Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2550results about "Glass pane fixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

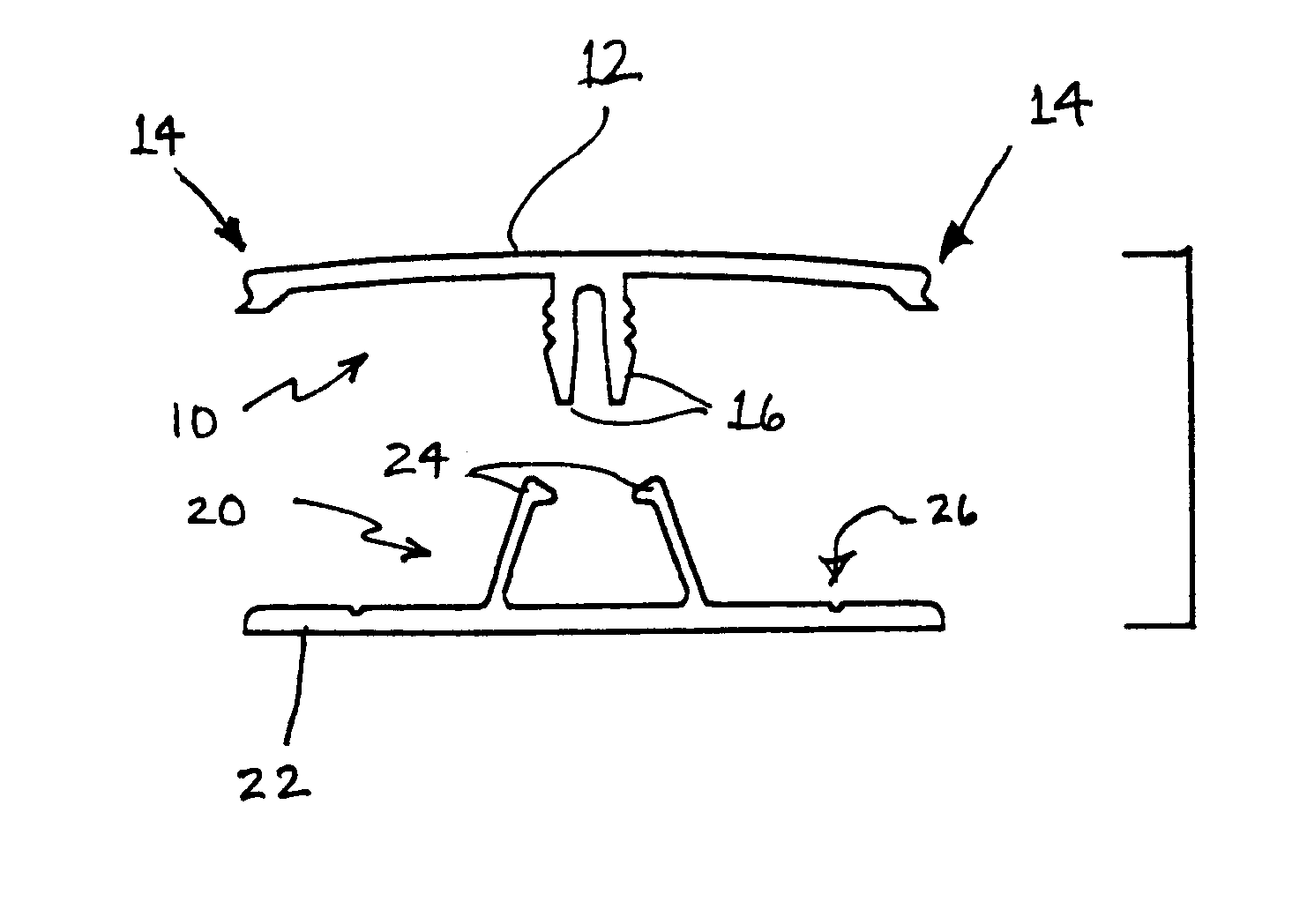

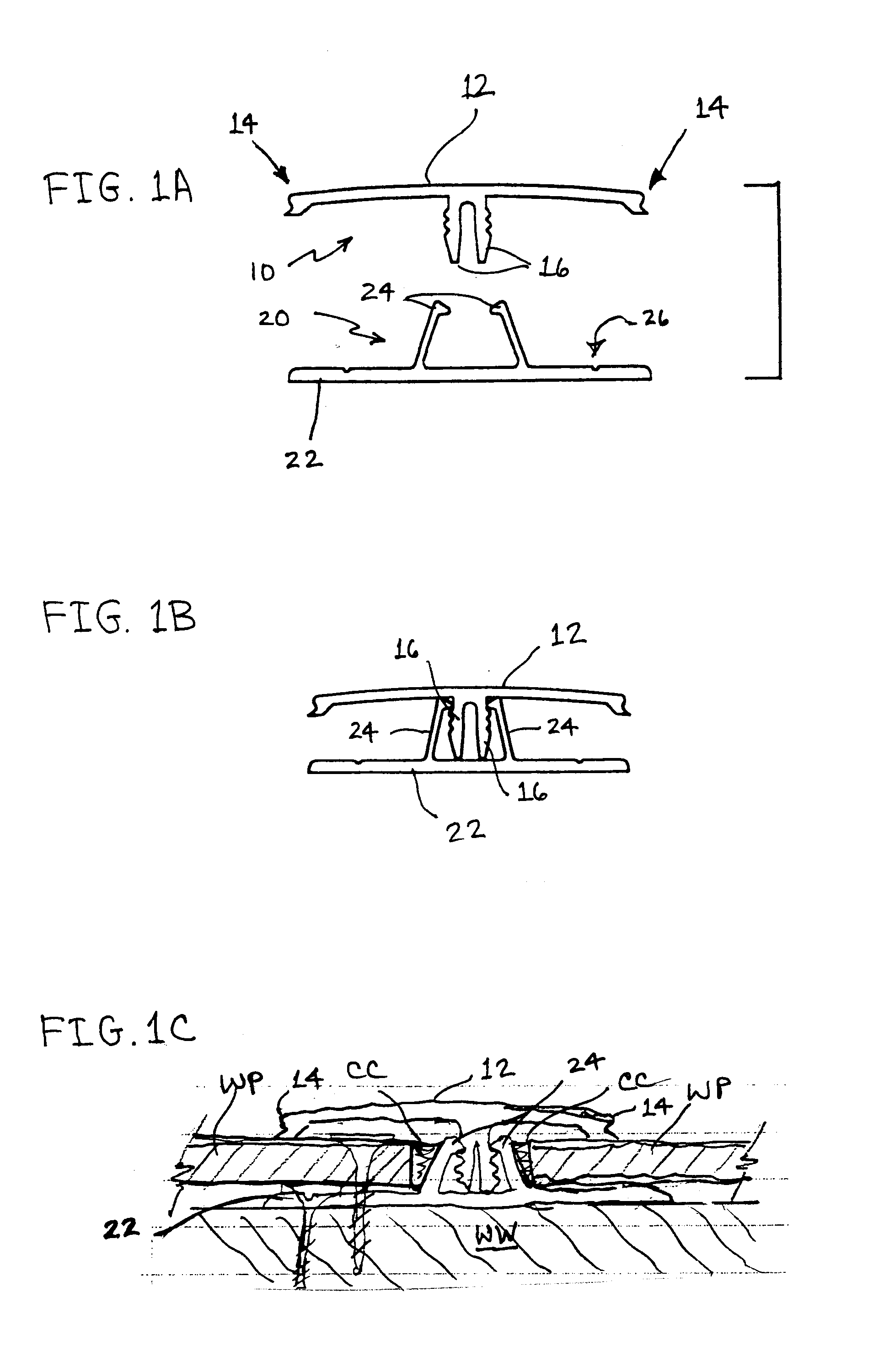

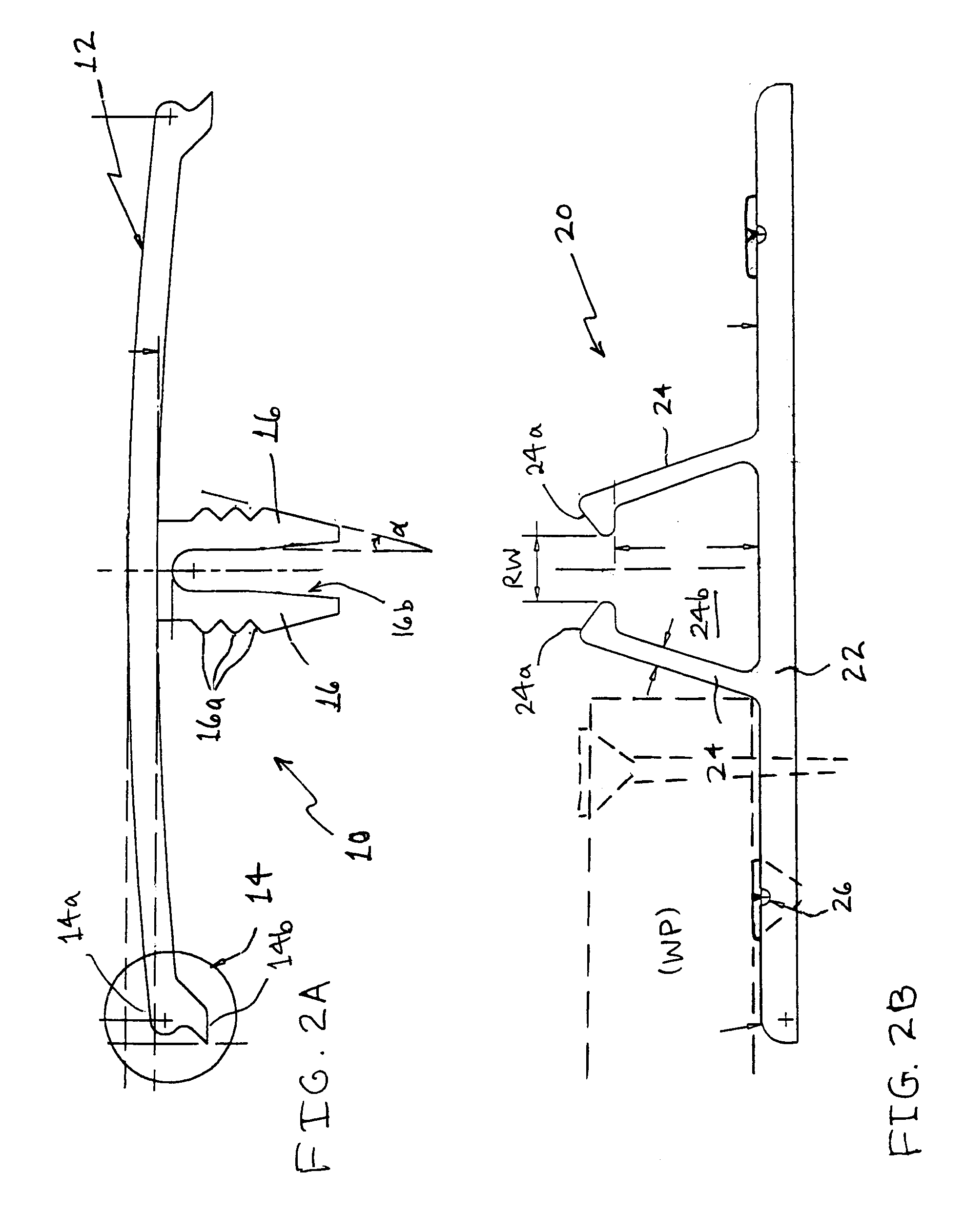

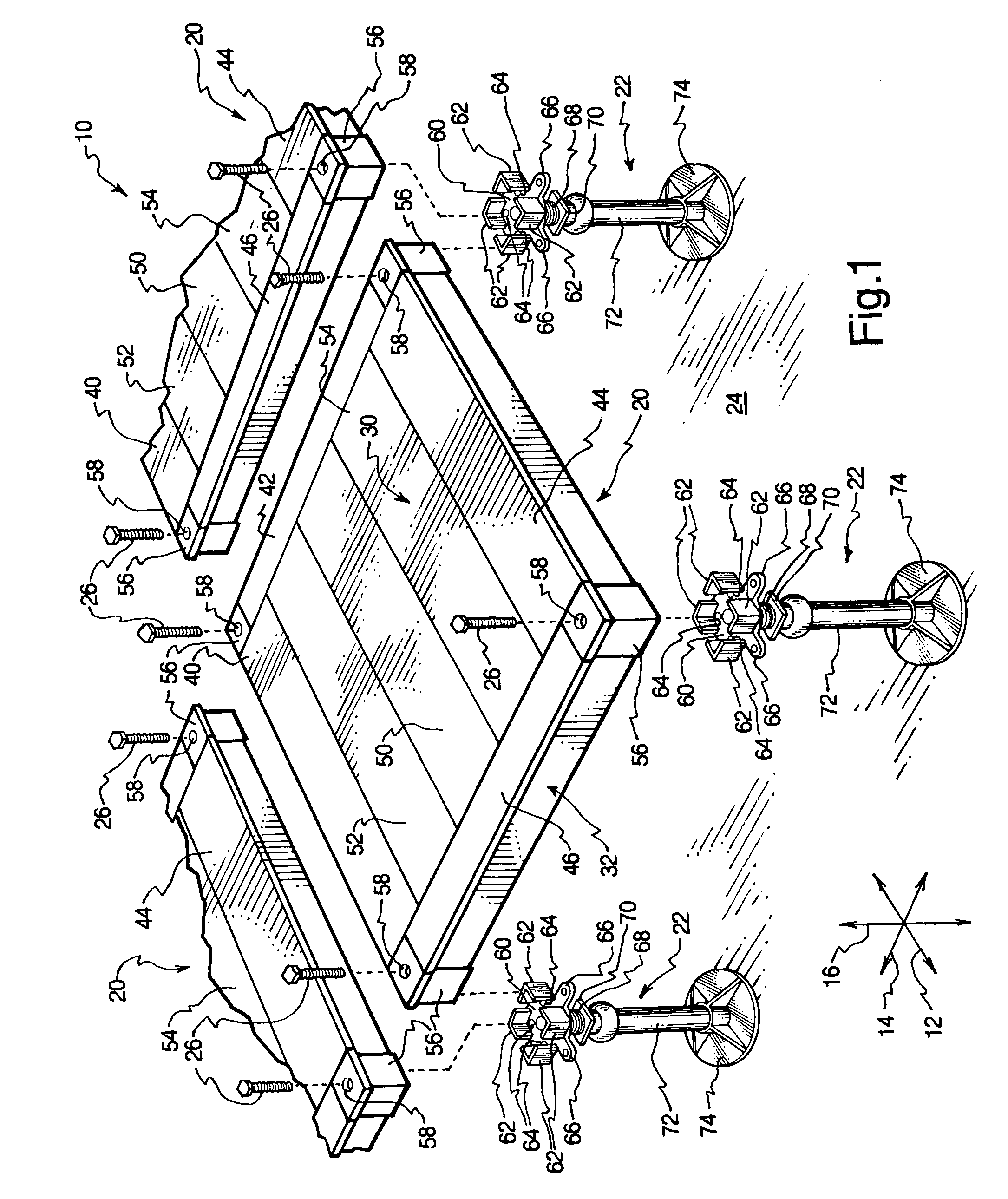

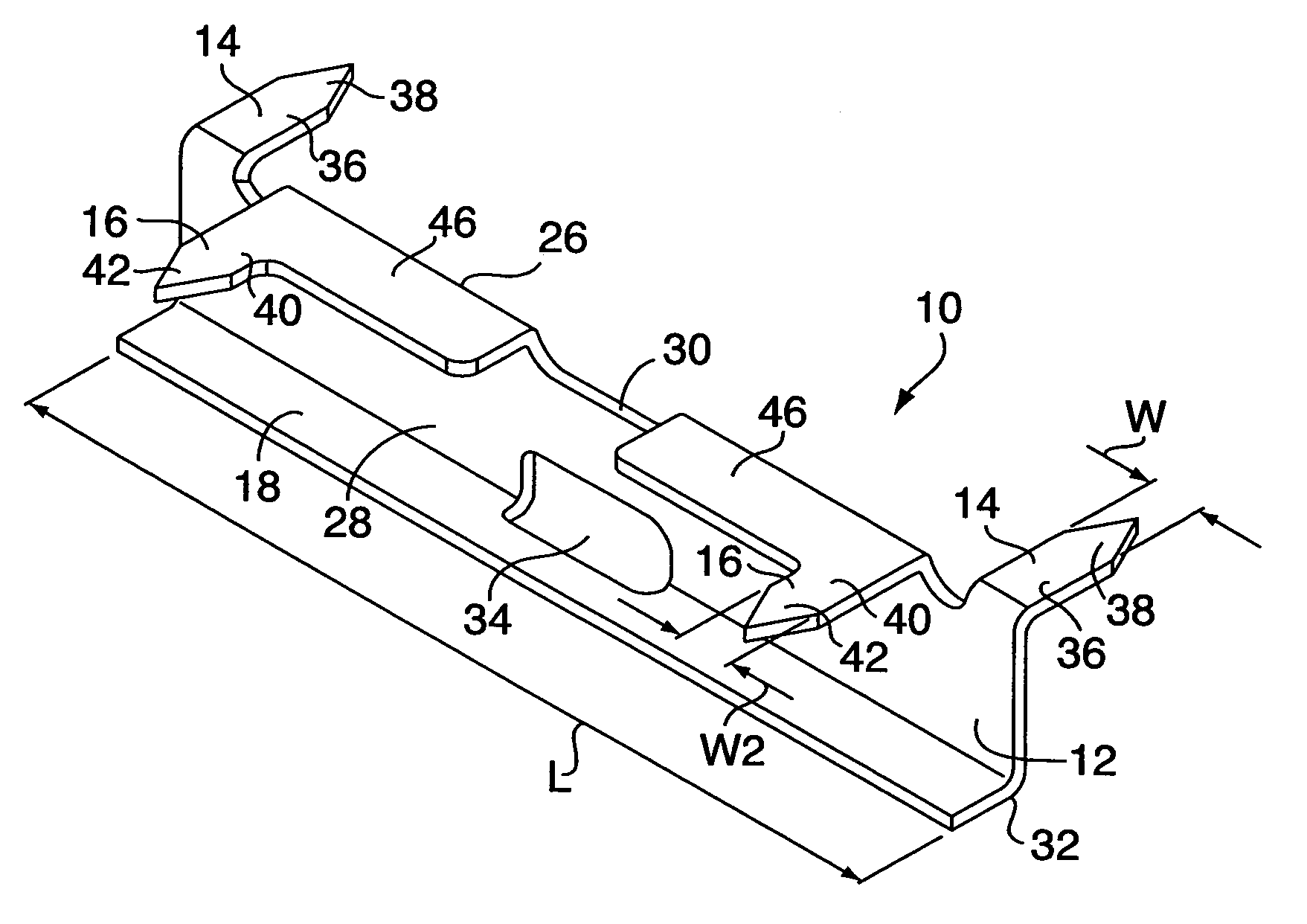

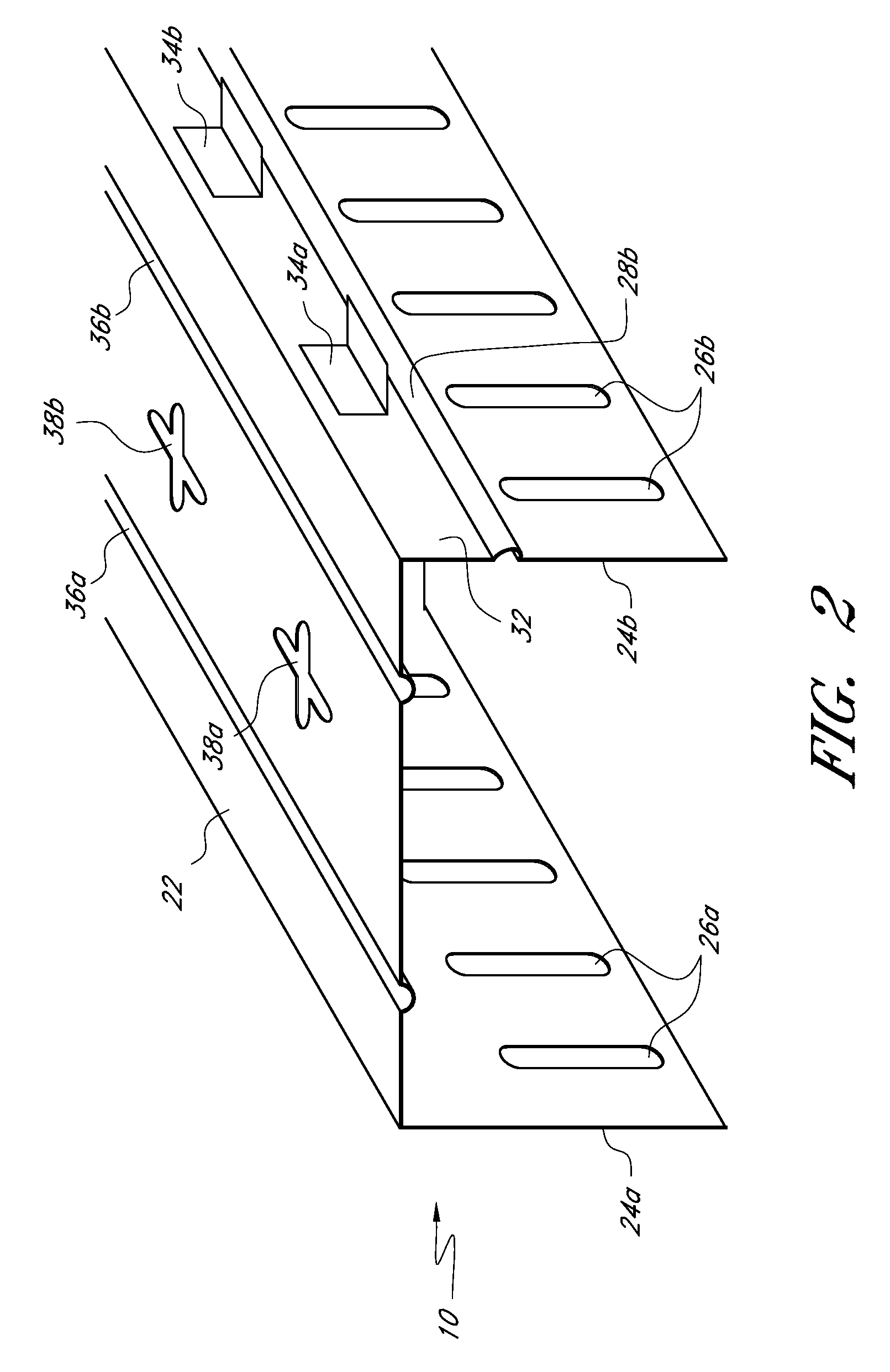

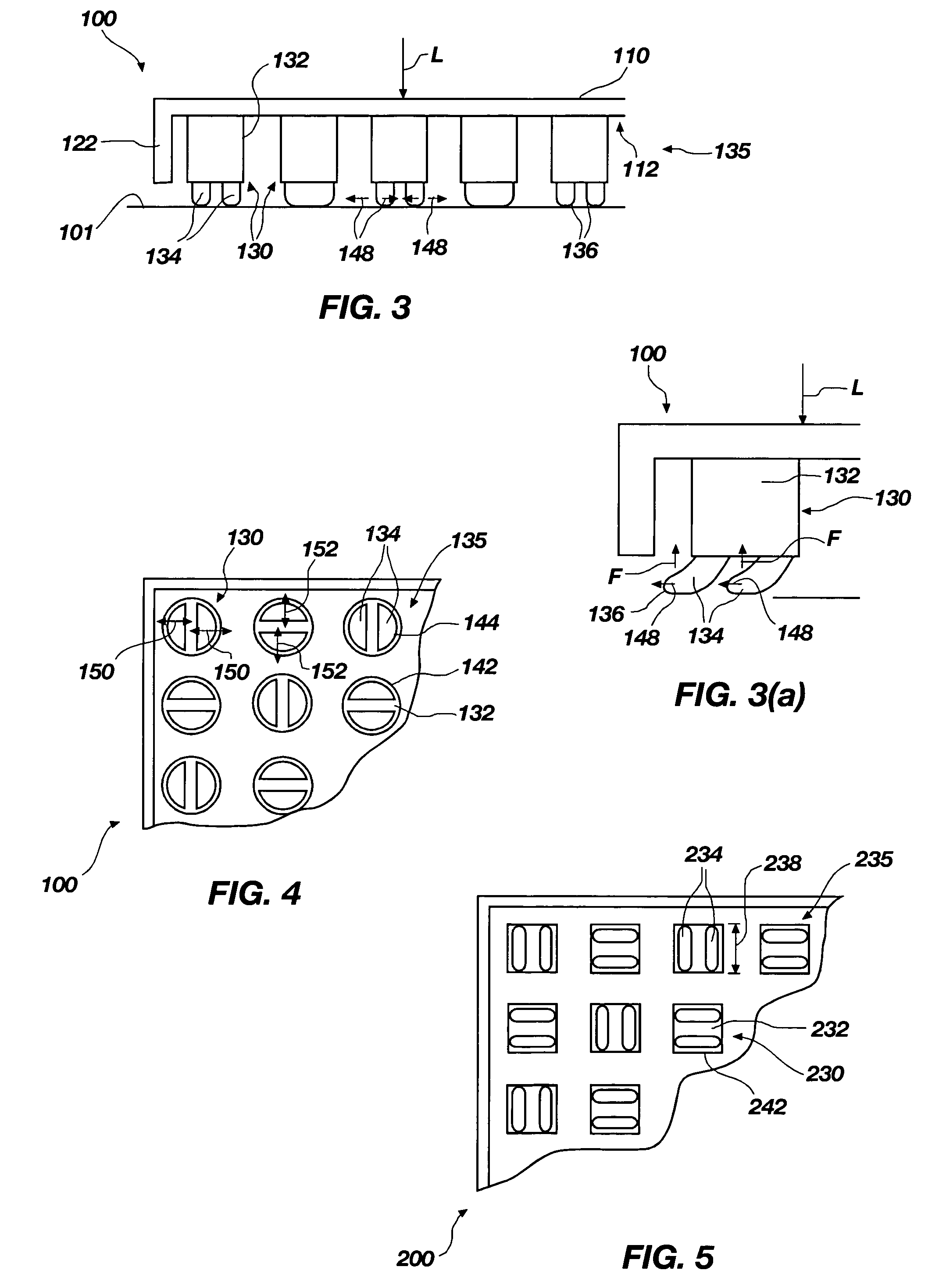

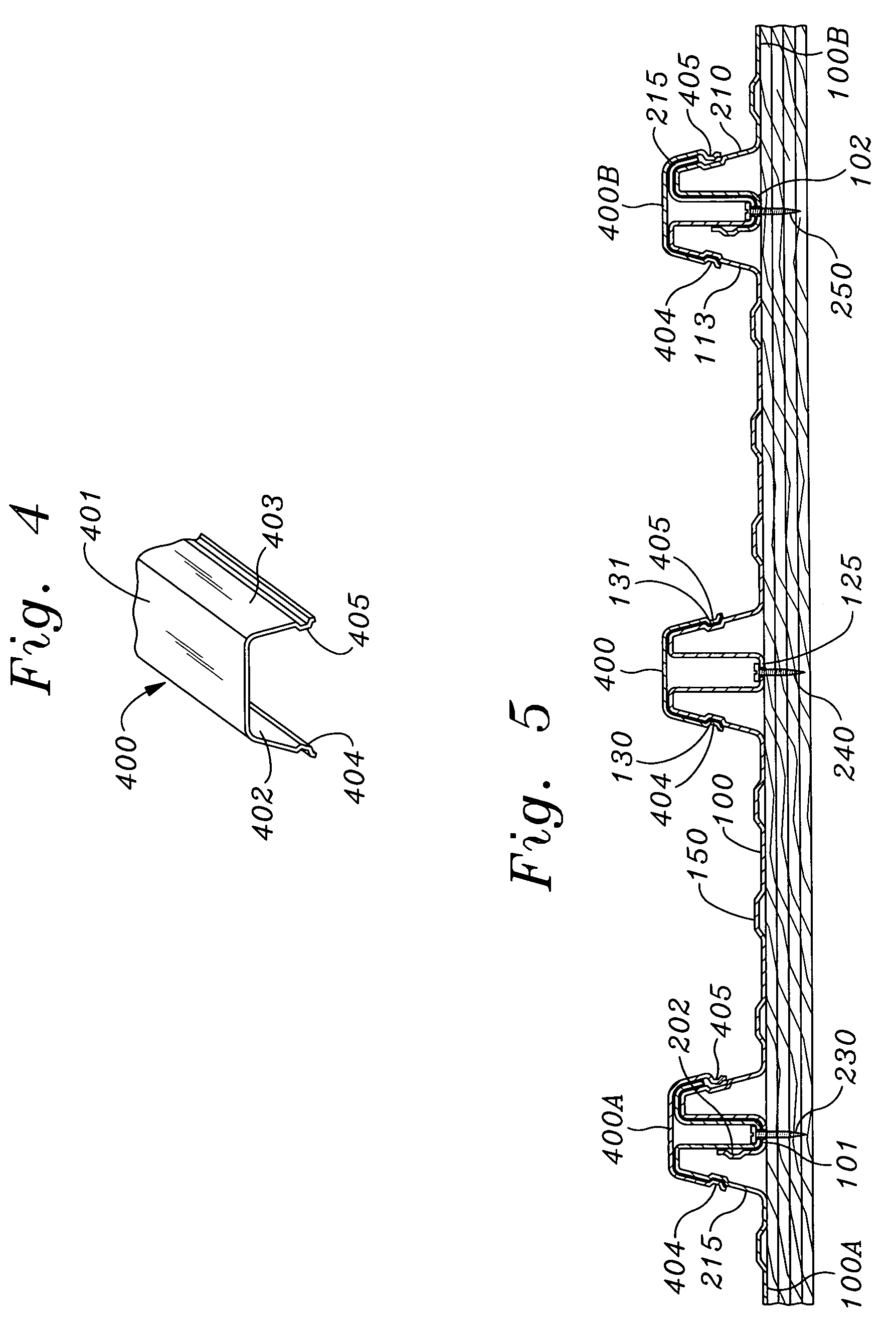

Extrusion devices for mounting wall panels

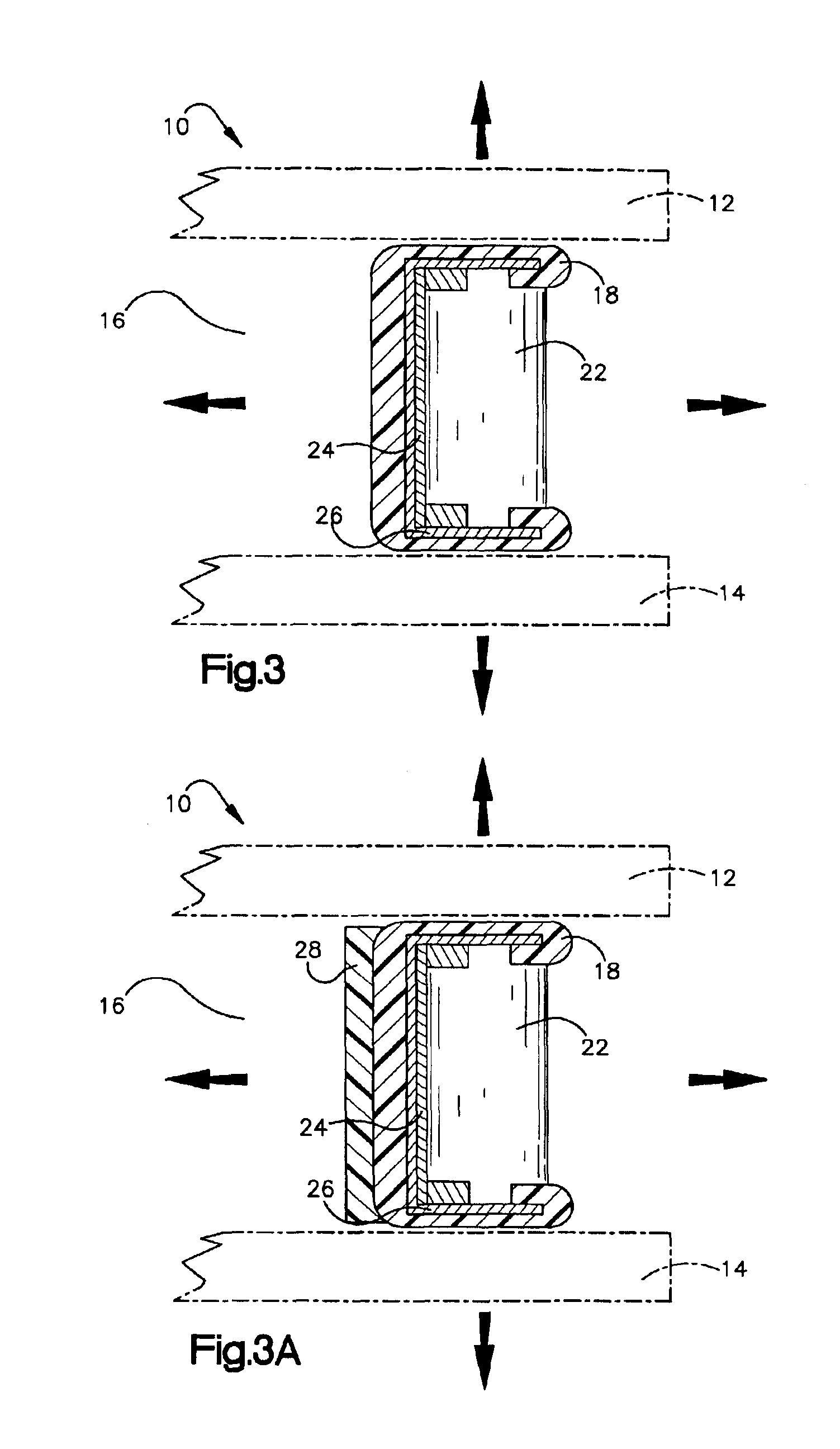

InactiveUS6588165B1Easy to insertImprove grip strengthCeilingsRoof covering using tiles/slatesEngineeringEdge space

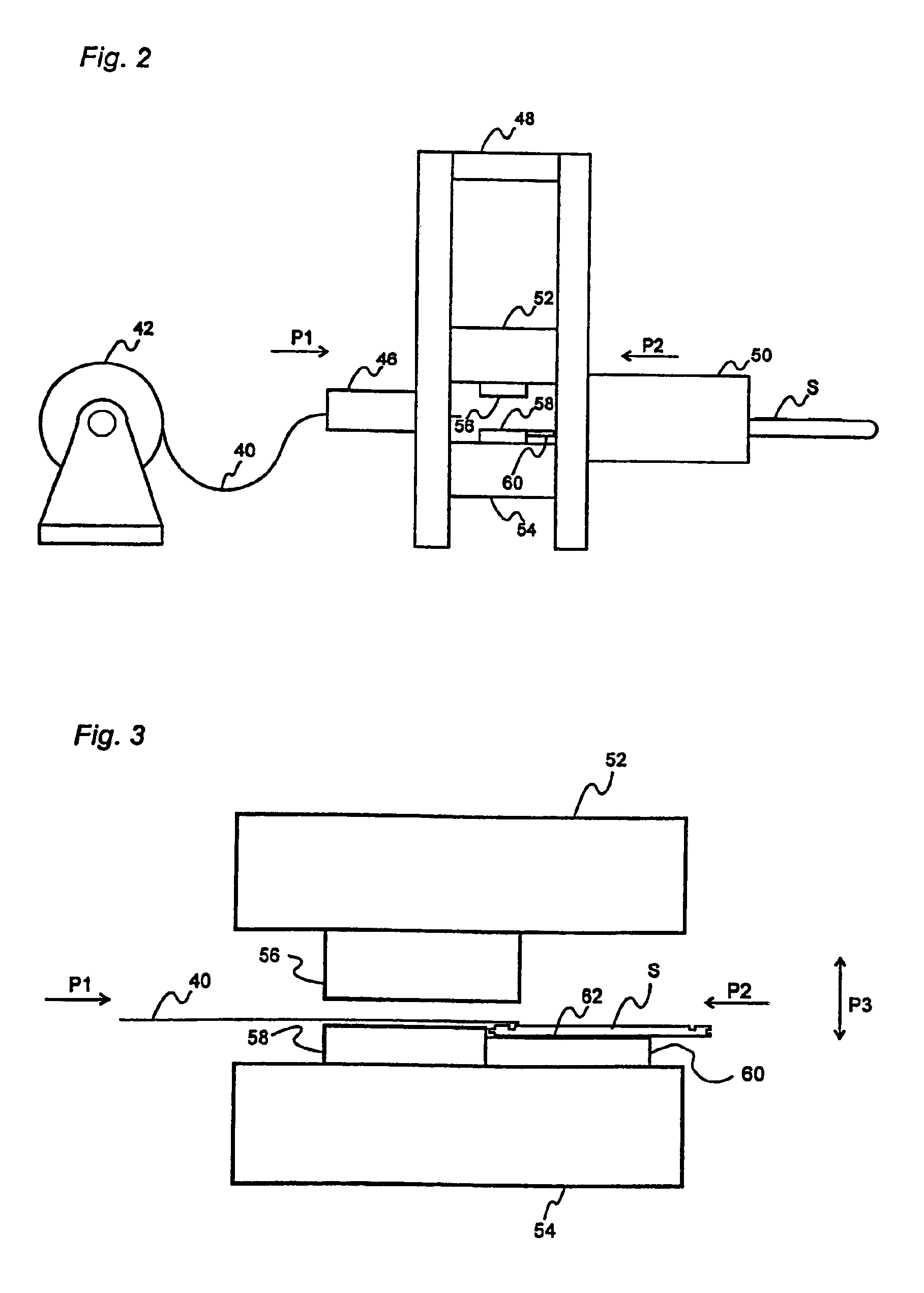

An extrusion device for mounting a wall panel has an outer cap extending to an edge on at least one side which is positioned against an outer surface of a wall panel, having a pair of spaced-apart insertion fingers, and a receiver base having a planar mounting portion and a pair of angled receiver flanges projecting upwardly to receive the insertion fingers therein. The two-piece extrusion permits wall panels to be mounted or removed from the underlying wall structure in on-sequential order. The receiver base and cap can be provided on both sides to form an "H" type extrusion, or on only one side in a "J" type extrusion. Preferably, the outer cap is made of metal, and the tips of the insertion fingers are beveled at a slight angle of about 7° to 14° to allow easy insertion into the receiver flanges. The cap has compound water-shedding edges formed with a rounded rain-drip edge spaced in close proximity to a sharply inclined knife edge. In another variation, a one-piece extrusion device has a rear base portion and a front cover portion forming a pocket therewith, and a ramp formed on the base portion within the width of the front cover portion for gradually forcing the edge of a wall panel inserted in the pocket toward the front cover portion clear of the heads of screws used to mount the base portion to the underlying wall structure. The base portion is formed with a hook indentation on a back side of the ramp on a rear surface of the base portion, and interconnects with a "Z" type extrusion having a hook end to form a right angle connection. The one-piece extrusion may be formed as a "J" (one-sided), "H" (two sided), "C" (corner), or other suitable types.

Owner:WRIGHT JOHN T

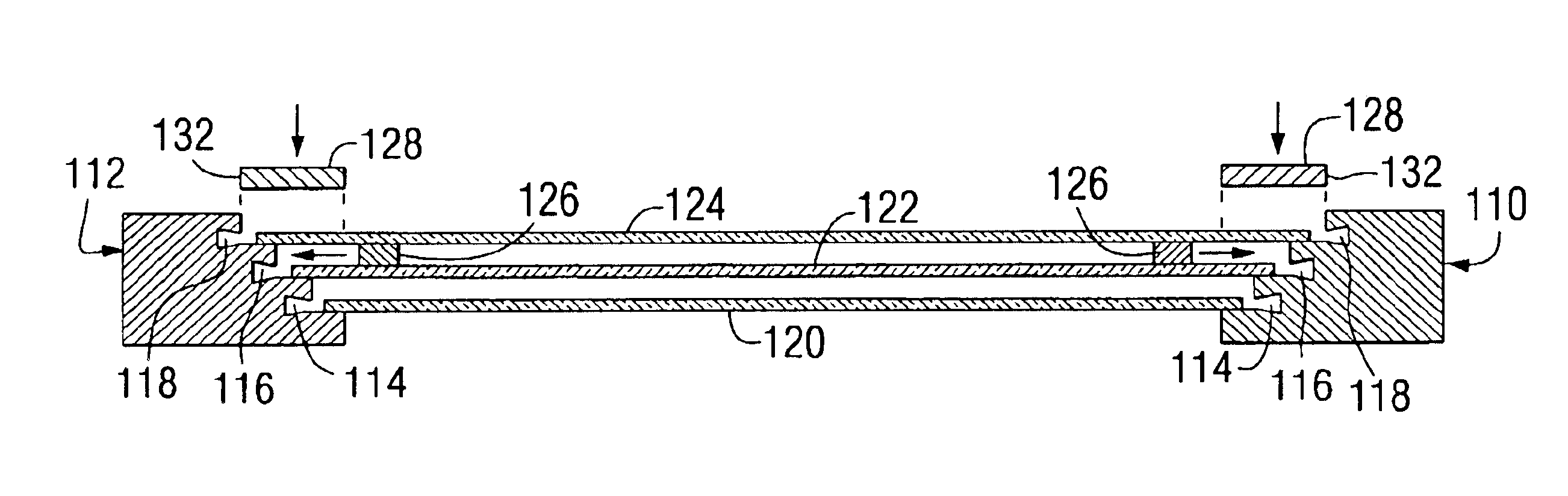

Glider bar for flooring system

A flooring system for use with floating floors is described which includes a glider bar having base portions including extending rails in the form of dovetail protrusions. The bases and rails are longitudinally moveable relative to anchoring plates, which anchoring plates are affixed to a subflooring. Flush finished floor moldings are slid longitudinally along the rails and are glued or mechanically fixed, at one side only, to the adjacent floating laminate flooring. By this assembly, smooth transitions between adjacent floating floors, or where floating floors meet another hard floor covering, or carpet, can be achieved. The system can also be used with flush stair nosing elements.

Owner:PERGO

Locking system and flooring board

A locking system for mechanical joining of floorboards. For horizontal mechanical joining there is a projecting portion with a locking element which cooperates with a locking groove in an adjacent board. A tongue-and-groove joint for vertical mechanical joining has cooperating upper abutment surfaces and cooperating lower abutment surfaces which are essentially parallel with the principal plane of the floorboards and of which the lower abutment surfaces are positioned essentially outside the outer vertical plane, i.e. displaced relative to the upper abutment surfaces. The tongue is movable at an angle into the groove and the locking element is insertable into the locking groove by mutual angular movement of the boards about the joint edges.

Owner:VÄLINGE INNOVATION AB

Resilient groove

A set of moisture proof floorboards and a flooring of such floorboards with a resilient surface layer provided with a decorative groove and / or a sealing means.

Owner:VÄLINGE INNOVATION AB

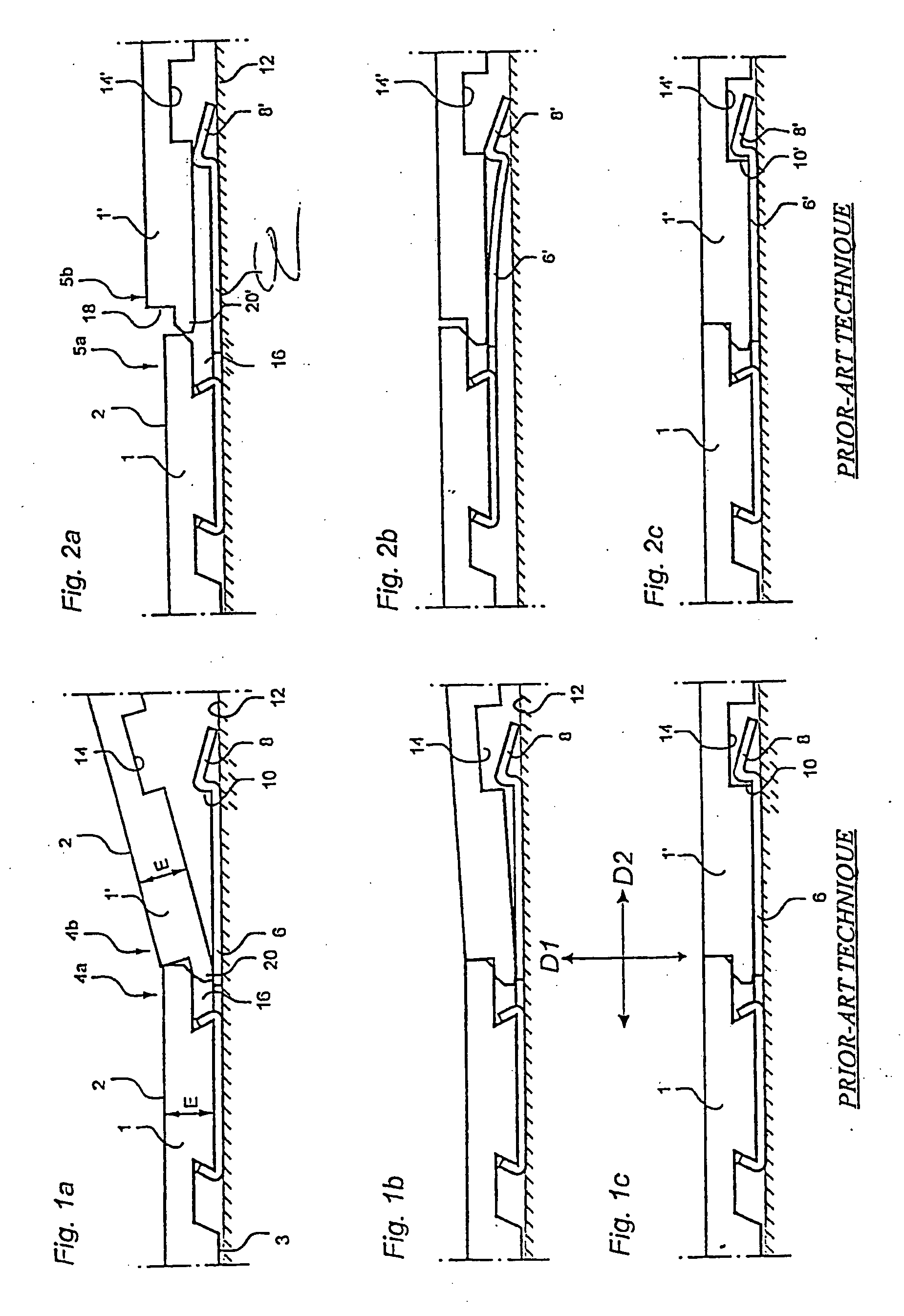

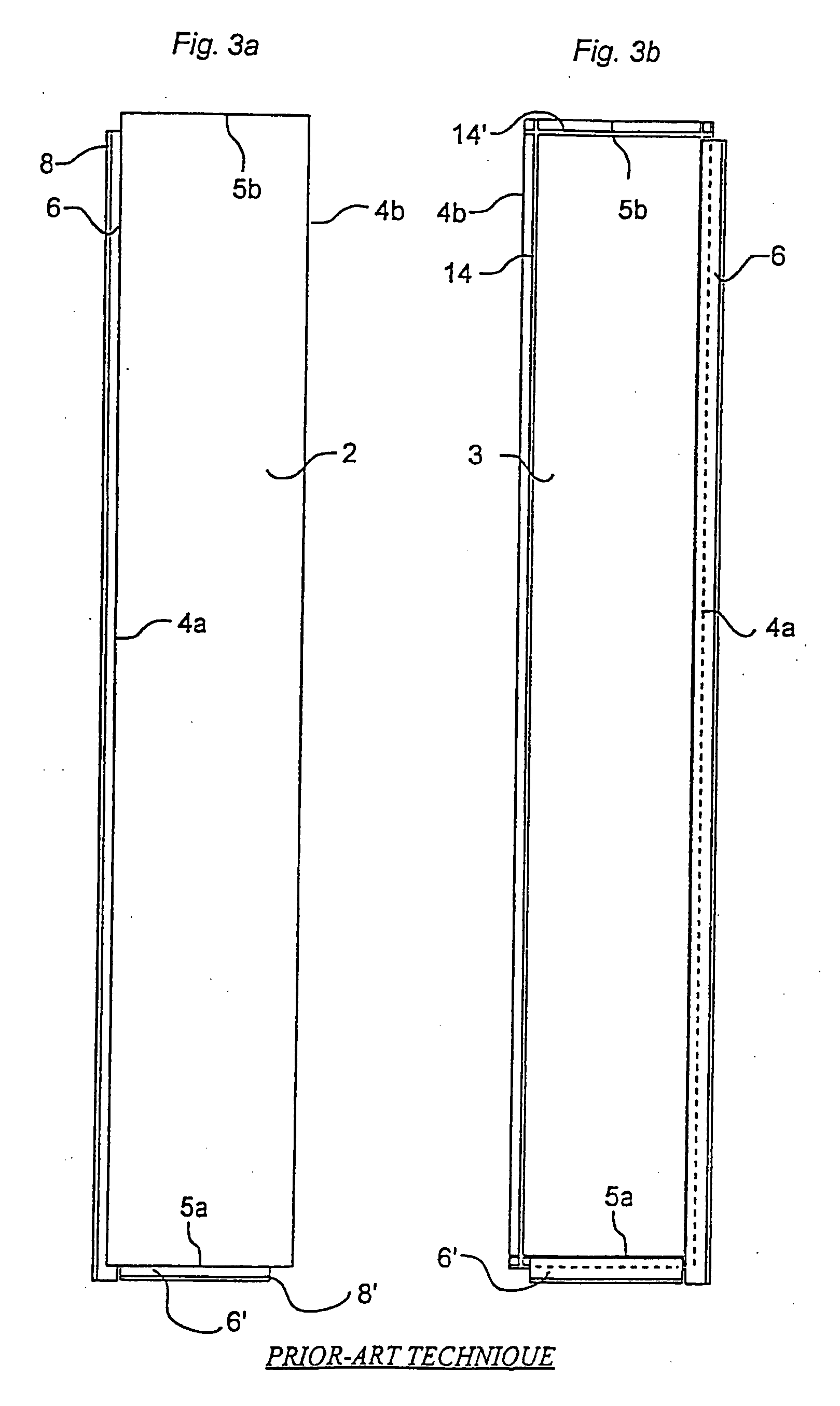

Locking systems for floorboards

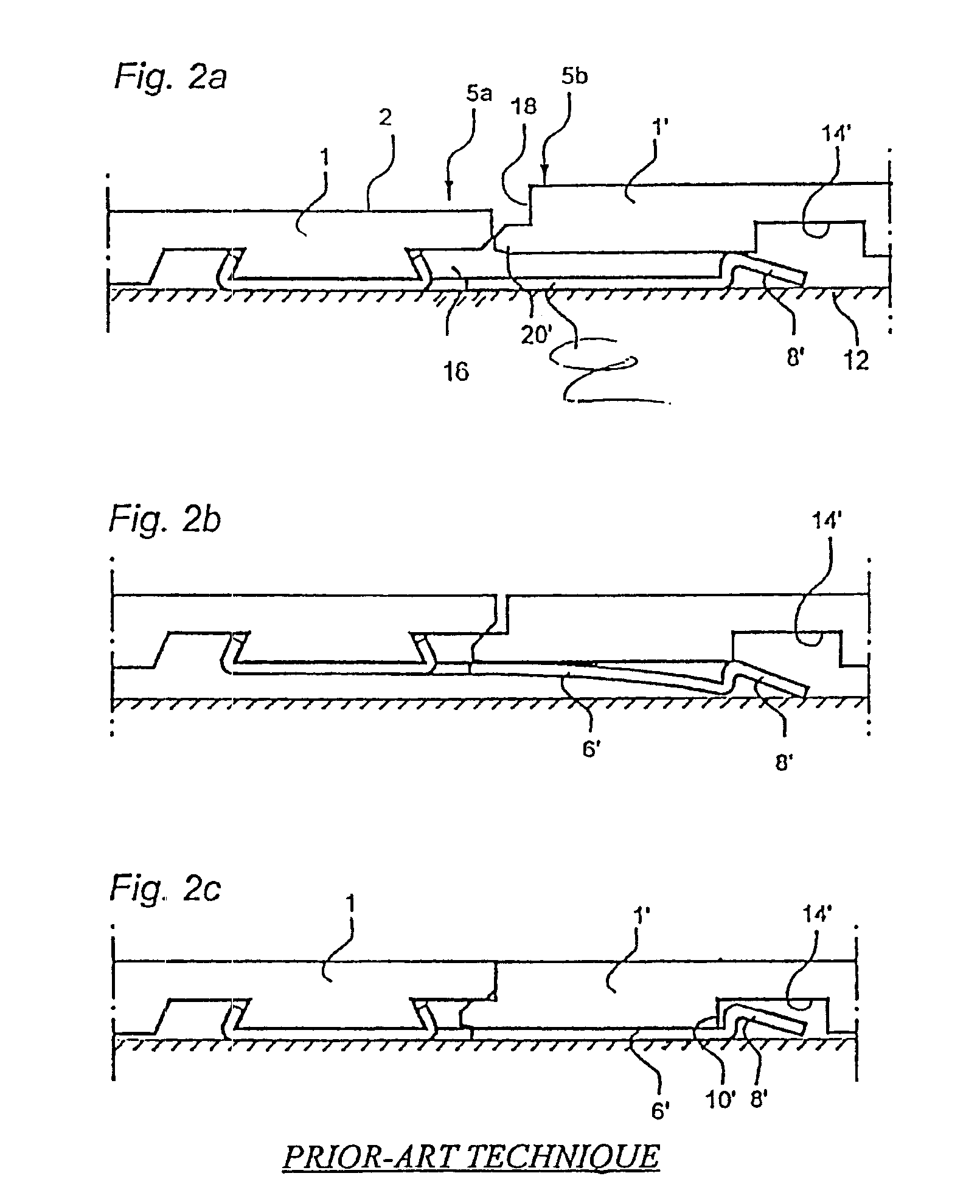

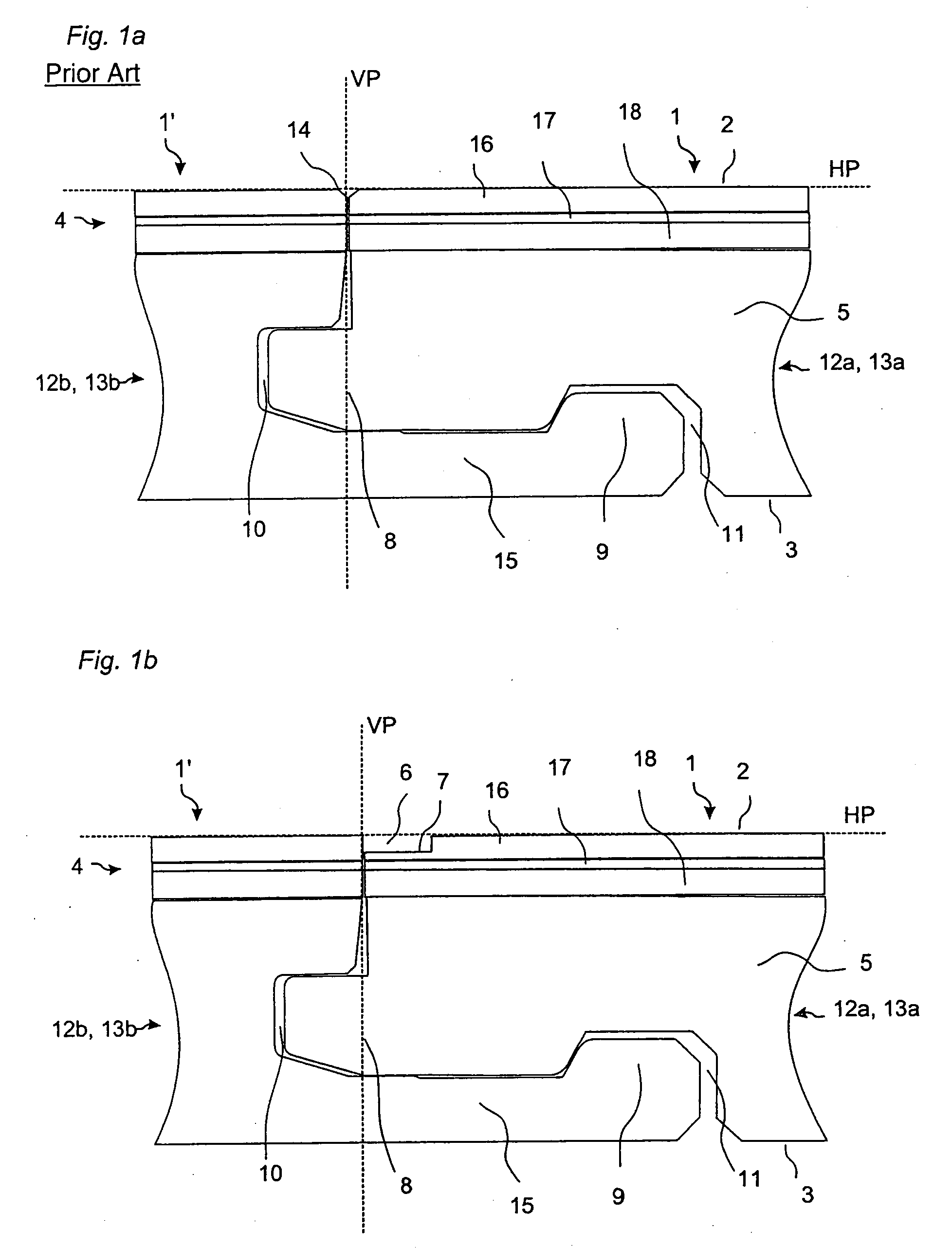

InactiveUS6918220B2Increase the differenceGood guiding effectCeilingsRoof covering using tiles/slatesVertical planeEngineering

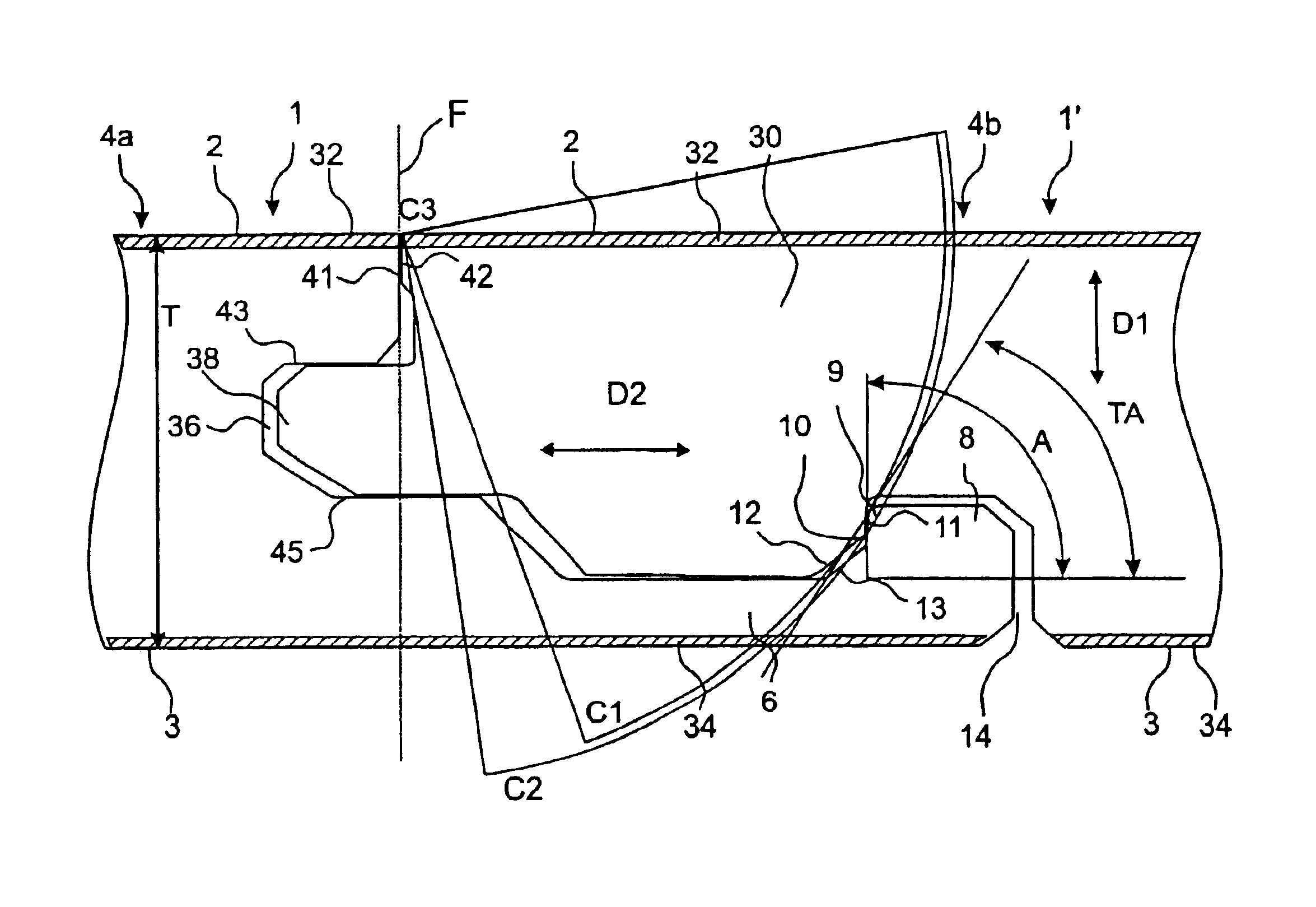

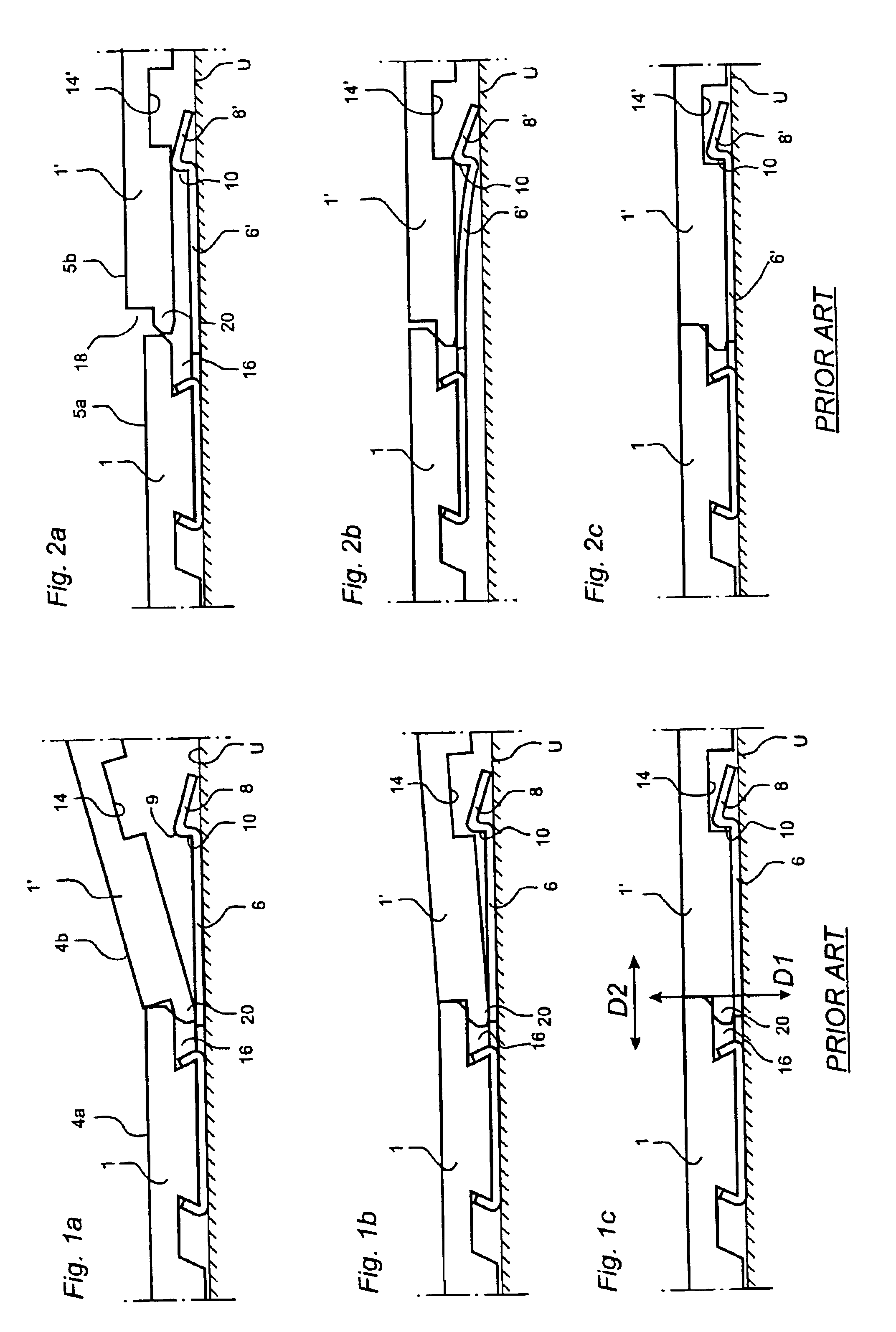

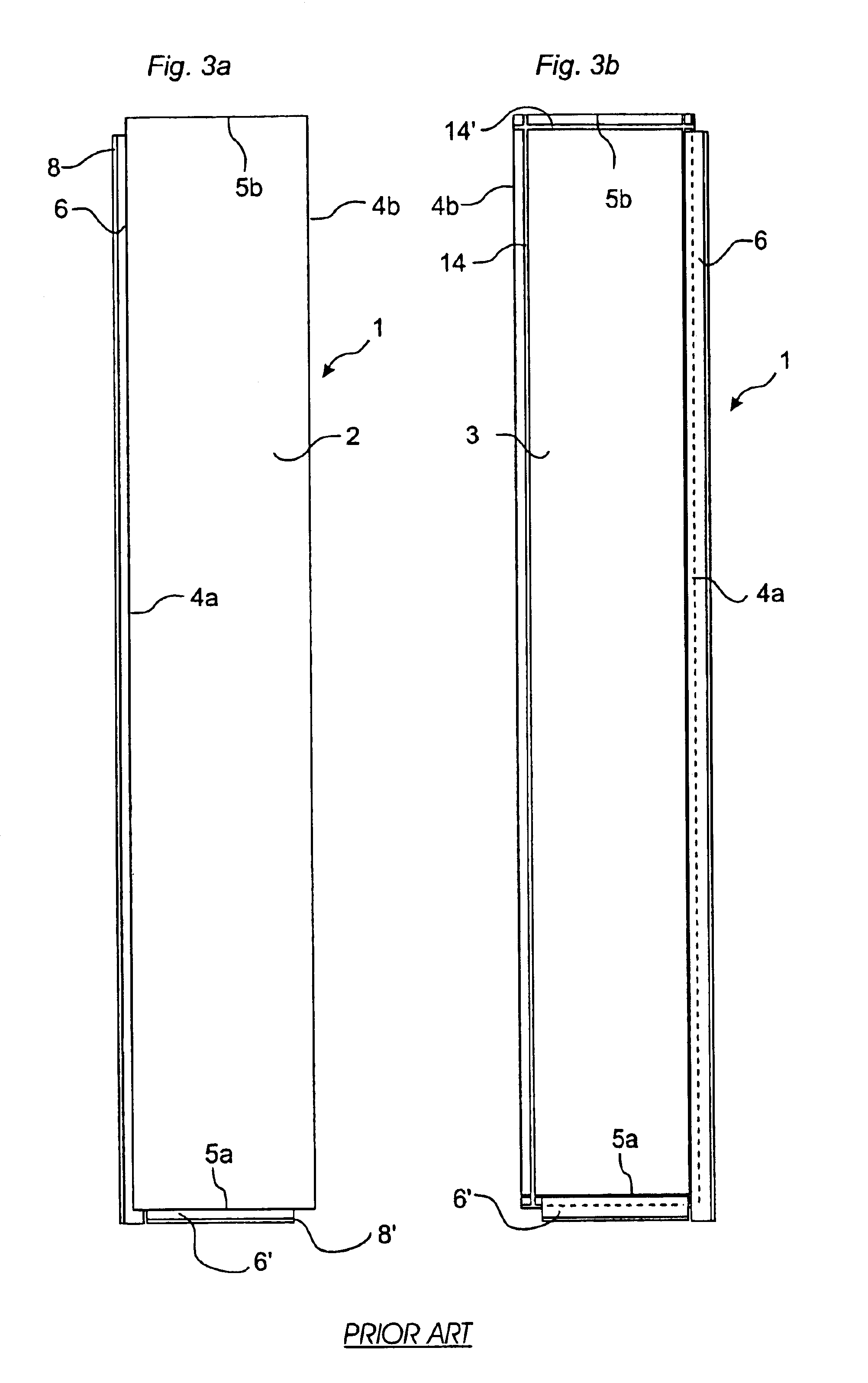

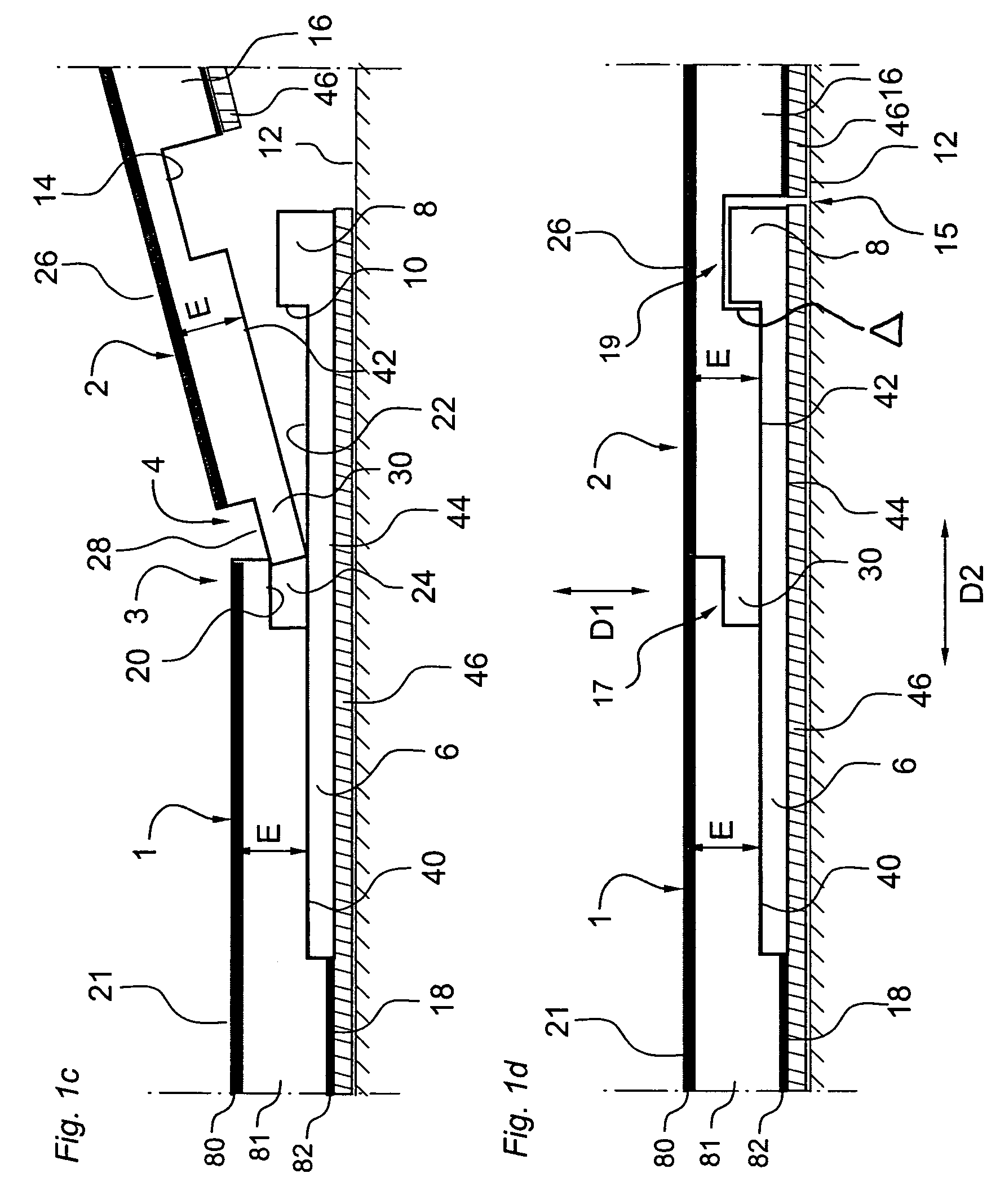

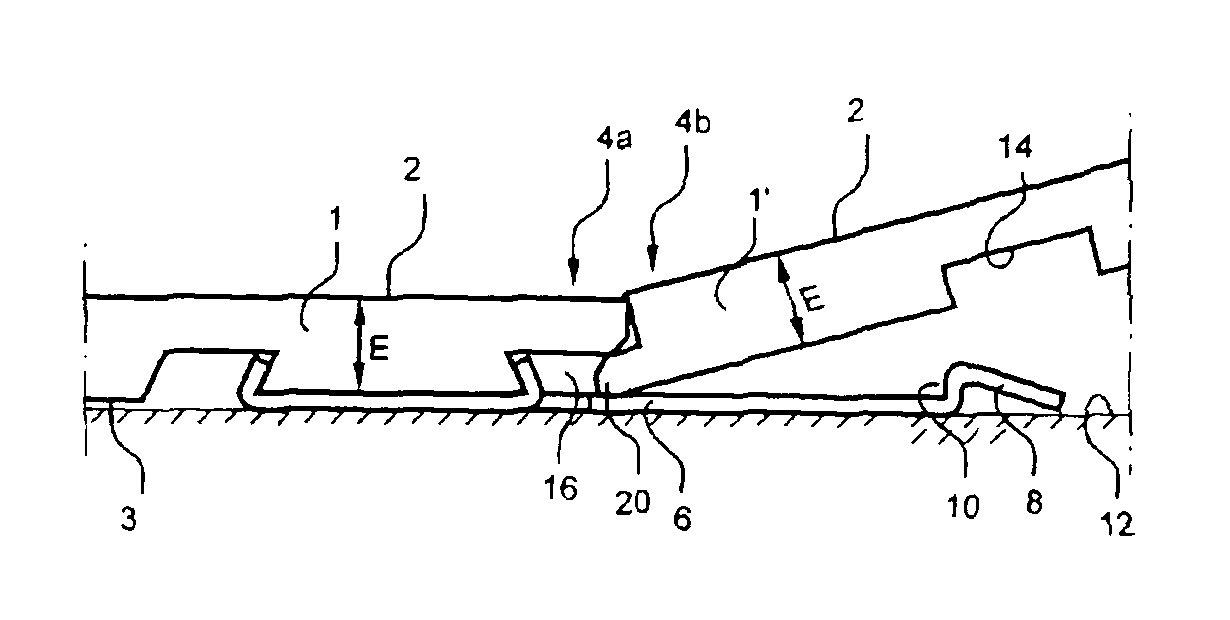

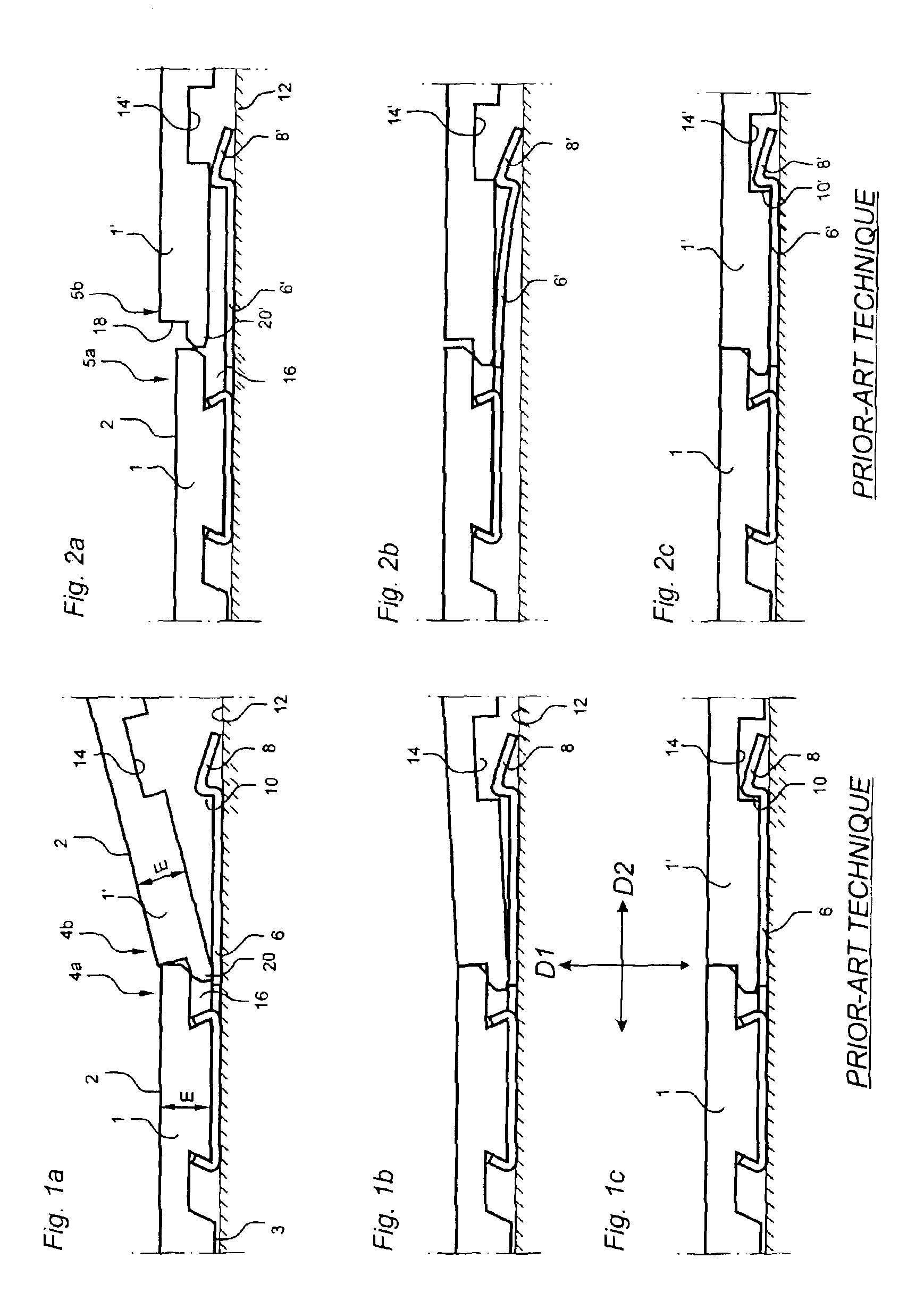

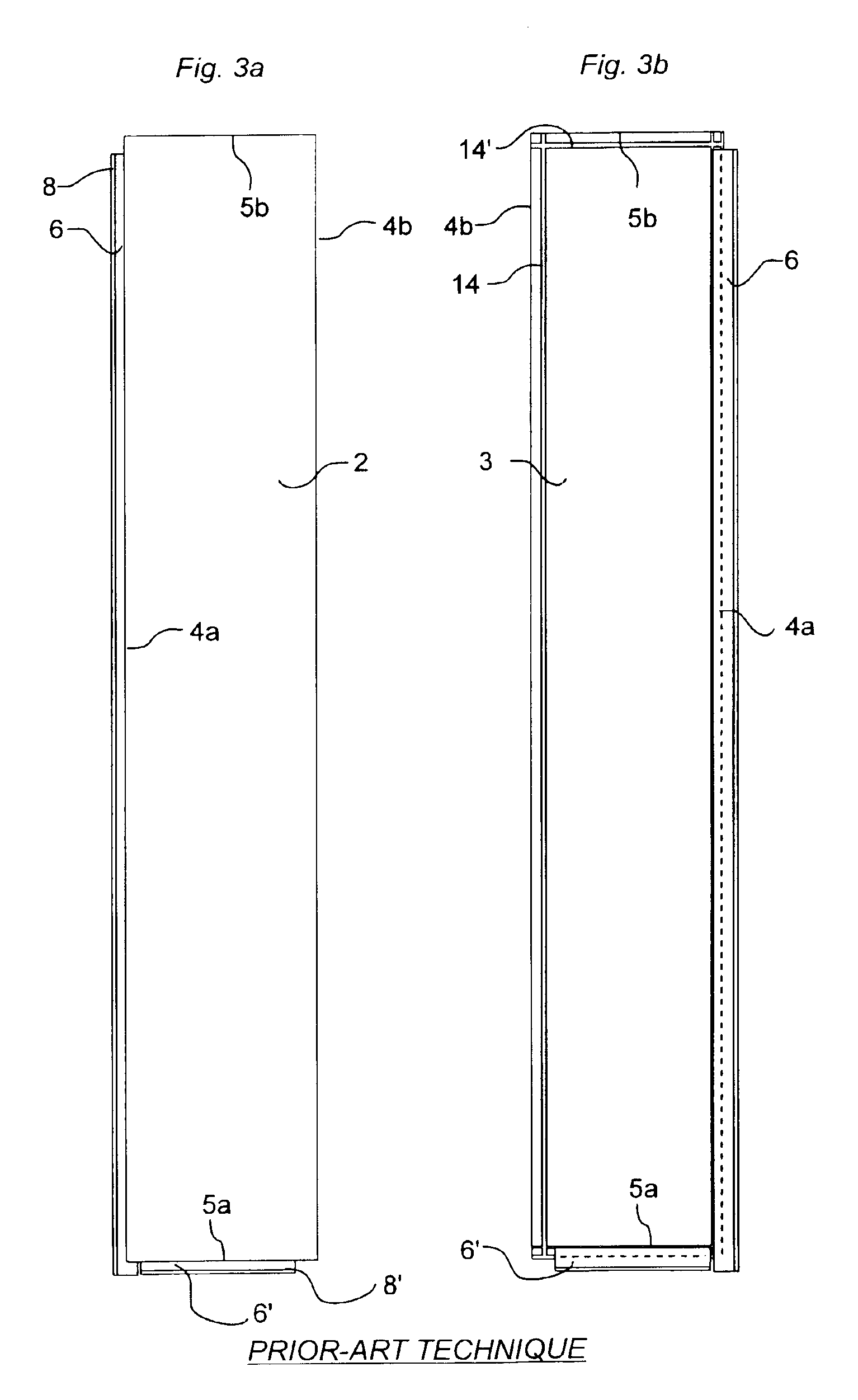

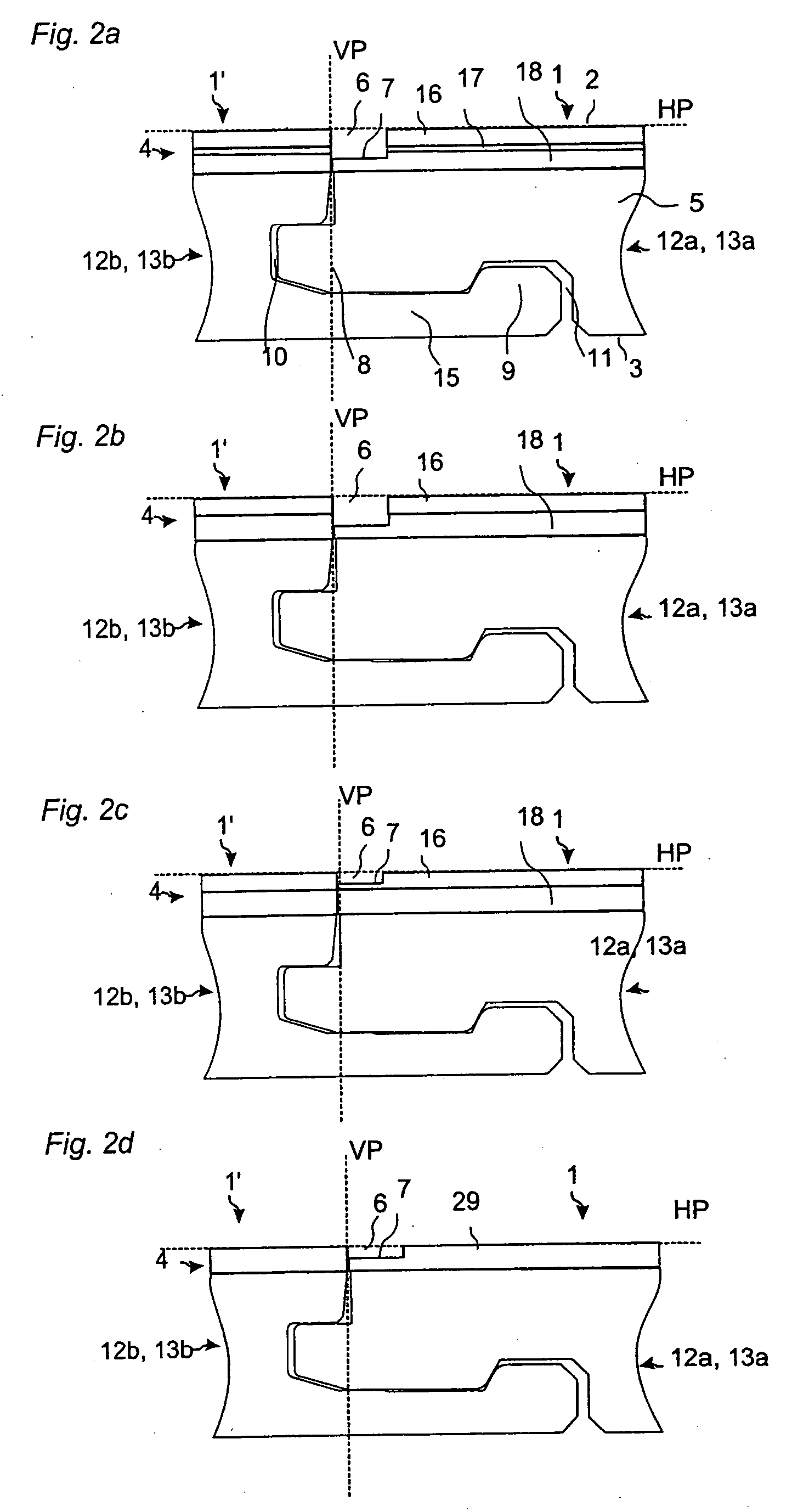

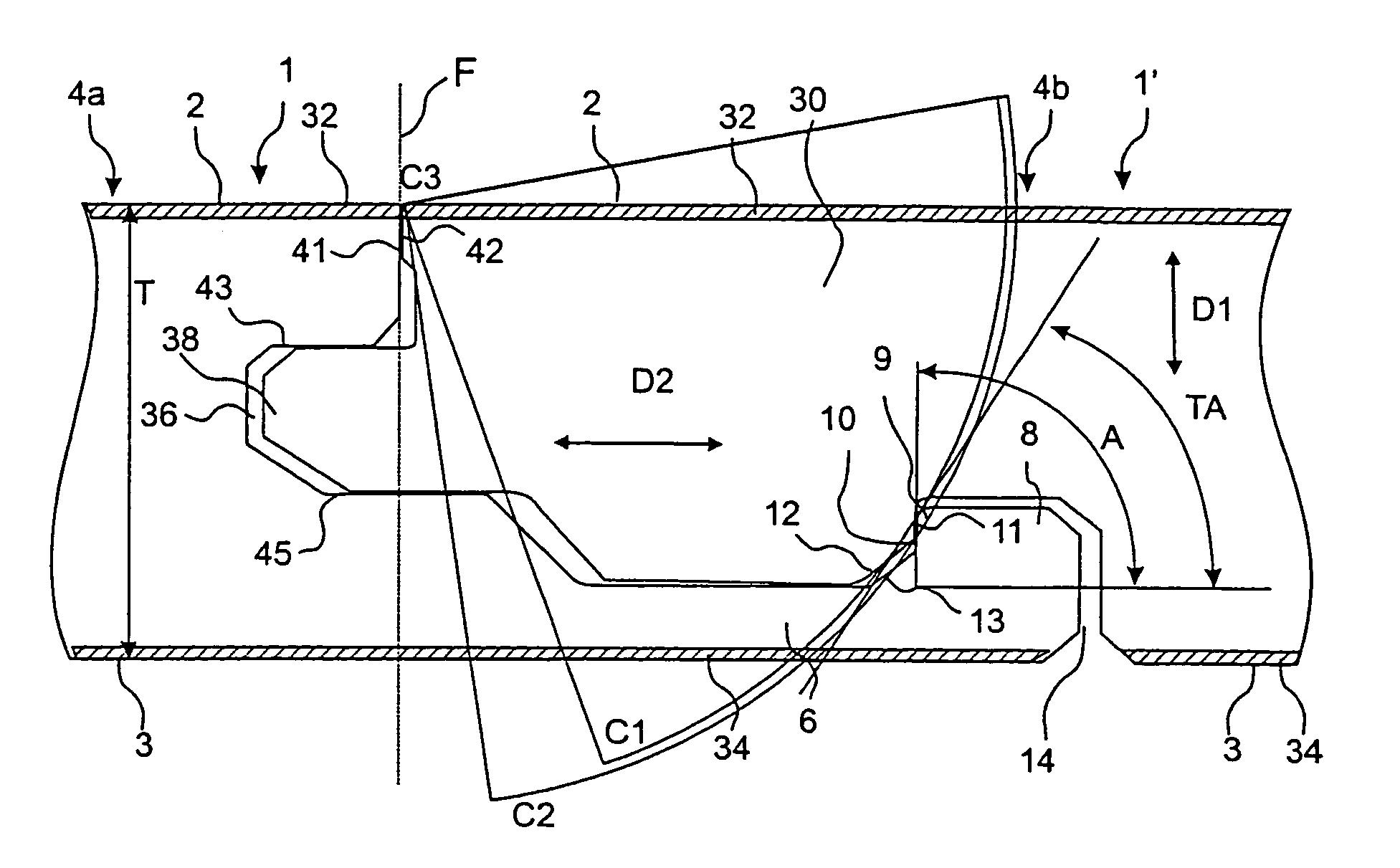

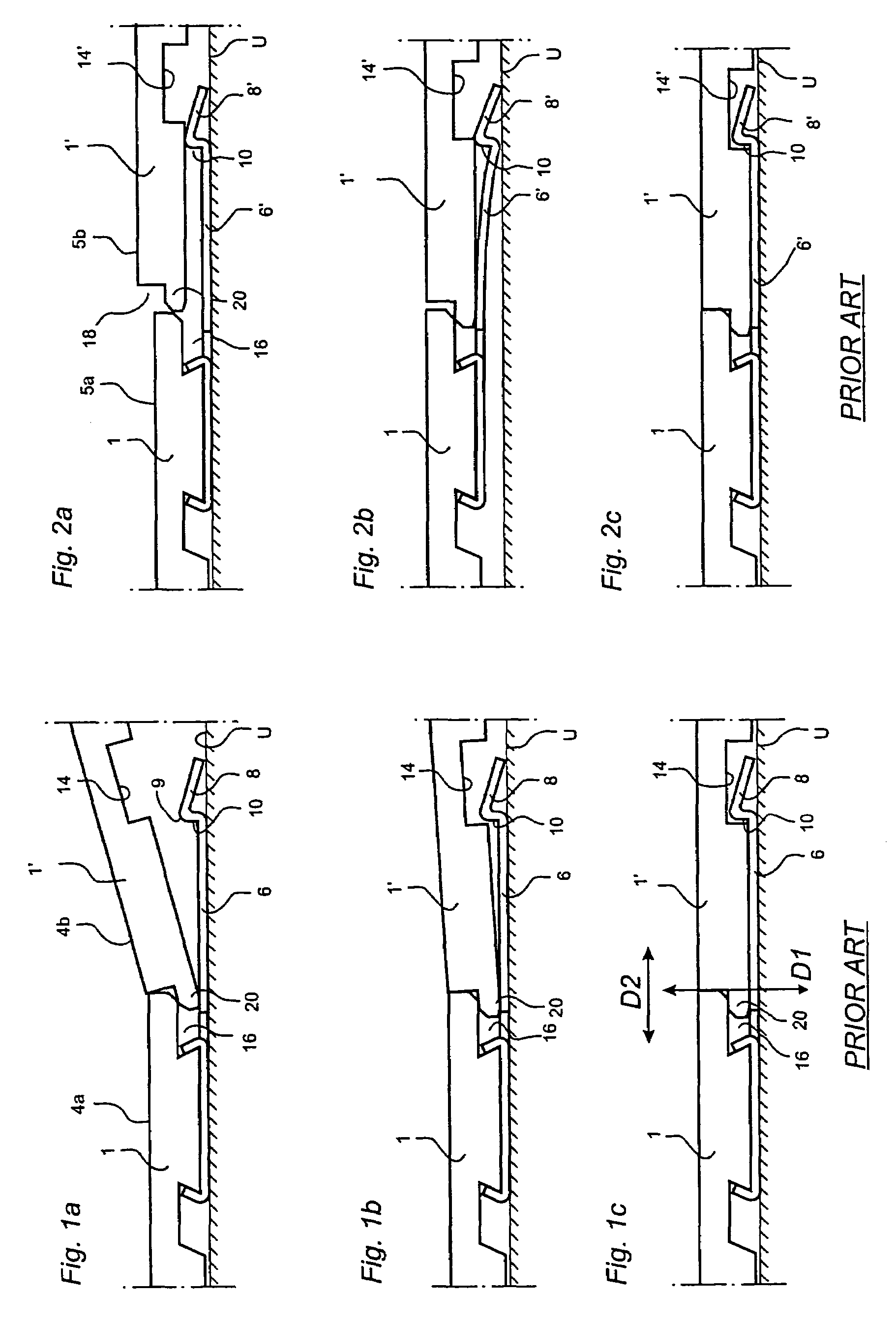

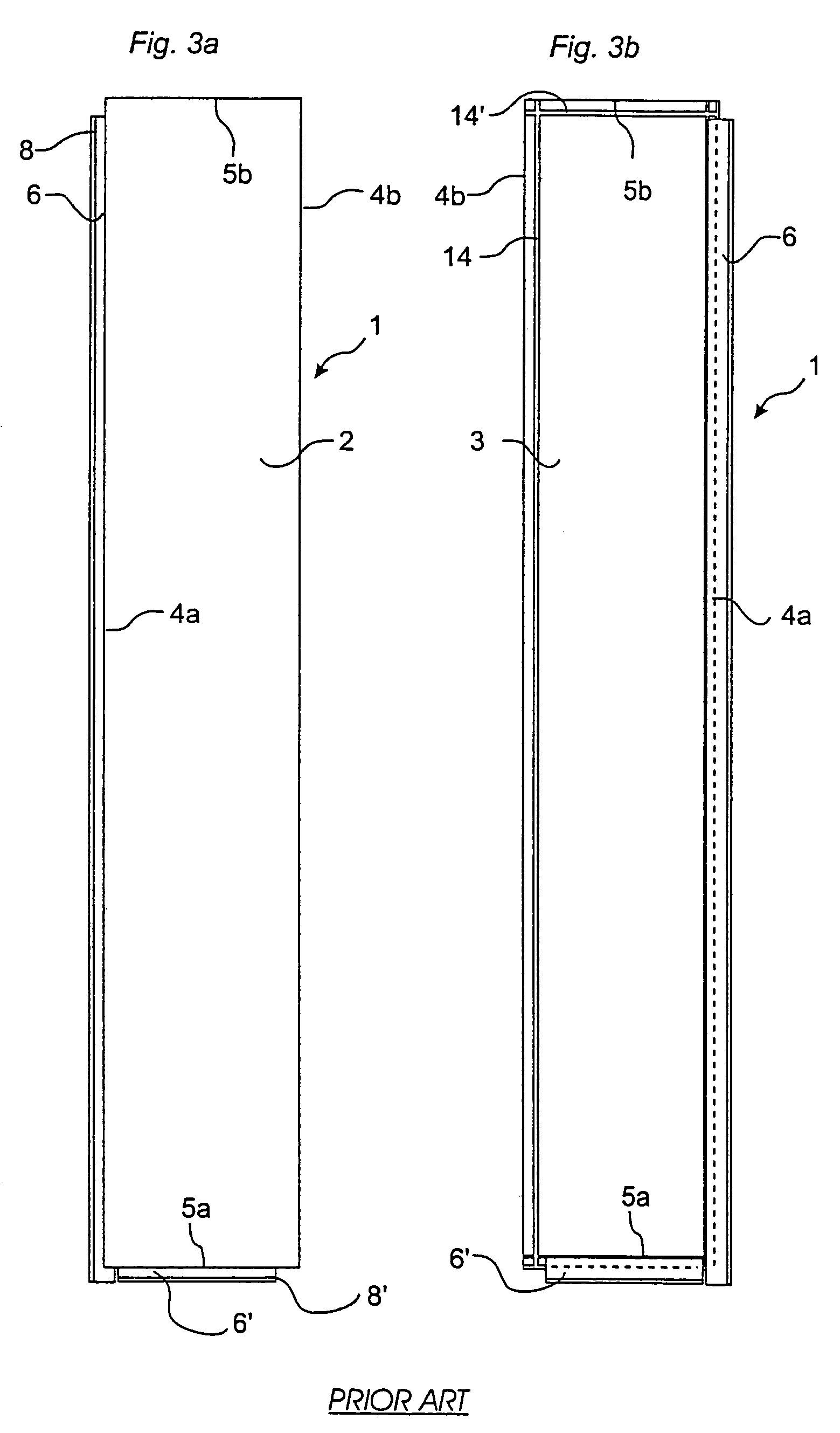

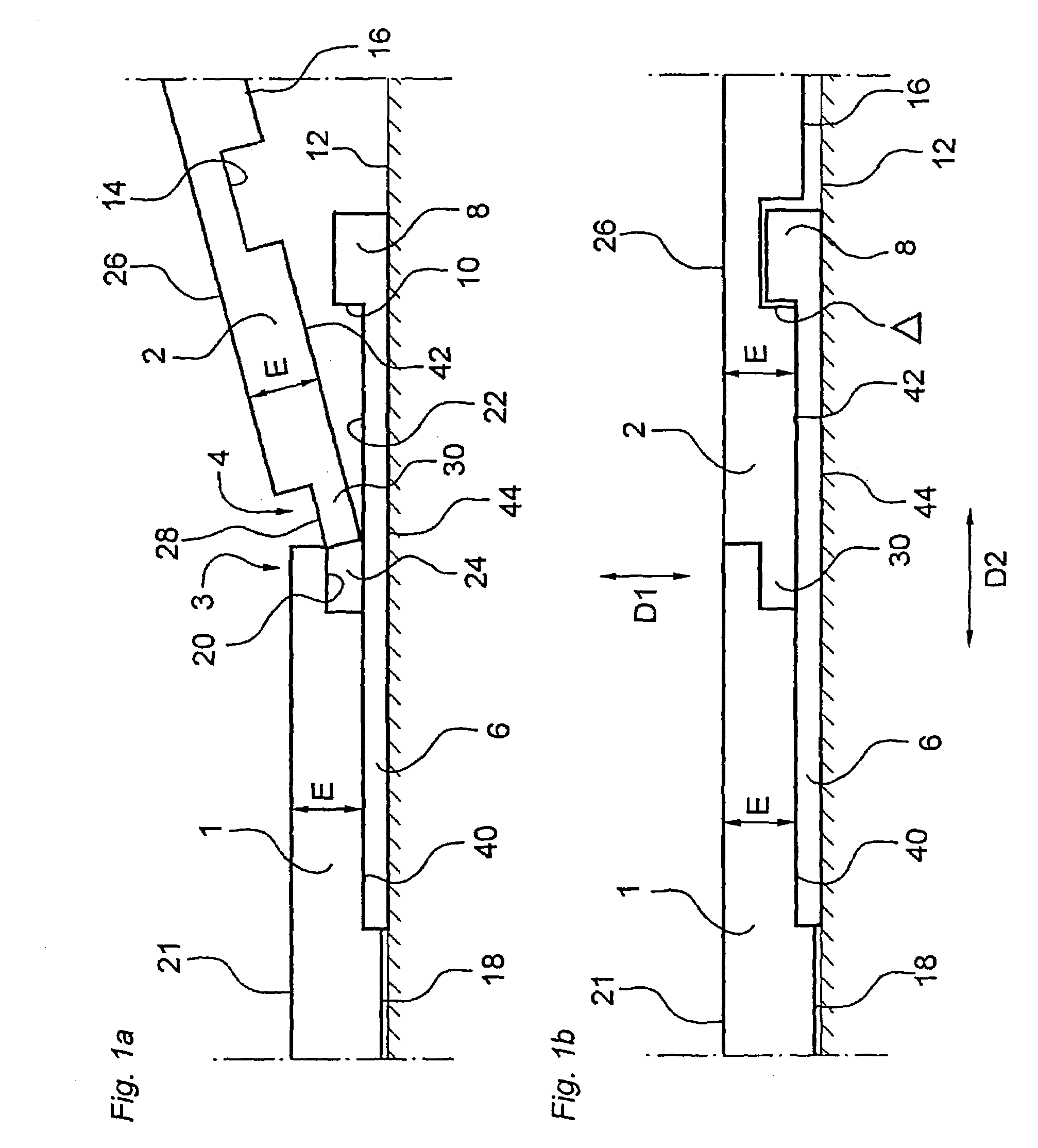

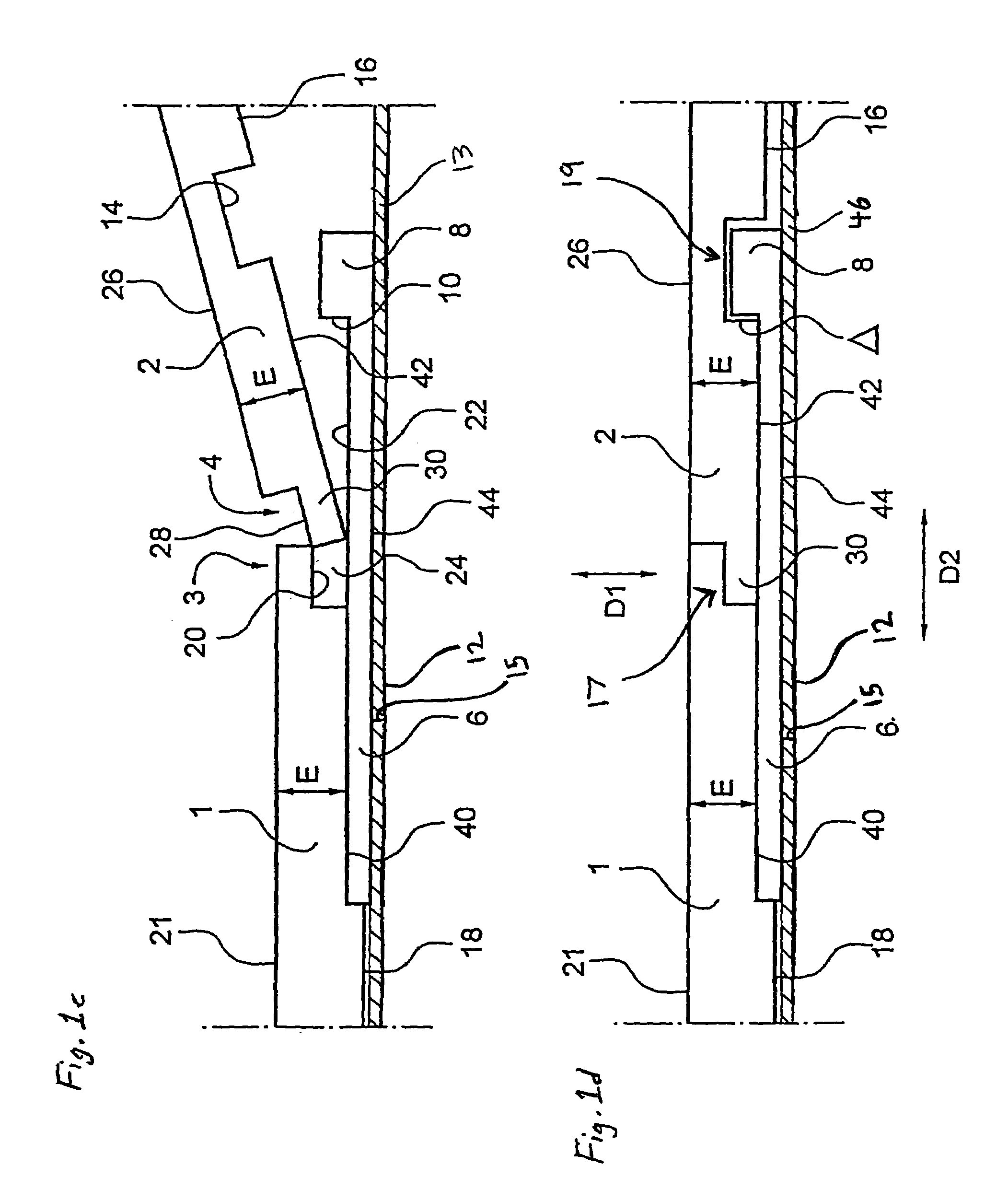

The invention relates to a locking system for mechanical joining of floorboards (1, 1′), a floorboard having such a locking system and a flooring made of such floorboards. The locking system has mechanical cooperating means (36, 38; 6, 8, 14) for vertical and horizontal joining of adjoining floorboards. The means for horizontal joining about a vertical plane (F) comprise a locking groove (14) and a locking strip (16) which is located at opposite joint edge portions (4a, 4b) of the floorboard (4). The locking strip (6) projects from the joint plane (F) and has an upwards projecting locking element (8) at its free end. The locking groove (14) is formed in the opposite joint edge portion (4a) of the floorboard at a distance from the joint plane (F). The locking groove (14) and the locking element (8) have operative locking surfaces (10, 11). The locking surfaces are essentially plane and spaced from the upper side of the projecting strip and inside the locking groove and make a locking angle (A) of at least 50° to the upper side of the board. Moreover the locking groove has a guiding part (12) for cooperation with a corresponding guiding part (6) on the locking element (8).

Owner:VÄLINGE INNOVATION AB

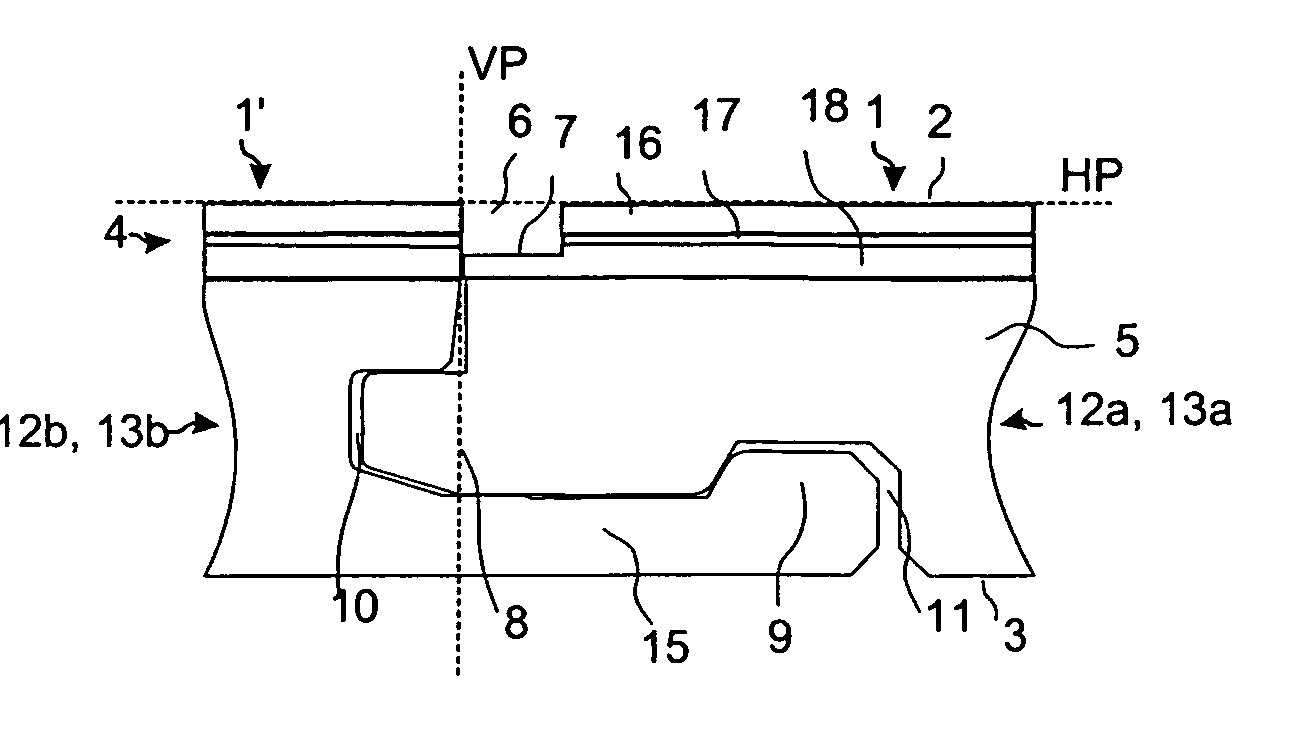

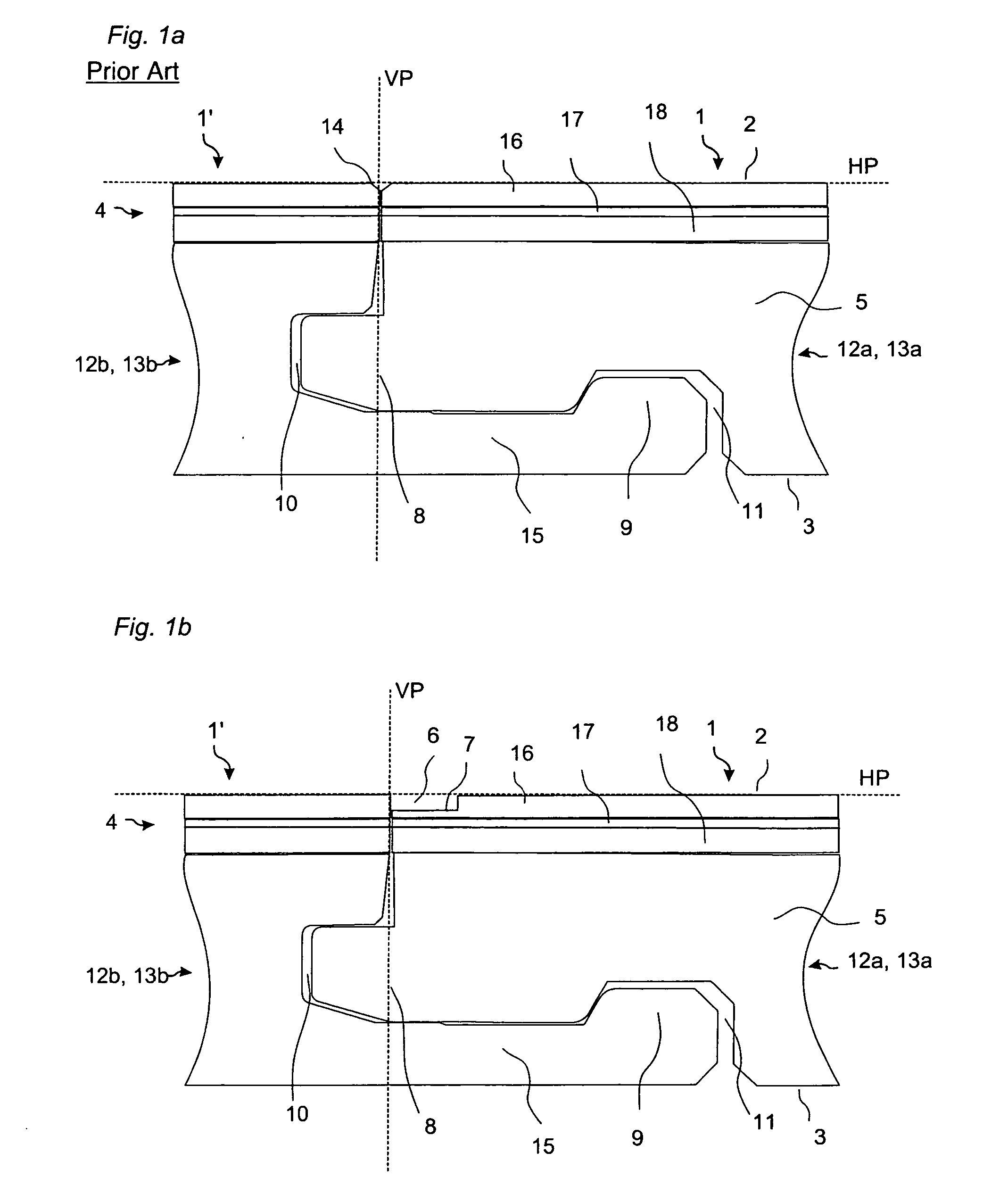

System for joining building panels

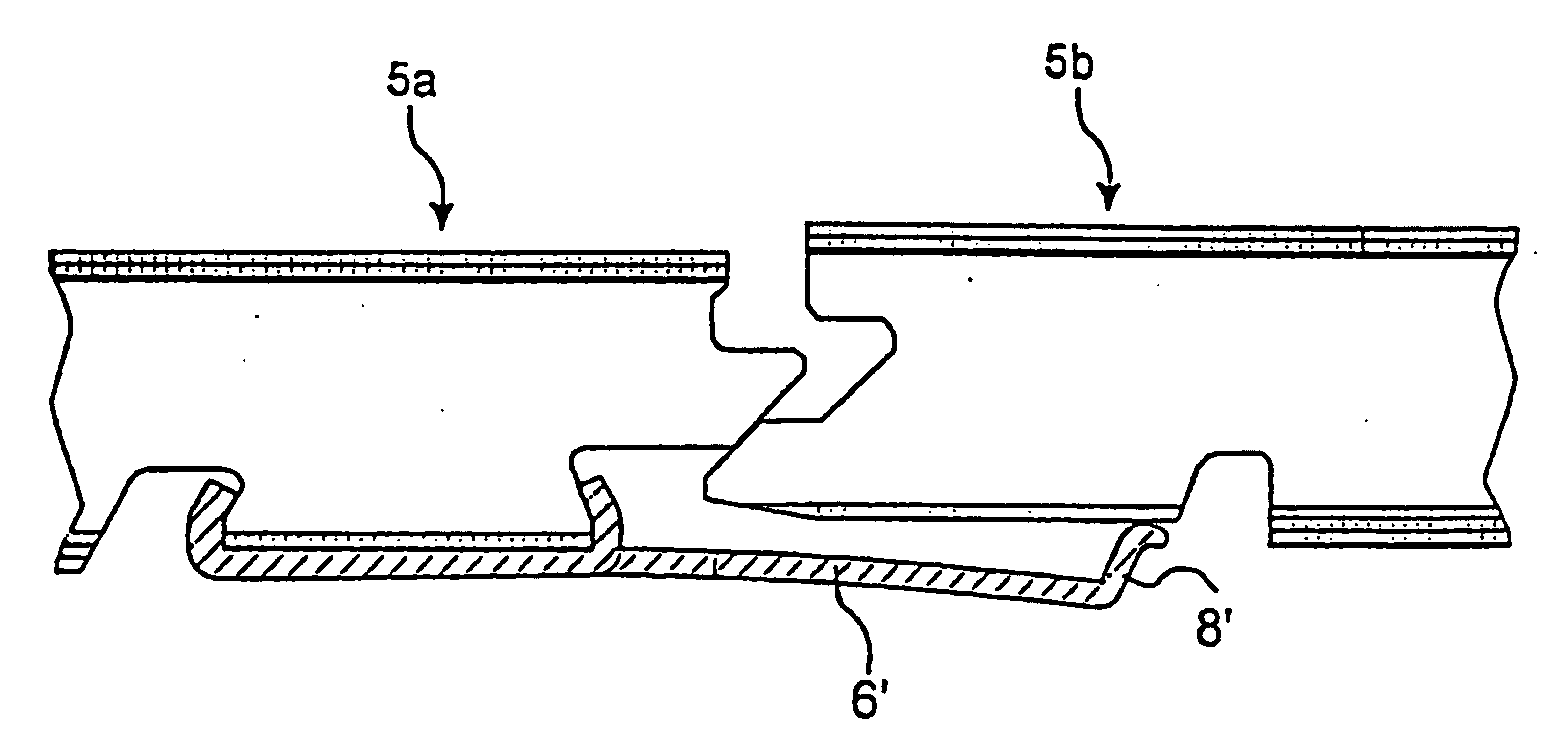

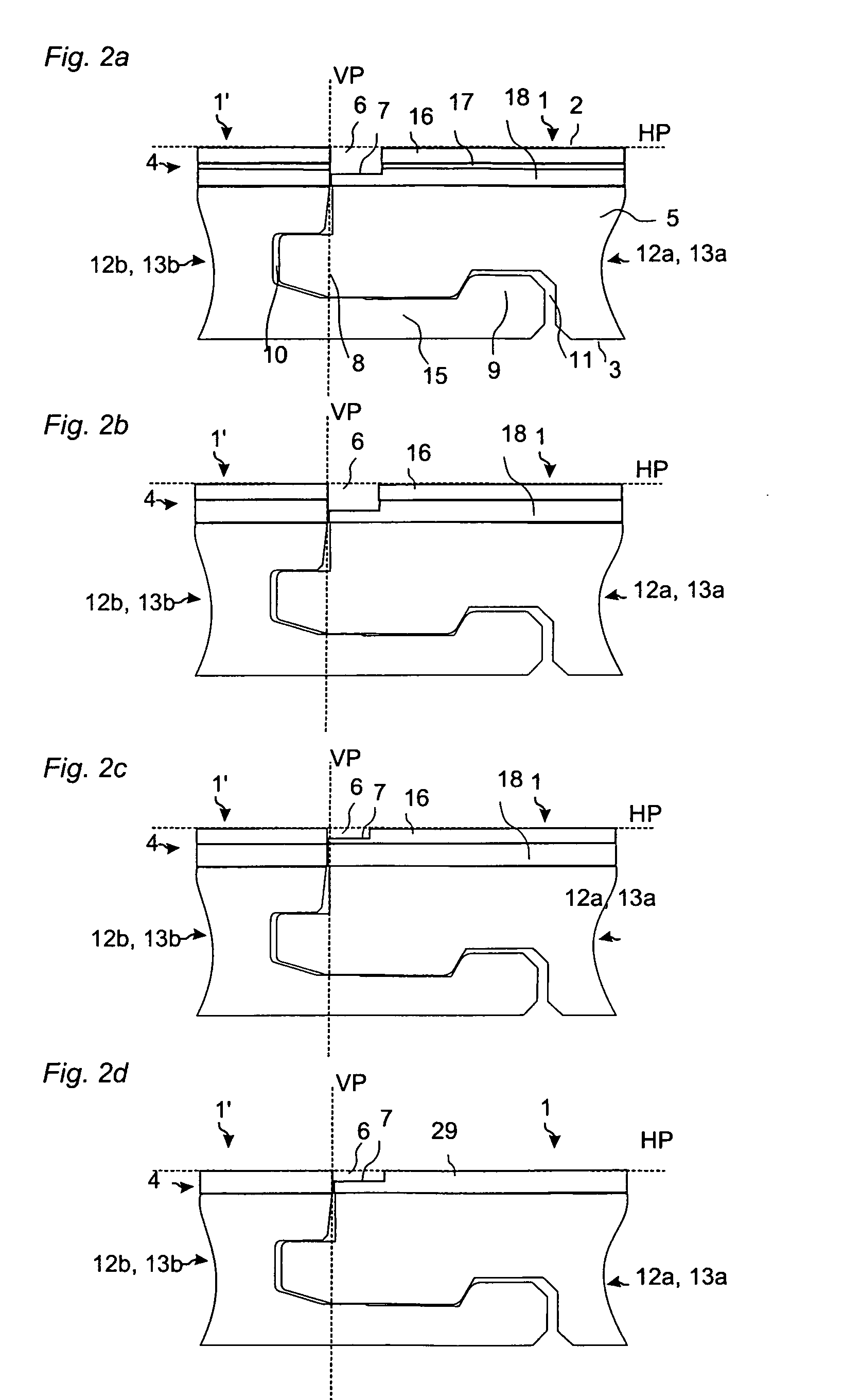

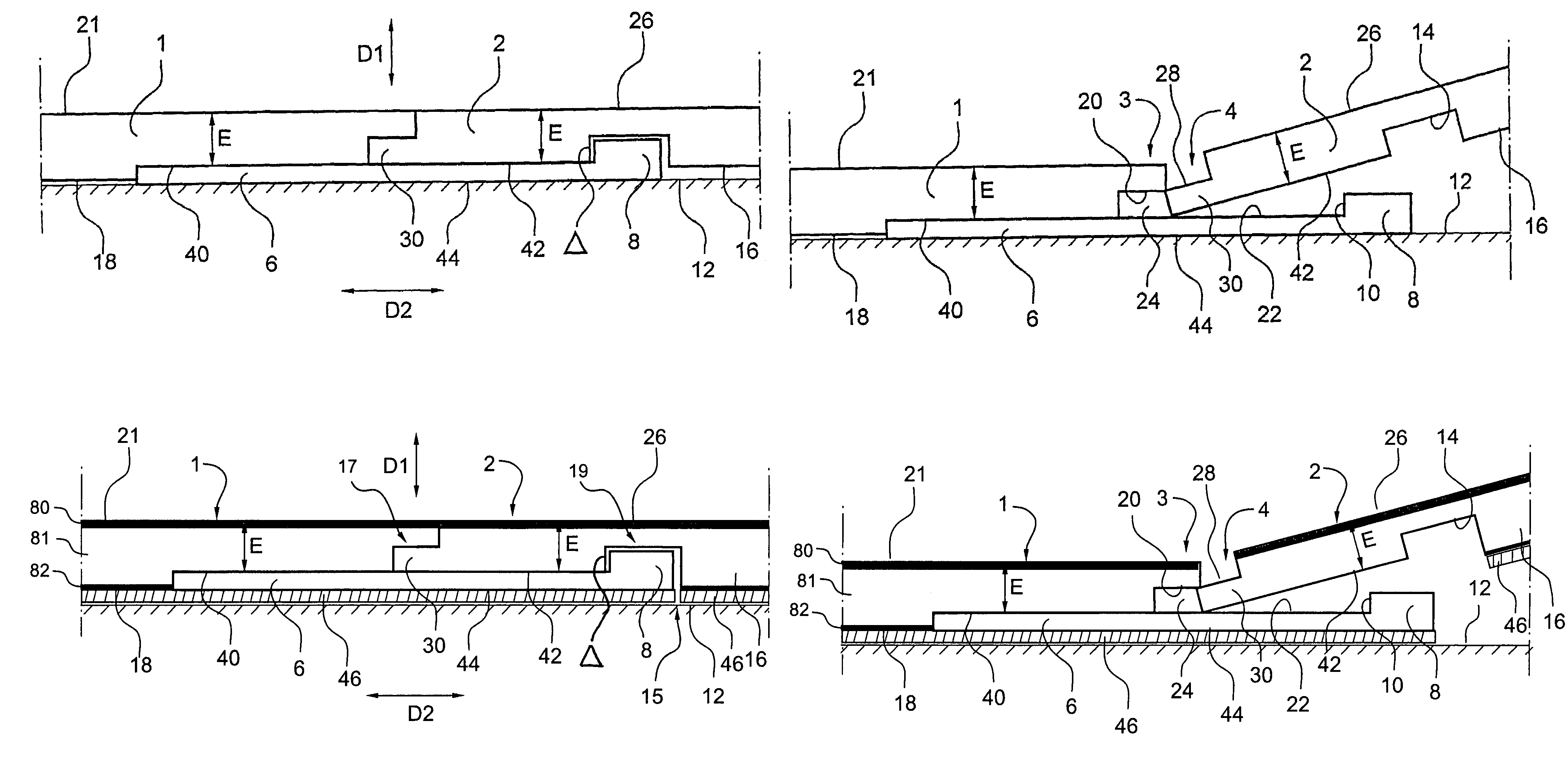

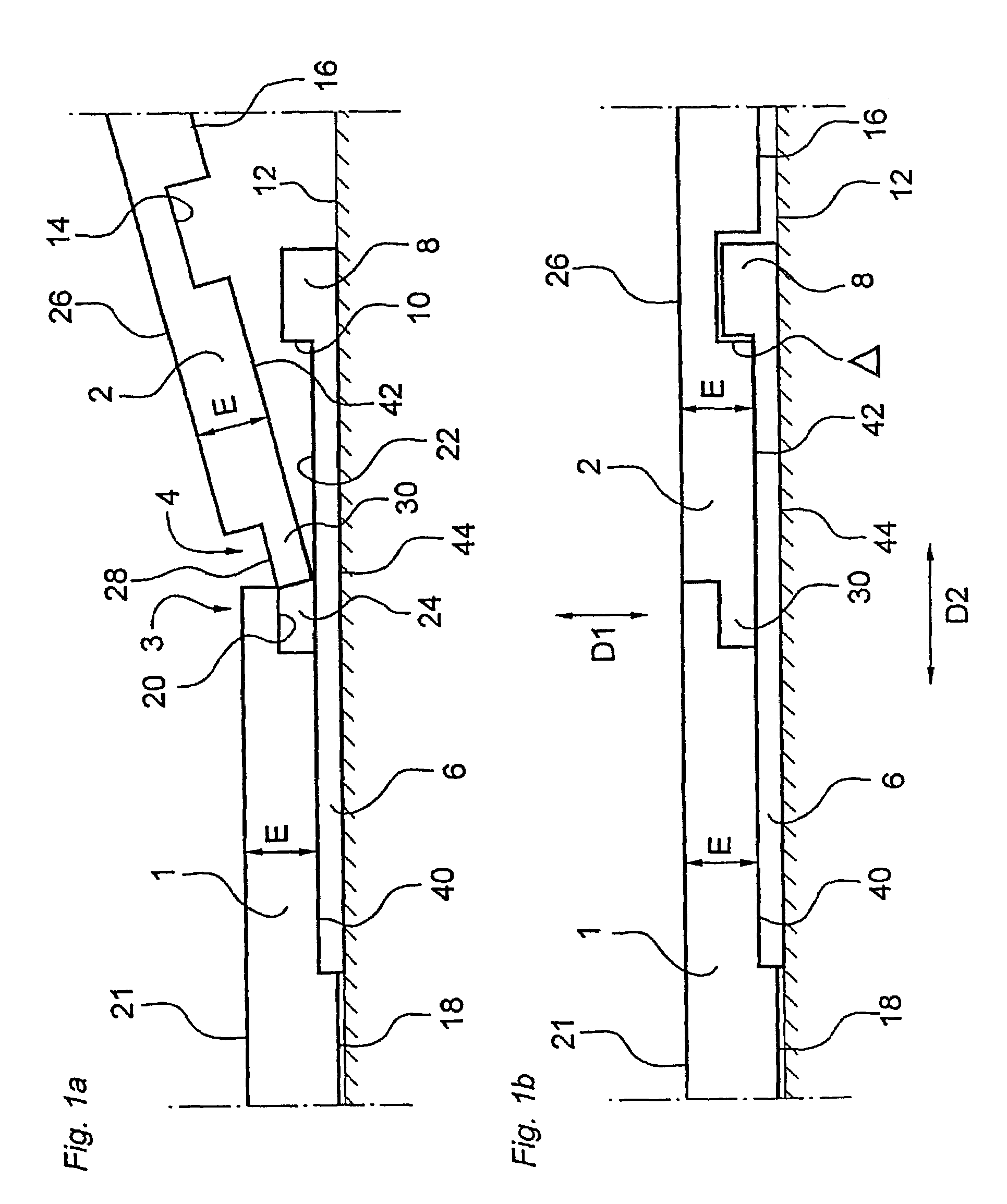

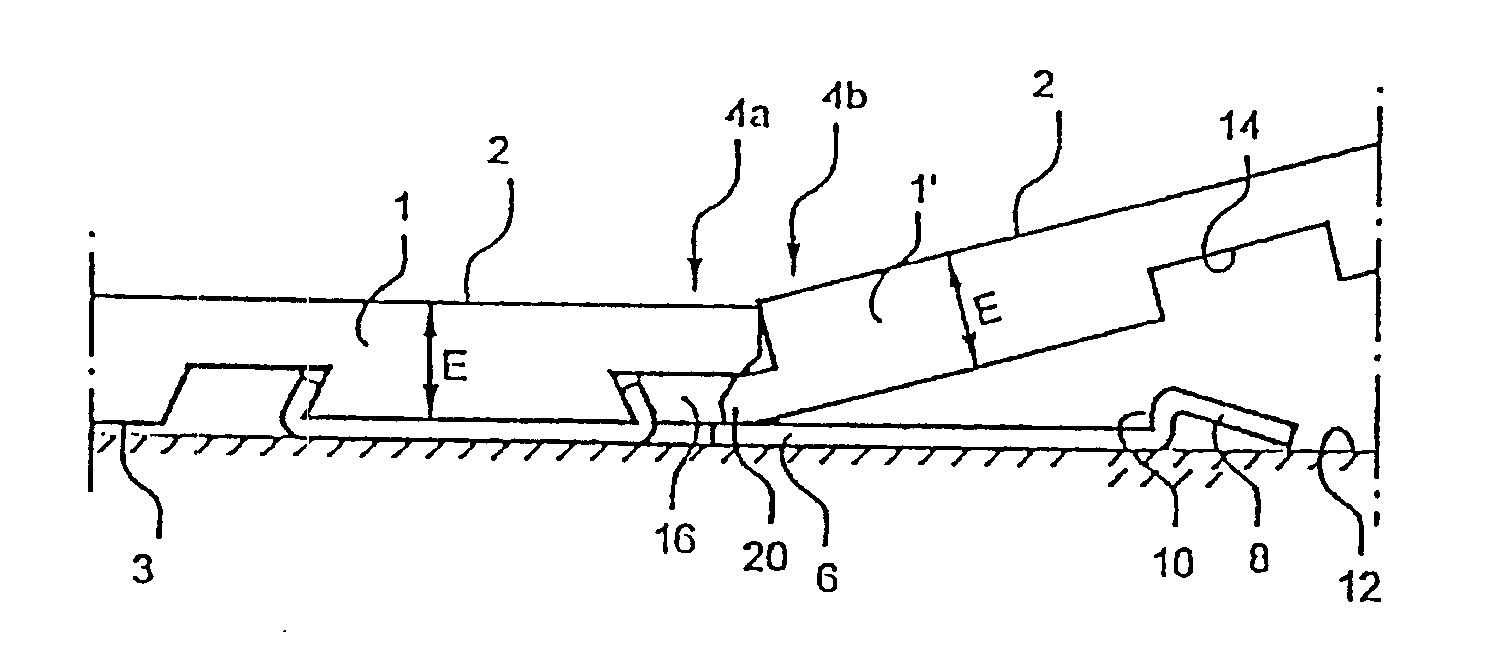

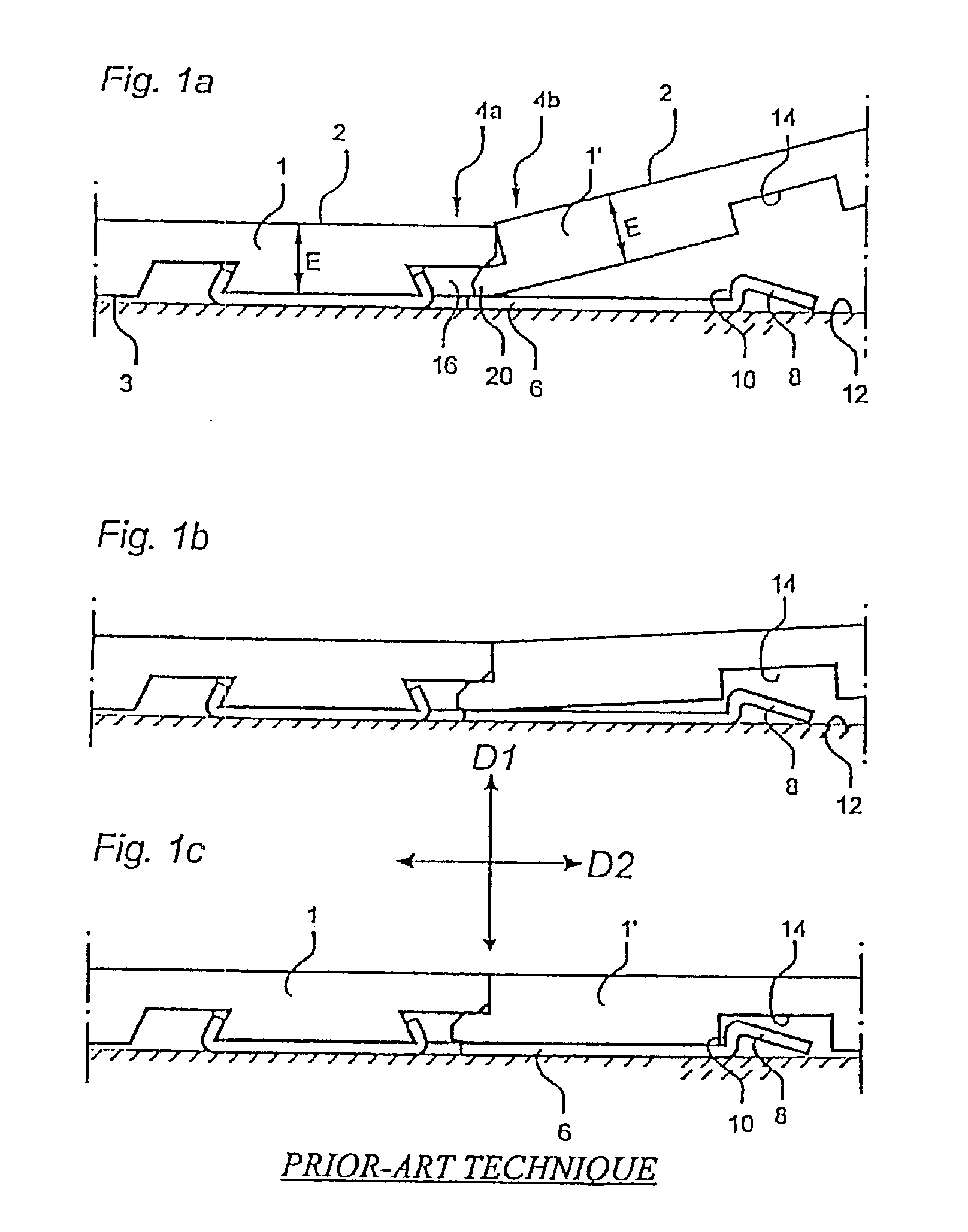

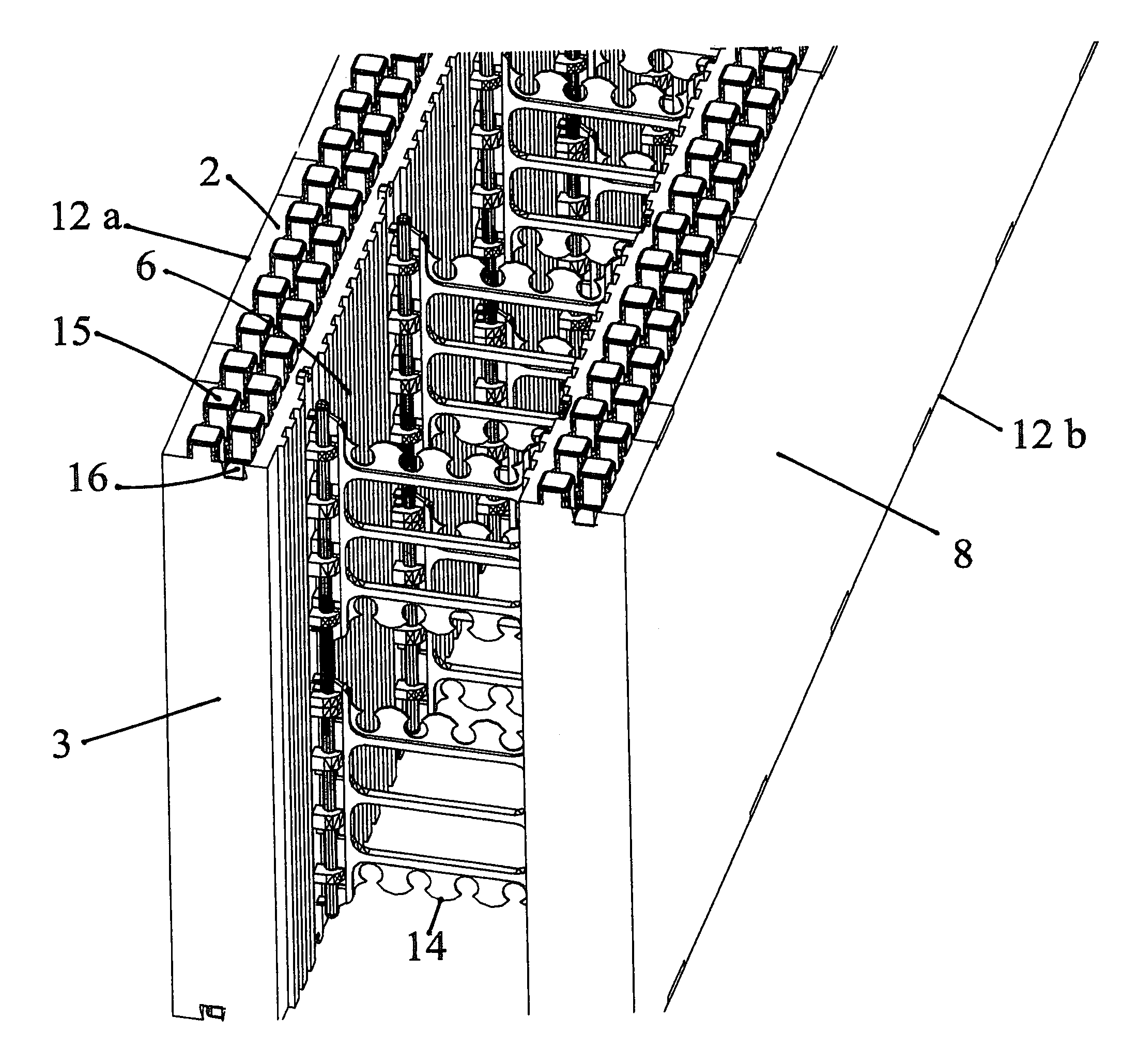

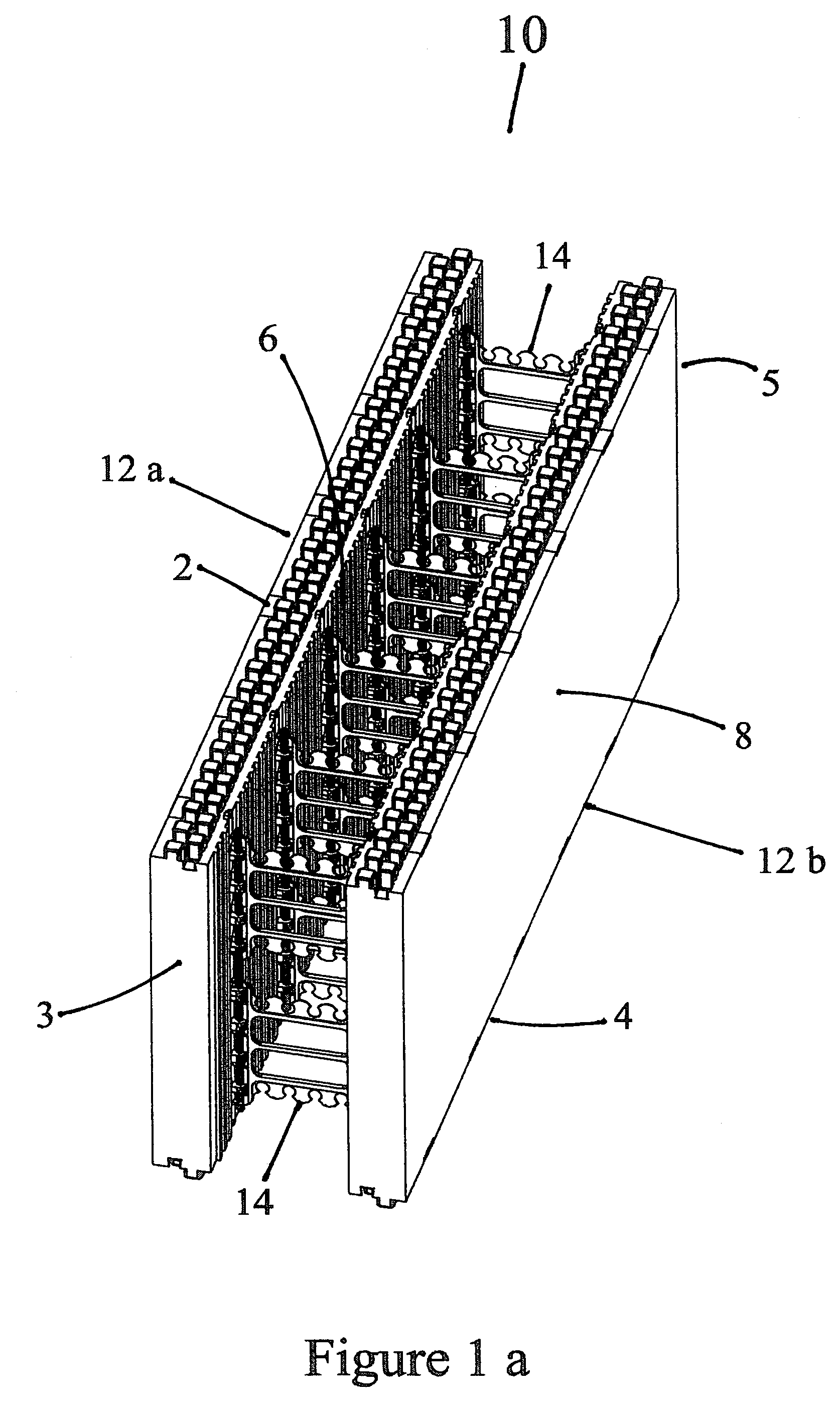

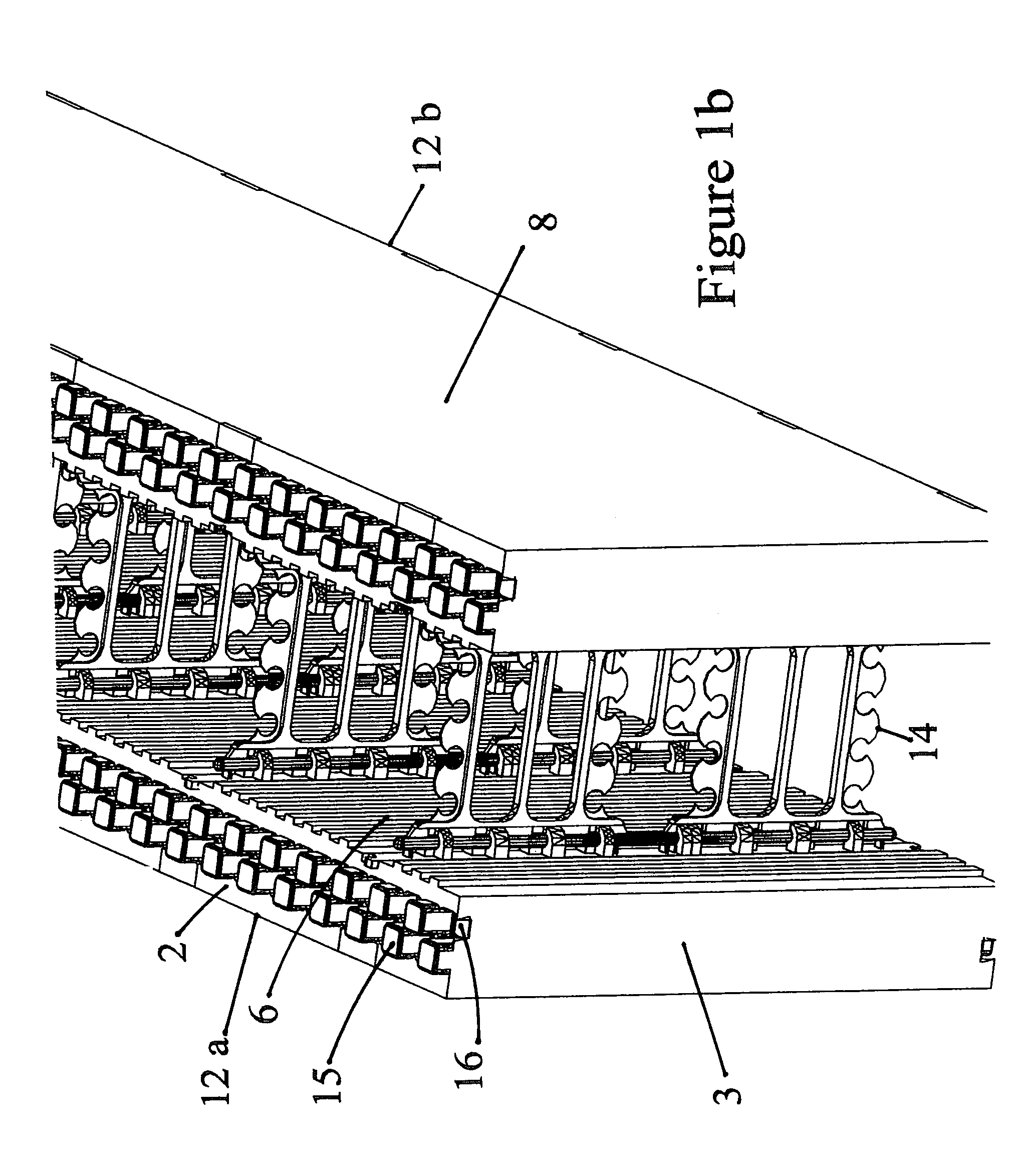

InactiveUS7086205B2Small thicknessSimpler and cheapCeilingsCovering/liningsMechanical engineeringFloating floor

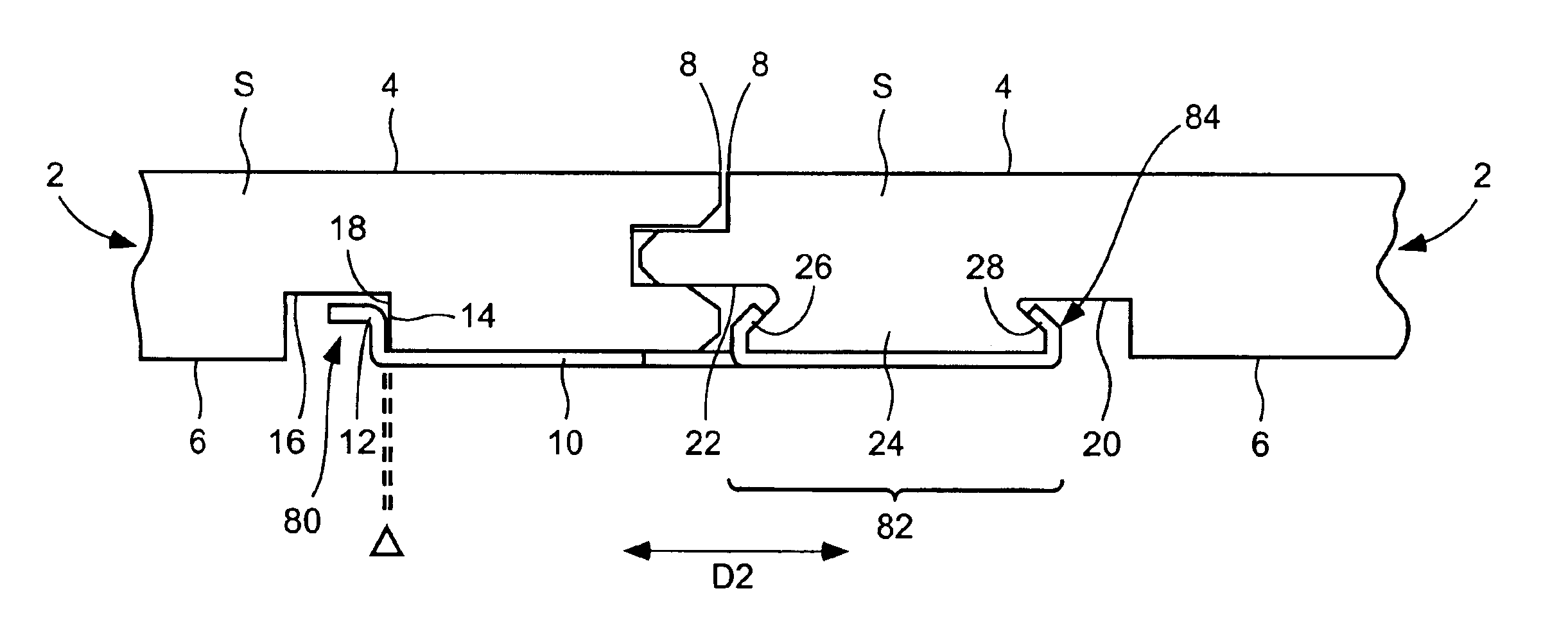

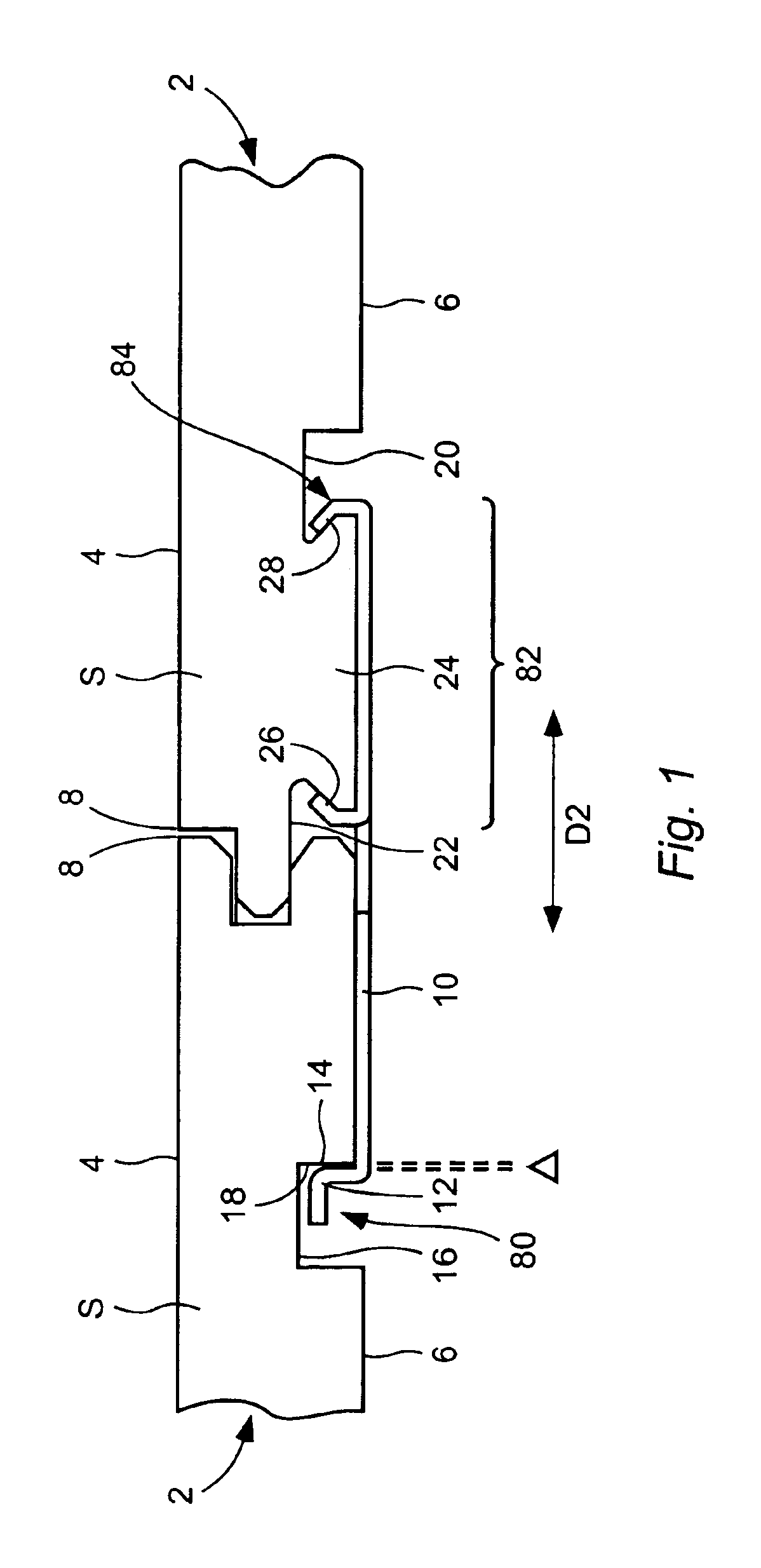

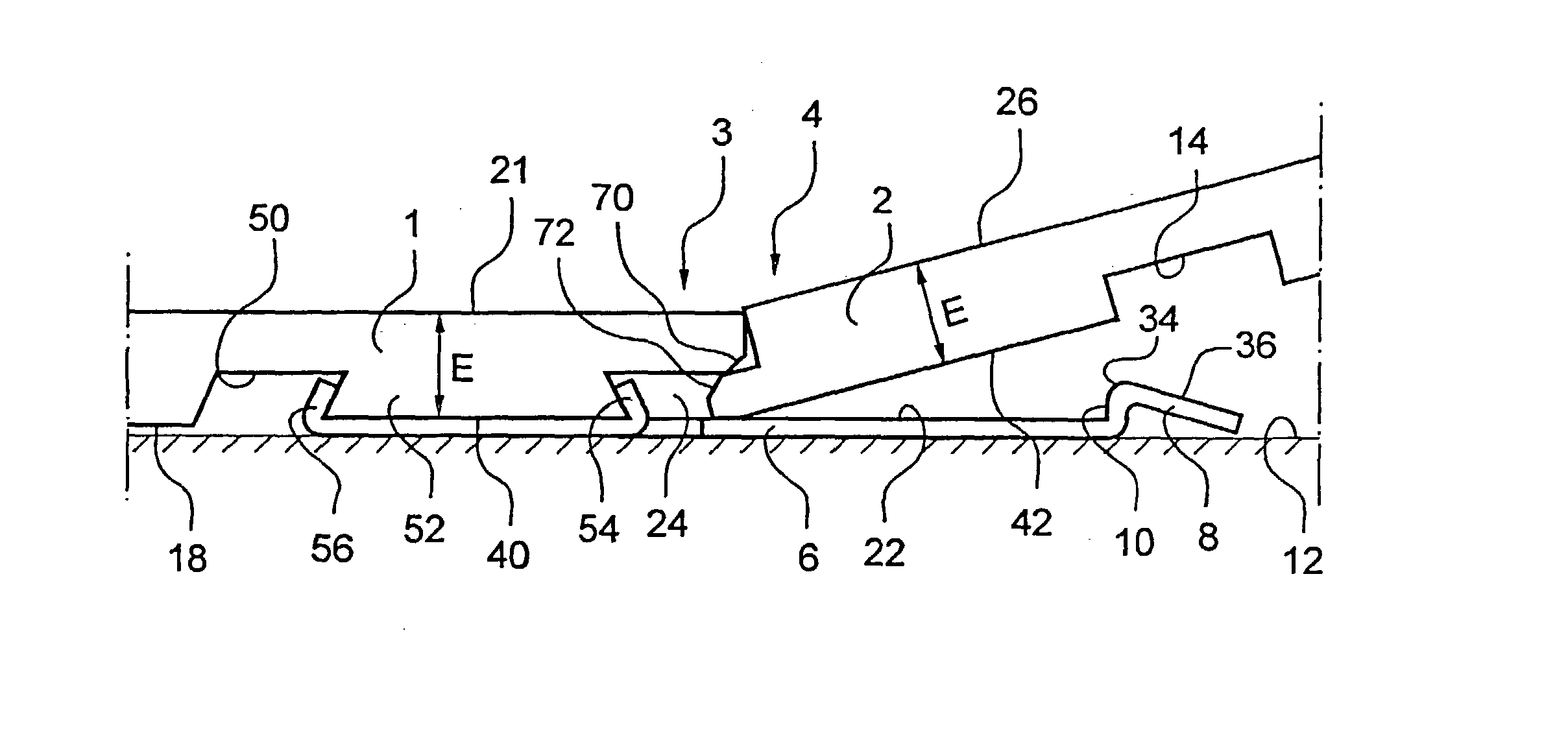

The invention relates to a system for laying and mechanically joining building panels, especially thin, hard, floating floors. Adjacent joint edges (3, 4) of two panels (1, 2) engage each other to provide a first mechanical connection locking the joint edges (3, 4) in a first direction (D1) perpendicular to the principal plane of the panels. In each joint, there is further provided a strip (6) which is integrated with one joint edge (3) and which projects behind the other joint edge (4). The strip (6) has an upwardly protruding locking element (8) engaging in a locking groove (14) in the rear side (16) of the other joint edge (4) to form a second mechanical connection locking the panels (1, 2) in a second direction (D2) parallel to the principal plane of the panels and at right angles to the joint. Both the first and the second mechanical connection allow mutual displacement of joined panels (1, 2) in the direction of the joint.

Owner:VALINGE ALUMINUM AB

Laminated display window and device incorporating same

ActiveUS20090049773A1Resisting delaminationReduce sensitivityFire rescueSubstation equipmentAdhesiveEngineering

A laminated window assembly for a device, such as a handheld electronic device (e.g., a media player or mobile telephone), includes a window layer that preferably is glass, and a larger, substantially transparent lip-forming layer to which it is laminated, preferably by a substantially clear adhesive. Additional adhesive preferably is placed at at least portions of the edge of the window layer adjacent the lip-forming layer, especially at the corners, to resist delamination. Holes preferably are formed in the lip—e.g., at the corners—to resist the lip-forming layer peeling apart from the window layer forming layer. The holes preferably make up at most about 33% of the periphery of the window layer.

Owner:APPLE INC

Locking system and flooring board

A floorboard system includes a plurality of floorboards, wherein each of the floorboards is a rectangular floorboard provided with long edges and short edges and having a floorboard body provided with an integrated long edge locking system and an integrated short edge locking system for mechanical joining, both vertically and horizontally, the floorboards, along the long edges thereof and along the short edges thereof. The long edge locking system differs from the short edge locking system in respect of at least one of material composition and material properties. And, at least one of the long edge locking system and the short edge locking system includes a separate element which is integrally connected with the floorboard body at the factory and is made of a material other than that included in the floorboard body.

Owner:VALINGE ALUMINUM AB

Metal strip for interlocking floorboard and a floorboard using same

InactiveUS6880305B2Not to damageUndesired joint gapCeilingsRoof covering using tiles/slatesMetal stripsMechanical engineering

Owner:VÄLINGE INNOVATION AB

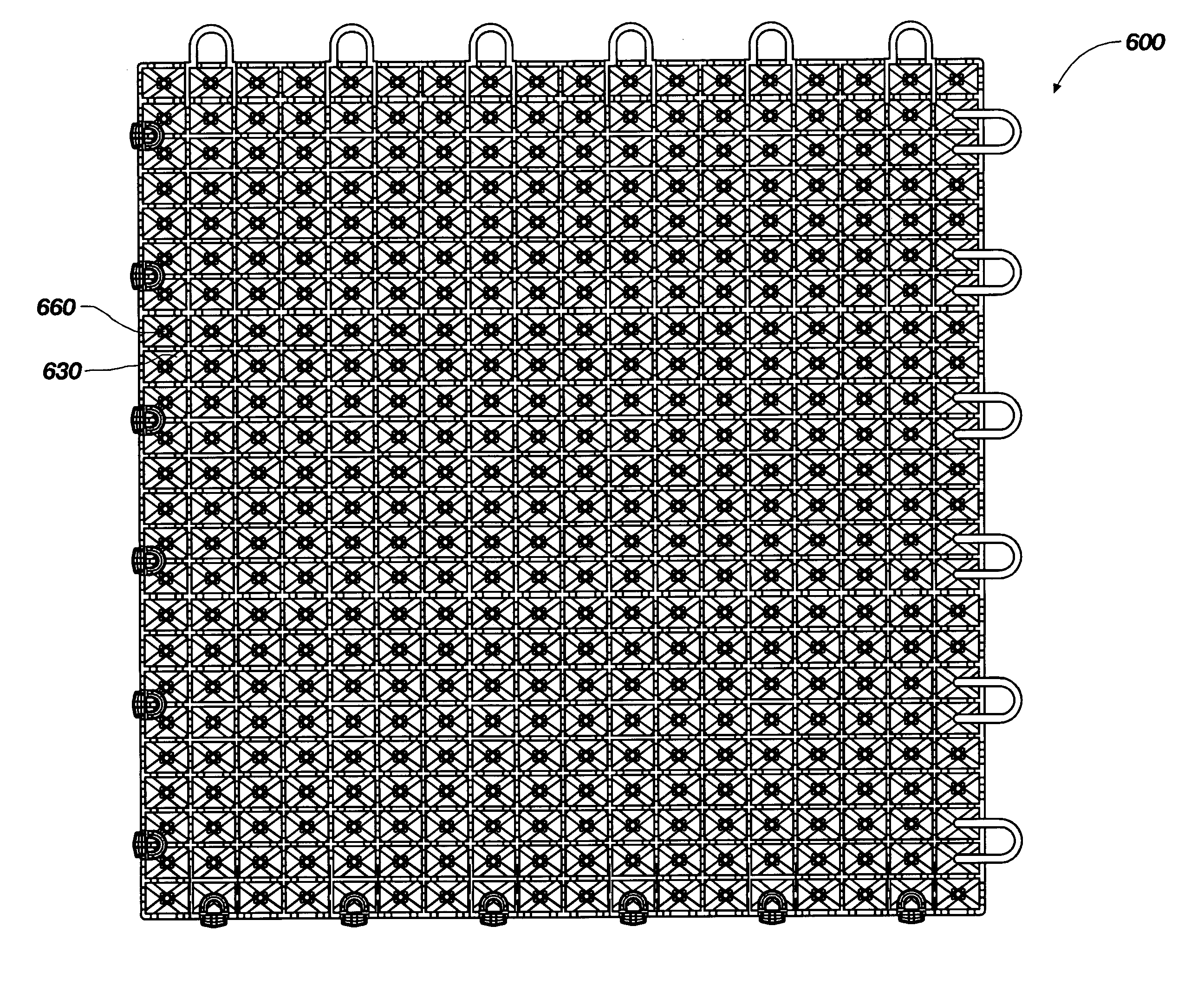

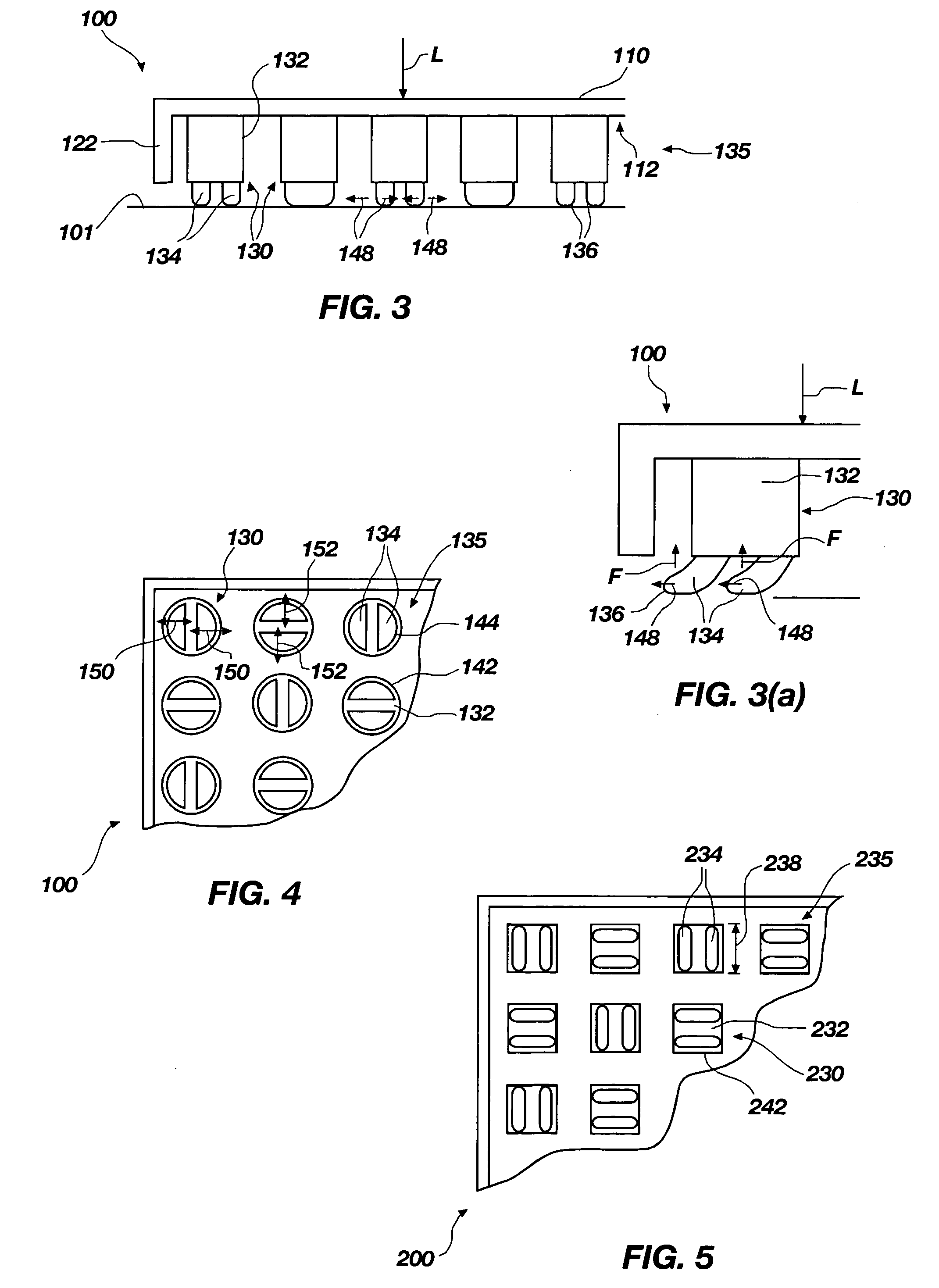

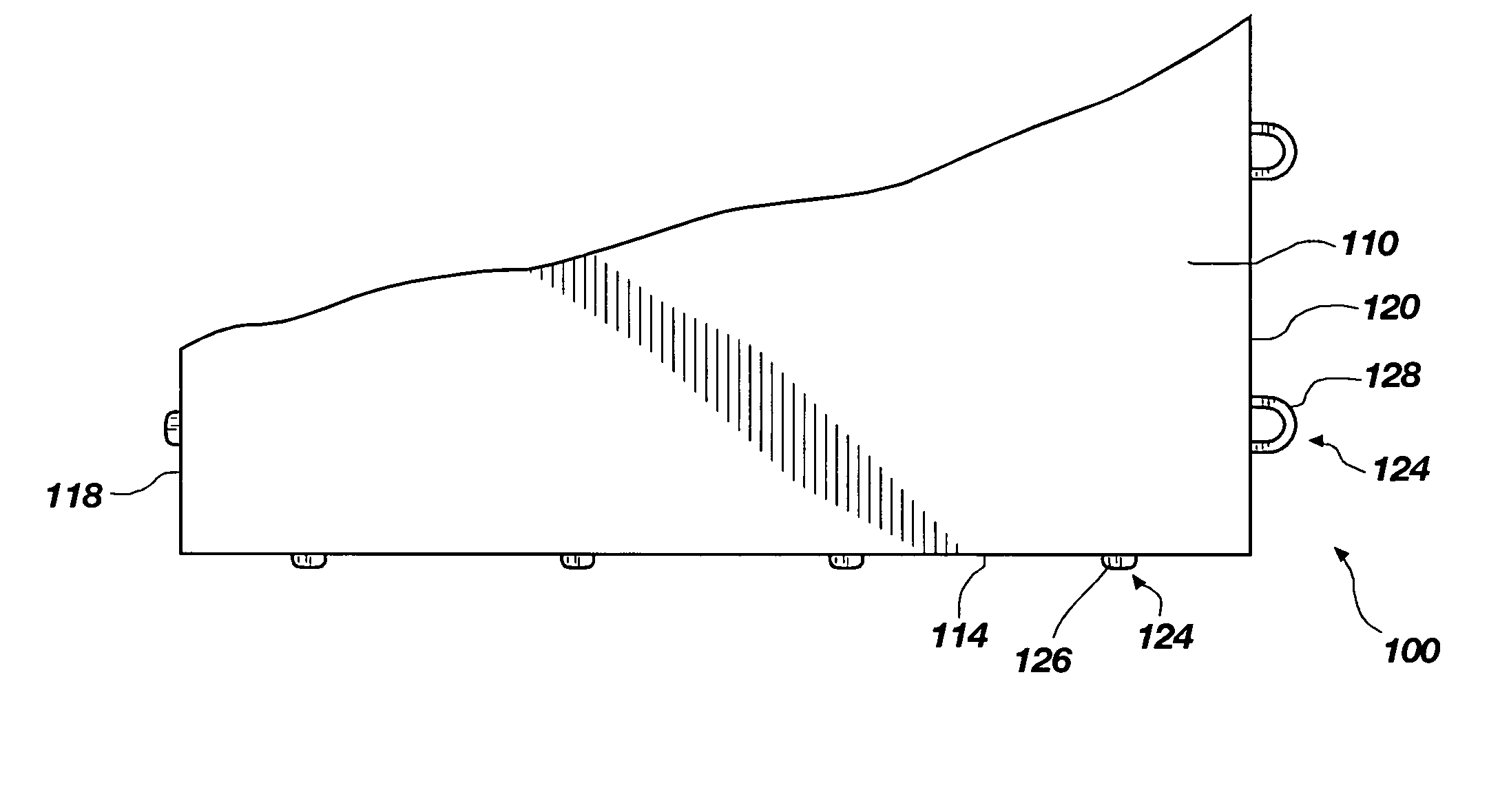

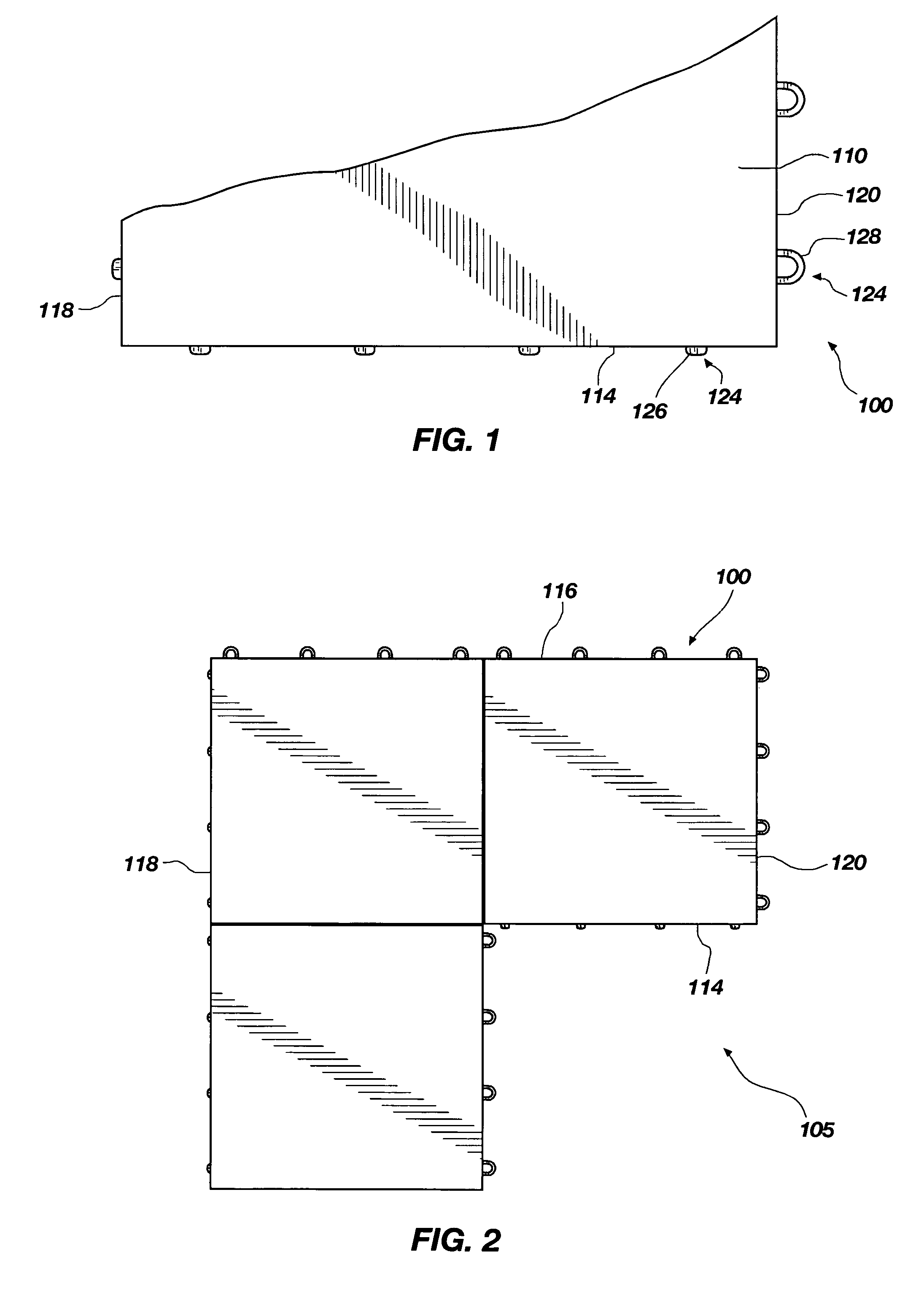

Modular tile with controlled deflection

A modular tile configured to interlock with multiple tiles to form a modular floor covering over a floor. The tile includes a top surface having a periphery defining side walls extending downward from the top surface, the side walls having a coupling portion configured to couple with other tiles adjacent thereto to form the modular floor covering. The tile also includes a bottom side, opposite the top surface, having a support grid including an array of downward extending polymeric post structures, at least some of the post structures including at least one resilient end portion with a radial end surface configured to be positioned against the floor to facilitate controlled deflection of the post structures. The post structures may comprise primary and secondary post structures, with the secondary post structures limiting the deflection of the primary post structures.

Owner:CONNOR SPORT COURT INT

Locking system and flooring board

A locking system for mechanical joining of floorboards. For horizontal mechanical joining there is a projecting portion with a locking element which cooperates with a locking groove in an adjacent board. A tongue-and-groove joint for vertical mechanical joining has cooperating upper abutment surfaces and cooperating lower abutment surfaces which are essentially parallel with the principal plane of the floorboards and of which the lower abutment surfaces are positioned essentially outside the outer vertical plane, i.e. displaced relative to the upper abutment surfaces. The tongue is movable at an angle into the groove and the locking element is insertable into the locking groove by mutual angular movement of the boards about the joint edges.

Owner:VÄLINGE INNOVATION AB

Resilient groove

A set of moisture proof floorboards and a flooring of such floorboards with a resilient surface layer provided with a decorative groove and / or a sealing means.

Owner:VÄLINGE INNOVATION AB

Raised access floor

A raised access floor has panels suspended by pedestals. Each panel may have a top surface and a frame extending around the top surface. Each panel may have extruded aluminum components including four edge members, two intermediate members, and a center member. Each edge member may have a frame portion with a box beam configuration. The frame portions can be press-fitted with corner members to provide the frame. Two edge members, the intermediate members, and the center member may have top surface portions coupled together to form the top surface. The top surface may be supported by support ribs with enlarged bottom ends that resist bending. The ends of the support ribs are press-fitted against the frame. Components may be modified or removed to alter the panel geometry. A cover plate may be used to cover the top surface. The cover plate and / or top surface may be continuous or perforated.

Owner:AIRTEX MFG LLLP

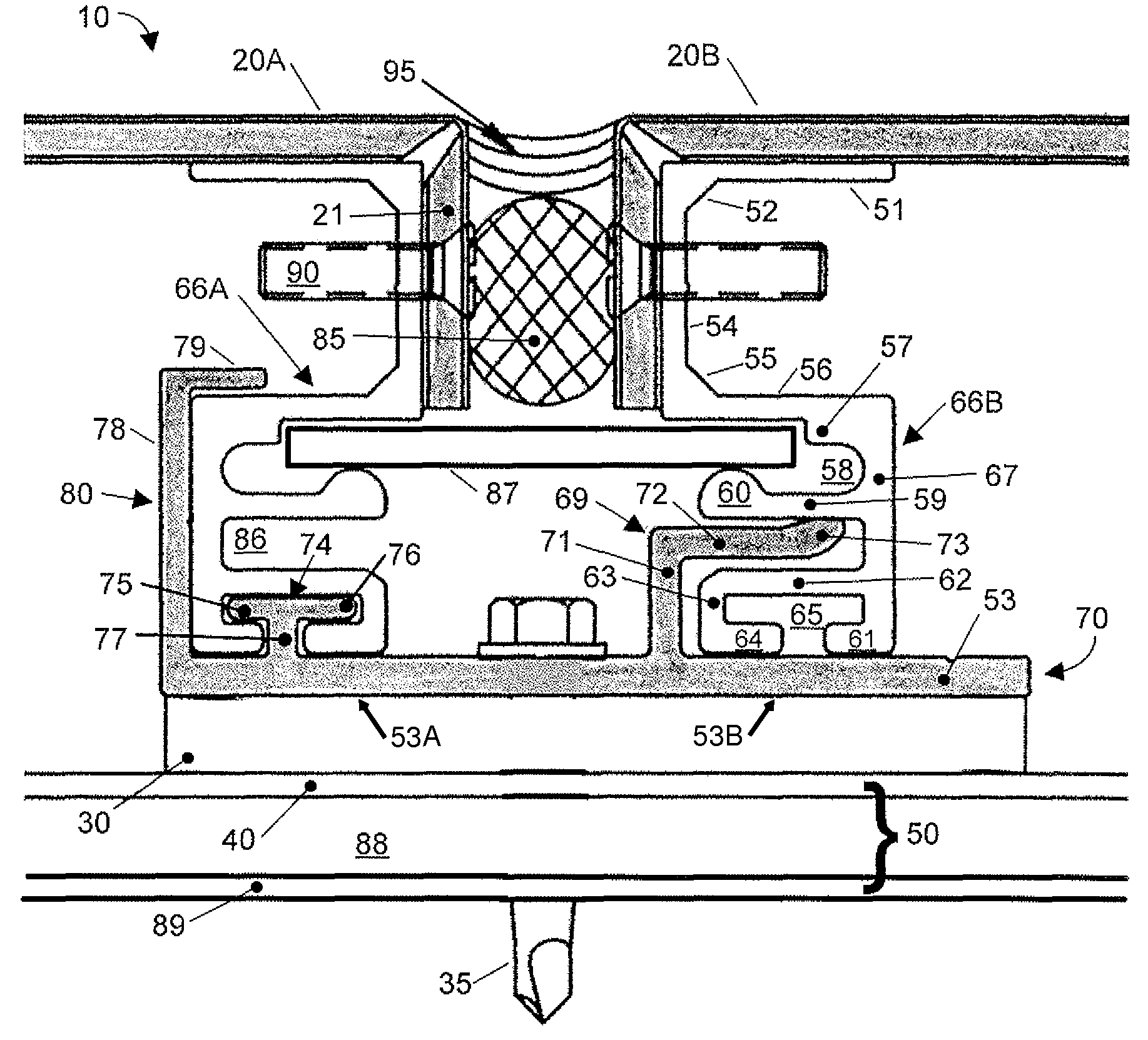

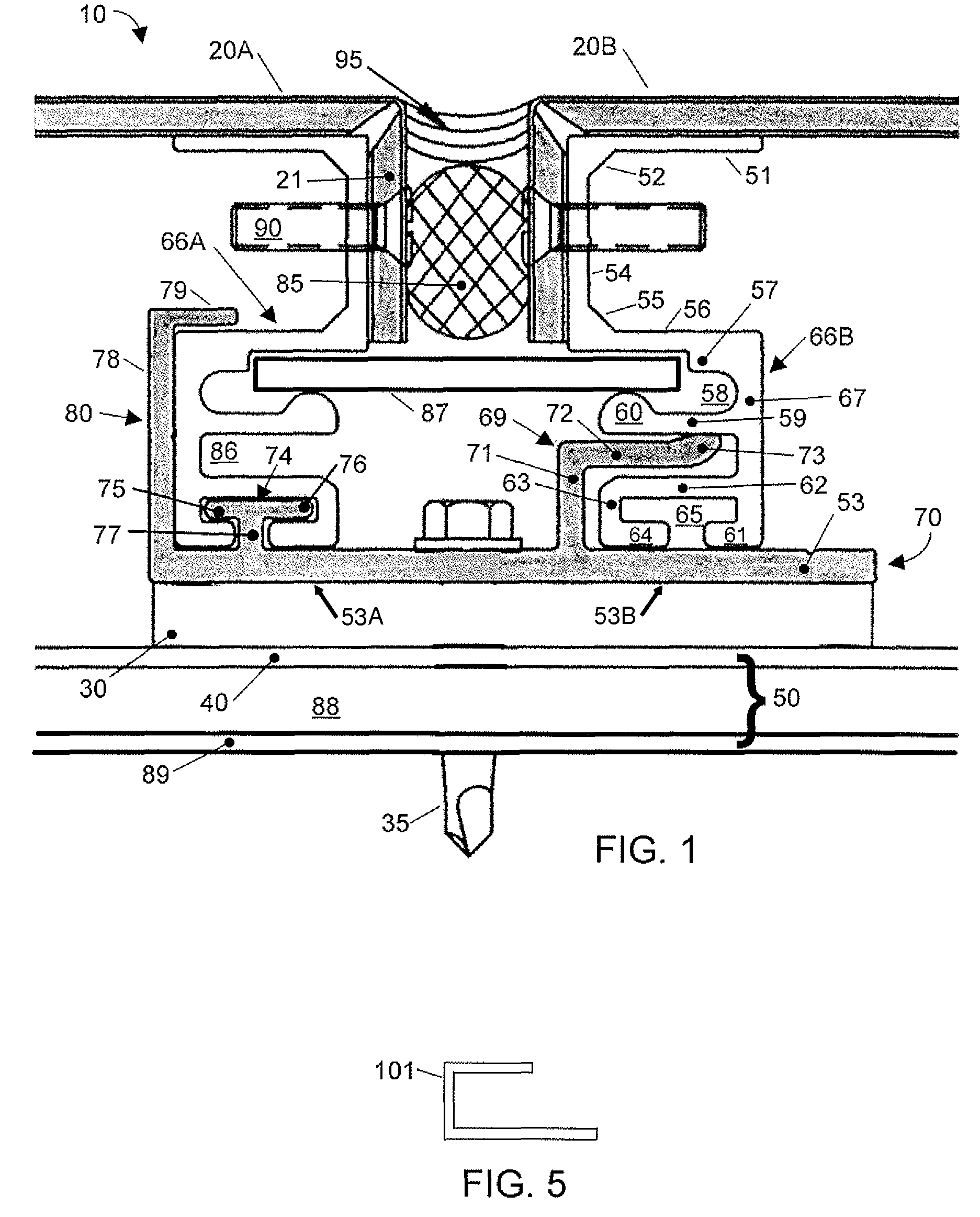

Attachment system for panel or facade

Panels (20A, 20B) are attached to extrusions (66A, 66B) by fasteners 90. Clips (70) are attached to a structure (50) by fasteners (35). The extrusions and the clips engage in a manner which allows the panels to move in any direction, as needed, without the panel detaching from the structure and falling. The extrusions also provide for the use of optional reveal strips (87). An extrusion has a restraining area (86), a reveal strip stop area (58), and a T-slot (65). A clip has a T-channel (74), a tensioning stop arm (69), and a secondary reinforcing arm (80). The panels can be installed in rows, in columns, or diagonally, as desired.

Owner:SECO ARCHITECTURAL SYST

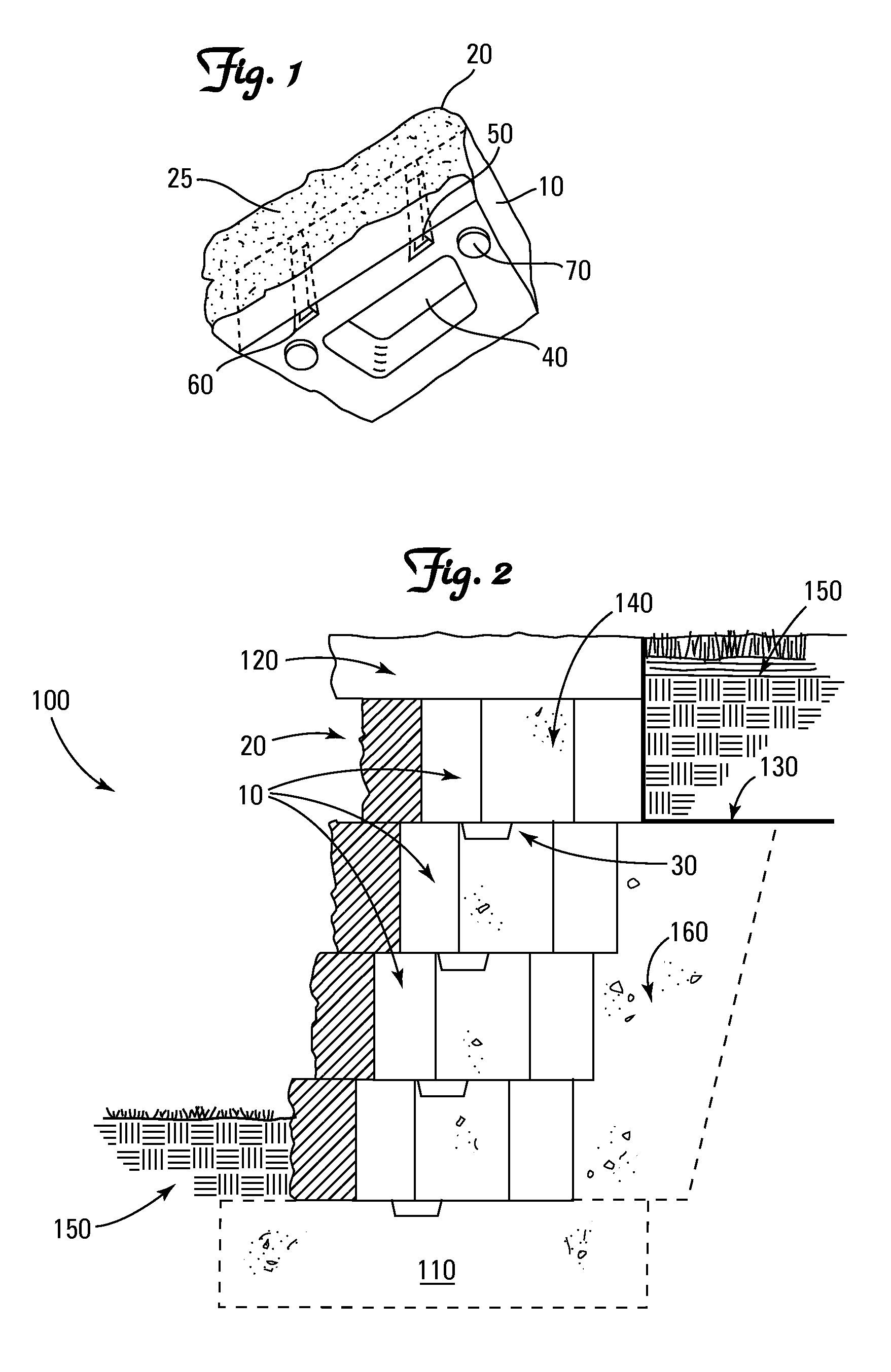

Masonry anchoring system

A masonry coupling system for use in commercial and residential construction is described. In one aspect, the invention includes an anchor channel mounted on a structure. The masonry coupling system further includes a key that interfaces the masonry veneer and interlocks with an anchor channel mounted on a structure.

Owner:ECI GRP LLC THE +1

Veneers for walls, retaining walls, retaining wall blocks, and the like

Veneers for walls, retaining walls, retaining wall blocks, gabions, wire faces, and other structures are provided. Various methods of attaching the veneers are also described. A combination of a wall block and a veneer is provided. The wall block has a front face with a block connection space, and the veneer has a front face with a veneer connection portion. The veneer is attached to the front face of the wall block by the veneer connection portion, which is disposed in the block connection space.

Owner:KEYSTONE RETAINING WALL SYST

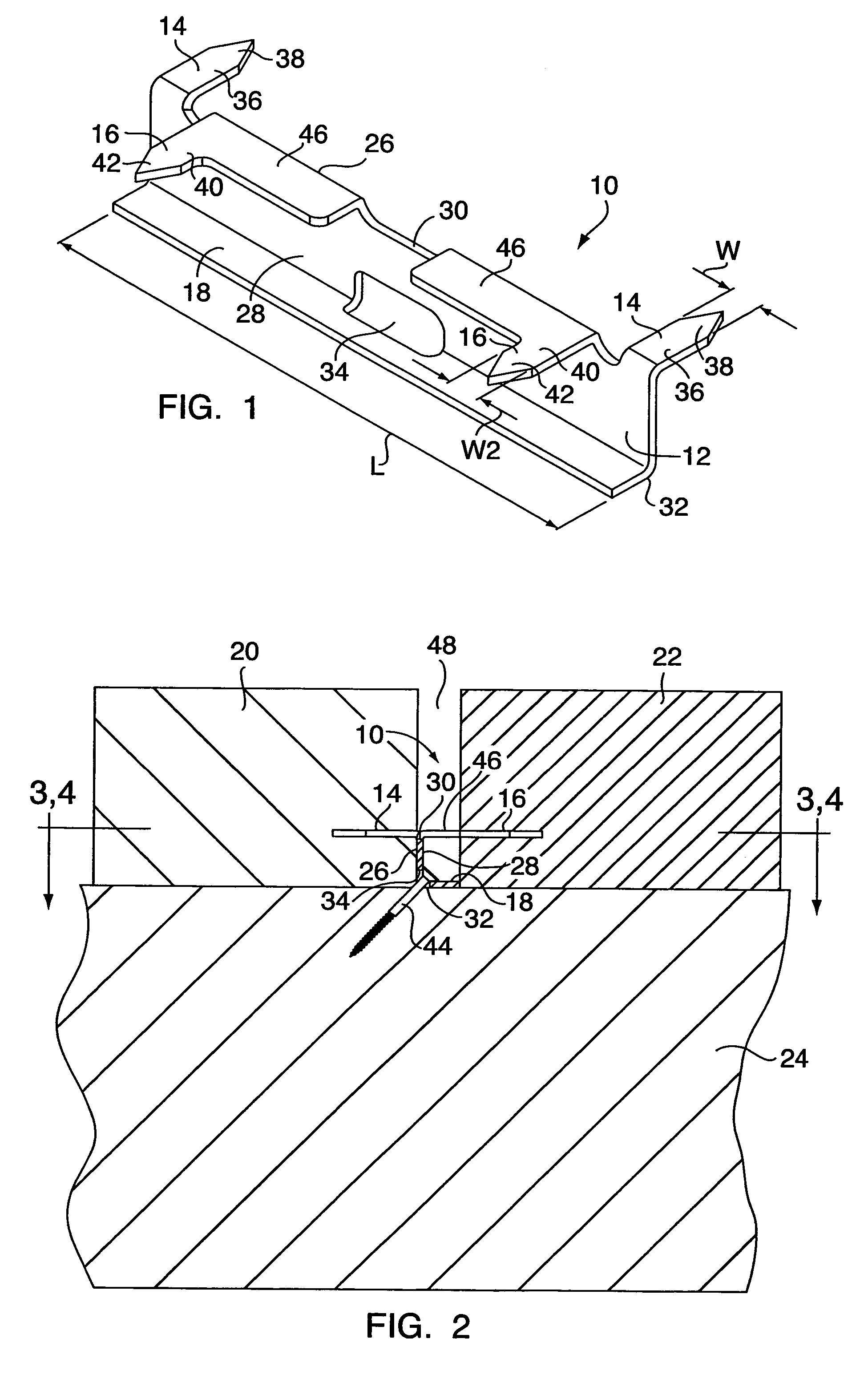

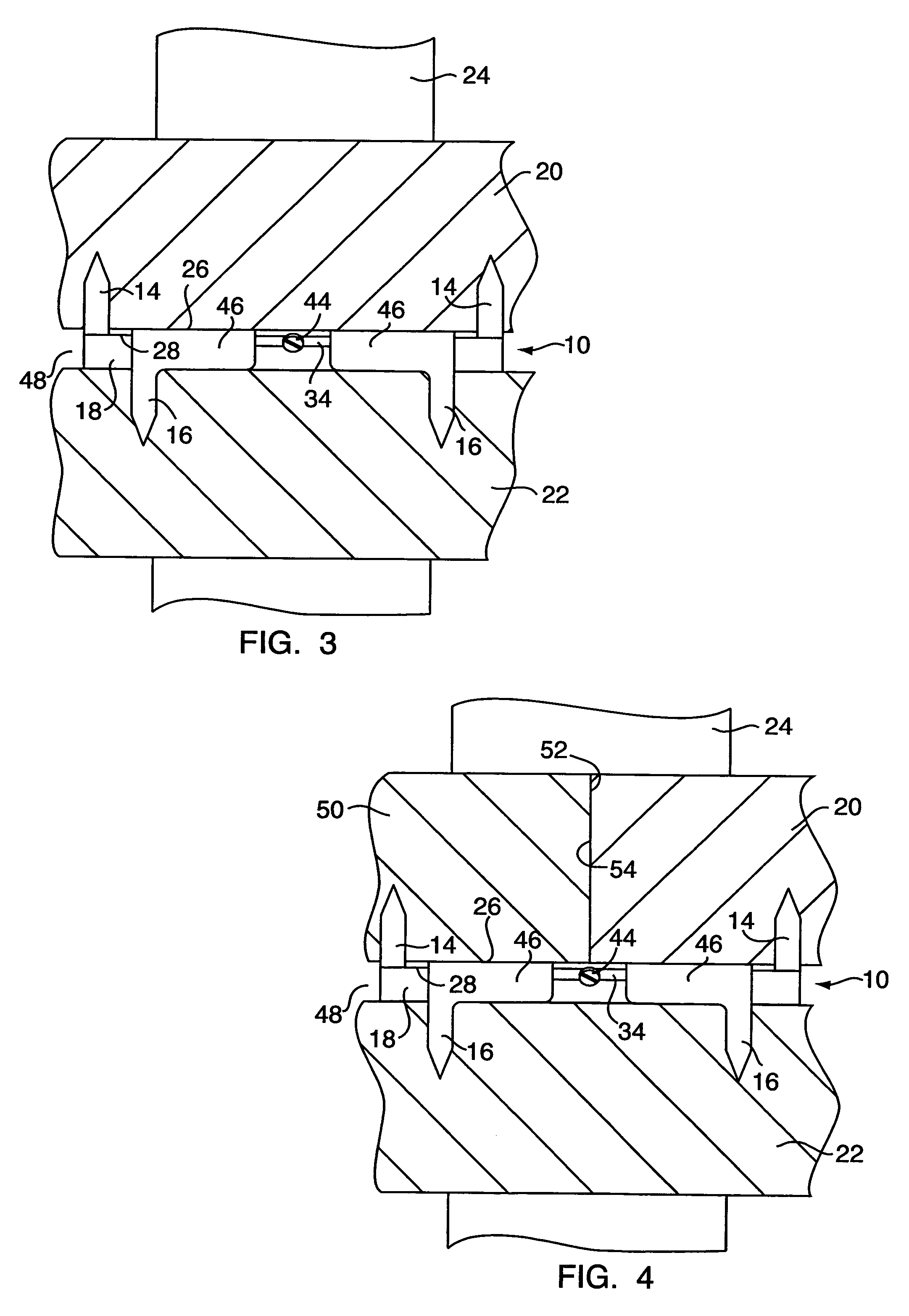

Deck board fastener with concave prongs

ActiveUS7398623B2Reduce the amount requiredClose positioningCeilingsConstruction materialOn boardInsertion point

According to the present invention, a fastener for securing a first board to an underlying supporting member and to at least one other board running adjacent and parallel to the first board. The fastener includes a body portion, first and second prongs, and a flange. The first prong extends outwardly from the body portion for driving into a first board. The second prong extends outwardly from the body portion for penetrating a second board. The body portion of the fastener includes an opening for receiving a connector. When installed, the connector passes through the opening in the body portion and into the supporting member, which supports and underlies the first and second boards. The flange extends outwardly from the body portion in order to maintain a desired gap between the first and second boards. The prongs may have concave insertion ends as defined by two spaced-apart insertion points.

Owner:OMG INC

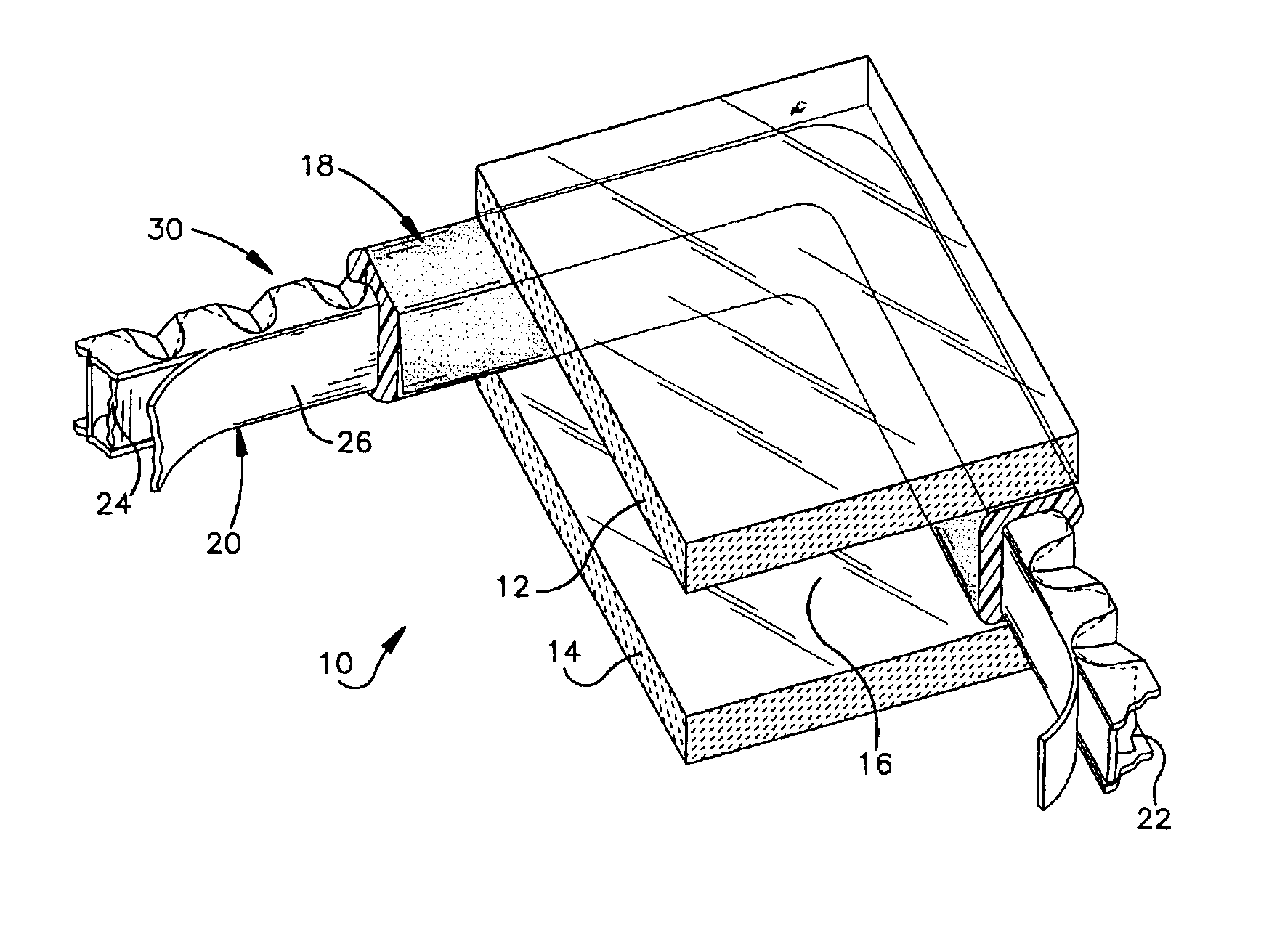

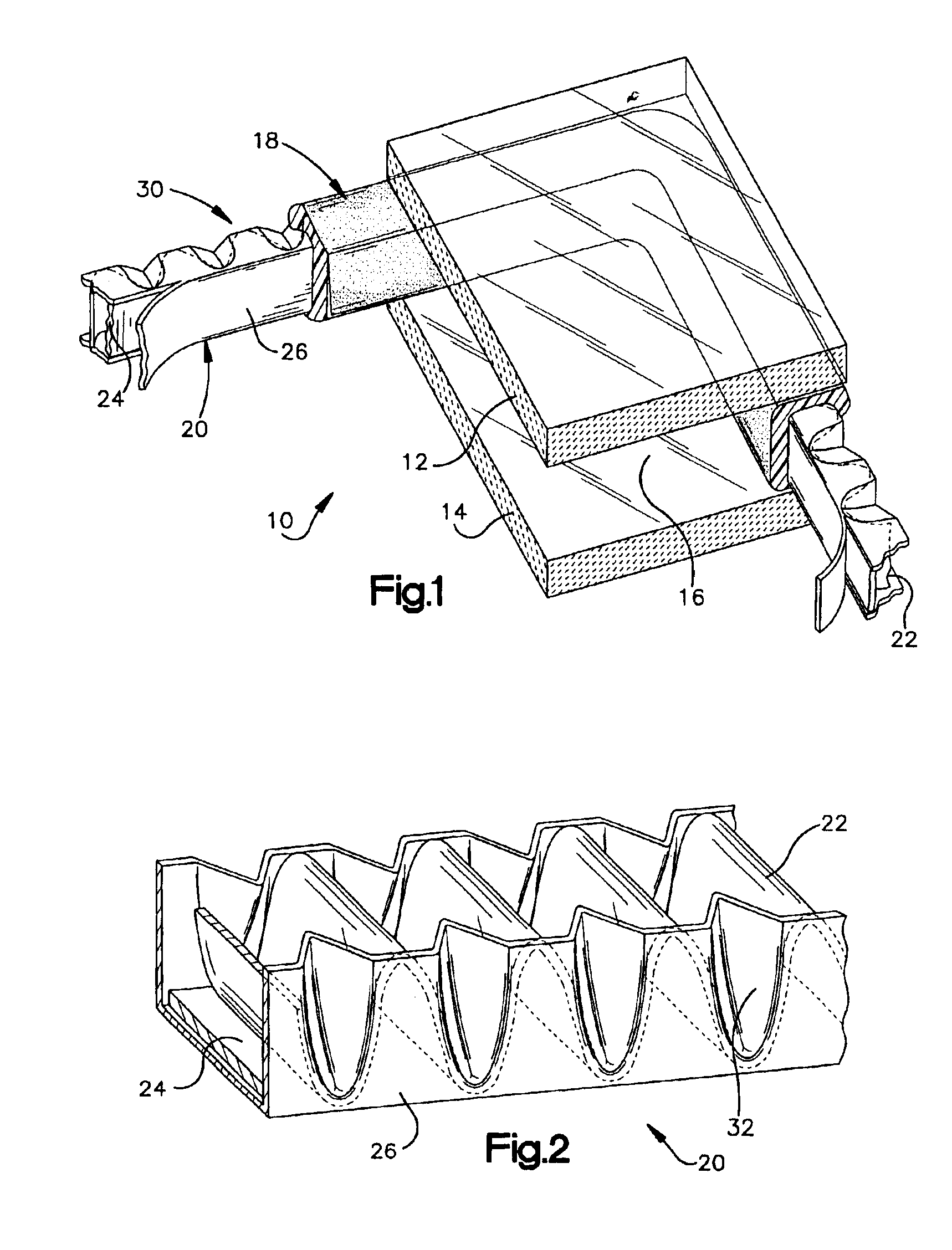

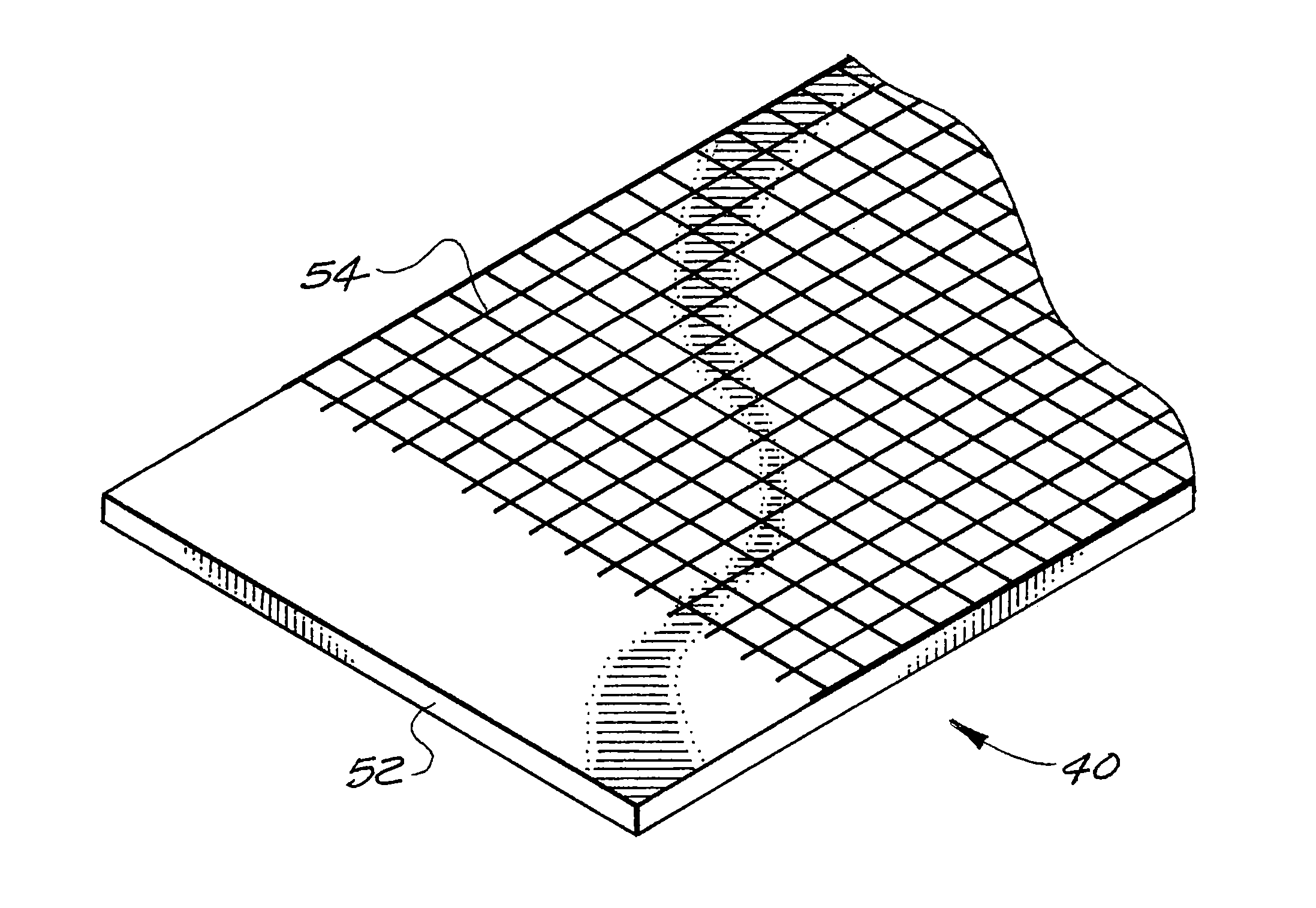

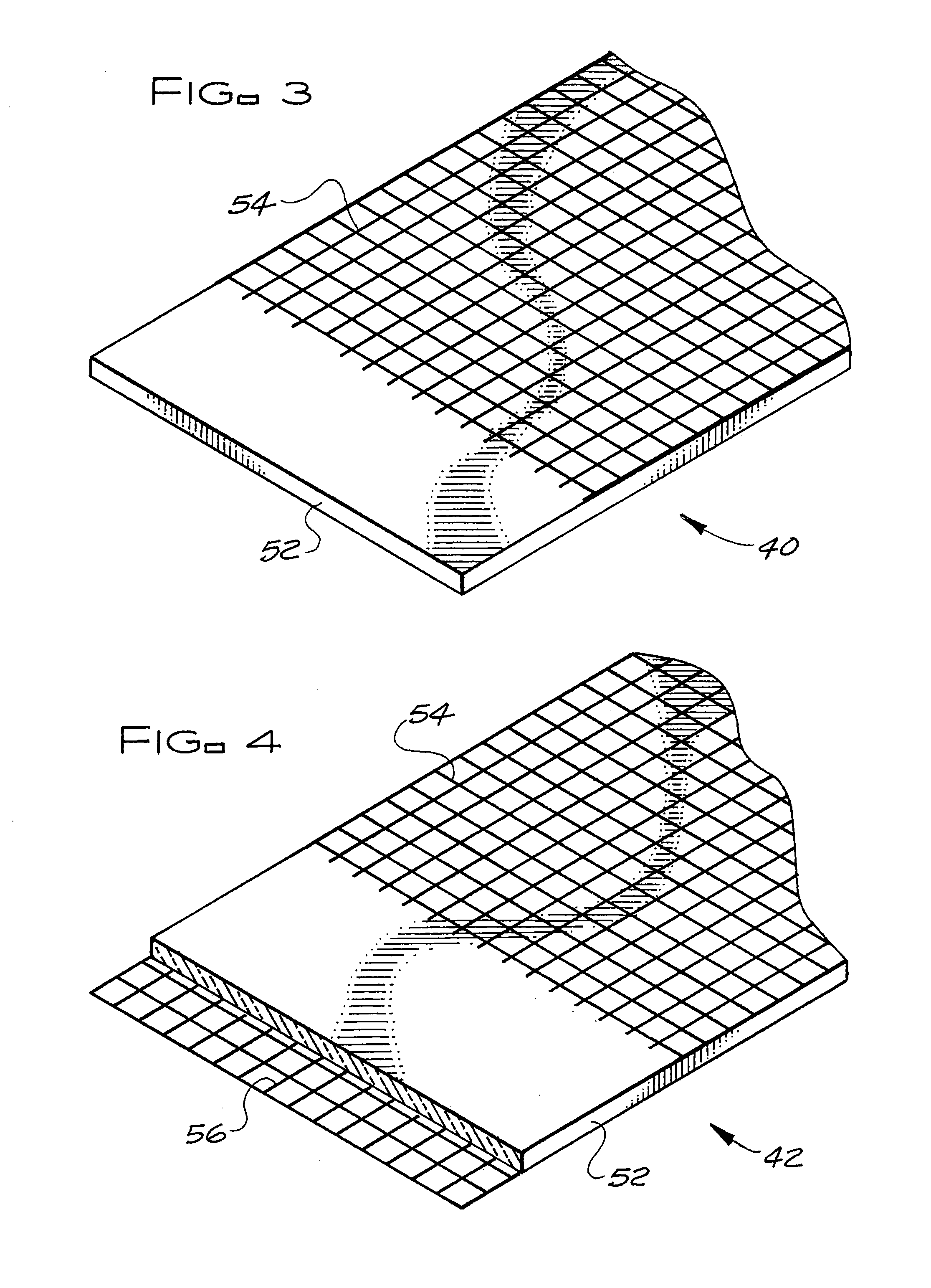

Continuous flexible spacer assembly having sealant support member

InactiveUS6877292B2Easy to produceImprove lateral stabilityTreadsCurtain accessoriesEngineeringSealant

A spacer and sealant assembly comprising a stretchable sealant support member having a planar surface bounded by first and second edges wherein said first and second edges have at least one pleated portion, a plastic shim having at least one undulating portion in contact with said first and second edges of said stretchable sealant support member so that said at least one pleated portion is oriented concavedly inward into said at least one undulating portion of said shim, a sealant joined to at least said first and second edges of said sealant support member.

Owner:QUANEX IG SYST INC

Insulated concrete wall forming system and hinged bridging webs

InactiveUS7082732B2Size reduction requirementsLower the volumeCeilingsStrutsEngineeringMechanical engineering

Owner:CANSTROY INT INC

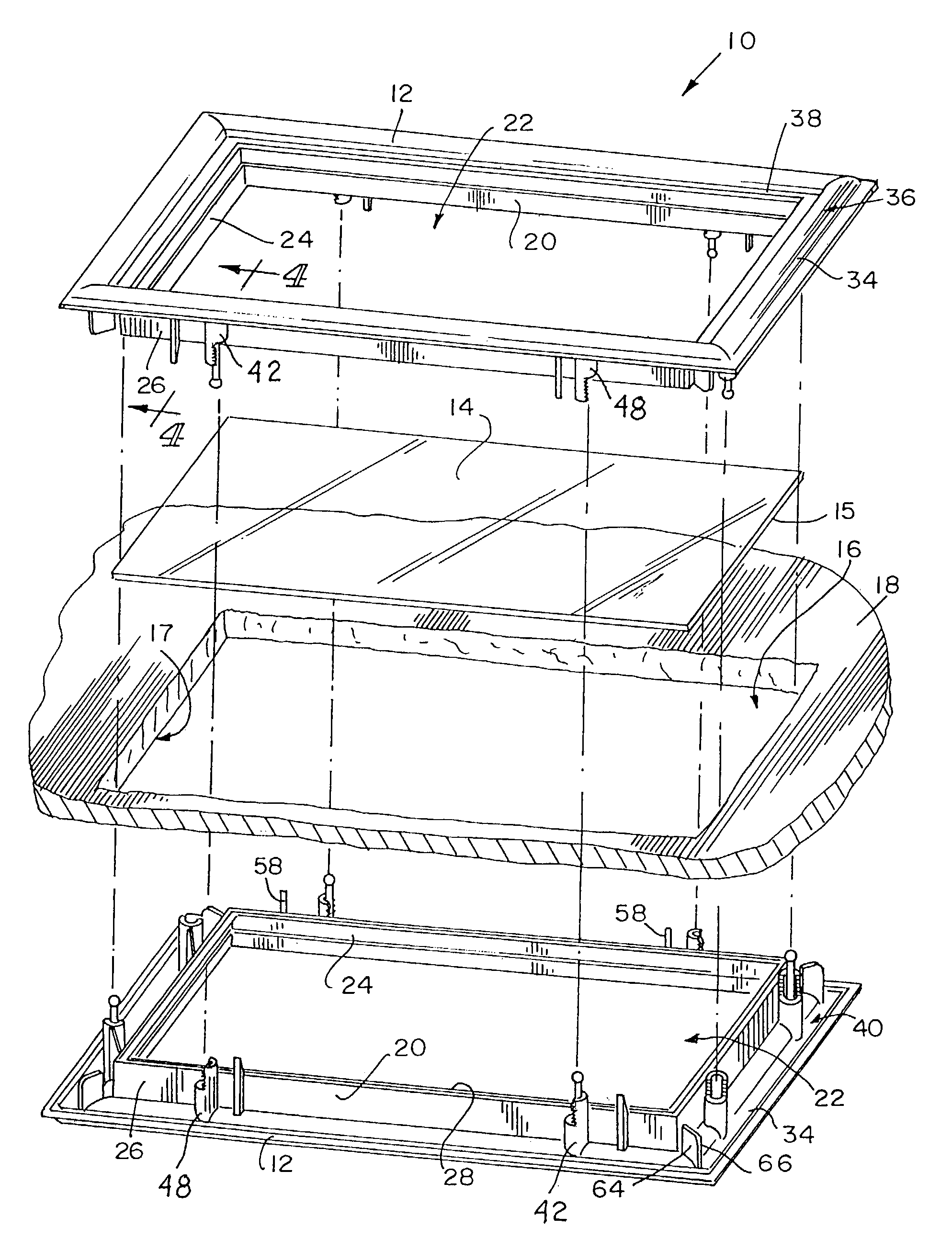

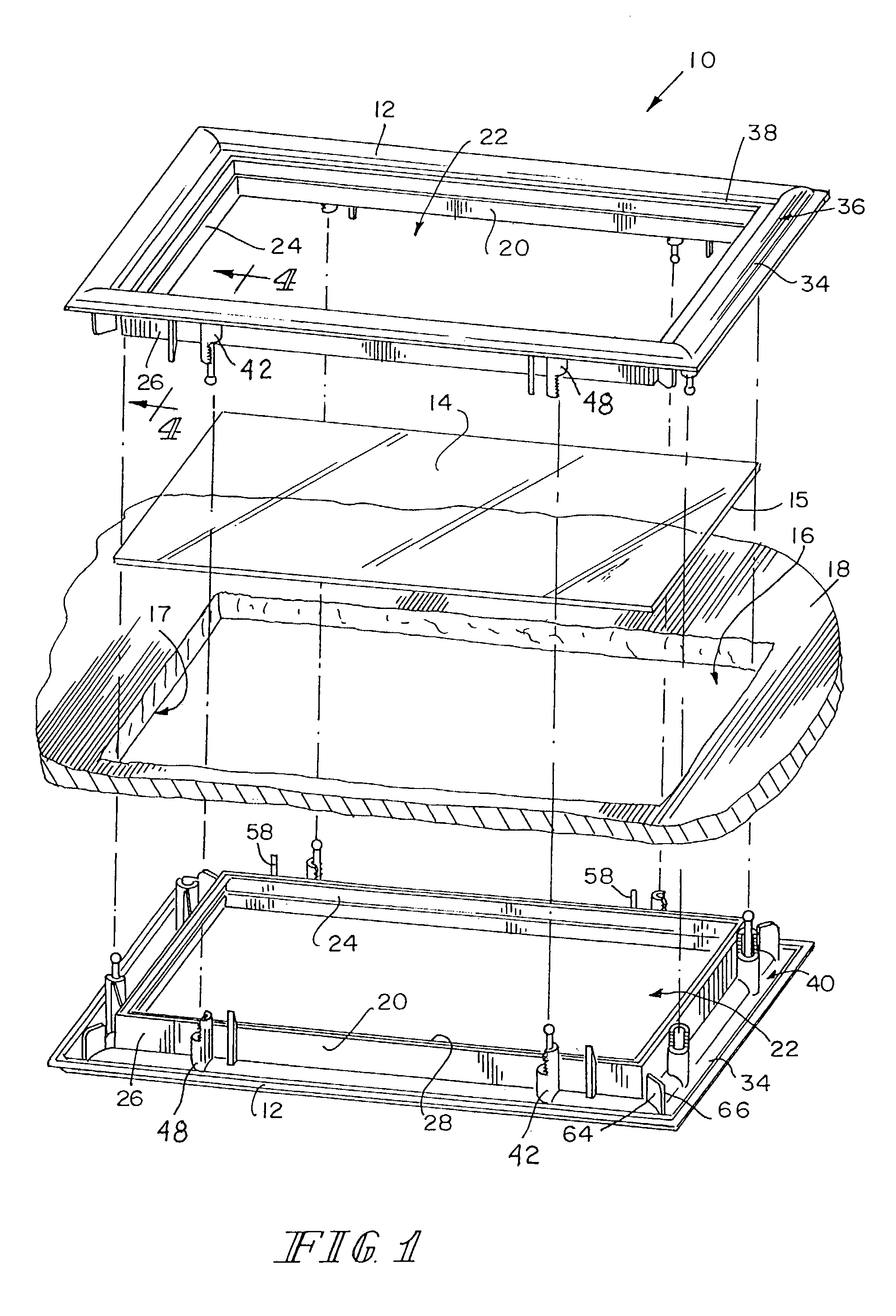

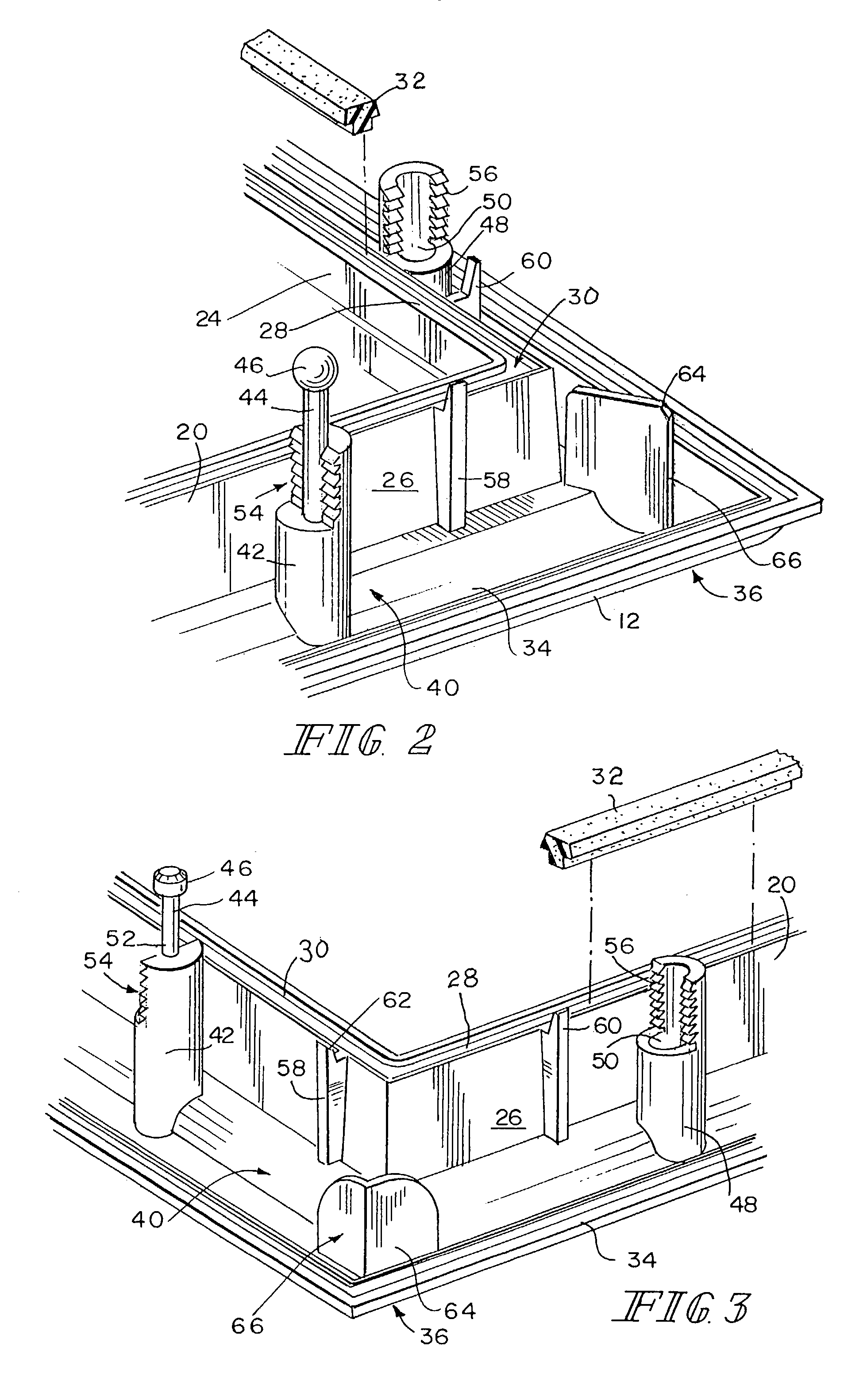

Molded snap-together frame

InactiveUS7010888B2Quick assemblyLower cost of capitalCorner/edge jointsWindow/door framesEngineeringFlange

A frame assembly is formed of two molded sub-assemblies, each sub-assembly being identical to the other. Each sub-assembly has a perimeter wall having an inner surface facing an opening and an outer surface to face a edge of an aperture in a partition. A first edge of the wall confronts a surface of the window while a flange projects outward from the outer surface of the perimeter wall. A plurality of joining elements are fixed to and project normally from the flange. Each joining element includes an alignment element and a locking surface to engage a similar surface on an aligned joining element of a confronting sub-assembly. The joining elements are arranged in a pattern that permits any two sub-assemblies made in the same mold to be permanently snapped together without the use of any separate fasteners.

Owner:L L CULMAT

Exterior wall construction product

Owner:CEMCO LLC

Locking system for floorboards

InactiveUS7003925B2Increase the differenceIncrease capacityCeilingsRoof covering using tiles/slatesVertical planeClassical mechanics

The invention relates to a locking system for mechanical joining of floorboards (1, 1′), a floorboard having such a locking system and a flooring made of such floorboards. The locking system has mechanical cooperating means (36, 38; 6, 8, 14) for vertical and horizontal joining of adjoining floorboards. The means for horizontal joining about a vertical plane (F) comprise a locking groove (14) and a locking strip (16) which is located at opposite joint edge portions (4a, 4b) of the floorboard (4). The locking strip (6) projects from the joint plane (F) and has an upwards projecting locking element (8) at its free end. The locking groove (14) is formed in the opposite joint edge portion (4a) of the floorboard at a distance from the joint plane (F). The locking groove (14) and the locking element (8) have operative locking surfaces (10, 11). The locking surfaces are essentially plane and spaced from the upper side of the projecting strip and inside the locking groove and make a locking angle (A) of at least 50° to the upper side of the board. Moreover the locking groove has a guiding part (12) for cooperation with a corresponding guiding part (6) on the locking element (8).

Owner:VÄLINGE INNOVATION AB

System for joining building panels

The invention relates to a system for laying and mechanically joining building panels, especially thin, hard, floating floors. Adjacent joint edges of two panels engage each other to provide a first mechanical connection locking the joint edges in a first direction perpendicular to the principal plane of the panels. In each joint, there is further provided a strip which is integrated with one joint edge and which projects behind the other joint edge. The strip has an upwardly protruding locking element engaging in a locking groove in the rear side of the other joint edge to form a second mechanical connection locking the panels in a second direction parallel to the principal plane of the panels and at right angles to the joint. Both the first and the second mechanical connection allow mutual displacement of joined panels in the direction of the joint.

Owner:VÄLINGE INNOVATION AB

Modular tile with controlled deflection

A modular tile configured to interlock with multiple tiles to form a modular floor covering over a floor. The tile includes a top surface having a periphery defining side walls extending downward from the top surface, the side walls having a coupling portion configured to couple with other tiles adjacent thereto to form the modular floor covering. The tile also includes a bottom side, opposite the top surface, having a support grid including an array of downward extending polymeric post structures, at least some of the post structures including at least one resilient end portion with a radial end surface configured to be positioned against the floor to facilitate controlled deflection of the post structures. The post structures may comprise primary and secondary post structures, with the secondary post structures limiting the deflection of the primary post structures.

Owner:CONNOR SPORT COURT INT

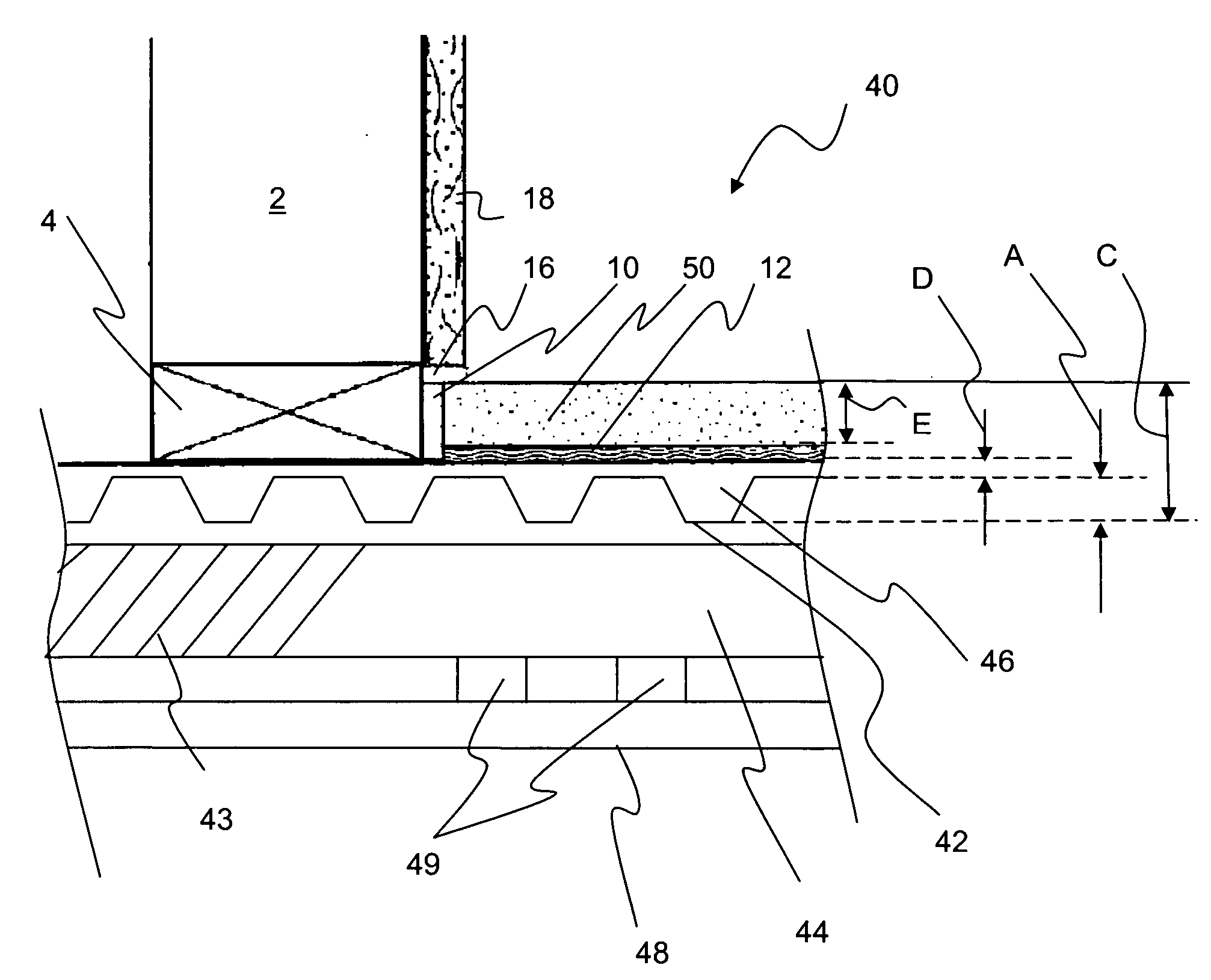

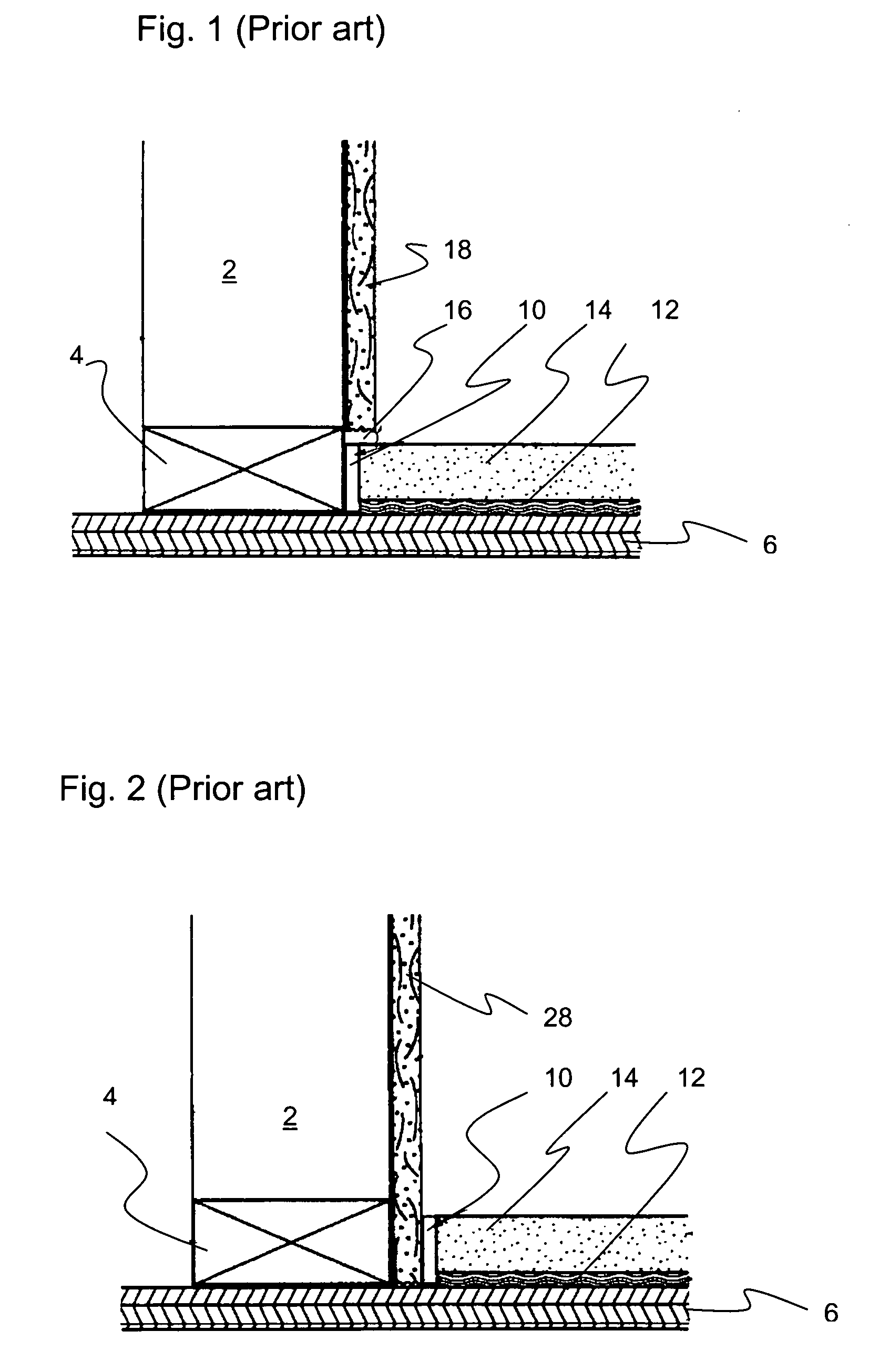

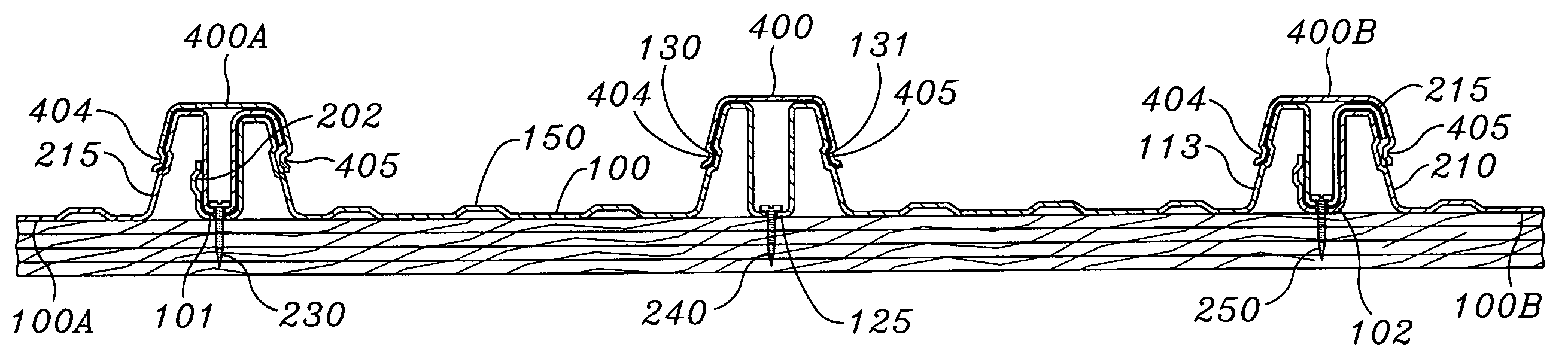

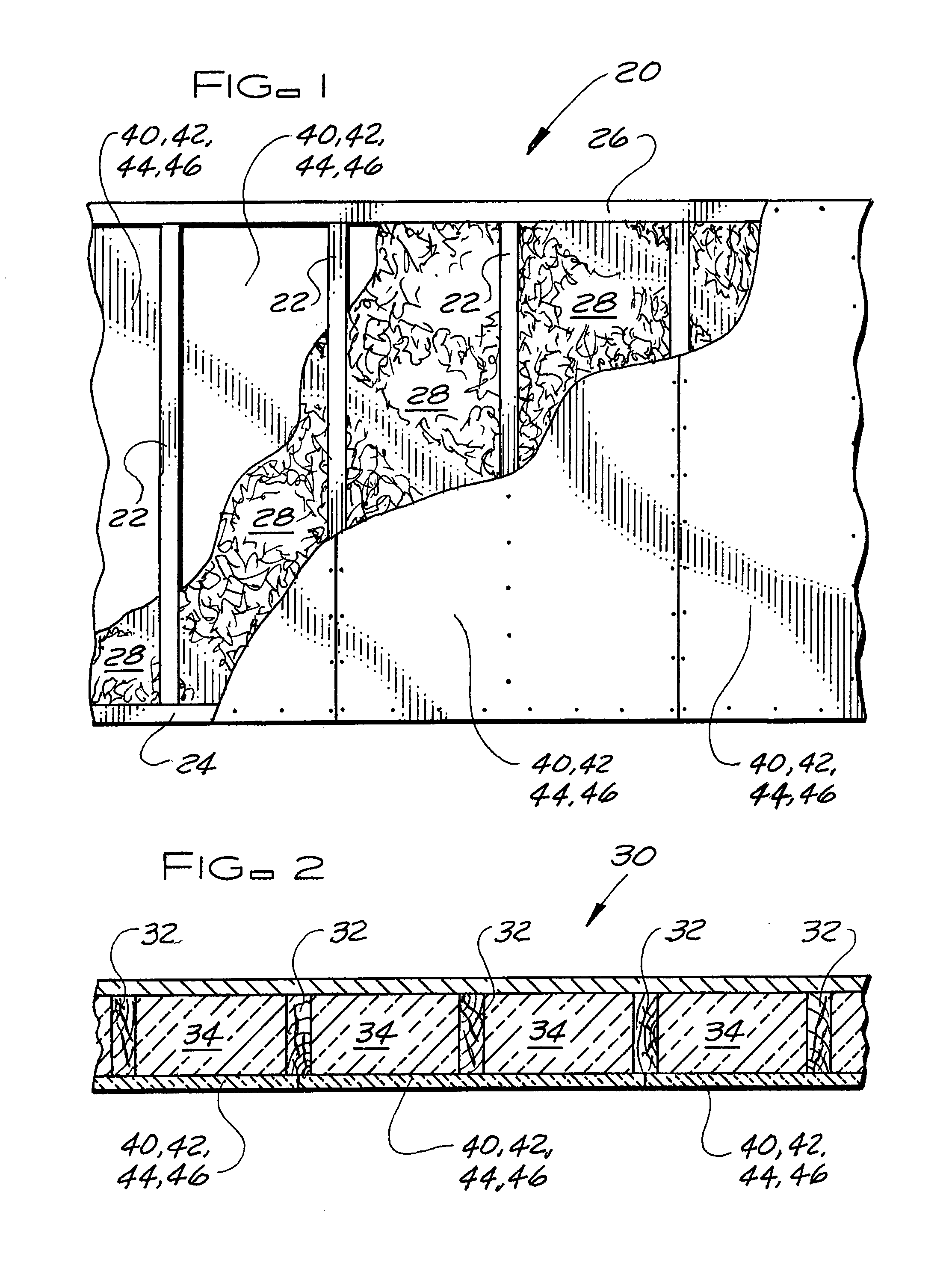

Corrugated steel deck system including acoustic features

ActiveUS20070000198A1Solve the slow construction speedReduce laborCeilingsCovering/liningsCarrying capacityEngineering

The present invention relates to a sound rated floor system for inhibiting sound transmission between floors. The system includes a corrugated steel deck; a first layer of cementitious material or board or sheet applied over the corrugated steel deck; a sound insulation mat or board applied over the first layer; a second layer of cementitious material applied over the sound insulation mat or board. The floor system has an IIC rating of at least 25 and the corrugated steel deck provides at least 50 percent of the ultimate load carrying capacity under static and impact loading of the floor system with a floor deflection of at most 1 / 360 of the floor span.

Owner:UNITED STATES GYPSUM CO

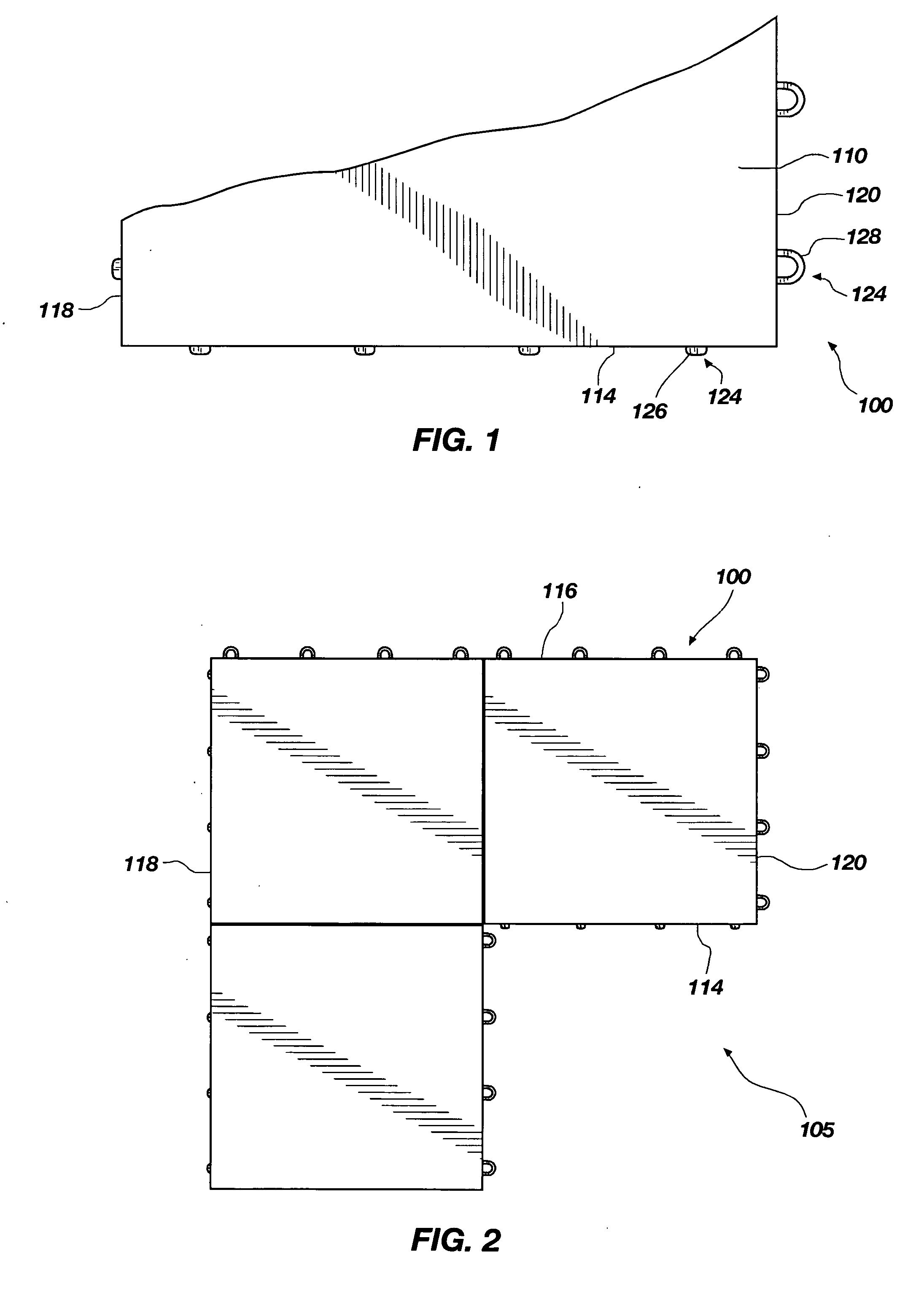

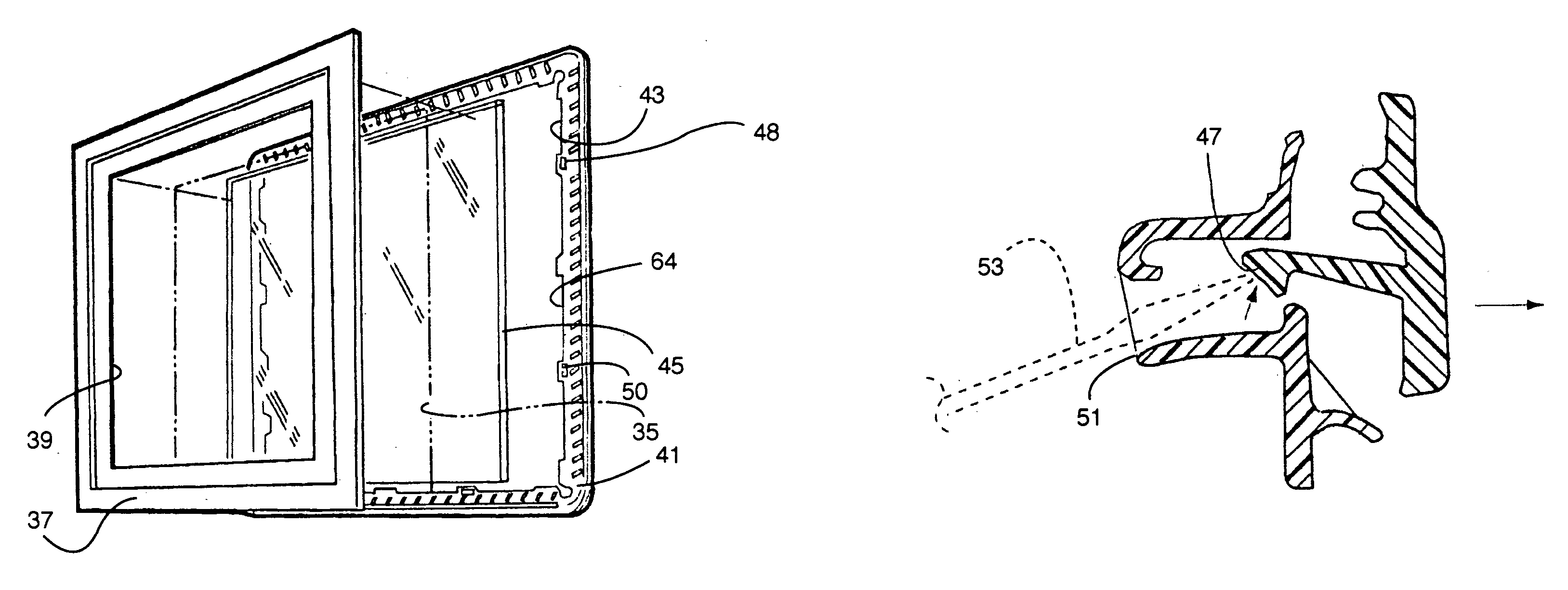

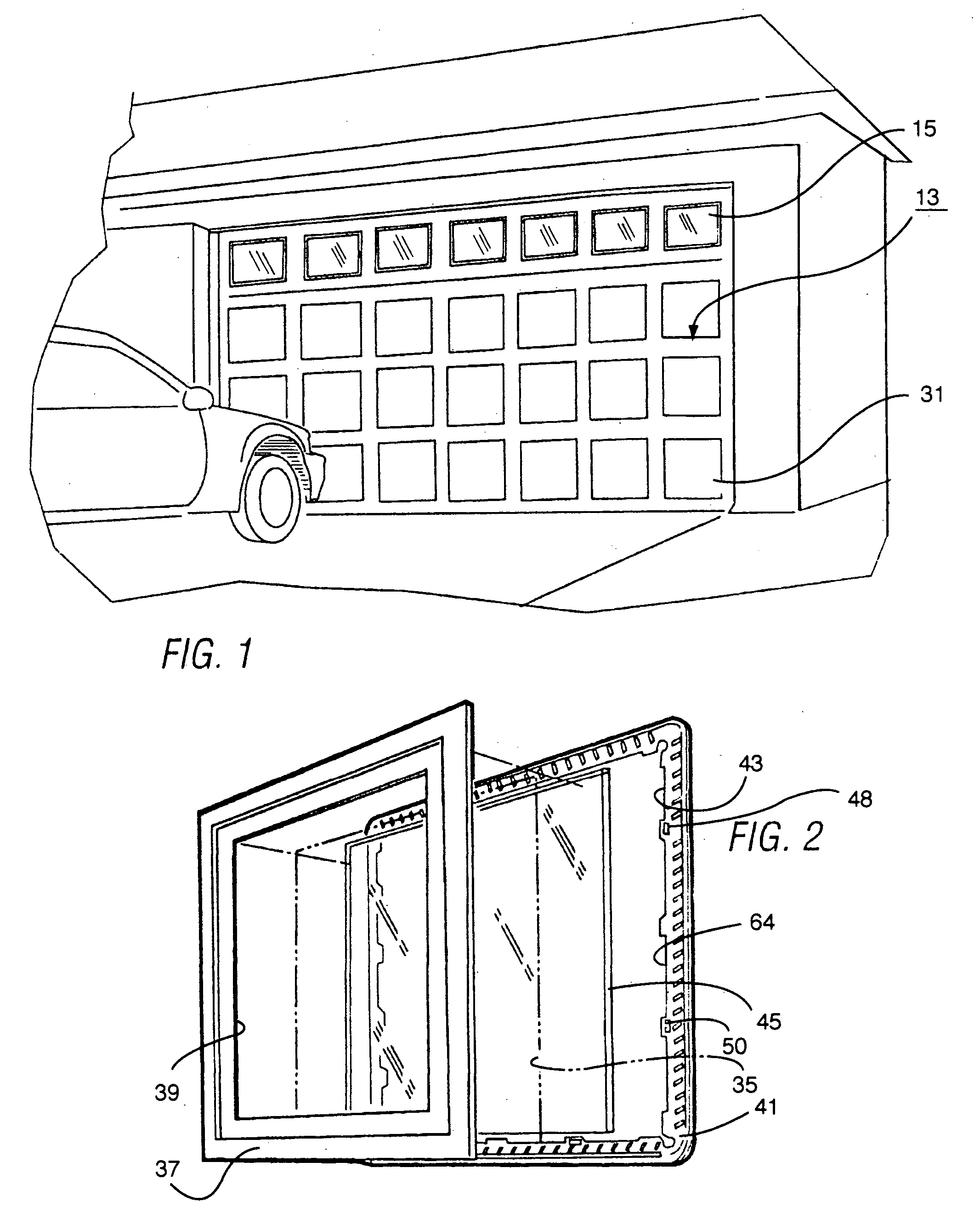

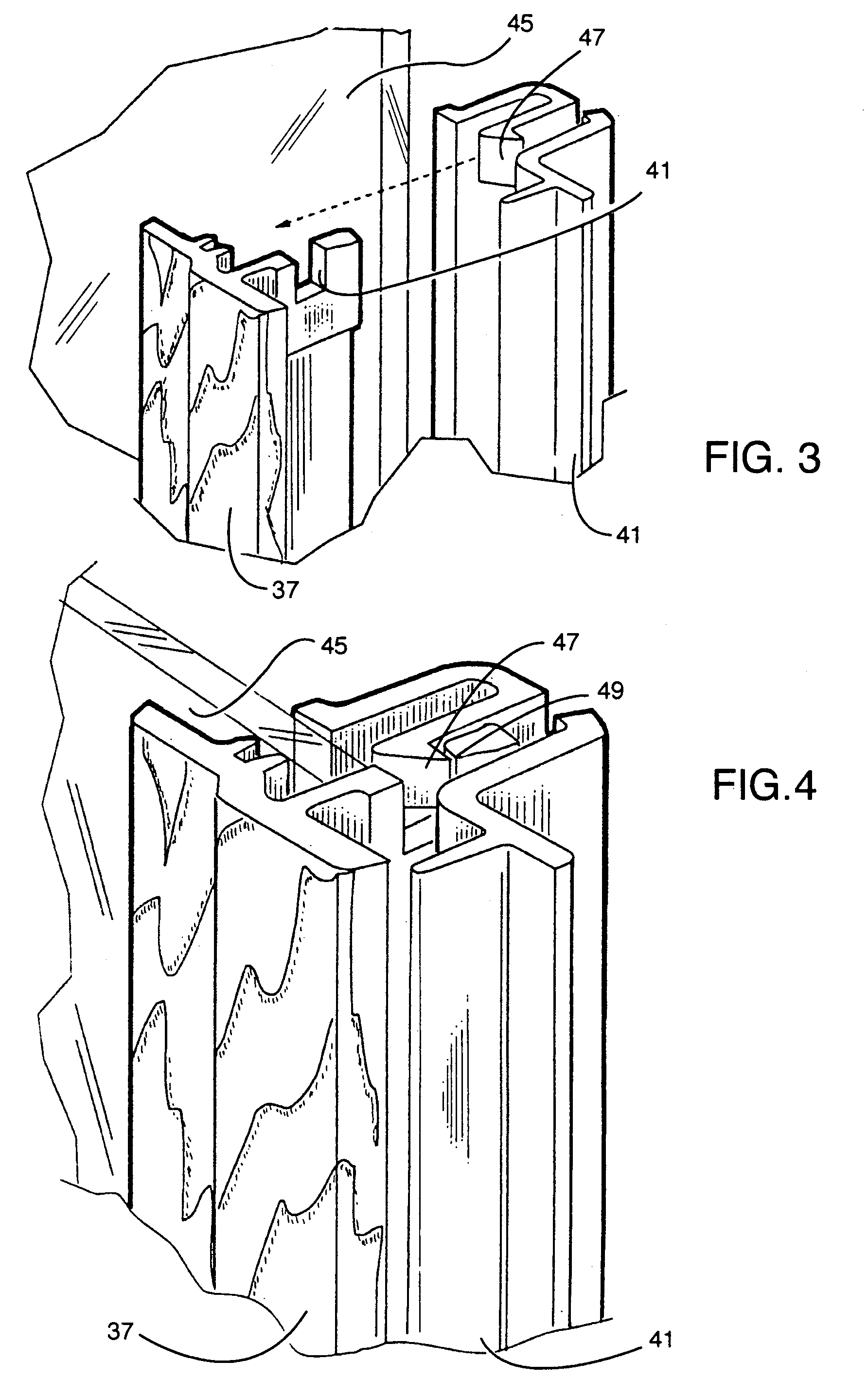

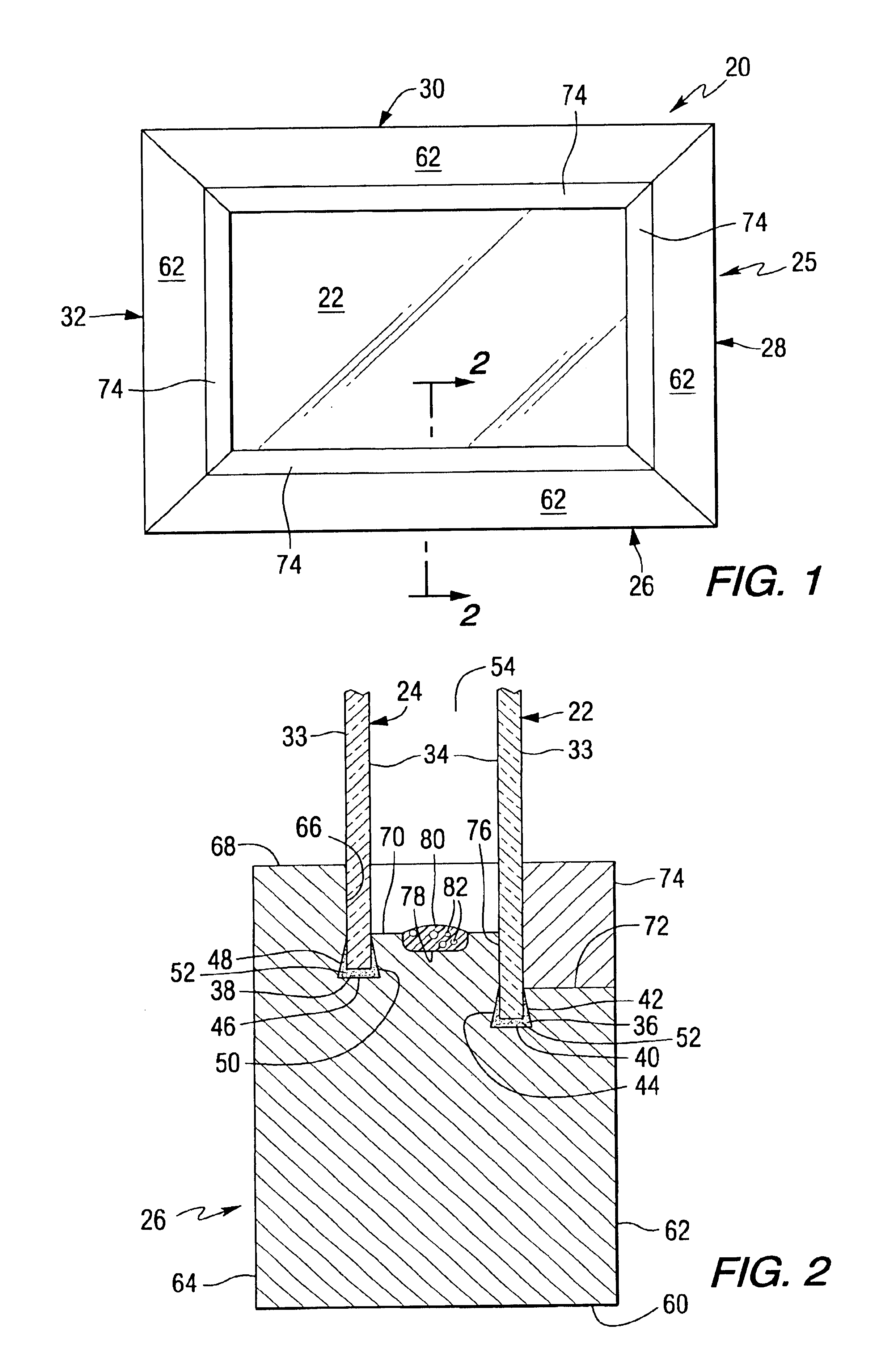

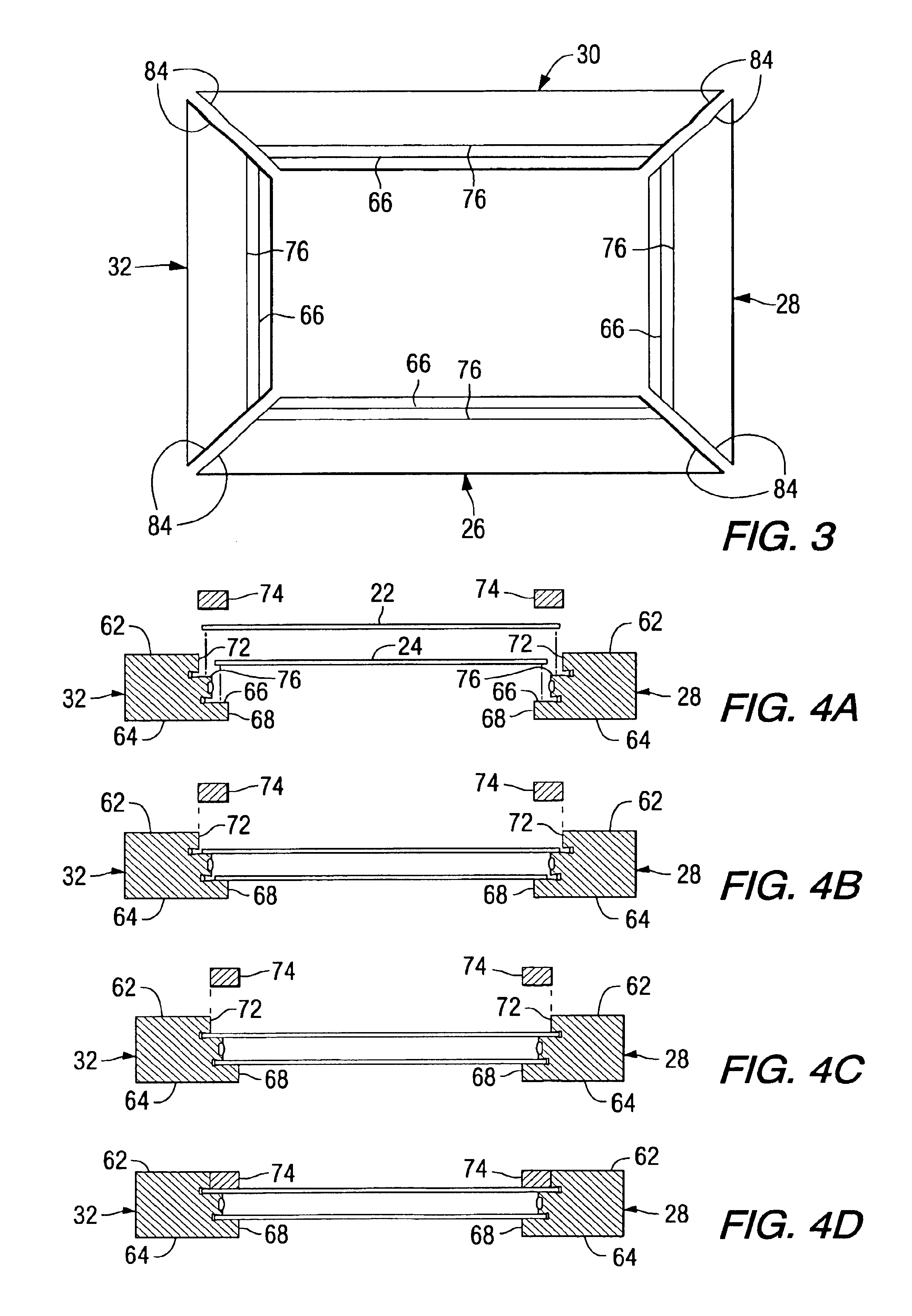

Garage door window frame and method of installation

ActiveUS7107736B2Easy to disassemblePromote repairWindow/door framesBuilding repairsWindow openingEngineering

A window frame assembly for installation within a garage door having front and rear exposed surfaces and one or more window openings. The assembly includes front and rear window frame members of injection molded plastic which are installed within the door opening on the front and rear exposed surfaces. The window frame members have engagement elements located about their peripheries which snap together in mating fashion to mount the frame members within the window opening. The engagement elements are also disenageable with a hand tool to separate the frame members and remove the members from the window opening.

Owner:NAT DOOR INDS

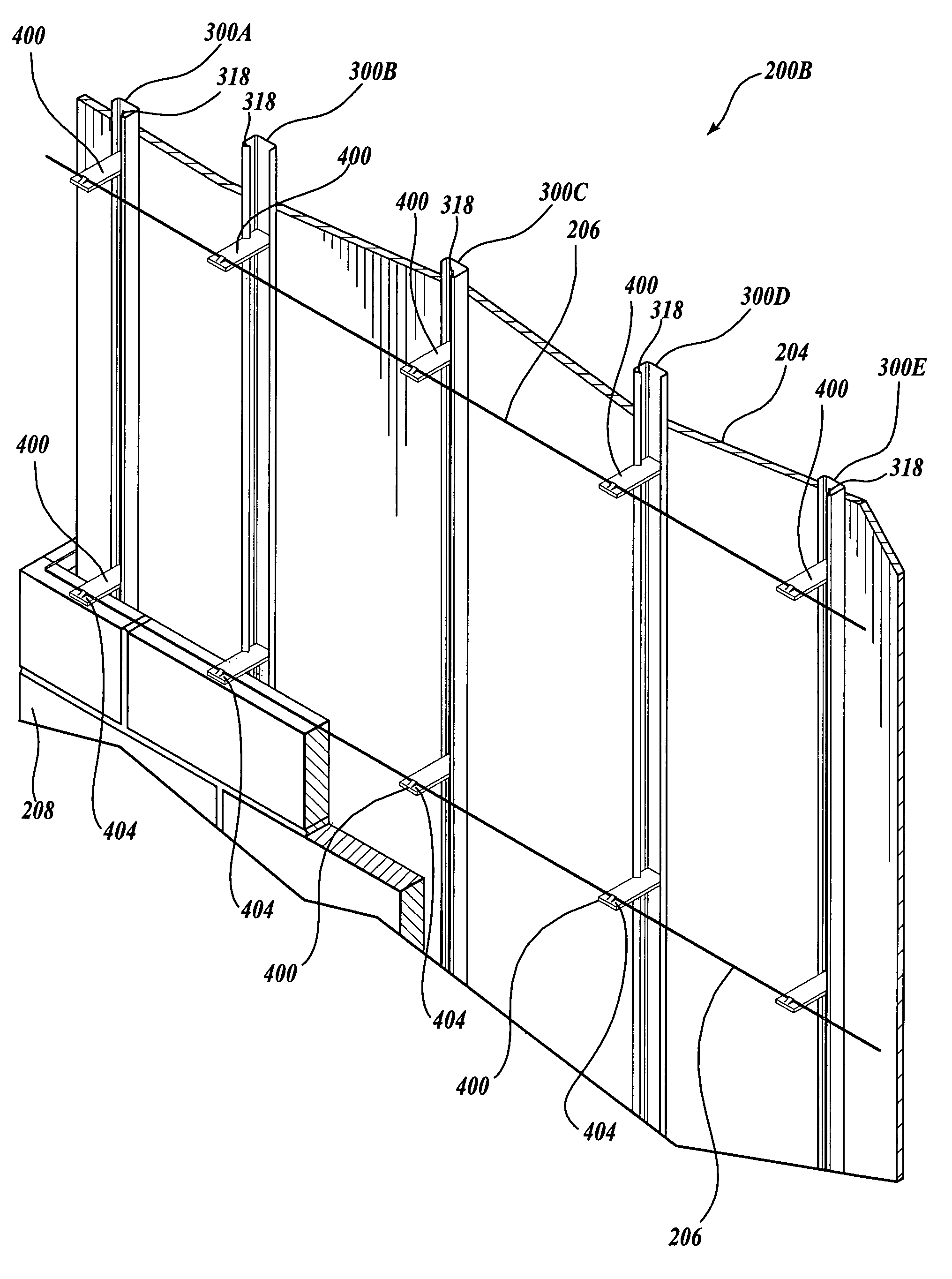

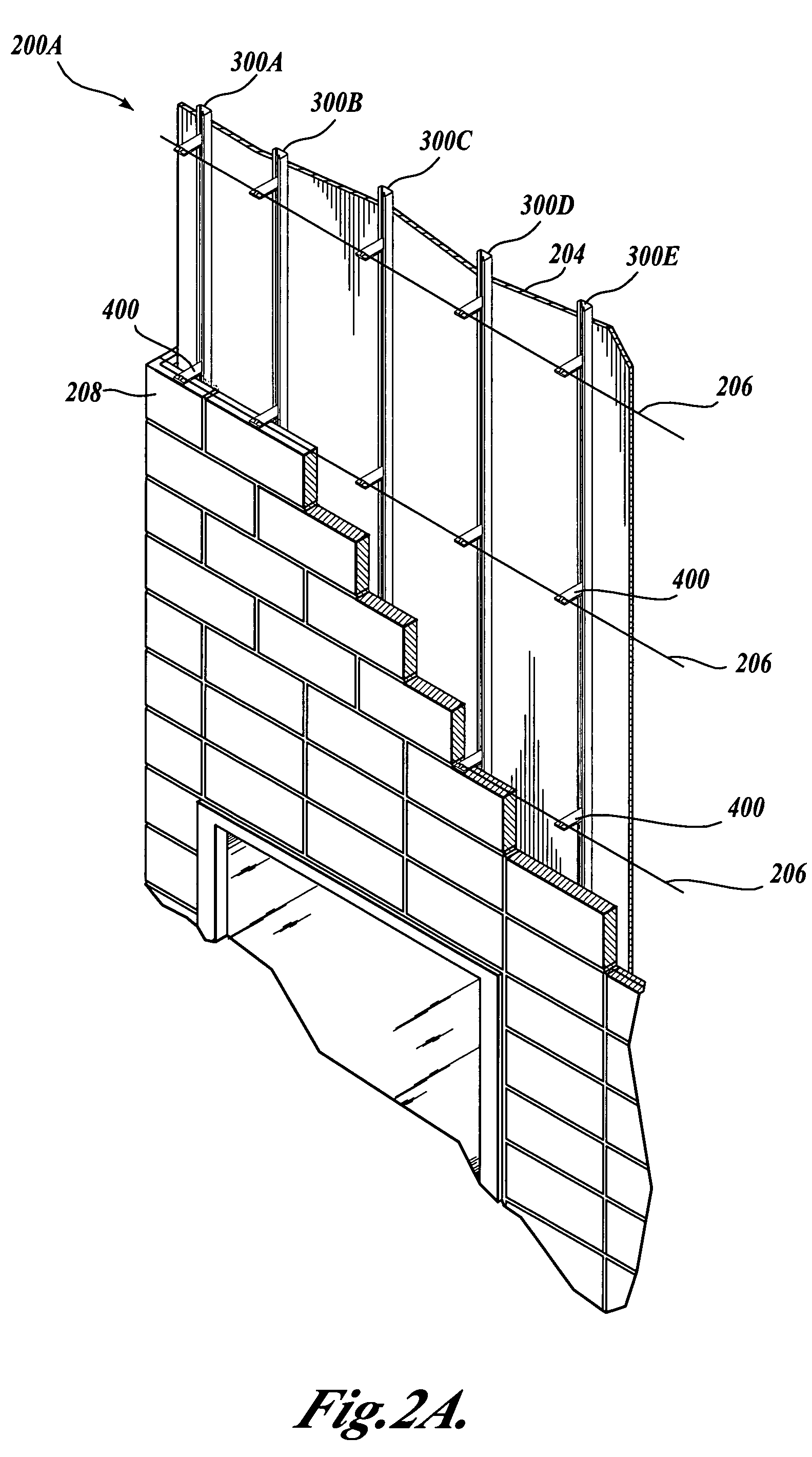

Modular system for cladding exterior walls of a structure and insulating the structure walls

ActiveUS20120137610A1Low costImprove insulation performanceCeilingsConstruction materialWall plateModular system

A modular system for cladding exterior walls of a structure and insulating the structure walls provides thermally isolated vertical girders secured to a structural wall. The thermally isolated vertical girders positionally maintain insulation adjacent the structure and provide a means for mounting exterior wall cladding to the structure. Planar wall panels carrying exterior wall cladding elements mount directly or indirectly to the vertical girders. Corner elements, carrying exterior corner cladding elements interconnect with the underlying system and visually appear to interconnect with adjacent edge portions of the planar wall panels.

Owner:KNIGHT WALL SYST

Standing seam structural panel

InactiveUS7104020B1Undesirable characteristicAdd shear strength valueRoof covering using slabs/sheetsCeilingsArchitectural engineering

A multi-ribbed, standing seam structural roof panel with double ribs which can be attached directly to building framing to create a structural rated building panel with shear values which also serves as waterproofing panel.

Owner:KORRIGAN RESOURCES

Polymer-based composite structural sheathing board and wall and/or ceiling system

ActiveUS7765761B2Improve integrityAdd dimensionCeilingsCovering/liningsUltimate tensile strengthPolymer chemistry

A wall and / or ceiling polymer-based composite structural sheathing board has a polymer material or predominantly polymer material core layer with a density between 1.6 lbs / ft3 and 25 lbs / ft3. A facer overlays at least one of the major surfaces of the core layer. The facer is generally coextensive with and bonded to the overlaid major surface of the core layer and enhances the integrity and fastener pull through strength of the polymer-based composite structural sheathing board as well as other desired physical and performance characteristics of the polymer based composite structural sheathing board. A wall and / or ceiling system of a building structure includes a plurality of the polymer-based composite structural sheathing boards overlaying and secured to a structural wall and / or ceiling frame and forming a wall and / or ceiling sheathing layer over the structural frame.

Owner:JOHNS MANVILLE CORP

Insulating unitless window sash

InactiveUS6886297B1Avoid problemsImprove thermal efficiencyCorner/edge jointsCondensed water formation preventionEngineeringMechanical engineering

An insulating unitless window sash includes a sash frame made of four linear sash members having their mitered edges joined together. Each of the sash members in cross section includes a peripheral surface, a first and outer side walls and a first groove spaced from a second groove. Each of the grooves has a base and spaced walls. The base of the first groove is spaced a greater distance from the peripheral surface than the base of the second groove. Peripheral and marginal edges of a first sheet are in the first groove and peripheral and marginal edges of a second sheet are in the second groove. A shim is mounted on the sash frame adjacent the outer surface of the first sheet to give a balance configuration.

Owner:VITRO FLAT GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com