Ladle clearing method and ladle clearing machine group

A cleaning method and unit technology, applied in mechanical cleaning, furnace components, descaling devices, etc., can solve the problems of high labor intensity, high damage rate of ladles, and environmental pollution, etc., and achieve low labor intensity and high integrity rate , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

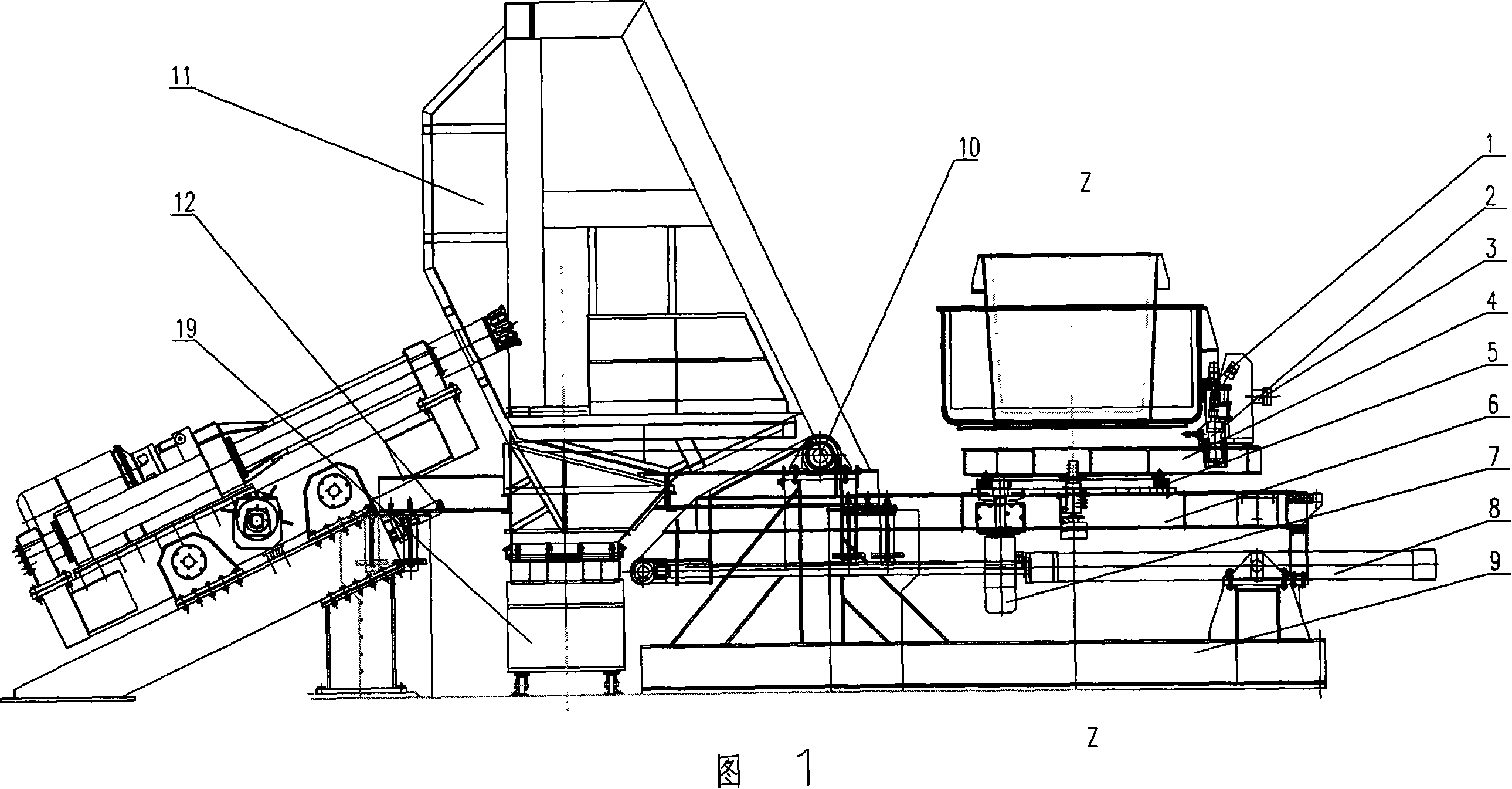

[0032] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

[0033] Ladle cleaning method: fix the ladle on the tilting mechanism, and the tilting mechanism drives the ladle to overturn, rotate, and turn around, so that the ladle is tipped to the cleaning tool 13; the cleaning tool 13 extends into the ladle Perform the actions of rotation, feeding, retracting and horizontal movement to complete the cleaning of the ladle, and the cleaning tool 13 matches the ladle; after cleaning, the tilting mechanism drives the ladle to reset to the initial position, completing the cleaning of the ladle Cleaning, the cleaned slag is collected in the protective cover 11 and transported away by the discharge car 19. During the cleaning process, the rotating direction of the ladle is opposite to that of the cleaning tool 13.

[0034] The more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com