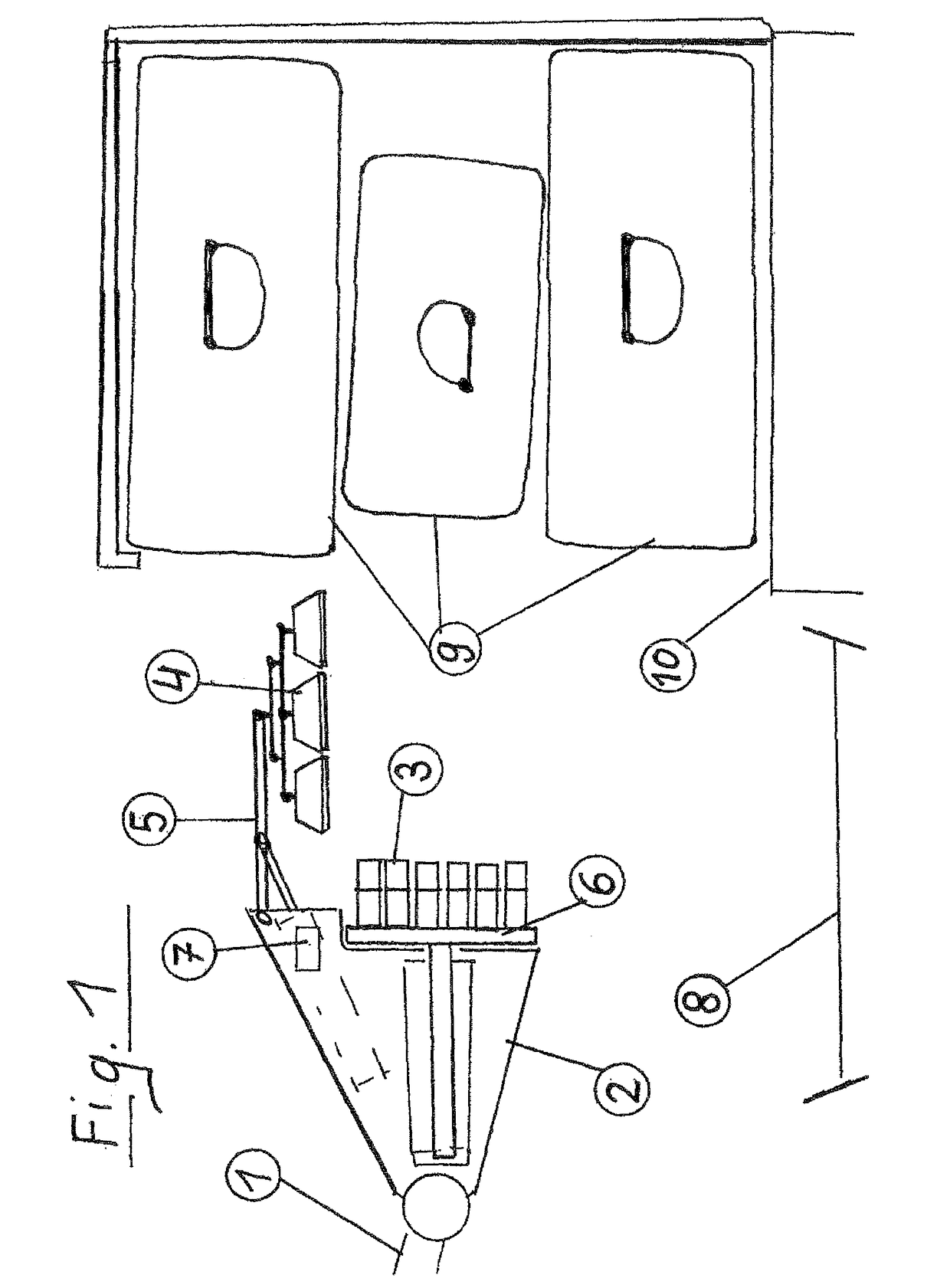

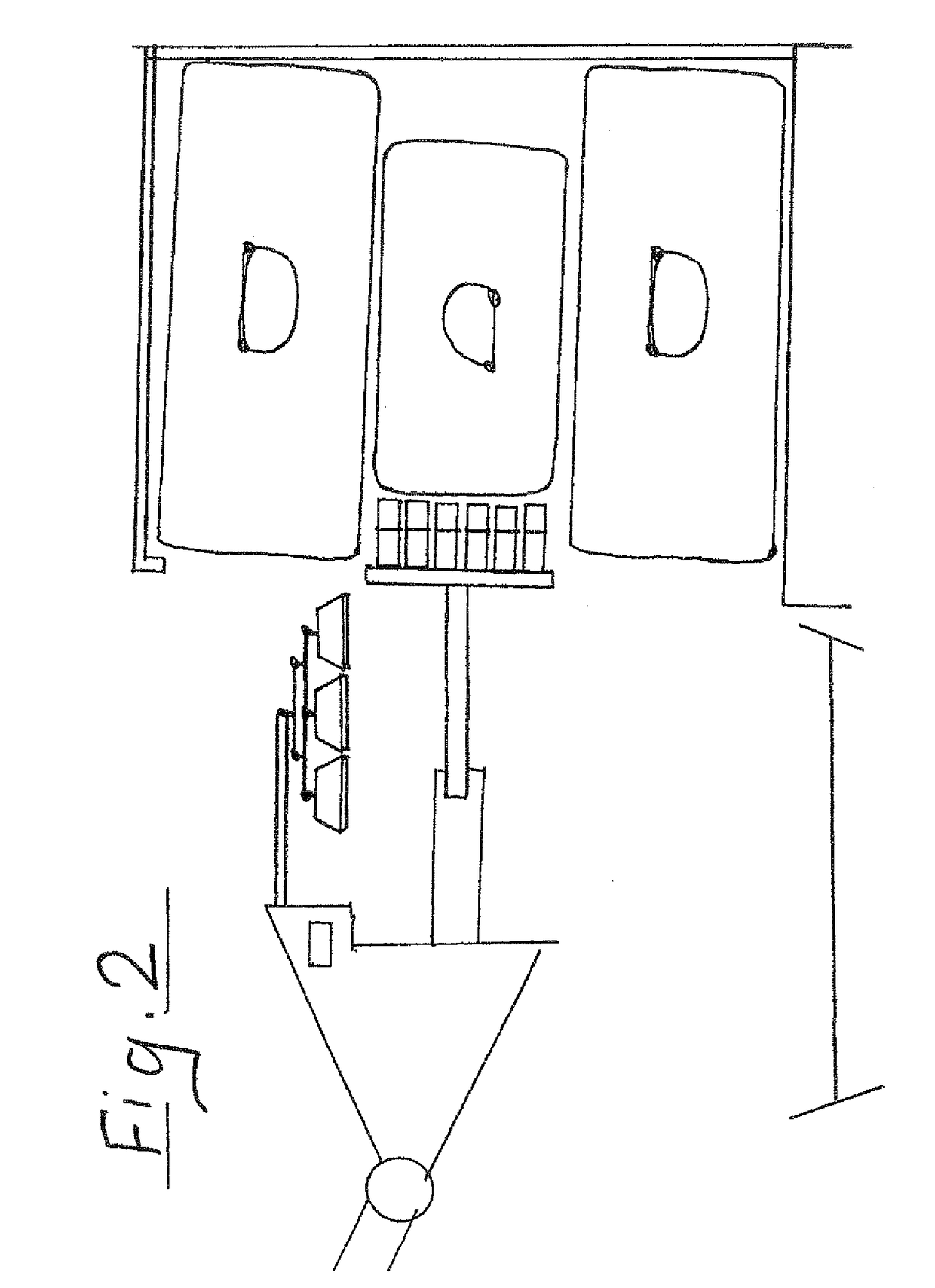

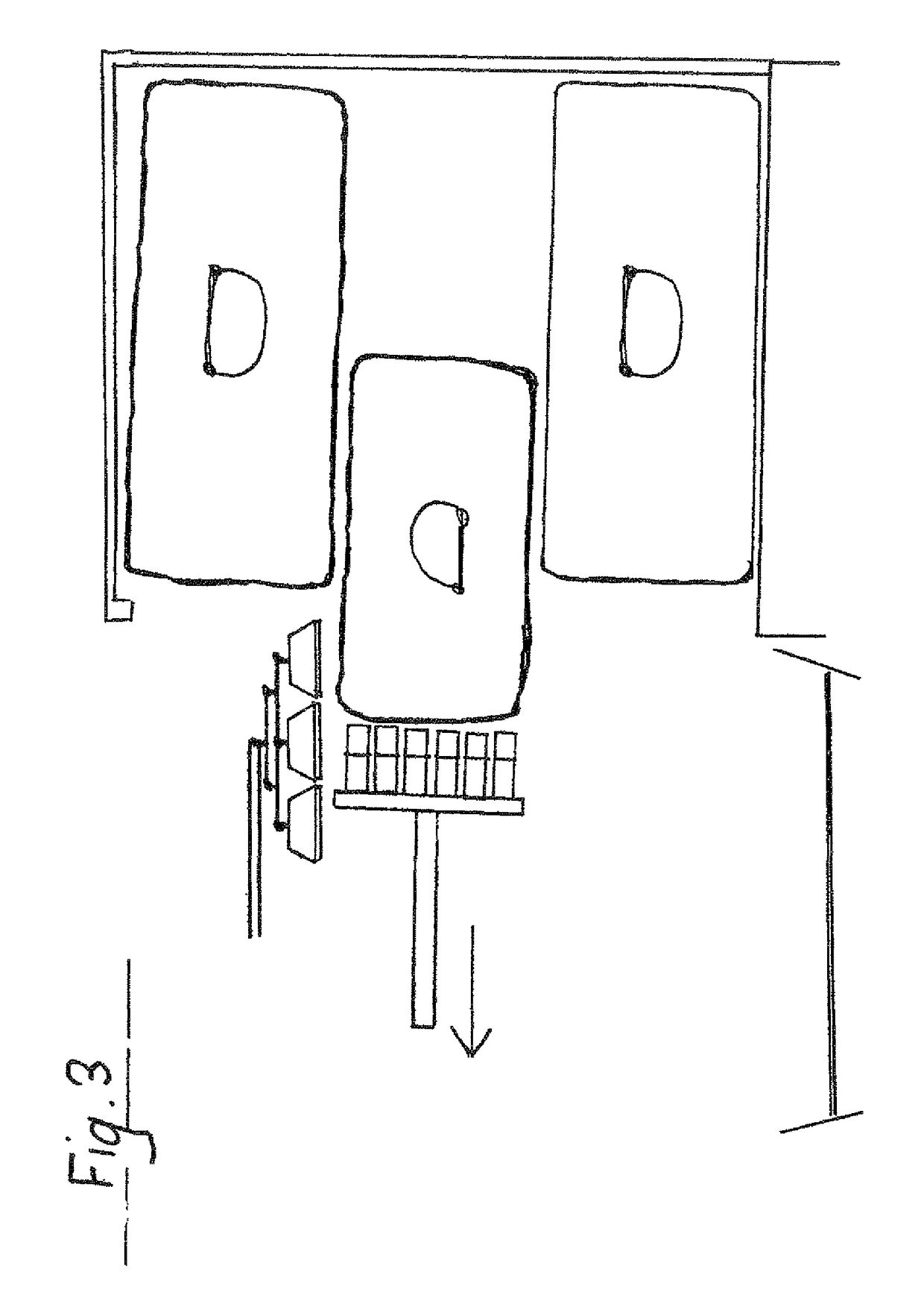

Method and apparatus for gripping and transferring pieces of luggage

ActiveUS8473094B2Increase suction pressureIncrease contact pressureDigital data processing detailsGripping headsEngineeringGrippers

A method and an apparatus for automatically removing pieces of luggage that have different surface properties and dimensions and getting the pieces of luggage ready for further transport by means of a gripper that is hingedly connected to a robot arm is described. The method includes: a) moving the gripper and the container that is to be emptied close together; b) determining the first piece of luggage to be removed; (c) gripping the piece of luggage using a horizontal suction elements (3) and withdrawing the luggage horizontally; d) if the vertical suction elements (4) are not yet able to sufficiently grip the luggage, the vertical suction elements (4) are repositioned and turned off, the vertical suction elements (5) are repositioned, and then turned on to re-grip the piece of luggage.

Owner:GRENZEBACH MASCHINENBAU GMBH

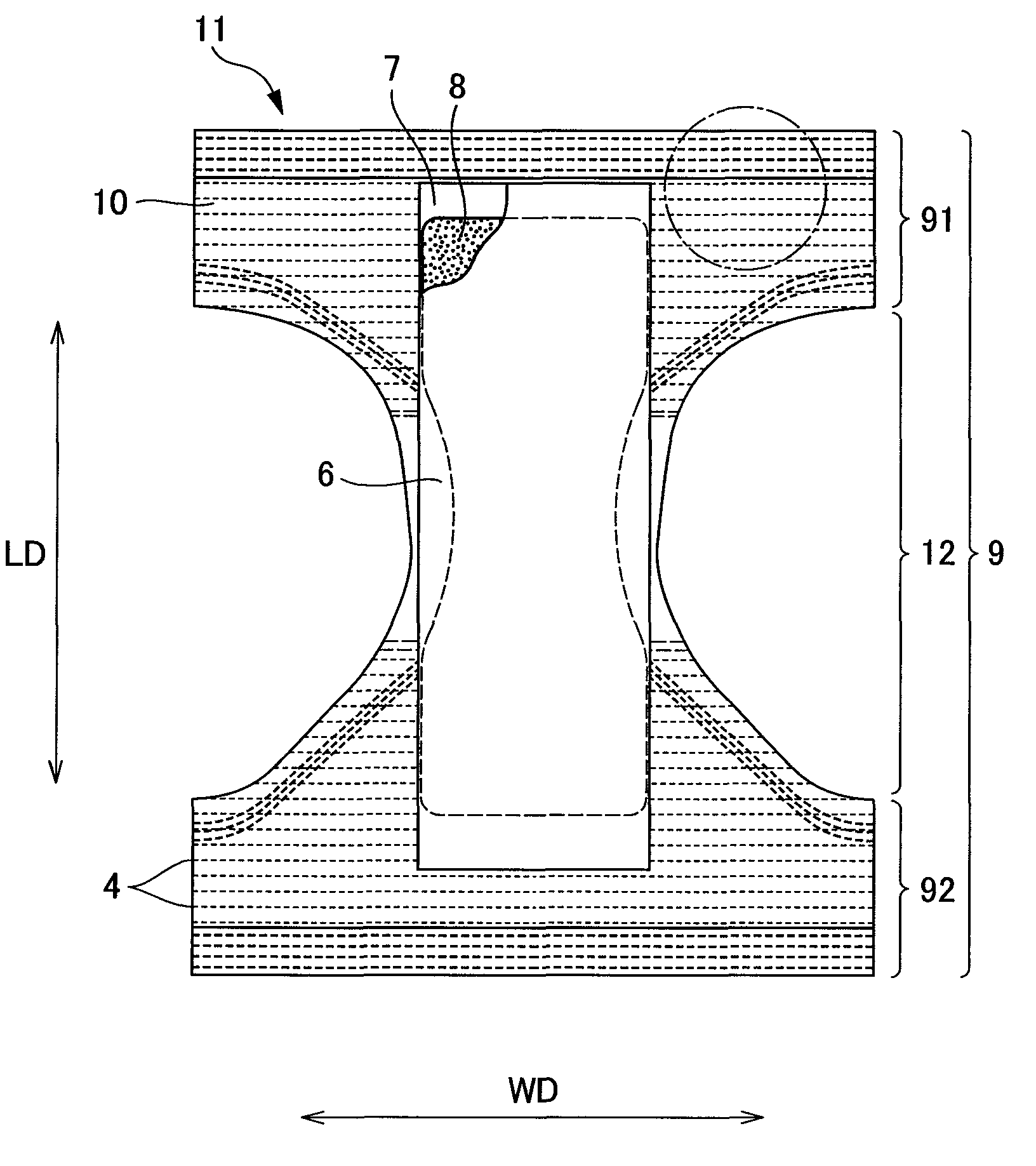

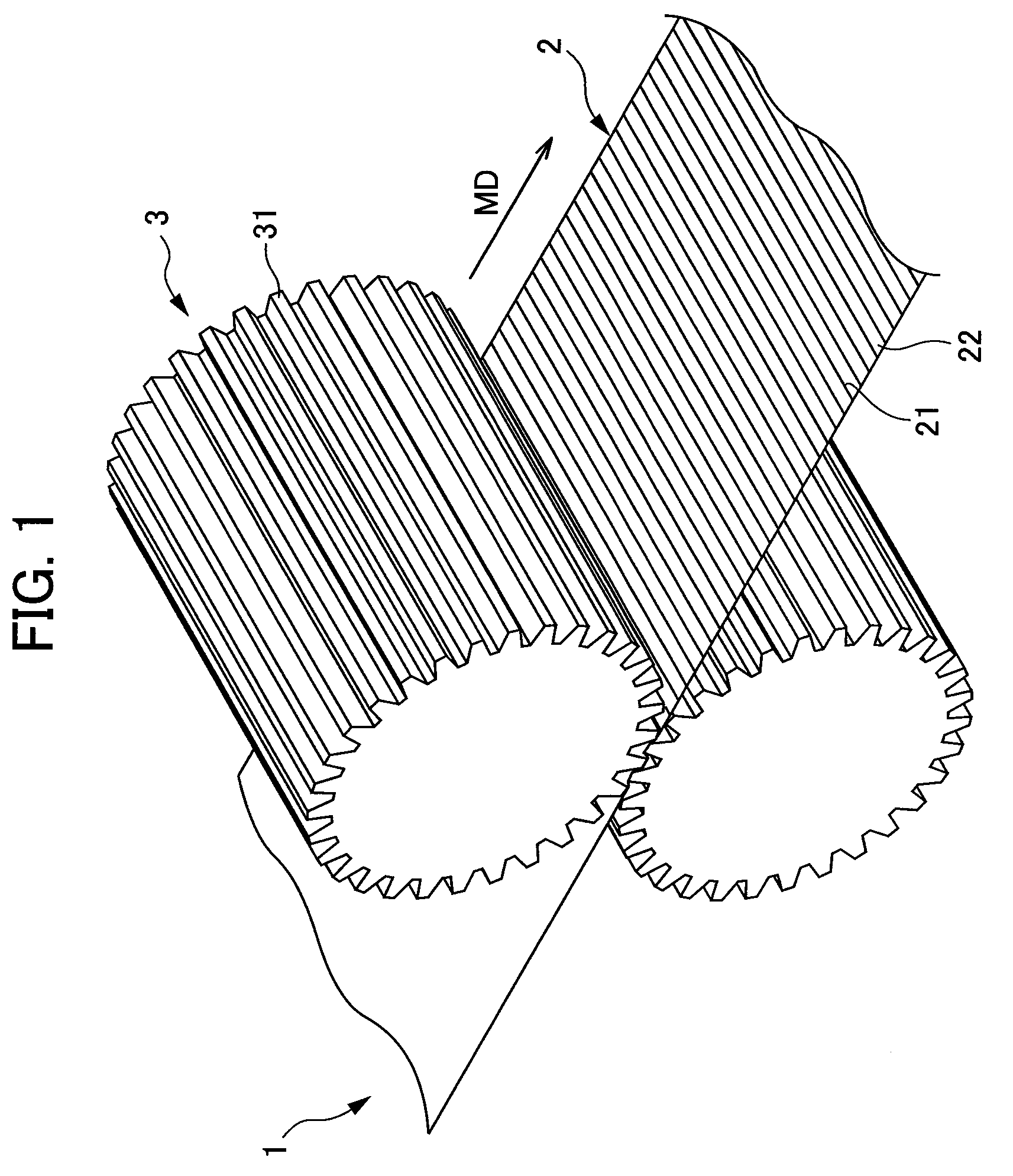

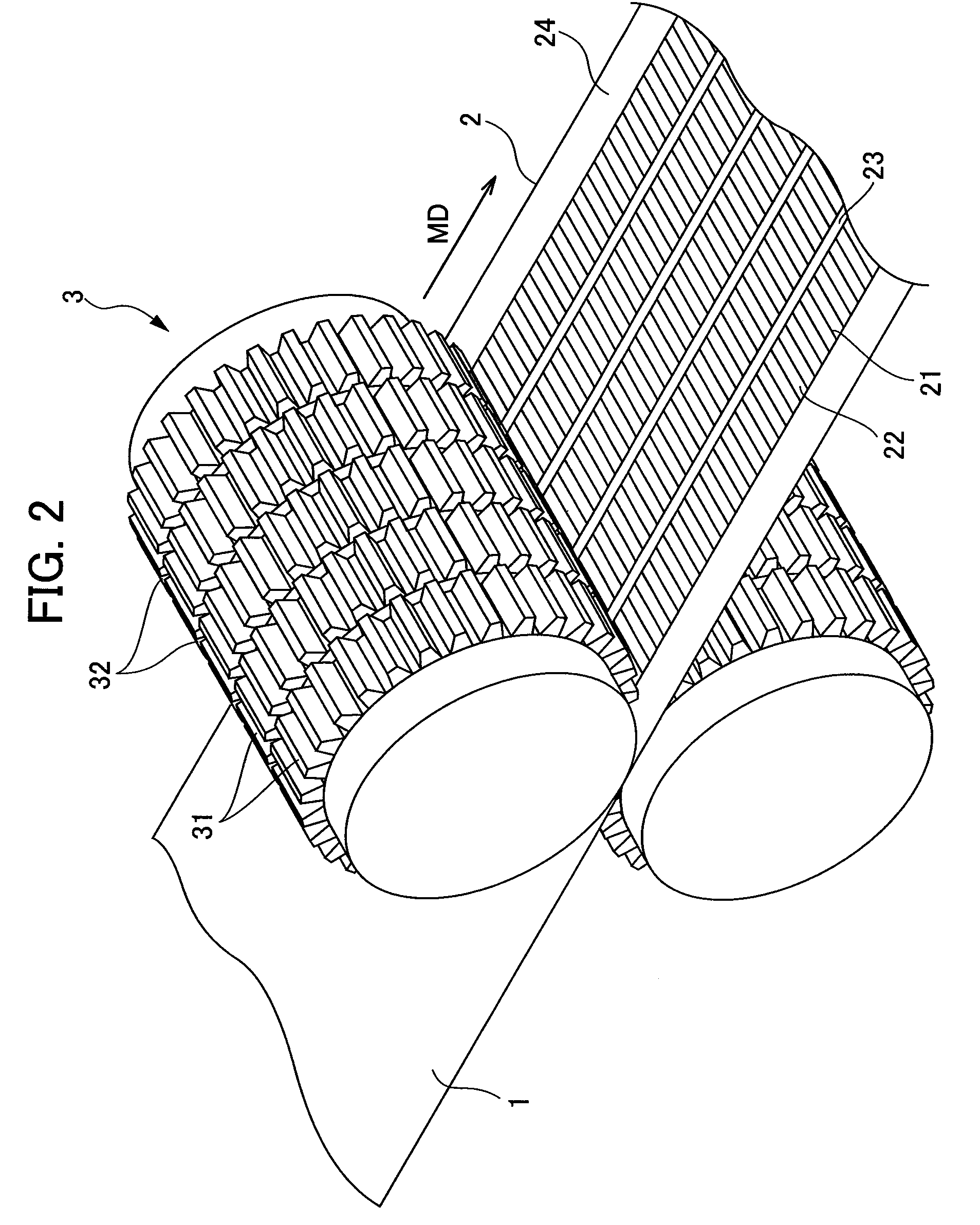

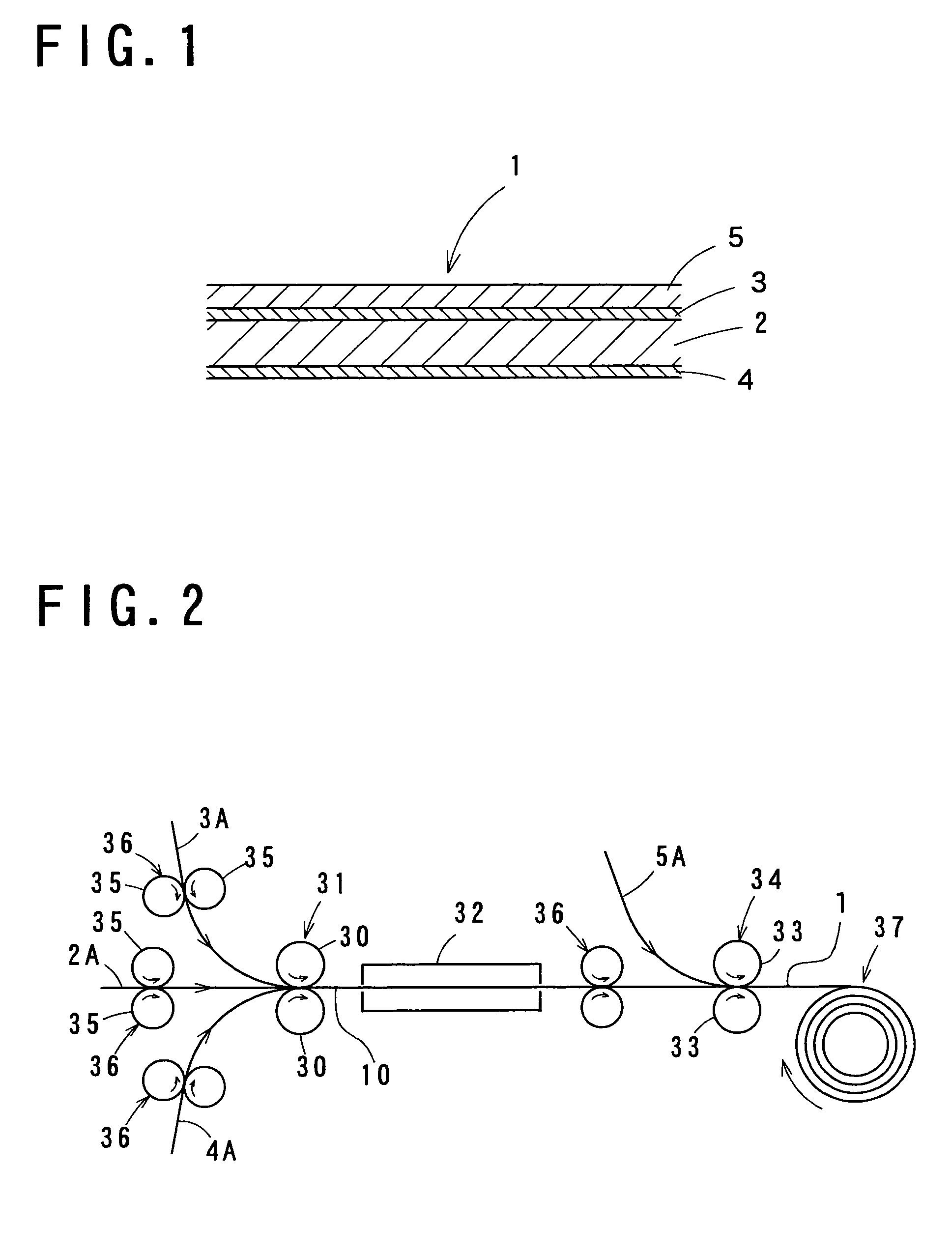

Sheet member, high-density region-containing sheet manufacturing method and disposable diaper using sheet member

Owner:UNI CHARM CORP

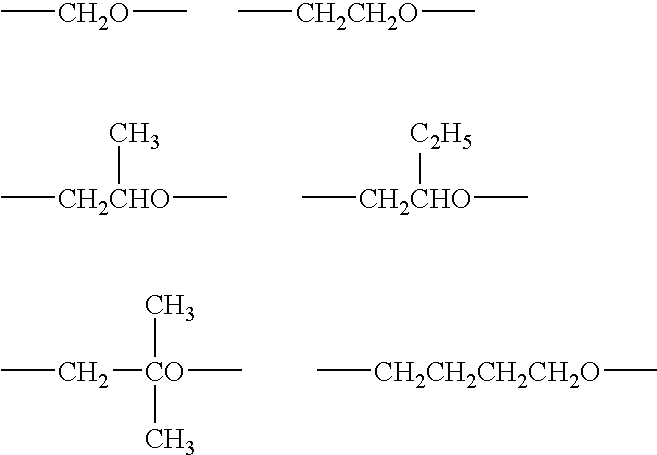

Pressure sensitive adhesives for optical film, manufacturing methods for pressure sensitive adhesive layer for optical film, pressure sensitive adhesive layers for optical film, pressure sensitive adhesion type optical films and image displays

ActiveUS20060121273A1Suppressing bowingSuppress light leakagePolyureas/polyurethane adhesivesSynthetic resin layered productsMeth-Hydroxy group

It is an object of the invention to provide a pressure sensitive adhesive for an optical film with which a pressure sensitive adhesive type optical film capable of suppressing bowing and light leakage caused by a stress accompanying a dimensional change of members such as an optical film, high in durability, excellent in handling ability in an aspect of a fabrication process thereof and good in quality can be obtained. There is provided a pressure sensitive adhesive for an optical film comprising: 100 parts by weight of a (meth)acrylic-based polymer (A) including an alkyl (meth)acrylate (a1) and a (meth)acrylic-based monomer containing a hydroxyl group (a2), as a copolymerizable component, in content in the range of from 0.01 to 5 parts by weight relative to 100 parts by weight of the alkyl (meth)acrylate (a1); 0.02 to 2 parts by weight of a peroxide (B); and 0.001 to 2 parts by weight of an isocyanate-based compound (C), the contents of the peroxide (B) and the isocyanate-based compound (C) being values relative to 100 parts by weight of the (meth)acrylic-based polymer (A).

Owner:NITTO DENKO CORP

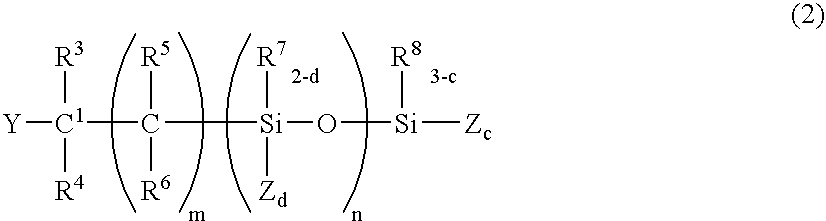

Curing composition

An object of the present invention is to provide a curing composition which is practically curable and highly adhesive even though a non-organotin compound is included as a curing catalyst. Problems involved are solved by a curing composition characterized by including (A) an organic polymer having one or more silicon-containing groups capable of cross linking by forming siloxane bonds, (B) a metal carboxylate and / or carboxylic acid, and (C) a silicon compound having a hetero atom on the carbon atom in the α or β position with respect to the silicon atom.

Owner:KANEKA CORP

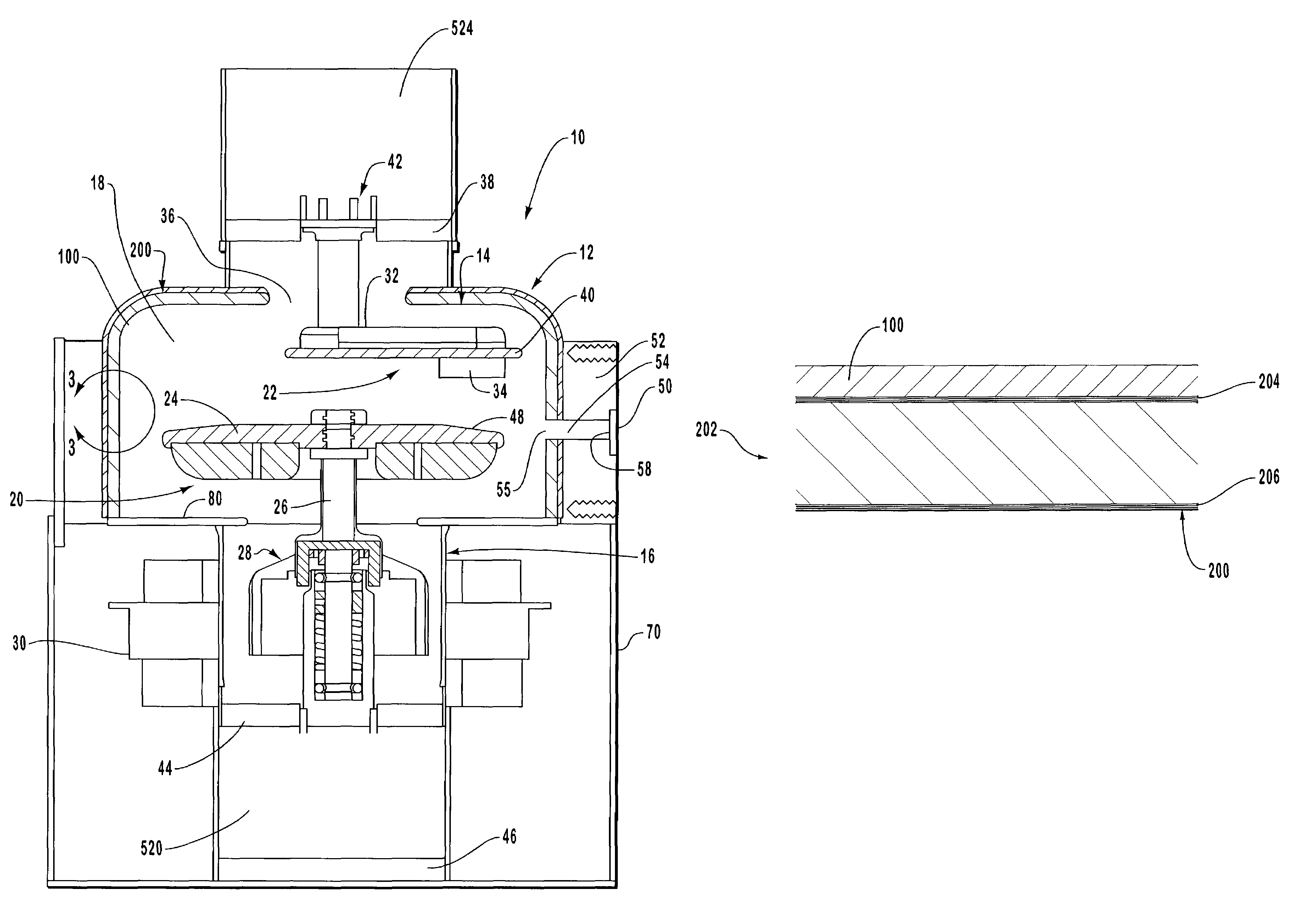

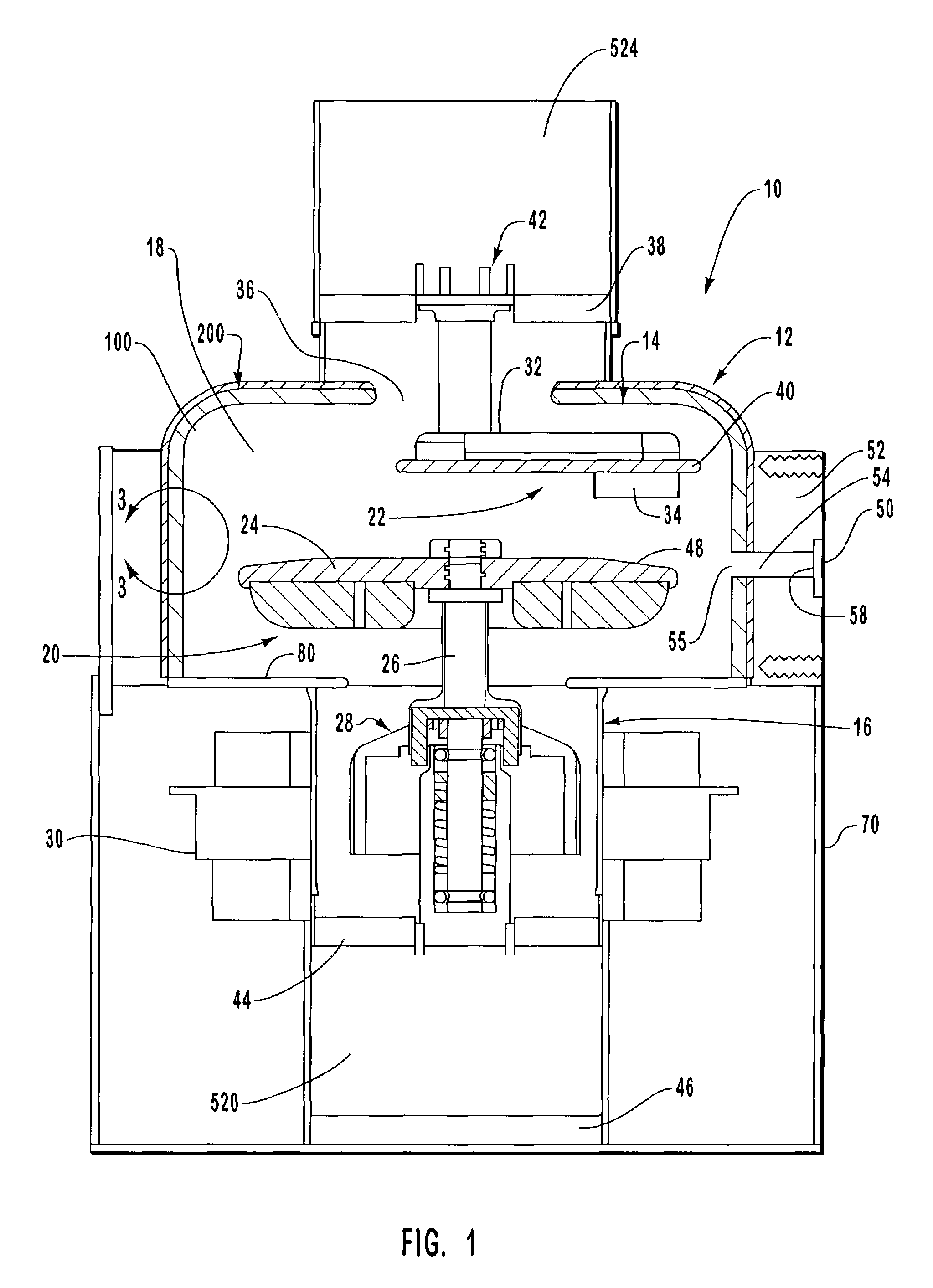

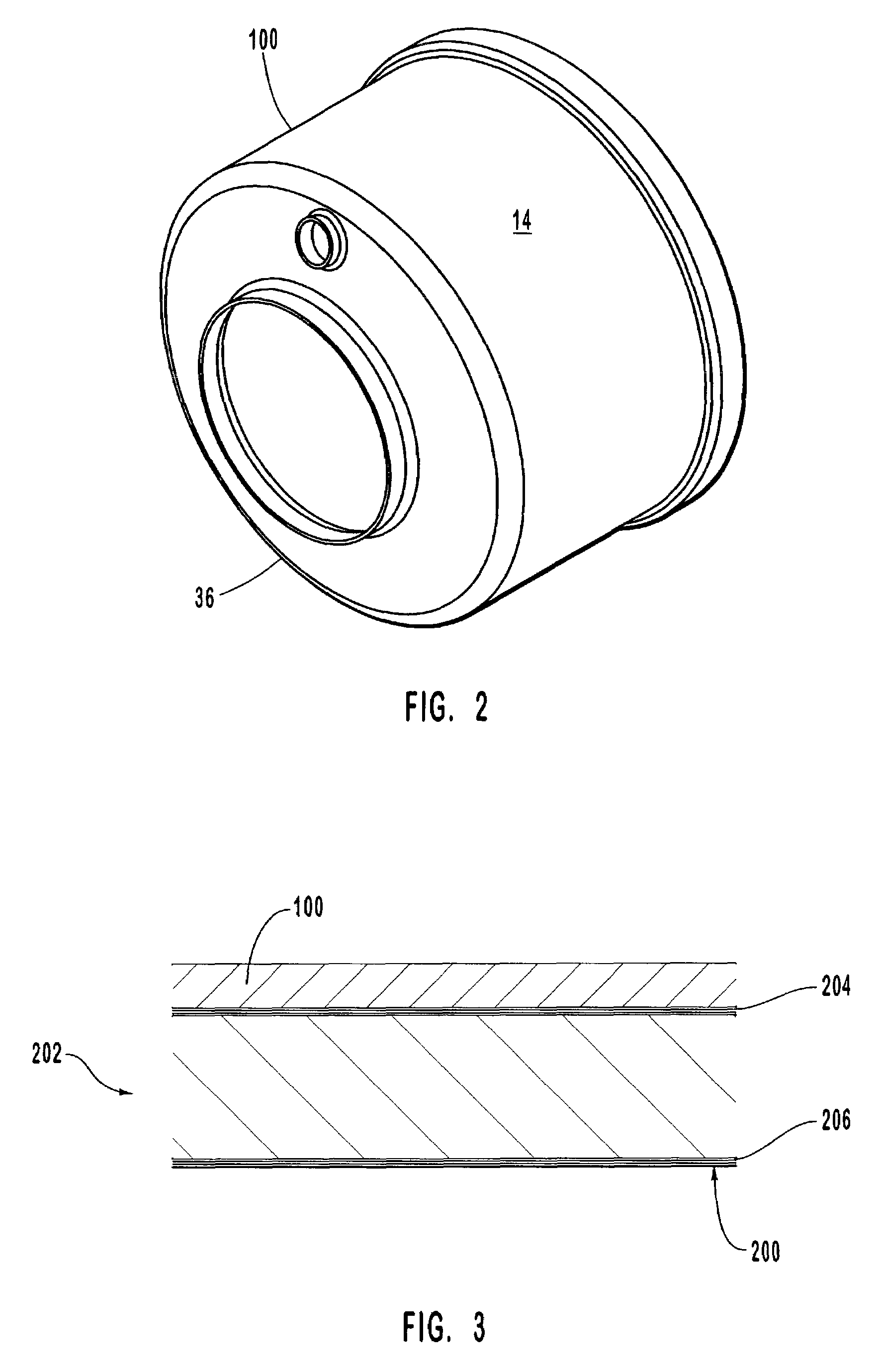

X-Ray tube and method of manufacture

InactiveUS7079624B1Reduce component countReduce weightX-ray tube electrodesConductive materialHydrogenPlasma sprayed

The present invention is directed to an air-cooled radiographic apparatus, and its method of manufacture, that utilizes a single integral housing for providing an evacuated envelope for an anode and cathode assembly. The integral housing is preferably formed from a substrate material that has a radiation shielding layer comprising a powder metal that is deposited with a plasma spray process. The powder metal includes, for example, tungsten and iron, so that the radiation shield layer provides sufficient radiation blocking and heat transfer characteristics such that an additional external housing is not required. In one alternative embodiment, the integral housing is composed of a solidified, integrated mixture of metallic powders that function together as both the integral housing wall and the radiation shielding. In another alternative embodiment, chromium is intermixed into the mixture of metallic powders to form a thermally emissive surface upon firing the housing in a wet hydrogen environment.

Owner:VAREX IMAGING CORP

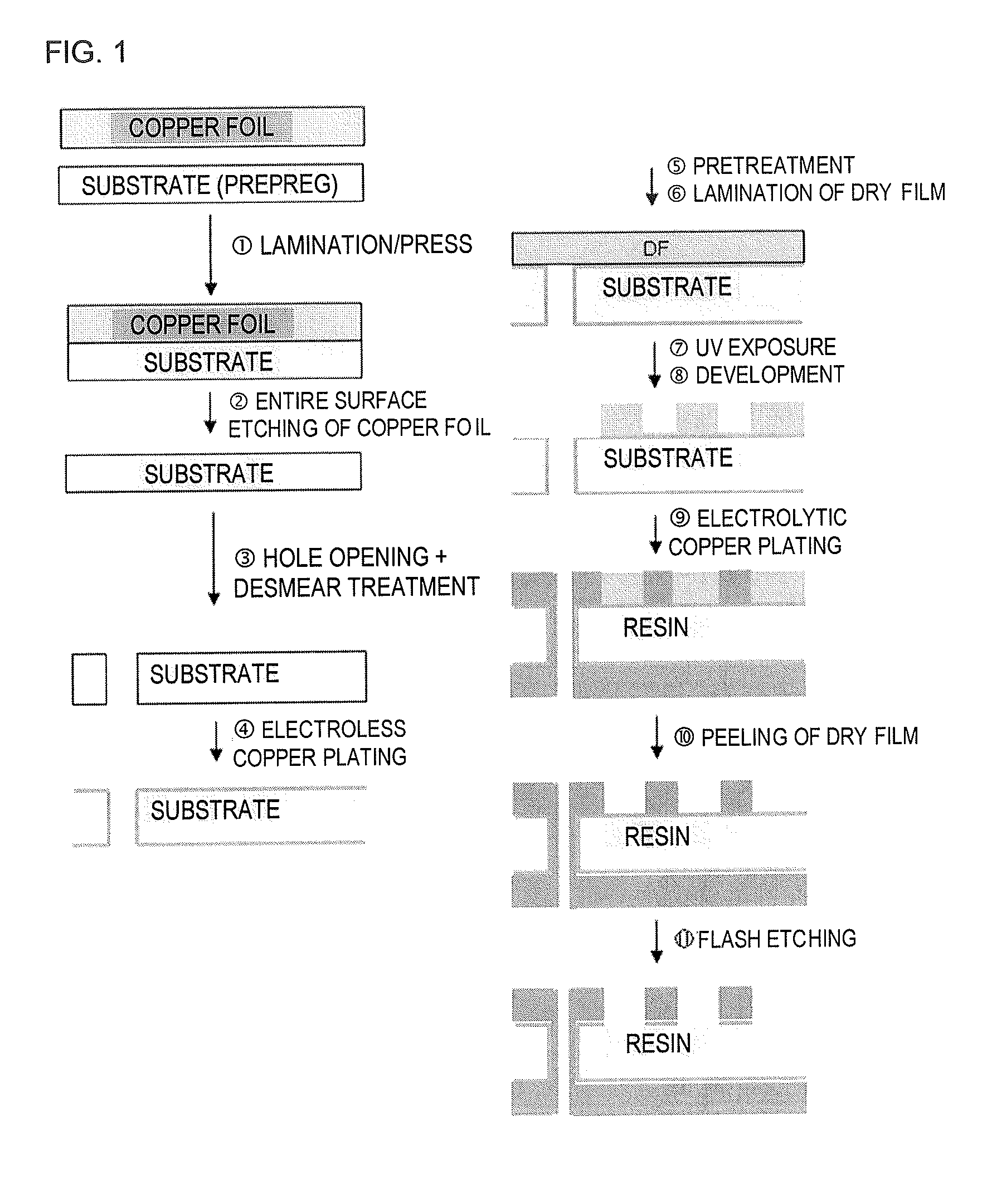

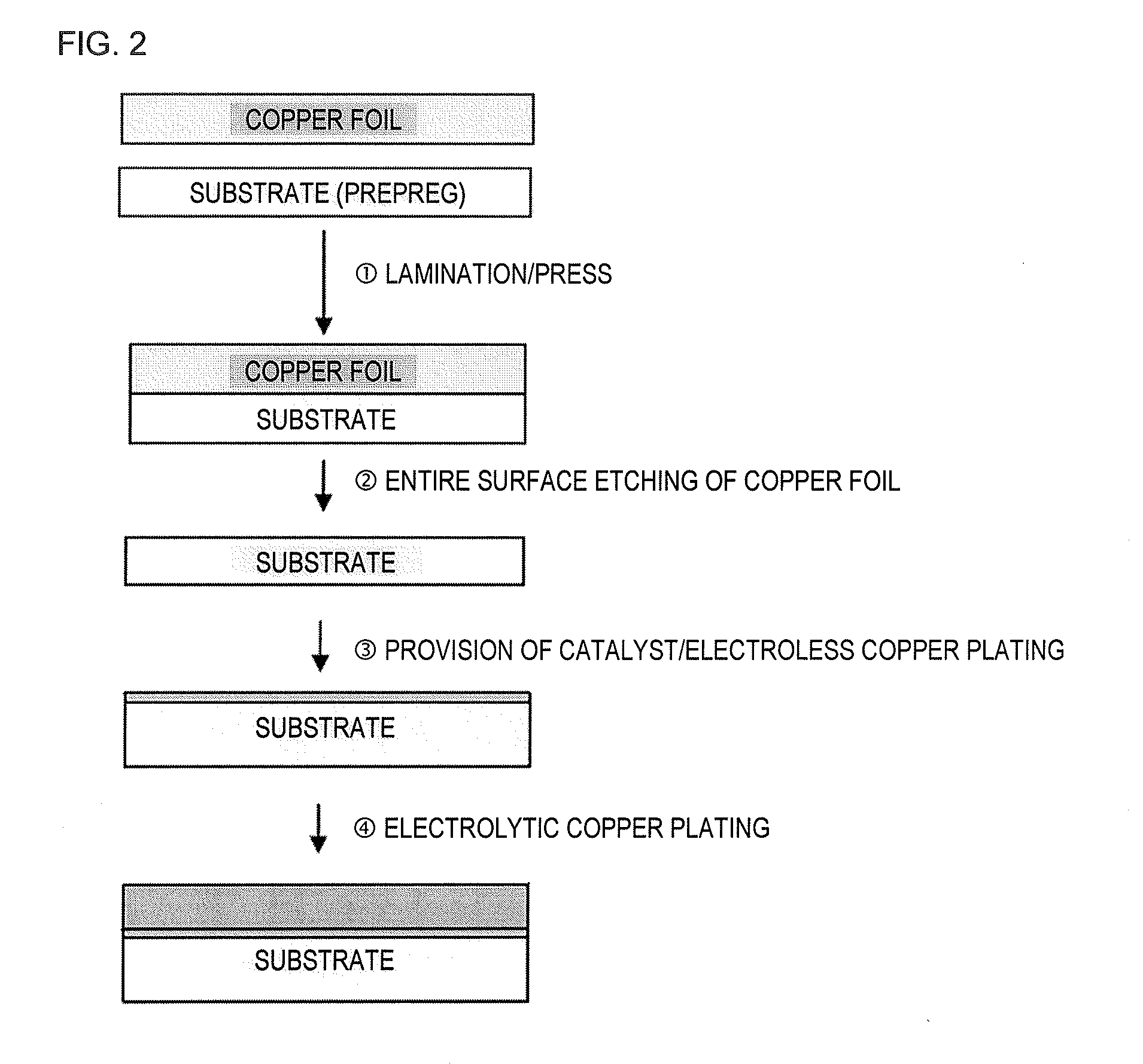

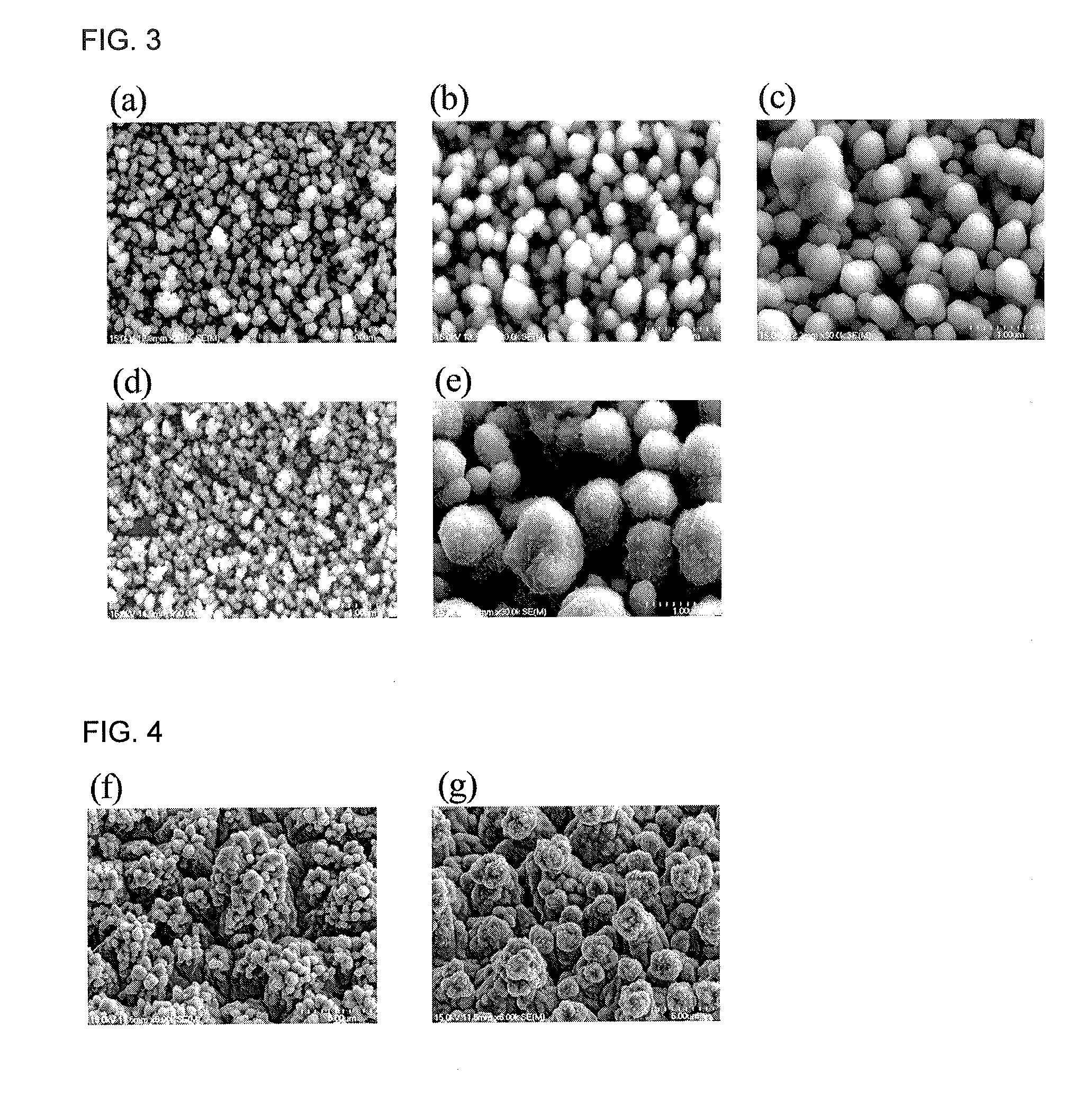

Surface-treated copper foil, copper foil with carrier, substrate, resin substrate, printed wiring board, copper clad laminate and method for producing printed wiring board

ActiveUS20160183380A1Satisfactory adhesionGood molding effectRecord information storageMagnetic recordingCopper platingSurface roughness

The present invention provides a surface-treated copper foil capable of imparting the profile shape of the substrate surface after removal of the copper foil, the profile shape maintaining fine wiring formability and achieving satisfactory adhesion of electroless copper plating coating. The present invention also provides a resin substrate provided with a profile shape of the surface maintaining fine wiring formability and achieving satisfactory adhesion of electroless copper plating coating. The surface-treated copper foil of the present invention is a surface-treated copper foil having a surface-treated layer formed on a copper foil, and the surface roughness Sz of the surface of the surface-treated layer is 2 to 6 μm.

Owner:JX NIPPON MINING & METALS CO LTD

Support Substrate for Separation Membrane

ActiveUS20080138596A1Excellent strike-through preventionHigh strengthSemi-permeable membranesArtificial filament physical treatmentApparent densitySingle fiber

A separation membrane support substrate characterized by being composed of a laminated nonwoven fabric comprising a front layer as the resin coating layer, a middle layer and a back layer which are integrally formed by heat bonding, and by satisfying the following conditions (1) to (5): (1) The front layer has at least one layer comprising thermoplastic resin filaments with a single filament diameter of 7-30 μm; (2) the middle layer has at least one layer comprising melt blown fibers with a single fiber diameter of no greater than 5 μm, and a fiber basis weight of at least 1 g / m2 and comprising no more than 30 wt % of the total fiber basis weight; (3) the back layer has at least one layer comprising thermoplastic resin filaments with a single filament diameter of 7-20 μm, and has a fiber basis weight of 3-40 g / m2; (4) the laminated nonwoven fabric has an apparent density of 0.67-0.91 g / cm3; and (5) the laminated nonwoven fabric has a thickness of 45-110 μm.

Owner:ASAHI KASEI FIBERS CORPORATION

Silicone resin compositions and coated articles

InactiveUS20050158566A1High hardnessImprove toughnessLayered productsCoatingsPolymer sciencePtru catalyst

To a silicone resin obtained through cohydrolytic condensation of 100 pbw of a mixture of 1-50 Si mol % of tetraalkoxysilane, 50-99 Si mol % of trialkoxysilane and 0-10 Si mol % of dialkoxysilane with less than 100 pbw of water, having a Mn of at least 1,500 and containing 30-80 mol % of R1SiO3 / 2 units and 20-70 mol % of R1SiO2 / 2(OX) and R1SiO1 / 2(OX)2 units combined, a curing catalyst and a solvent are added to formulate a silicone resin composition. It is applied and heat cured to a plastic substrate to form a protective coat having a high hardness and improved properties such as mar resistance, crack resistance, adhesion, water resistance, heat resistance and weathering resistance.

Owner:SHIN ETSU CHEM IND CO LTD

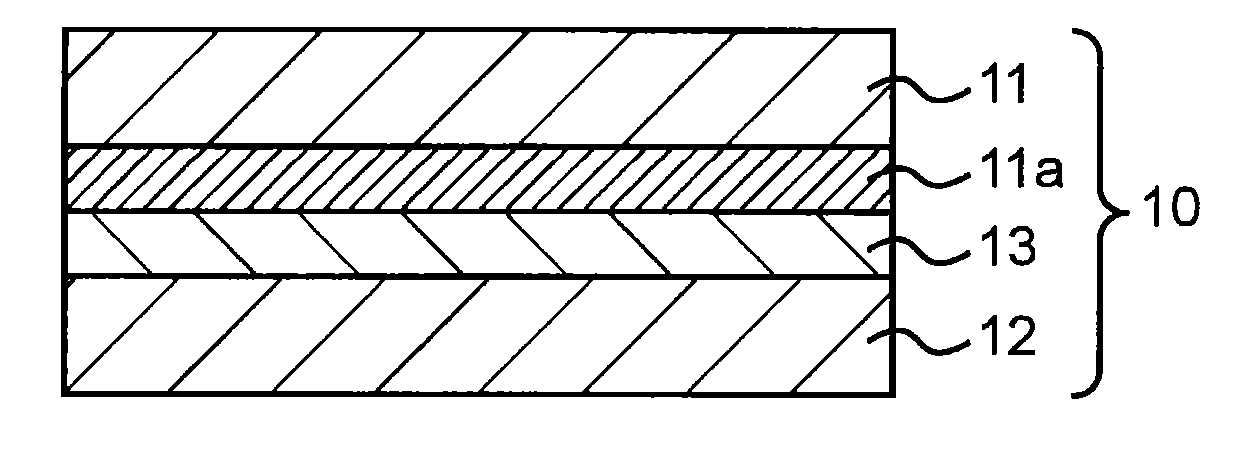

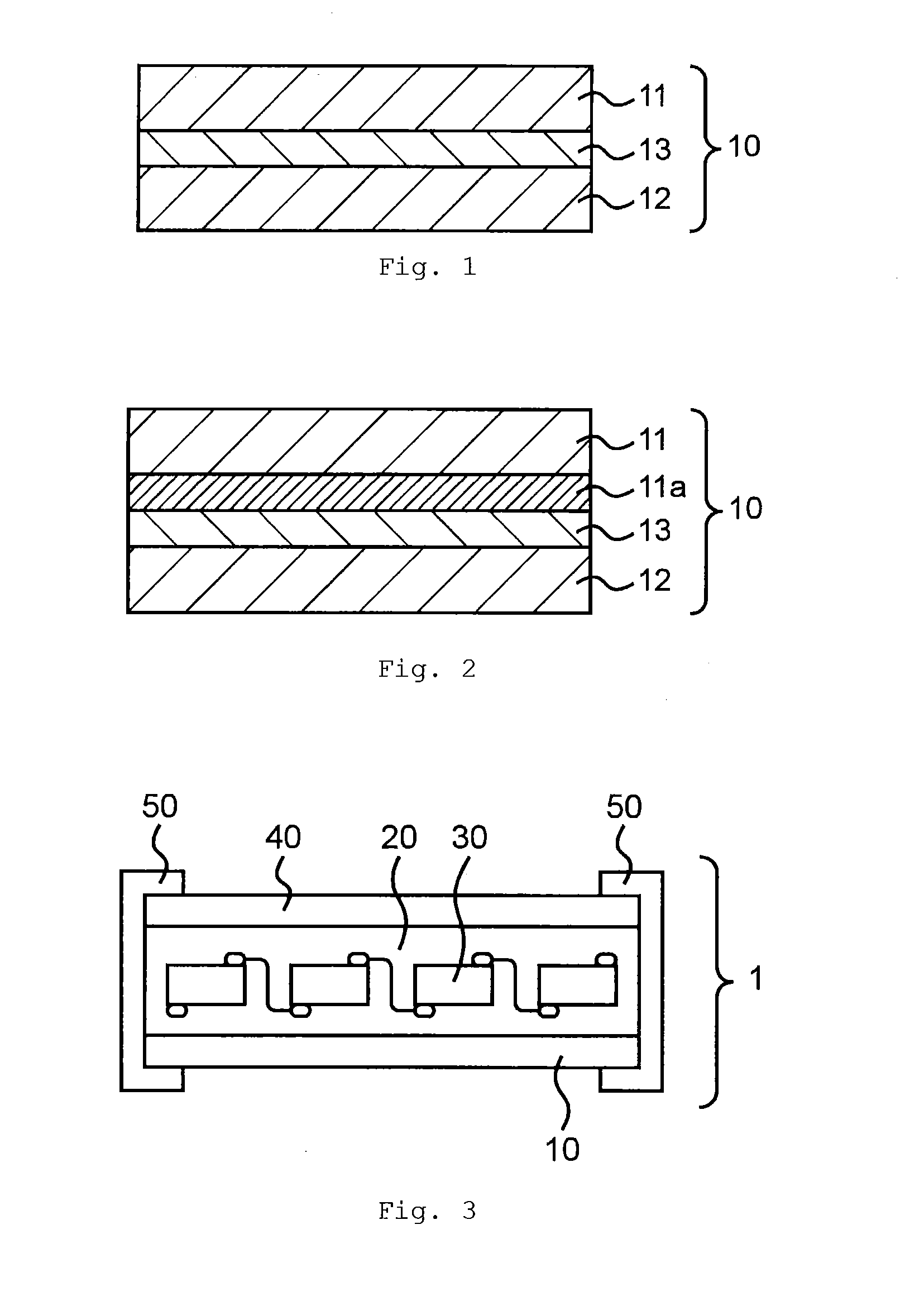

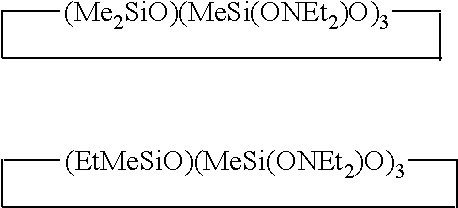

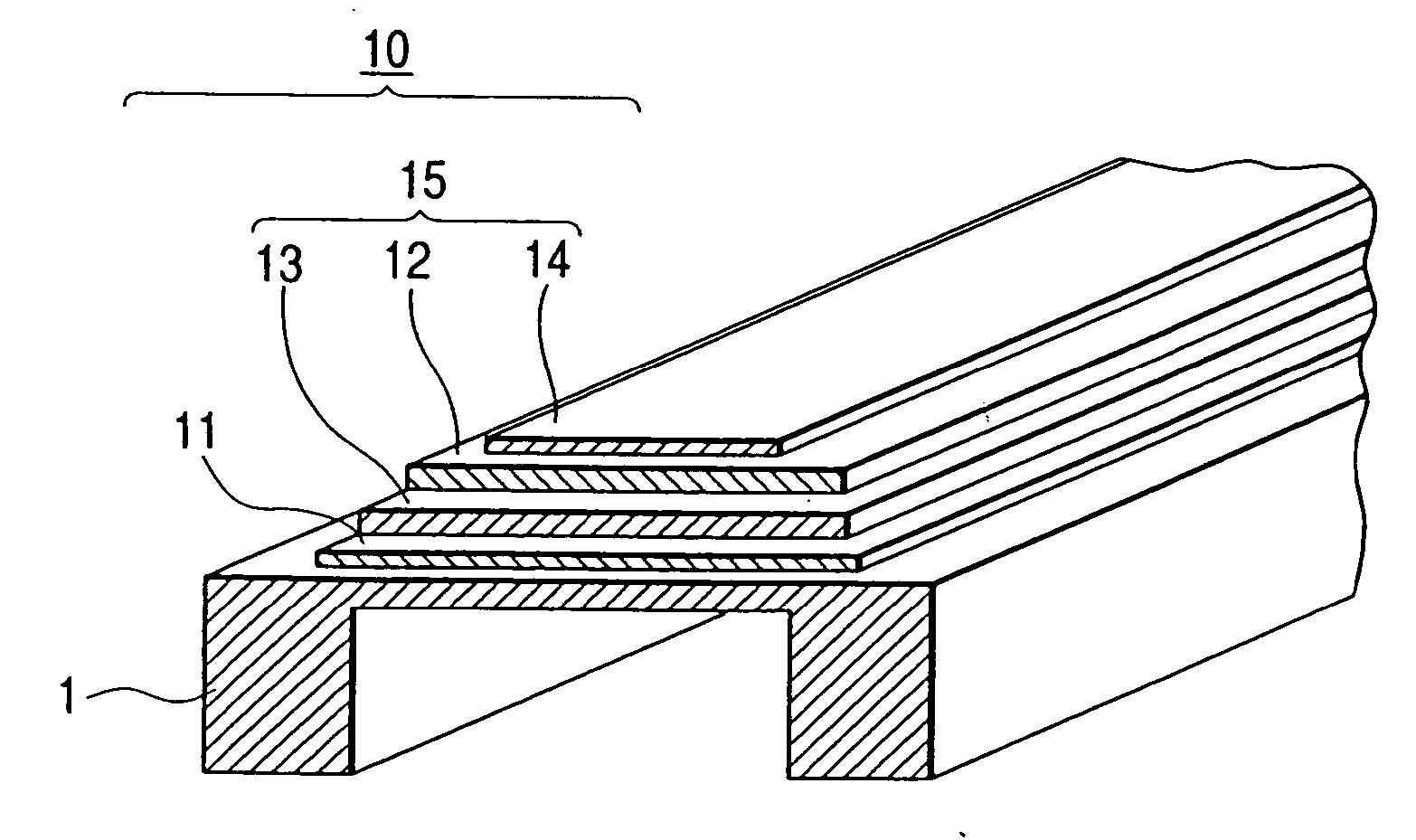

Barrier laminate, method of manufacturing the laminate, gas barrier film and device

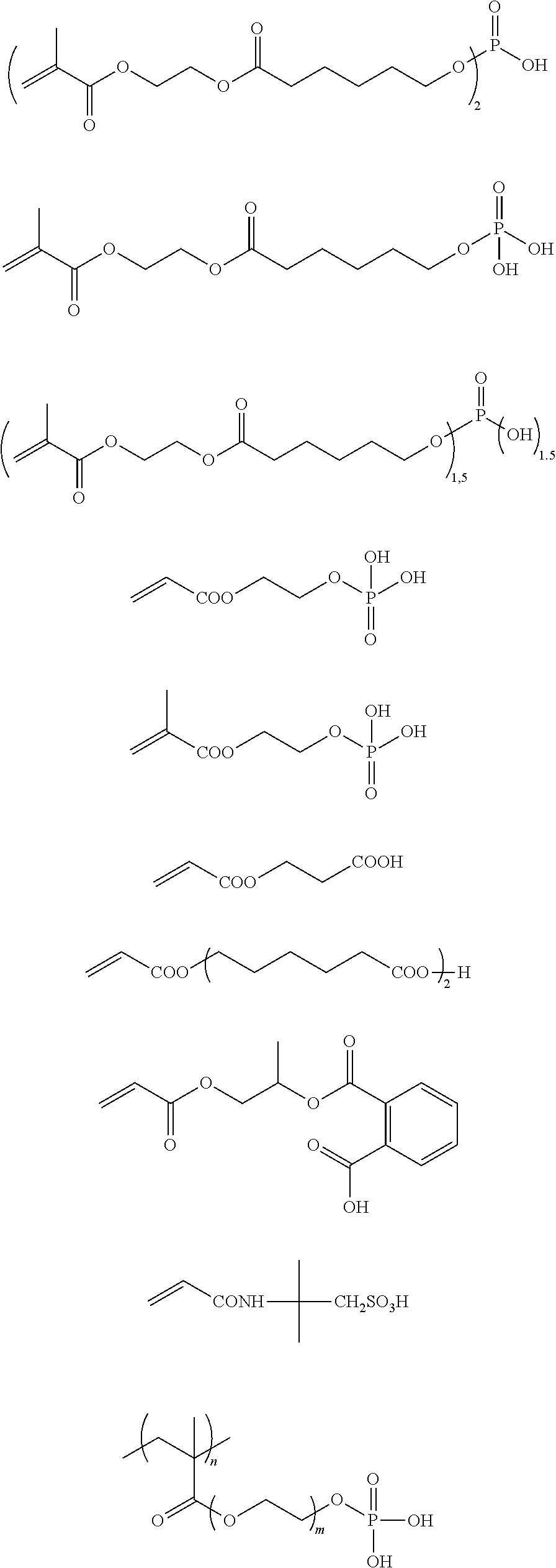

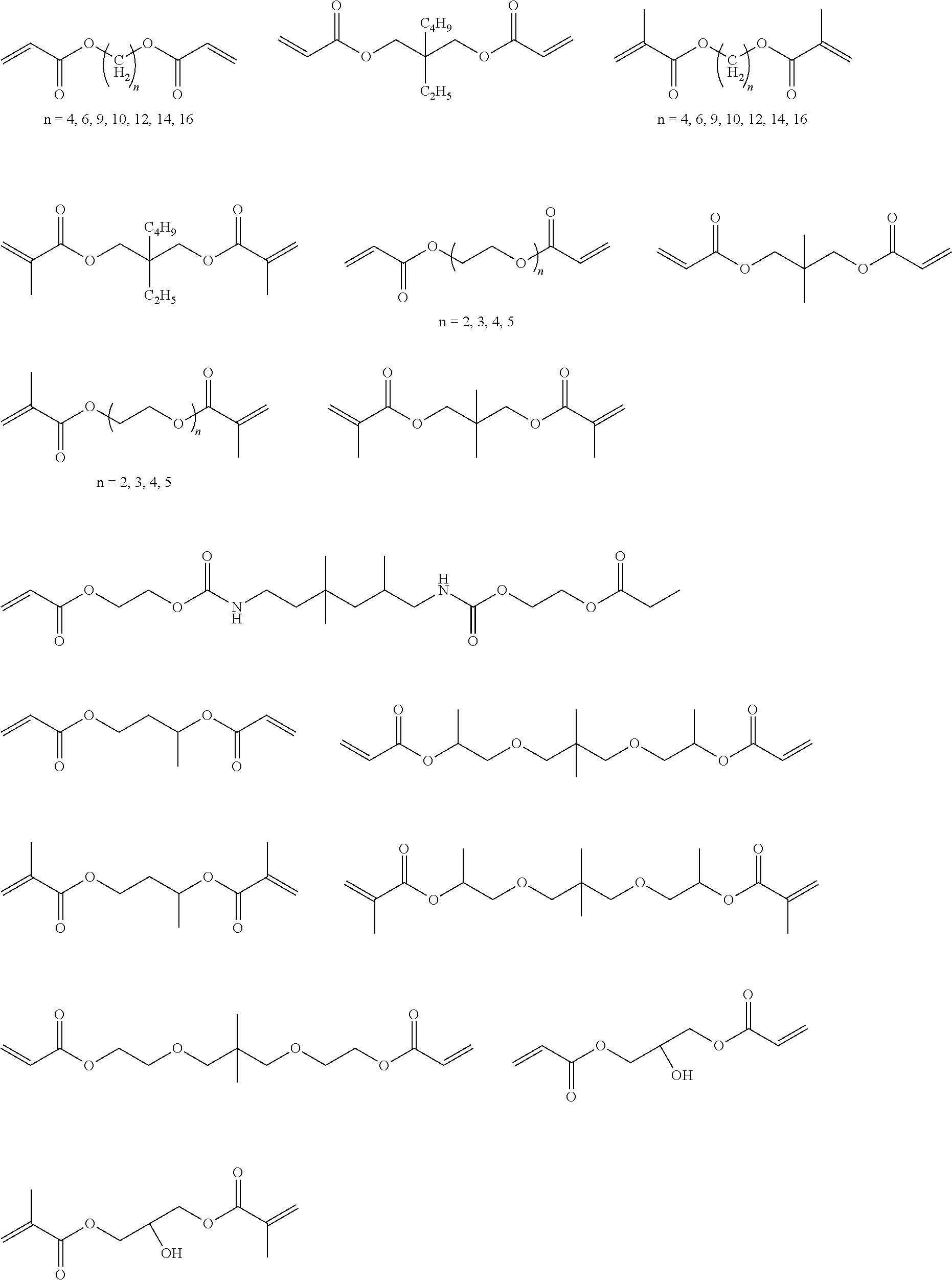

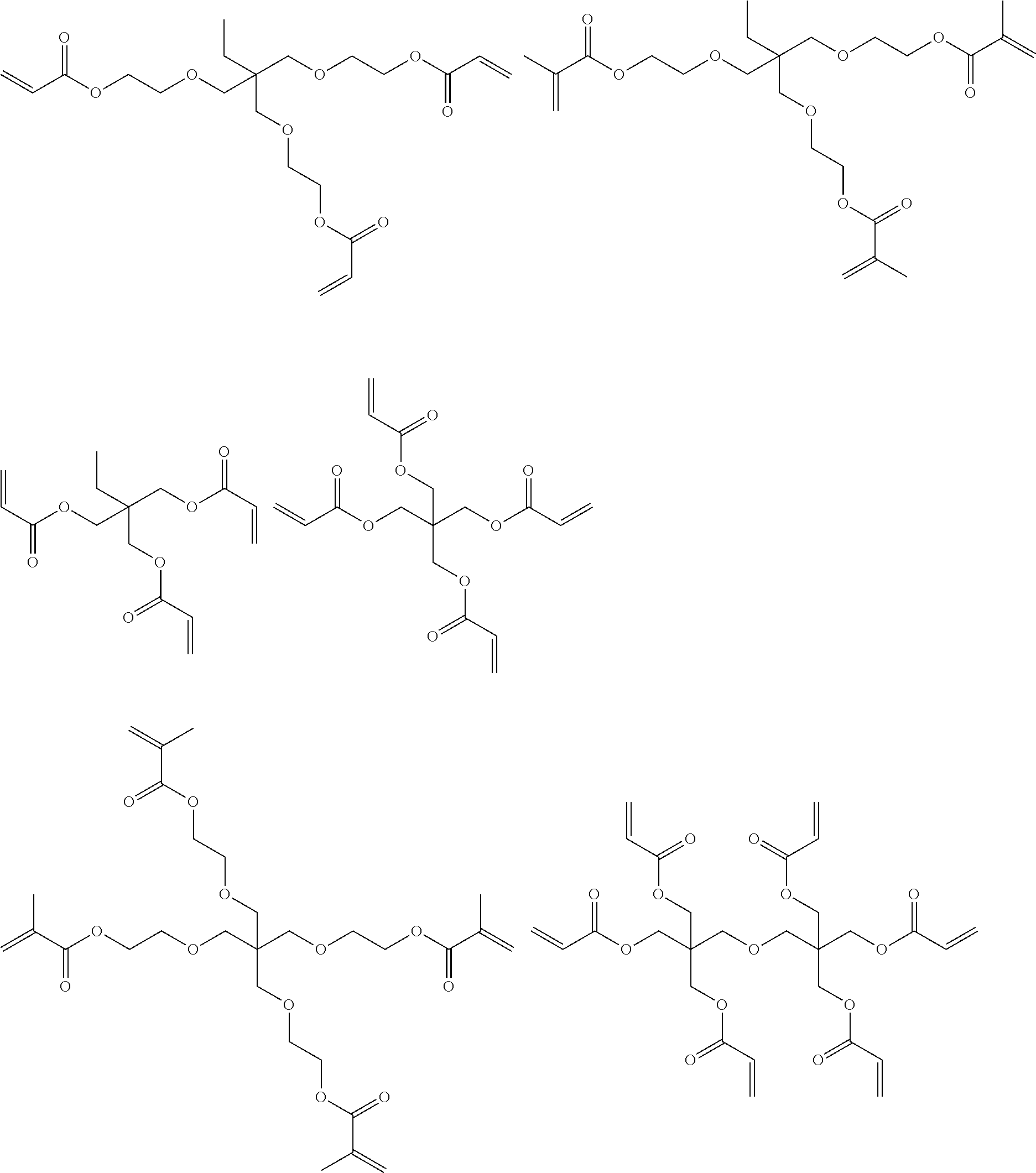

InactiveUS20110232726A1Improve surface smoothnessSatisfactory adhesionPV power plantsSynthetic resin layered productsOligomerMeth-

A method of manufacturing an organic / inorganic laminate including forming a first organic layer by laminating and hardening a composition containing (A) a polymerizable acidic compound, oligomer or polymer, (B) a polymerizable compound, and (C) a silane coupling agent on a first inorganic layer, and forming a second organic layer by laminating and hardening a composition containing (D) a polymerizable compound and (E) a (meth)acrylate having an aromatic group on the first organic layer or on one or more organic layers disposed on the first organic layer.

Owner:FUJIFILM CORP

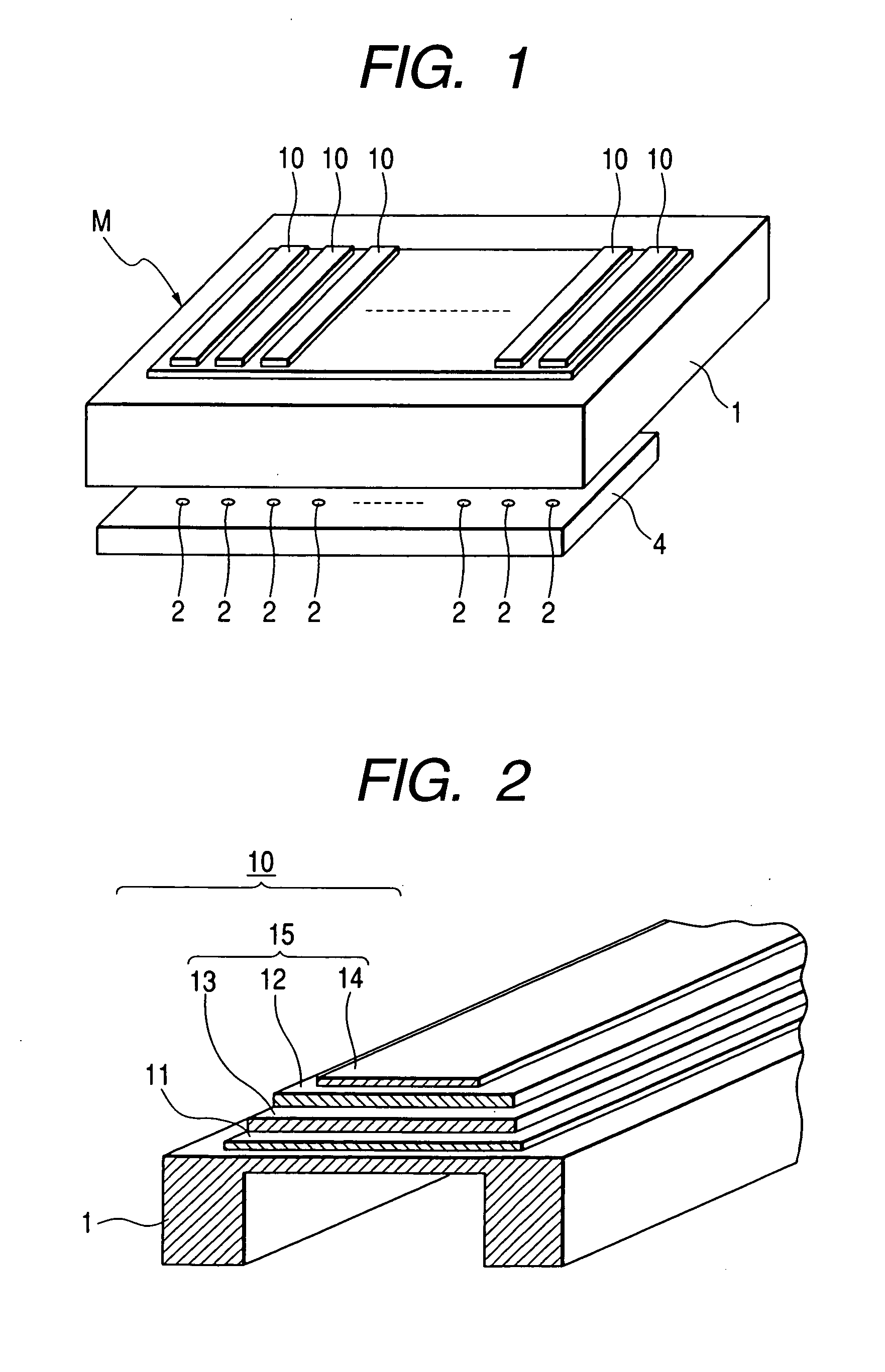

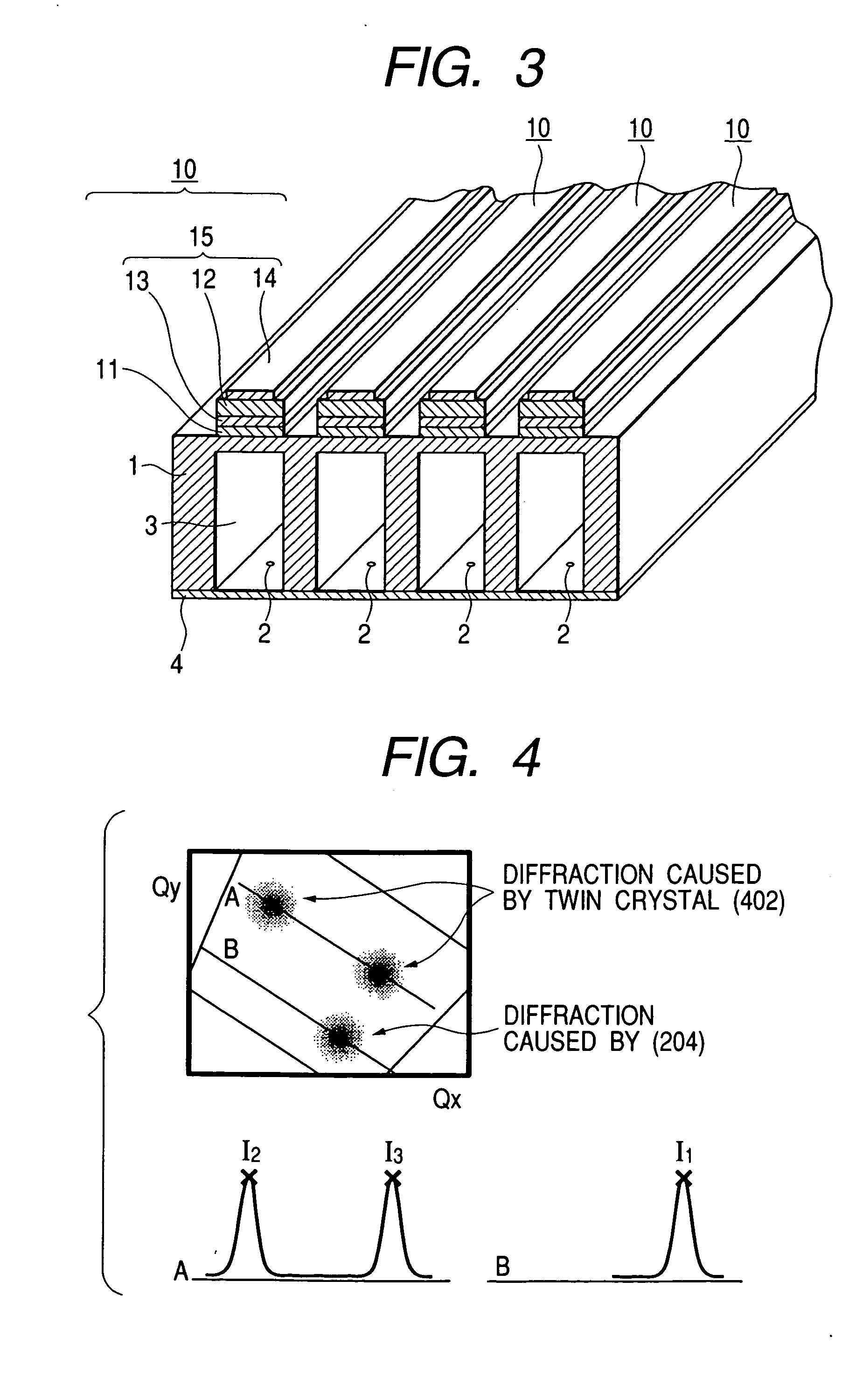

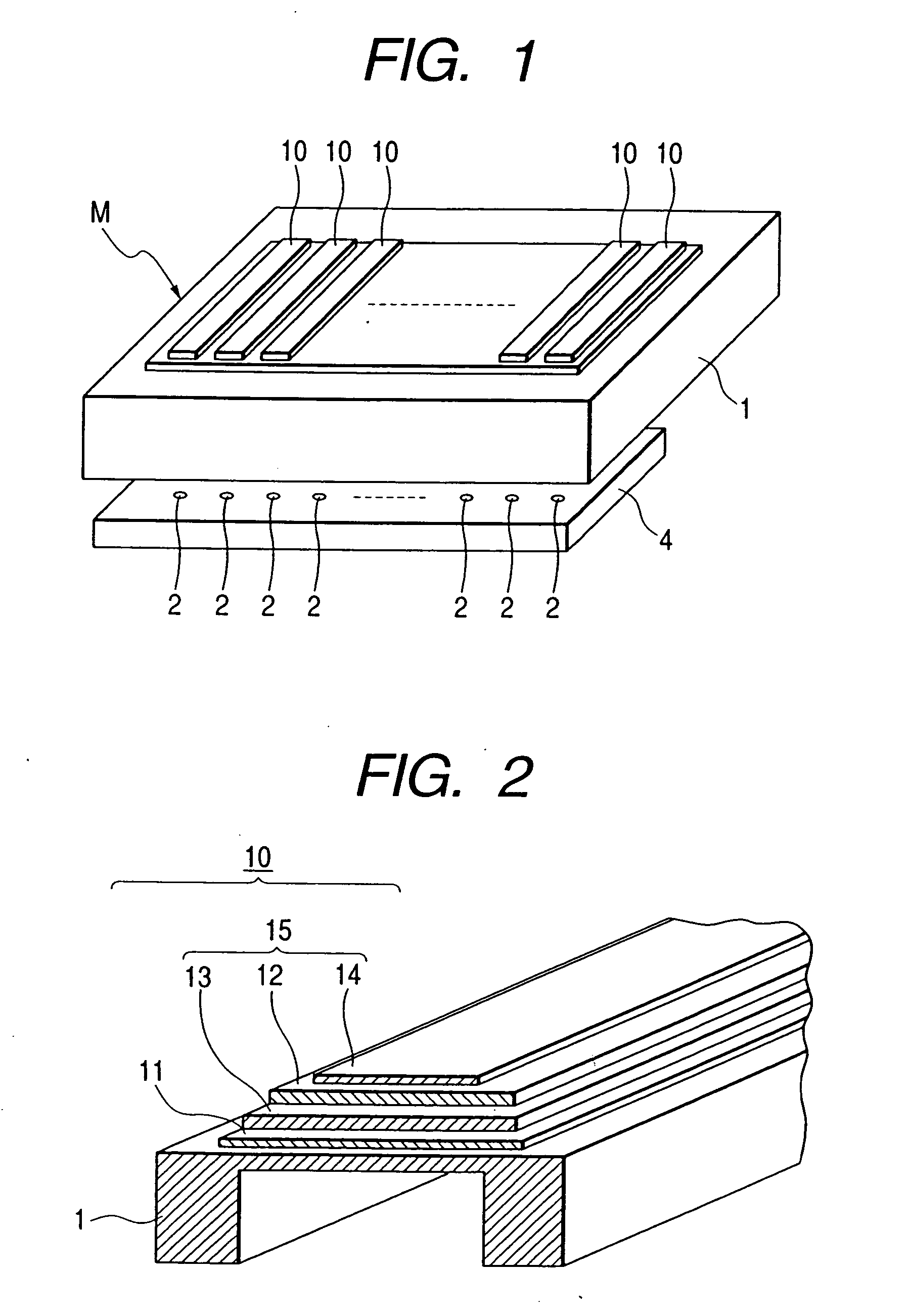

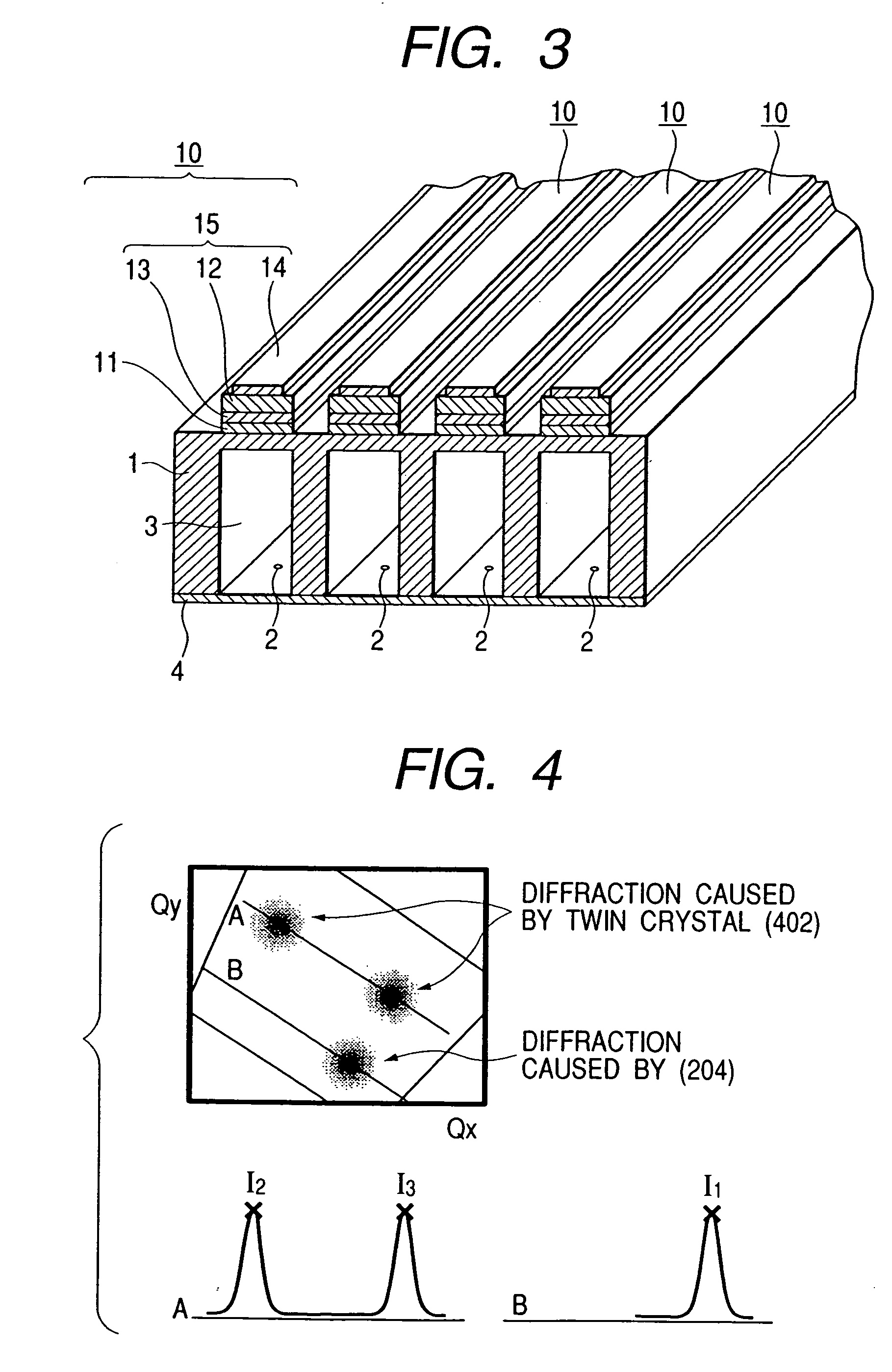

Piezoelectric element

ActiveUS20060012648A1Excellent piezoelectric propertiesSatisfactory adhesionPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusMetallurgyComposite oxide

A piezoelectric element including an upper electrode, a piezoelectric and / or electrostrictive material and a lower electrode, characterized in that the piezoelectric and / or electrostrictive material is a composite oxide constituted by ABO3 as general formula and the piezoelectric and / or electrostrictive material has a twin crystal.

Owner:CANON KK +1

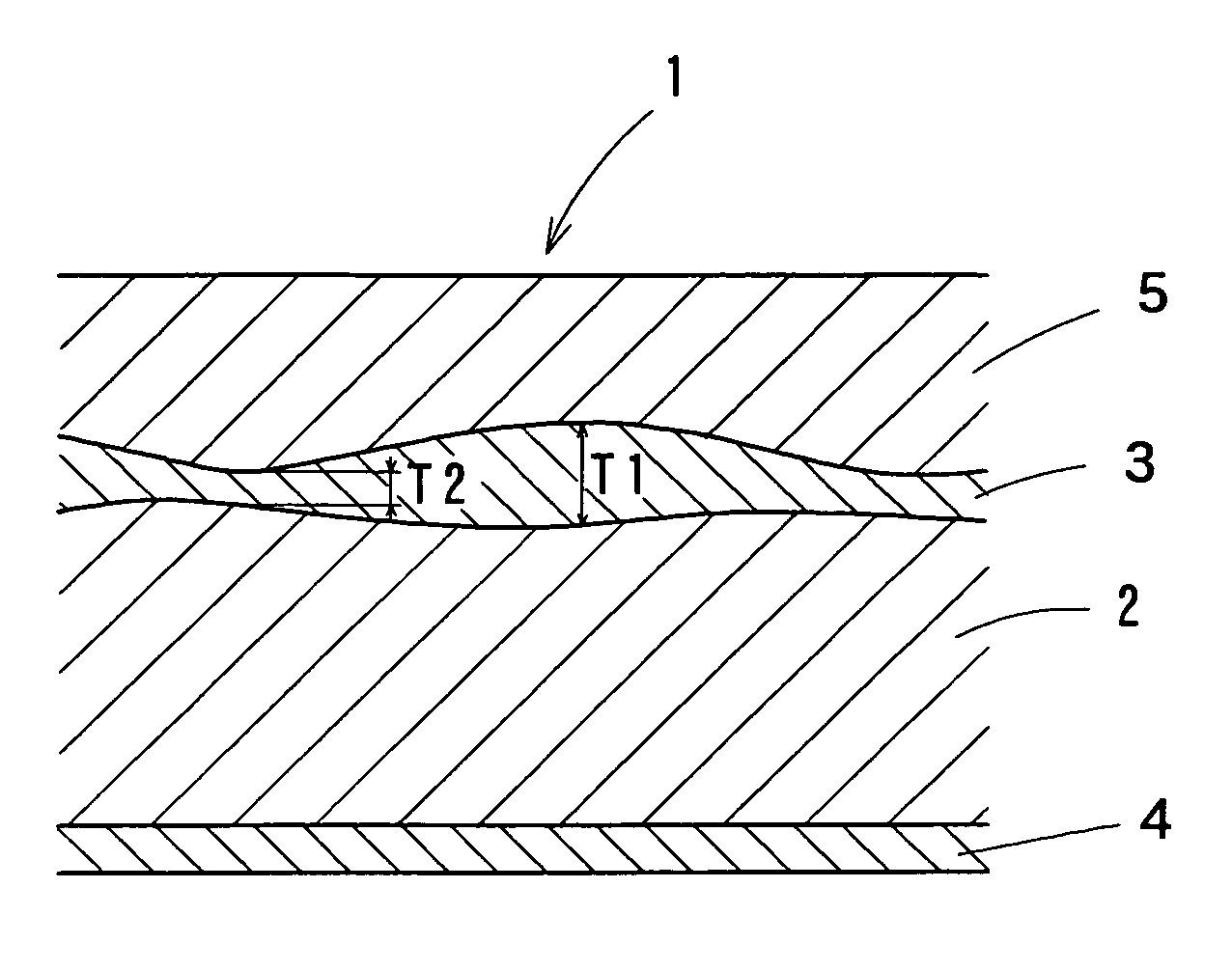

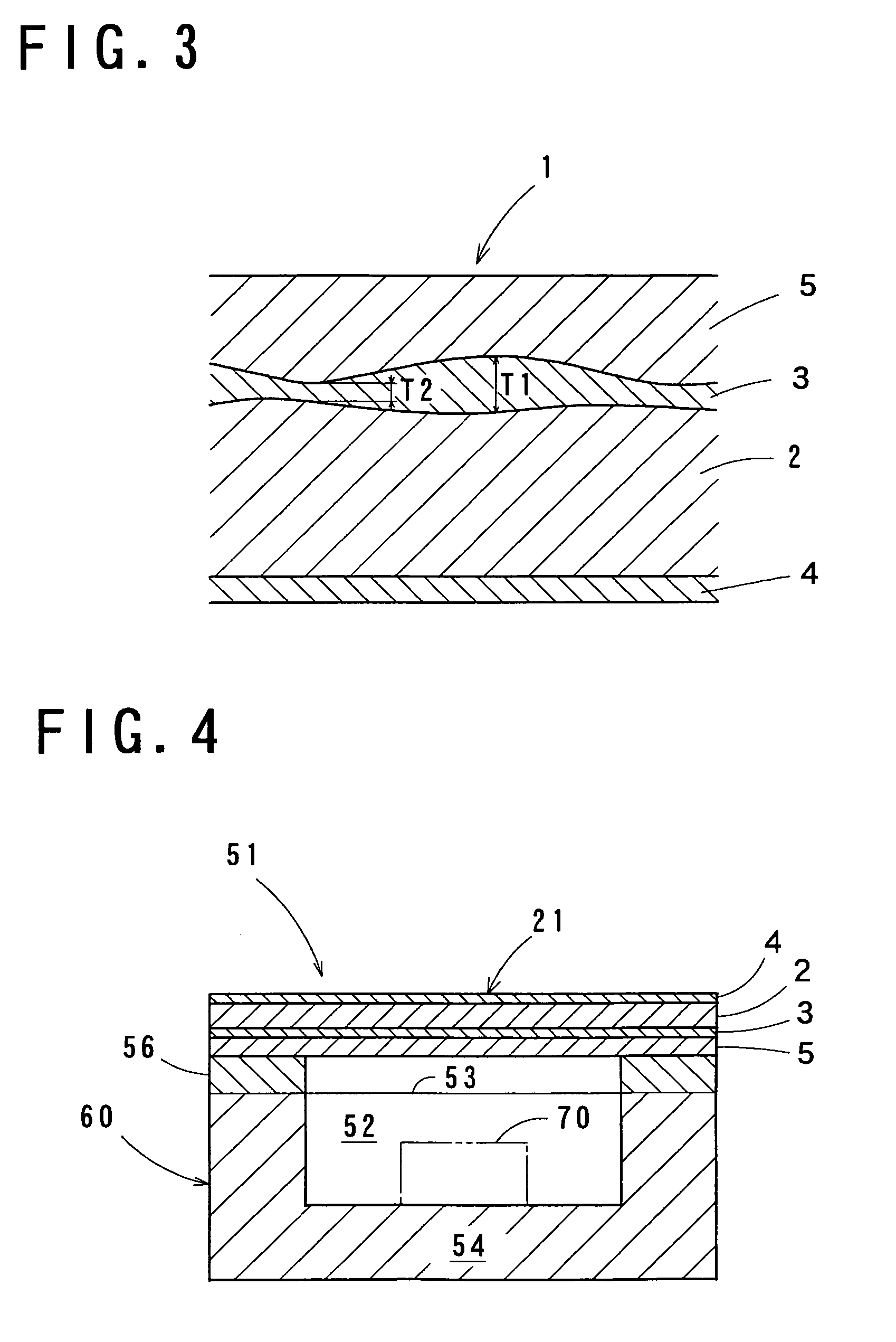

Package for electronic component, lid material for package lid, and production method for lid material

InactiveUS6974635B1Improve sealingExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesMetal foilReduction ratio

A lid material is provided which comprises: a core layer composed of an Fe—Ni alloy or an Fe—Ni—Co alloy; a nickel-based (Ni-based) metal layer press- and diffusion-bonded onto the core layer and composed of a Ni-based metal, such as pure Ni, mainly comprising Ni; and a brazing material layer press-bonded onto the Ni-based metal layer. The Ni-based metal layer has a maximum-to-minimum thickness ratio T1 / T2 of 1.4 to 15. The lid material is produced by press-bonding a Ni-based metal foil onto a core sheet for formation of the Ni-based metal layer on the core layer, then diffusion-annealing the Ni-based metal layer and the core layer, and press-bonding a brazing material foil onto the Ni-based metal layer with a reduction ratio of 30 to 65%.

Owner:NEOMAX MATERIALS

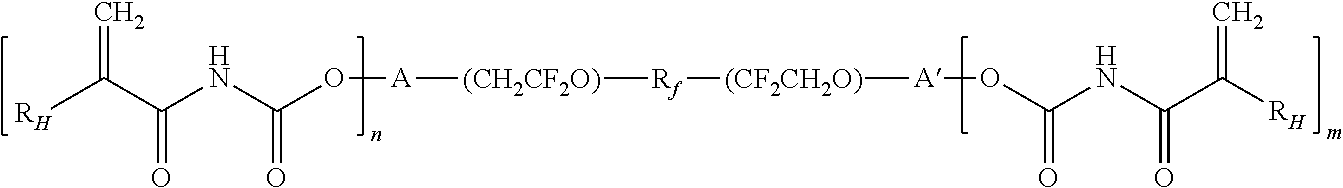

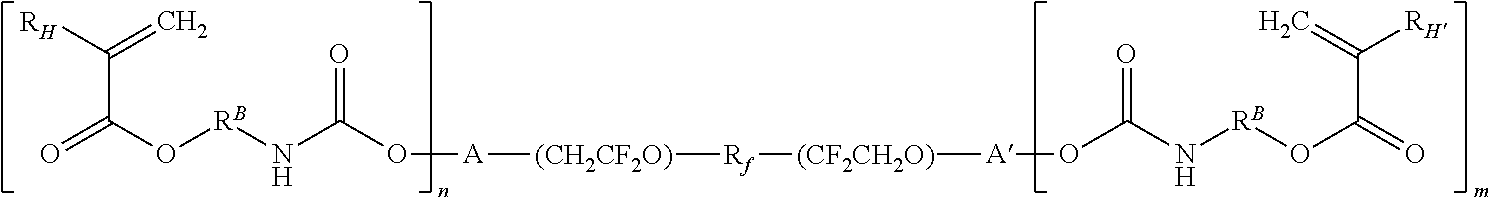

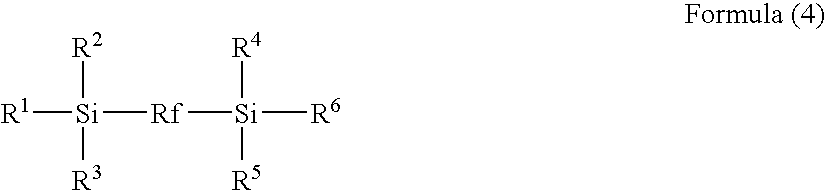

Composite membrane comprising layer of perfluoropolyether on hydrophilic substrate

InactiveUS20150129496A1Easy to manufactureOutstanding thermal stabilityMembranesRadiation applicationsPorous substratePerfluoropolyether

The invention relates to a composite comprising a porous substrate at least partially coated with a coating layer prepared from curing a coating composition (C), the coating composition (C) comprising at least one curable perfluoropolyether (PFPE) polymer. The invention further relates to a process for manufacturing a composite as afore-described, comprising the steps of: (a) providing a coating composition (C) comprising at least one curable perfluoropolyether (PFPE) polymer; (b) depositing said coating composition (C) on a porous substrate; and (c) crosslinking said coating composition (C) to form a porous substrate at least partially coated.

Owner:SOLVAY SOLEXIS

Cohesive coating for snack food packaging

ActiveUS7235294B2Satisfactory adhesionConvenientlyFlexible coversWrappersWater basedAdditive ingredient

Owner:BOSTIK INC

Process for producing thin photosensitized semiconducting films

InactiveUS20070166872A1Increase photosensitivitySatisfactory adhesionLight-sensitive devicesSolid-state devicesPolymer scienceHYDROSOL

The invention relates to a process for producing thin, semiconducting films photosensitized by one or more chromophores, which comprises at least one cycle comprising, in succession, the following steps: a) a step of depositing, on a support, at least one film of a solution obtained by sol-gel polymerization of one or more precursors of a semiconducting oxide or semiconducting oxides, said semiconducting oxide or oxides being chosen from metal oxides, metalloid oxides and mixtures thereof; b) a drying step carried out on the film obtained at a); c) an acid, basic or neutral treatment step carried out in liquid or gaseous medium on the film obtained at b); and d) a step of photosensitizing the film obtained at c) by one or more chromophores, by bringing this film into contact with a solution containing the chromophore(s). Application to the production of electrodes for photovoltaic cells and to light-emitting diodes.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

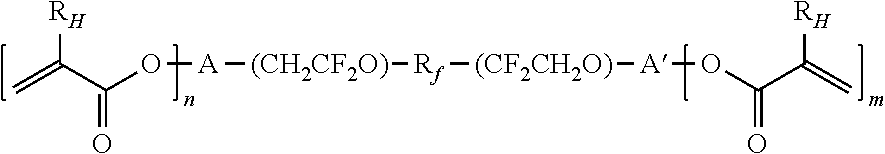

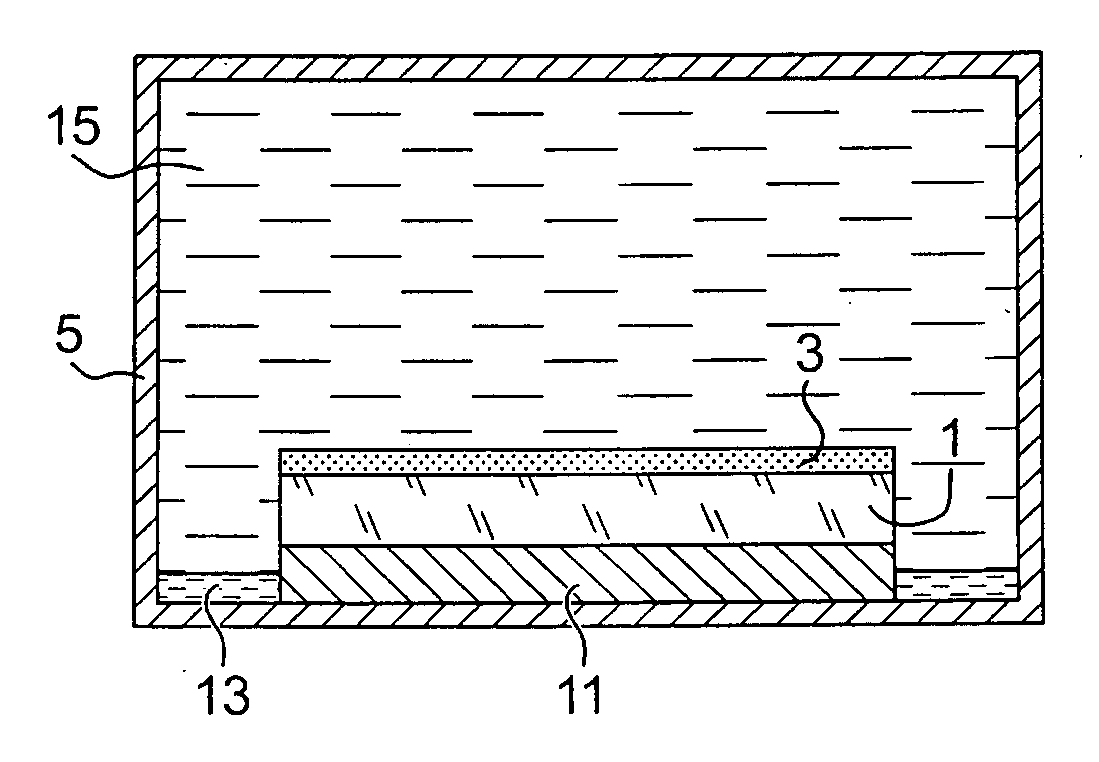

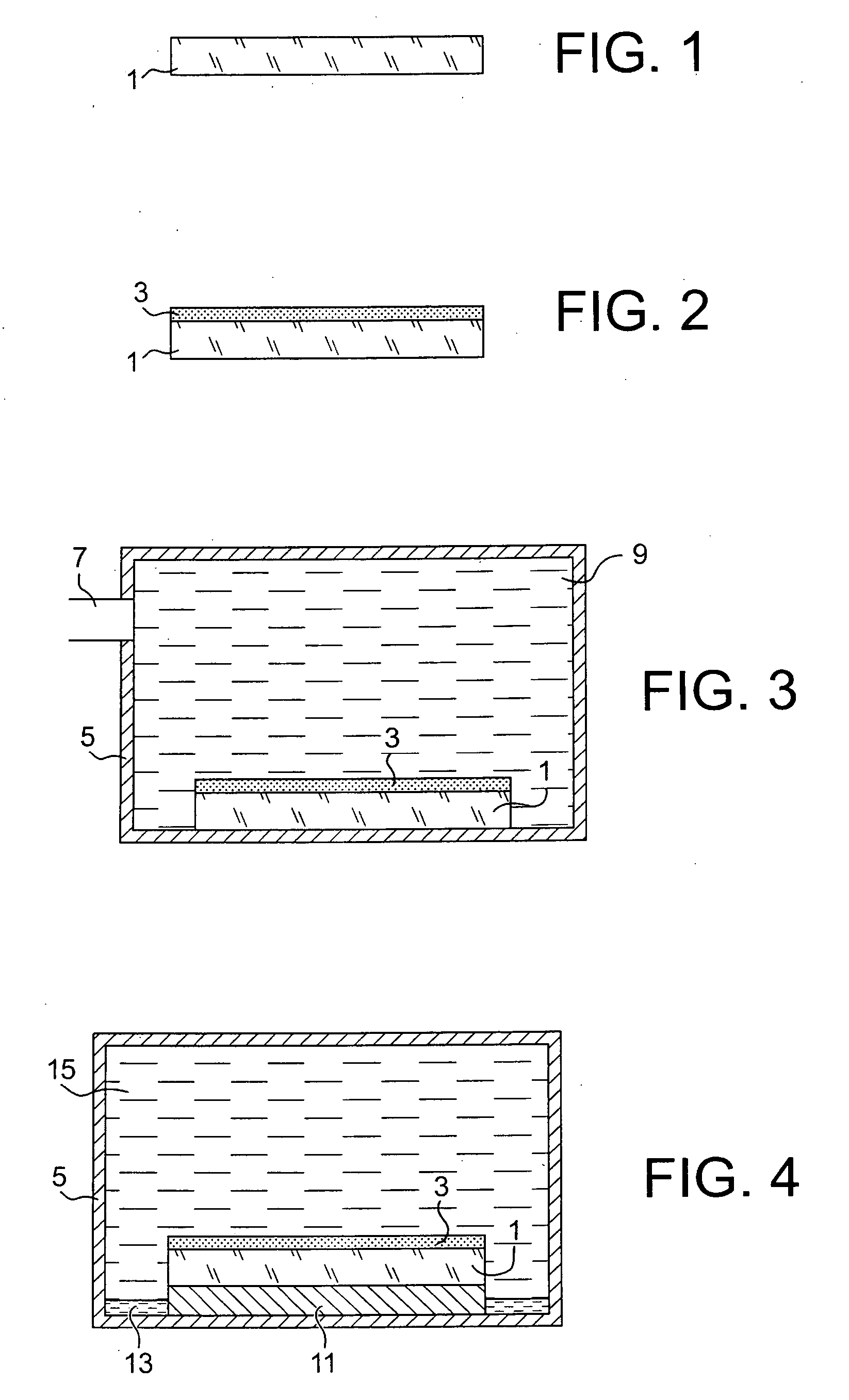

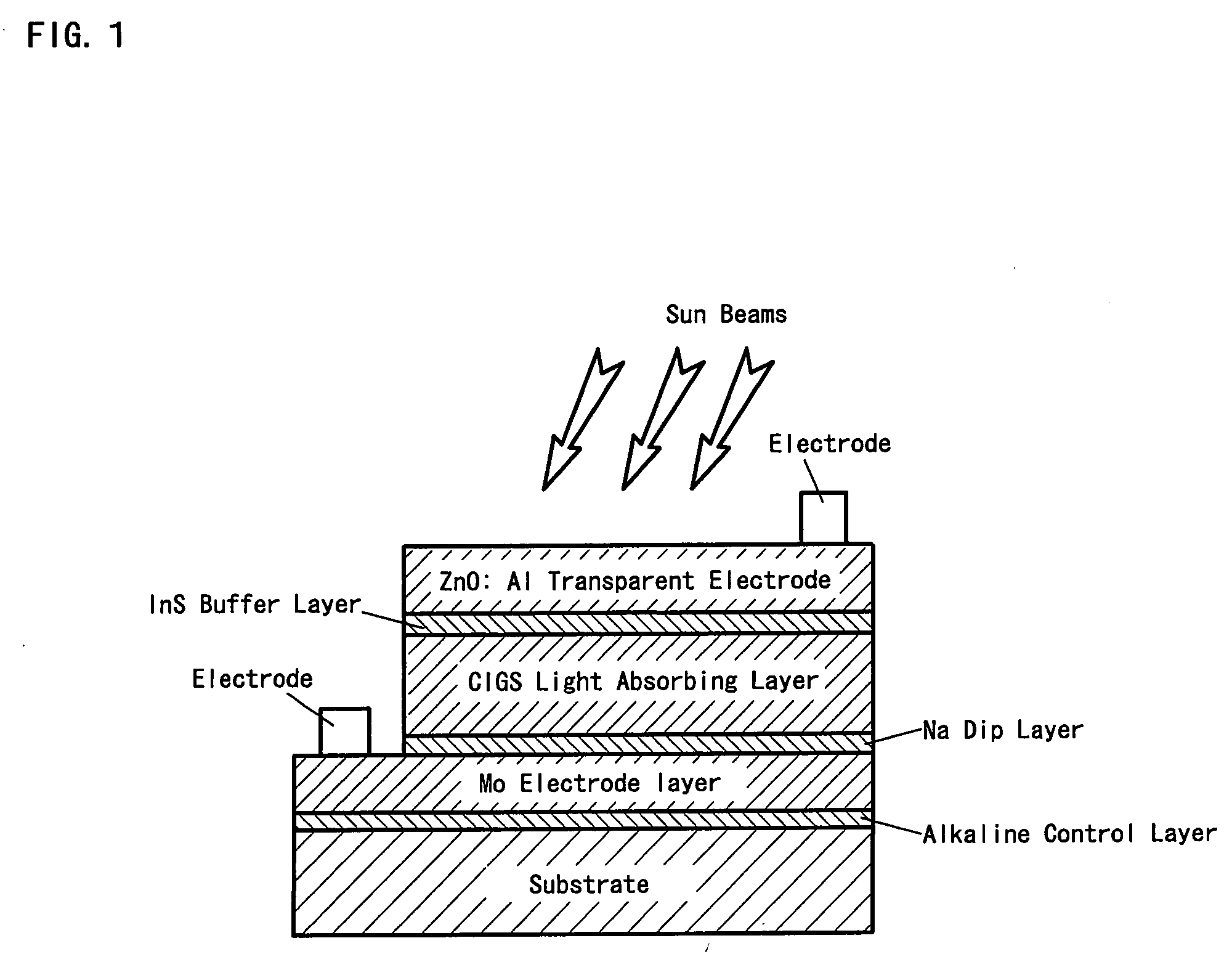

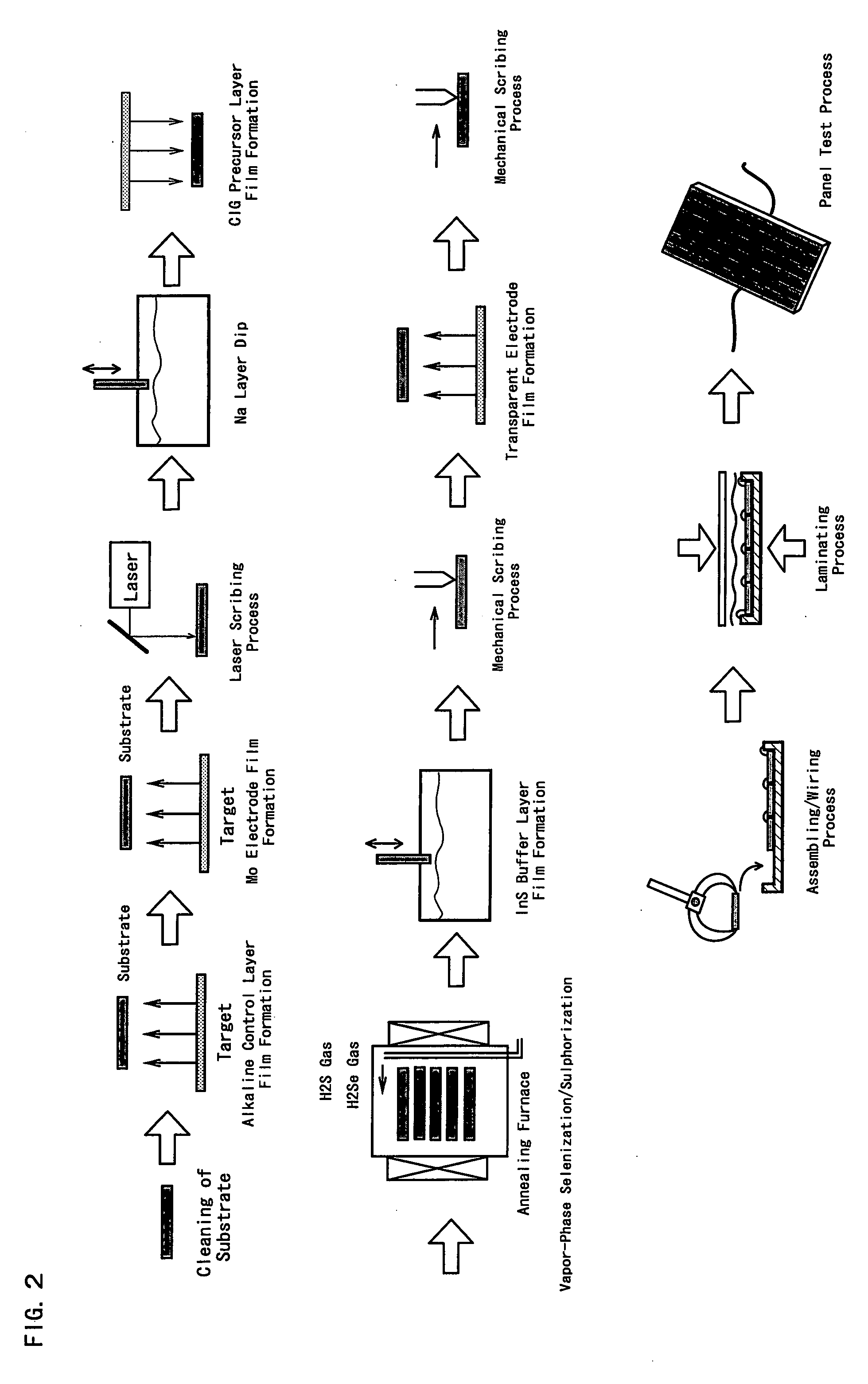

Chalcopyrite Solar Cell and Manufacturing Method Thereof

InactiveUS20090205715A1Light weightIncrease flexibilityFinal product manufactureSemiconductor/solid-state device manufacturingGas phasePliability

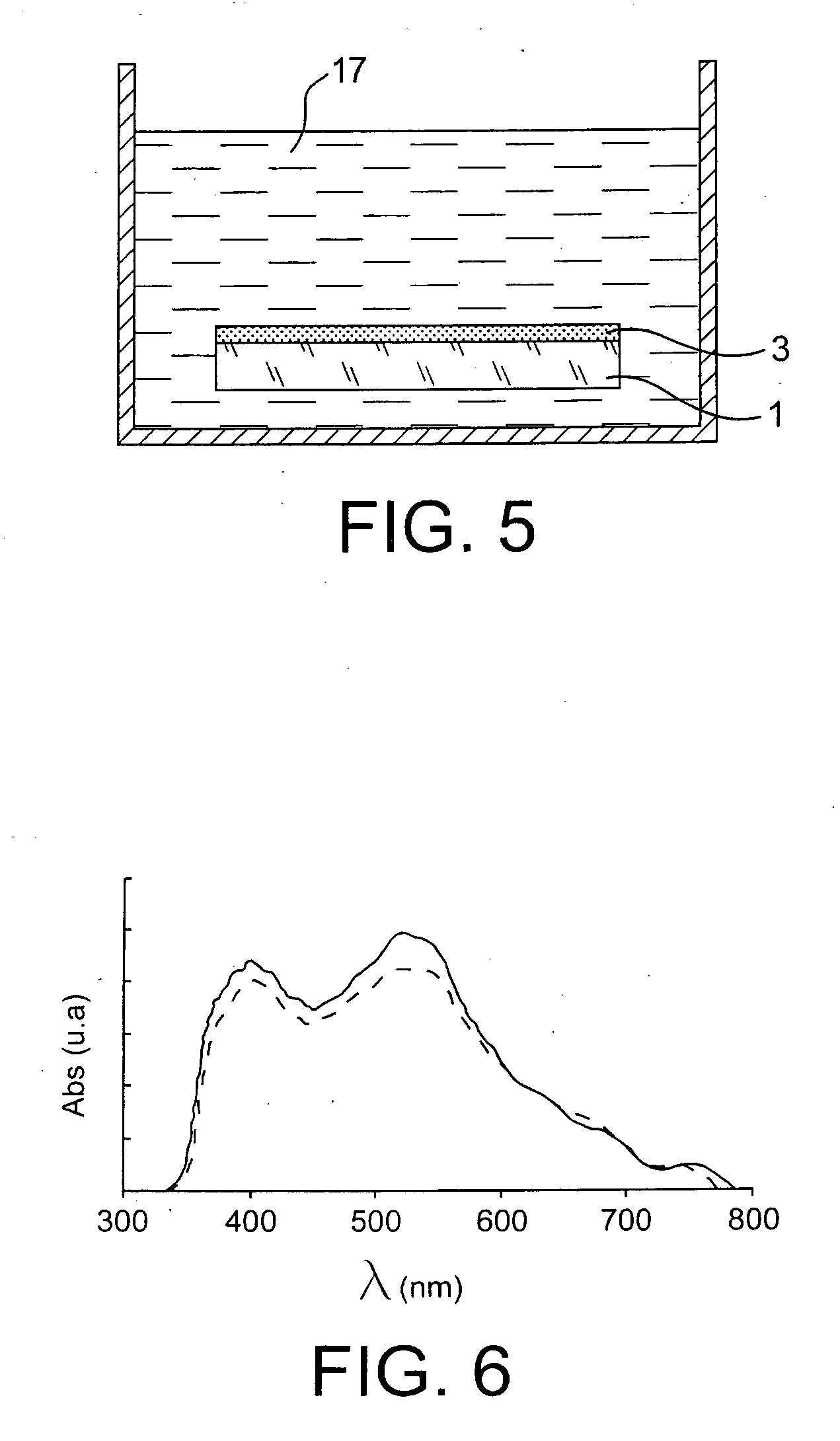

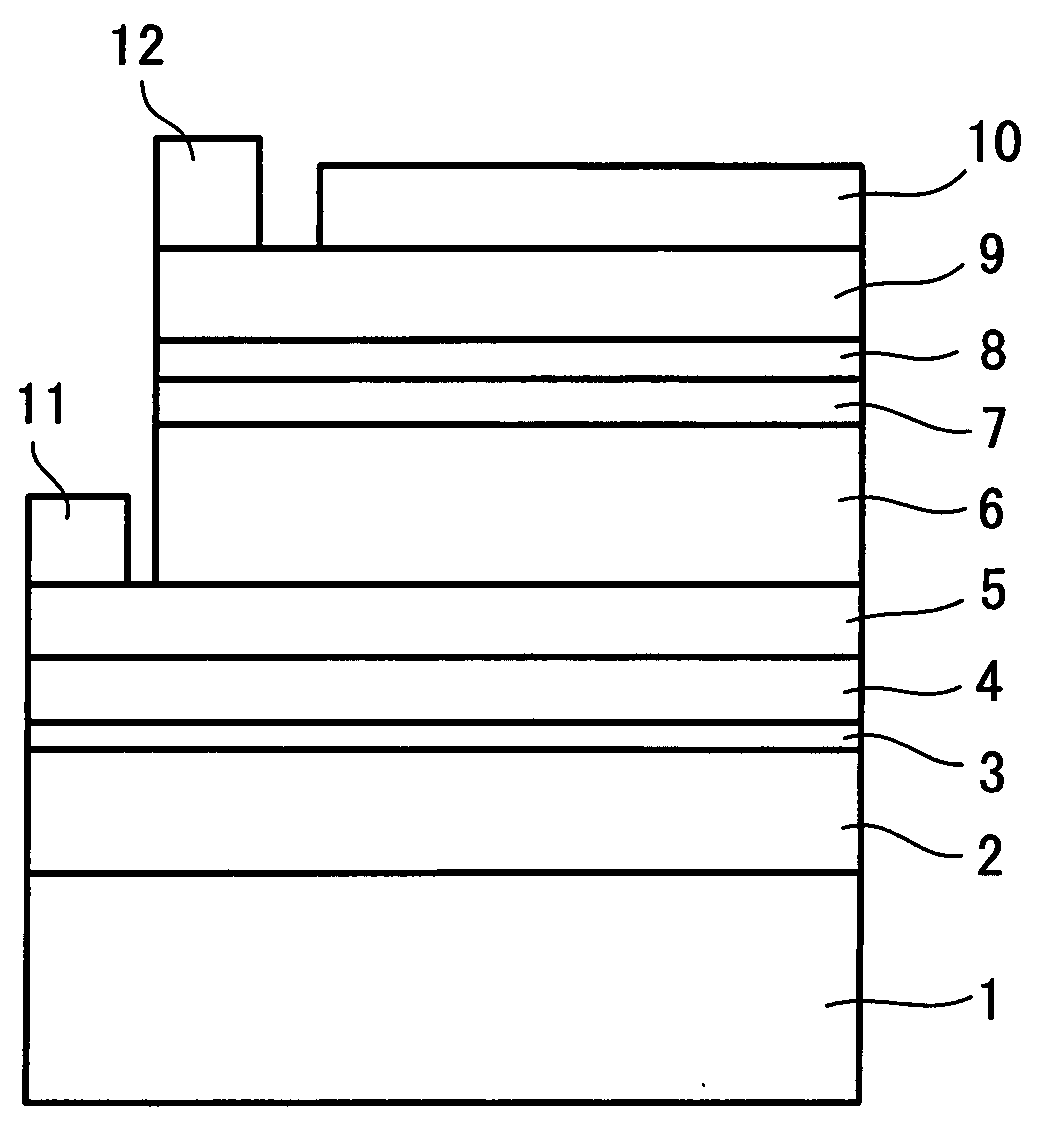

A solar cell having high conversion efficiency and excellent flexibility is realized. A mica substrate or laminated mica substrate is used as substrate 1. The mica and laminated mica have high insulating property and heat resistance temperature, which can be selenized at an appropriate treatment temperature through vapor-phase selenization process, high conversion efficiency and excellent flexibility resultantly suitable for mass-production can be obtained. On the other hand, because the surfaces of the mica and laminated mica have large surface roughnesses, it is impossible to induce leakage to obtain high conversion efficiency in the case where a chalcopyrite based light absorbing layer 6 is simply formed. In the present invention, an intermediate layer 2 of ceramic based material and binder layer 4 are interposed between the mica substrate 1 and a molybdenum electrode 5. By providing the intermediate layer 2 and binder layer 4, surface coating property is enhanced and a solar cell having high conversion efficiency can be realized.

Owner:HONDA MOTOR CO LTD

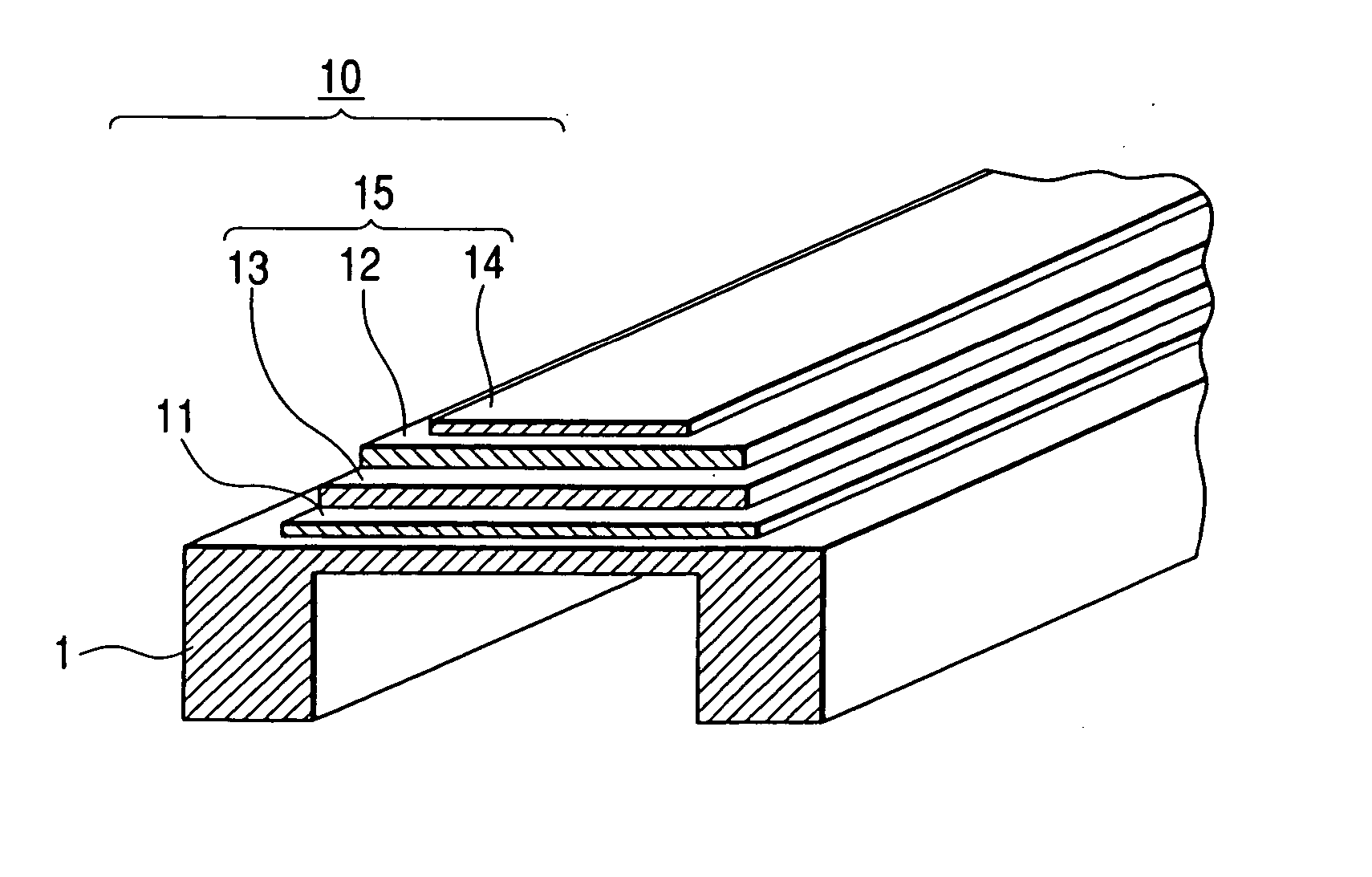

Titanium fuel cell separator

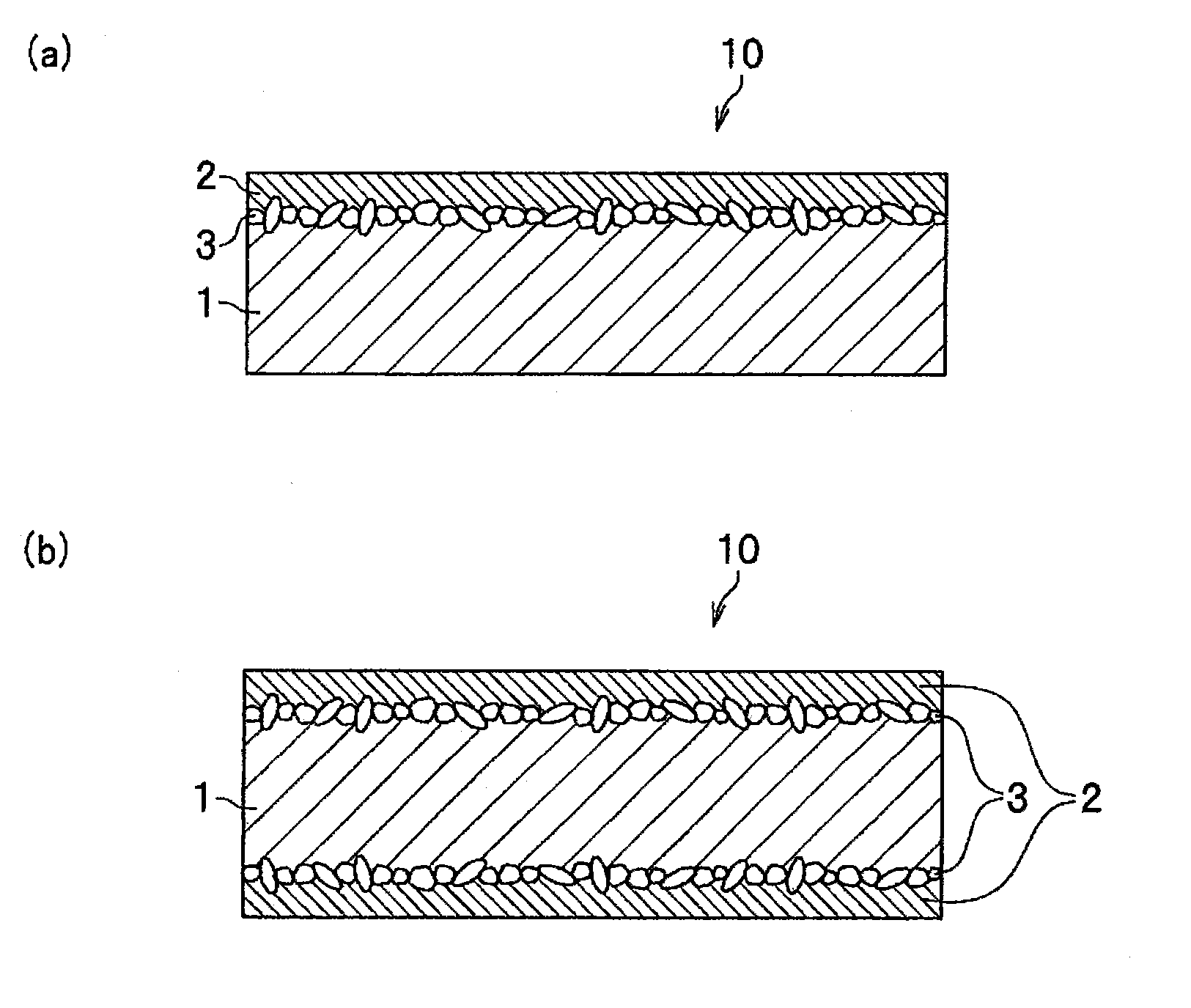

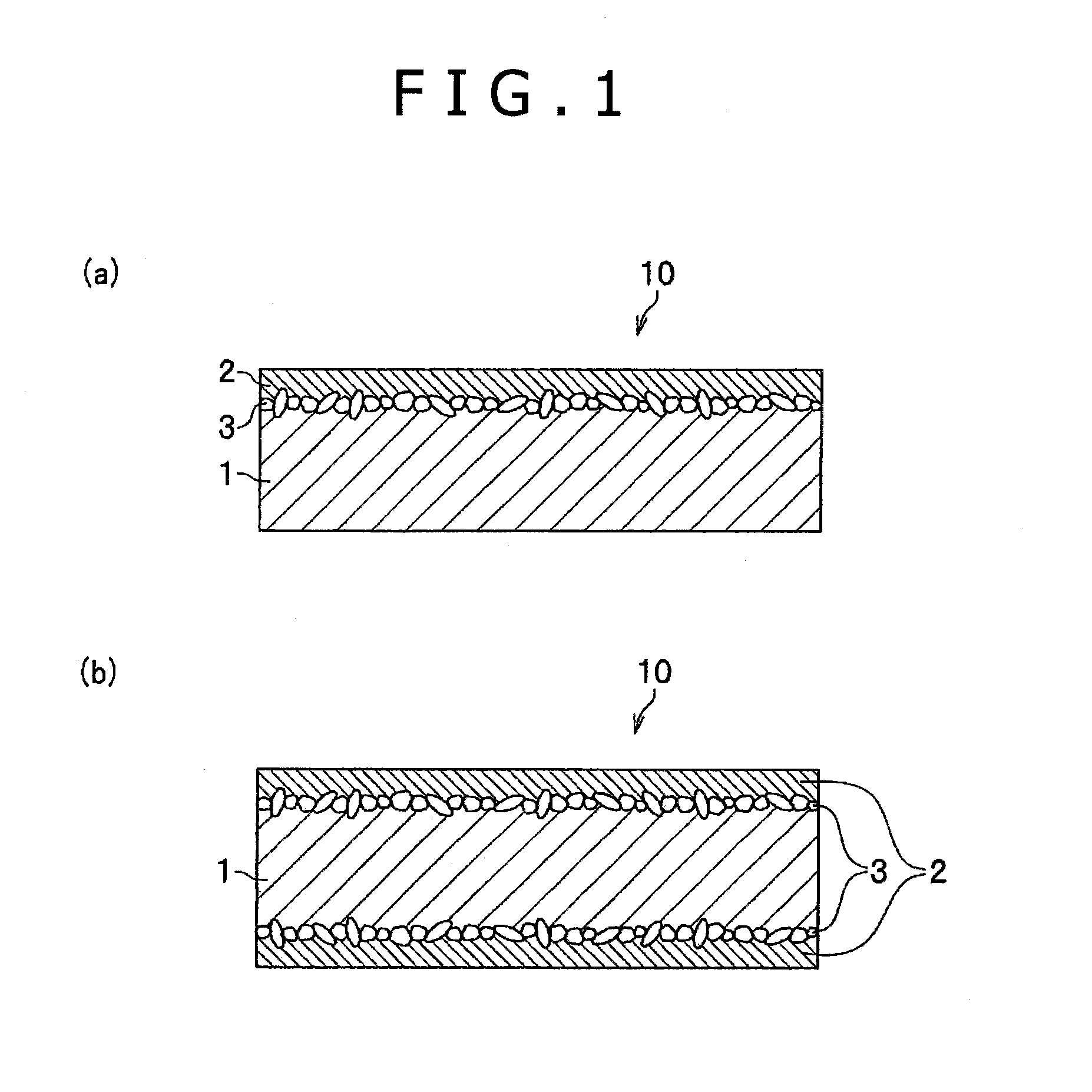

InactiveUS20130164654A1Improve conductivityImprove adhesionCell component detailsSolid electrolyte fuel cellsCarbon layerFuel cells

Disclosed is a titanium fuel cell separator having excellent conductivity and durability. In the disclosed titanium fuel cell separator (10), a carbon layer (2) is formed on the surface of a substrate (1) formed from pure titanium or a titanium alloy. An intermediate layer (3) is formed on the interface between the substrate (1) and the carbon layer (2). The intermediary layer (3) has lined-up granular titanium-carbide in the direction parallel to the carbon layer (2).

Owner:KOBE STEEL LTD

Antireflection Film, Manufacturing Method of Antireflection Film, Hard Coat Film, Polarizing Plate and Display

InactiveUS20090002820A1Satisfactory adhesionSynthetic resin layered productsPretreated surfacesActinic RaysOLEYL ETHER

An antireflection film comprising a hard coat layer and an antireflection layer on at least one side of a transparent resin film, wherein the hard coat layer contains a polyoxyethylene oleyl ether compound and an actinic ray curable resin.

Owner:KONICA MINOLTA OPTO

Label for in-mold forming and resin container with the label

ActiveUS20080182117A1Satisfactory suitabilitySatisfactory adhesionSynthetic resin layered productsWood working apparatusPorosityAntistatic agent

A label for in-mold forming which comprises a thermoplastic resin film base layer (I), a heat-sealable resin layer (II), and an antistatic layer (III), wherein the heat-sealable resin layer (II) comprises a heat-sealable resin including a copolymer of propylene and α-olefin having 4-20 carbon atoms and has a degree of non-crystallinity of 60-90% as determined with a differential scanning calorimeter (DSC) at temperatures less than 90° C., the antistatic layer (III) comprises an antistatic agent in an amount of 0.001 to 1 g per unit area (m2) and the surface of the layer has a wettability index (JIS-K-6768) of 32-54 mN / m, and the label has a porosity higher than 10% and not higher than 70% and has an opacity (JIS-P-8138) higher than 20% and not higher than 100%; and a labeled container with the label.

Owner:YUPO CORP

Electroconductive silicone pressure-sensitive adhesive composition

InactiveUS6991751B2Satisfactory adhesionImprove conductivityConductive materialNon-conductive material with dispersed conductive materialConductive polymerCore Particle

A conductive powder is incorporated in a pressure-sensitive adhesive composition comprising a silicone gum, an MQ resin, and a crosslinking agent. The conductive powder consists of core particles of inorganic material or organic resin, an interlayer of silicon-base polymer, and a metal plating. The resulting conductive silicone pressure-sensitive adhesive composition is satisfactorily adherent to silicone rubber and cures into a product that exhibits stable conductivity and adhesive properties in the temperature region where silicone rubber is used.

Owner:SHIN ETSU CHEM IND CO LTD

Photosensitive ceramic composite and method for manufacturing multilayer substrate including the composite

InactiveUS20040249040A1Avoid reflectionsGreat advantagePhotography auxillary processesOther chemical processesInorganic particleCeramic composite

The present invention relates to a photosensitive ceramic composite and a method for manufacturing a multilayer substrate using the composite. The photosensitive ceramic composite and manufacturing method of the present invention are applicable to circuit members and components for ceramic multilayer substrates for high-frequency wireless communication. The photosensitive ceramic composite contains inorganic particles and a photosensitive organic component. The inorganic particles have at least surface sections containing an inorganic material having a refractive index less than that of inner sections of the inorganic particles.

Owner:TORAY IND INC

Adhesive for solar battery back sheets

InactiveUS20150005450A1Excellent adhesionExcellent balancePolyureas/polyurethane adhesivesEpoxy resin adhesivesPrepolymerChemistry

An adhesive for solar battery back sheets obtainable by mixing (A) a urethane prepolymer having an isocyanate group at the end with (B) a polyol, wherein the urethane prepolymer (A) is obtainable by a reaction of a hydroxyl group-containing compound with an isocyanate compound, and the hydroxyl group-containing compound comprises a polycaprolactone polyol. Also, cured reaction products of the adhesive. Also, a solar battery back sheet and a solar cell module comprising the adhesive.

Owner:HENKEL KGAA

Oil-In-Water Silicone Emulsion Composition

InactiveUS20110319557A1Satisfaction intensitySatisfactory rubbery elasticityTransportation and packagingMixingColloidal silicaSilicon dioxide

An oil-in-water silicone emulsion composition comprising (A) 100 mass parts of a polyorganosiloxane that contains in each molecule at least two groups selected from the group consisting of the silicon-bonded hydroxyl group, silicon-bonded alkoxy groups, and silicon-bonded alkoxyalkoxy groups, (B) 0.1 to 200 mass parts of a colloidal silica, (C) 0.1 to 100 mass parts of an aminoxy group-containing organosilicon compound that contains at least three silicon-bonded aminoxy groups in each molecule, (D) 0.1 to 50 mass parts of a surfactant, and (E) 10 to 200 mass parts water. Such oil-in-water silicone emulsion composition that contains little low molecular weight silicone can form, even without the use of a tin catalyst, a cured film that exhibits a satisfactory strength and a satisfactory adherence to substrate, through the removal of the water fraction.

Owner:DOW CORNING TORAY CO LTD

Piezoelectric element

InactiveUS20060256167A1Excellent piezoelectric propertiesSatisfactory adhesionPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusComposite oxideCrystal

Owner:CANON KK +1

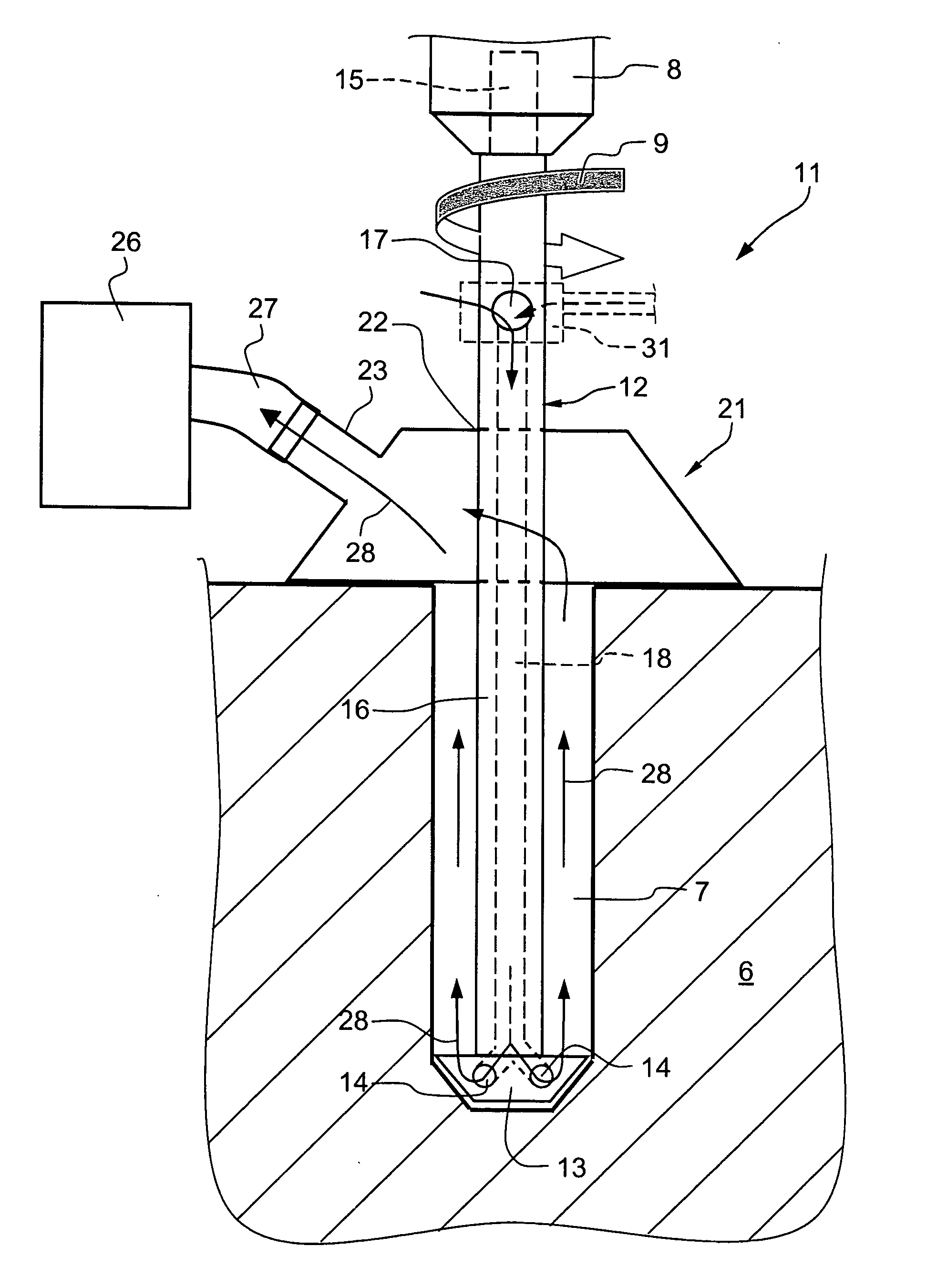

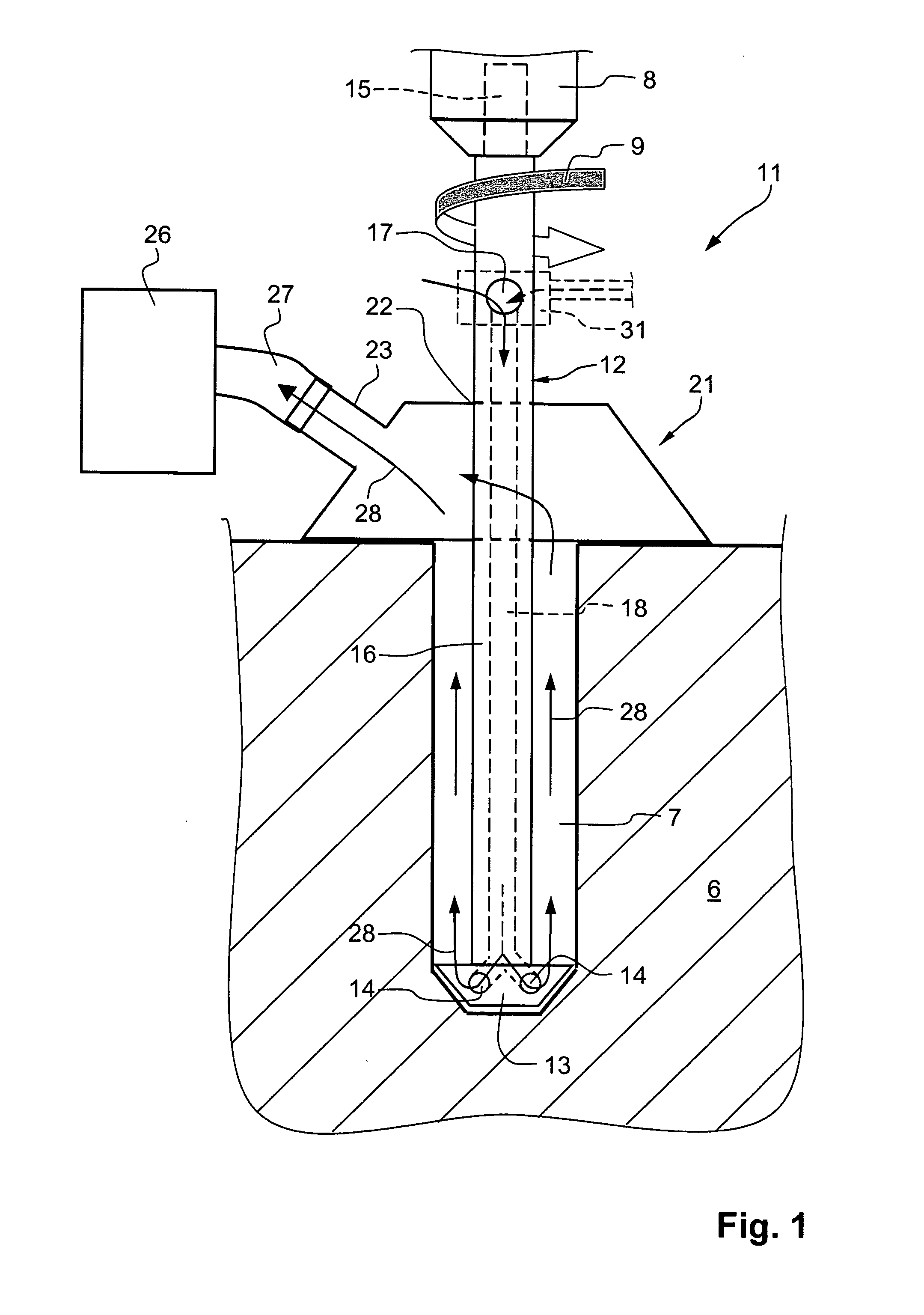

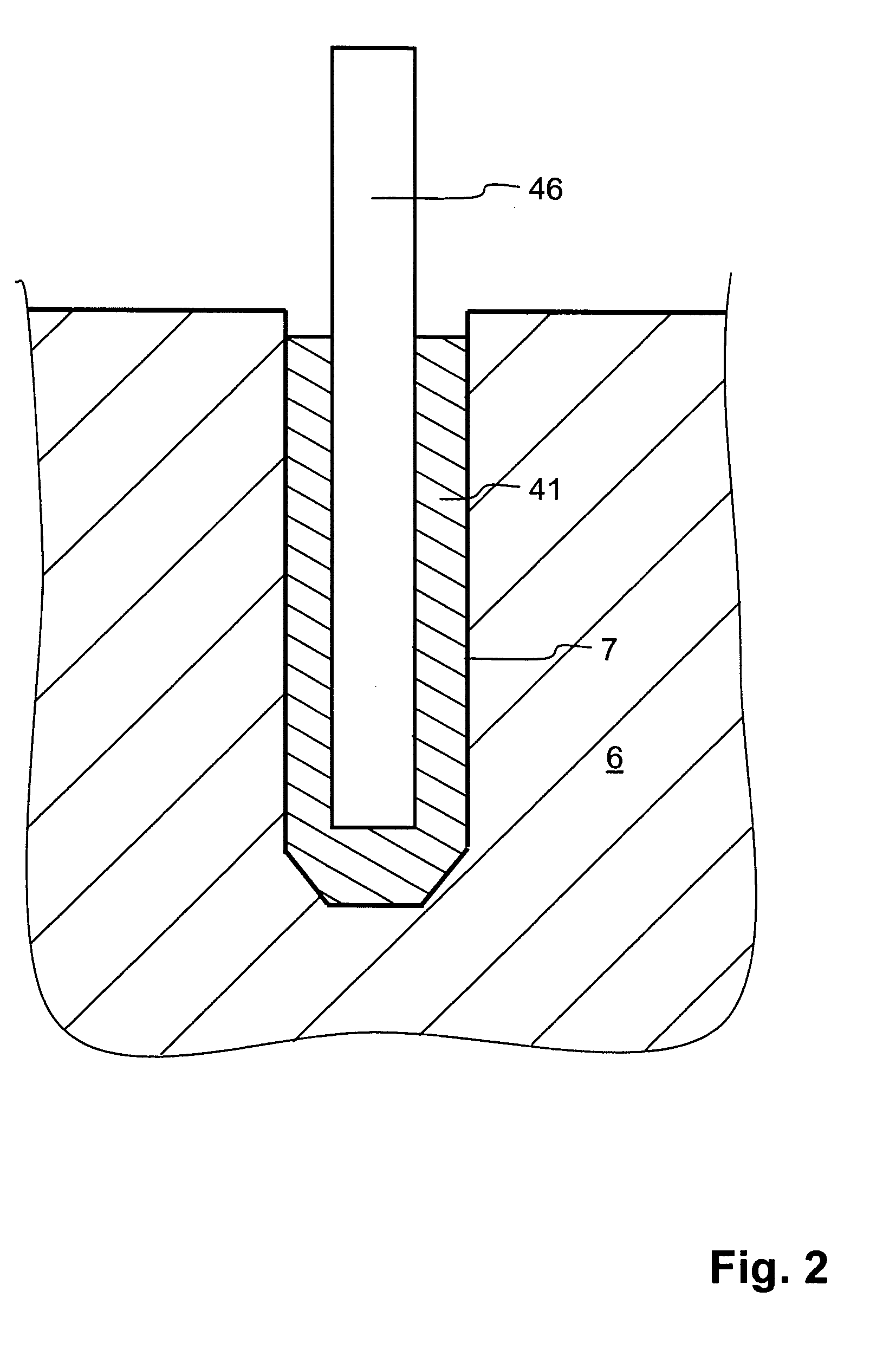

Method of anchoring fastening element

InactiveUS20100126112A1Increase drilling speedImprove productivityBuilding repairsPrinted circuit manufactureEngineeringDrill

A method of anchoring a fastening element includes drilling a borehole (7) in a constructional component (6) with a percussively-rotationally driven hollow drill (12), while aspirating produced drillings and drilling dust with a vacuum source (26) through a gap between an outer side of the hollow drill (12) and a wall of the borehole (7) during drilling of the borehole (7), immediately after formation of the suction-cleaned borehole (7), filling the borehole (7) with a self-hardenable mortar (41), and inserting the fastening element (46) into the self-hardenable mortar (41).

Owner:HILTI AG

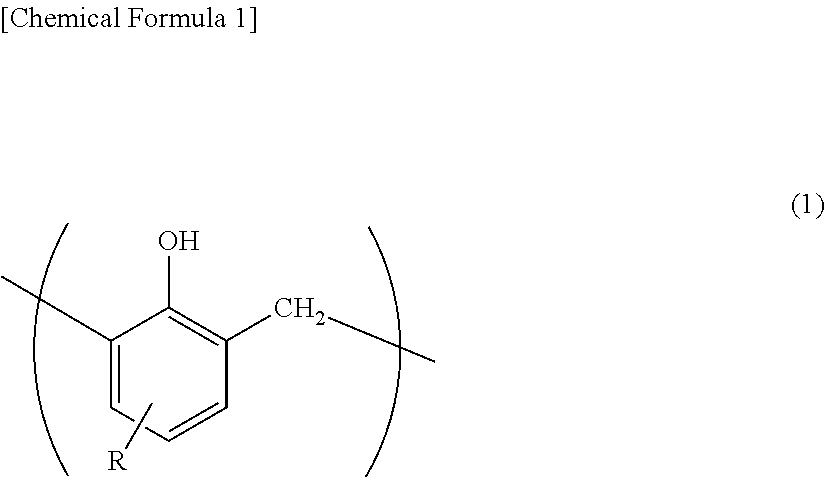

Acrylic pressure-sensitive adhesive tape or sheet, and method for producing the same

InactiveUS20100021730A1Satisfactory adhesionImprove adhesionRadiation applicationsFilm/foil adhesivesMeth-Microsphere

Disclosed is an acrylic pressure-sensitive adhesive tape or sheet that exhibits satisfactory adhesion to hard-to-adhere adherends.The acrylic pressure-sensitive adhesive tape or sheet includes a microsphere-containing viscoelastic layer (X); and a pressure-sensitive adhesive layer (Y) arranged on at least one side of the viscoelastic layer (X). The pressure-sensitive adhesive layer (Y) is derived from an acrylic pressure-sensitive adhesive composition through the application of an active energy ray, and the acrylic pressure-sensitive adhesive composition contains (a) a vinyl monomer mixture mainly containing an alkyl(meth)acrylate (a1) whose alkyl moiety has 2 to 14 carbon atoms, or a partial polymer of the vinyl monomer mixture; (b) a photoinitiator; and (c) an alkylphenol tackifier. The acrylic pressure-sensitive adhesive composition preferably contains 0.001 to 5 parts by weight of the photoinitiator (b) and 0.01 to 25 parts by weight of the alkylphenol tackifier (c) per 100 parts by weight of the vinyl monomer mixture or a partial polymer thereof (a).

Owner:NITTO DENKO CORP

Pressure sensitive adhesives for optical film, manufacturing methods for pressure sensitive adhesive layer for optical film, pressure sensitive adhesive layers for optical film, pressure sensitive adhesion type optical films and image displays

ActiveUS7435779B2Suppressing bowing and light leakageIncreased durabilityLiquid crystal compositionsPolyureas/polyurethane adhesivesMeth-Optical thin film

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com