Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

367results about How to "Press firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

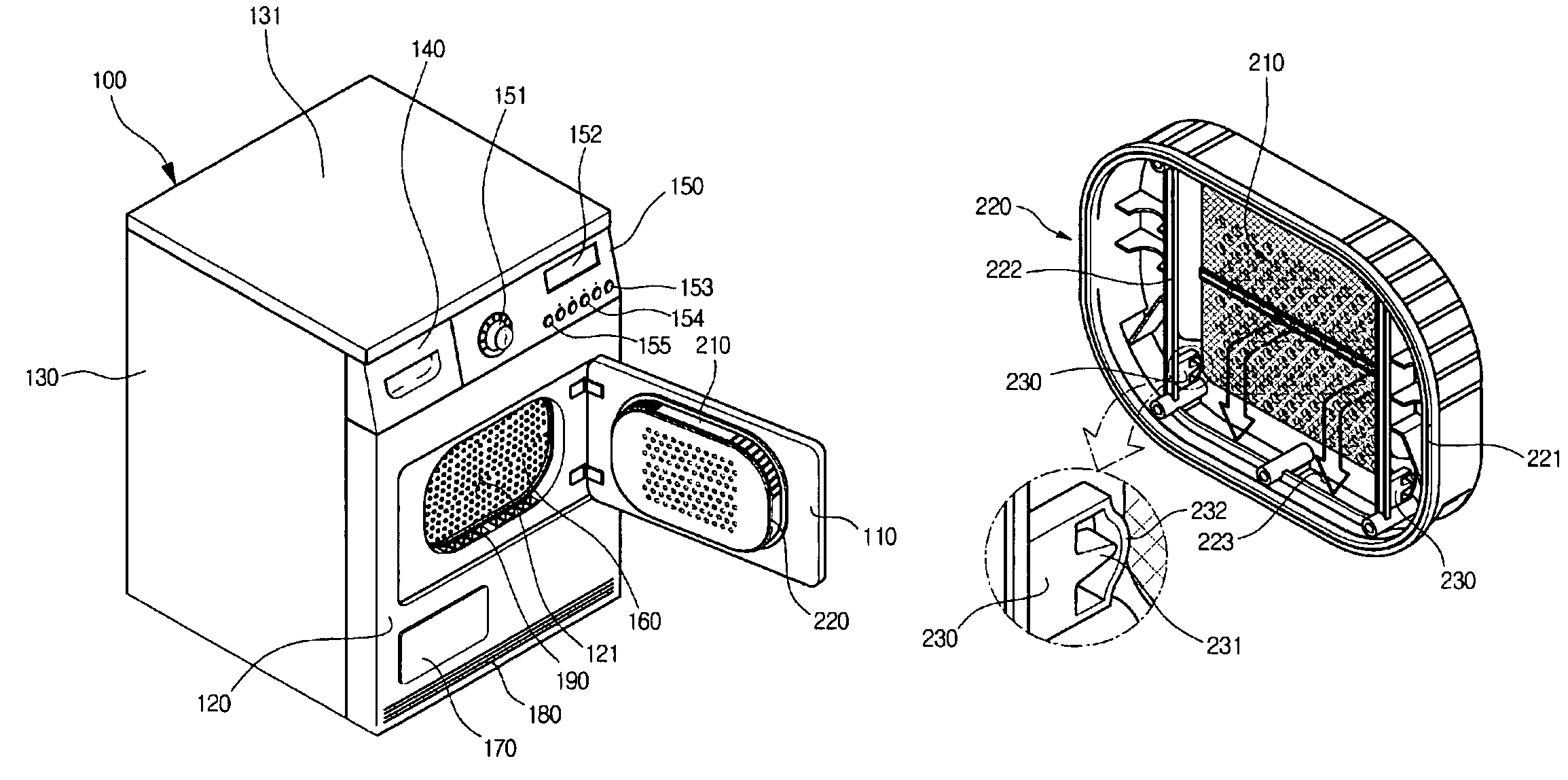

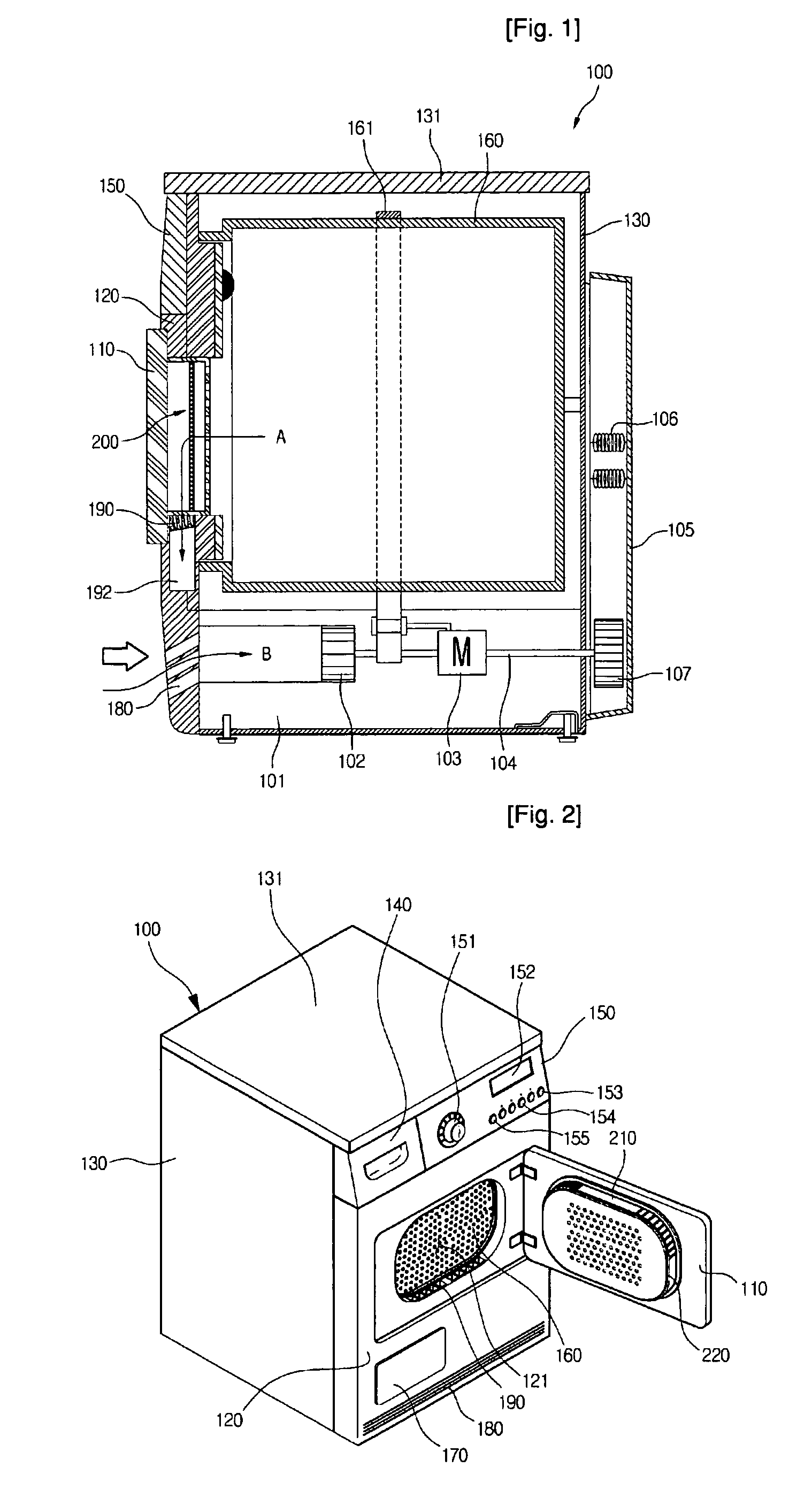

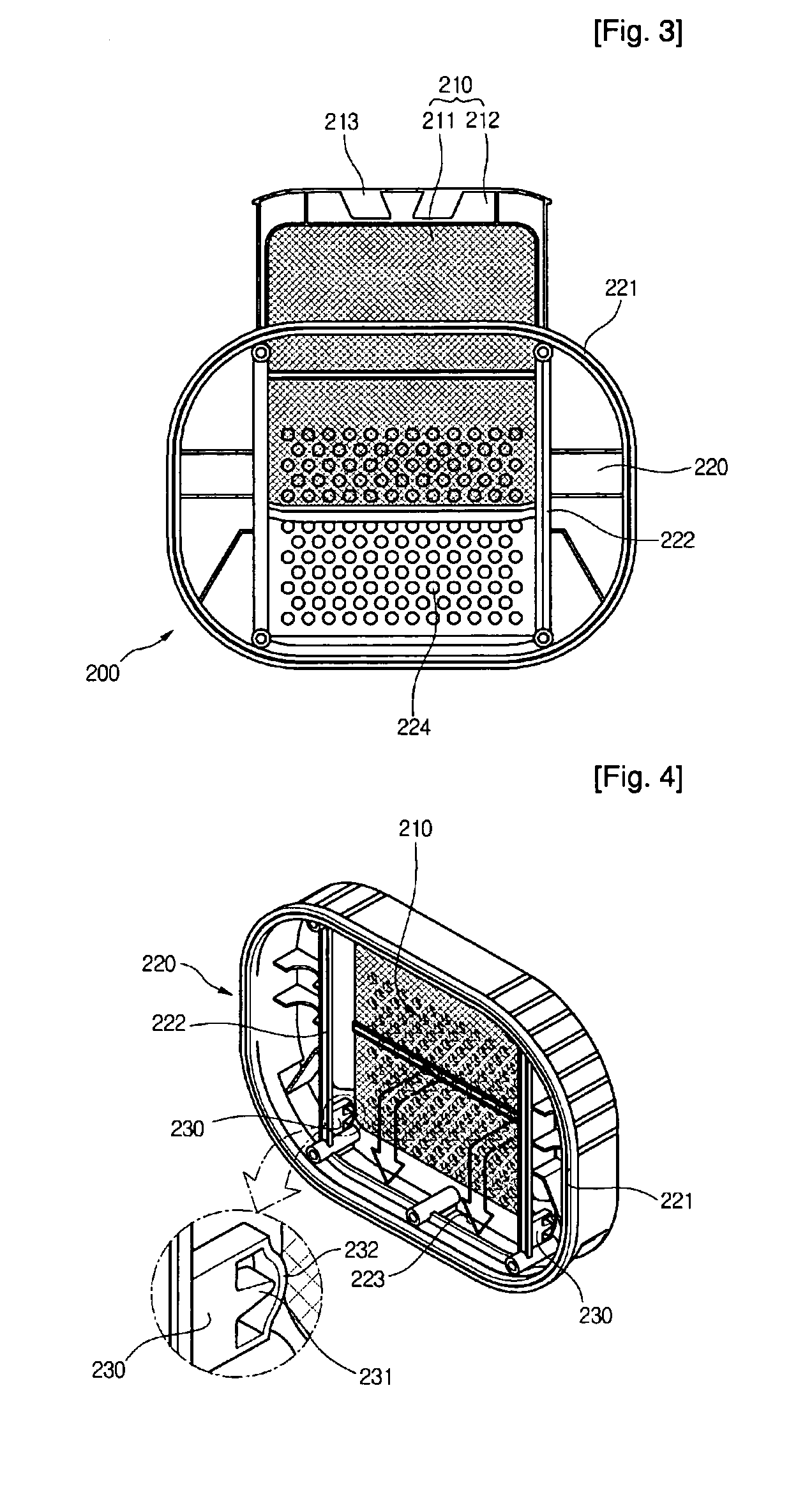

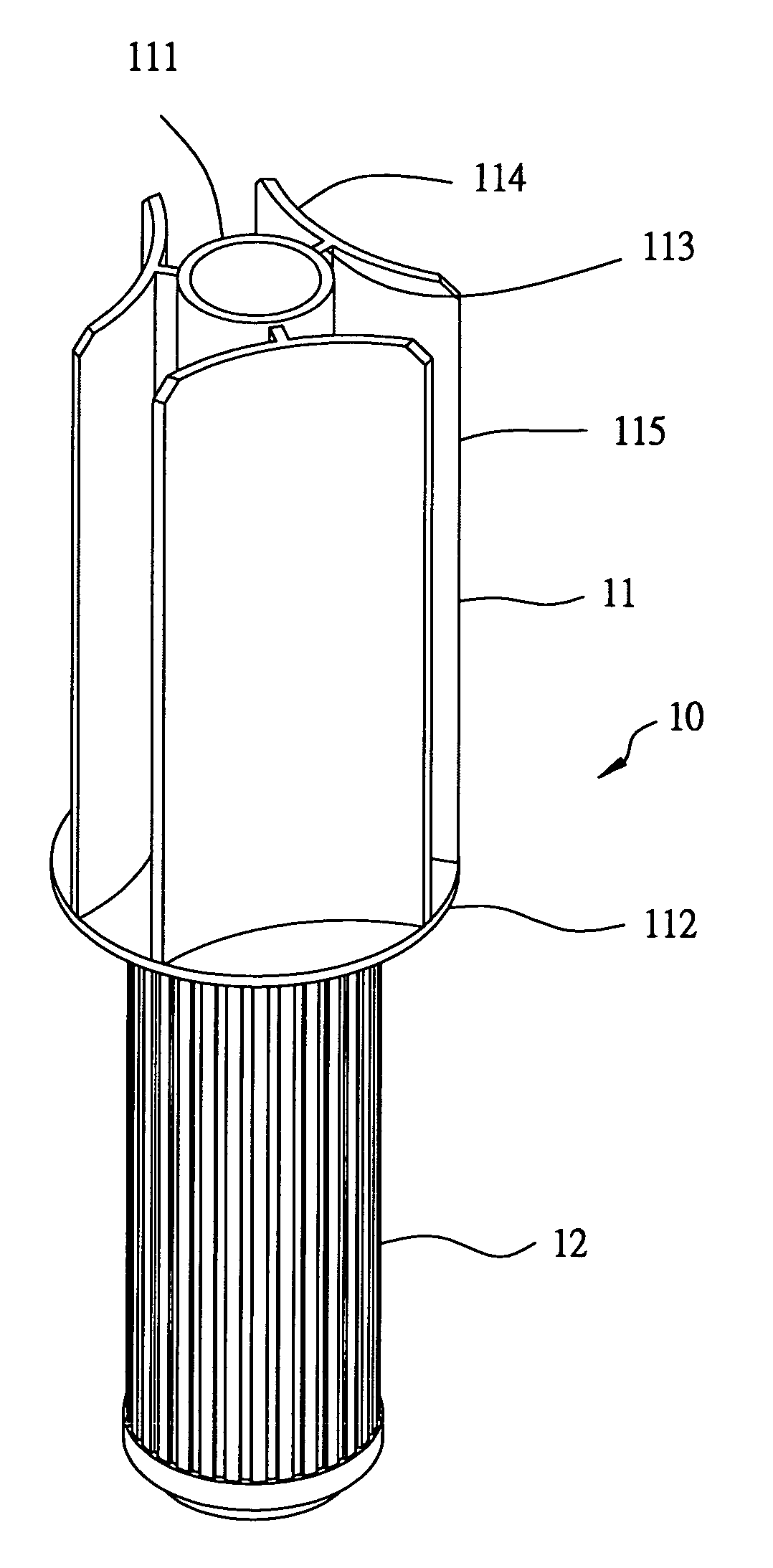

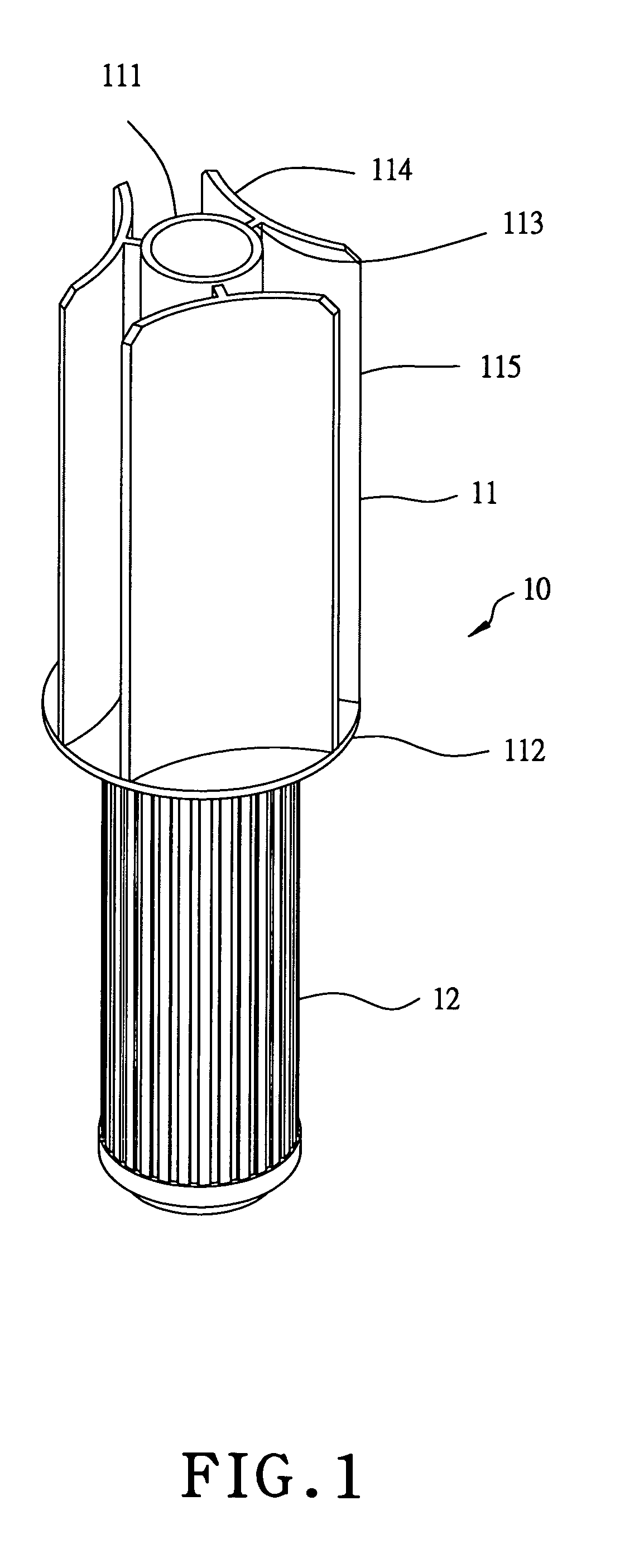

Lint filter assembly of laundry dryer

InactiveUS7644515B2Press firmlyAvoid accumulationTextile treatment machine partsDrying gas arrangementsEngineeringLaundry

Owner:LG ELECTRONICS INC

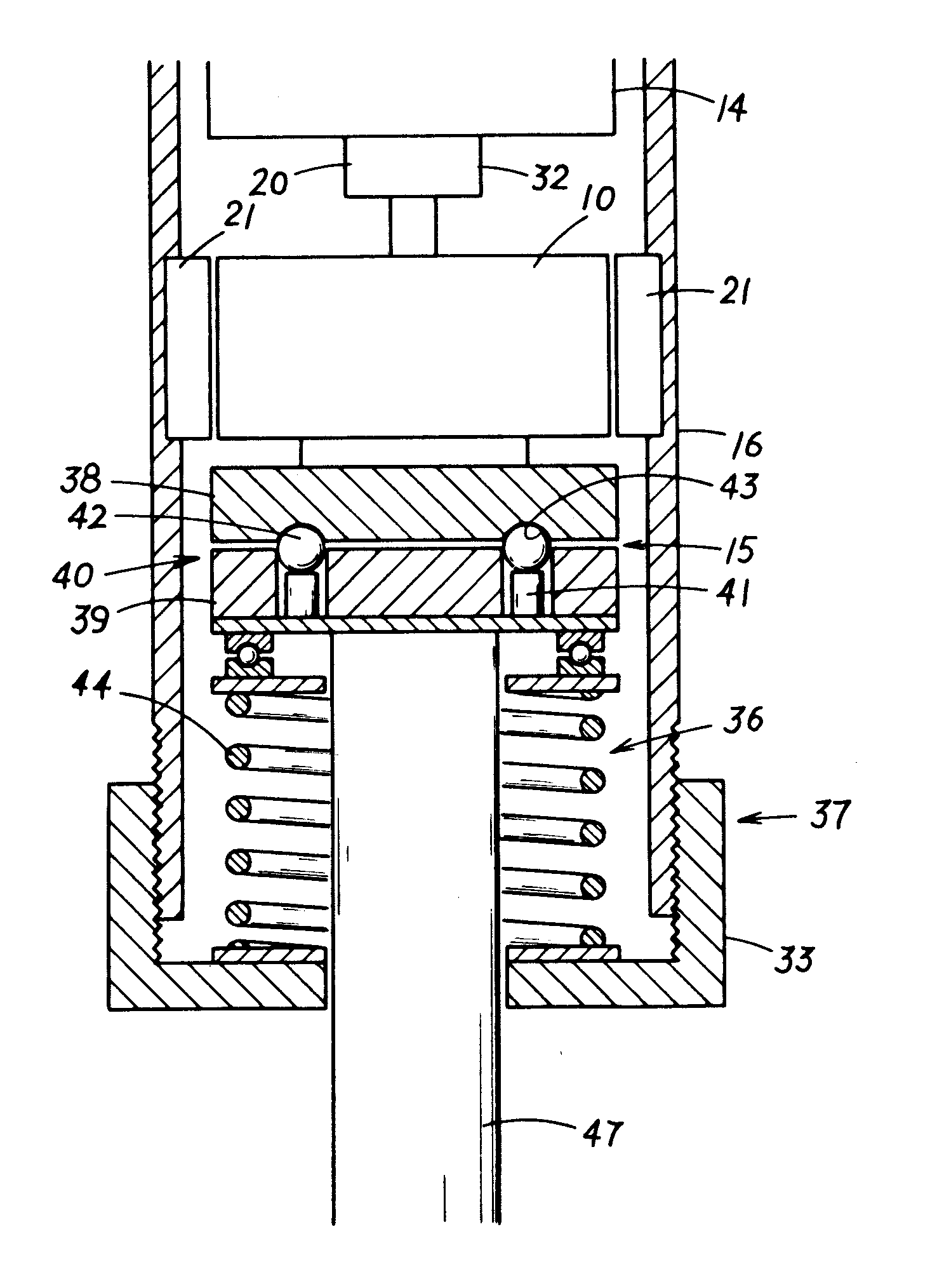

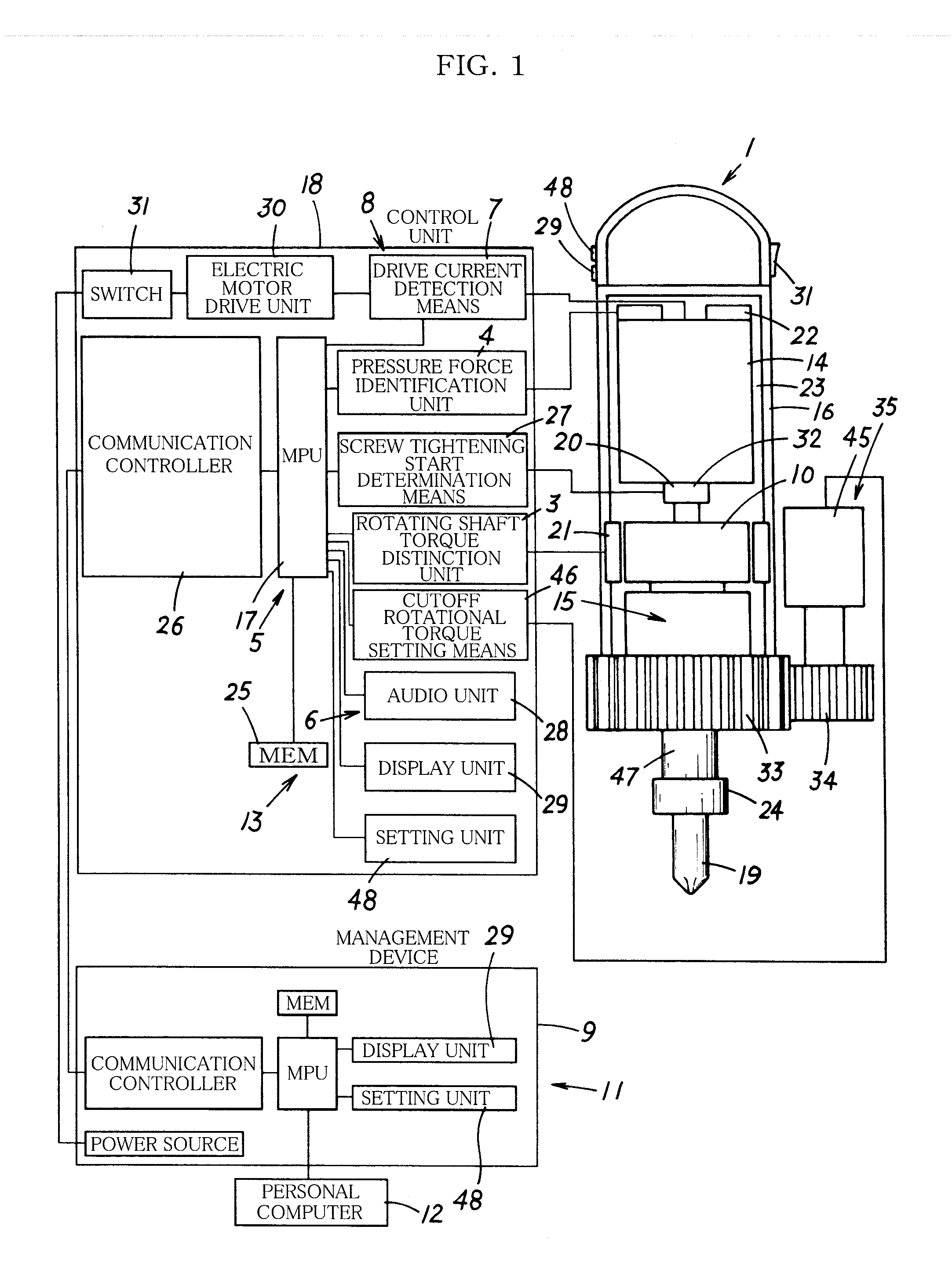

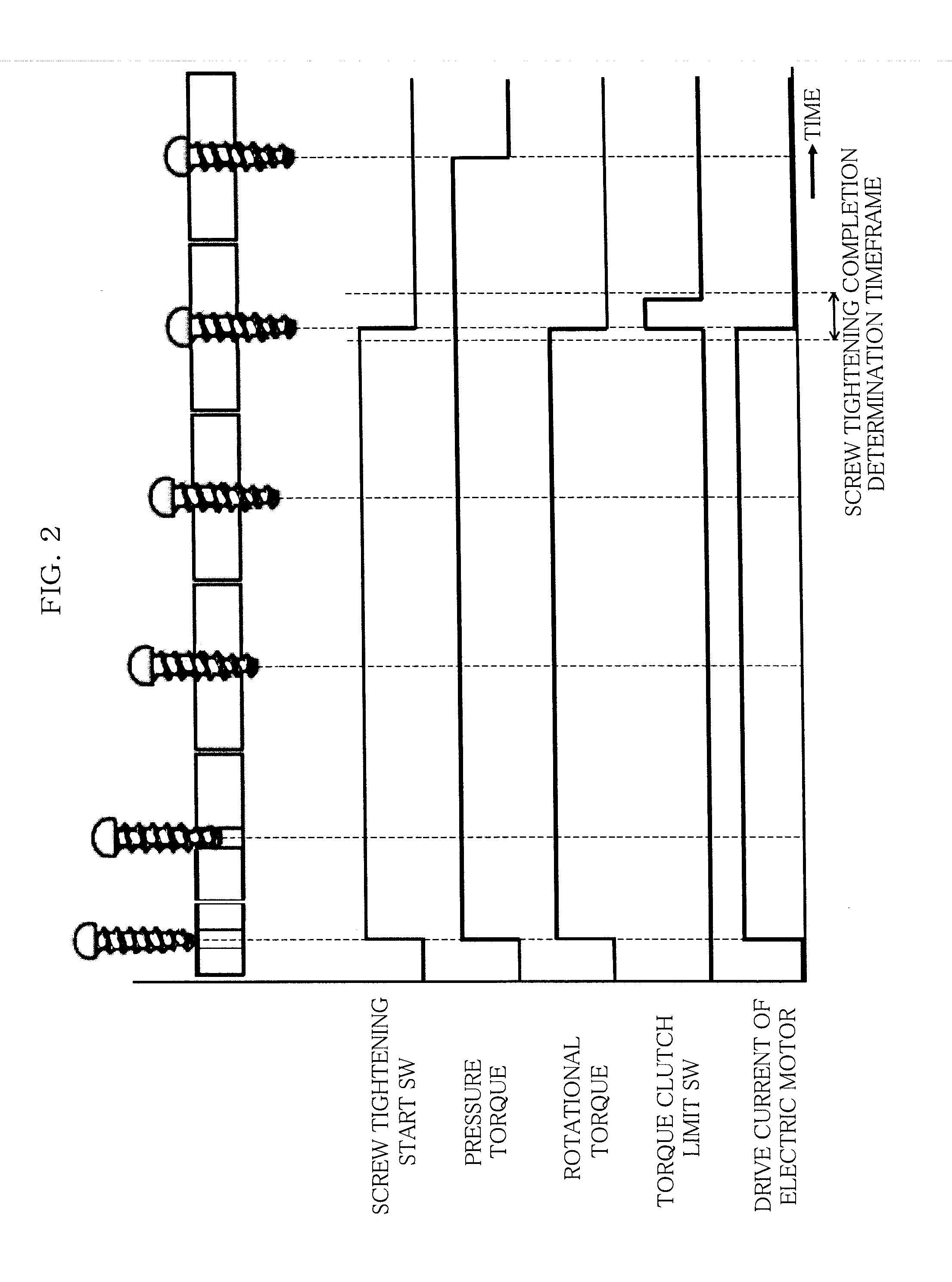

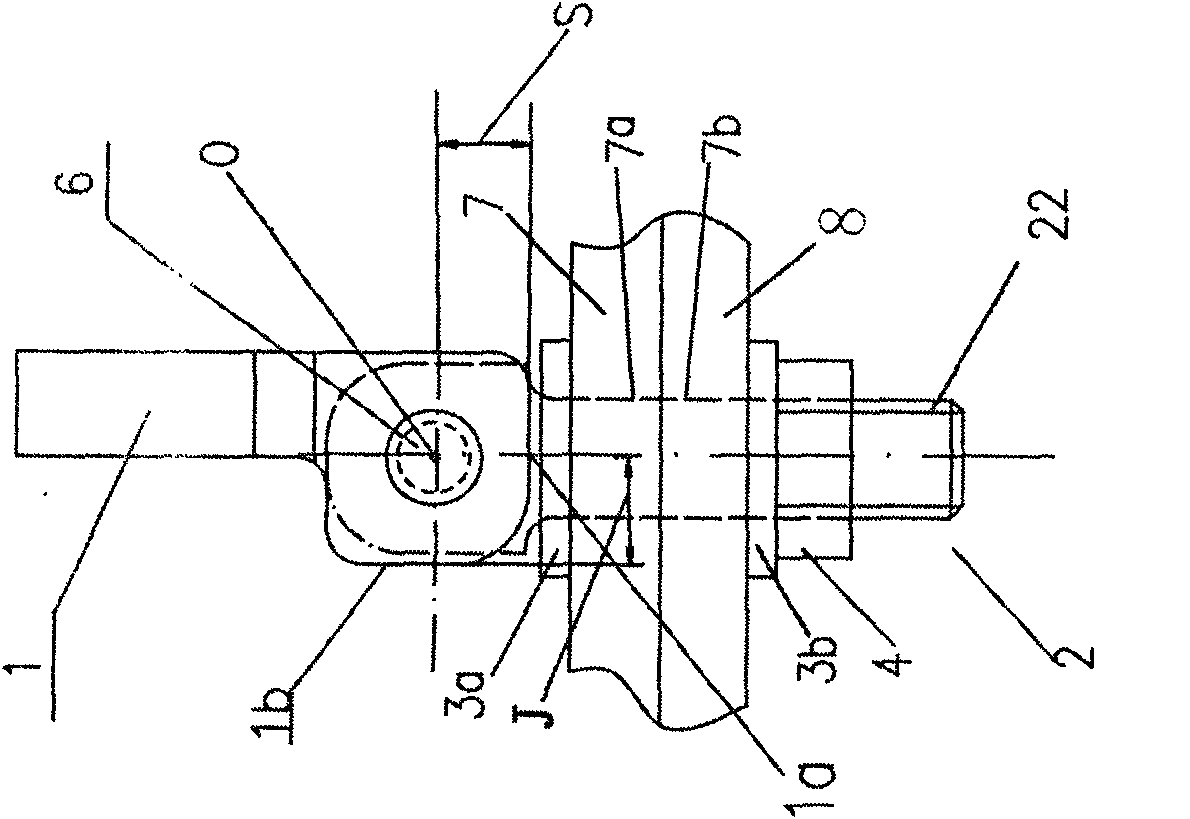

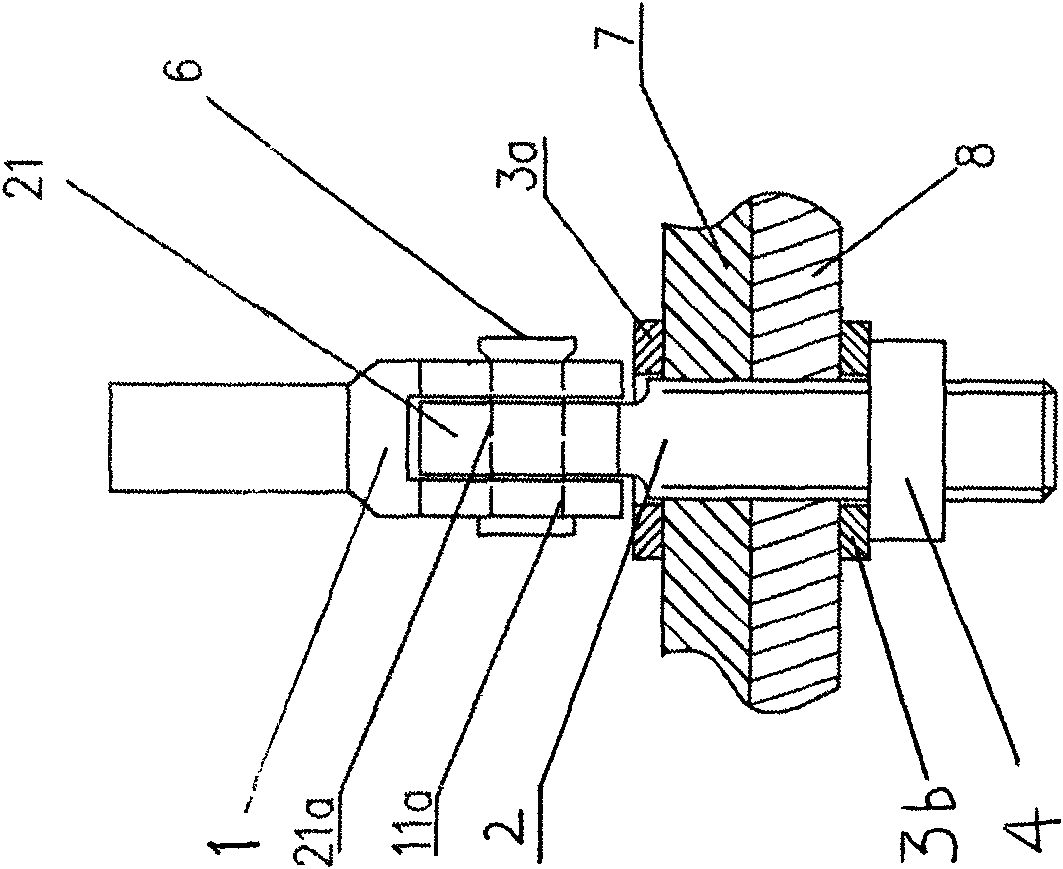

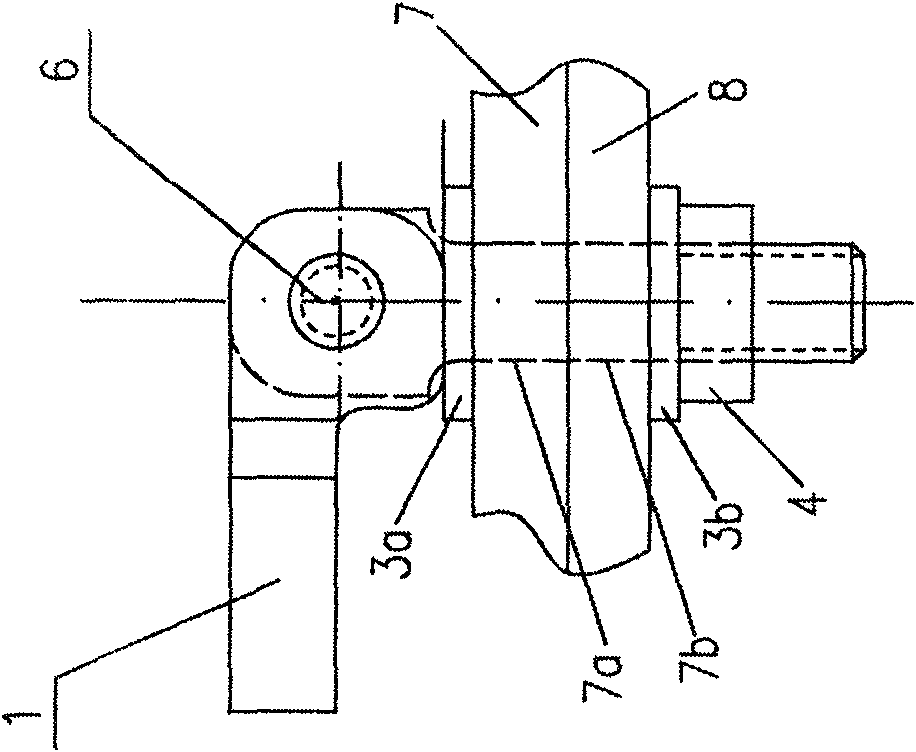

Screw tightening diagnostic device and electric driver

InactiveUS20110185864A1Quality is determinedWork reliablyMeasurement of torque/twisting force while tighteningWork measurementTime rangeEngineering

The present invention provides a screw tightening diagnostic device which can easily and reliably detect a state of incomplete screw tightening and can allow reliable screw tightening work to be performed. The screw tightening diagnostic device comprises rotational torque detection means for detecting that rotational torque occurring in a rotating shaft of an electric driver has reached a preset rotational torque within a predetermined time range past a minimum required screw-tightening time that has been set in advance according to the length of the screw being tightened, pressure force detection means for detecting that pressure force created by the electric driver pressing the screw when the screw is being tightened has reached a preset pressure force, and screw tightening diagnostic means for diagnosing that screw tightening has been performed in a normal manner when the rotational torque detection means detects that the preset rotational torque has been reached within the predetermined time range past the minimum required time and the pressure force detection means has detected the preset pressure force.

Owner:IDEKEIKI

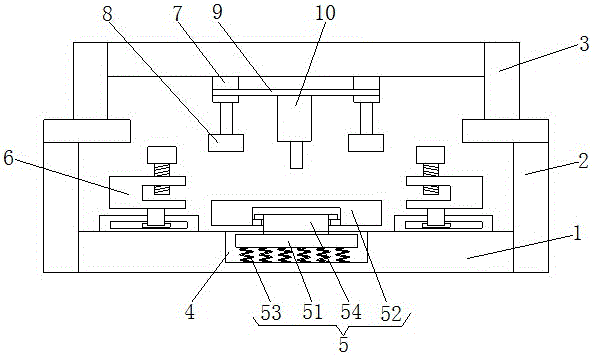

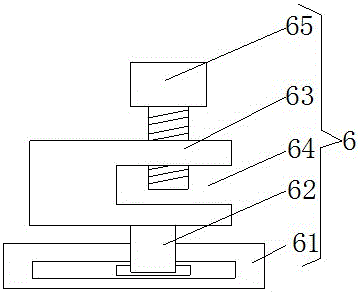

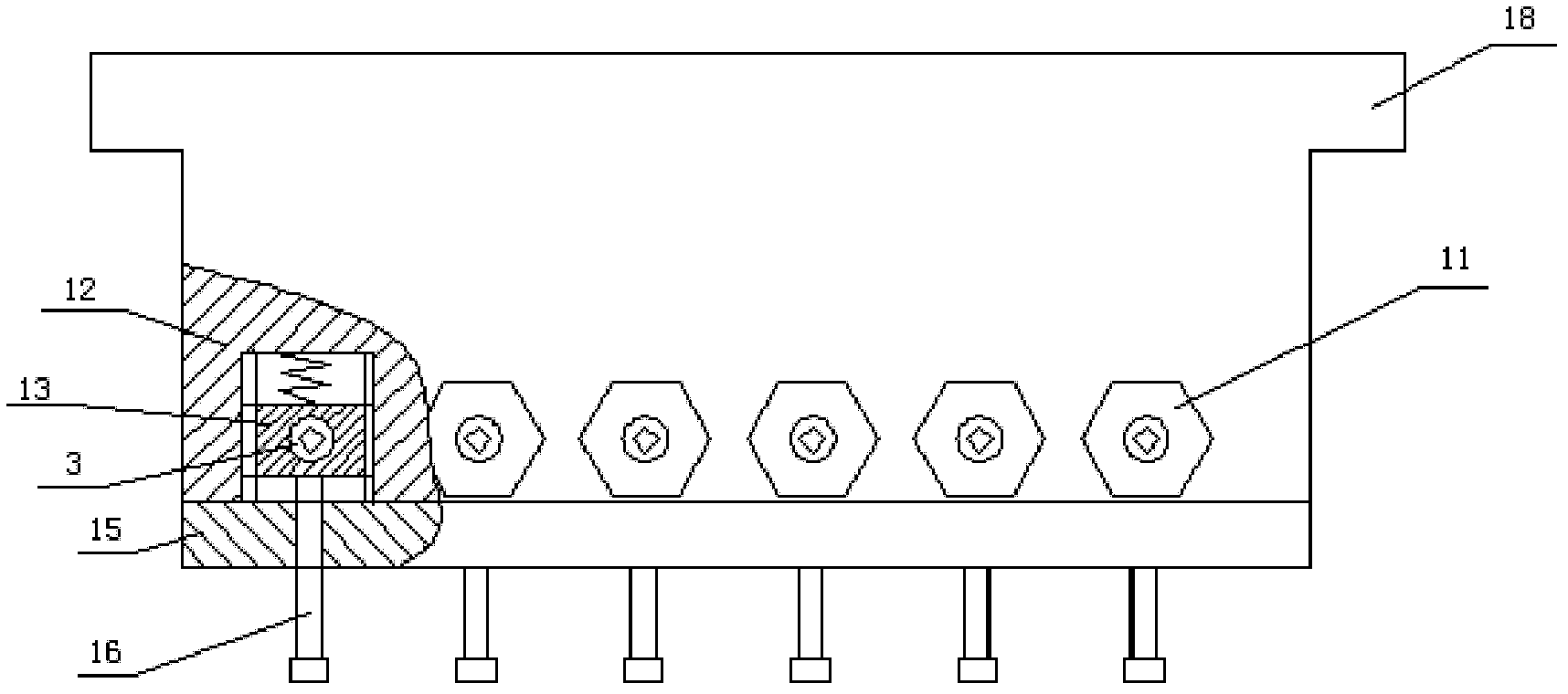

Hardware machining perforating machine

InactiveCN105689494APress firmlyEasy to compressMetal-working feeding devicesPositioning devicesBuffer tankEngineering

The invention discloses a hardware machining perforating machine. The hardware machining perforating machine comprises a chassis; fixed plates are fixedly mounted on two sides of the chassis; bearing plates are fixedly mounted at the tops of the fixed plates; a buffer tank is formed in the middle part of an inner cavity of the chassis; a mounting device is fixedly mounted in the buffer tank; the top end of the mounting device penetrates through the buffer tank to expose above the chassis; a pressing device is fixedly mounted on the upper surface of the chassis; two electric extension rods are fixedly mounted on the lower surfaces of the bearing plates; and lower pressing blocks are fixedly mounted at the bottoms of the two electric extension rods. The hardware machining perforating machine presses hardware objects more stably and more conveniently through arranging the electric extension rods, the lower pressing blocks and the pressing device, is matched with a mounting device to enable the pressing of the hardware objects to become more convenient and more stable and to enable the machining effect of the hardware objects to become better, reduces the machining errors of the hardware objects, and is higher in machining precision.

Owner:WUXI JIANLING ELECTRIC APPLIANCE CO LTD

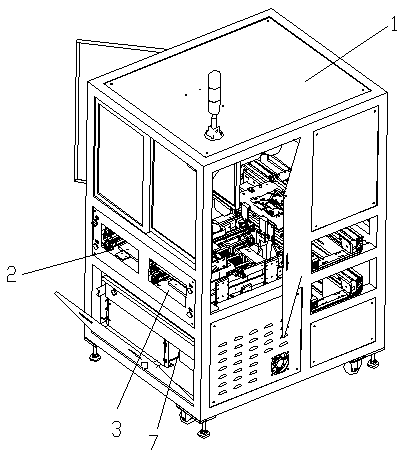

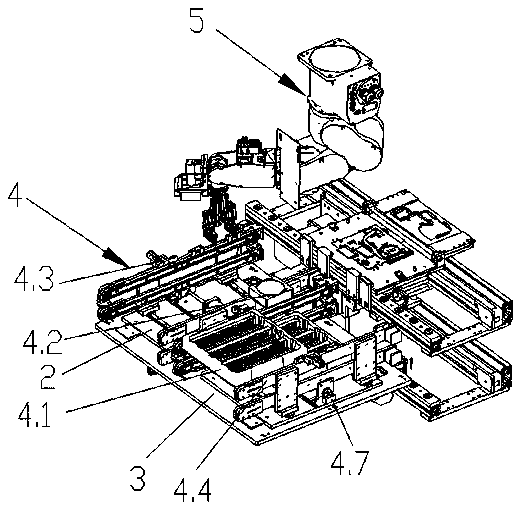

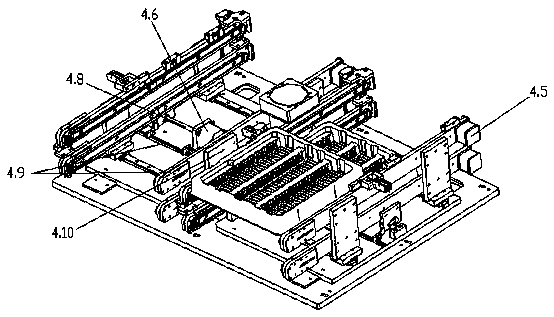

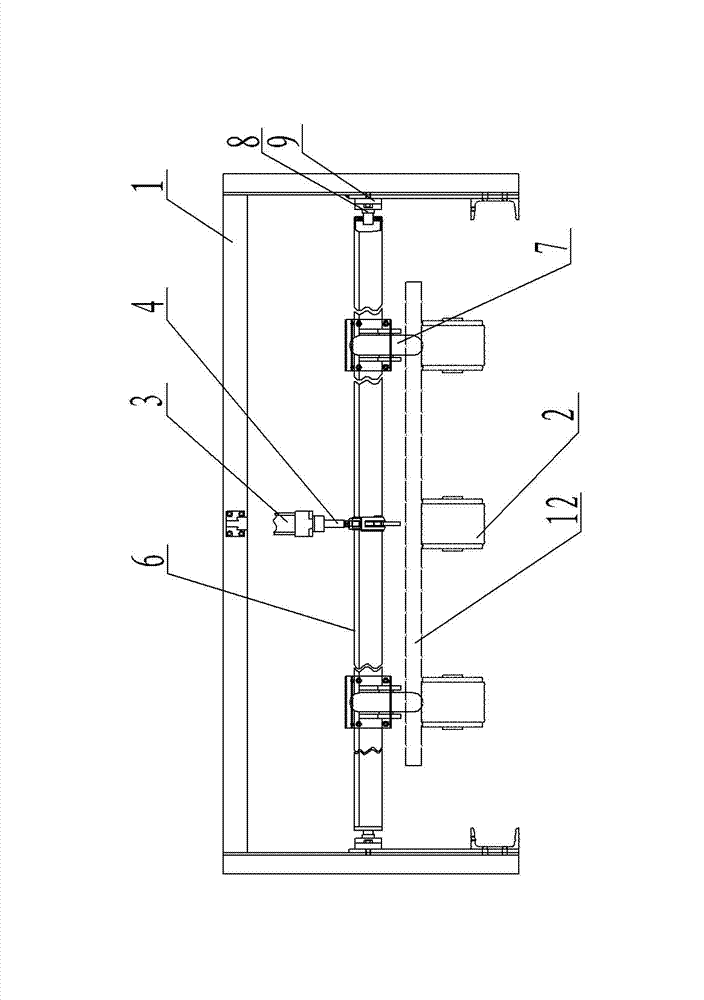

Automatic memory bar assembling machine for computer mainboard assembling

ActiveCN105499961AAccurate pressure settingPress firmlyMetal working apparatusControl systemEngineering

The invention relates to an automatic memory bar assembling machine for computer mainboard assembling and belongs to the technical field of production tools. The automatic memory bar assembling machine comprises a cabinet, and further comprises a material carrying input system, a robot grabbing system, a mainboard carrier conveying system and a control system which are arranged in the cabinet, a memory bar entry is arranged on the side face of the cabinet, the material carrying input system comprises two bilayer belt rails in side-by-side arrangement, and material trays arranged above the belt rails, input ends of the belt rails are connected with the memory bar entry, the mainboard carrier conveying system is arranged on one side of the material carrying input system and connected with output ends of the belt rails, the robot grabbing system is arranged above the material carrying input system and the mainboard carrier conveying system, and the control system is arranged at the bottom in the cabinet. By using the automatic memory bar assembling machine, a memory bar can be arranged in a memory slot of a mainboard in a pressing manner accurately and firmly, so that finished product rate of memory bar assembling is increased.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

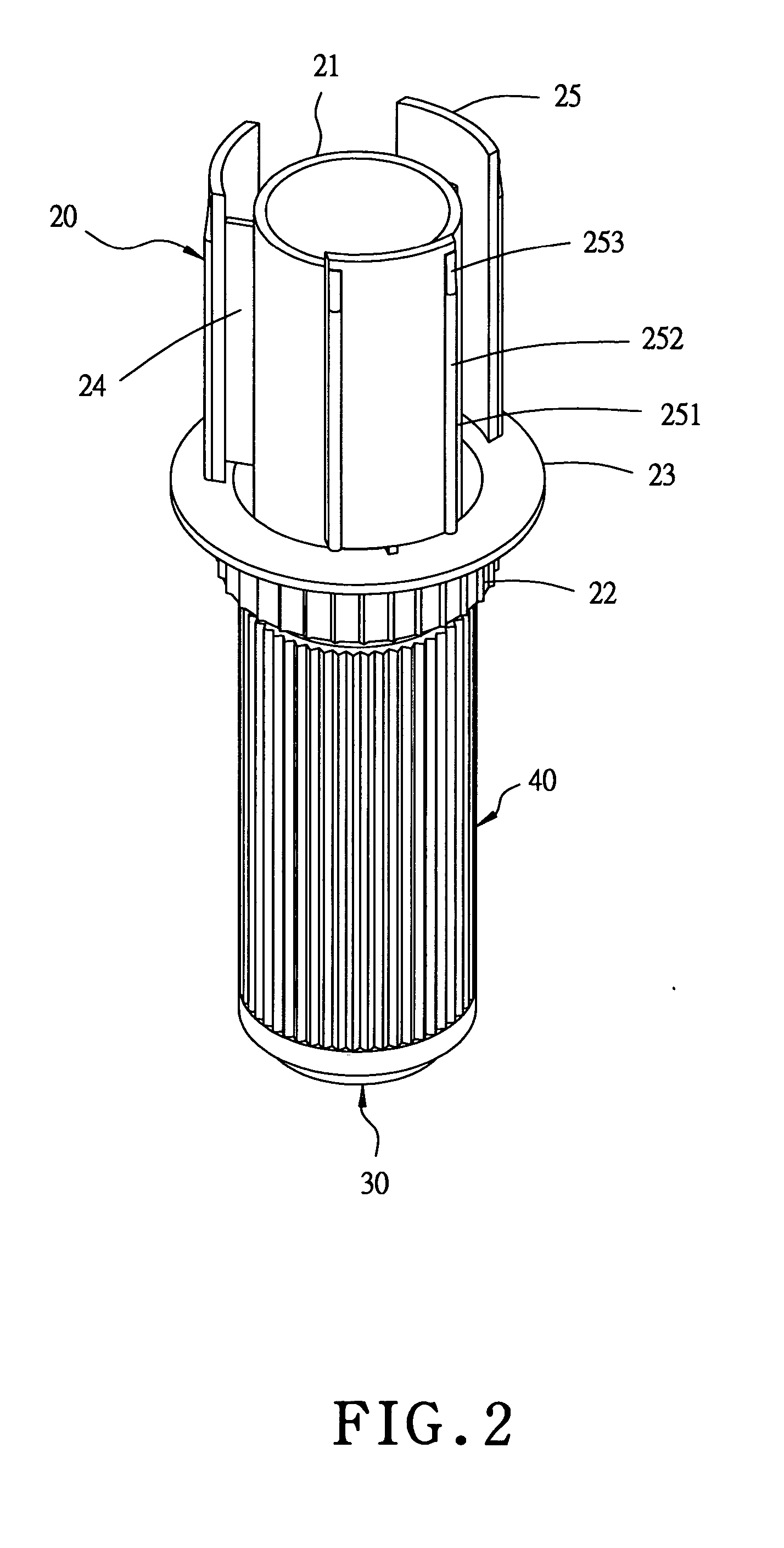

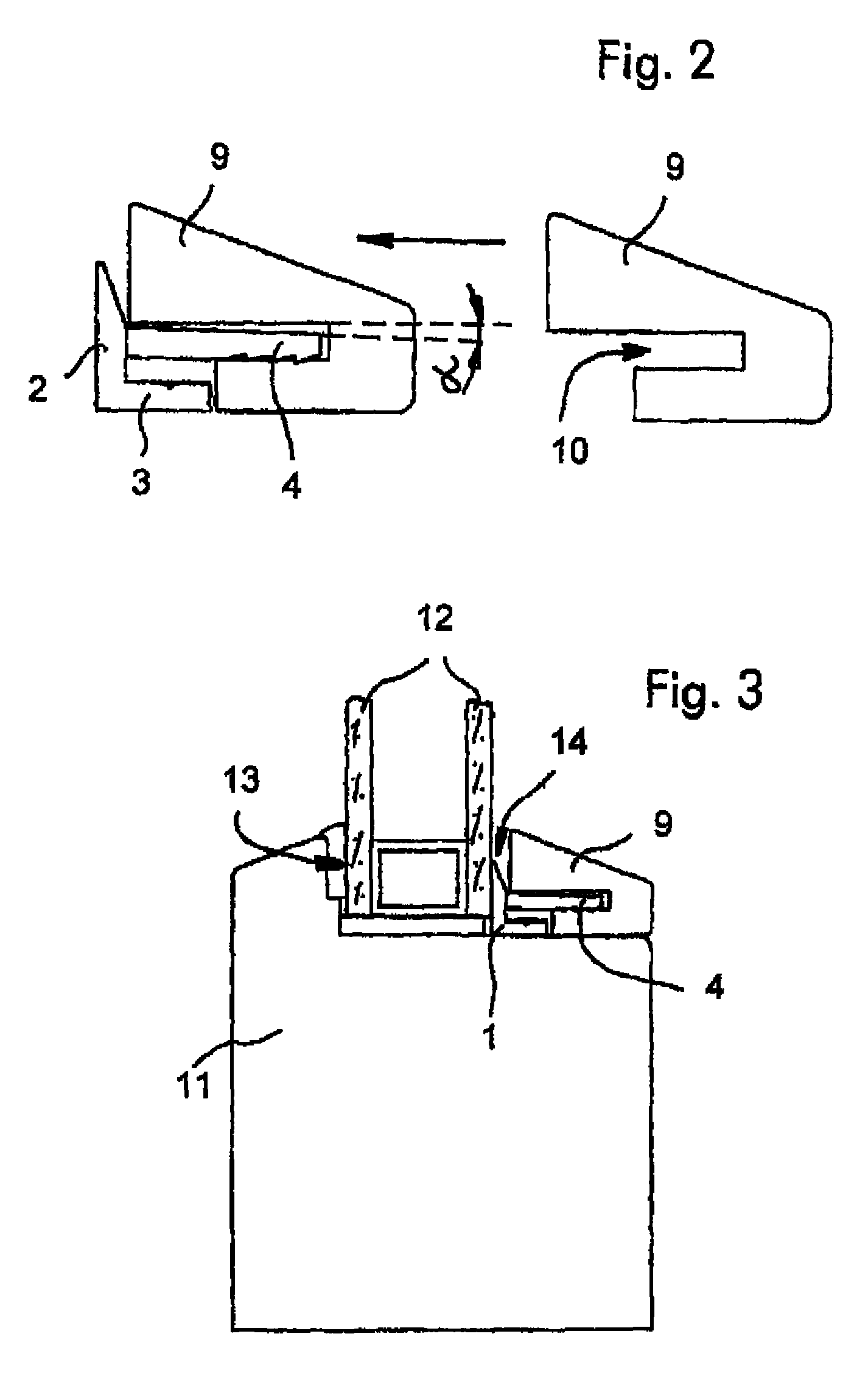

Membrane reel fixing device for a membrane strapping dispenser

InactiveUS20060278751A1Press firmlyContainers for annular articlesFilament handlingEngineeringMechanical engineering

A membrane reel fixing device for a membrane strapping dispenser includes a reel pivot having its outer circumference formed integral with three support ribs respectively connected with a convex holding plate extending along the circumference of the reel pivot. The three holding plates have their lower sides suspended in midair; therefore, when pressed diametrically, the holding plates can be elastically shifted and deformed and after a membrane reel is fitted on the reel pivot, the holding plates can firmly prop the inner wall of the central tube of the membrane reel. Different-sized membrane reels can be firmly fitted on the reel pivot by means of the holding plates that can be elastically shifted and deformed.

Owner:CHEN HSIU MAN YU

Fixture for elbows with space curves as axes

InactiveCN102581665ASimple structureEasy to usePositioning apparatusMetal-working holdersScrew threadIndustrial engineering

The invention discloses a fixture for elbows with space curves as axes. The fixture comprises a fixture main body, a supporting and adjusting mechanism and a clamping device. The fixture main body is used for fixing and consists of a fixture body and pressing edges with holes. the pressing edges are arranged at two edges of the fixture body, the fixture body and the pressing edges are integrated, the fixture body is fixed onto a worktable by bolts via the holes at the pressing edges, the supporting and adjusting mechanism consists of sliders, slider supporting guide plates, slide grooves, springs, pressure plates, adjusting bolts and fixing screws, the clamping device comprises screw stems, the screw stems are symmetrically arranged on upper end surfaces and lower end surfaces of the slider supporting guide plates and are connected with the corresponding sliders in a threaded manner, first locking nuts and second locking nuts are arranged at joints of the upper portion of the screw stems and outer end surfaces of the slider supporting guide plates, and V-shaped chucks are disposed at lower ends of the screw stems. The fixture is simple in structure and convenient in use and maintenance, can firmly and reliably compress the elbows with optional space curves as axes, and brings convenience for machining.

Owner:WUXI INST OF COMMERCE

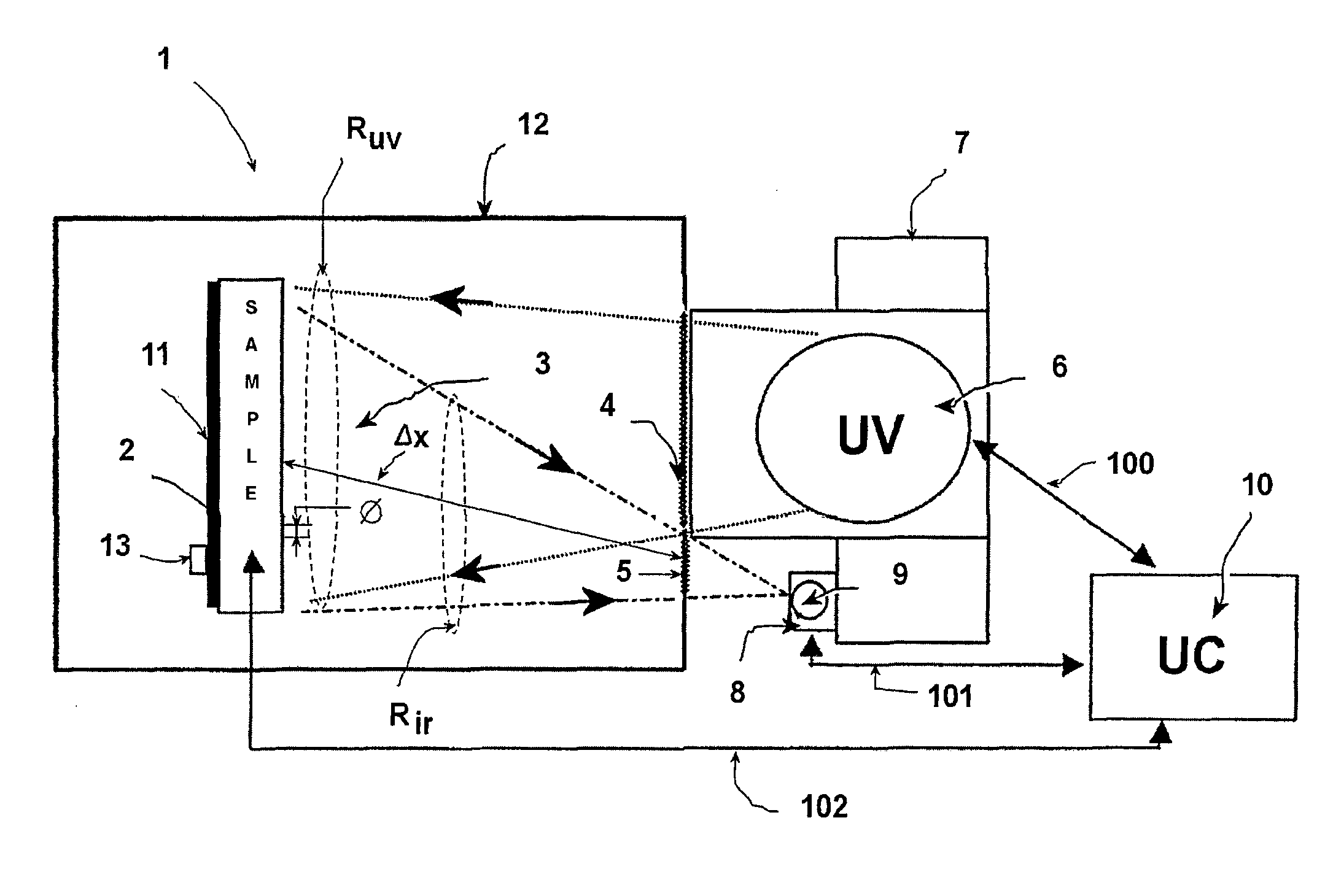

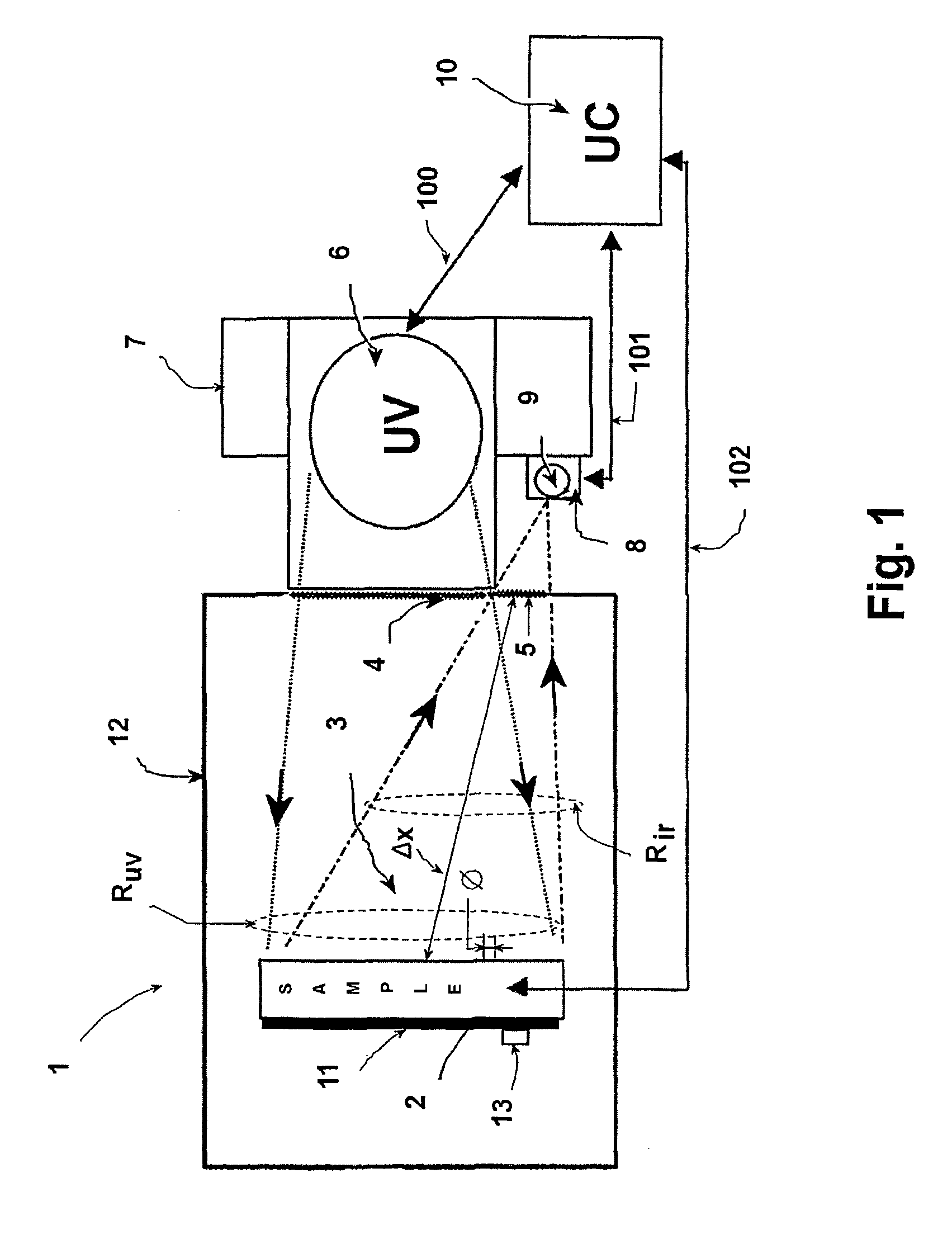

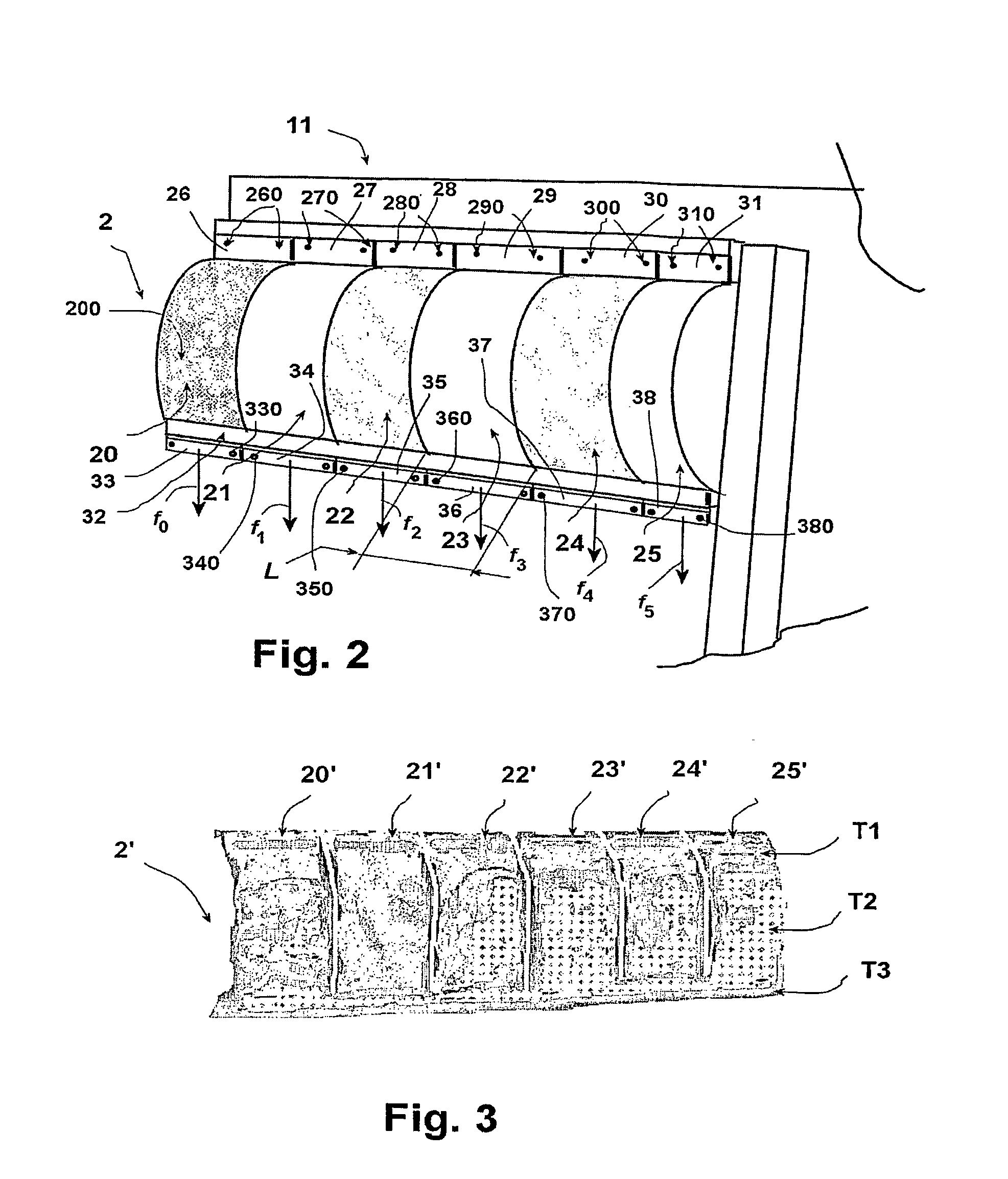

Equipment for Non-Contact Temperature Measurement of Samples of Materials Arranged Under Vacuum

InactiveUS20080224044A1Improve reflectivityIncrease freedomRadiation pyrometryMaterial analysis by optical meansMaterial DesignMeasurement point

The invention concerns an equipment for non-contact temperature measurement (1) of samples of materials (2) arranged in a vacuum chamber (12). A UV lamp (6) illuminates the samples (2) through a window (4), so as to subject them to a predetermined thermal cycle and to perform an environmental test, in particular for materials designed for space missions. An external pyrometer measures the temperature of the samples (2) through a window (6). It is associated with a scanning module (9) including a mobile mirror, with two axes of rotation and three orthogonal axes of translation, arranged on the optical path of the infrared radiation (Rir) so as to obtain a two-dimensional scanning of each sample (2) by means of a measuring spot focused on the surface of the samples. In a preferred embodiment, the samples are of slight thickness and locked pressed against a convex support The whole assembly is monitored by an automatic data processing system with recorded programme (10).

Owner:EUROPEAN SPACE AGENCY

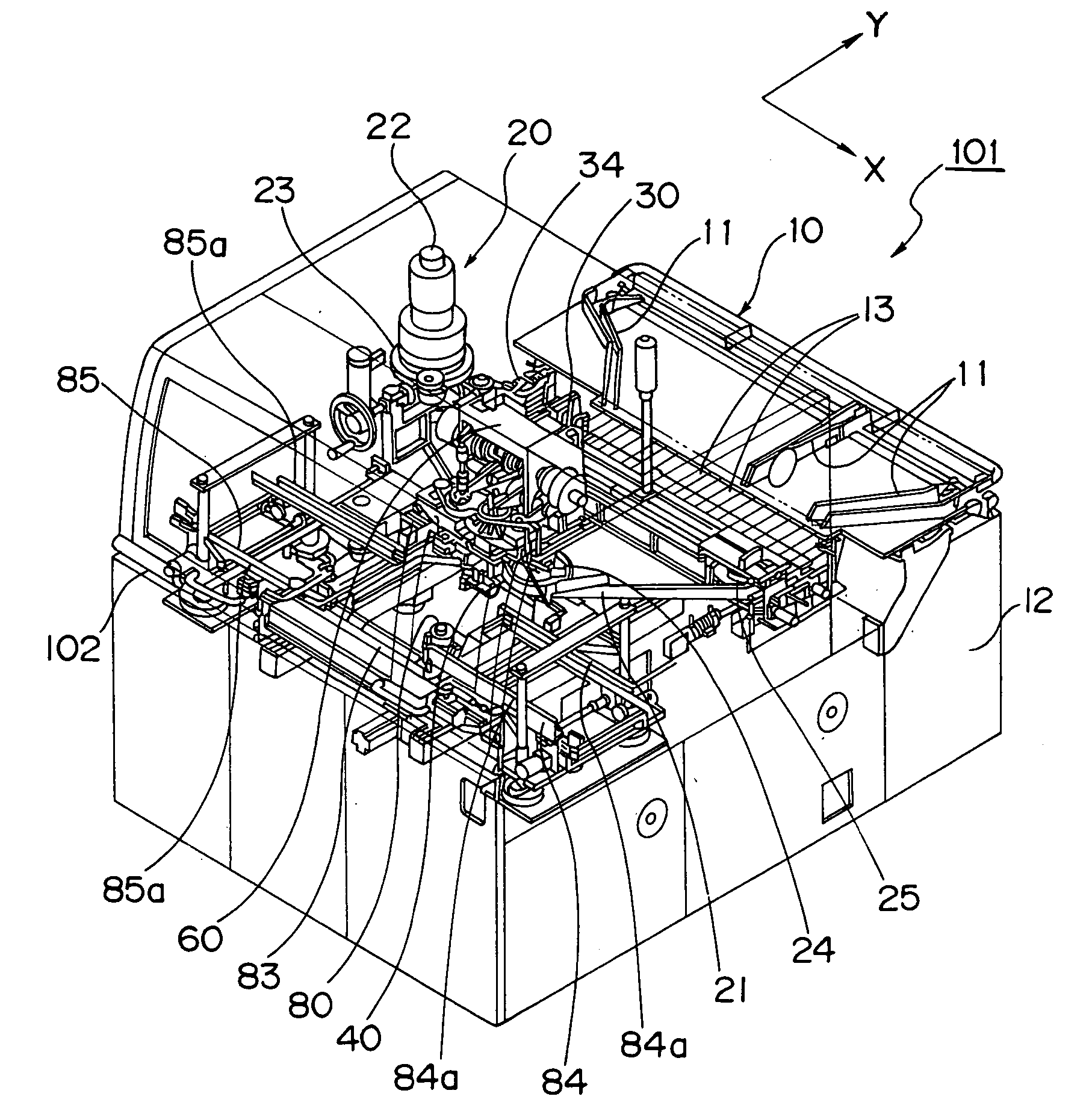

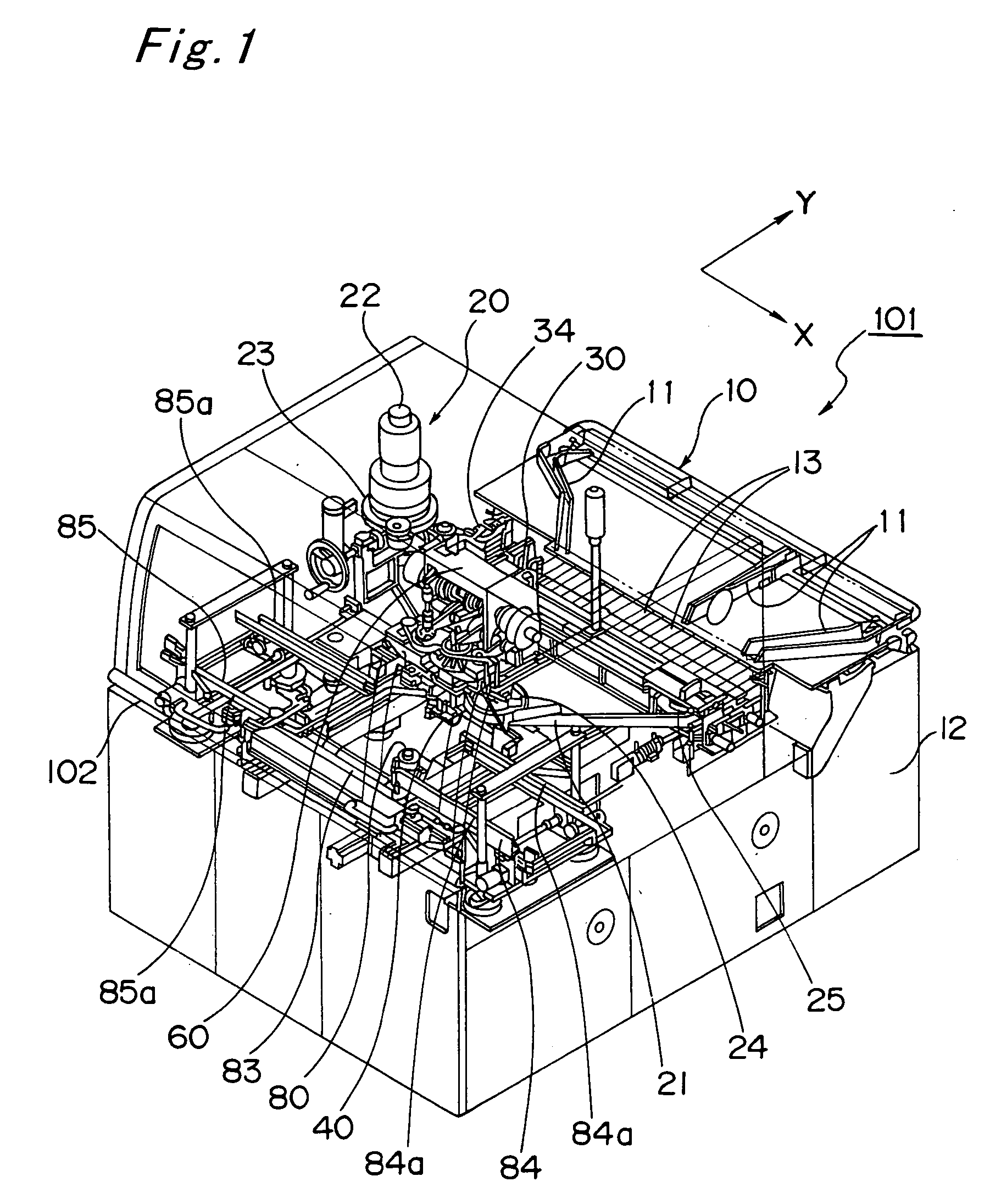

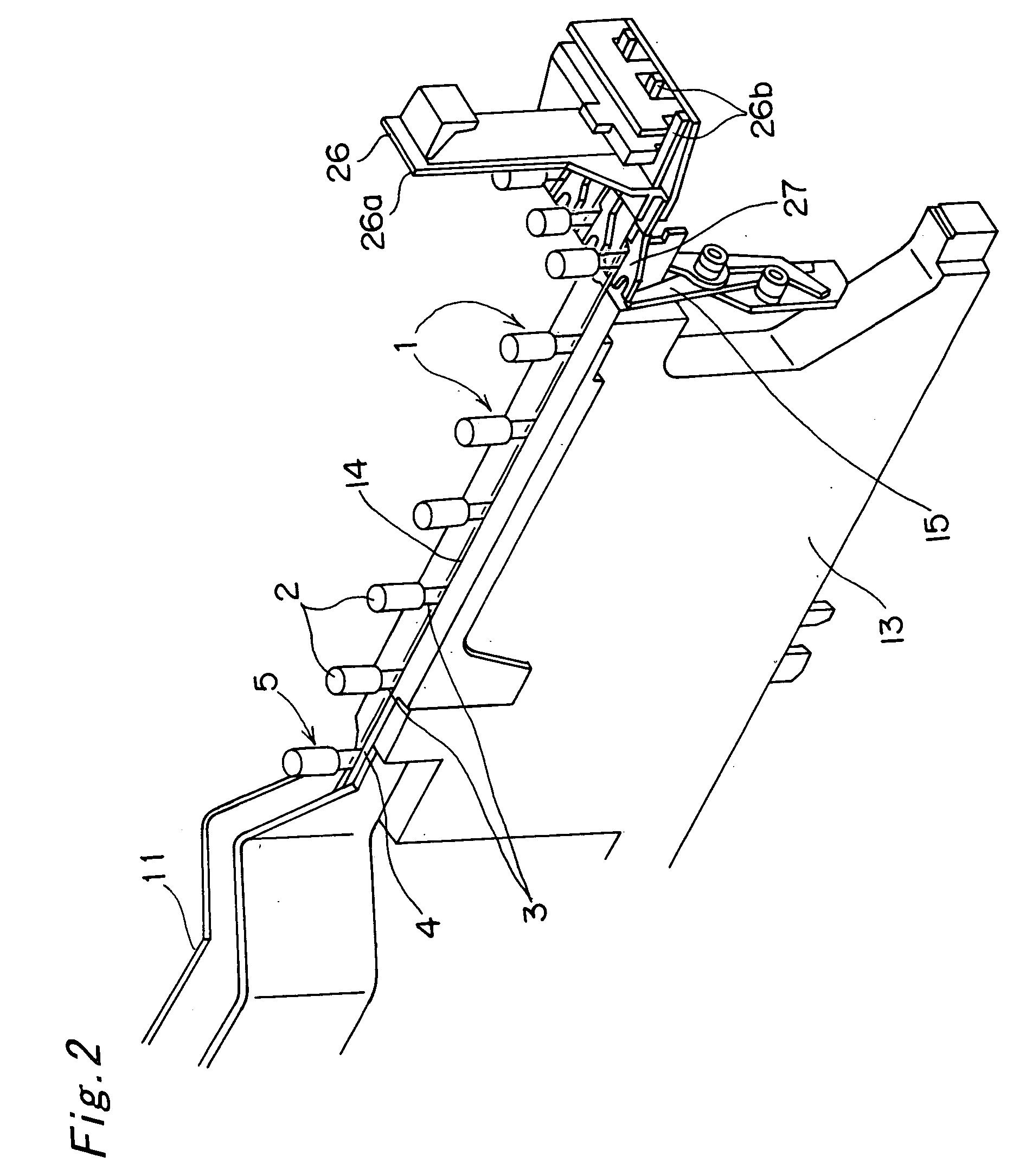

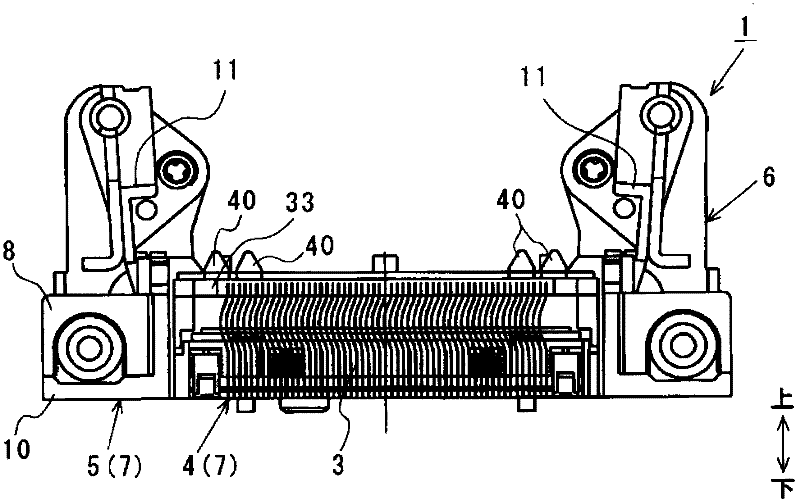

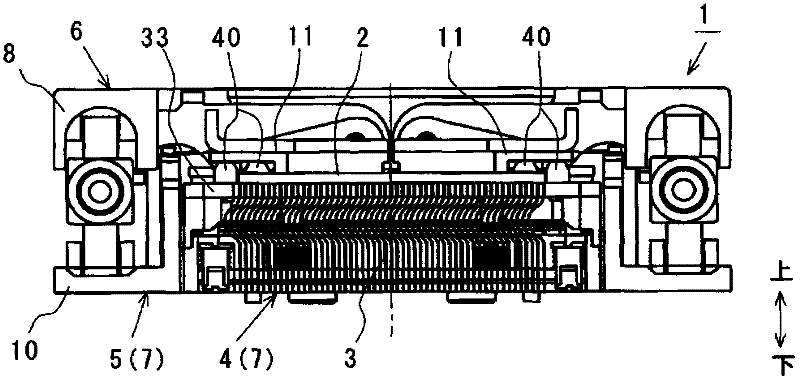

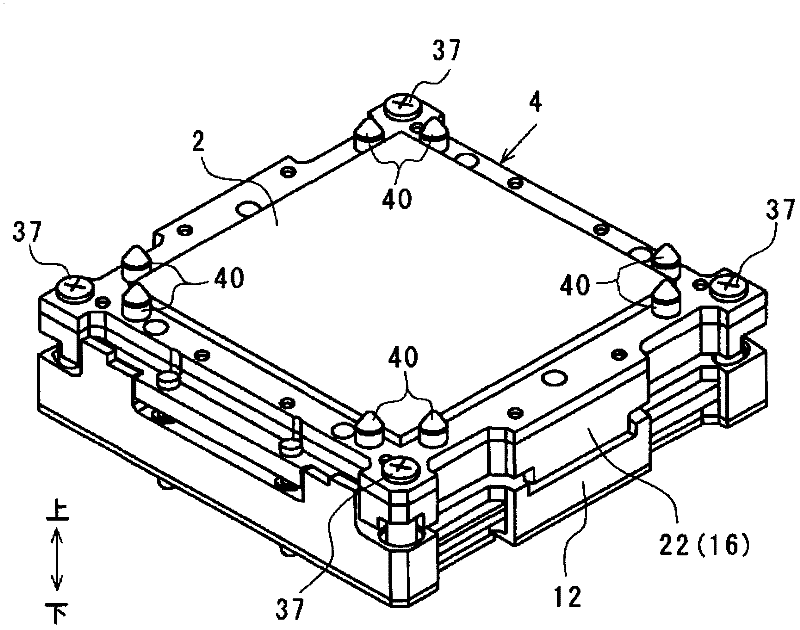

Part inserting head device, part inserting device, and part inserting method

InactiveUS20060164794A1Precise bendingAccurate insertionPrinted circuit assemblingSubstation/switching arrangement detailsProduction rateBiomedical engineering

In a component insertion apparatus, there are provided a component insertion apparatus and a component insertion method capable of realizing productivity improvement by simplifying apparatus construction, downsizing the apparatus and further reducing the time required for component insertion. In a component insertion head, by grasping of a device portion of a component by a device chuck, a lead wire is stretched on a fulcrum given by a grasping position of the lead wire by a transfer chuck so that the device portion comes to be placed at a component insertion position, by which correction of insertion posture of the component is performed, and the lead wire of the component that has been corrected in its insertion posture is inserted into an insertion hole of a board.

Owner:PANASONIC CORP

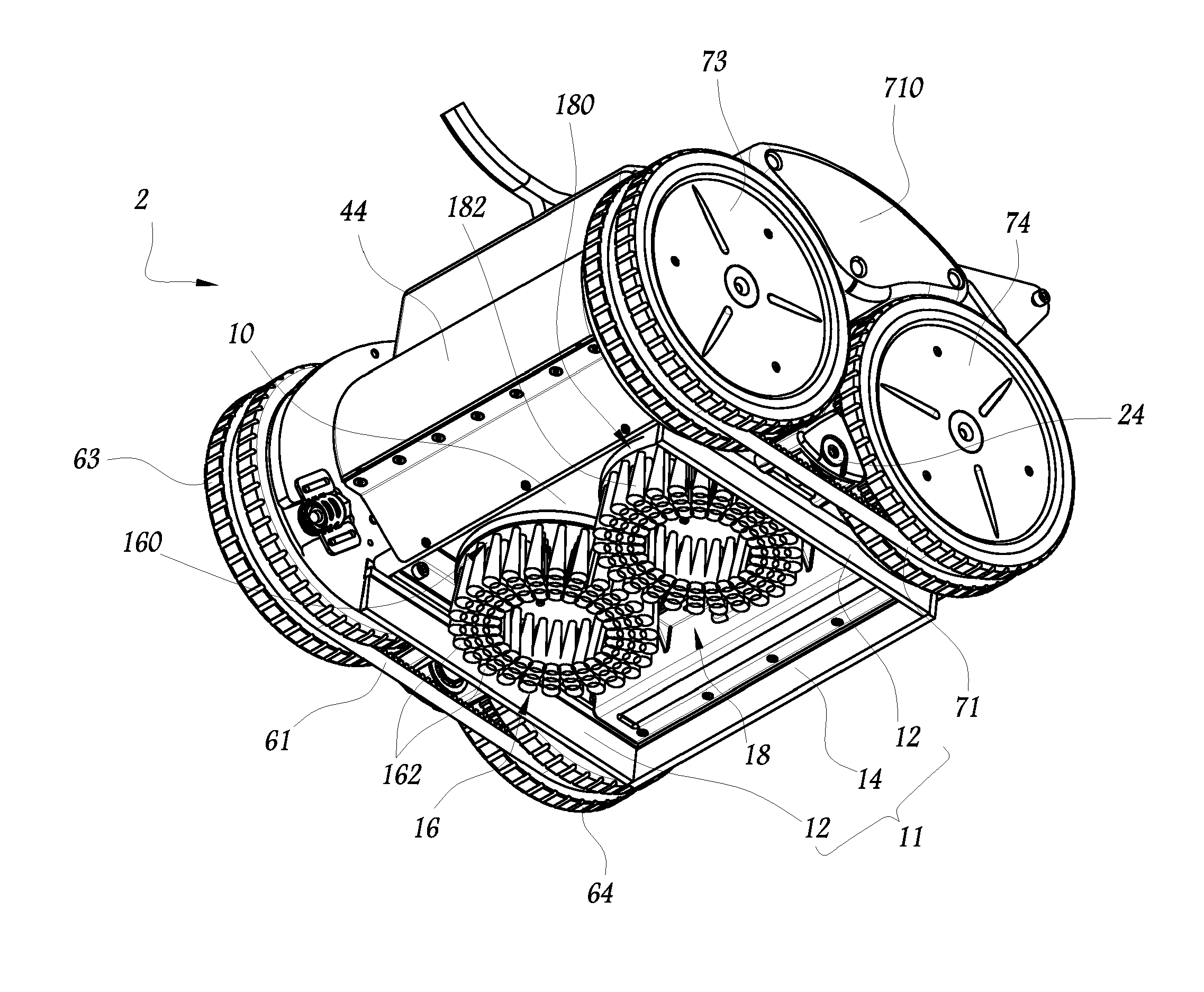

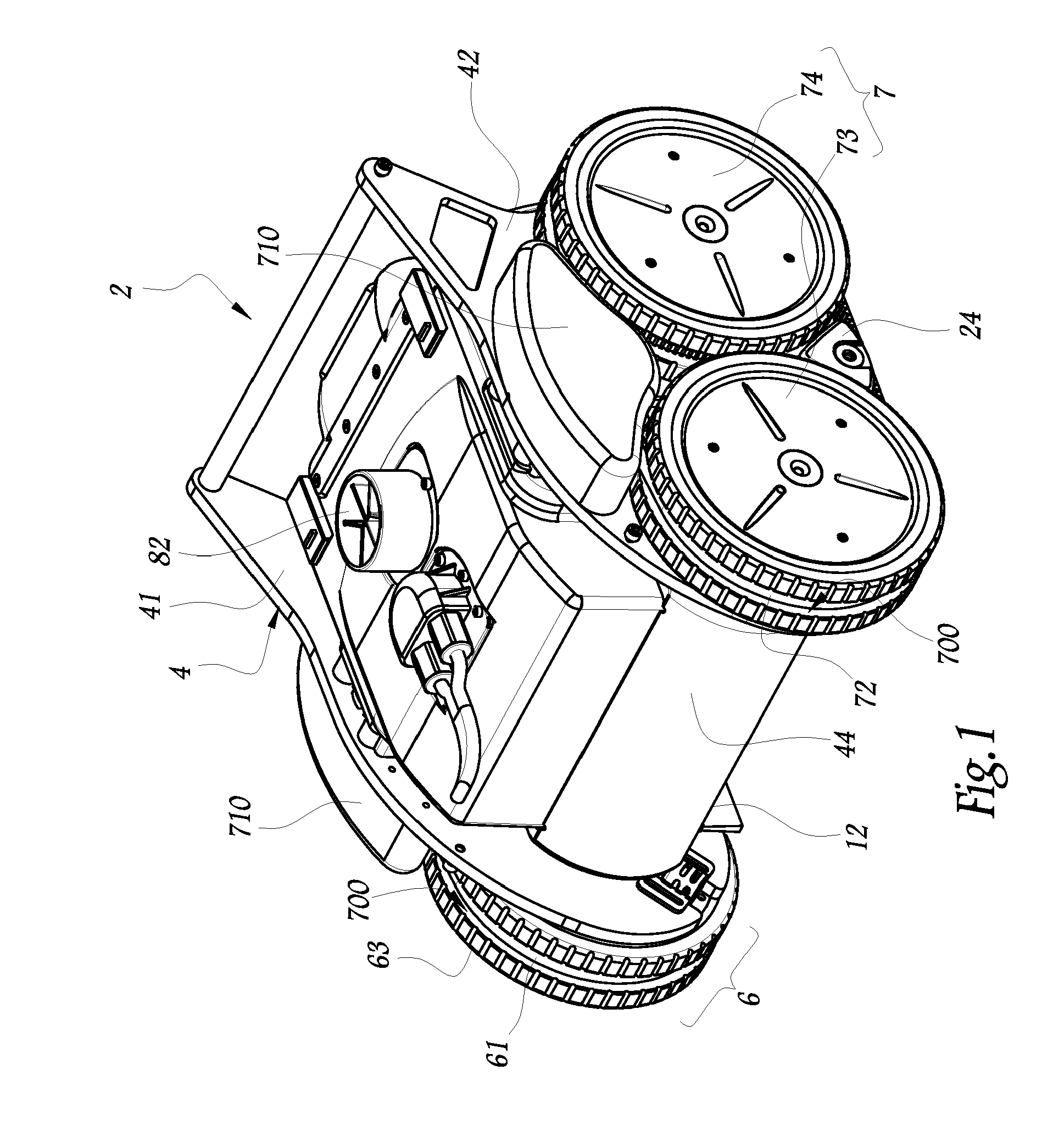

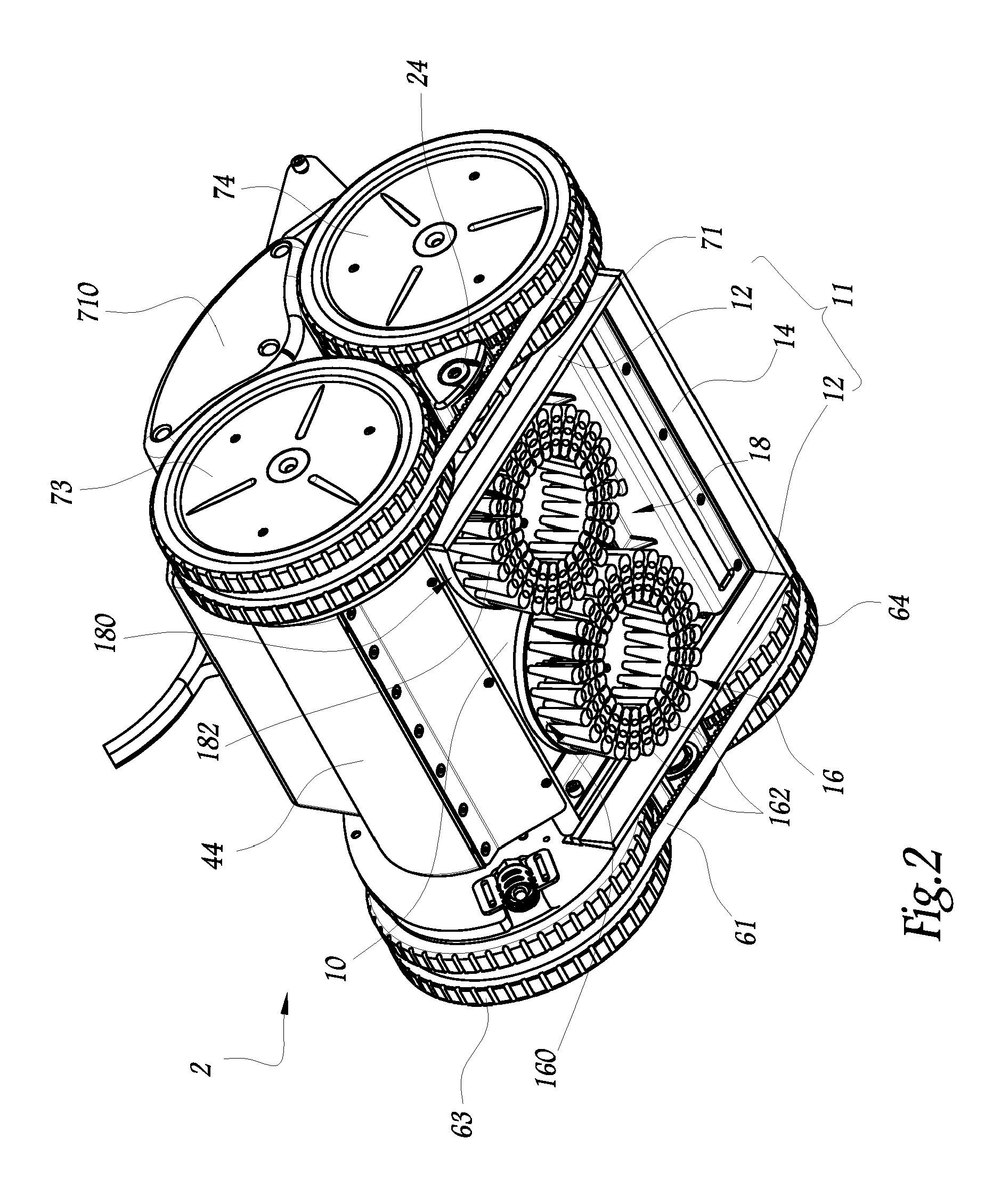

Underwater vehicle for cleaning submerged surfaces

InactiveUS20140116316A1Inexpensive and effectivePress firmlyVessel cleaningHullsUnderwater vehicleTranslatory motion

This underwater vehicle for cleaning submerged surfaces comprises a chassis and at least one brush for cleaning the surface to be cleaned, rotationally driven by a motor about an axis of rotation of this brush, the brush being able to move, with respect to a fixed part of the vehicle, in a translational movement along its axis of rotation in such a way that it can be pressed firmly against the surface to be cleaned under the effect of a vacuum created by the rotation of the brush, the brush comprising a rotation shaft inserted into a sleeve that rotates as one with the brush and rotationally driven by a drive system, the brush rotating as one with the sleeve because of fingers fixed to the sleeve and inserted into holes of the brush with the possibility of sliding parallel to the axis of rotation of the brush.

Owner:HULLTIMO

Bolt device being quickly fastened and disassembled

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT

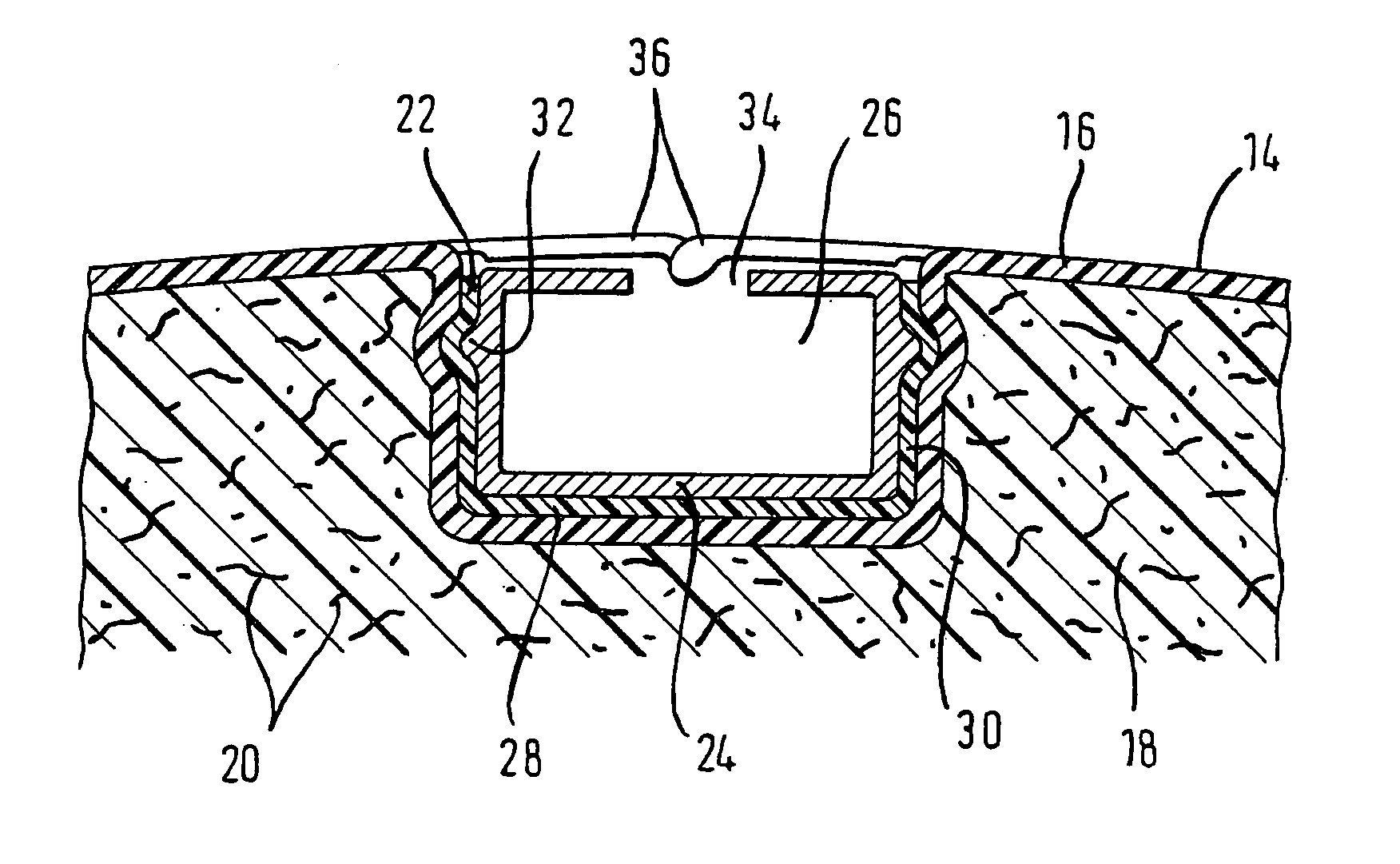

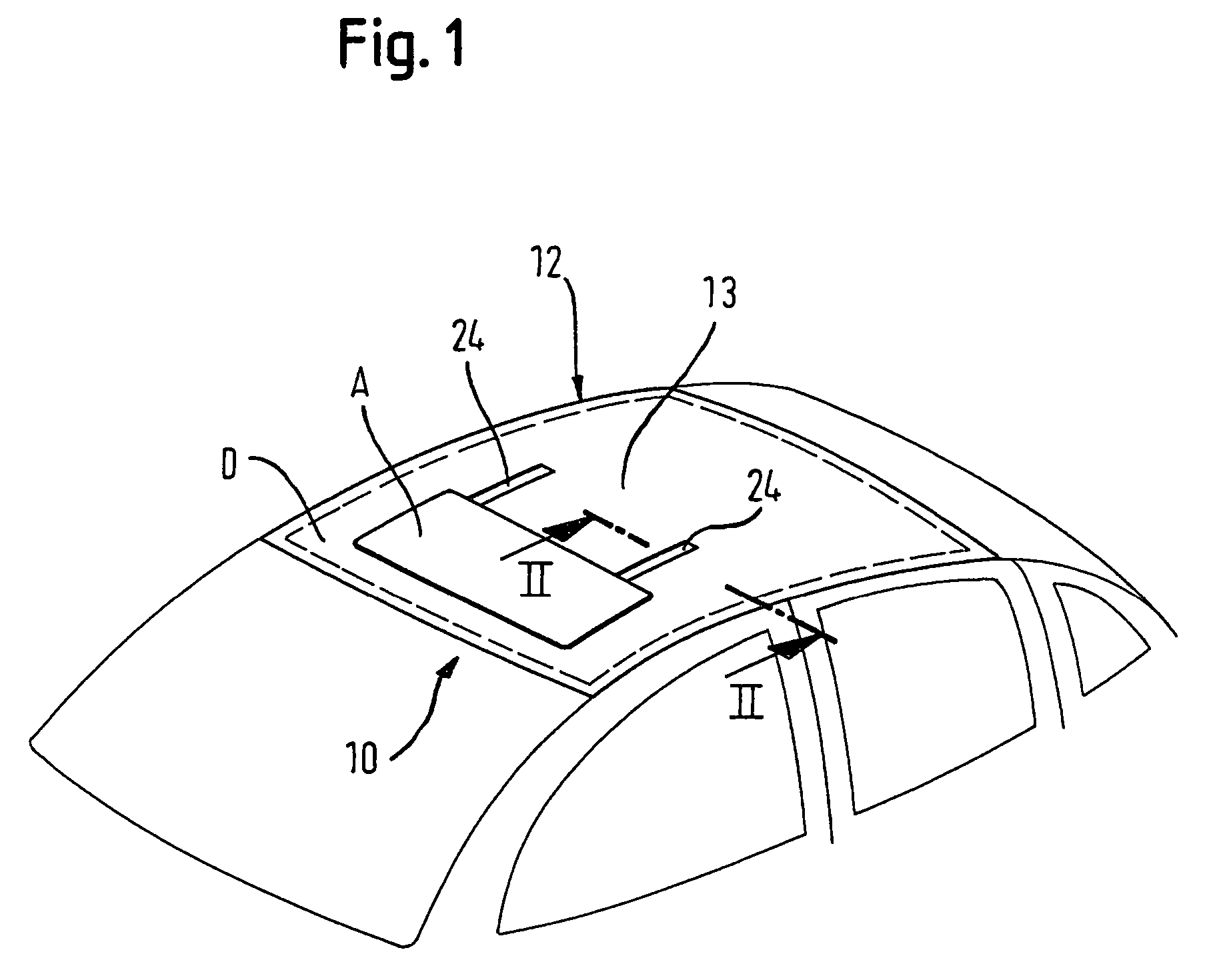

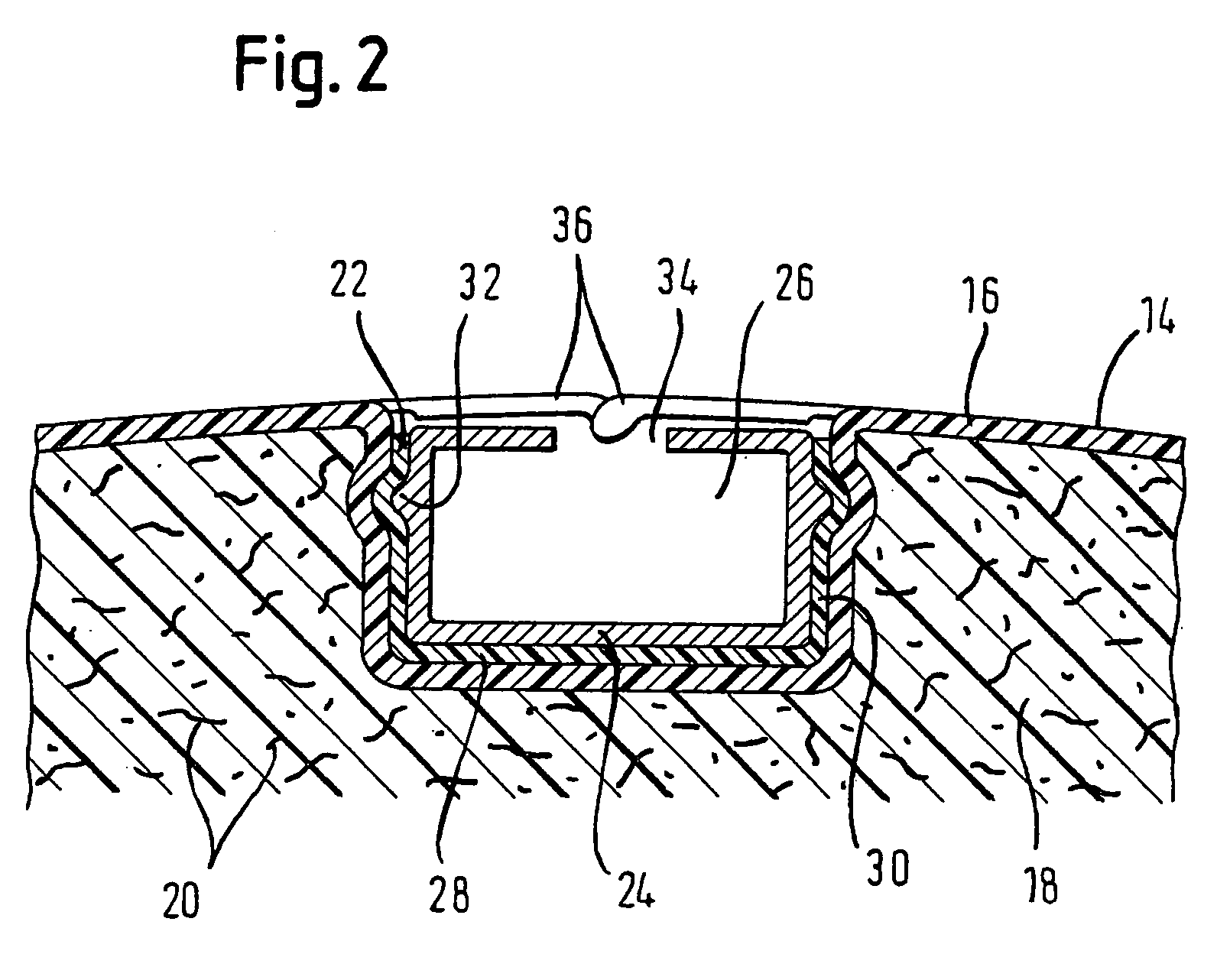

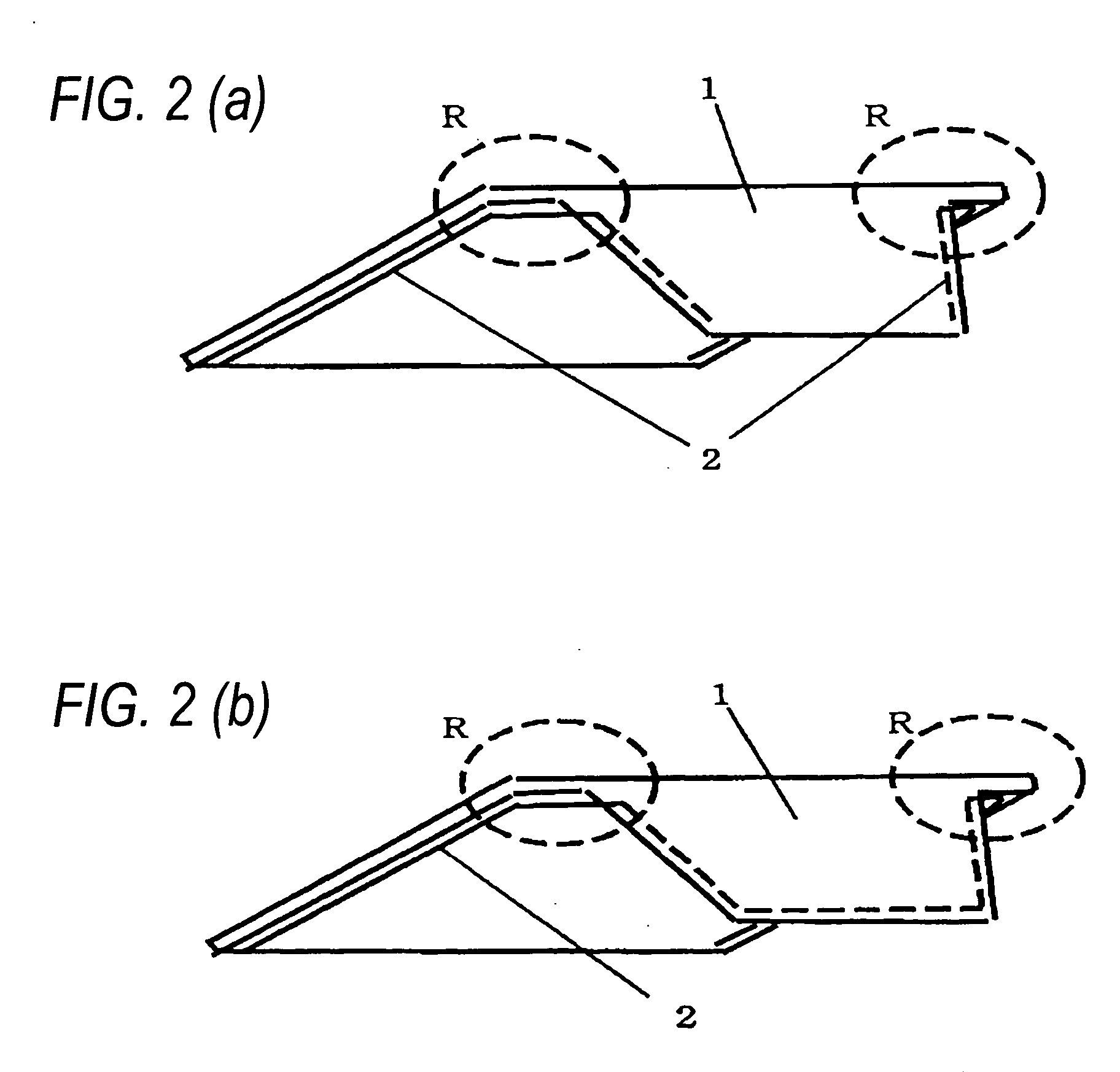

Composite component, in particular, a car body attachment part for a motor vehicle

InactiveUS7201436B2Prevents any undesirable, irritating side noiseDirect contact guaranteeSuperstructure subunitsRoofsMobile vehicleMotor vehicle part

The invention relates to a composite component and a method of producing such composite component, in particular a car body attachment part for a motor vehicle, which includes an outer skin that is defined by an outer skin foil associated with the motor vehicle. An inner layer made of plastic is applied to a rear side of the outer skin foil by providing a foamed or injection-molded backing. A mounting piece is disposed in a depression of the outer skin foil and is anchored therein. An intermediate foil is situated between the mounting piece and the outer skin foil and prevents, at least in sections, any direct contact between the mounting piece and the outer skin foil.

Owner:ROOF SYST GERMANY

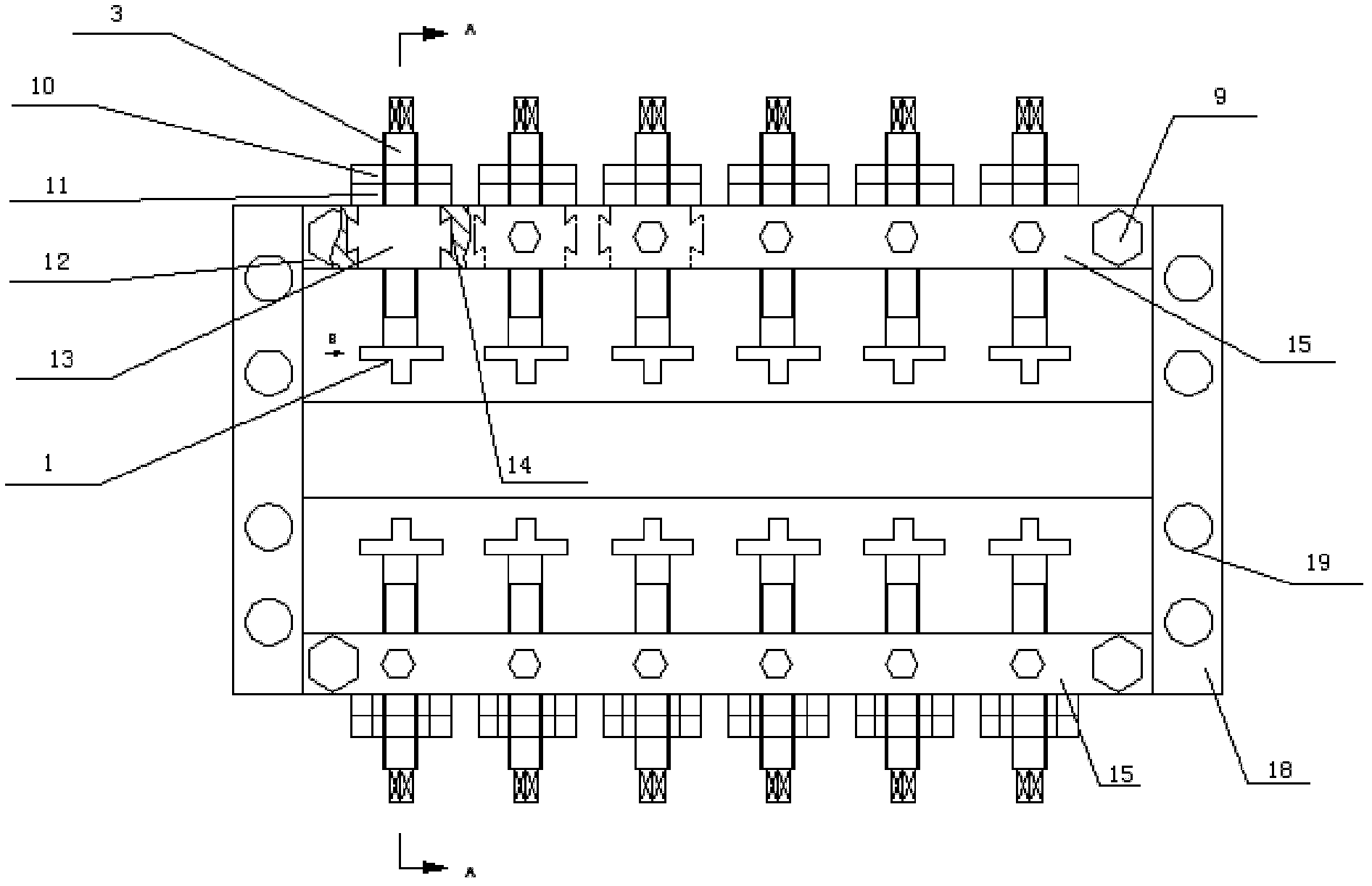

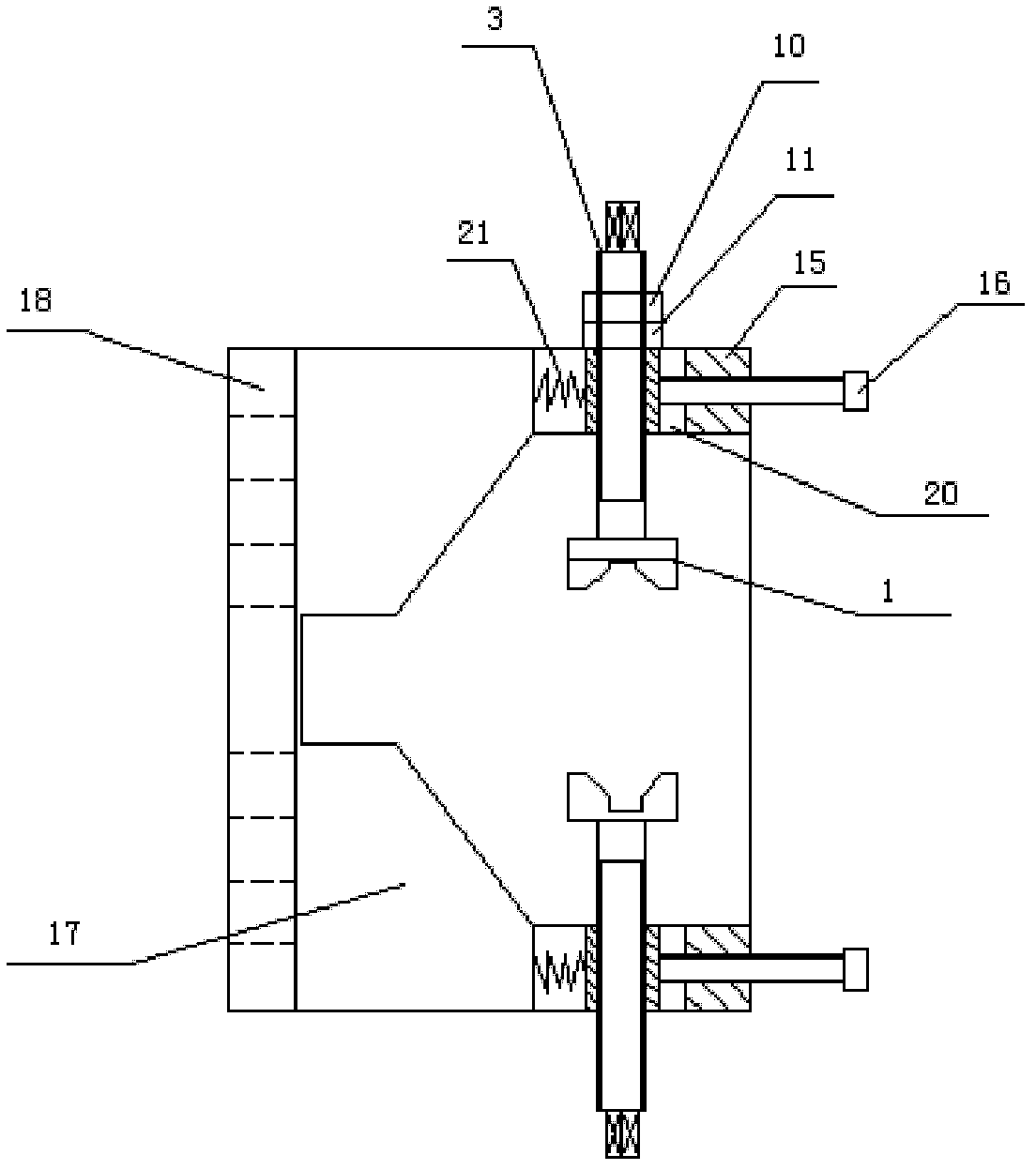

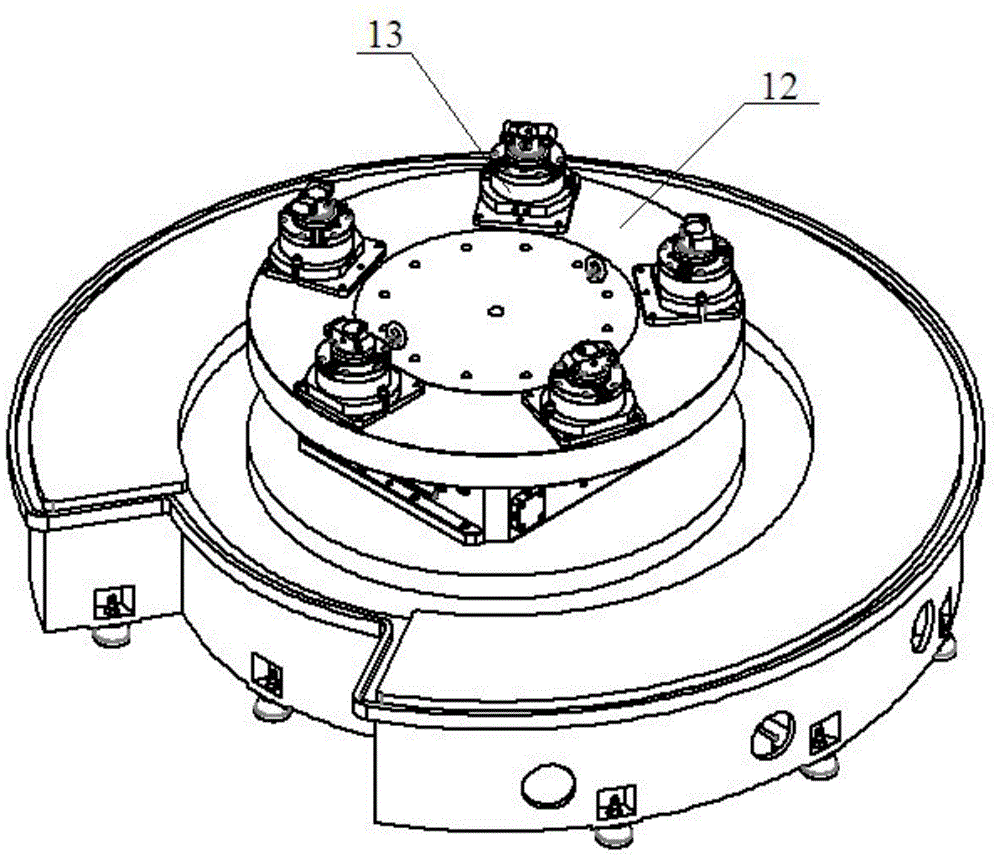

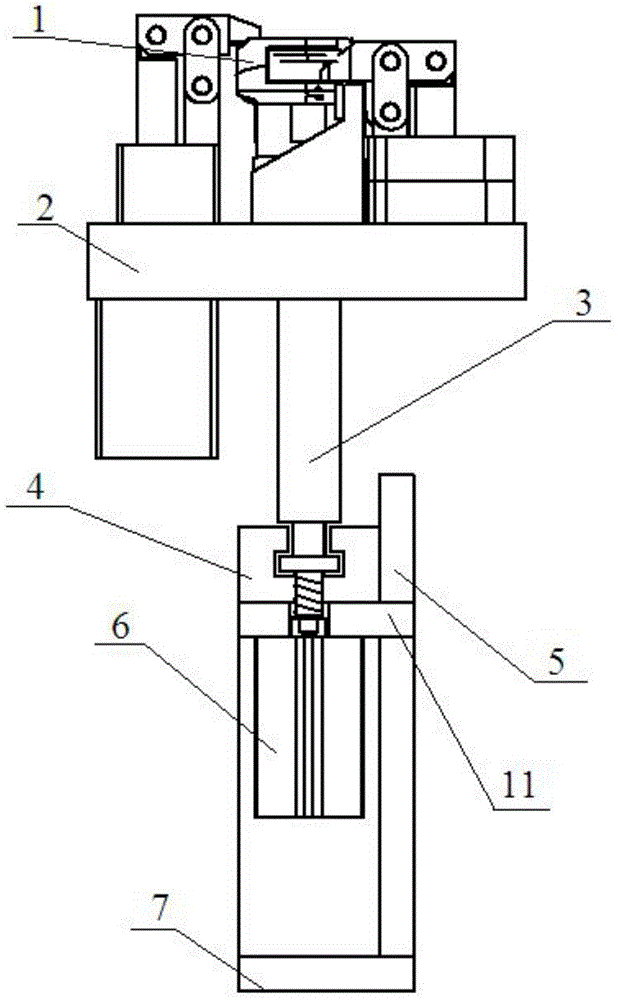

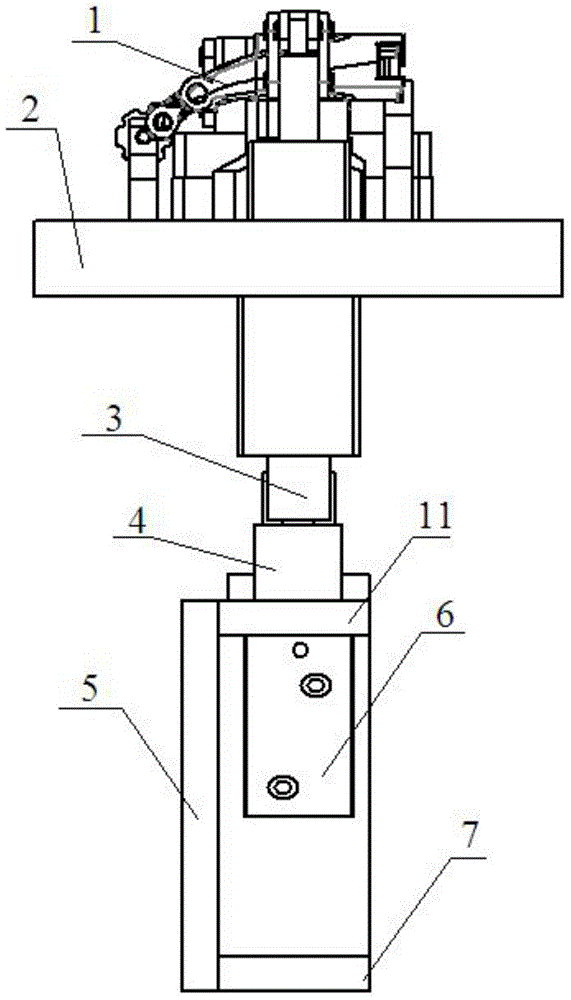

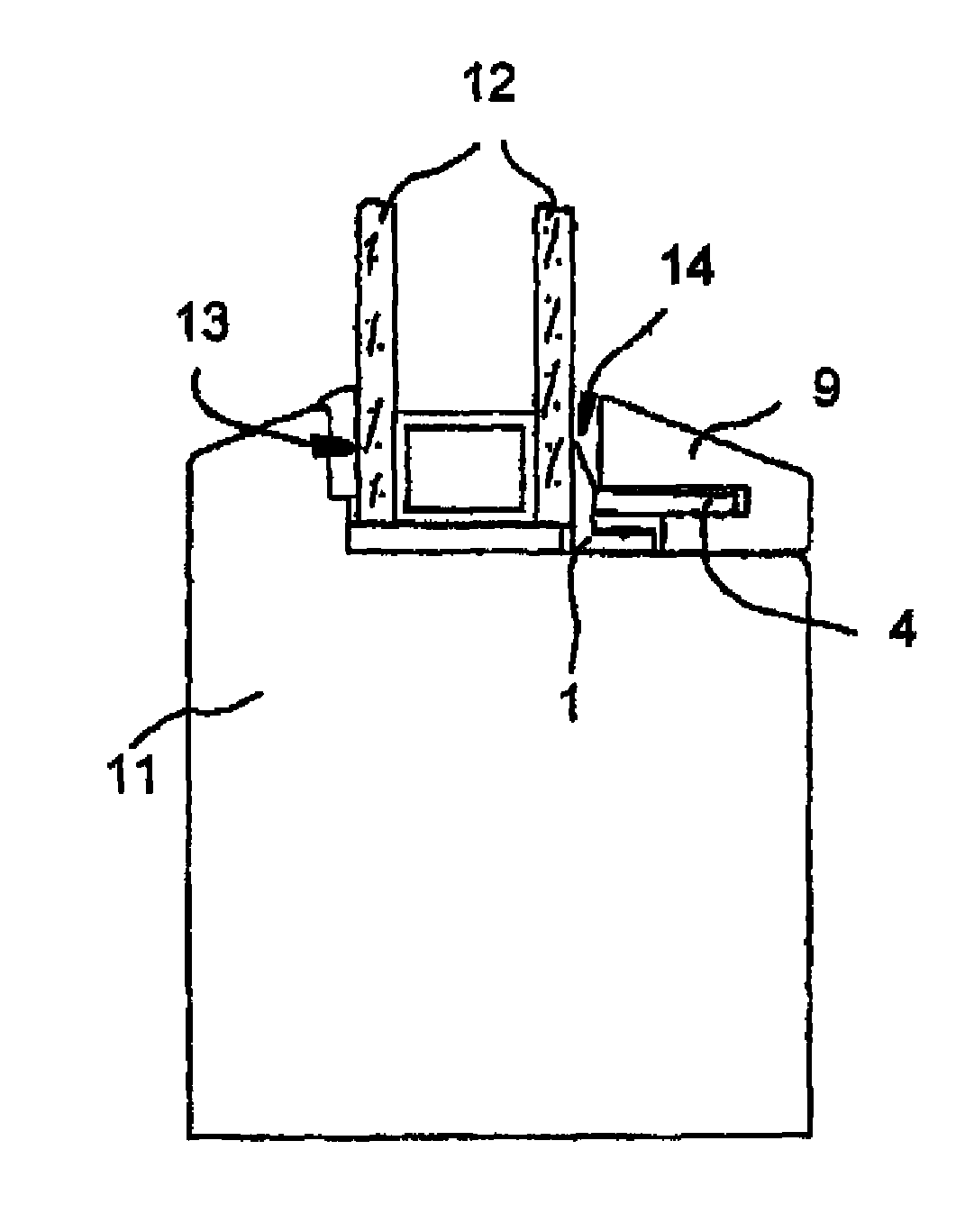

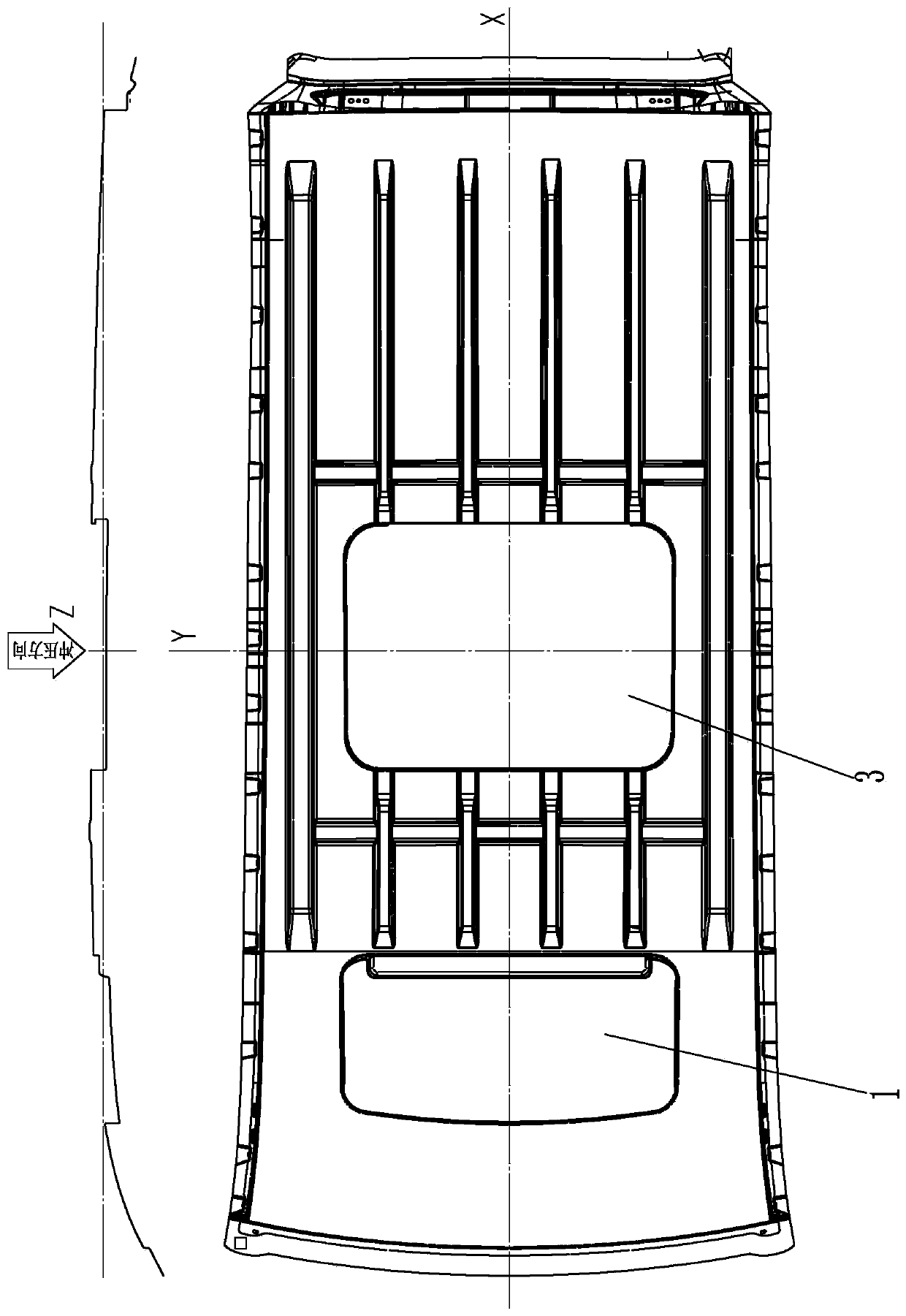

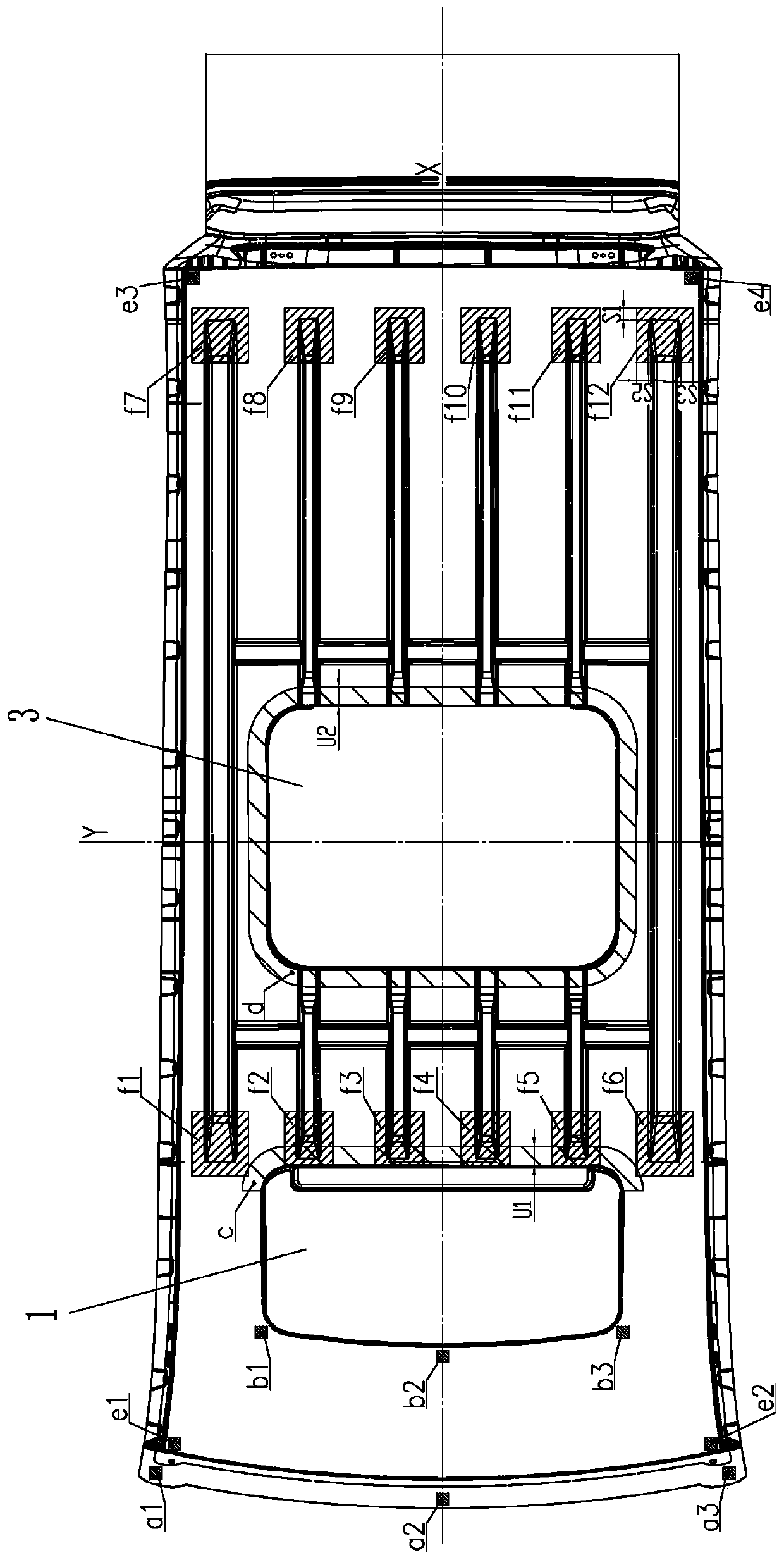

Multi-station machine tool for machining air intake and exhaust rocker arms of automobile and air intake and exhaust rocker arm machining method thereof

ActiveCN104476331AGuaranteed uptimeRealize automatic positioning and pressingMetal working apparatusPositioning apparatusEngineeringMachine tool

The invention discloses a multi-station machine tool for machining air intake and exhaust rocker arms of an automobile. The multi-station machine tool comprises workpiece air intake and exhaust rocker arms and a disc type turntable base which is placed on a worktable of the machine tool and can turn around an axis, wherein a plurality of machining stations which are located through workpiece air intake and exhaust rocker arm holes are distributed on the disc type turntable base, the workpiece air intake and exhaust rocker arms are placed at the machining stations, locating members are plugged into the rocker arm holes for location, and clamping devices which can be used for automatically plugging / unplugging the locating members into / from the workpiece rocker arm holes are further arranged at the machining stations. With the adoption of the technical scheme of the invention, the clamping devices are located through the rocker arm holes, one-step clamping and continuous machining are carried out, and the machining accuracy of the rocker arms is guaranteed; the multi-station machine tool in the technical scheme of the invention has the advantages that the locating accuracy is high, the compatibility is strong, the rigidity is good, multiple actions in machining can be realized, the machining accuracy is guaranteed, and the defects in the prior art that a lot of people and repeated clamping are required, the requirements on the rigidity of the clamping devices are very high, and the machining accuracy of the workpieces is still hard to guarantee due to the fact that the rocker arm workpieces are machined by adopting a disc type multi-station machine tool are overcome.

Owner:南京诺克精密机械有限公司

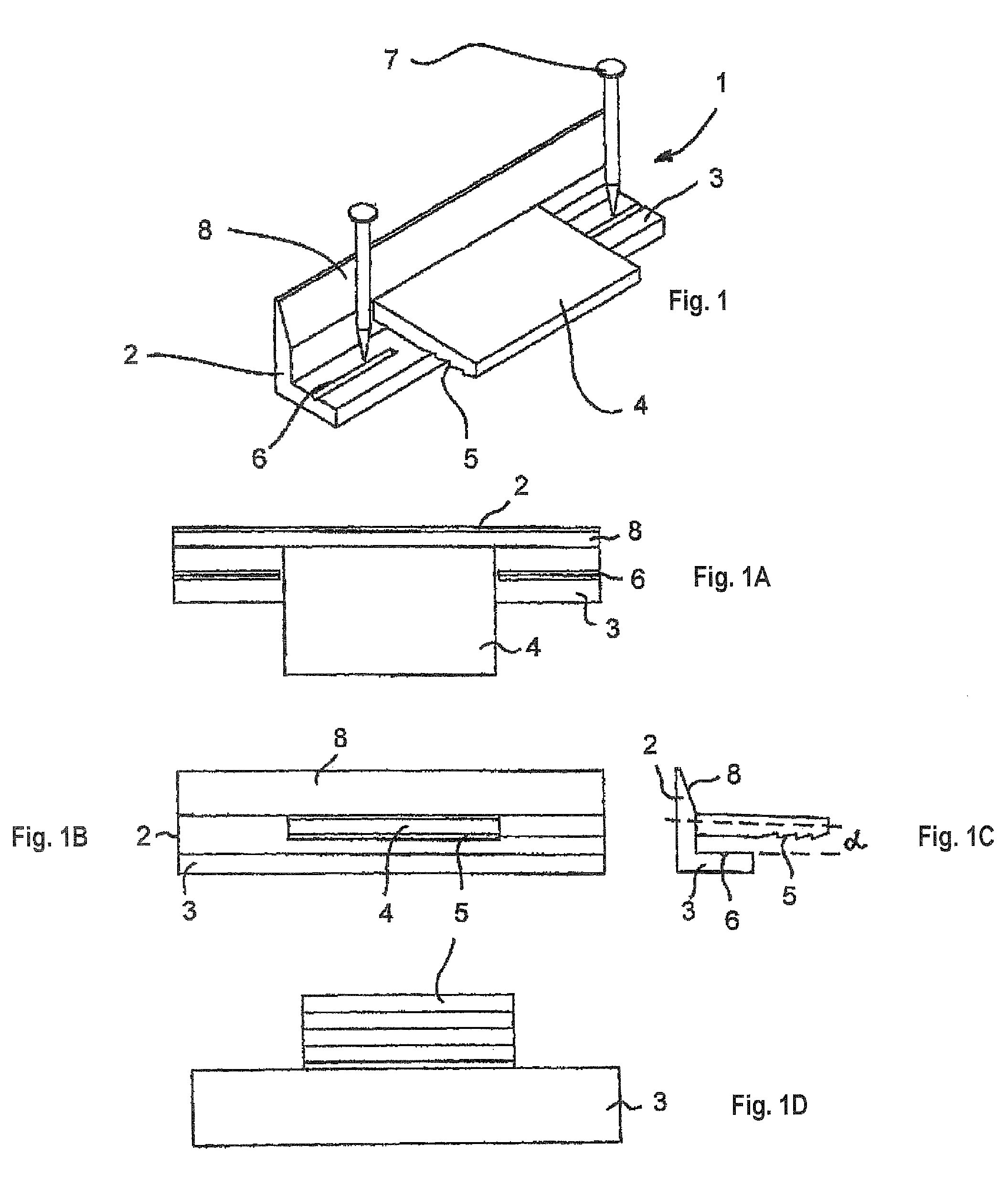

Fastening device with improved fastening portion for securement of a glass pane or a plate in a frame

InactiveUS7877939B2High strengthEasy to installGlass pane fixingSpecial door/window arrangementsPlastic materialsEngineering

Owner:KNAPP FRIEDRICH

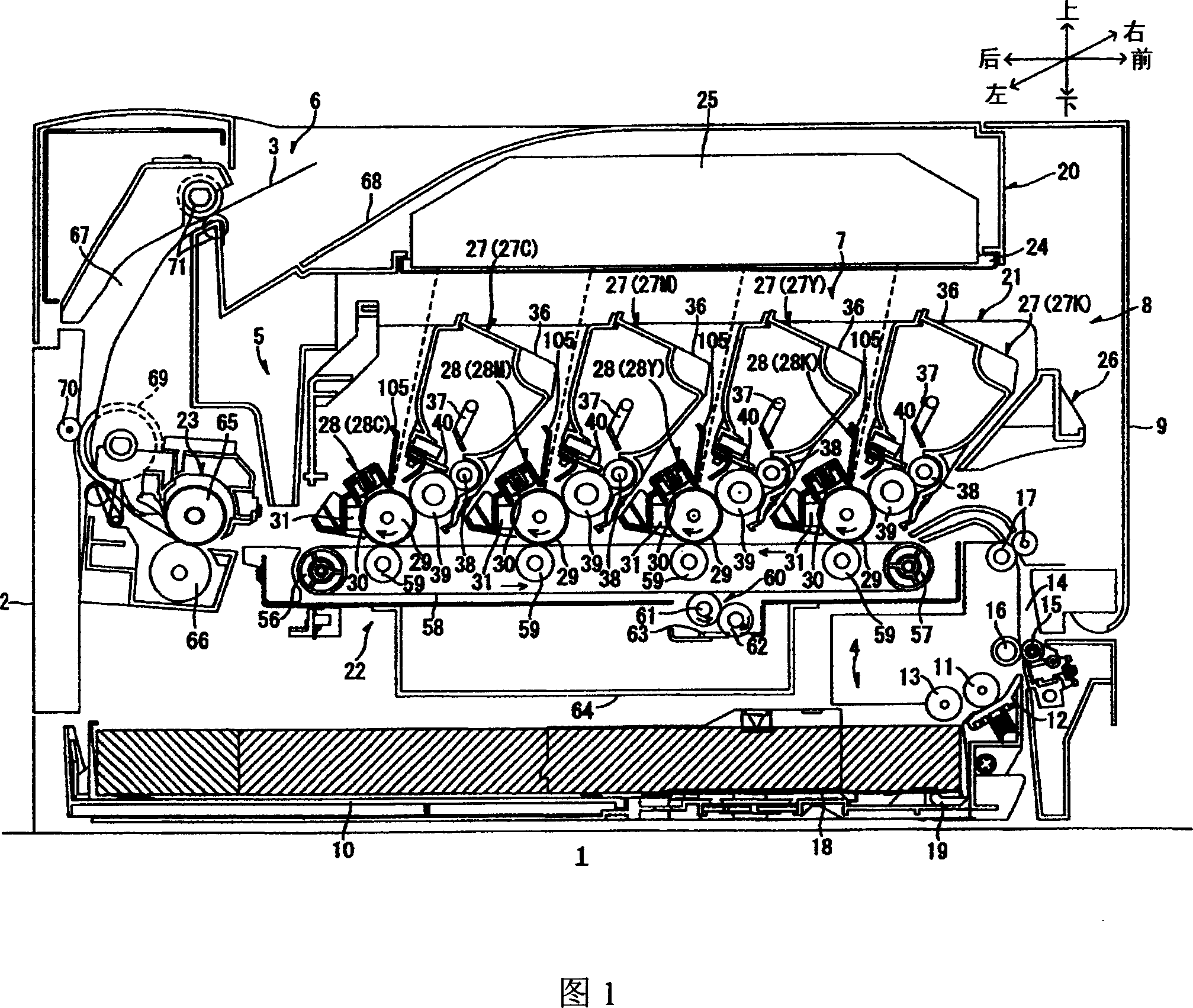

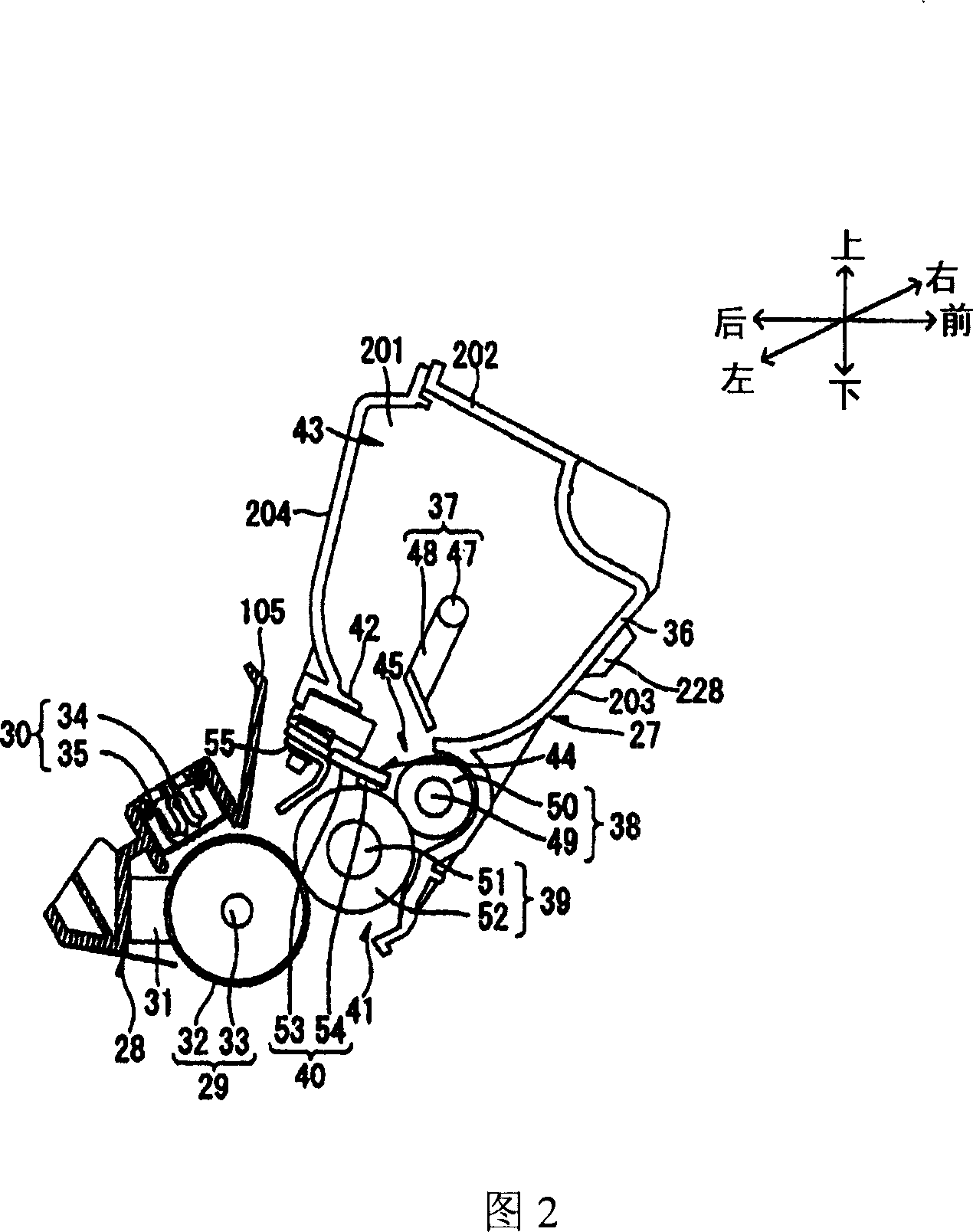

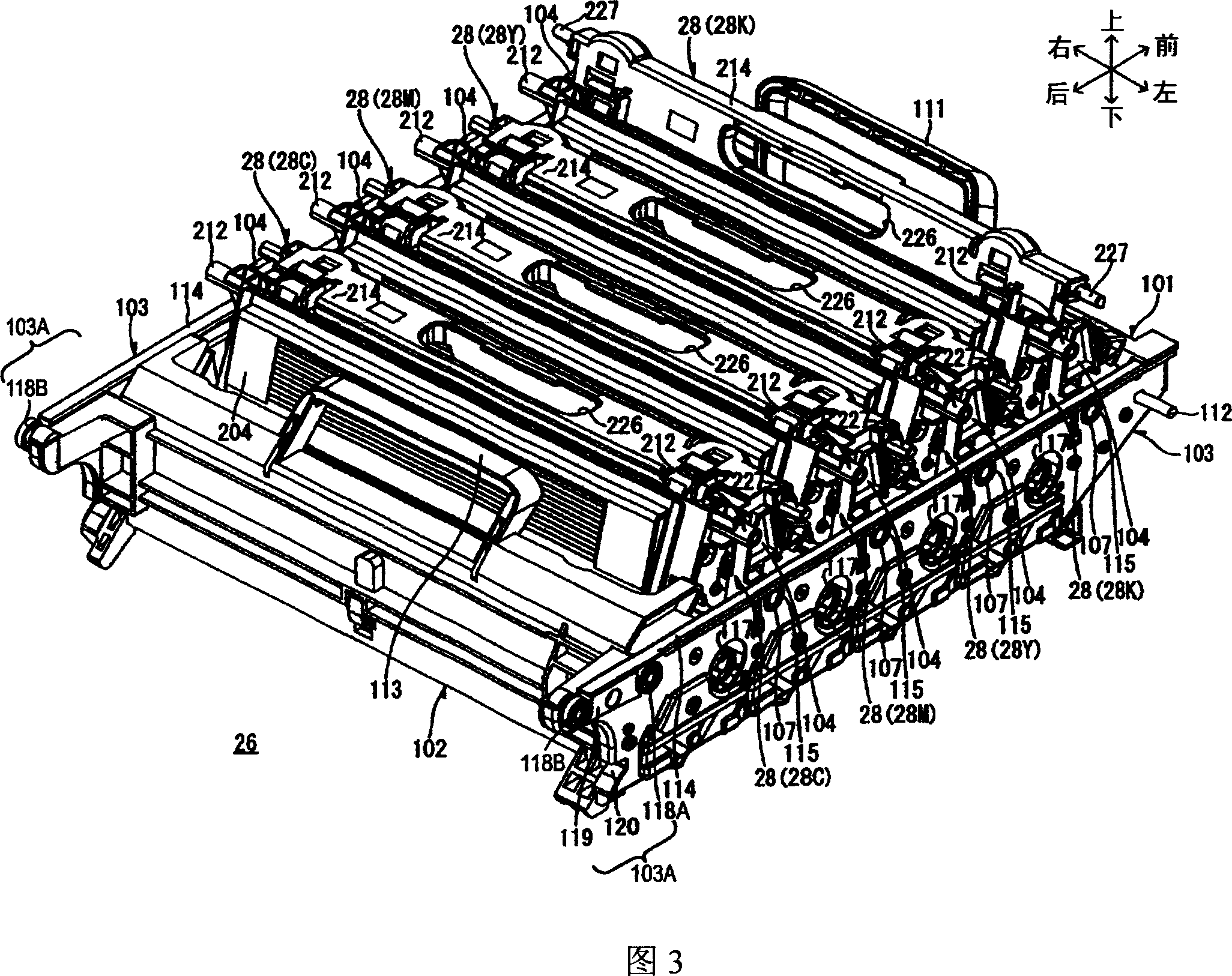

Developing cartridge and image forming device

A developing cartridge (27) that maintains a pressing condition to press a developer carrier (39) against the image carrier (29) is described. The developing cartridge (27) may include a coil spring (218) that presses the developer carrier (39) against the image carrier (29). The coil spring (218) may include a handle (214) that transmits a pressing force to the coil spring (218) via the contacting member (217). By doing so, every time the developing cartridge (27) is replaced, a new coil spring (218) and handle (214) can be provided for the color laser printer (1) with the developing cartridge (27) attached. Therefore, a constant pressure by the coil spring (218) can be continuously maintained. Thus, a preferable pressure condition of the developer carrier (39) against the image carrier (29) can be continuously maintained.

Owner:BROTHER KOGYO KK

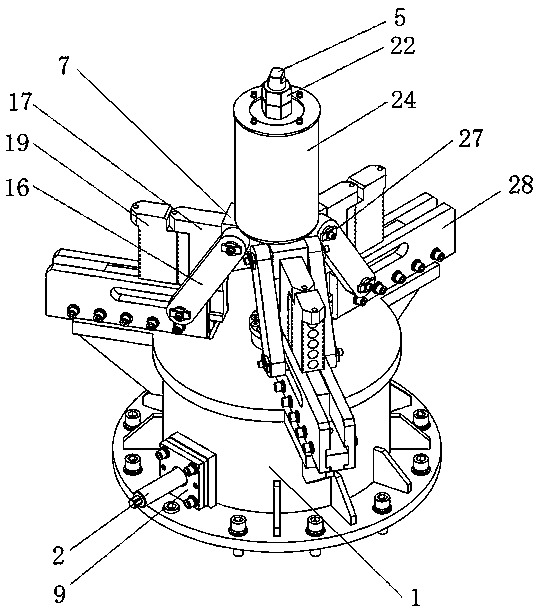

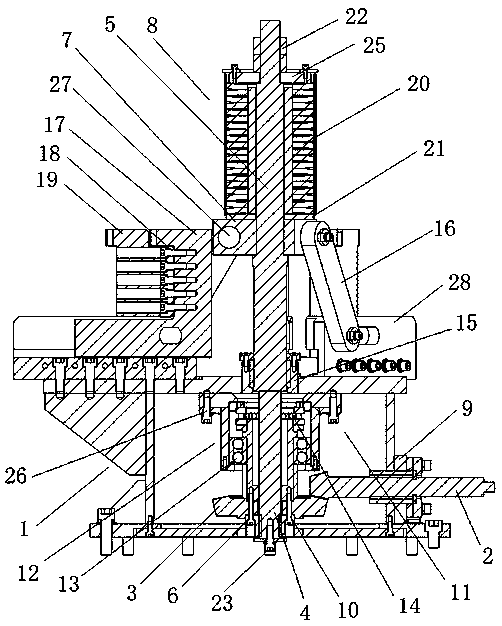

Three-claw inner support clamp assembly

PendingCN110216499AGuaranteed pressing forcePress firmlyPositioning apparatusMetal-working holdersHorizontal forceEngineering

The invention discloses a three-claw inner support clamp assembly. A supporting frame, a small bevel gear shaft, a large bevel gear, a first lead screw, a second lead screw, a lead screw nut, a connecting block and a disc spring are included. A fixing base with a middle opening is arranged on one side of the supporting frame. The small bevel gear shaft is in meshing transmission with the large bevel gear located at the center position of the supporting frame. The large bevel gear is in transmission connection with the lead screw nut through a first screw. The first lead screw and the second lead screw are fixedly connected and combined into an ejector rod lead screw. A guiding base is located above a bearing block, and rotation of the ejector rod lead screw is limited through cooperation of a guiding key in the guiding base and a key groove in the surface of the second lead screw. The rotating power of the small bevel gear shaft drives the large bevel gear to rotate through cooperationof the small bevel gear shaft and the large bevel gear, the lead screw nut connected with the large bevel gear drives the ejector rod lead screw to ascend and descend at the same time so that a sliding block can be driven to move in the horizontal direction, accordingly, axial force is further converted into horizontal force, and the function of workpiece pressing is achieved.

Owner:南京合信智能装备有限公司

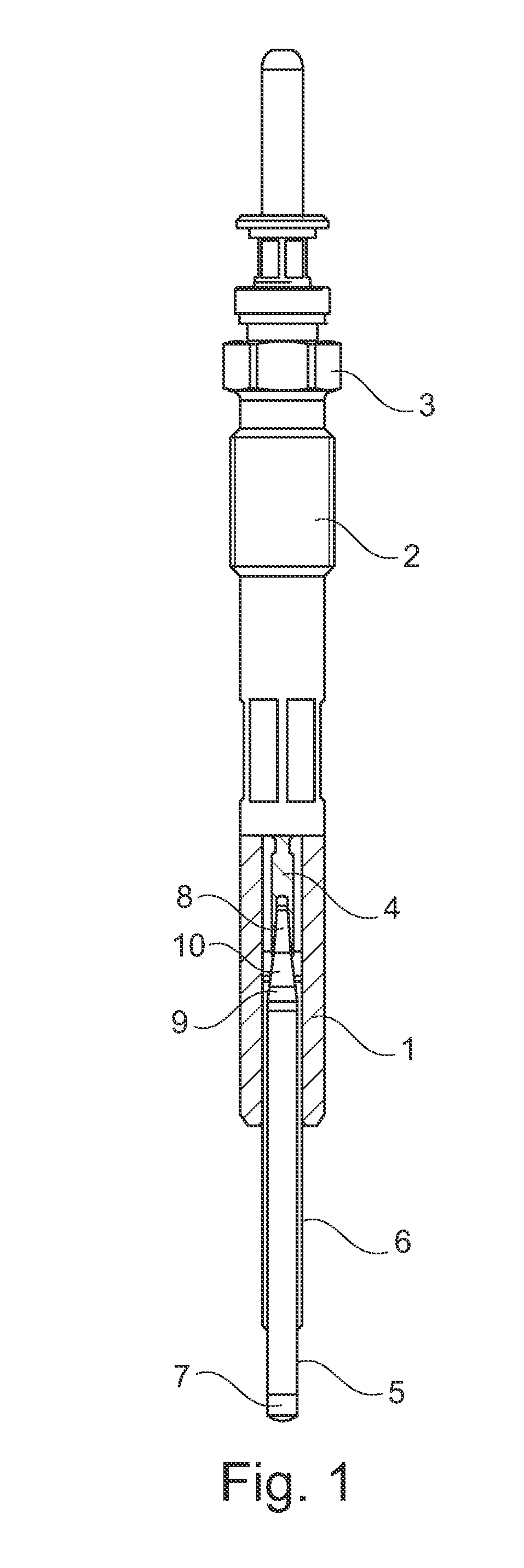

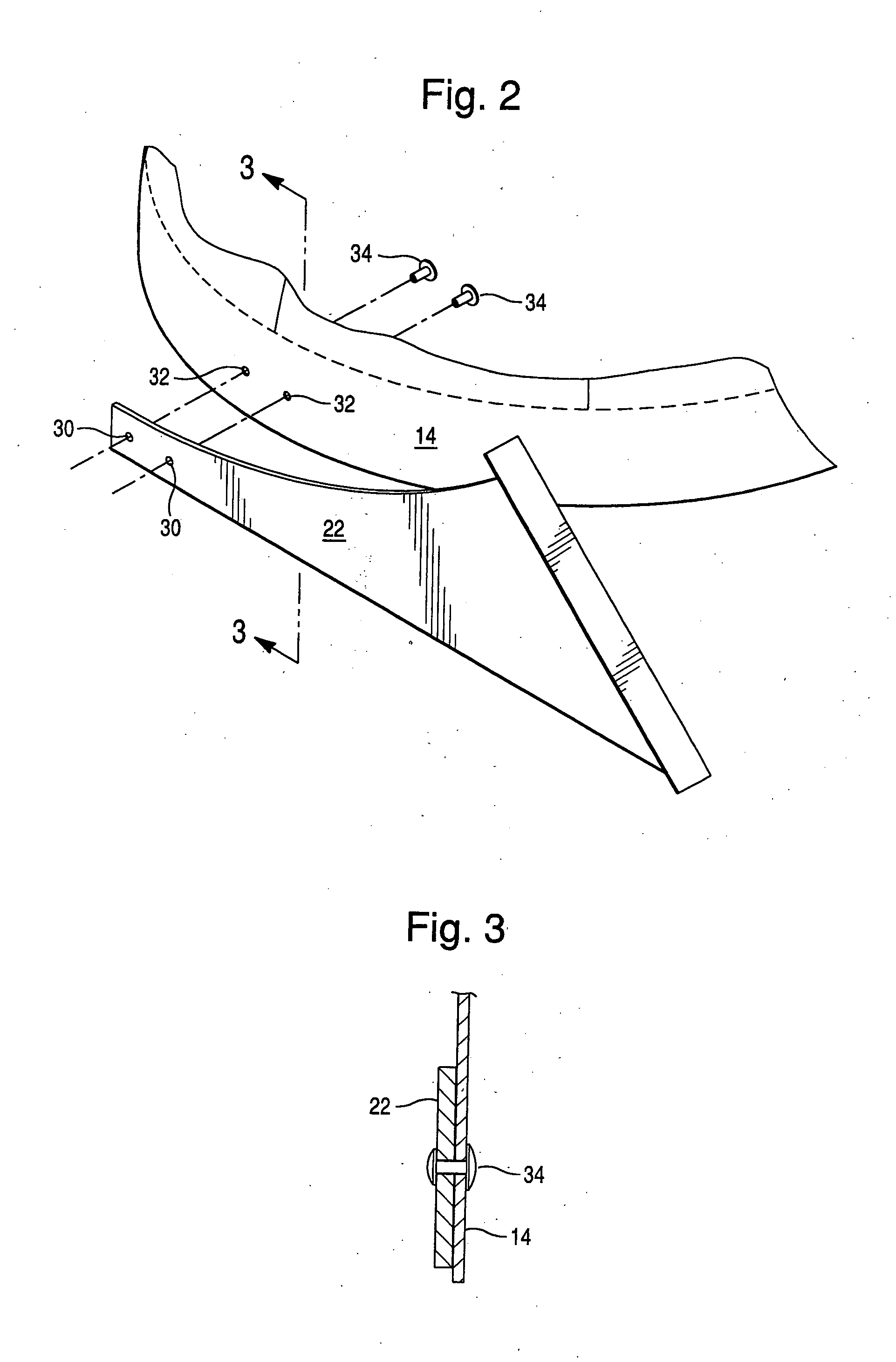

Glow plug and method for connecting a pin made of functional ceramic to a metal sleeve

ActiveUS20120043309A1Reliable and robust connectionSimple and cost-effective productionIncandescent ignitionResistor mounting/supportingElectrical conductorEngineering

The invention relates to a glow plug comprising a housing in which an inner conductor is disposed, a metal sleeve which is inserted into the housing, and a ceramic glow pin which is disposed in the metal sleeve, wherein the two ends of the glow pin protrude from the metal sleeve and the rear end of the pin is connected to the inner conductor, and wherein the metal sleeve has a tapering section at the rear end, the section enclosing a tapering section of the glow pin. According to the invention, the glow pin is pressed into the metal sleeve. The invention further relates to a method for connecting a pin made of functional ceramic to a metal sleeve.

Owner:BORGWARNER BERU SYST

Socket for electrical parts

InactiveCN102386541APower failure does not occurAvoid deformationEngagement/disengagement of coupling partsElectric discharge tubesElectrical connectionSpring force

A socket for an electrical part prevents a bad electrical connection with a circuit by preventing a deformation of a tip of a contact pin. When a tip of the other terminal is pressed to a substrate under a state that first and second holes of first and second holding plates are shifted each other, an upper terminal of the held portion of the other terminal contacts to a lower surface of the second holding plate, and makes the second holding plate to separate from the first holding plate against a spring force of a urging member. At this time, the portion projecting from the lower surface of the first holding plate toward the substrate moves into the first hole.

Owner:ENPLAS CORP

Wood board compaction device

The invention relates to the field of wood machining equipment, in particular to a wood board compaction device capable of rapidly pressing down and lifting up a pressure roller, and not only stably compacting wood boards, but also realizing accurate and efficient automation requirement of a production line. The wood board compaction device comprises a bracket and is characterized in that a conveyer belt is arranged below the bracket, a revolving shaft is arranged on the bracket corresponding to the conveyer belt, and movable oscillating rods are arranged on the revolving shaft corresponding to two sides of the conveyer belt, one end of each oscillating rod is connected with the pressure roller respectively, the movable oscillating rods at two sides are connected by a connecting rod, a compaction cylinder is arranged on the bracket, and a piston rod of the compaction cylinder is connected with the connecting rod.

Owner:WUXI FORMEN TECHN

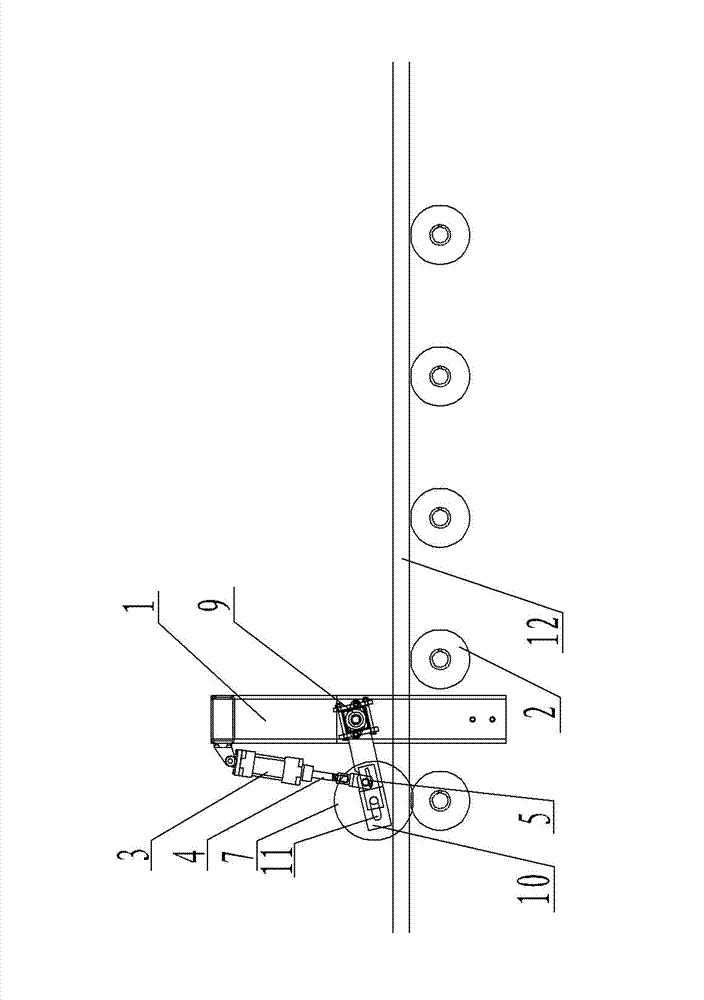

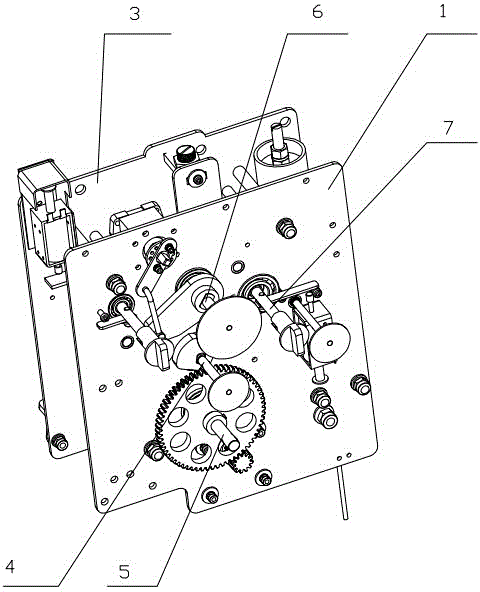

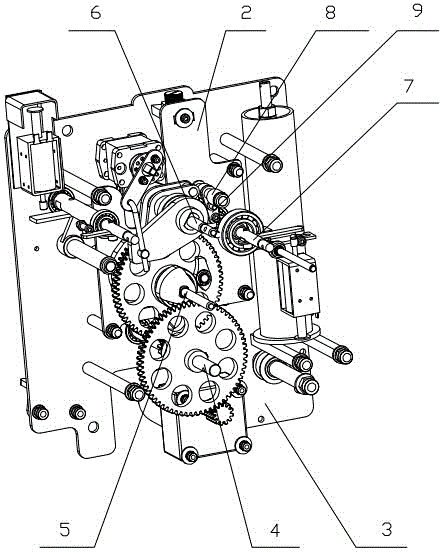

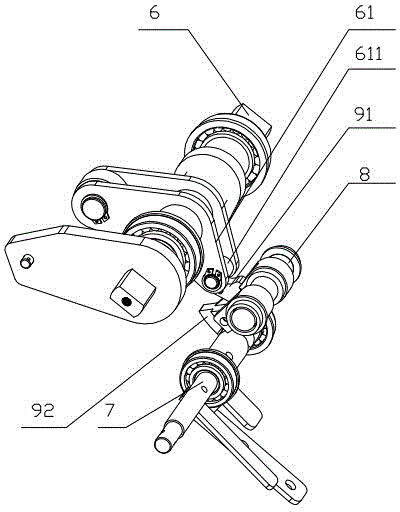

Spring operating mechanism

ActiveCN104701039APress firmlyRealize opening in placeContact driving mechanismsSwitch power arrangementsEngineeringMechanical engineering

Provided is a spring operating mechanism. The problem that an existing brake opening pawl is not reliable in actions is solved. The spring operating mechanism comprises a front plate, a middle plate and a base plate, wherein an output spindle is arranged between the front plate and the base plate, a brake opening half shaft and a mounting shaft are arranged between the middle plate and the front plate, a press crank arm is arranged on the output spindle, a brake opening pawl is arranged on the mounting shaft and comprises a pressing block and a limiting block, and the first state that the pressing block is pressed by the press crank arm, the second state that the limiting block is pressed to enable the limiting block and the brake opening half shaft to be clamped mutually, the third state that the pressing block rotates to enable the press crank arm to be limited in rotation and the fourth state that the brake opening pawl resets to enable the pressing block and the press crank arm to be unlocked after brake opening are set for the pressing block. The spring operating mechanism is provided with the pressing block and the limiting block, so that the press crank arm of the output spindle can reliably press the pressing block, the pressing block reliably drives the limiting block to move and enables the limiting block to be reliably clamped with the brake opening half shaft.

Owner:XINGJI ELECTRIC APPLIANCE CO LTD

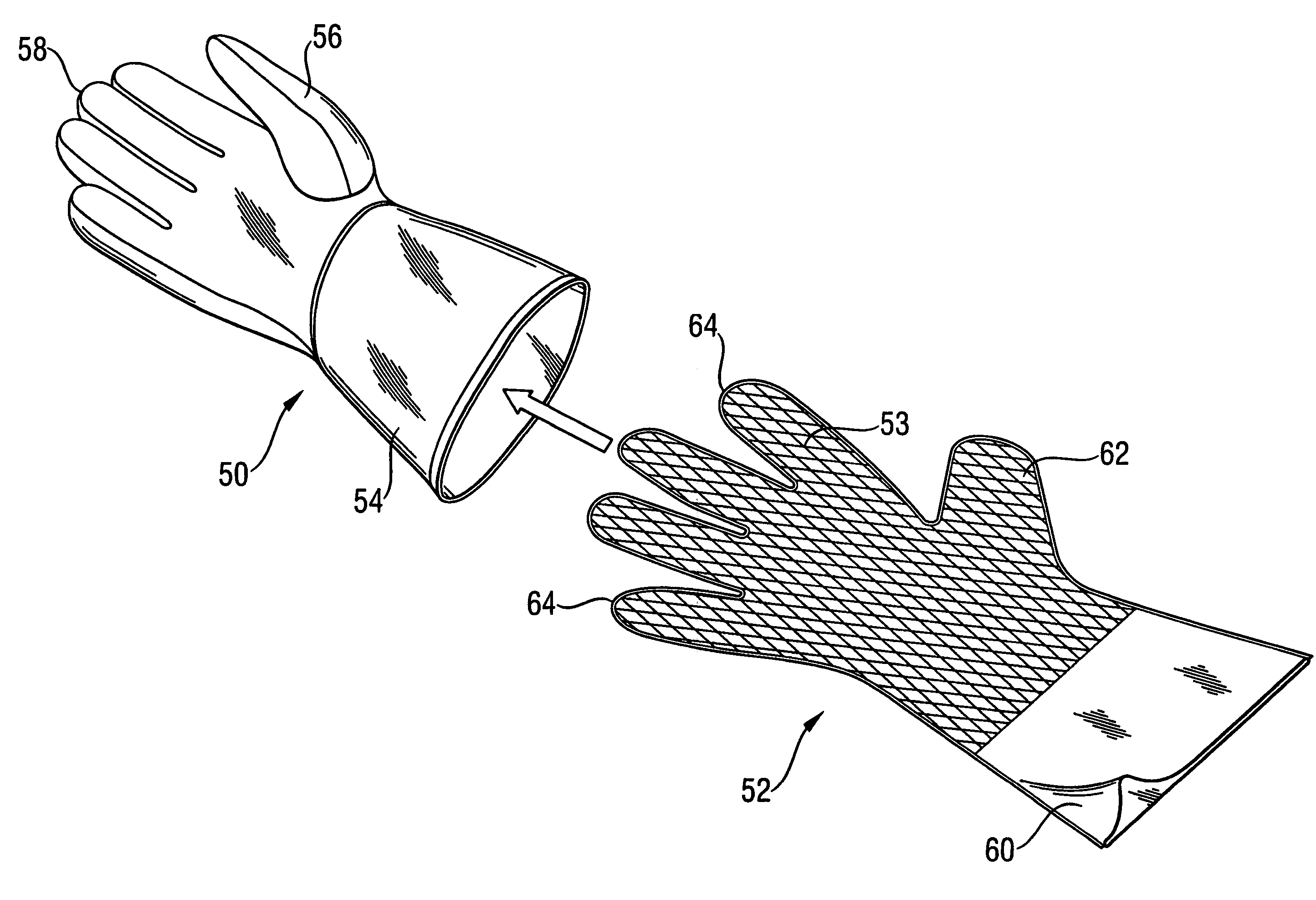

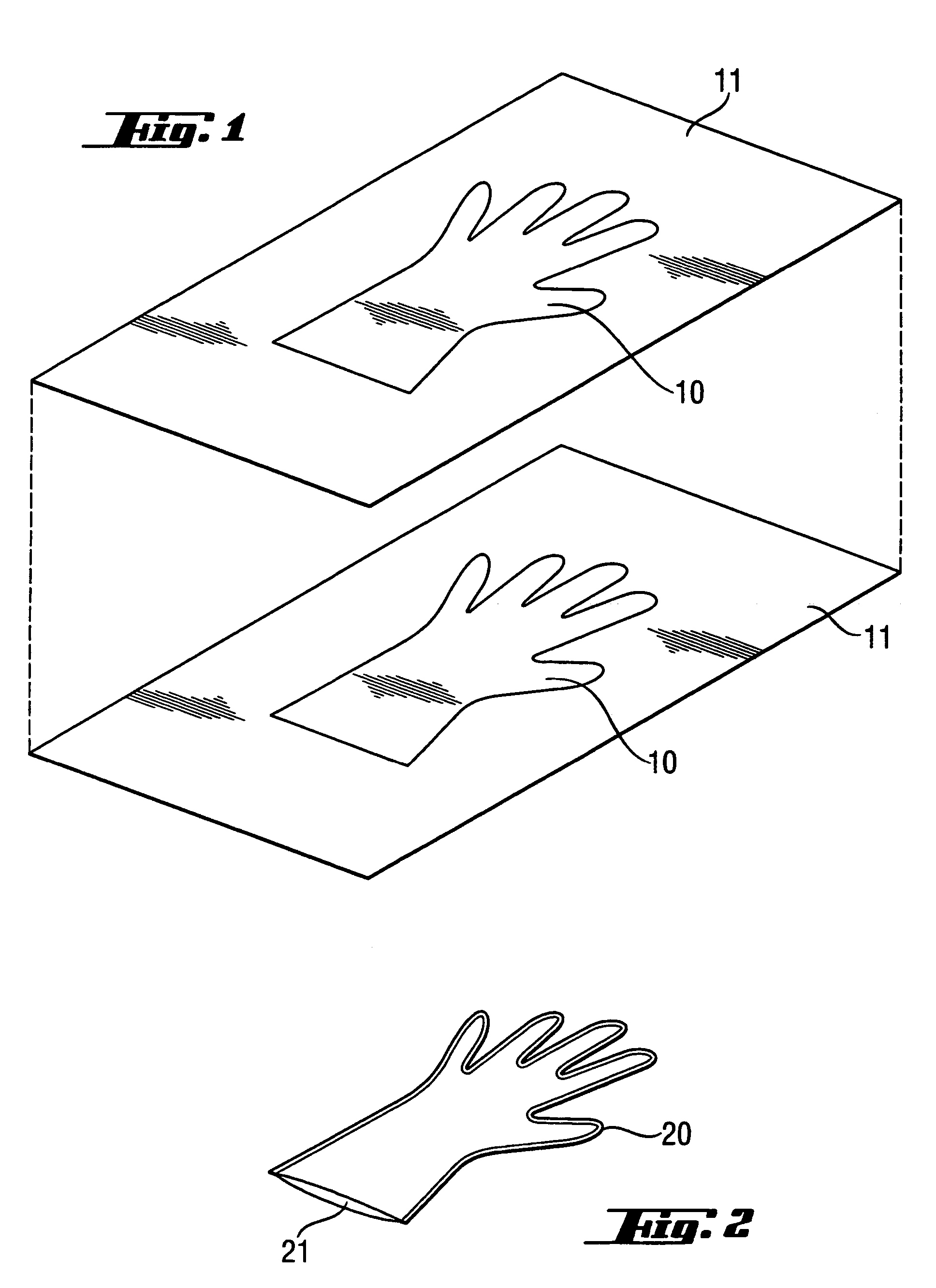

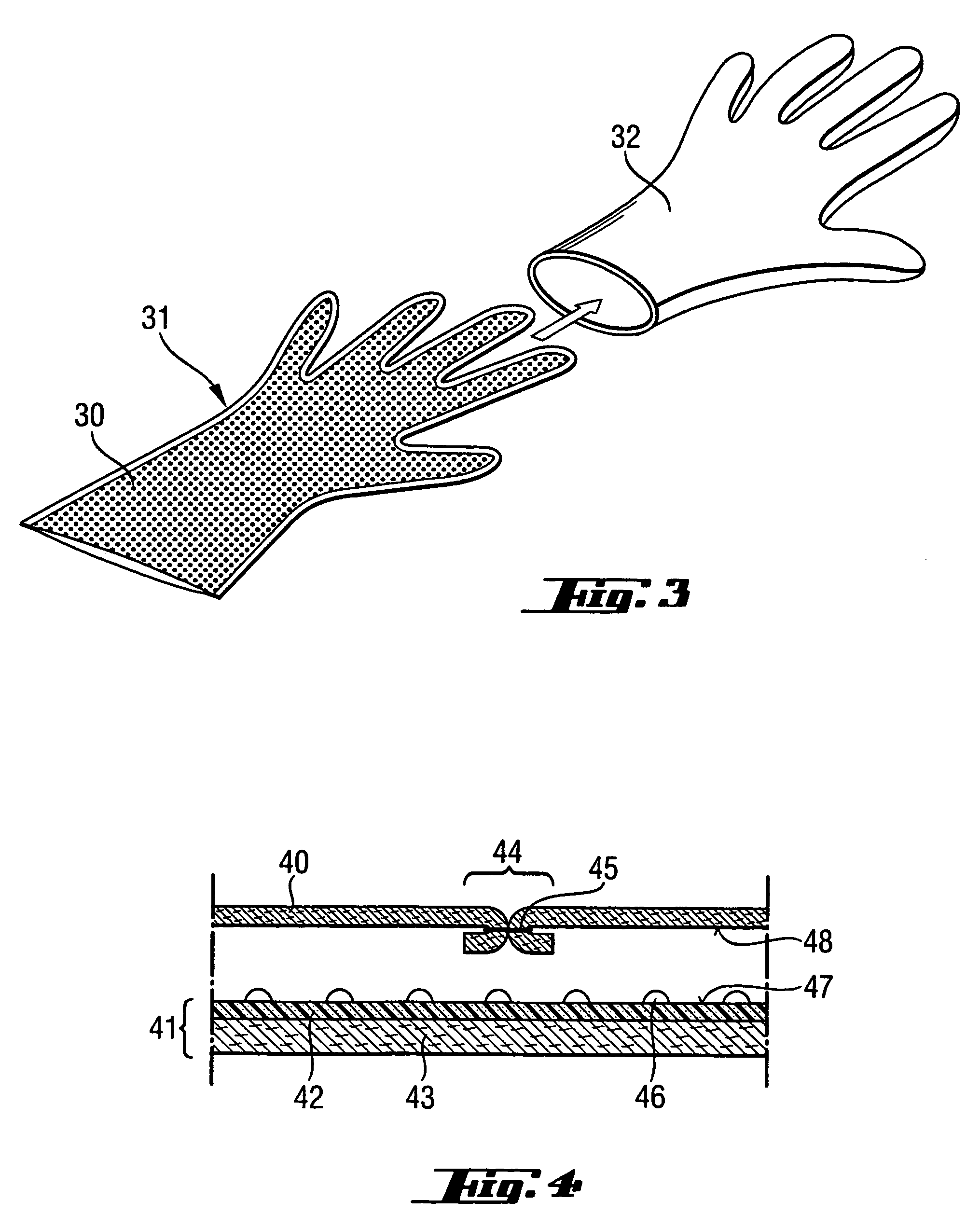

Handcovering

InactiveUS7162748B2Improve breathabilityOptimize softnessSynthetic resin layered productsGlovesWater vaporEngineering

Handcovering, i.e. glove (72) or mitten, comprising an outer shell (50) and an inner glove insert (52) adhered to the shell (50). The glove insert (52) comprises a lining fabric laminated to a functional layer (42) that is water vapor permeable waterproof. The inner glove insert (52) is substantially free of folds or bunching of the insert (52) inside the glove (72).

Owner:HOTTNER MARTIN +1

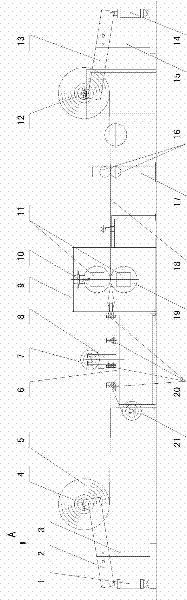

Production equipment for plastic drainage strips

InactiveCN102400457AIncrease productivityGuaranteed water flowLaminationLamination apparatusEngineeringMechanical engineering

The invention discloses production equipment for plastic drainage strips. The equipment comprises a driving device, and also comprises a feeding device, a pressing device and a winding device from end to end in turn, wherein a plurality of groups of raw materials are parallelly arranged in the feeding device; each group of raw material comprises a core plate coil (5), an upper filter membrane coil (7) and a lower filter membrane coil (21); and the driving device is connected with and drives the pressing device. After the structure is adopted, the plurality of groups of raw materials are parallelly arranged in the feeding device, namely a plurality of drainage strips can be produced at one time simultaneously, so that production efficiency is greatly improved.

Owner:宁波广宏工程塑料有限公司

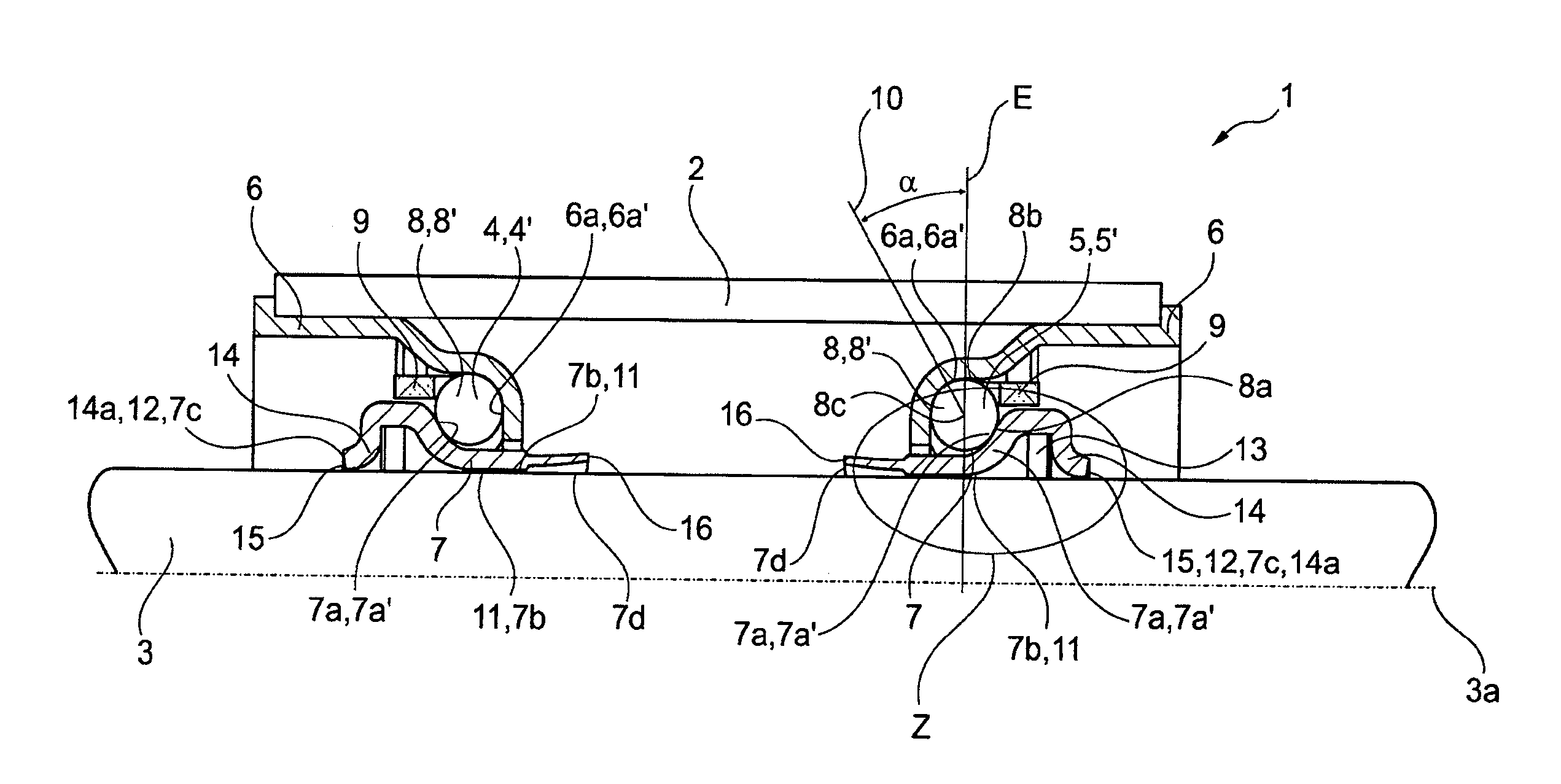

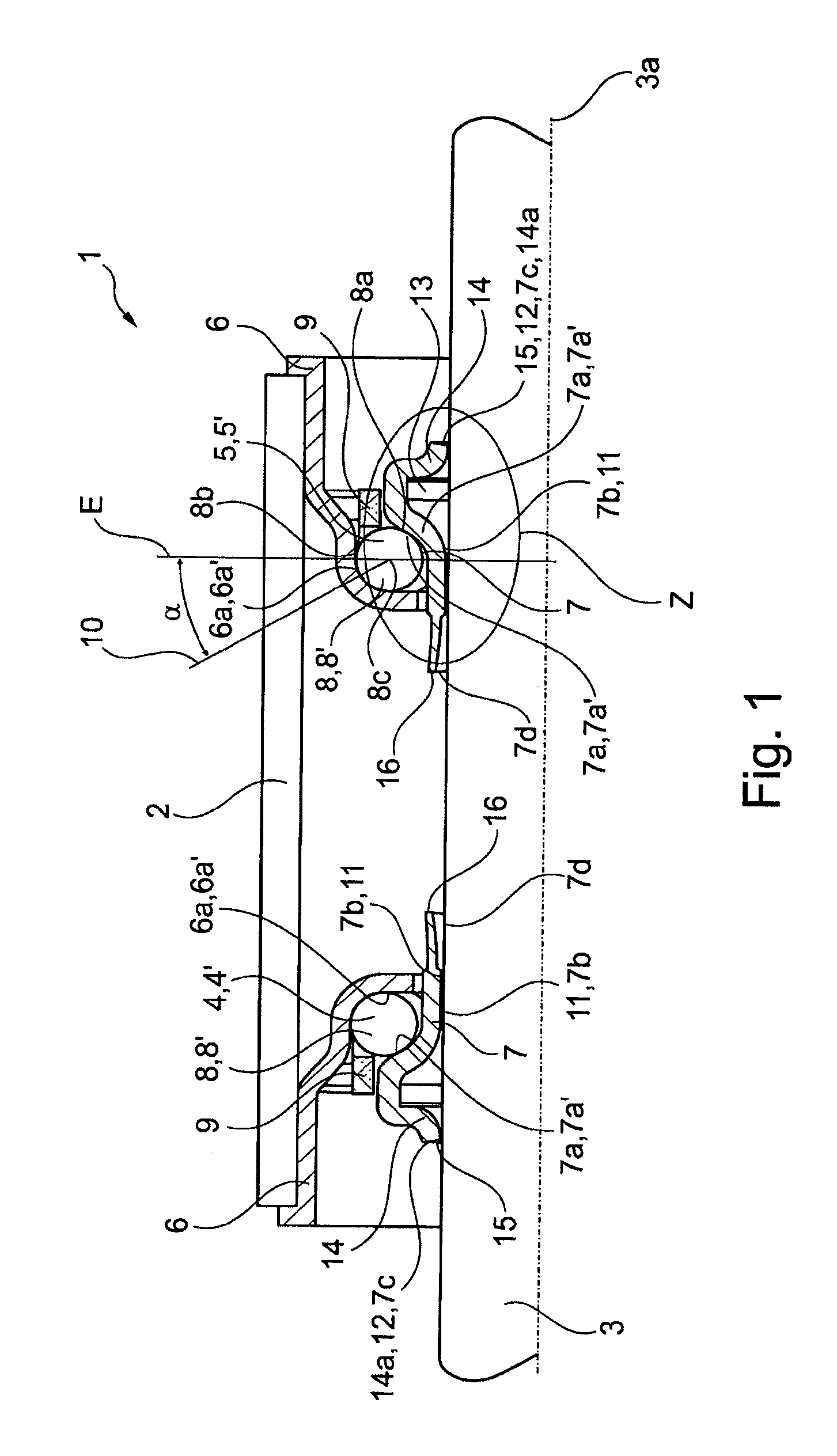

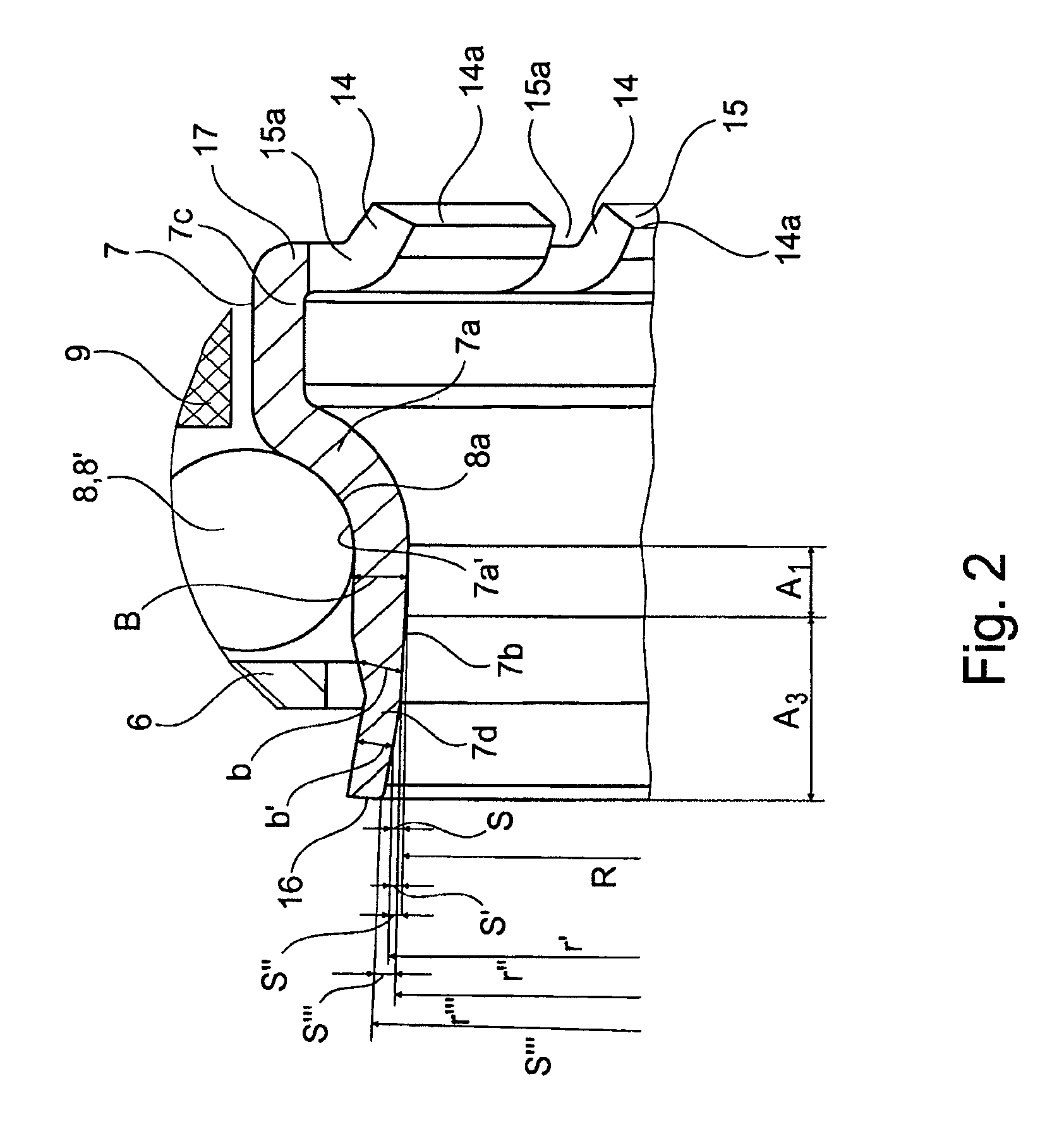

Steering column comprising a steering bearing, and a steering bearing of a steering column

InactiveUS20140157938A1Avoid contactPress firmlyBall bearingsSteering columnsSteering columnControl theory

A steering column with a steering-column tube, a steering spindle and at least one steering bearing for the rotatable mounting of the steering spindle in the steering-column tube, the steering bearing having an outer ring sitting in the steering-column tube, an inner ring and rolling bodies arranged between the outer ring and a track section of the inner ring, wherein the inner ring bears against the steering spindle at only two points and, for this purpose, has a first section which axially adjoins the track section and bears under prestress against the steering spindle at the first point, and a second section which is axially spaced apart from the first section, which axially adjoins the track section, and which has a first end of the inner ring in interaction with the steering spindle at the second point.

Owner:SCHAEFFLER TECH AG & CO KG

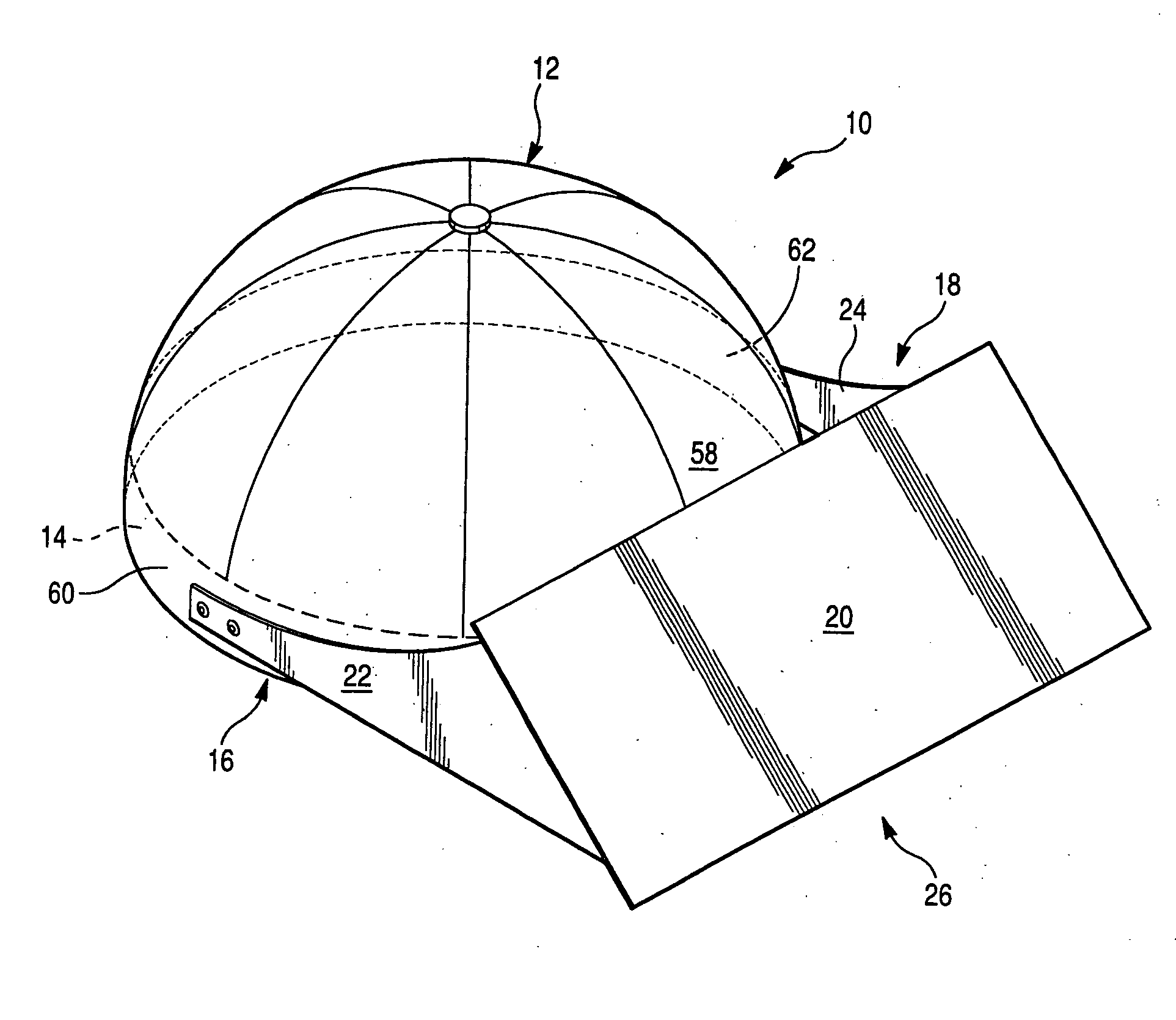

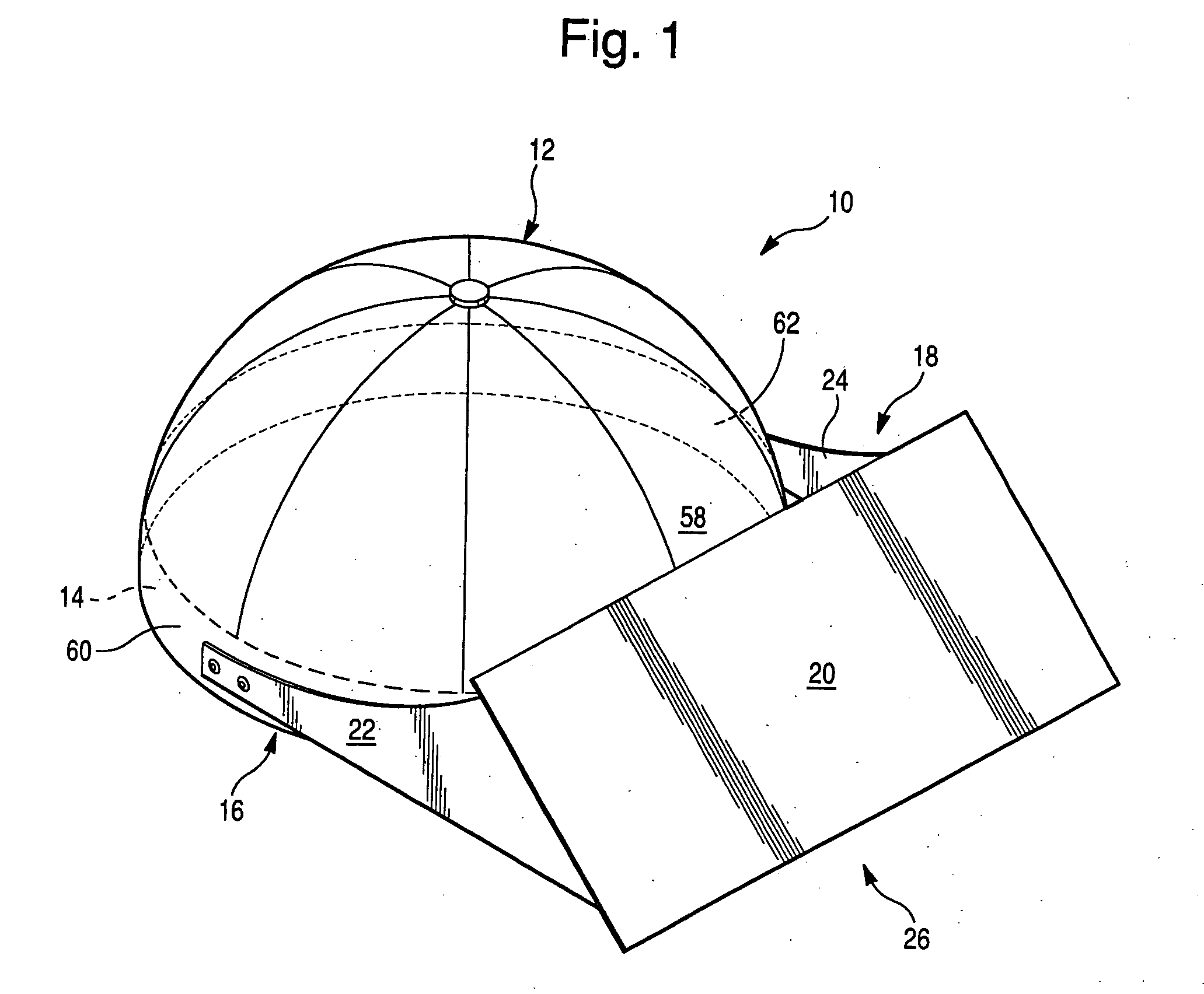

Headgear having airflow characteristics

A visor or cap brim is disclosed that prevents the pressure of the wind from blowing the cap off of the user's head. The visor portion is a generally planar surface that is held out away from the front of the cap portion that sits on the user's head. This creates a single large passage between the visor / bill and the cap and the visor / bill is held at such an angle that it acts a “spoiler” to press the hat down more firmly on the user's head in a high wind while at the same time shading the eyes and forehead from the sun. The visor portion of the cap is removably attached to a semi-rigid headband that encircles the base of the main body of the cap. This attachment is accomplished by a plastic “rivet” type arrangement connected at the terminal ends of a pair of arms attached to the novel visor portion. The visor portion includes a wind or air dam along its upper edge to increase stability and is also slidable up and down the arms.

Owner:STEPHENSON MICHAEL

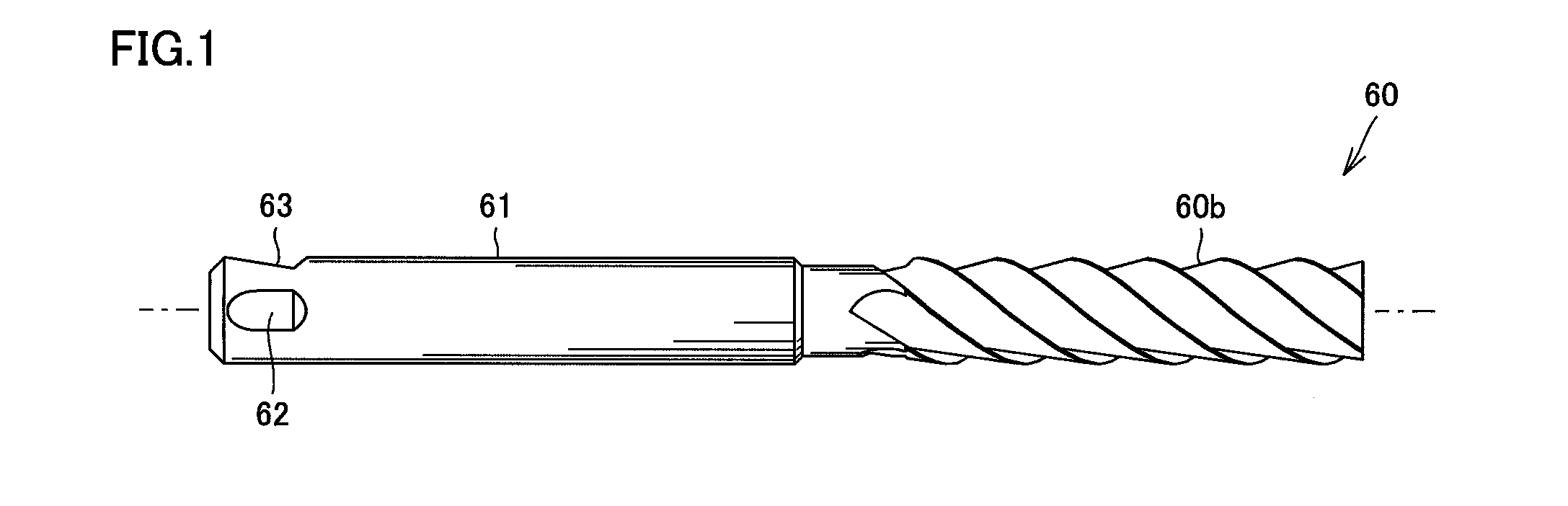

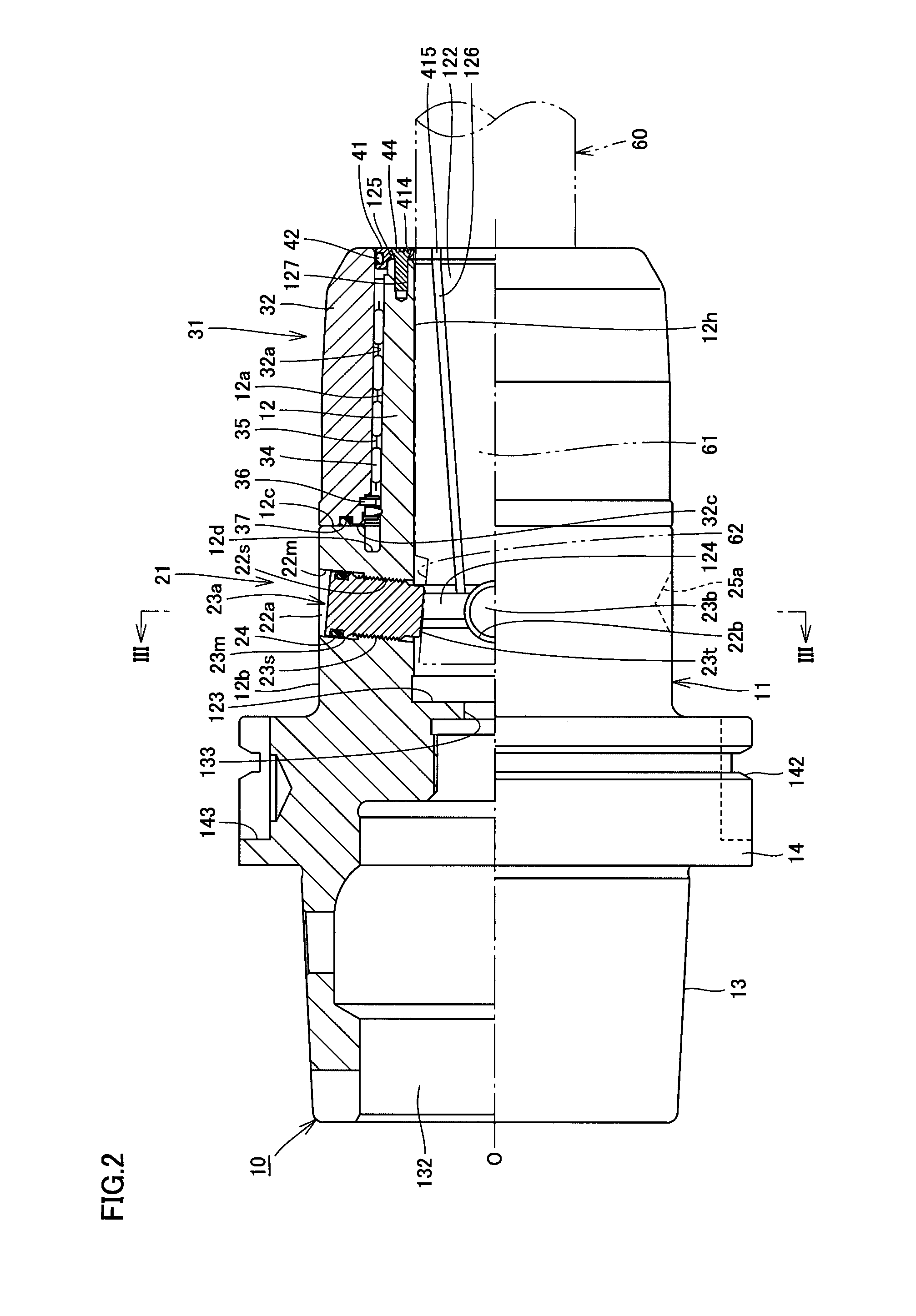

Shank Structure of End Mill and Tool Holder

ActiveUS20130322980A1Reliably chuckedIncrease coefficient of frictionSleeve/socket jointsMilling cuttersMilling cutterEngineering

In a shank portion of an end mill which is chucked by a tool holder, flat surfaces are formed at a plurality of circumferential positions in the outer periphery of the shank portion so that the flat surfaces abut on side lock bolts attached to a body of the tool holder.

Owner:NIKKEN KOSAKUSHO WORKS LTD

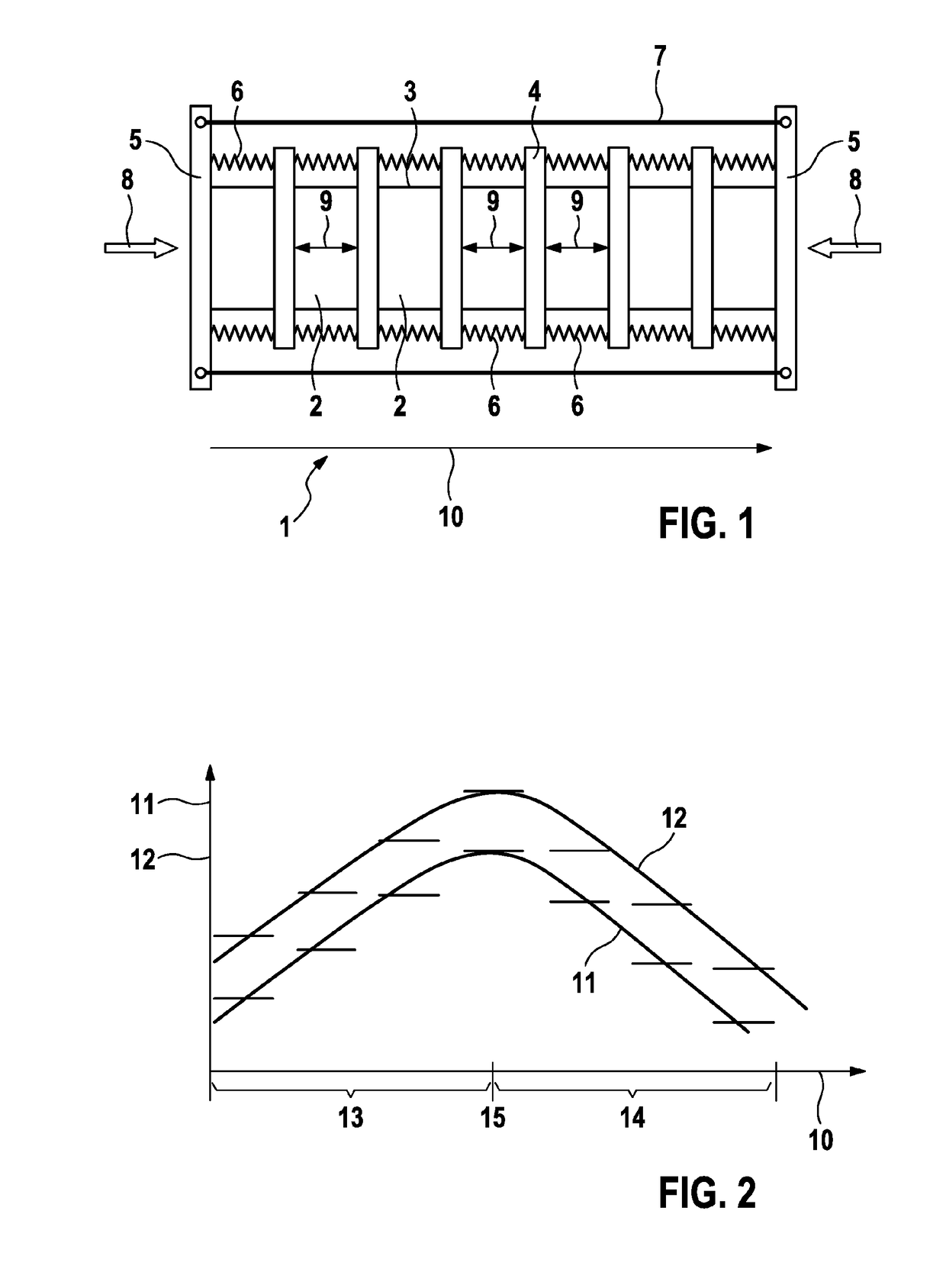

Battery module having a plurality of battery cells, method for the production thereof, and battery

ActiveUS20190044113A1Influence rate of agingDifferent rate of agingFinal product manufactureSecondary cells manufactureEngineeringLithium-ion battery

The invention relates to a battery module having a plurality of battery cells, in particular lithium-ion battery cells, having a plurality of partitions (4), wherein a battery cell (2) is arranged between two partitions (4), and a spring element (6) is furthermore arranged between two partitions (4) adjacent to a battery cell (2), in particular a tension and / or compression spring element, which is arranged in a manner contacting and / or connected to the two partitions (4) such that a value of a deformation constant (12) of the spring element (6) determines a force transmitted by the two partitions (4) to the battery cell (2).

Owner:ROBERT BOSCH GMBH

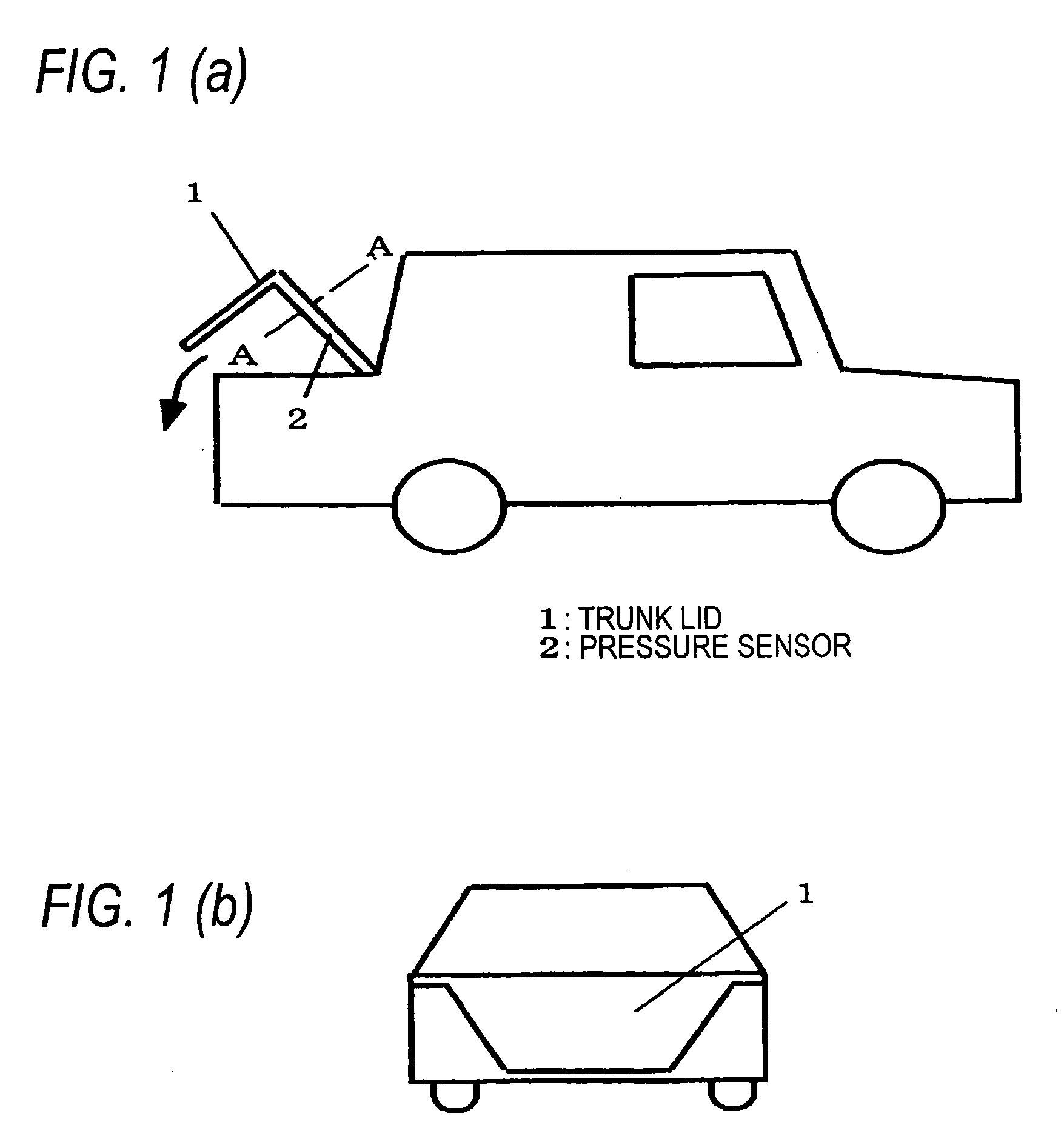

Pinch detection device and opening/closing device

InactiveUS20060131915A1Improve reliabilityLarge output signalForce measurement using piezo-electric devicesPower-operated mechanismPressure sensorEngineering

A pinching detection apparatus having a pressure sensor 2 disposed along the geometry of a trunk lid 1 in a flexible manner, and determination means 16 for detecting that an object is being pinched between a body opening section 7 and the trunk lid 1, in accordance with a signal output from the pressure sensor 2. Since the pressure sensor 2 is disposed along the geometry of the trunk lid 1 in a flexible manner, pinching by the trunk lid 1 can be detected.

Owner:PANASONIC CORP

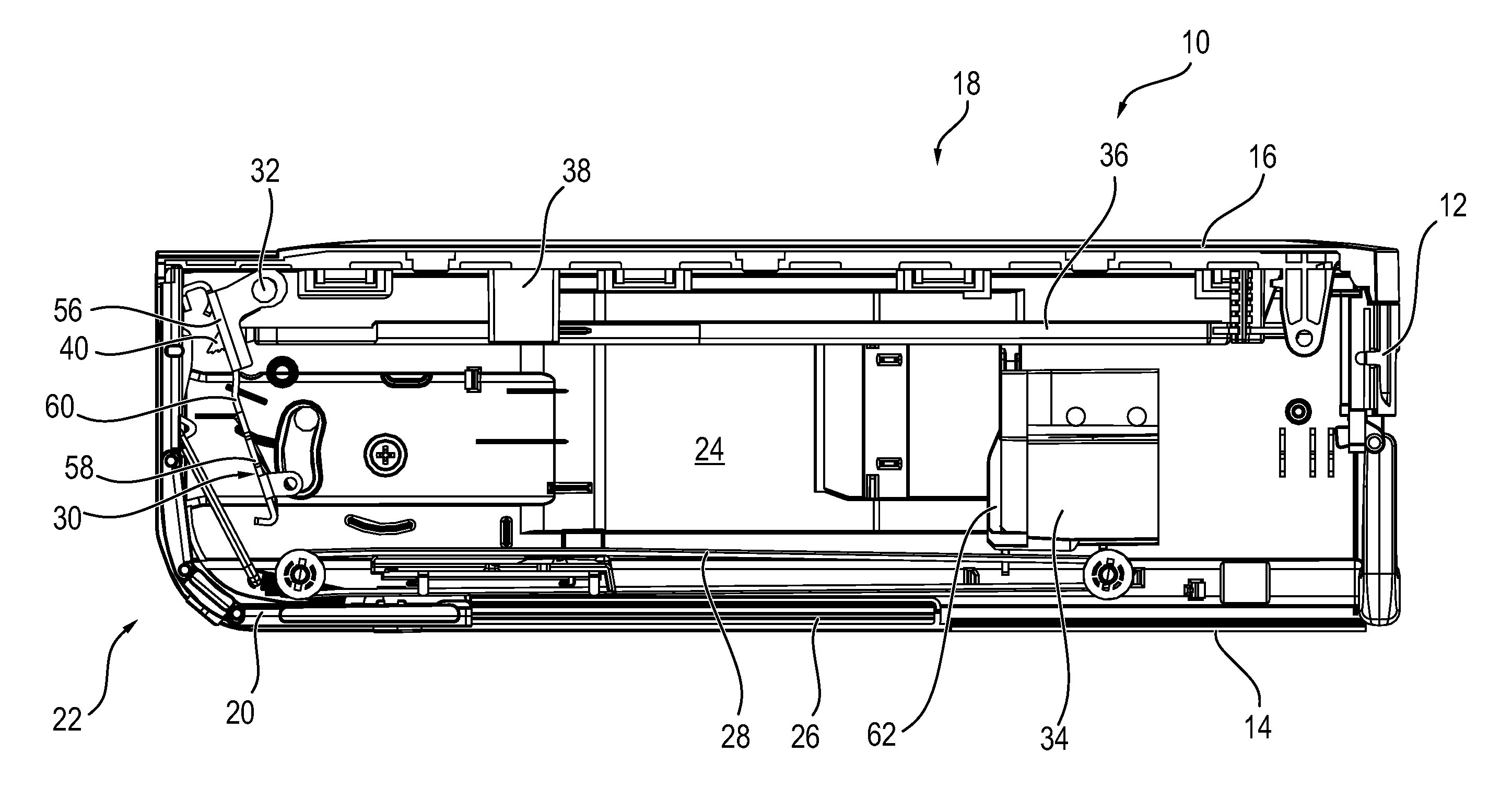

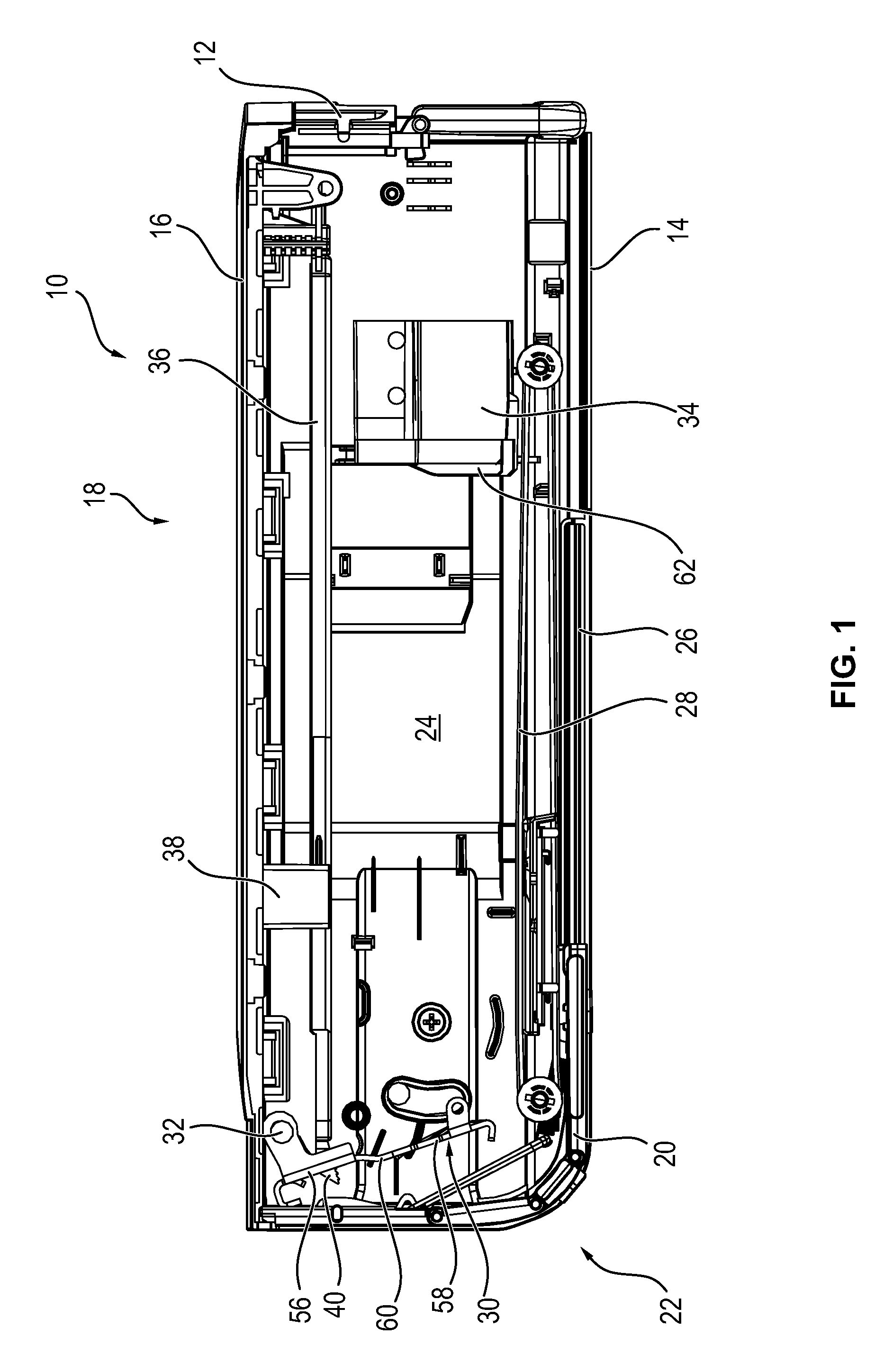

Cash box with a height limiter engaging with the retaining element

ActiveUS9388624B2Sufficient forceEasy constructionCoin/currency accepting devicesSafesMechanical engineeringLimiter

The invention relates to a cash box (10, 100, 102) comprising a receiving area (24) for receiving a value note stack and a first opening (18) for manually feeding and removing notes of value, which first opening is closable by a cover (16). On the cover (16), a height limiter (36) for adjusting the height of the receiving area (24) is provided, this height limiter (36) comprising at least one finger (40, 42) which, at least when the cover (16) is closed, projects into a recess (44, 46) of a retaining element (30).

Owner:DIEBOLD NIXDORF SYST GMBH

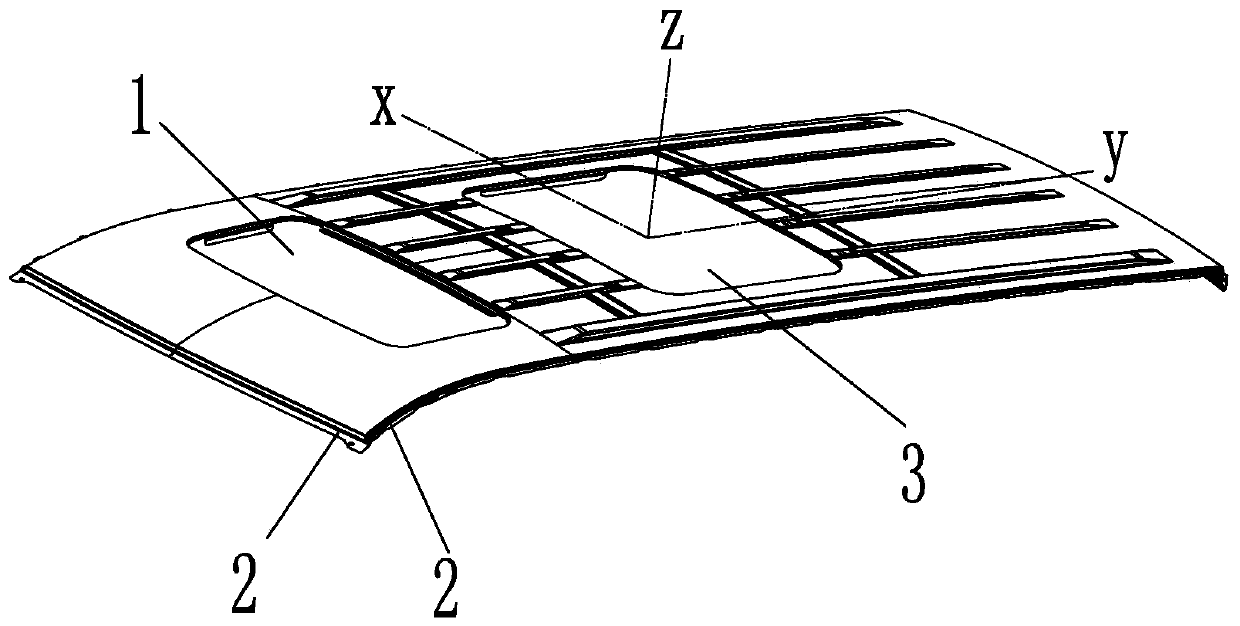

Stamping process profile compensation method for vehicle roof cover with sunroof

The invention discloses a stamping process profile compensation method for a vehicle roof cover with a sunroof. A stamping process for the vehicle roof cover with the sunroof comprises the following four procedures: 1. drawing; 2. trimming, punching and side shaping; 3. trimming, flanging and shaping; 4. trimming, punching, side punching, side shaping and upward flanging. As for the stamping process profile compensation method, die profiles from the first procedure to the third procedure are compensated. Through the method of the invention, the stamping process profiles are compensated by thepreliminary CAE analysis, and the process compensation scheme is formulated at the process design stage, thereby greatly reducing the die debugging workload, shortening the die forming cycle of complicated panel dies such as the roof cover, reducing die development costs, and improving the quality of the large panel dies.

Owner:柳州业泰汽车零部件有限公司

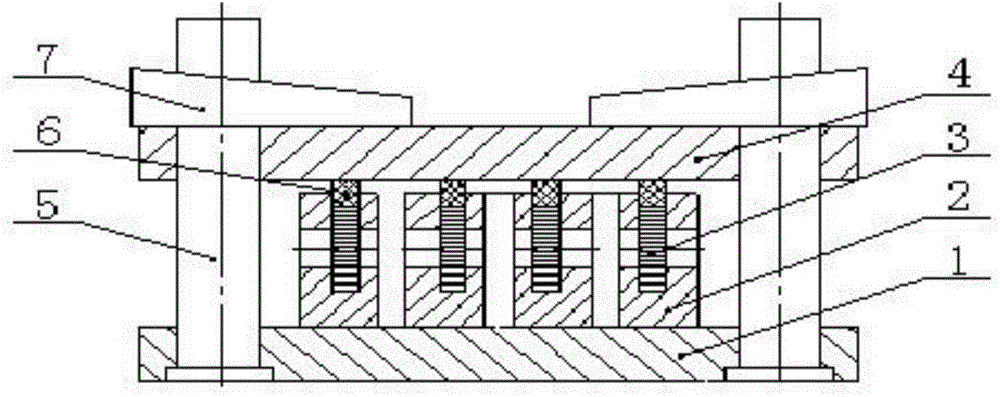

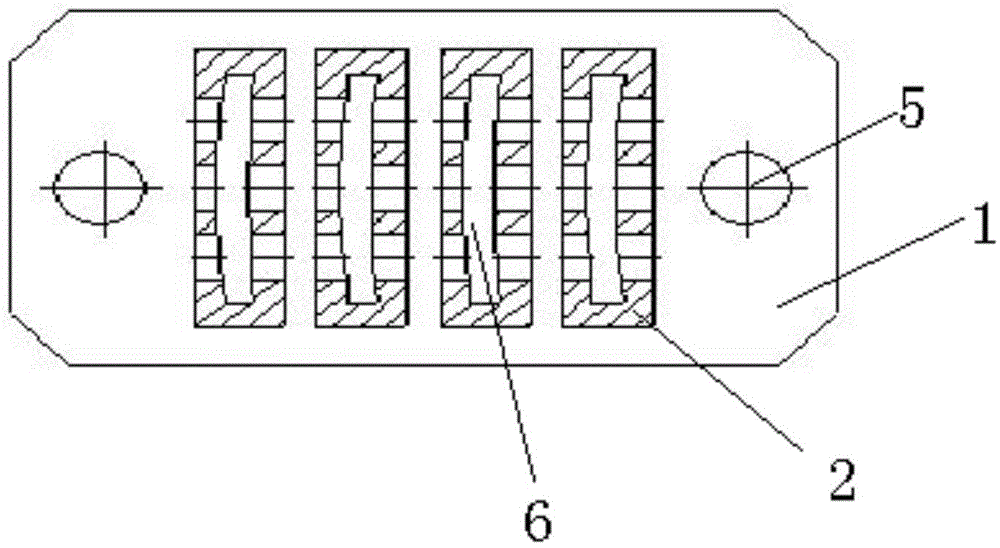

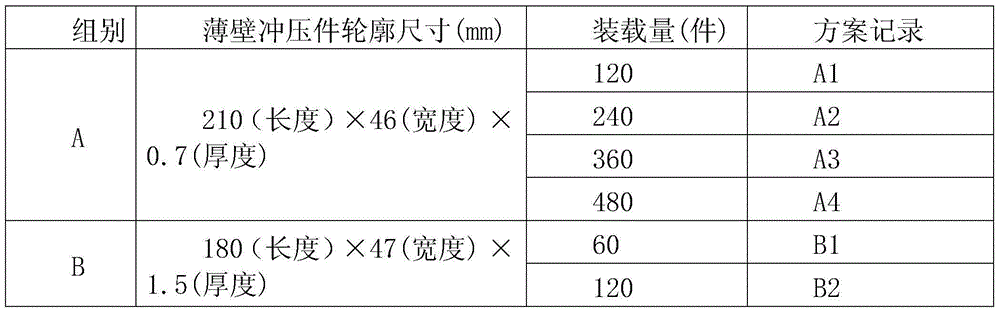

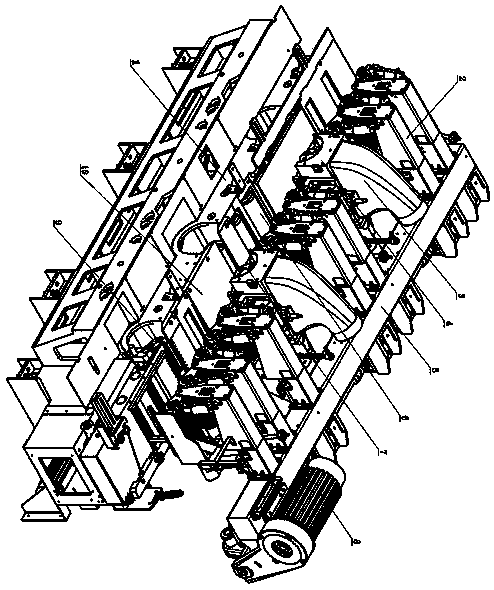

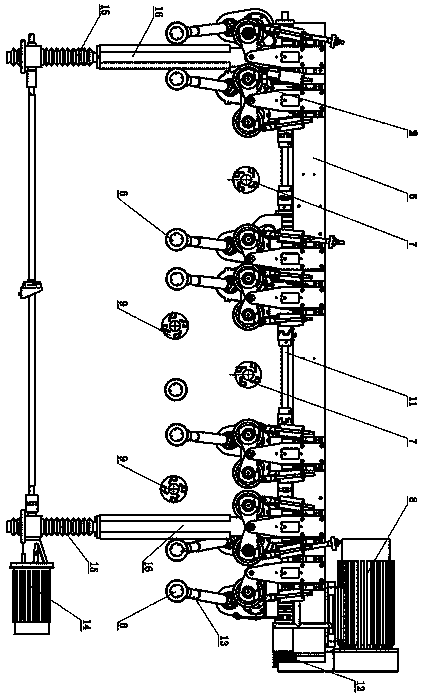

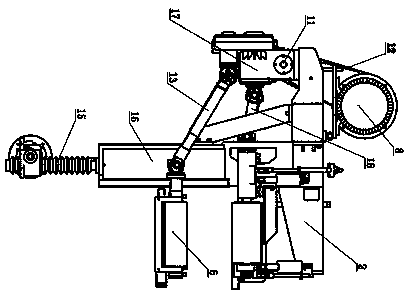

Hot sizing device and hot sizing method for thin-wall stamping part

ActiveCN104451047AAvoid misalignmentAvoid scrappingFurnace typesHeat treatment furnacesEngineeringMechanical engineering

The invention discloses a hot sizing device and hot sizing method for a thin-wall stamping part, and aims at solving the problems of warping and deformation of the thin-wall stamping part which is subjected to hot sizing to improve the production efficiency and reduce the production cost. The adopted technical scheme is as follows: the hot sizing device comprises a bottom plate (1) and positioning pins (5), wherein the positioning pins (5) are fixedly arranged at two ends of the bottom plate (1); the bottom plate (1) is provided with a plurality of loading boxes (2), a plurality of thin-wall stamping parts (3) can be placed in the loading boxes (2) in a stacked way, cavities inside the loading boxes (2) are matched with the thin-wall stamping parts (3) in size structure, and the stacked height of the plurality of thin-wall stamping parts (3) is aligned to the upper planes of the loading boxes (2); and the upper ends of the loading boxes (2) are provided with press plates (4), and the press plates (4) are sleeved on the positioning pins (5) so as to press the thin-wall stamping parts (3) in holes of the loading boxes (2).

Owner:AECC AVIATION POWER CO LTD

Fine double-sided planer

PendingCN107866868AReduce processing stepsIncrease productivityFlat surfacing machinesFeeding forceStructural engineering

The invention discloses a fine double-sided planer which comprises a machine frame, wherein two rotary lower plane cutters are supported by the machine frame, the positions of the two lower plane cutter corresponds to a work table, two rotary upper plane cutter are further arranged above the work table, and cutter shafts of the upper plane cutters and cutter shafts of the lower plane cutters are in parallel mutually; a plurality of lower feeding rollers are further supported by the machine frame in a rotary mode, the lower plane cutters and the lower feeding rollers are arranged in a mutuallystaggered mode, a plurality of upper feeding roller assemblies are arranged above the work table, the upper plane cutter and the upper feeding roller assemblies are arranged in a staggered mode, and feeding roller spindles of the upper feeding roller assemblies are parallel to the axes of the lower feeding rollers; the feeding roller spindles and the lower feeding rollers are connected with a feeding roller speed reducer respectively through upper feeding roller driving cardan joints and lower feeding roller driving cardan joints. The planer can provide strong, powerful and stable pushing feeding force and a reliable press restraining effect for wood; furthermore, the planer can achieve one-step type rough planing and fine planing on the wood.

Owner:JIANGSU JIANGJIA MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com