Patents

Literature

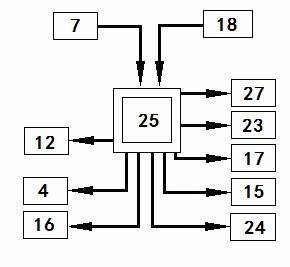

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

418results about "Sanitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

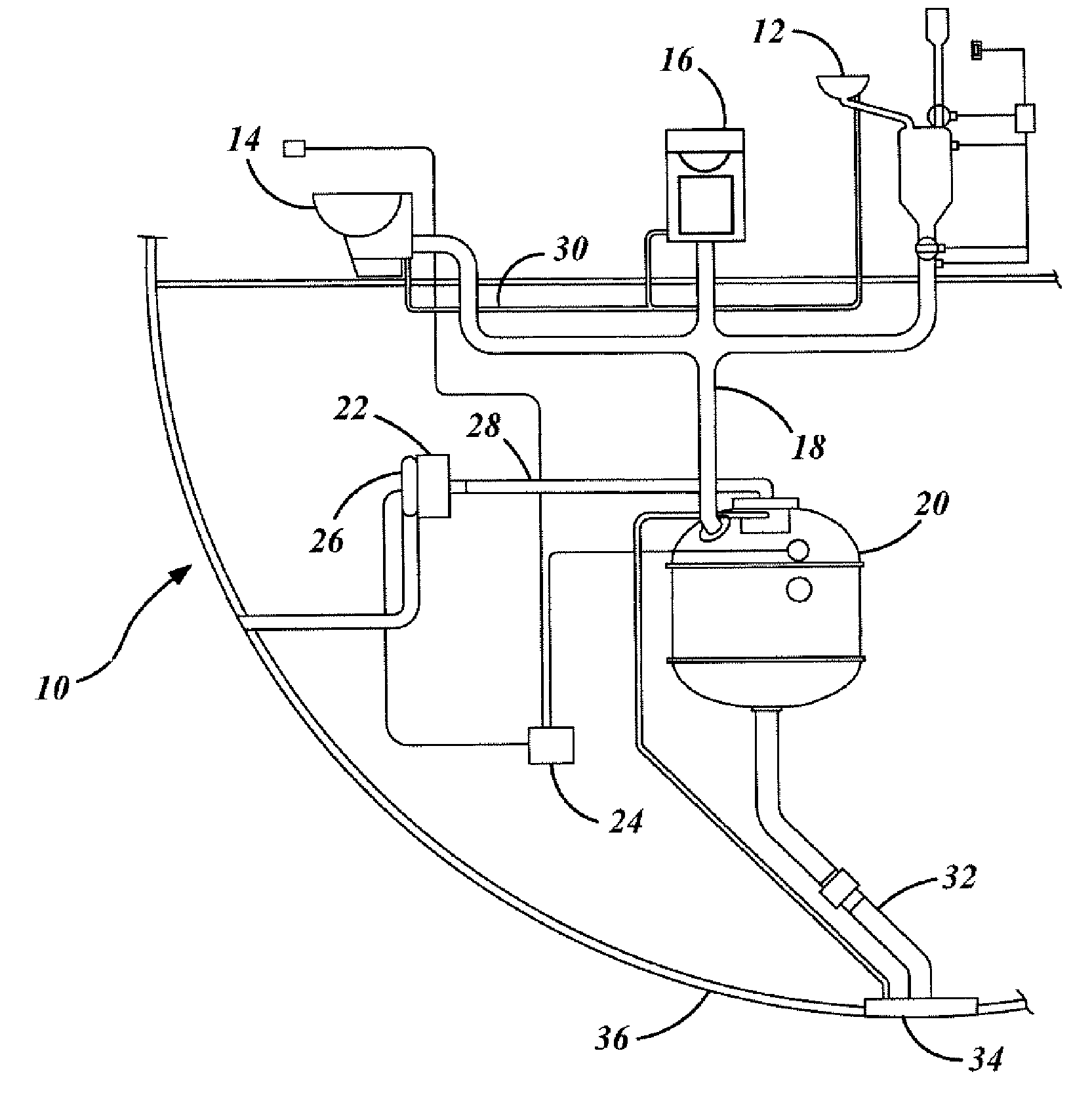

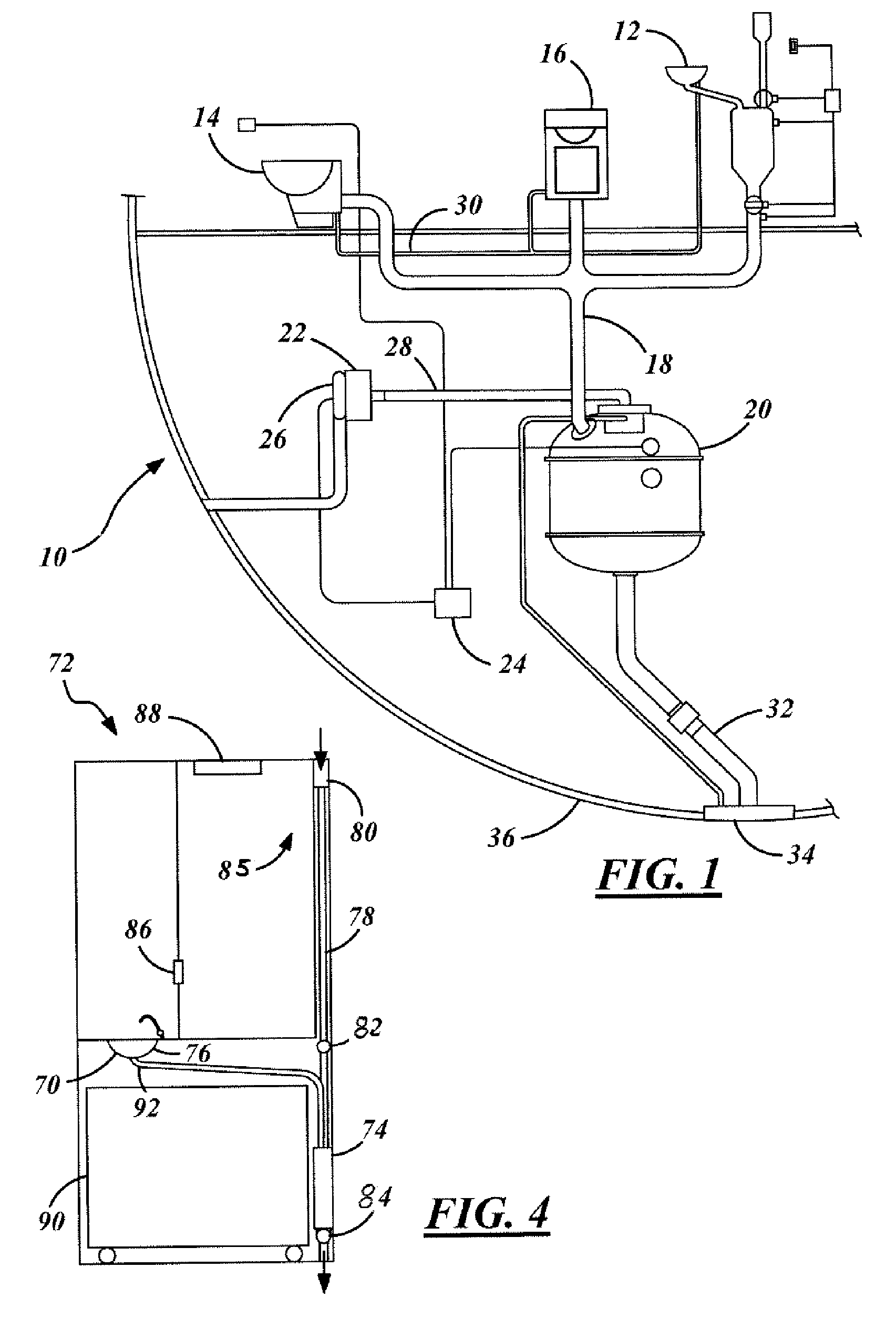

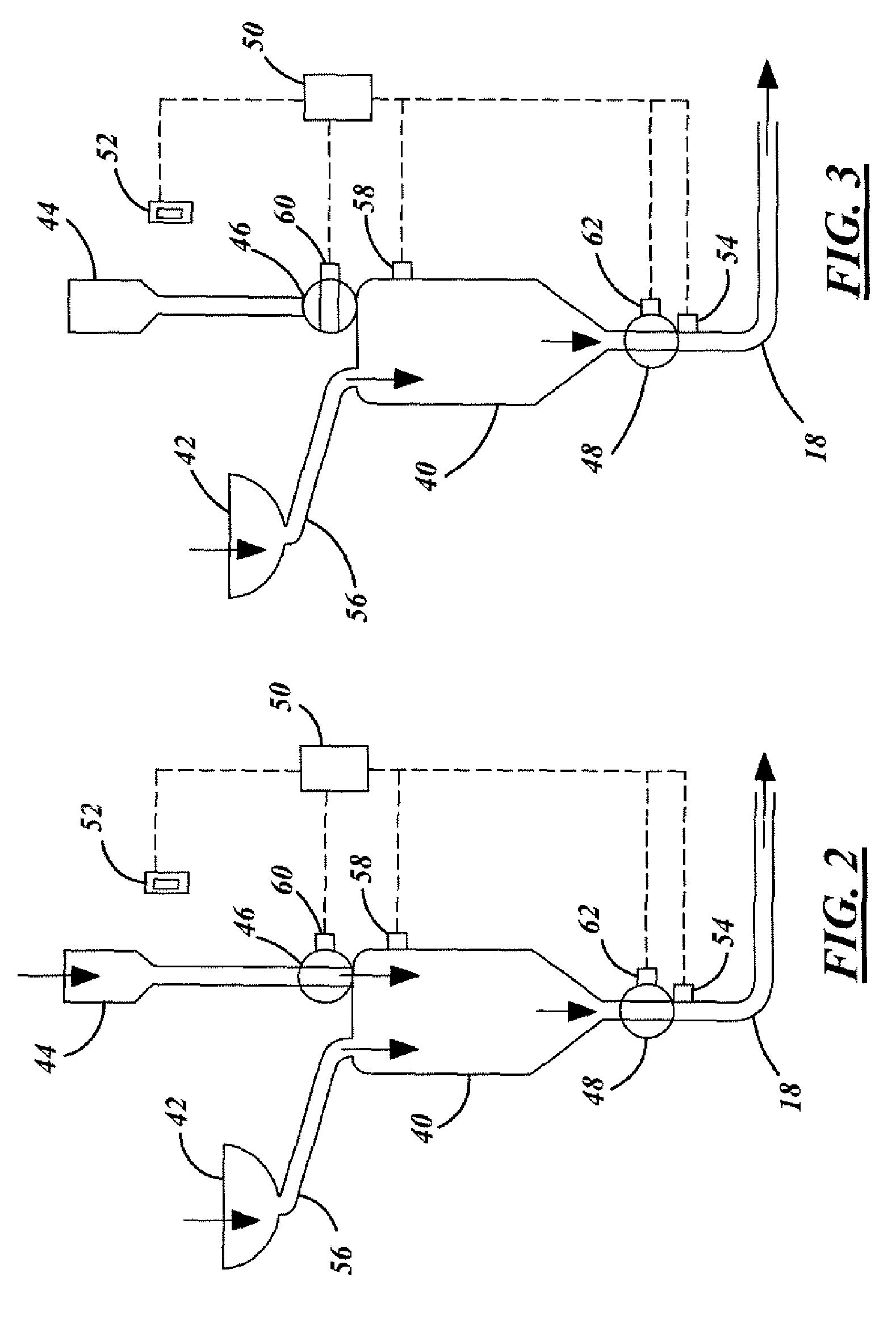

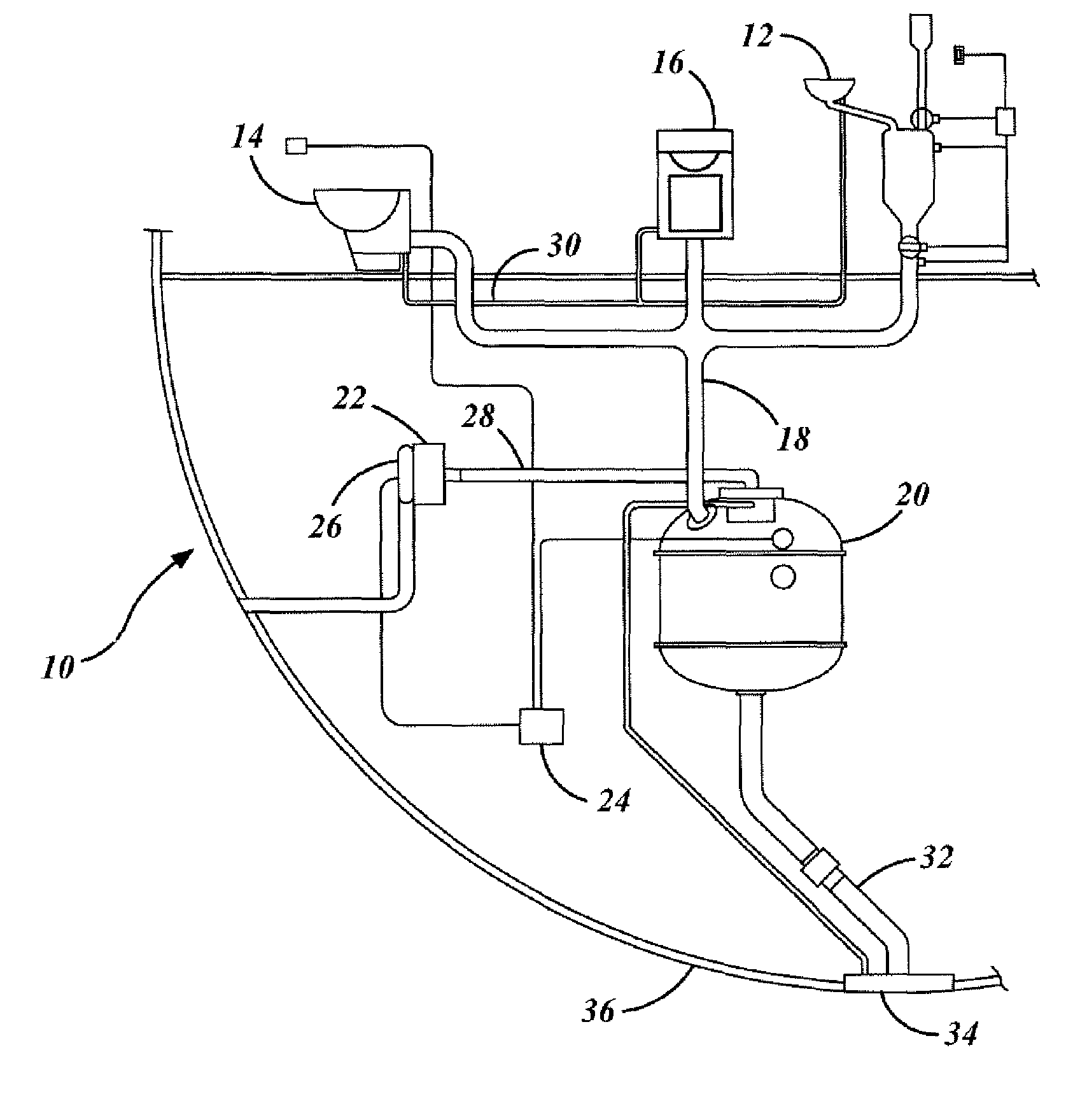

Aircraft sink with integrated waste disposal function

InactiveUS20060225200A1Save weight and cost and spaceGalleysBathroom accessoriesEngineeringCommon line

A sink system includes a sink and a storage area receiving and storing matter from the sink. The storage area receives air from the bypass line during a flush. Also, matter from the storage area and sink is vacuumed through a common line during the flush. A valve limits an amount of air supplied by the bypass line such that increased suction is applied to the sink through the common line. The valve may be manually operated or operated by a controller.

Owner:THE BOEING CO

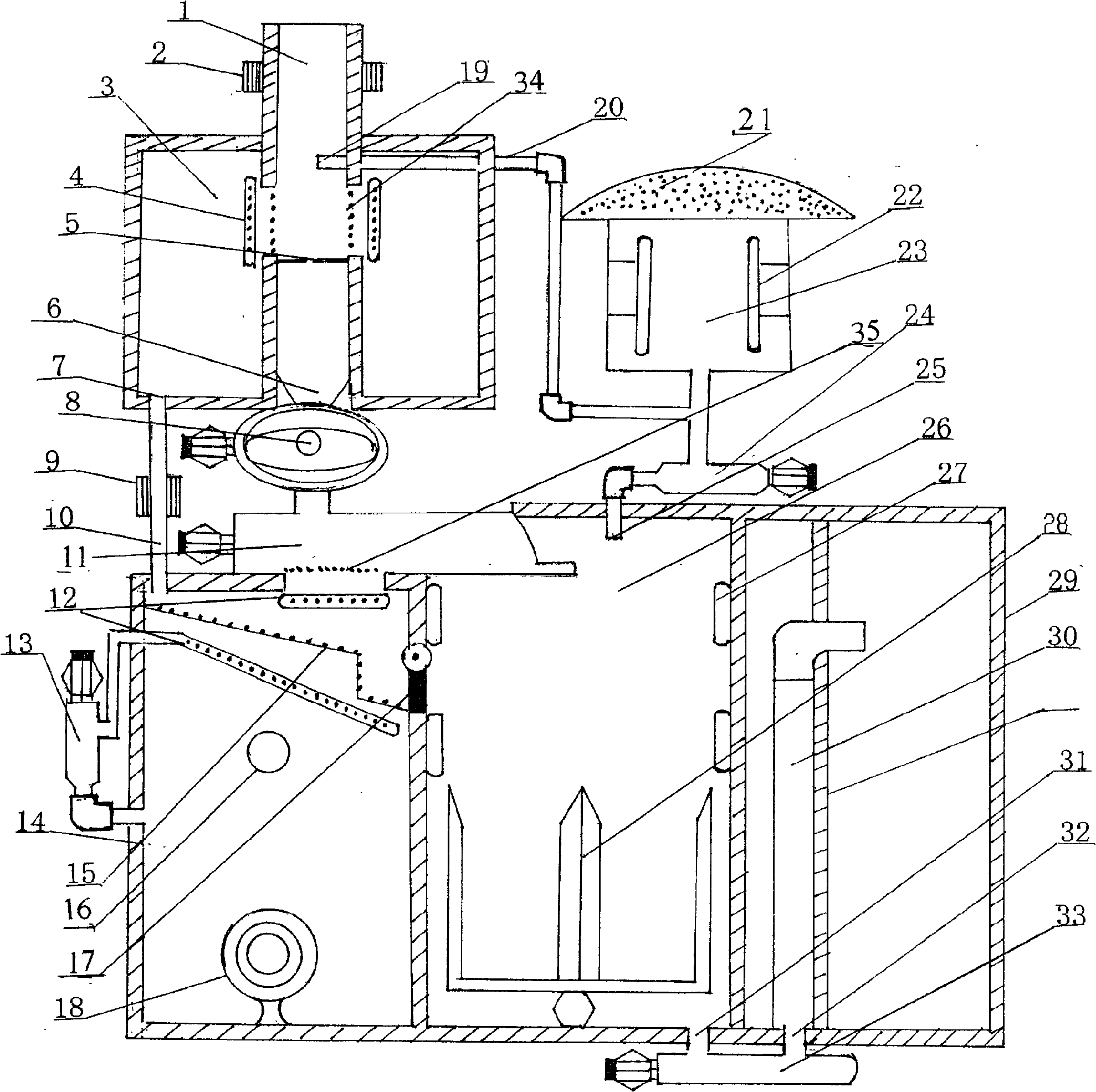

Environmental sanitation treating apparatus for fast decomposing, sterilizing and drying solid-liquid feculence dejection

InactiveCN101265004AKill eggs quicklyImprove sterilizationMaintainance for emmission reductionSludge treatmentHuman bodyDecomposition

The invention relates to a device for rapid decomposition, sterilization, drying and sanitary treatment of solid / liquid feces, aiming to solve the problems of human feces including environmental pollution, disease transmission and body health damage. The device comprises a solid-liquid separator, a semi-solid finishing machine, a secondary solid-liquid separation spiral pump, a urine treatment tank, a microwave sterilization drying chamber, a dry matter storage tank, and a deodorizing aeration tower. The feces can be rapidly sterilized, deodorized and dried after leaving human body, so as to become sterile and odorless dried particles in a short time, which can be used as fertilizer. The inventive device prevents transmission of pathogenic bacteria from source and solves fecal pollution problem. The inventive device has the advantages of low volume, light weight, and low energy consumption; and can be used in any places. Except fixed places, the device is more suitable for being installed and used in personal vehicles such as passenger train, passenger long-distance bus and passenger ship.

Owner:齐梓凡

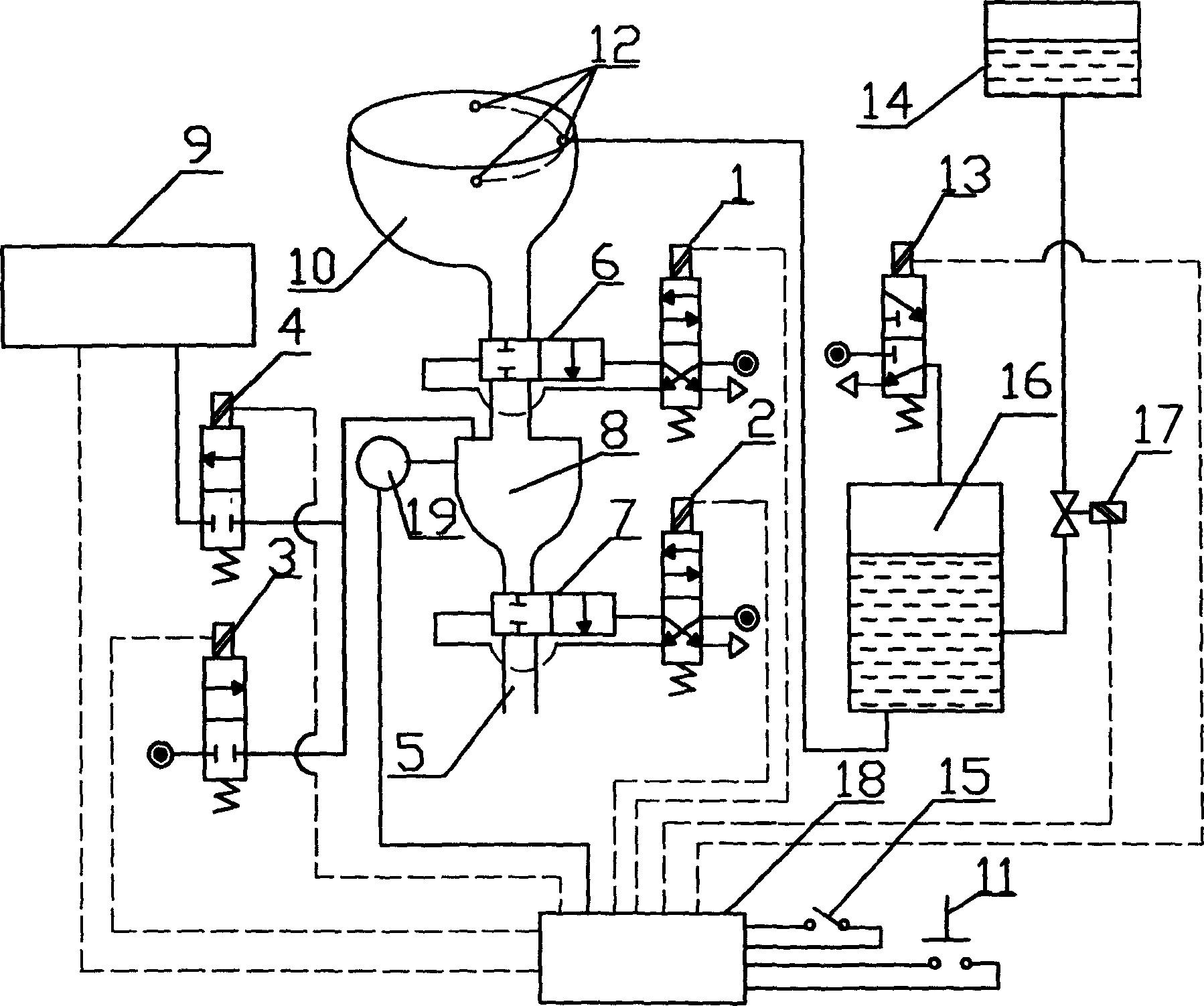

Railway train dung collection system

InactiveCN101117119ASimple structureWork reliablyLavatory sanitorySanitationVacuum pumpingWater source

The invention provides a railway train excrements collection system comprising a urinal and a soil box. The system is also provided with a vacuum pumping device of the soil box. The system is further provided with a water pressure intensifier and a flushing valve, wherein the flushing valve is an air-controlled two-position three-way directional control valve, and the flushing valve is connected with the water pressure intensifier, the flooding nozzle of the urinal and a water supply respectively. The system is also provided with the flushing valve controlled by a first electromagnetic directional valve and the compressed air supply circuit of the water pressure intensifier. The system is provided with a dejection valve arranged between the urinal and the soil box, and a working cylinder cavity for driving the valve plate of the dejection valve is arranged in the dejection valve. The system is provided with the compressed air supply circuit of the working cylinder controlled by a second electromagnetic directional valve. The system is provided with an air inlet pipeline which connects a train compressed air source and the first electromagnetic valve and the second electromagnetic valve. The system of the invention which can be actuated pneumatically by the train air supply system with a simple structure and reliable performance is applicable to trains.

Owner:YUNZHOU GEARBOX ZHEJIANG PROV

Recycling excrement-collecting device

InactiveCN102583826ARealize online disposalShrink volumeSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentControl systemEnvironmental engineering

The invention discloses a recycling excrement-collecting device which comprises a solid-liquid separation device, a solid-liquid separating treating device, a recycled water containing box and a dry excrement-collecting box, wherein urine or excrement is separated by the solid-liquid separation device, so as to form a filtrate and half-dry excrement; the solid-liquid separating treating device comprises a filtrate treating device and an excrement residue treating device; the filtrate treating device is used for treating the separated filtrate into the recycled water; the excrement residue treating device is used for treating the separated half-dry excrement into the excrement residue; the recycled water is collected by the recycled water containing box; the dry excrement residue is contained in the dry excrement-collecting box; and a control system is used for controlling the solid-liquid separation device and the solid-liquid separating treating device to recycle the resources from the urine or excrement. The recycling excrement-collecting device is used for realizing the complete excrement on-line treatment; after being separated from body, the urine and the excrement are immediately sterilized, disinfected and de-odorized; the excrement is formed into a sterile, odorless and stable solid within a short period of time; and the pollution is stopped from source, the volume is reduced, the weight is reduced, and the wastes are turned into renewable resources.

Owner:SHANGHAI MONA ENVIRONMENTAL PROTECTION TECHCO

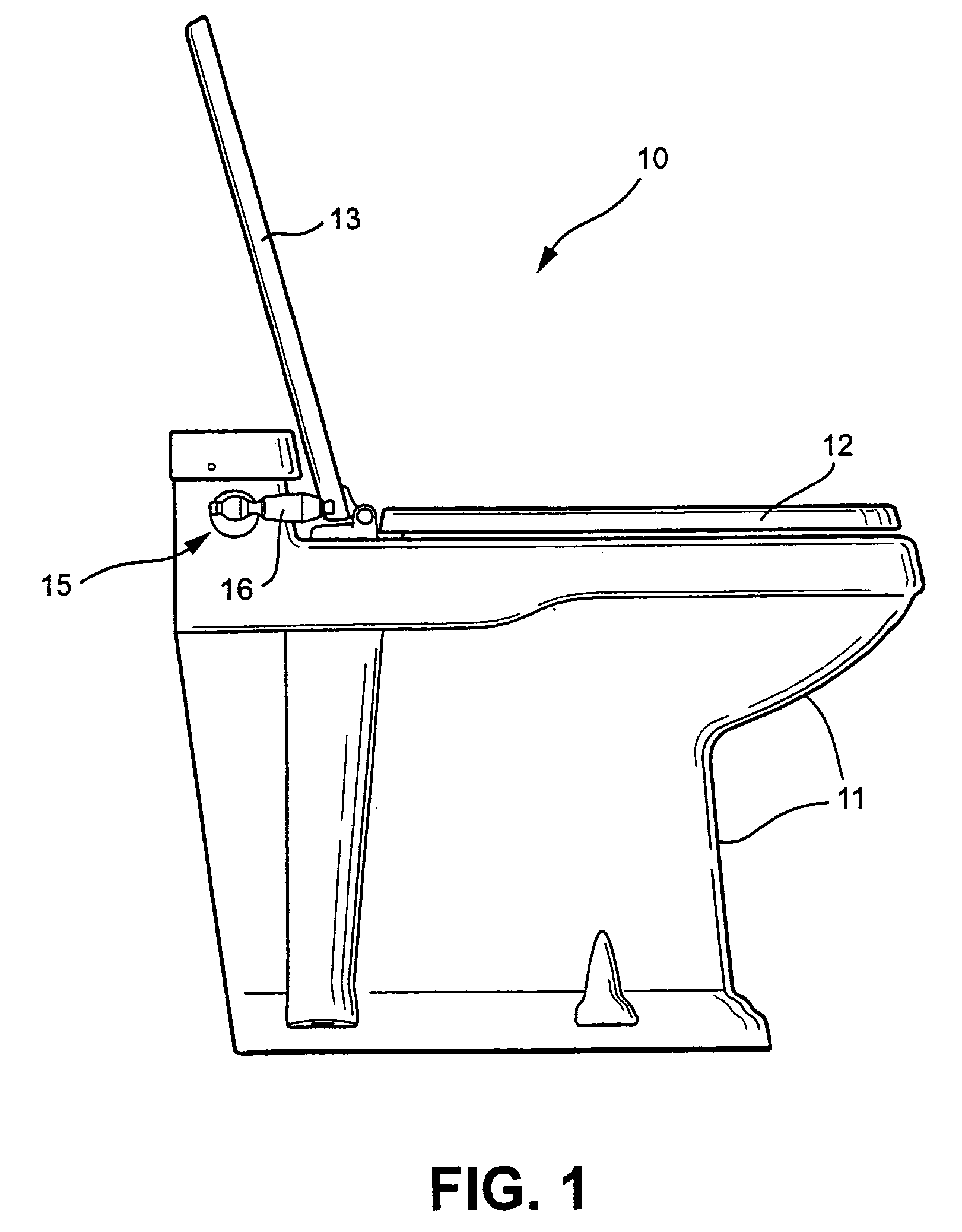

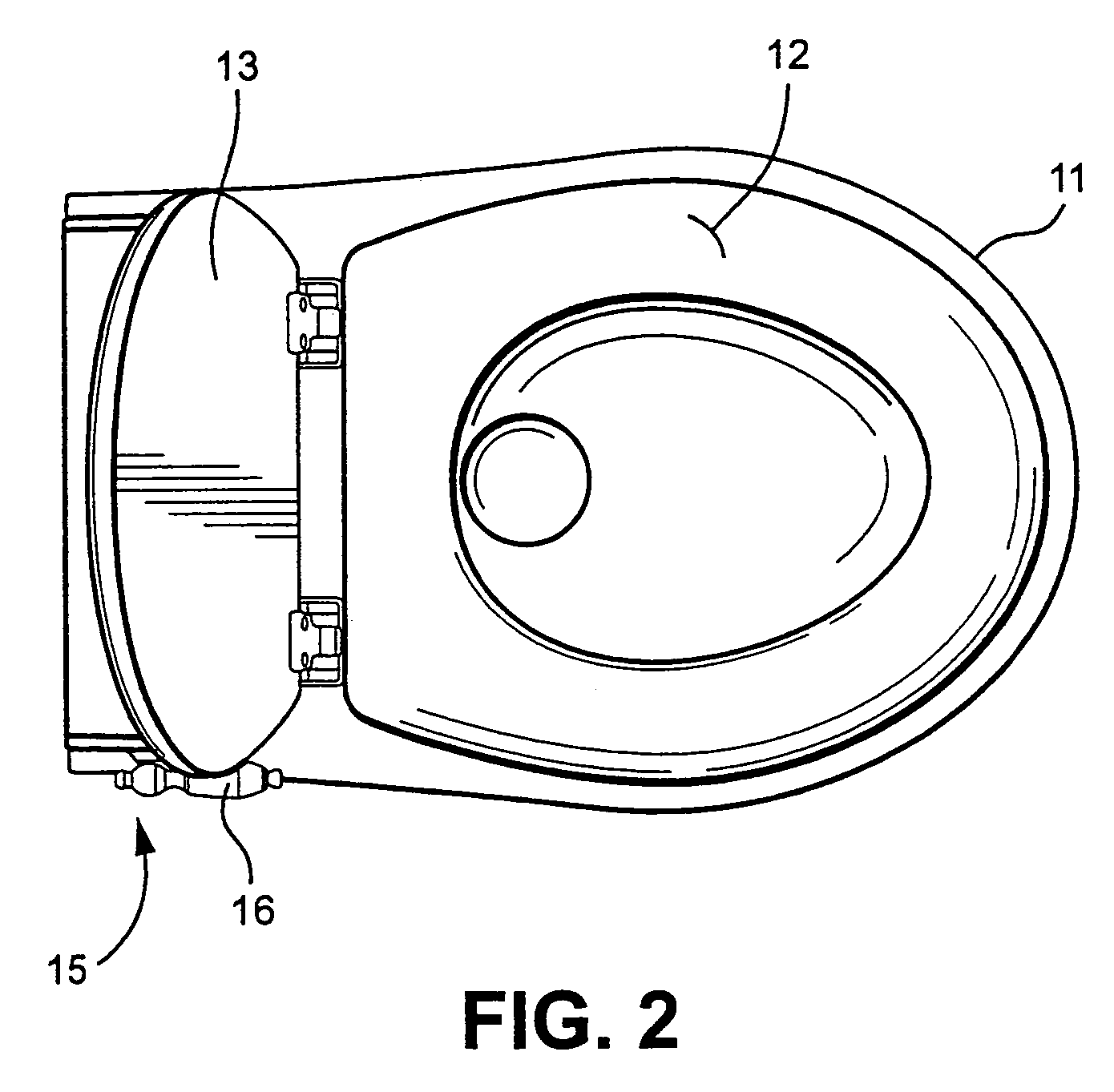

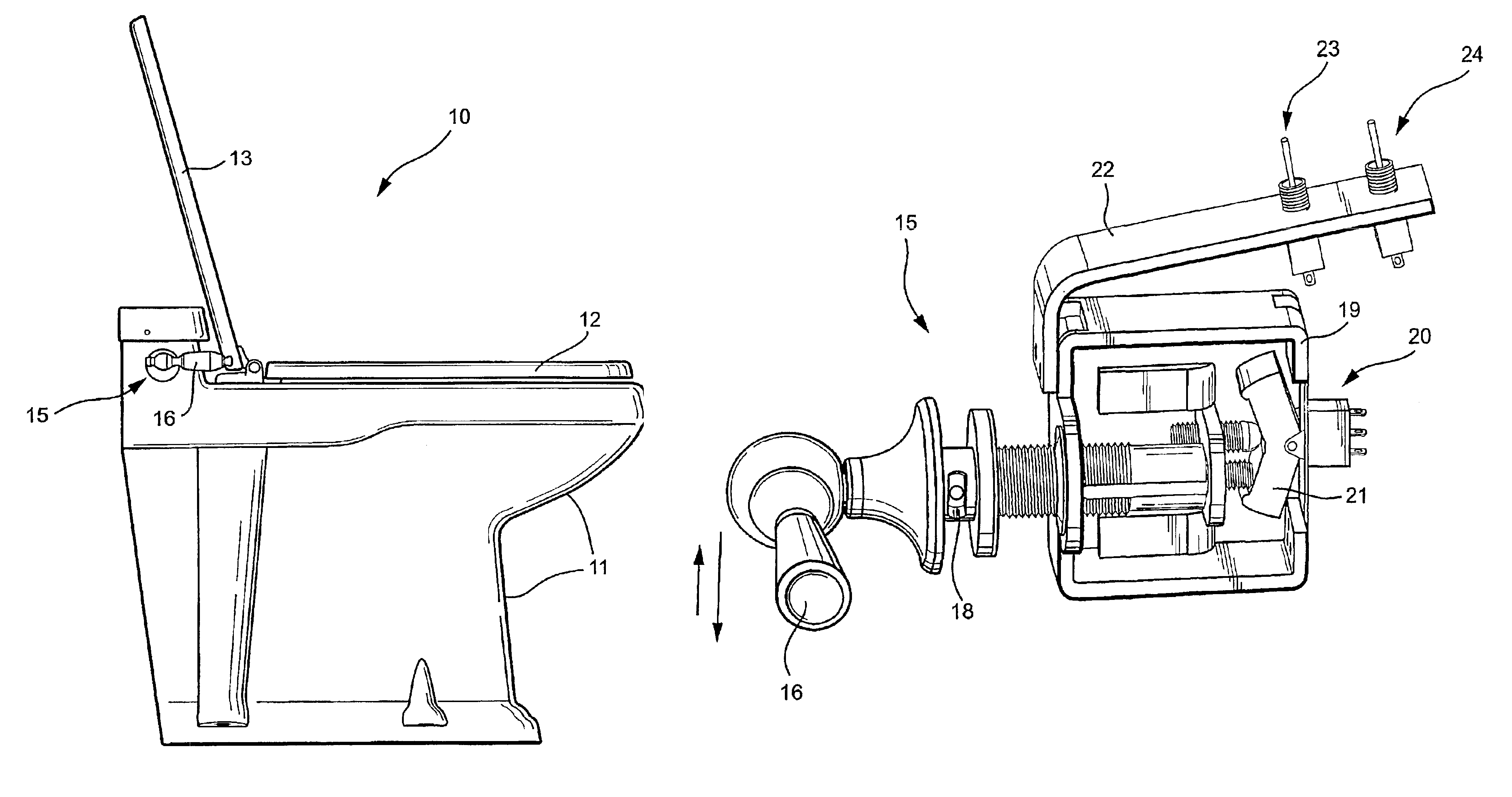

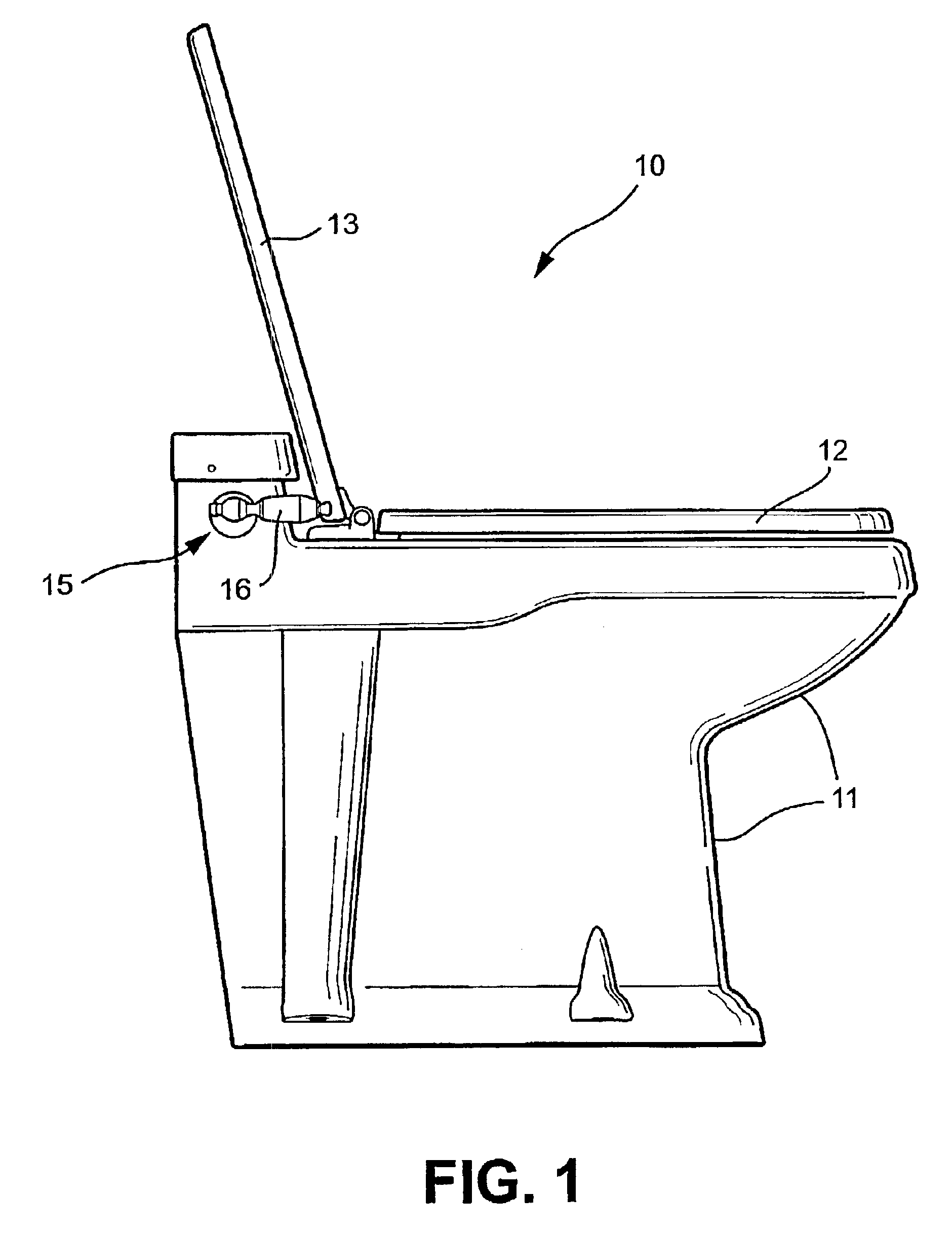

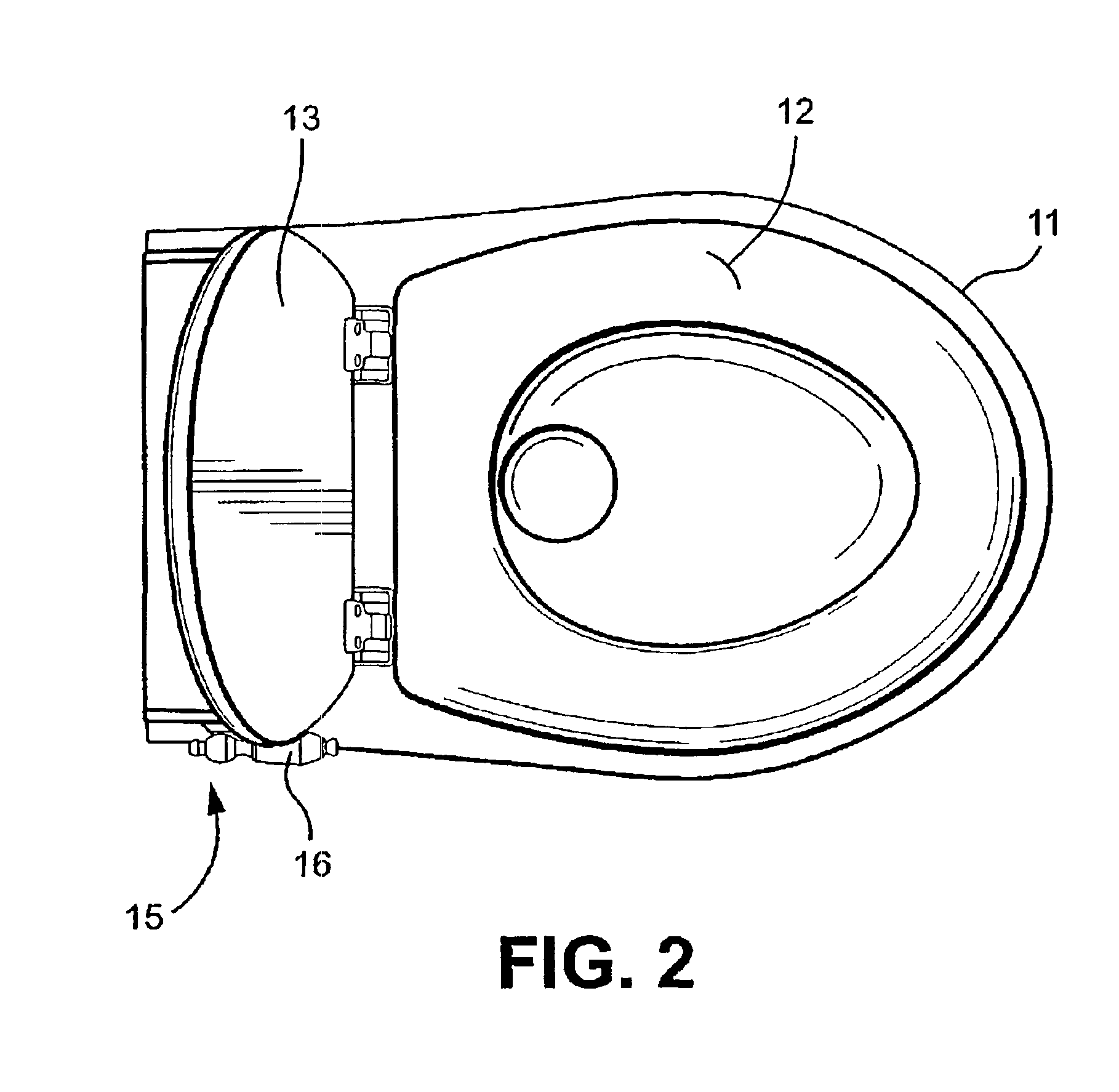

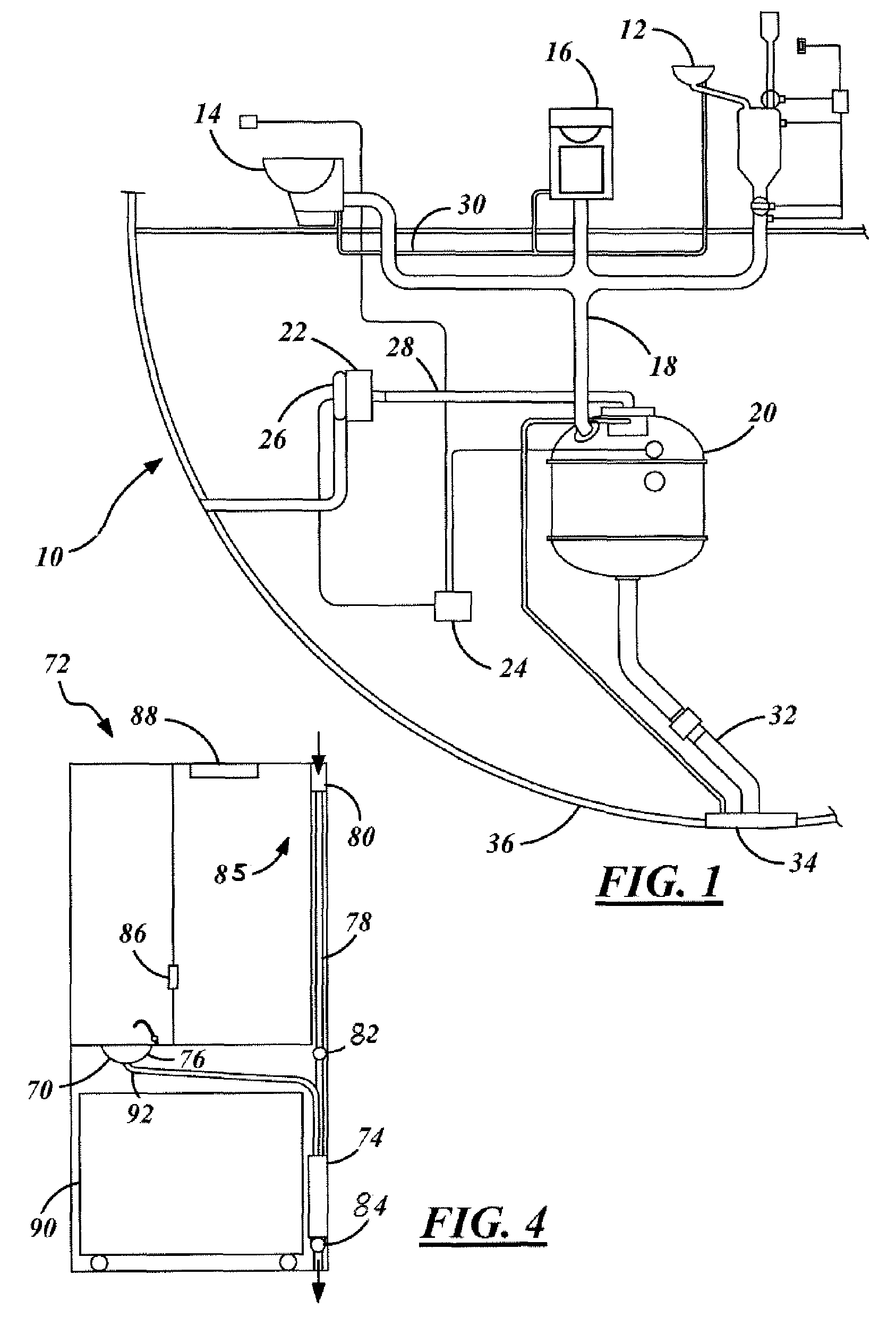

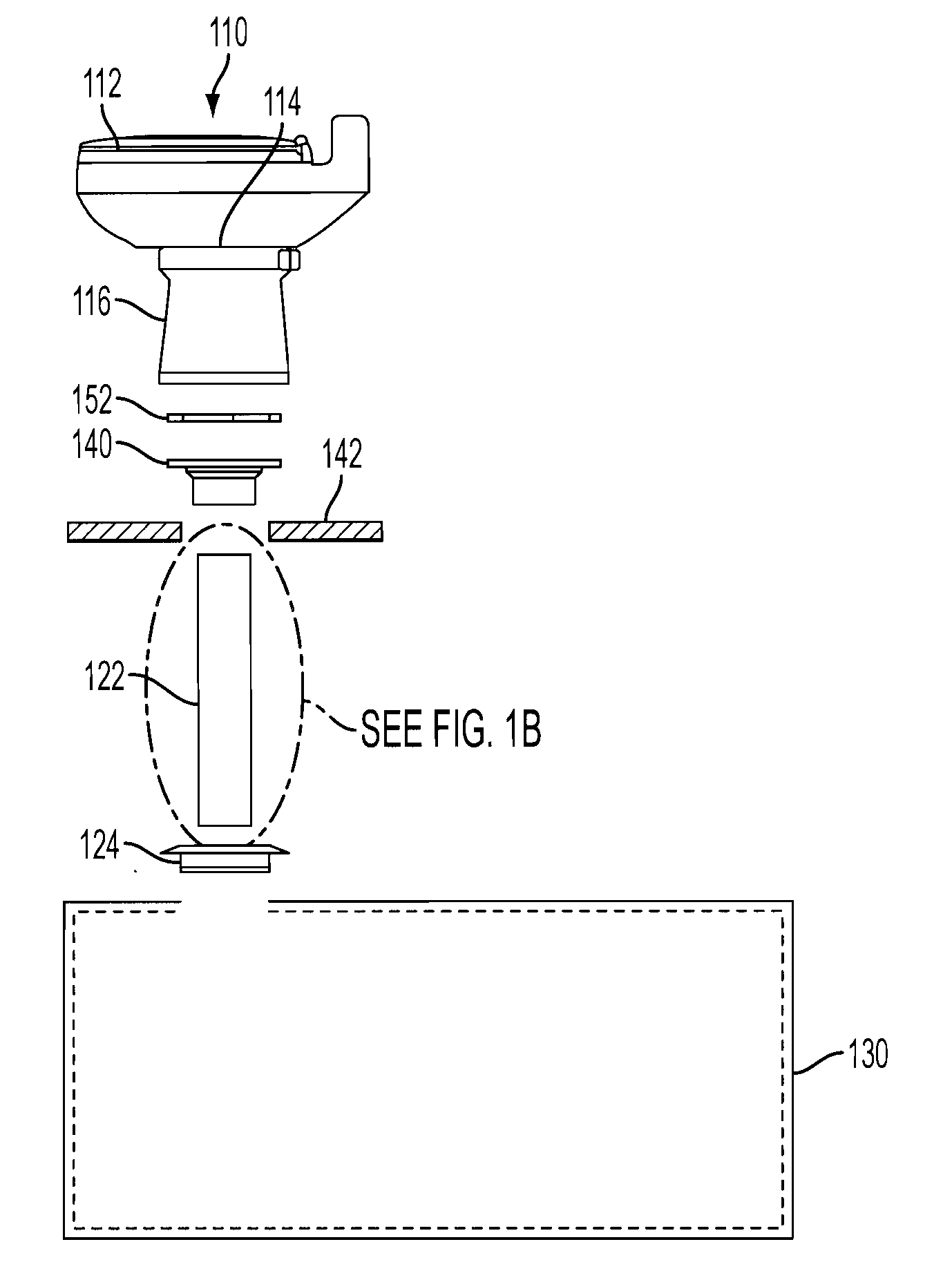

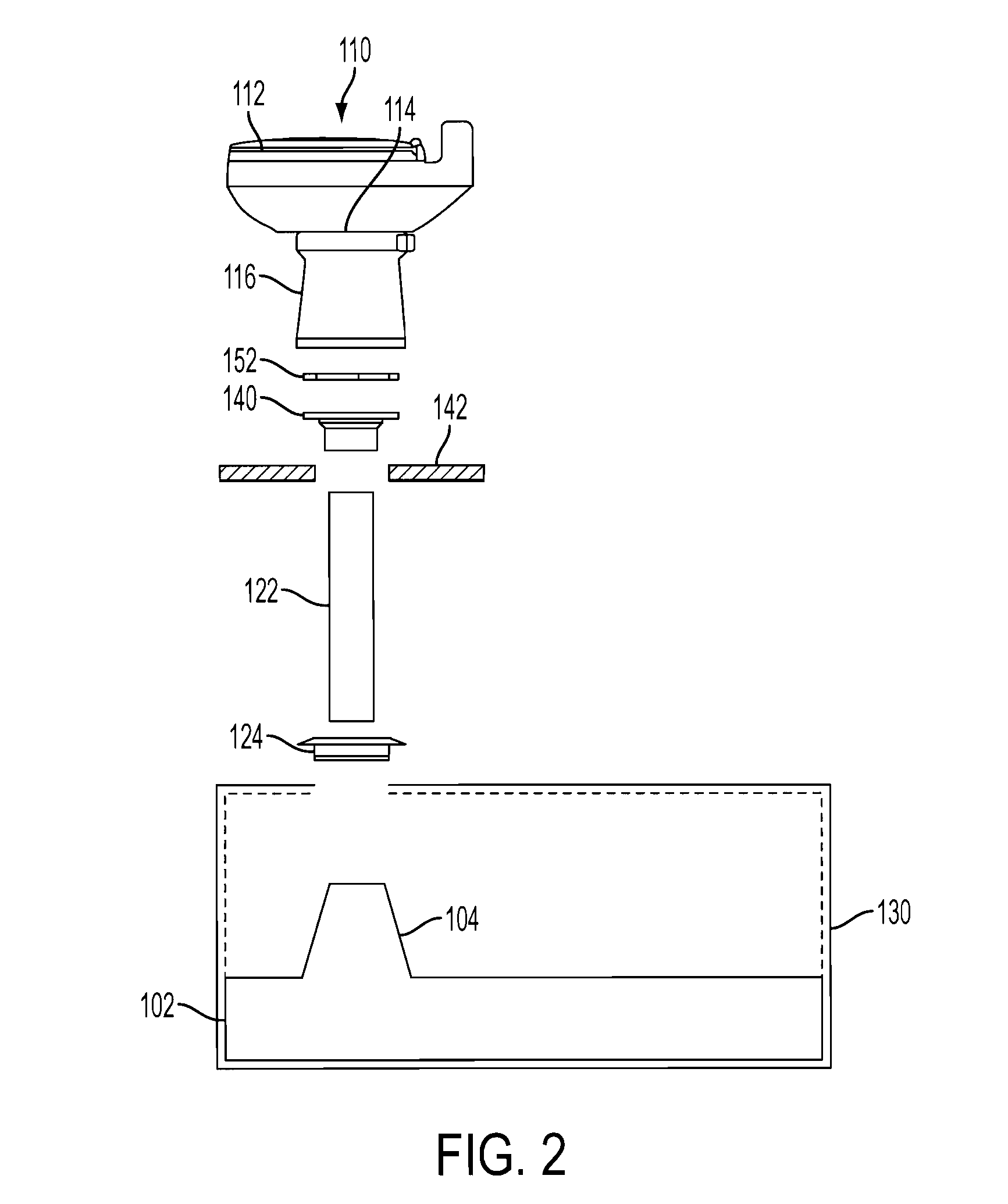

Toilet and method of operation

InactiveUS6981285B2Quality improvementWater closetsFlushing devicesInlet valveMicroprocessor controller

A toilet and toilet system suitable for a boat, recreational vehicle, bus or the like is operated via a microprocessor controller to effect a convenient and efficient operation. The toilet includes a base assembly having an electrically-operated flush valve that opens and closes a passage to a waste receiving area. A flush lever assembly has a flush lever displaceable from a neutral position toward one of a “flush” position and an “add water” position. In this context, the flush lever initiates a flush cycle in the “flush” position and initiates an add water cycle in the “add water” position. The controller communicates with a water inlet valve, the flush valve and the flush lever assembly. In operation, the controller opens and closes the water inlet valve and controls a position of the flush valve in accordance with a position of the flush lever.

Owner:DOMETIC CORP

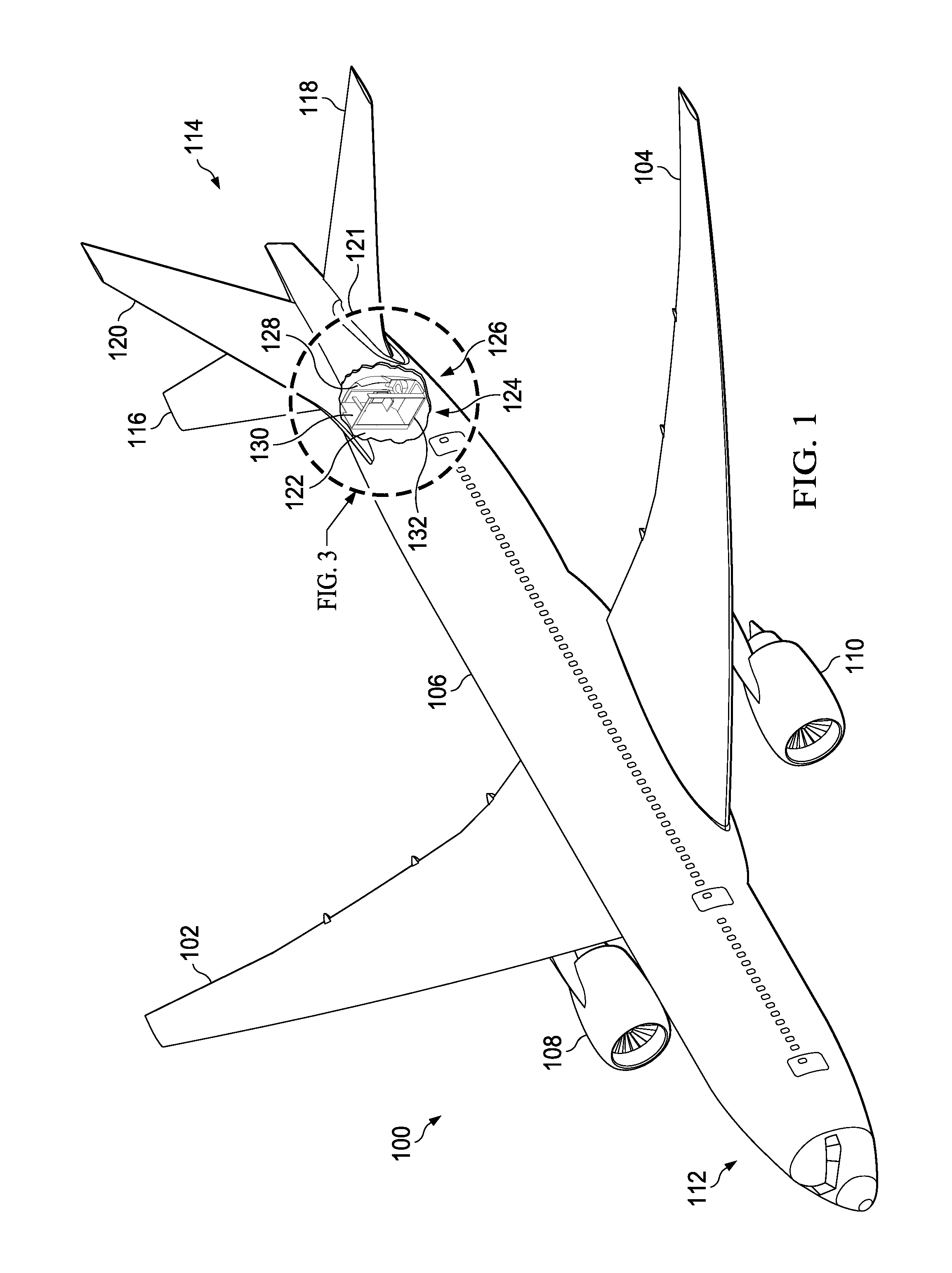

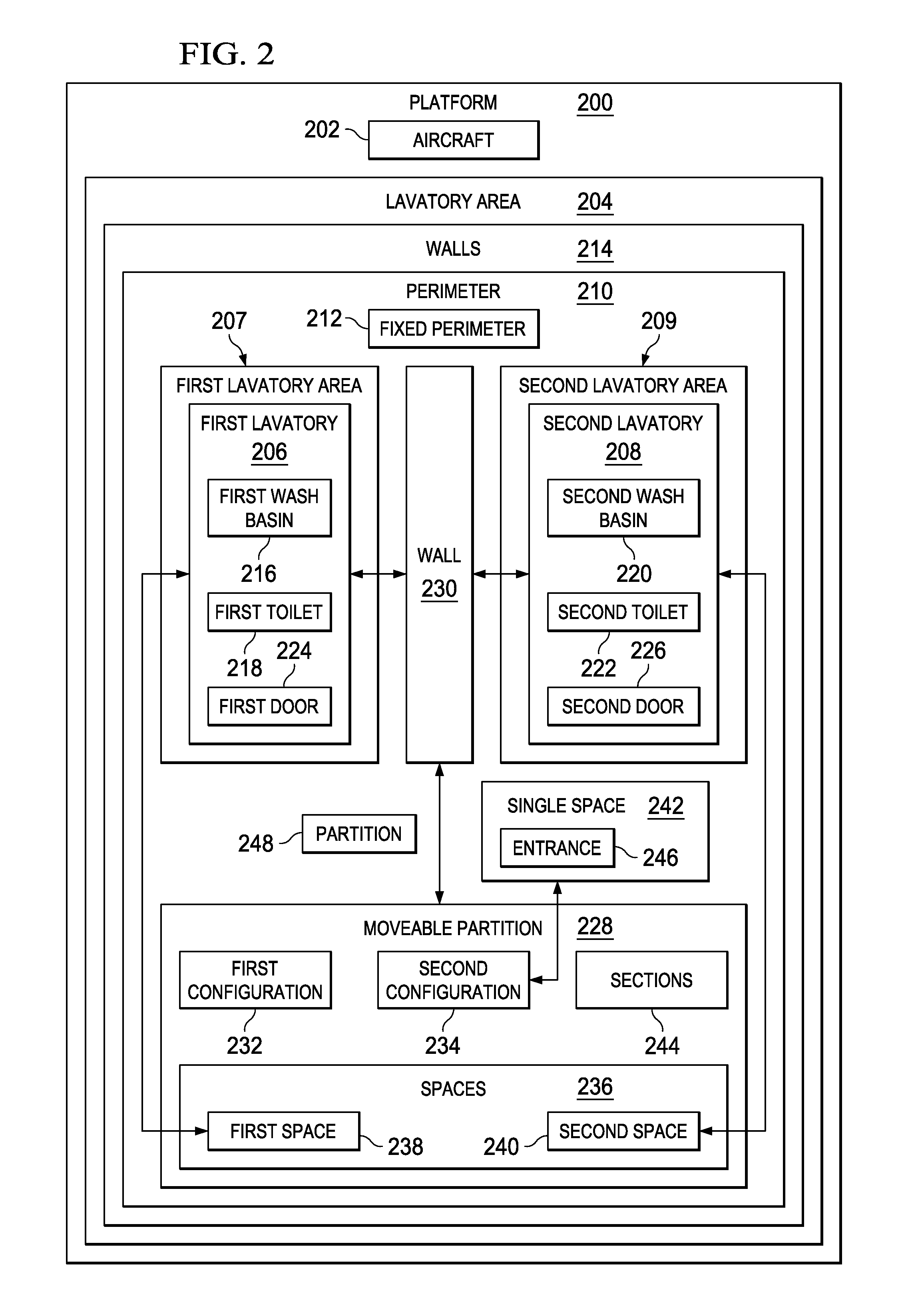

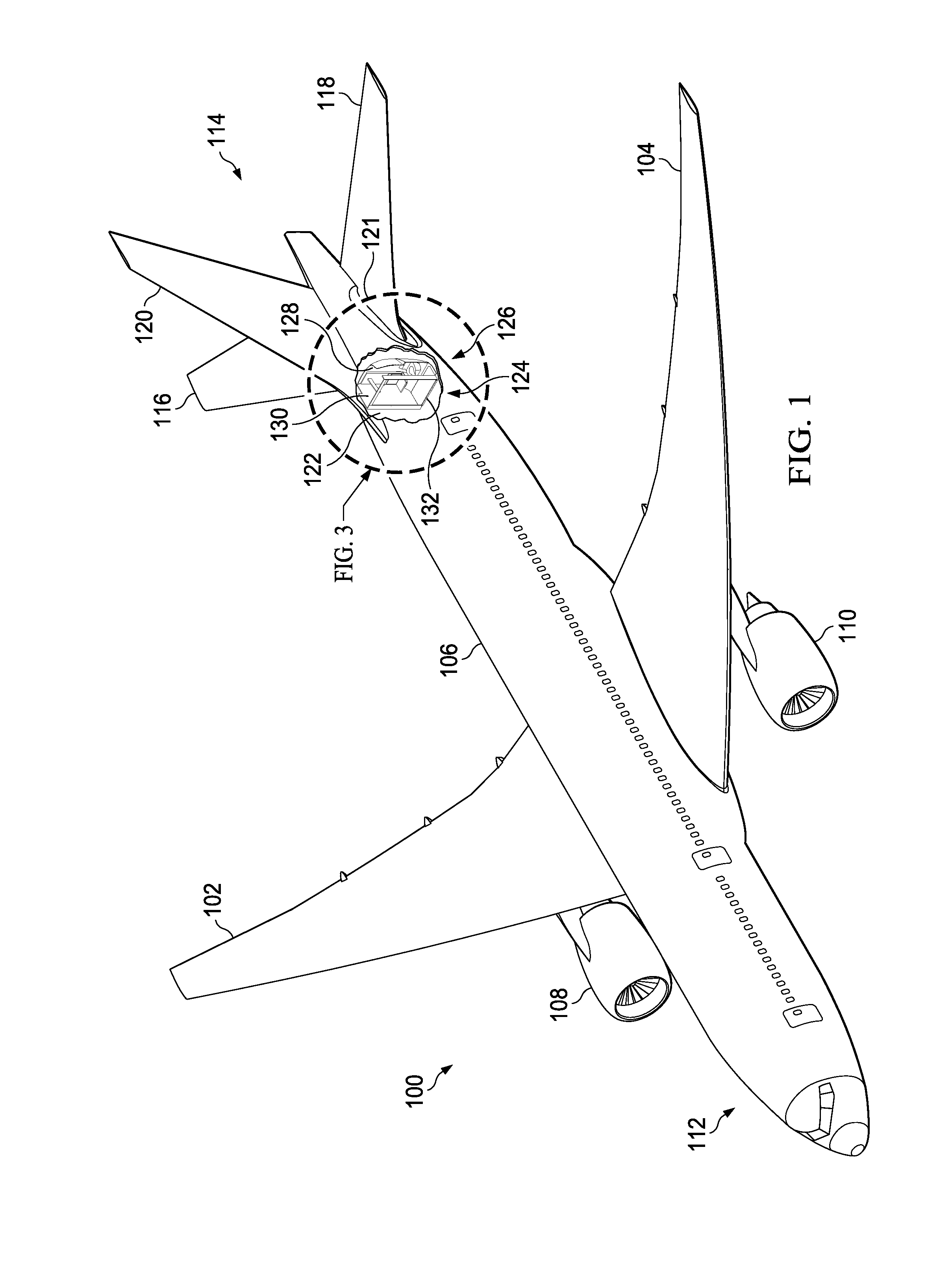

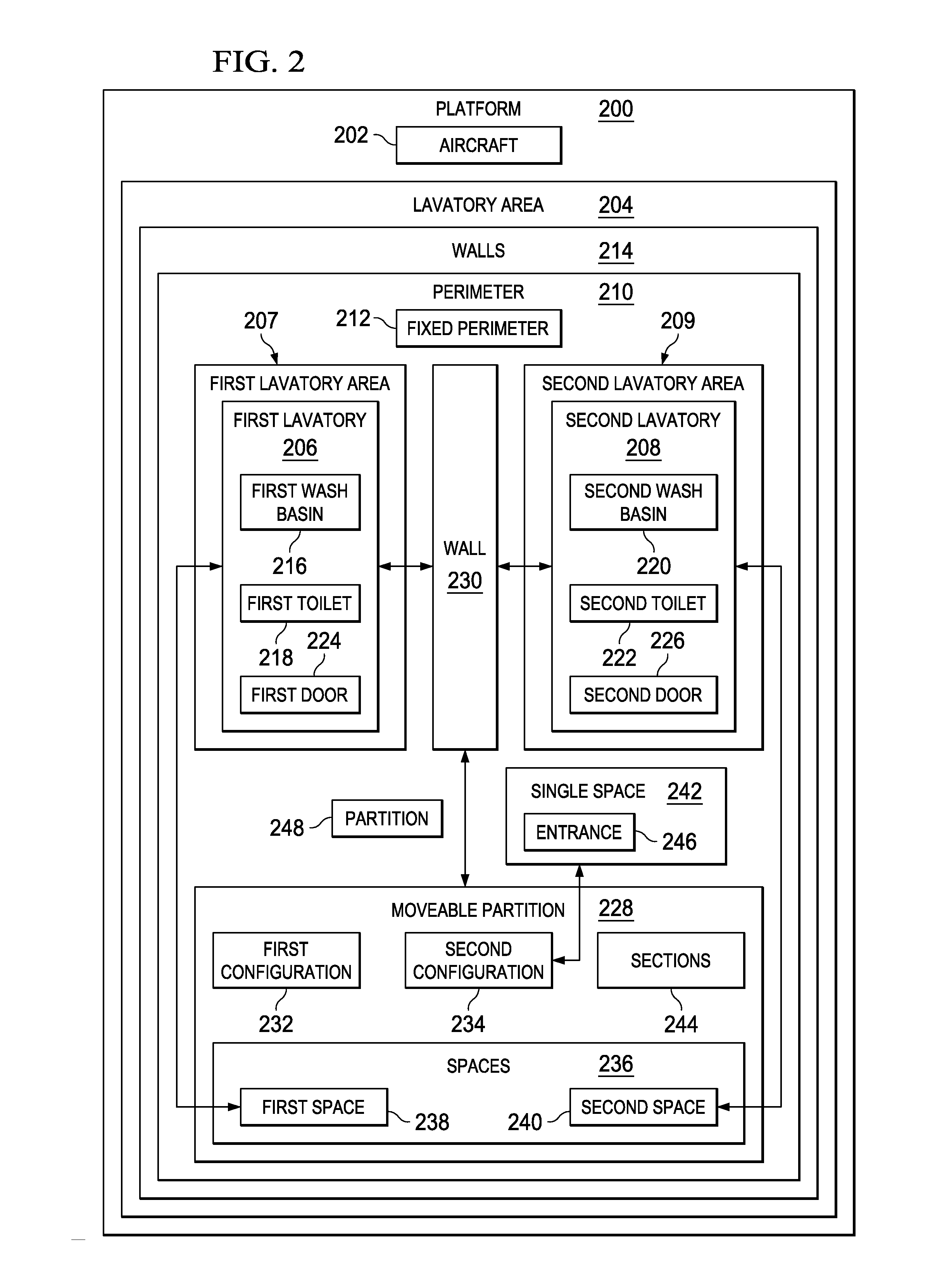

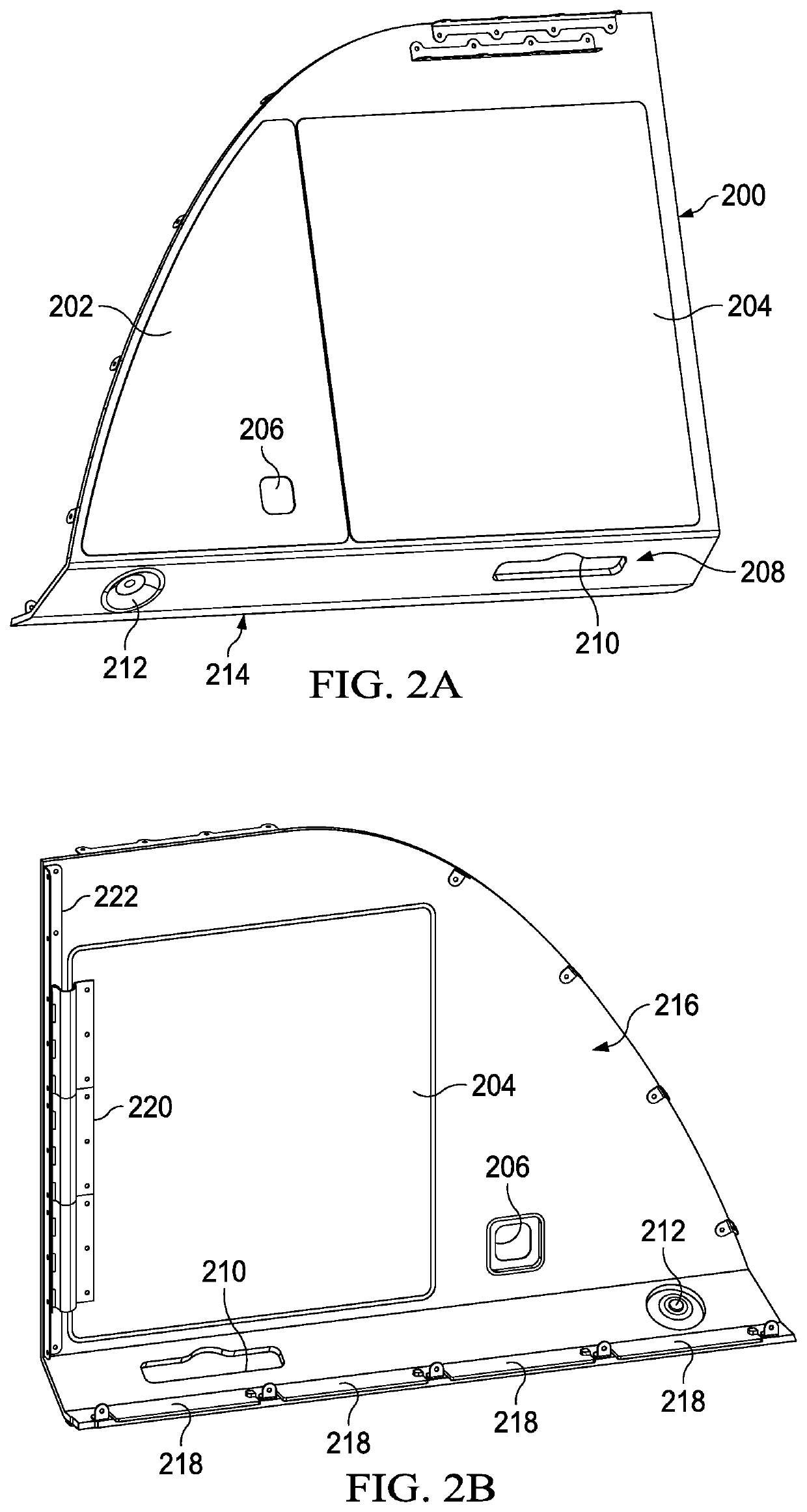

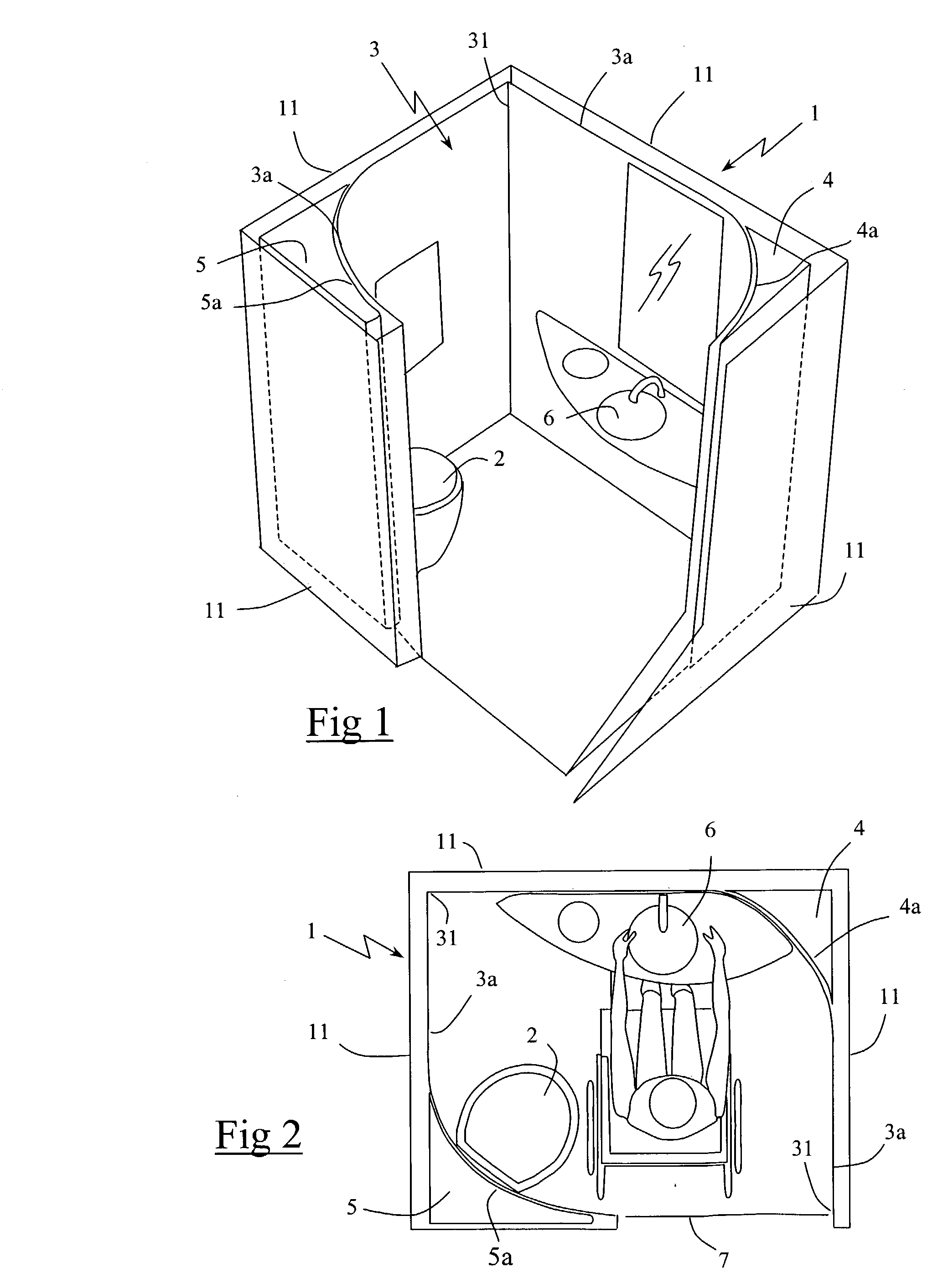

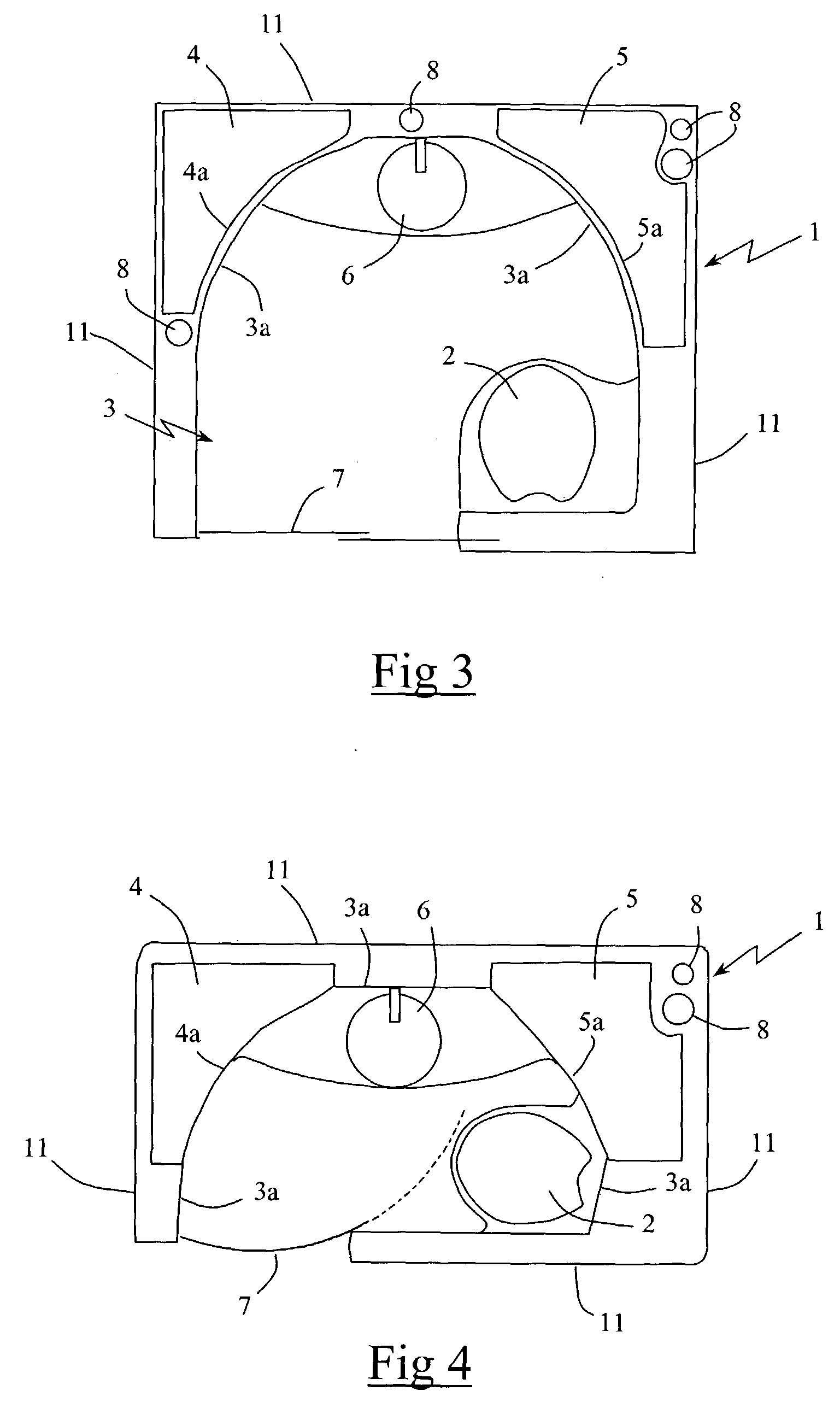

Lavatory reconfiguration system

ActiveUS8944377B2Water closetsAir-treatment apparatus arrangementsEngineeringElectrical and Electronics engineering

Owner:THE BOEING CO

Toilet and method of operation

A toilet (10) and toilet system suitable for a boat, recreational vehicle, bus or the like is operated via a microprocessor controller to effect a convenient and efficient operation. The toilet includes a base assembly (30) having an electrically-operated flush valve that opens and closes a passage to a waste receiving area. A flush lever assembly (15) has flush lever displaceable from a neutral position toward one of a “flush” position and an “add water” position. In this context, the flush lever initiates a flush cycle in the “flush” position and initiates an add water cycle in the “add water” position. The controller communicates with a water inlet valve, the flush valve and the flush lever assembly. In operation, the controller opens and closes the water inlet valve and controls a position of the flush valve in accordance with a position of the flush lever.

Owner:DOMETIC CORP

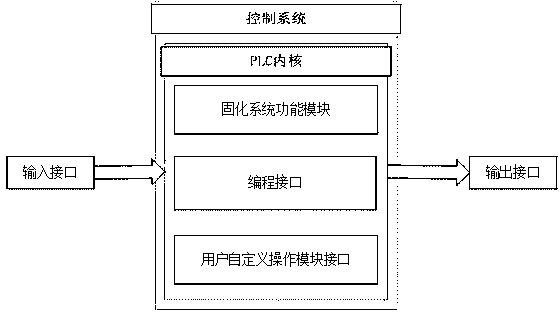

Intelligent excrement collector for train

InactiveCN102251566AHigh intelligenceImprove applicabilityFlushing devicesSanitationWater savingElectricity

The invention relates to flushing equipment for a train, in particular to an intelligent excrement collector for a train. The intelligent excrement collector for the train comprises a pedestal pan, a flushing device, a sewage box, a vacuum generator and a DCS (Distribution Control System), wherein a water outlet of the flushing device is connected with a water inlet of the pedestal pan; a sewage draining opening of the pedestal pan is connected with the sewage box; the vacuum generator is connected with the sewage box; the DCS is used for controlling the excrement collector to start and stop and displaying the work state of the excrement collector in real time; a flushing electromagnetic valve, an excrement-flushing electromagnetic valve and an air electromagnetic valve for controlling switches of the pedestal pan, the flushing device and the vacuum generator are arranged on the DCS; and the flushing electromagnetic valve, the excrement-flushing electromagnetic valve and the air electromagnetic valve are electrically connected with the DCS. The invention has the advantages of high intelligent degree, better system adaptability, water saving, sanitation and environment friendliness, no odor and the like.

Owner:刘雪松 +1

Toilet excrement discharge system for high speed train

The toilet excrement discharge system for high speed train includes urinal, water jet, two pneumatic valves, small container, vacuum generator, solenoid valves, button, emergency switch, small water tank, electromagnetic water valve, vacuum and pressure detecting unit, etc. The urinal is flushed with jetted water in small quantity, and excrement is concentrated in the bottom of the urinal and vacuum sucked into one small container before pressurized to jet to railway bed via the discharge port or to the large container in the lower part of the train. The present invention can avoid blowing of excrement, reduce train pollution and rust and ensure safe running of the train and the health of passengers. The technology of the present invention may be used also in coach bus, hotel in water-lacking area, etc.

Owner:ZHEJIANG UNIV

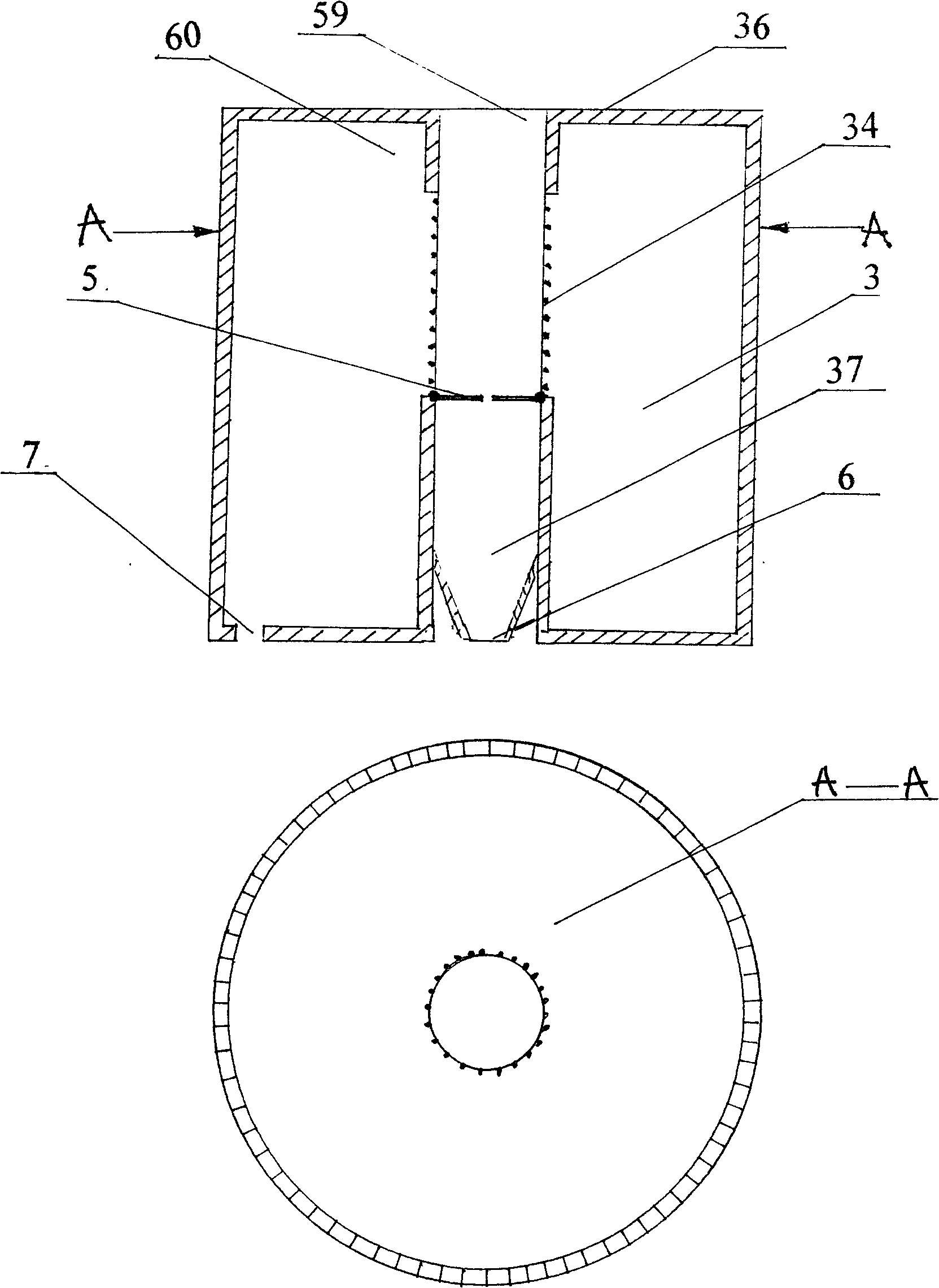

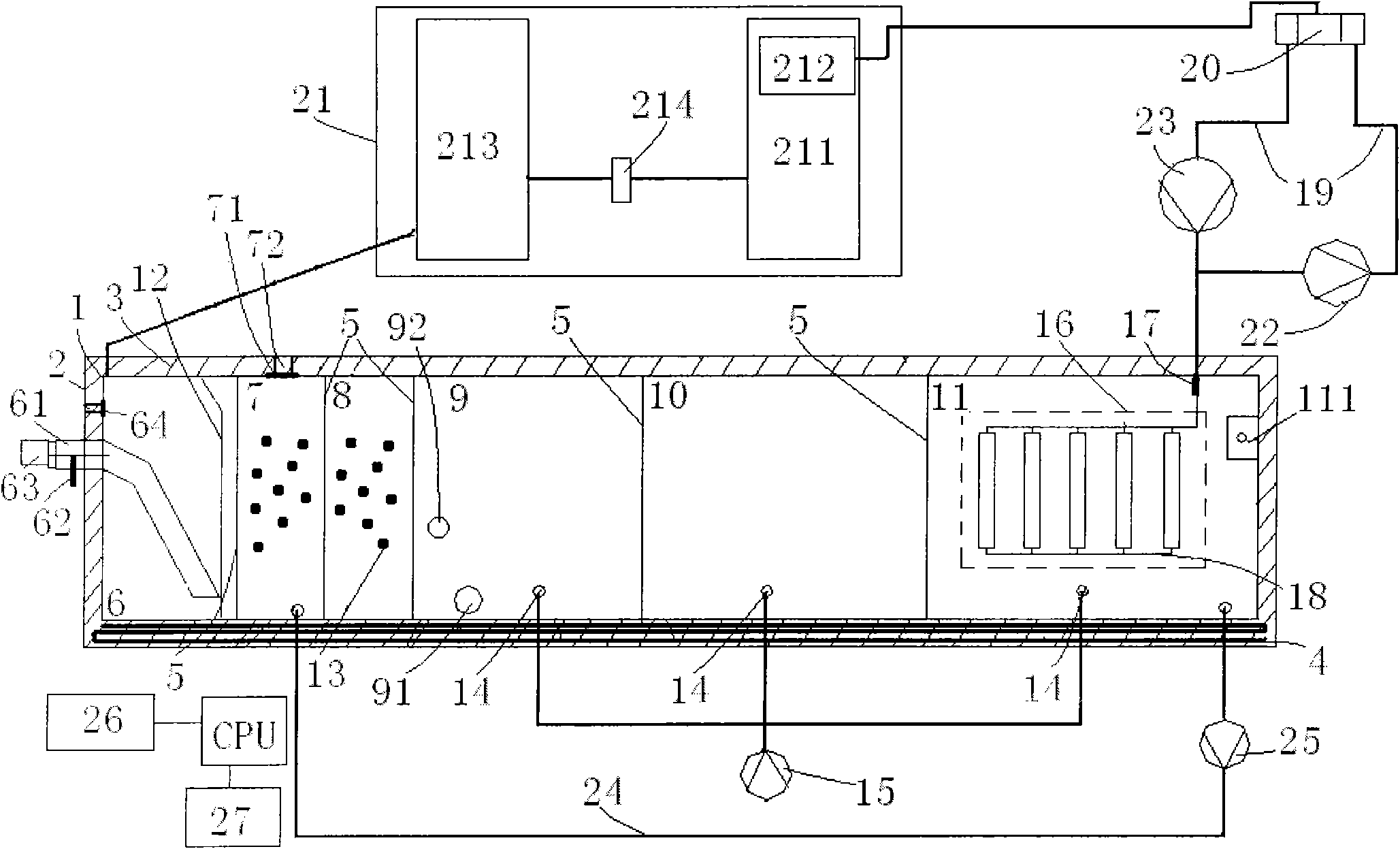

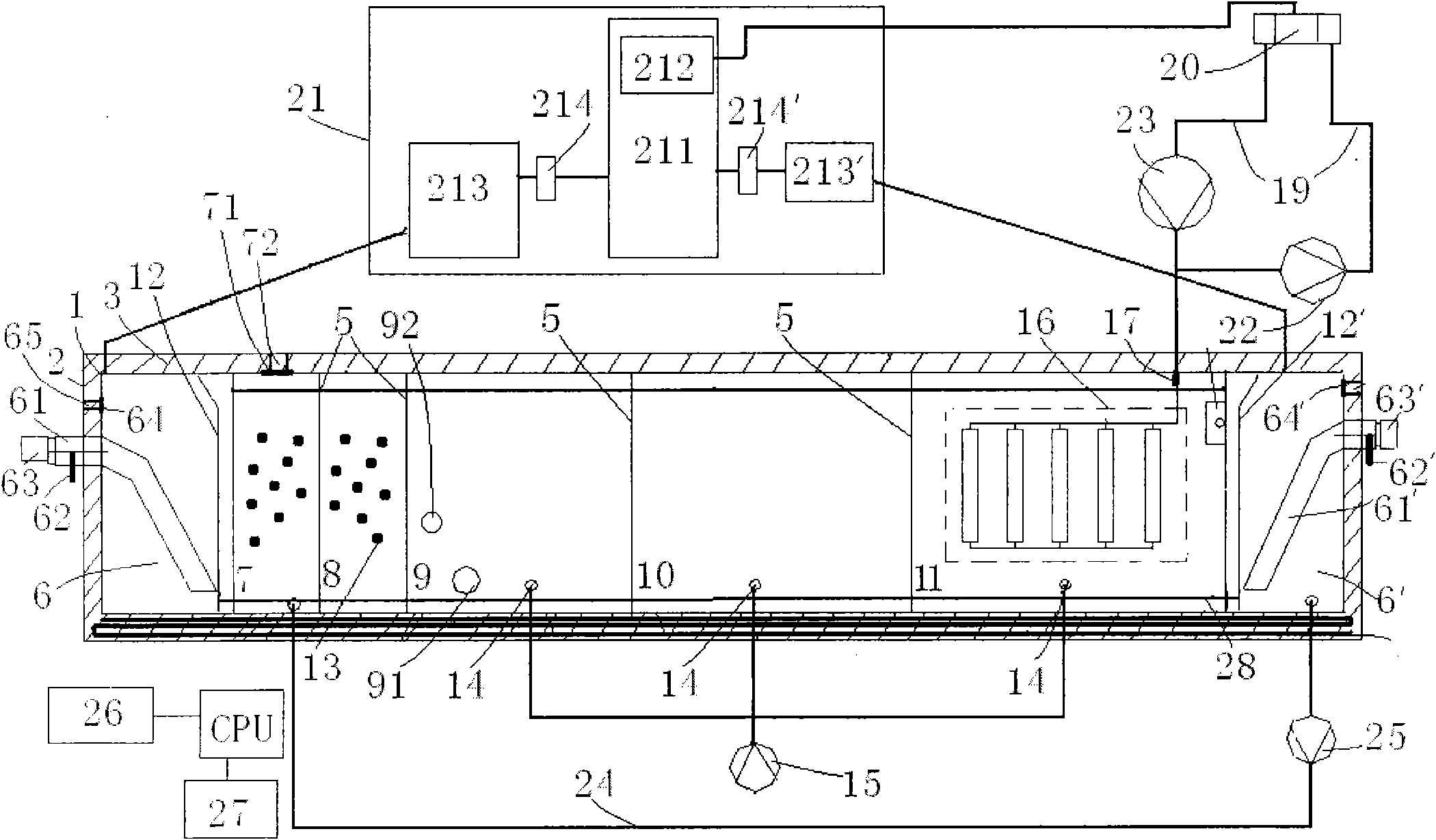

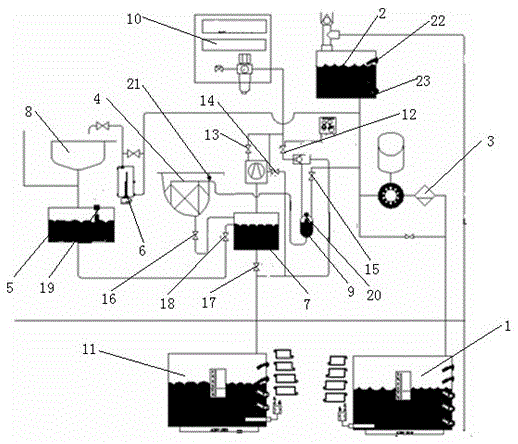

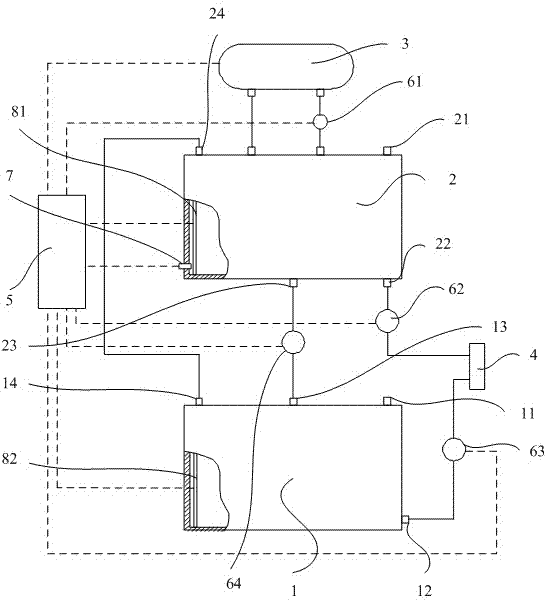

Recovery processing system for dejection and sewage of train

InactiveCN101792240AAchieve recyclingSave waterWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesElectricityAnaerobic chamber

The invention relates to a recovery processing system for dejection and sewage of a train, which comprises an inner box and an outer box; an insulating layer and a heat tracing device are arranged between the inner box and the outer box; a plurality of dummy plates are arranged in the inner box, and divide the inner box into a solid-liquid separation chamber, a first anaerobic chamber, a second anaerobic chamber, a first aerobic chamber, a second aerobic chamber and a third aerobic chamber; one end of each dummy plate is fully distributed with holes; according to the sort order of the dummy plates, the holes are staggered from top to bottom on the dummy plates, so that a zigzag return circuit is formed on a liquid flow path; the solid-liquid separation chamber is provided with a discharge pipe and a breather pipe; the first anaerobic chamber and the second anaerobic chamber are provided with a plurality of biologic fillers, and the top of the first anaerobic chamber is provided with a strain injecting opening; the first aerobic chamber, the second aerobic chamber and the third aerobic chamber are provided with aerator pipes, and each aerator pipe is provided with a plurality of ostioles and is connected with an air pump; a heater and a temperature sensor are arranged in the first aerobic chamber, the third aerobic chamber is provided with a liquid level sensor and a plurality of membrane components, one end of each membrane component is connected with a water outlet pipe in parallel, and the other end is connected with a supporting tube in parallel; the water outlet pipe is connected with a self-priming pump and a recoil pump in parallel, the self-priming pump and the recoil pump are connected with a middle water box in the train; and the heater, the temperature sensor, the liquid level sensor, the self-priming pump, the recoil pump and the air pump are electrically connected with a CPU. The invention can be widely applied in different trains.

Owner:YUNZHOU GEARBOX ZHEJIANG PROV +1

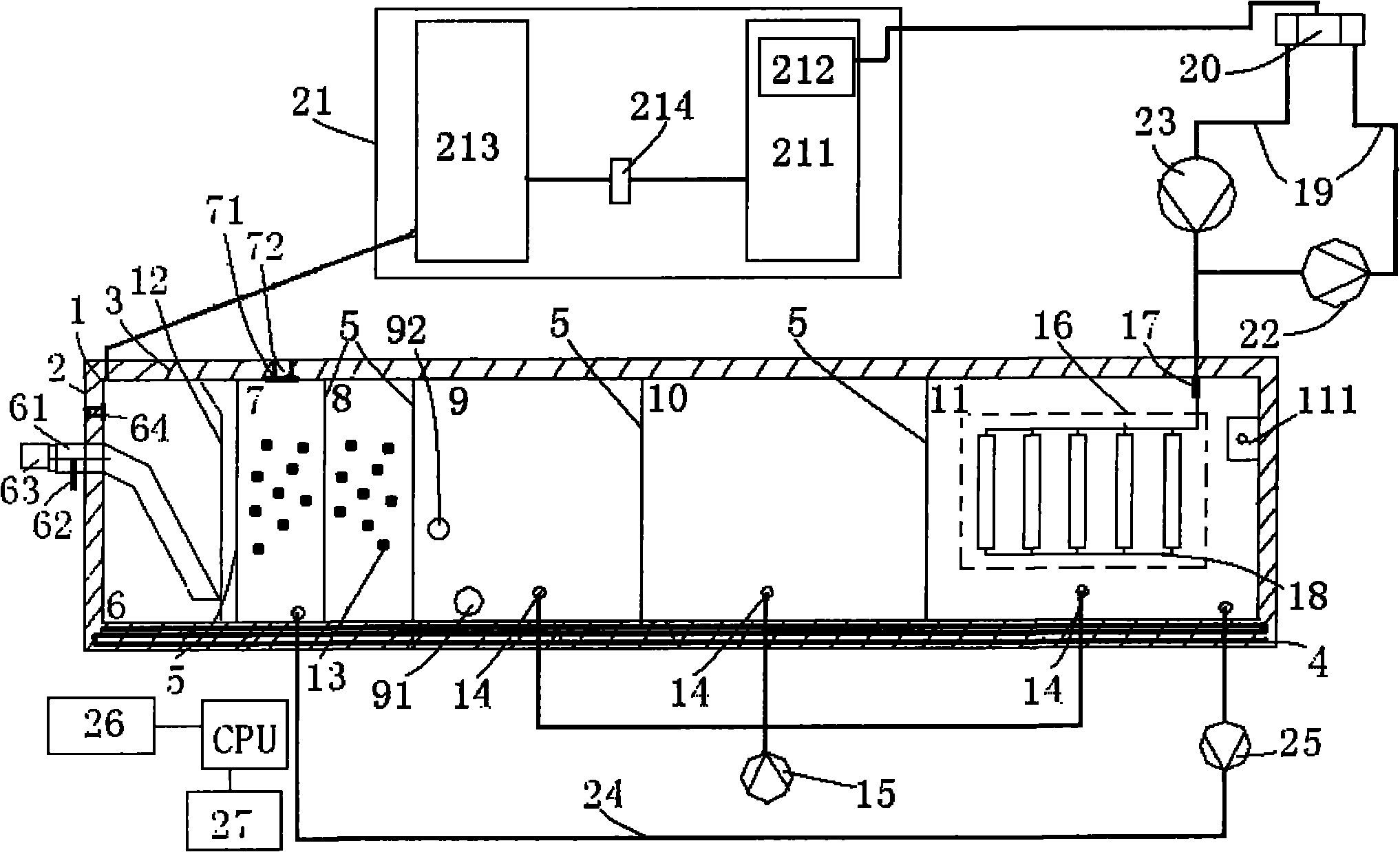

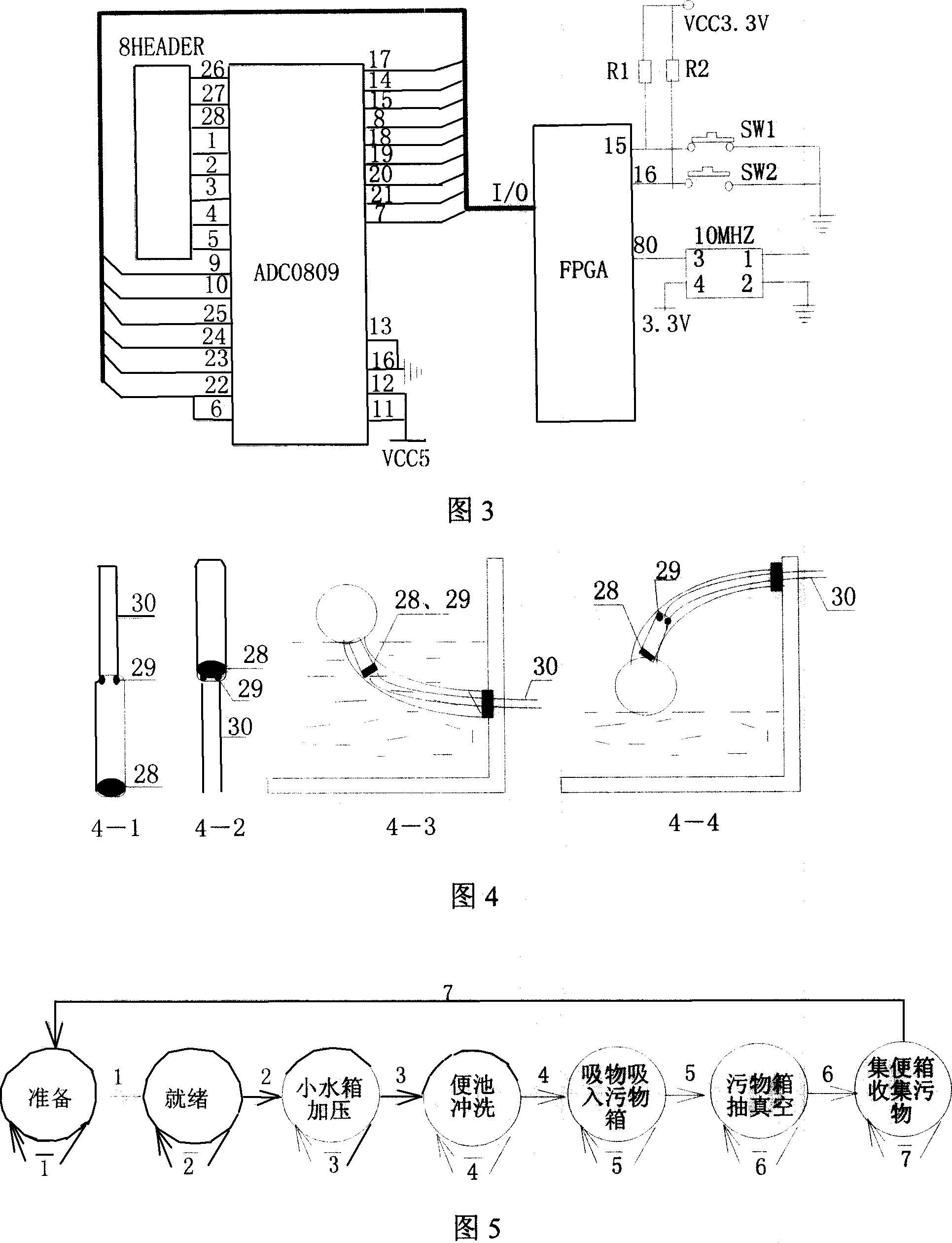

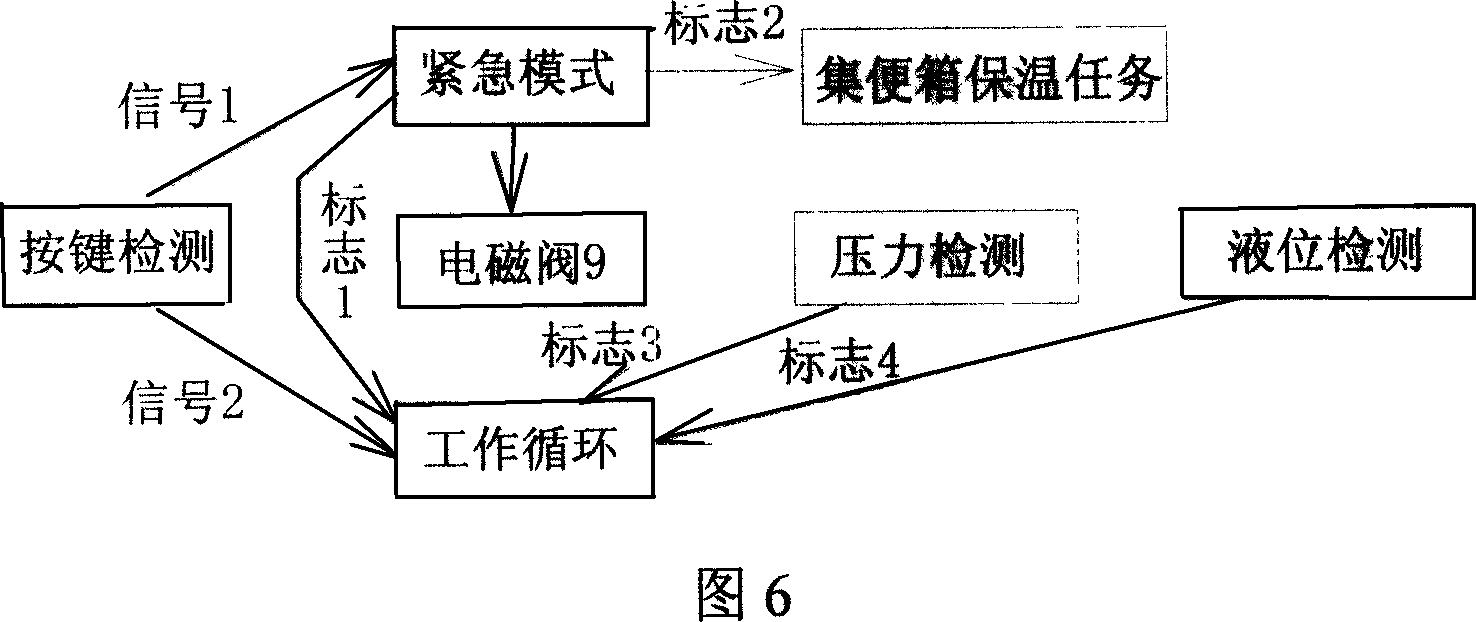

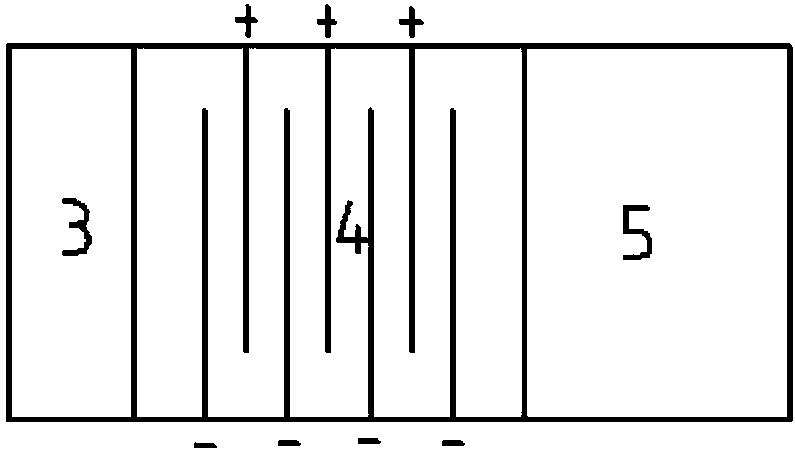

Vacuum storage tank type defecation discharge system for high speed train

The invention discloses a vacuum tank high-speed train excreta disposal system. It includes excrement collector mechanical components assembly, control executive valve components, dirt bin and controller. The excrement collector mechanical components assembly consists of urinal, washing ring, small water chamber and vacuum generator; the control executive valve components consist of one two-position four-way valve, one two-position three-way valve, two two-position two-way valves, one air-operated blow-off valve, two magnetic valves, three ball valves and a dirt bin antifreeze electric heating blanket power switch; the dirt bin is equipped with heat-insulating layer on the outer surface and anti-wave plate on the inner surface, the bin interlayer is equipped with antifreeze electric heating blanket; two pairs of controller are cold duplicate controller each other and consist of input, output and MCU module, it is the control central of whole system. The vacuum tank high-speed train excreta disposal system eliminates the pollution of train direct disposal washing rooms to the train route environment, solves the corrosion of dirt to the train running components and the problems of dirt is harm at the physical and mental health of passengers and railway maintenance staff.

Owner:ZHEJIANG UNIV

Train washing water treatment and reuse method and device

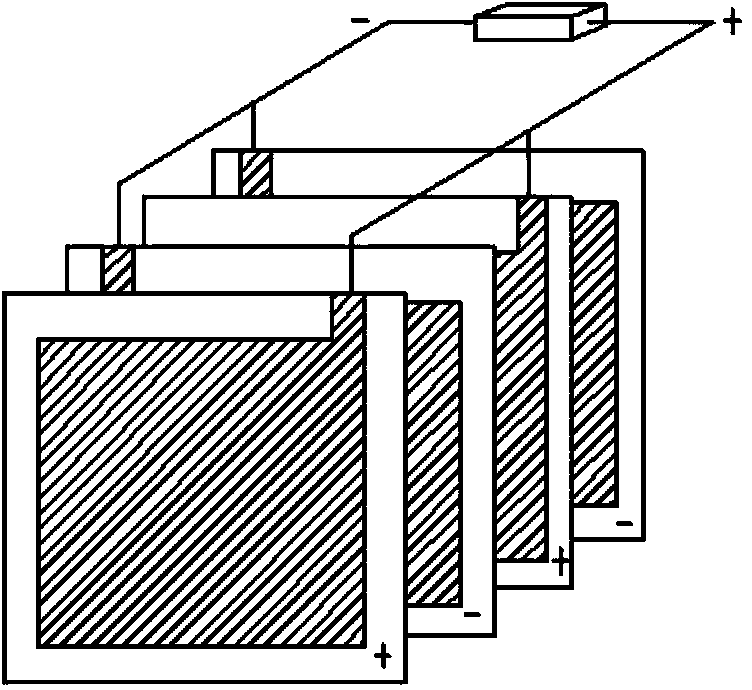

ActiveCN103612643AReduce the frequency of standing by for water replenishmentReduce loadDomestic plumbingSanitationFlocculationParticulates

The invention discloses a train washing water treatment and reuse method. After large particulate matters in drained water of a washing basin are removed through a mesh filter, the drained water is collected into a water inflow buffer area, returns via the bottom of a baffle, flows into an electrolytic oxidation area in a plug-flow type flow state and flows through internal electrolytic pole plates in the electrolytic oxidation area in a plug flow state of returning back and forth, and washing water is purified via single action or multiple collaborative actions of electrolytic oxidation, electrolytic floatation and electrolytic flocculation; the water subjected to electrolytic purification overflows to a produced water collection area from the upper portion of another baffle, and water in the produced water collection area is pumped into a flushing water pressurizing tank in real time via a reuse water pump for flushing. Meanwhile, the invention further discloses a device of the method. By the method and the device, water is saved by more than 50%, load of an on-board water tank can be reduced effectively, frequency that a train stops at a station for water supplementation is reduced, and contradiction of water supply and water consumption of the train is solved.

Owner:JIANGSU CRRC ENVIRONMENT CO LTD

Compact faeces collecting system

The invention provides a compact faeces collecting system which comprises a water purification water tank, a top water tank, a transfer tank, a warm water tank, a wastewater collecting tank, a dirt tank, a toilet stool, a water supply disc and a control module, wherein the capacity of the transfer tank is 15L; the transfer tank comprises a container tank, a vacuum generator and a pressurizing water tank; the container tank is made of a 316L stainless steel material in a welded manner; the pressurizing water tank is connected with the top water tank; the inlet of the transfer tank is connected with the discharge hole of the toilet stool; negative pressure can be generated in the transfer tank by virtue of the vacuum generator; by using the pressure difference principle, dirty water in the toilet stool can be sucked into the transfer tank. The outlet of the transfer tank is connected with the inlet of the dirt tank, positive pressure can be generated in the transfer tank, and dirty water in the transfer tank can be fed into the dirt tank. By adopting the compact faeces collecting system provided by the invention, faeces and wastewater can be collected into the dirt tank through the pressure difference principle, so that both the water can be saved and the environment is not polluted.

Owner:CHANGCHUN LANGRUISI RAILWAY EQUIP

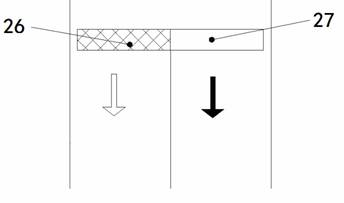

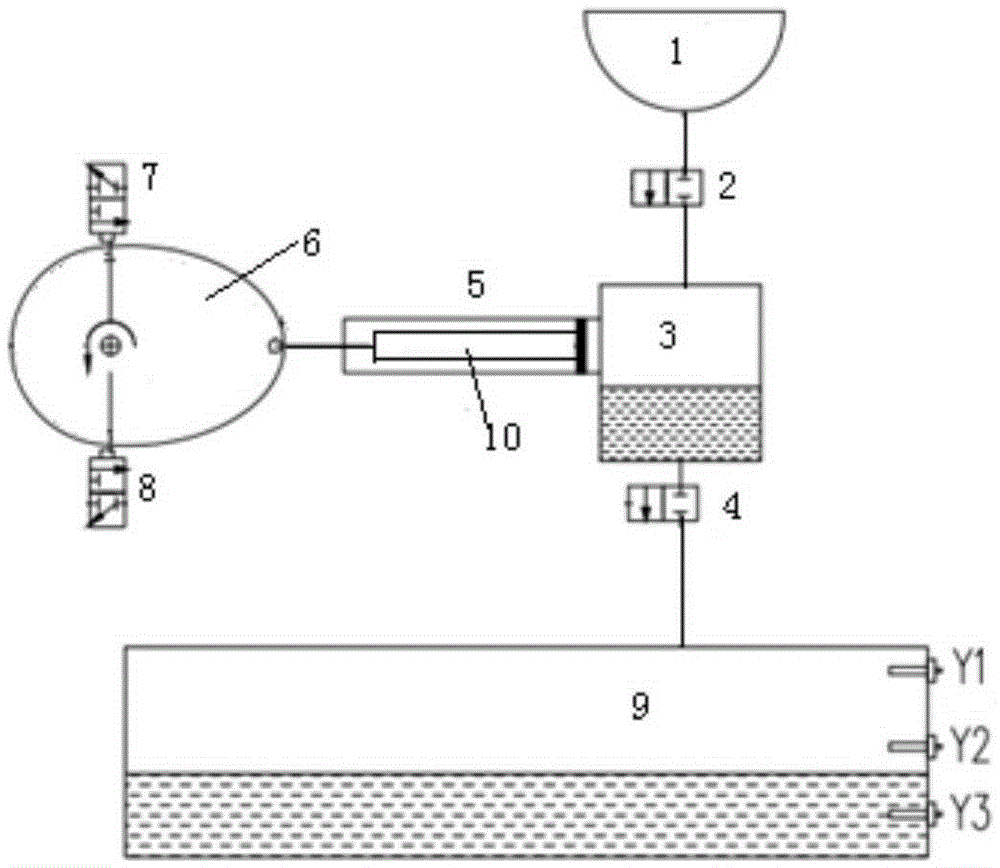

Excrement collection system and excrement collection method

ActiveCN103419804AEasy to operateSet up quicklySanitationVehicle sanitationCollection systemCollection methods

The invention discloses an excrement collection system and an excrement collection method. In a standby state, an air cylinder is disconnected from a toilet bowl and an excrement collection box, and negative pressure is produced in an excrement guide pipe by the air cylinder; in the process of use, when a flushing valve of the toilet bowl is pressed, excrement in the toilet bowl can be absorbed into the air cylinder temporarily by communicating the air cylinder with the toilet bowl; then, the air cylinder is disconnected from the toilet bowl and is communicated with the excrement collection box, and the excrement in the air cylinder is pushed into the excrement collection box by a piston in the air cylinder; at last, the air cylinder is disconnected from the excrement collection box and returns to the standby state, and the process is repeated according to the method. The excrement collection system and the excrement collection method have the advantages that operation is simple, and most importantly, the problem that bad air in the excrement collection box can be exhausted to a washroom through the excrement guide pipe in the flushing process is solved.

Owner:CHANGCHUN LANGRUISI RAILWAY EQUIP

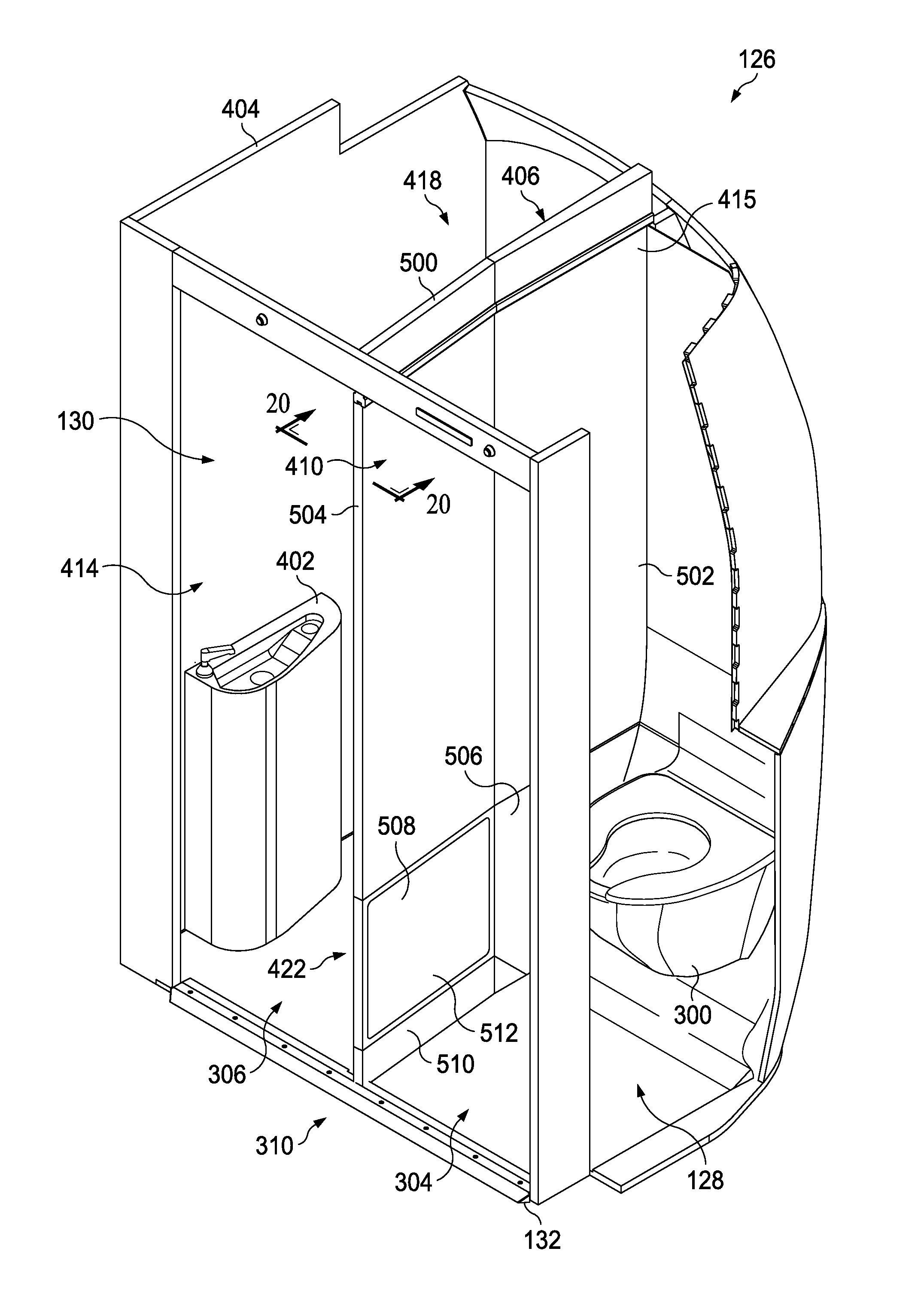

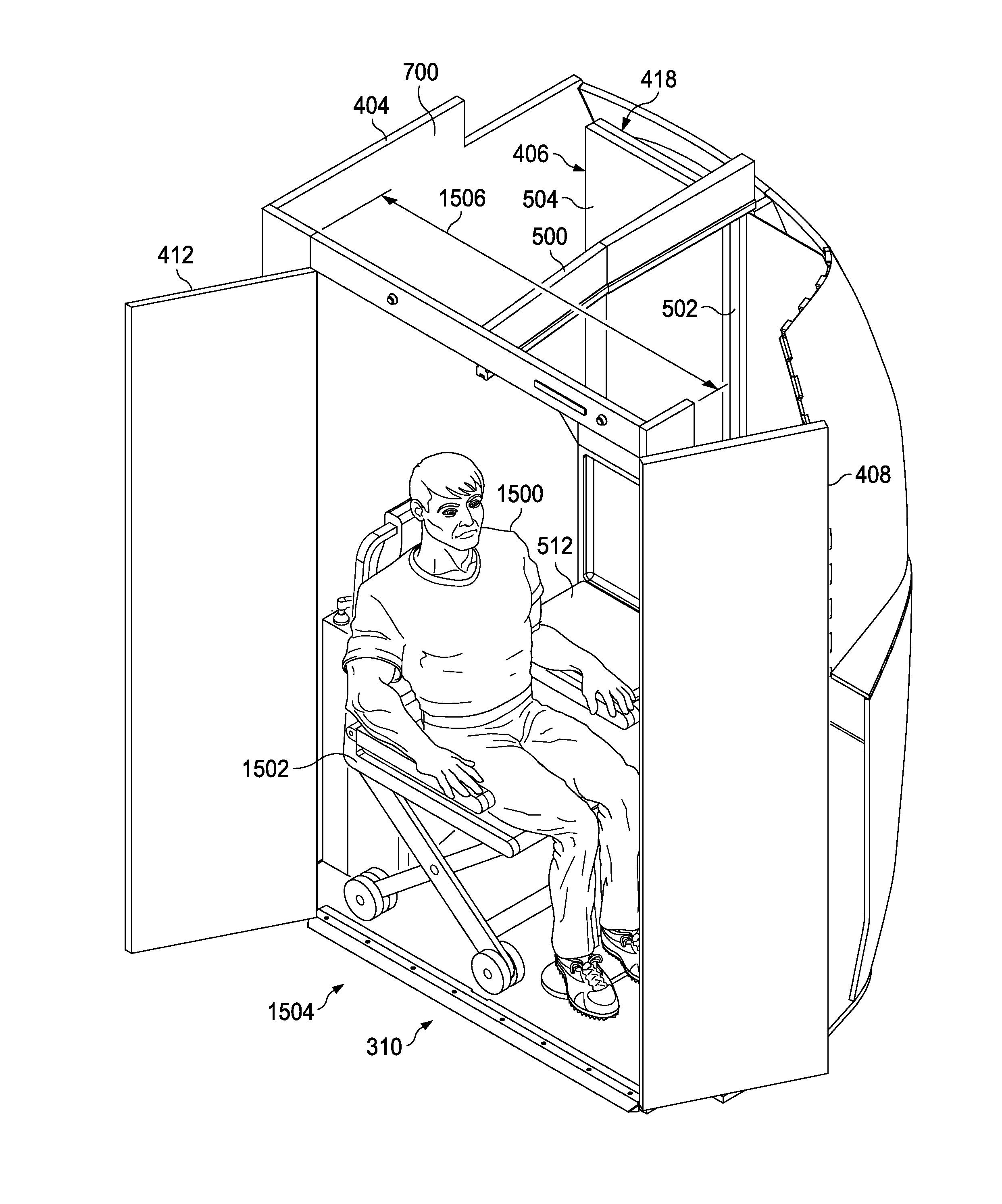

Lavatory Reconfiguration System

ActiveUS20140360099A1Water closetsCosmonautic crew accomodationsEngineeringElectrical and Electronics engineering

Owner:THE BOEING CO

Railway vacuum sewage unloading treatment system

ActiveCN106946432AEasy to cleanImprove processing efficiencyToilet black water treatmentSludge treatment by de-watering/drying/thickeningElastomerLiquid waste

The invention discloses a railway vacuum sewage unloading treatment system which includes an excrement collection tank, a squeezing device and a cultured bacteria tank body. The excrement collection tank is connected to a vacuum suction device. The outlet of the vacuum suction device is connected to a primary filtering storage tank. A chamber, at the right side of a separation board, discharges a filtered waste liquid into a primary sedimentation liquid mixing tank through a second elastomer cam rotor pump. Waste materials, at the left side of the separation board, are connected to a first cutting machine. A crushed material outlet pipe of the first cutting machine is connected to a stirring disinfection chamber. The stirring disinfection chamber is connected to the squeezing device through a squeezing material feeding pipe. The outlet of a sterilizing cabinet is connected to a second cutting machine. A water outlet of the squeezing device is connected to a condenser through a first elastomer cam rotor pump. The bottom of the primary sedimentation liquid mixing tank is connected to the stirring disinfection chamber. One side of the primary sedimentation liquid mixing tank is connected to a waste liquid heating tank. Water vapor in the waste liquid heating tank is communicated with a water vapor condenser of the sterilizing cabinet. The system has simple structure, is high in sewage treatment efficiency, and can be widely promoted and applied.

Owner:杭州求是化工机械有限公司

Lavatory monument for aircraft

An aircraft including a lavatory monument. The lavatory monument includes an outboard wall and a shell wall removably connected to the outboard wall, both walls extending radially inwardly relative to a fuselage of the aircraft. The lavatory monument also includes a floor panel connected to and between the outboard wall and the shell wall. The lavatory monument also includes a toilet connected to the floor panel. The lavatory monument also includes a plurality of lavatory fixtures individually removably attached to at least one of: the outboard wall, the shell wall, the floor panel, or the toilet. Each of the plurality of lavatory fixtures is individually removable. Common interface points on each of the plurality of lavatory fixtures are unchangeable with respect to the lavatory monument.

Owner:THE BOEING CO

Vacuum toilet wastewater collector

InactiveCN104846987ASimple structureEasy to useFlushing devicesLavatory sanitoryIsolation valveWastewater

The invention discloses a vacuum toilet wastewater collector comprising a squatting pan, a vacuum tank, a dirt cache box, a sewage pump, a vacuum pump, a PLC controller, a vacuum switch, a self-priming pump, a flush water temporary storage tank, an air temporary storage tank and an air compressor. The squatting pan is connected with the dirt cache box which is connected with the vacuum tank. The vacuum tank is connected with the vacuum pump. The sewage pump is installed in the dirt cache box. The self-priming pump is connected with the squatting pan. The vacuum switch is arranged between the squatting pan and the dirt cache box. An air and water isolating valve is arranged between the air temporary storage tank and the flush water temporary storage tank. A flush water electromagnetic valve is arranged between the flush water temporary storage tank and the squatting pan. The flush water temporary storage tank is connected with the external part via a pressure release electromagnetic valve. The PLC controller is respectively connected with the air and water isolating valve, the flush water electromagnetic valve, the pressure release electromagnetic valve and a vacuum air valve. The sewage pump in the dirt cache box has cutting and smashing effects so that pipeline blocking can be effectively reduced. The vacuum tank is arranged so that vacuum establishing time is saved and noise is reduced in comparison with existing vacuum toilet wastewater collectors.

Owner:HEFEI HONGSHIDA ENVIRONMENTAL PROTECTION TECH

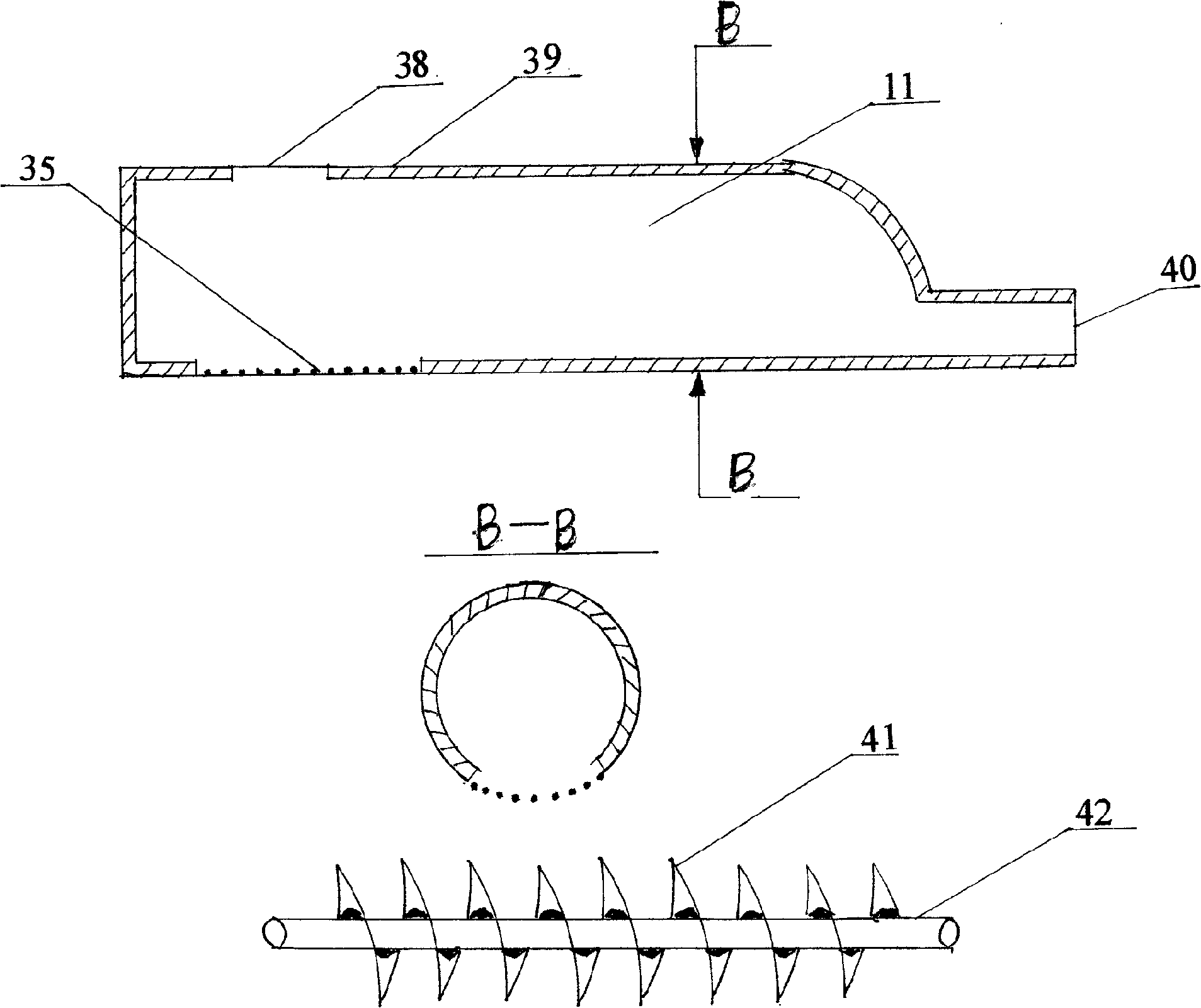

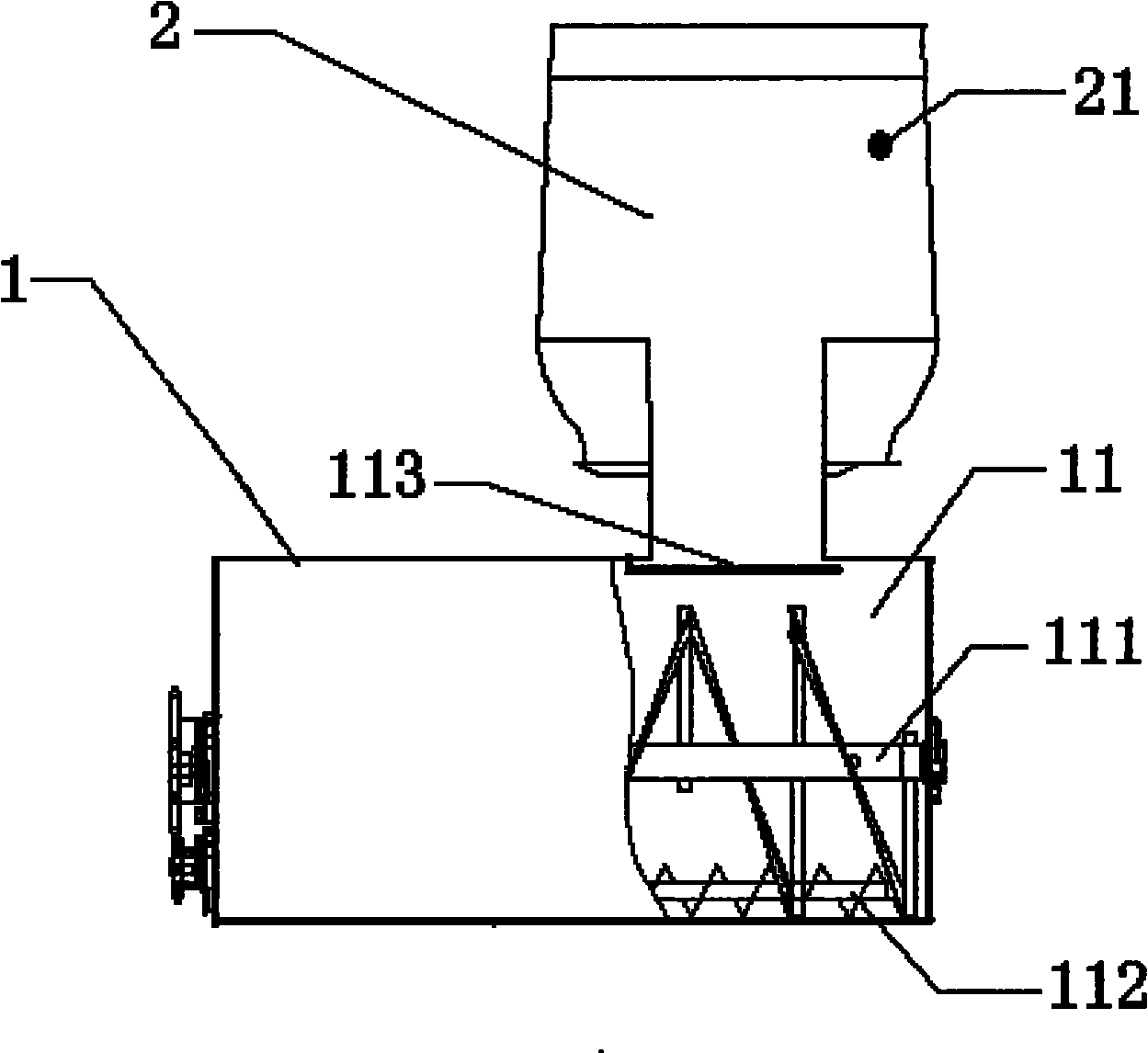

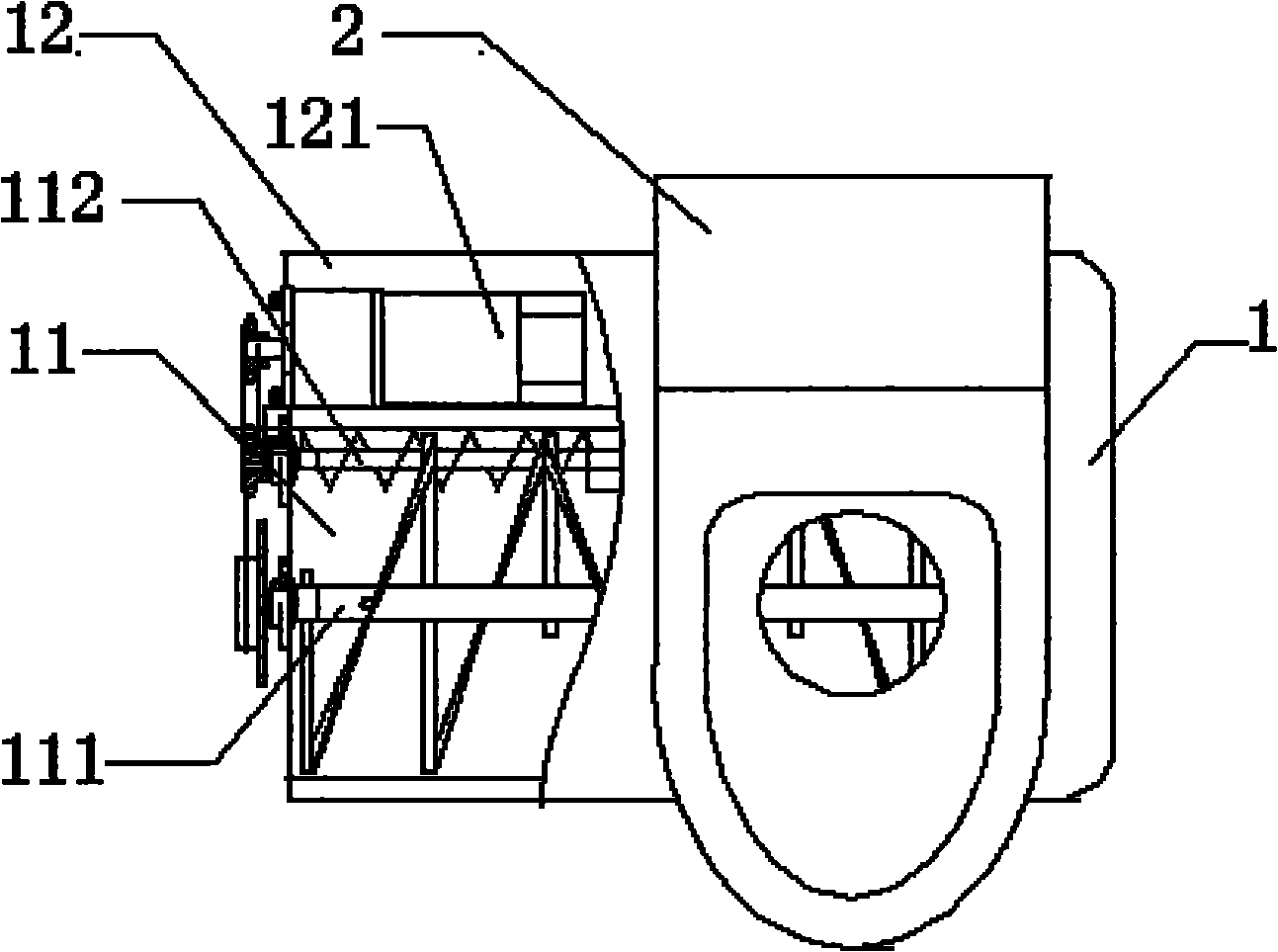

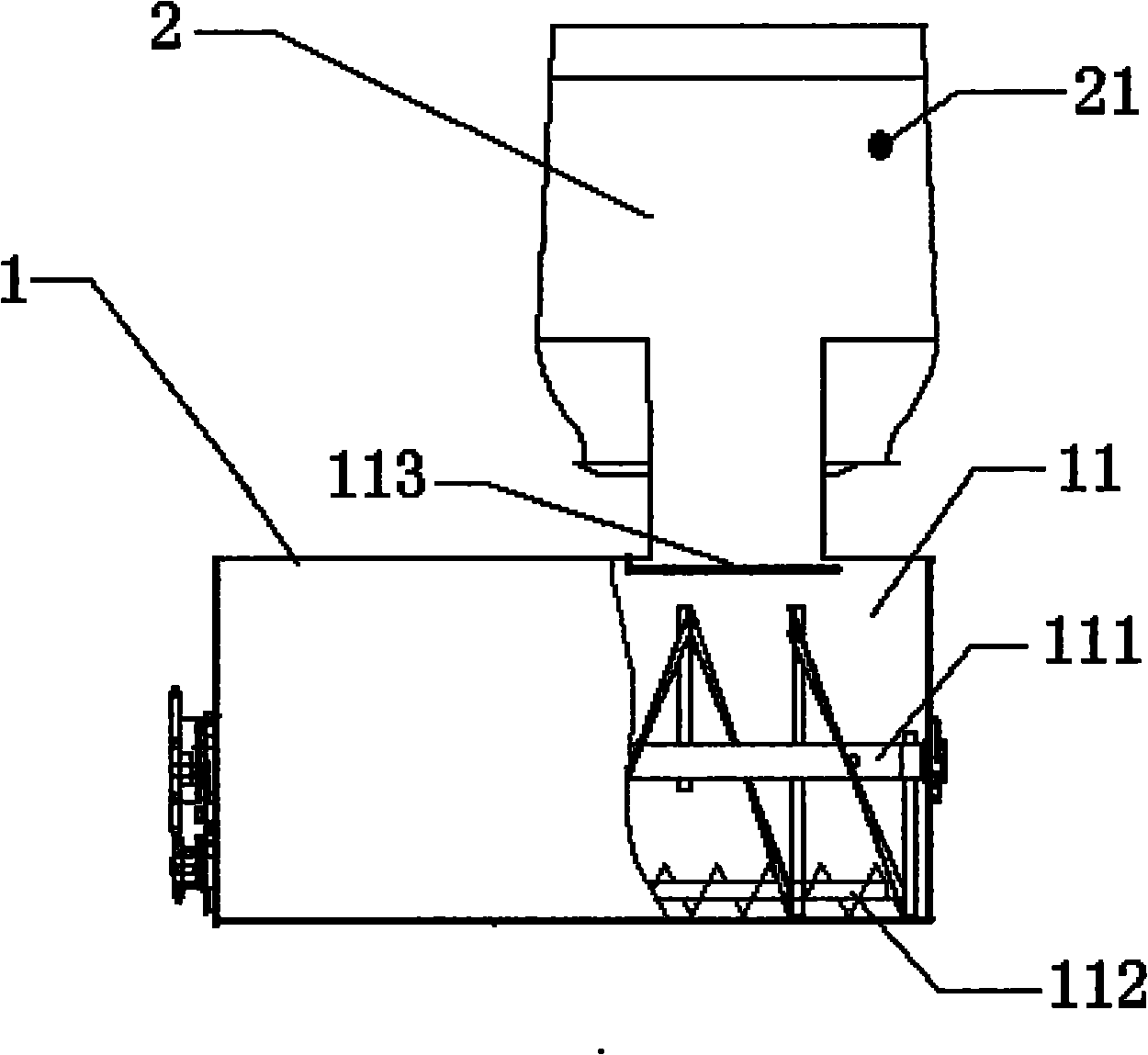

Ecological toilet suitable for locomotive or steamship drivers

InactiveCN101797129ASafe and reliable degradation effectQuality improvementSolid waste disposalBathroom accessoriesMicrobial agentEngineering

The invention relates to an ecological water-free excrement treatment device, which comprises a mainframe and a pedestal pan, wherein the main frame comprises a fermentation tank and a motor chamber which are parallelly arranged; a motor is arranged in the motor chamber; the upper part of the fermentation tank is provided with an opening corresponding to a movable baffle on the bottom of the pedestal pan; a first stirrer and a second stirrer connected with the motor through a mechanical transmission device are arranged in the fermentation tank, and have a stirring cage structure respectively, wherein the second stirrer is parallelly arranged on the lower lateral part of the first stirrer, and the volume swept by stirring of the second stirrer is smaller than that swept by stirring of the first stirrer; a microbial agent is filled in the fermentation tank; and the outer bottom of the fermentation tank is provided with a heating device. The excrement treatment device is particularly suitable for locomotive or steamship drivers.

Owner:生态洁环保科技股份有限公司

Preparation method of glass reinforced plastic batten for bath room

ActiveCN102229752AThe appearance is rich in colorAvoid collisionLamination ancillary operationsSynthetic resin layered productsSurface layerBatten

The invention discloses a glass reinforced plastic batten for a bath room. The glass reinforced plastic batten is prepared by the following steps of: preparing a gel coat layer, a surface layer and an enhanced layer; and then curing with a mould; and finally demoulding and cutting. The glass reinforced plastic batten is convenient to install and maintain and has the multiple characteristics of fire retardance, corrosion resistance, water tightness, skid resistance, impact resistance and the like, has full and bright color and is easy to clean; by the adoption of the glass reinforced plastic batten, labor intensity is reduced, and efficiency is increased.

Owner:来安县永阳知识产权运营有限公司

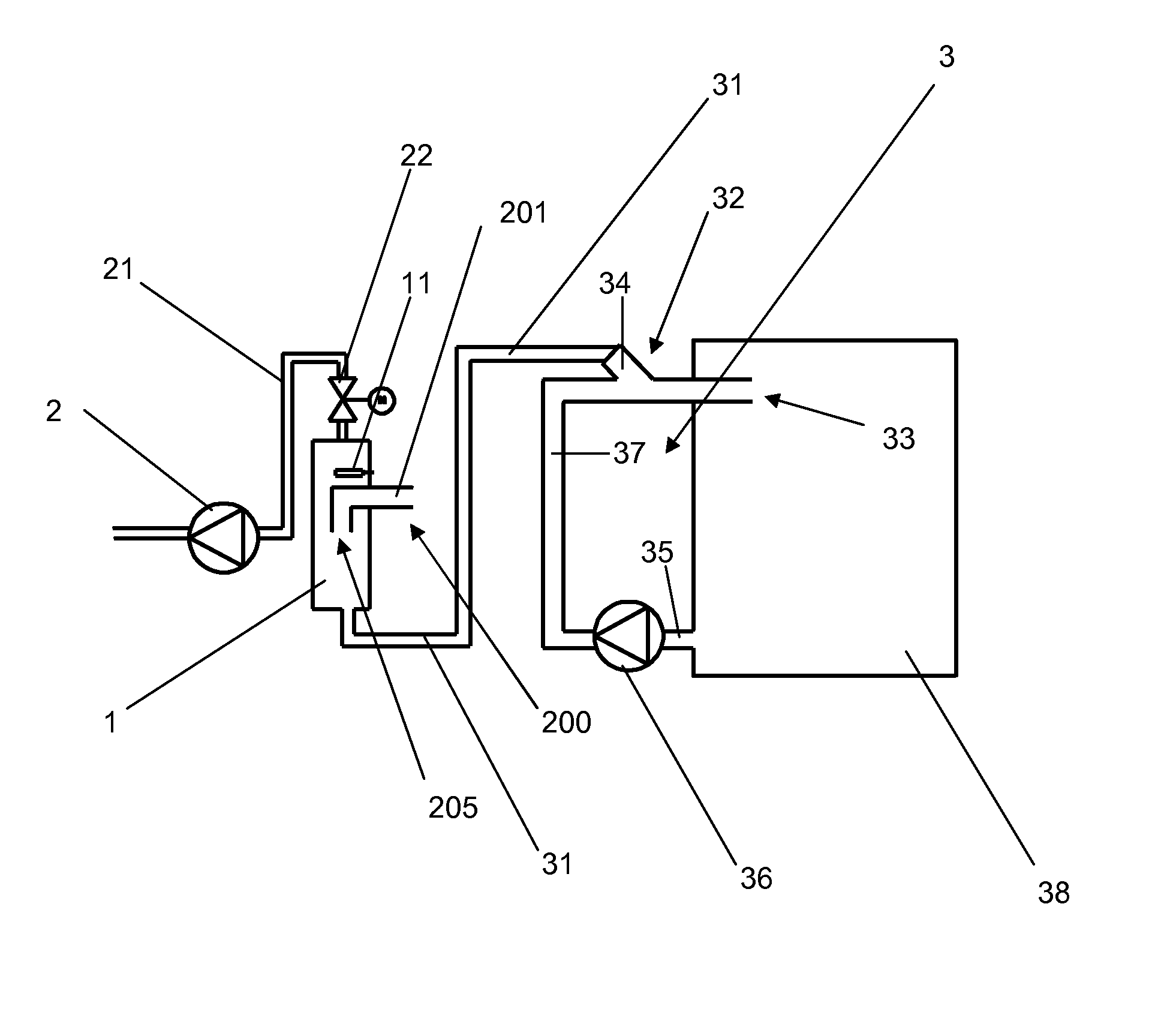

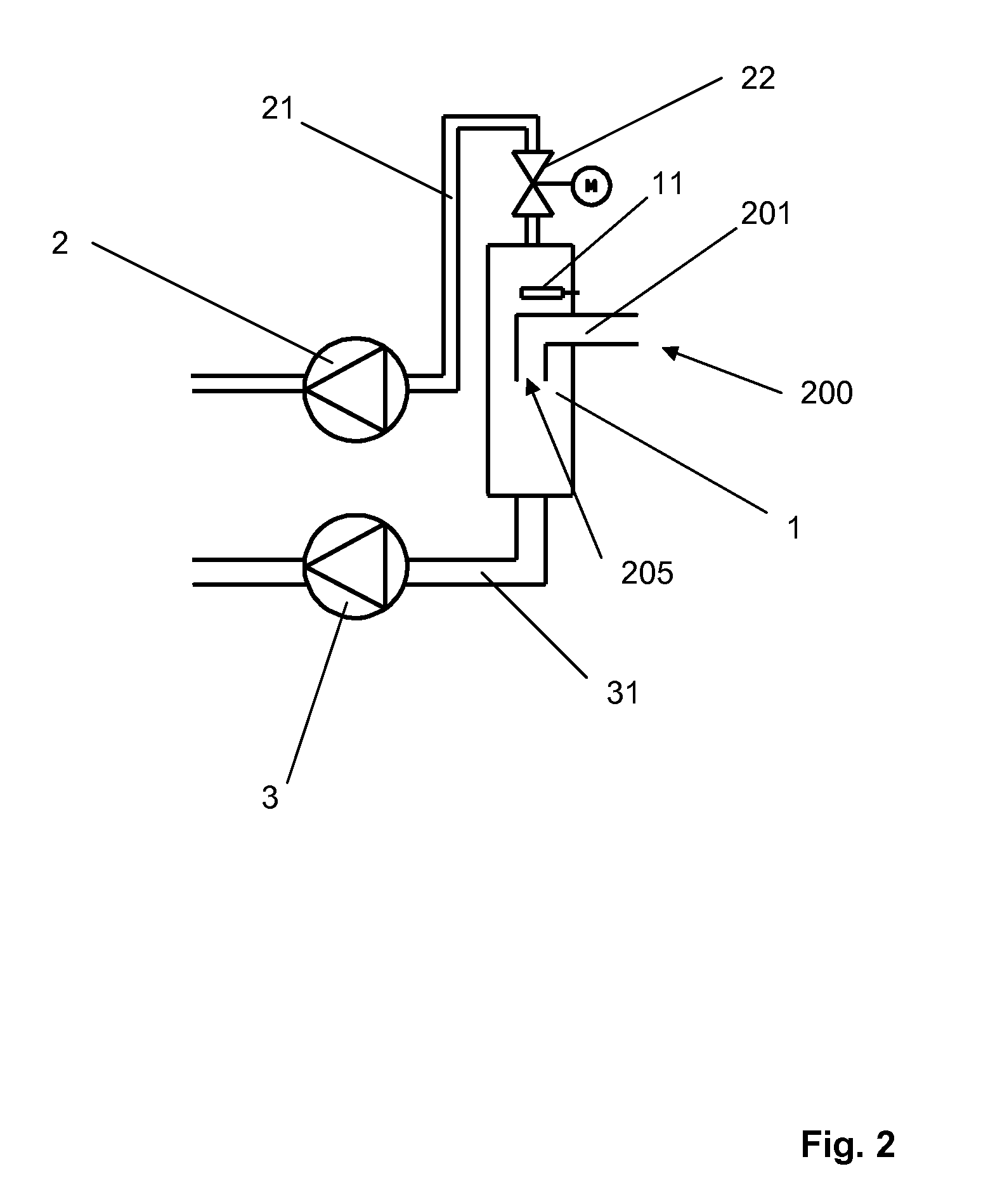

Vacuum sewage system

ActiveUS20100031432A1Effective sewage transportReduced space requirementsWater closetsFlushing devicesVacuum pumpToilet

The invention relates to a vacuum sewage system, which includes a sanitary unit, such as a toilet unit, vacuum sewer piping (200) connected to the sanitary unit, a discharge valve between the sanitary unit and the vacuum sewer piping, and a vacuum generating device for generating vacuum in the vacuum sewer piping. The system comprises an on-line separator device (1) in the vacuum sewer piping (200, 201) and a first pump means (2) and a second pump means (3) connected in parallel with the on-line separator device (1). The first pump means (2) is a vacuum pump for generating vacuum in the vacuum sewer piping (200, 201) and for evacuating air from the sewage flow flowing into the on-line separator device (1) and the second pump means (3) is arranged for pumping mainly sewage from the sewage flow flowing into the on-line separator device (1).

Owner:EVAC INT

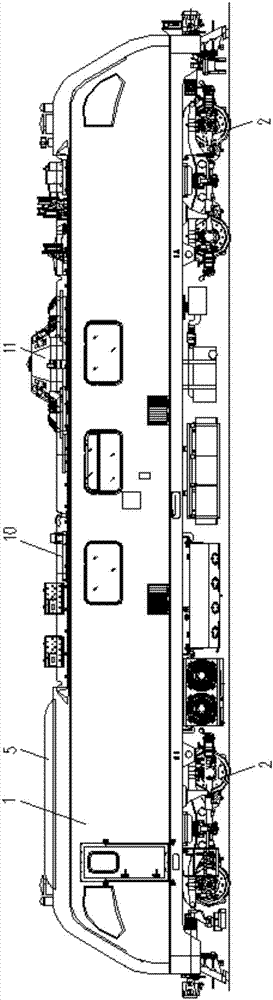

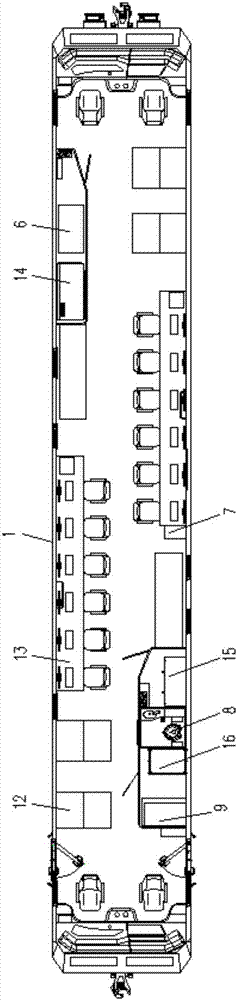

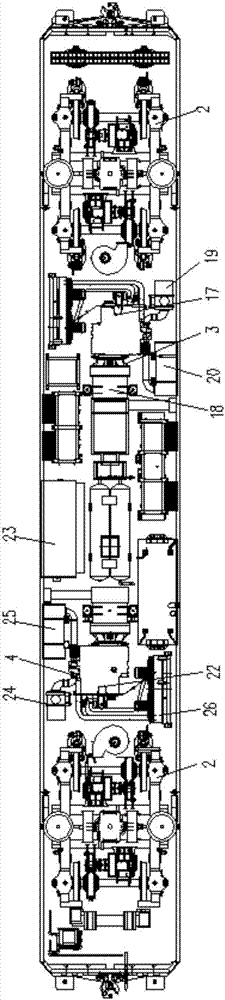

Electric transmission type comprehensive inspection vehicle for railway

PendingCN107472269AImprove securityFirmly connectedRailway inspection trolleysElectric locomotivesBogieVehicle frame

The invention provides an electric transmission type comprehensive inspection vehicle for a railway. A vehicle body is mounted on a power steering frame through a vehicle frame, living facilities and a maintenance detection unit are arranged at the top of the vehicle body and the interior of the vehicle body correspondingly, an electric port and an external socket capable of being connected with an outside vehicle and electric equipment are arranged at the front end and the rear end of the vehicle body, a power system I and a power system II are arranged at the bottom of the vehicle body, the power system I is connected with a power steering frame and a driving control unit controlling the vehicle to run, and after the power system II is connected with the living facilities and the maintenance detection unit, an independent power supply mode of vehicle operation and the living facilities and the maintenance detection unit is achieved. The electric transmission type comprehensive inspection vehicle for the railway supplies power to vehicle operation and the living facilities and the maintenance detection unit independently by arranging the power system I and the power system II which are located at the bottom of the vehicle body, the safety property of vehicle operation is improved, the comprehensive inspection vehicle integrates power supply, public work, and electric work system detection functions into a whole, the speed of the inspection vehicle can be as high as 160 km / h, the working efficiency is improved greatly, and the requirements of a high-speed rail for detection are met.

Owner:BAOJI CSR TIMES ENG MACHINERY +1

Aircraft sink with integrated waste disposal function

InactiveUS8011033B2Save weight and cost and spaceGalleysBathroom accessoriesCommon lineWaste treatment

A sink system includes a sink and a storage area receiving and storing matter from the sink. The storage area receives air from the bypass line during a flush. Also, matter from the storage area and sink is vacuumed through a common line during the flush. A valve limits an amount of air supplied by the bypass line such that increased suction is applied to the sink through the common line. The valve may be manually operated or operated by a controller.

Owner:THE BOEING CO

Rail train, shower system for rail train, and shower system control method

The invention provides a rail train, a shower system for the rail train, and a shower system control method. The shower system for the rail train is characterized by comprising a cold water tank arranged under a carriage of the rail train, a hot water tank arranged above the carriage, a volume type water heater, a shower nozzle and a control panel, wherein the hot water tank and the cold water tank are respectively provided with a water inlet and a water outlet; the hot water tank is internally provided with a temperature gauge which is electrically connected with the control panel; the volume type water heater is communicated with the hot water tank, so that a circulation flow path can be formed; a first water pump is also arranged between the volume type water heater and the hot water tank; the water outlet of the hot water tank is connected with a second water pump; the water outlet of the cold water tank is connected with a third water pump; the second water pump and the third water pump are respectively communicated with the shower nozzle; and the first water pump, the second water pump and the third water pump are respectively and electrically connected with the control panel. After the shower system for the rail train is adopted, a user can take a shower bath on the rail train, so that the use comfortableness of the rail train can be improved.

Owner:CRRC SIFANG CO LTD

Toilet unit for a vehicle, in particular a rail vehicle

A toilet unit for a vehicle, in particular a rail vehicle, the toilet unit comprising a cubicle equipped at least with a toilet pan or with a handbasin, said toilet unit defining a limiting volume that is in the shape of a rectangular block, and that is suitable for fitting into a space provided in the rail vehicle for this purpose, said toilet unit incorporating, inside said limiting volume, at least a clean water tank and a waste water retention tank, wherein said clean water tank and said waste water retention tank are disposed vertically in respective corners of the rectangular limiting volume, each tank having an outside wall that is wedge shaped to match the shape of the corner of the rectangular limiting volume, and an inside wall on its side that faces into the cubicle that substantially matches the shape of said cubicle.

Owner:ALSTOM SA

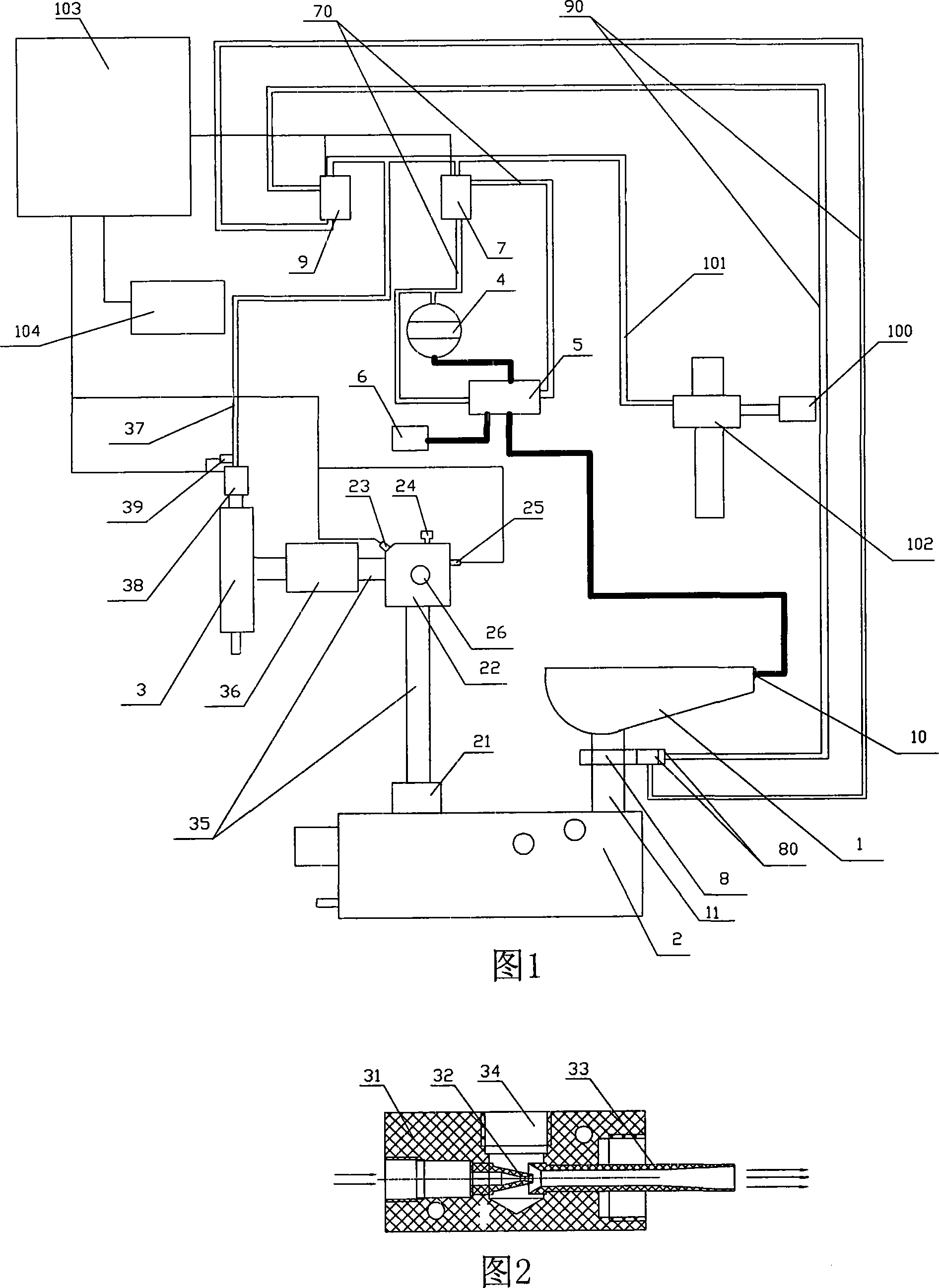

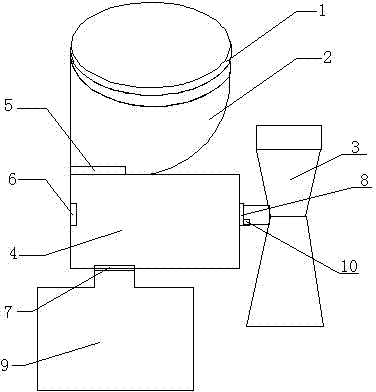

Pneumatic control unit of excrement collecting system for bullet train

A pneumatic control unit of an excrement collecting system for a bullet train is mounted in a position close to the excrement collecting system, and comprises a mounting board, wherein a stop valve, a main filter pressure reducing valve, an adjusting valve A, an electromagnetic valve A, a transfer box pressure detection switch, a pressure regulating valve B, a transfer box pipeline valve control electromagnetic valve, a pressure detection switch B, an electromagnetic valve B and a non-return valve are mounted on the mounting board, and the stop valve, the main filter pressure reducing valve, the electromagnetic valve A, the electromagnetic valve B, the pressure detection switch B, the pressure detection switch B, a transfer box pipeline valve control electromagnetic valve set and a vacuum-pumping electromagnetic valve are controlled by an excrement collecting controller; after passing through the stop valve and the main filter pressure reducing valve through an air inlet, compressed gas is divided into four branches for supplying to all gas using units. According to the invention, a control unit is integrally mounted on a mounting board, the structure is compact, the occupied area is small, and the repair and maintenance are convenient.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Toilet assembly

A toilet assembly for use in a vehicle includes a toilet, a macerator assembly for receiving material from the toilet, and a holding tank in association with the macerator assembly along a discharge tube. The material is configured to pass from the macerator assembly, through the discharge tube, and to the holding tank. A mounting structure is further included for attaching the discharge tube to a supporting surface. The mounting structure includes a floor flange attached to the supporting surface, an adapter plate assembly, and a seal positioned between the adapter plate assembly and floor flange. The adapter plate assembly is sealingly engaged with the discharge tube, such that the discharge tube is sealed with the supporting surface.

Owner:DOMETIC APPLIANCES

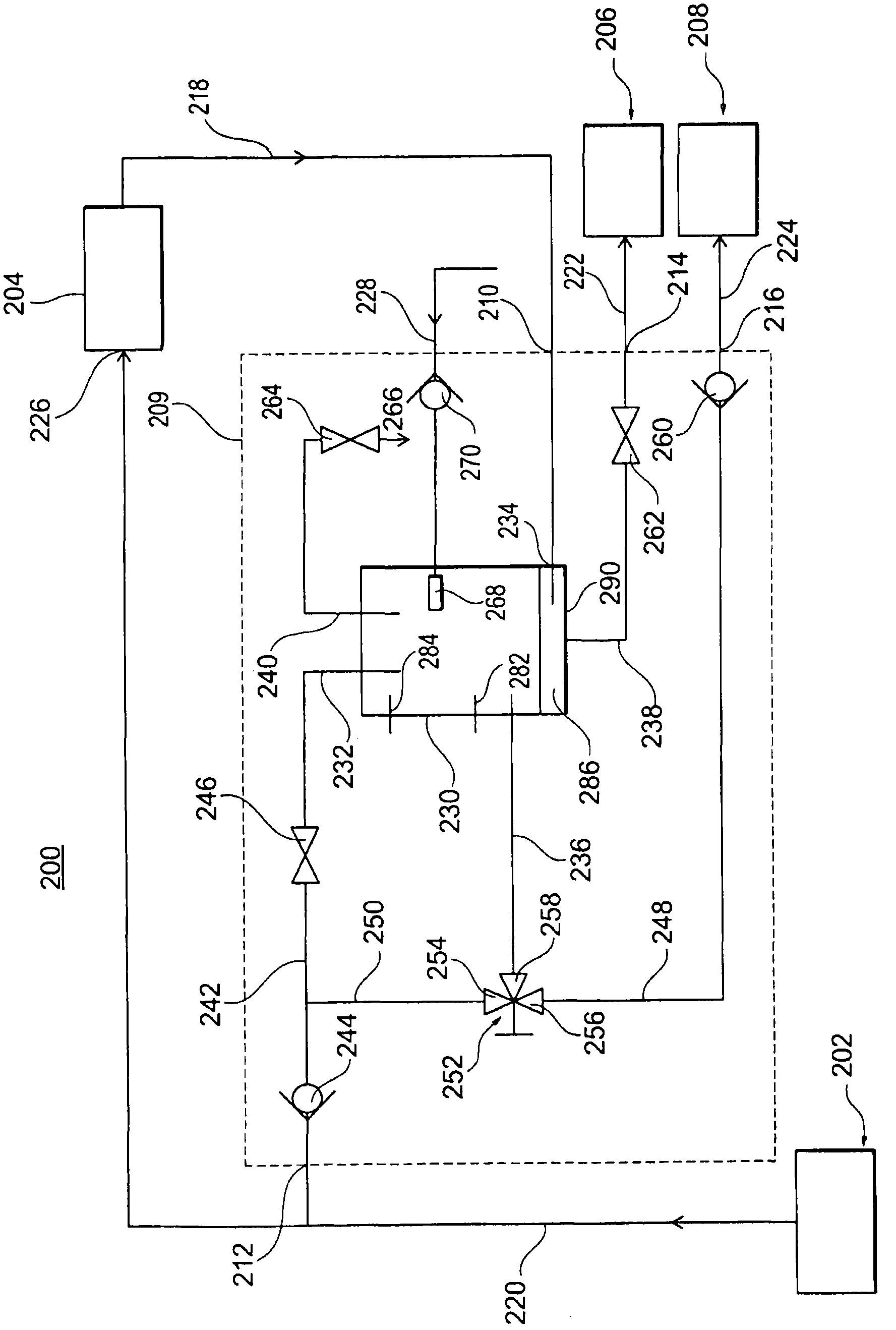

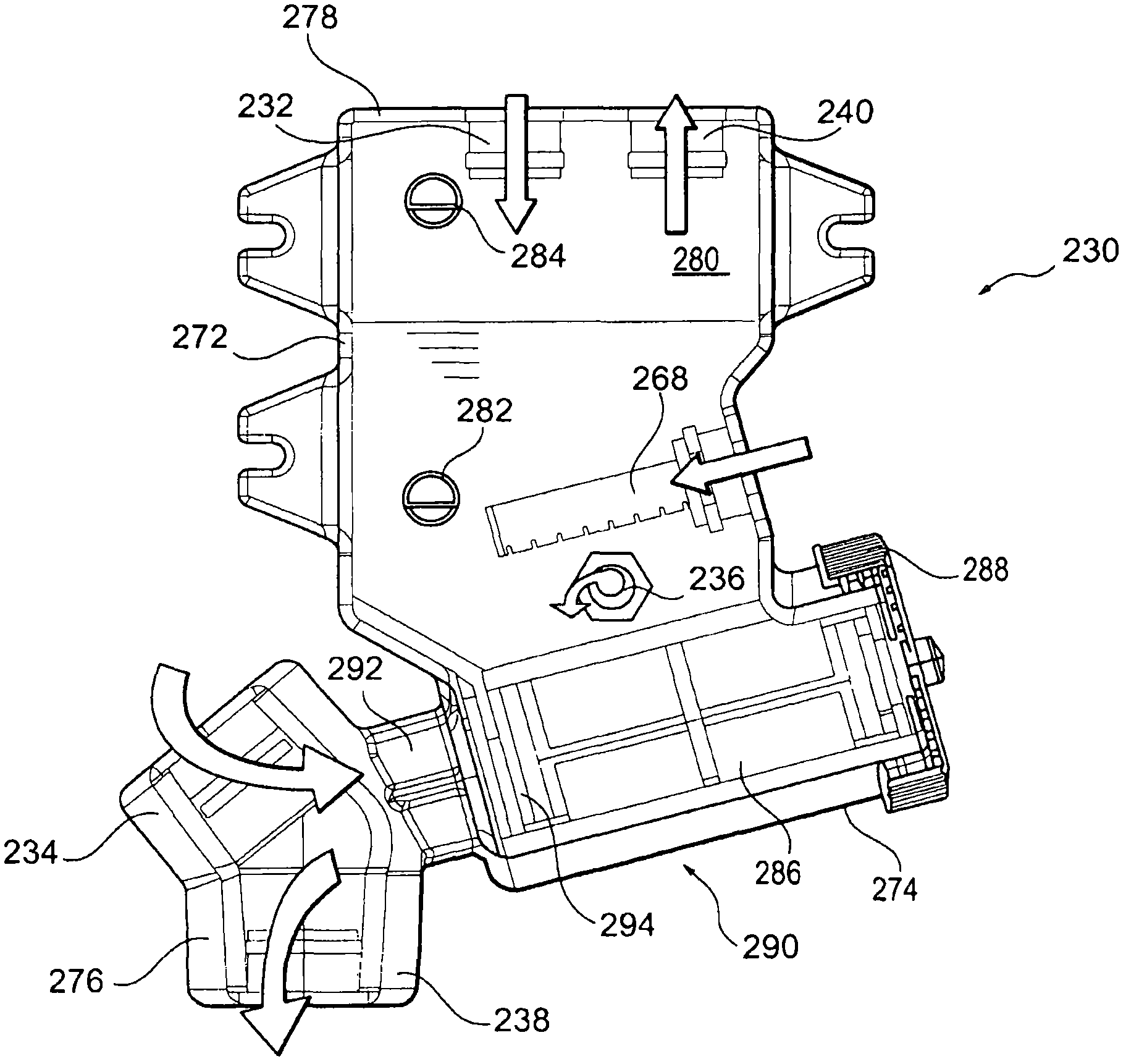

A water storage and distribution system having a water tank by pass

A system (209) for storing and distributing water, the system comprising: - a water tank (230) having a fresh water inlet (232), a collected water inlet (234), and a main water outlet (236); - a fresh water conduit (242) connected to the fresh water inlet; and - a main drain (248) connected to the main water outlet, the system being characterized by a water tank bypass (250) connecting the fresh water conduit to the main drain and by a device (252) for switching the system between a first mode, wherein the bypass (250) is closed and the main water outlet (236) is open, and a second mode, wherein the bypass (250) is open and the main water outlet (236) is closed.

Owner:ALSTOM TRANSPORT TECH SAS

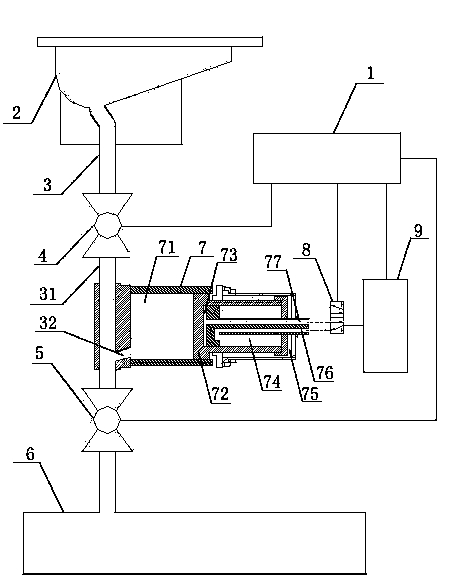

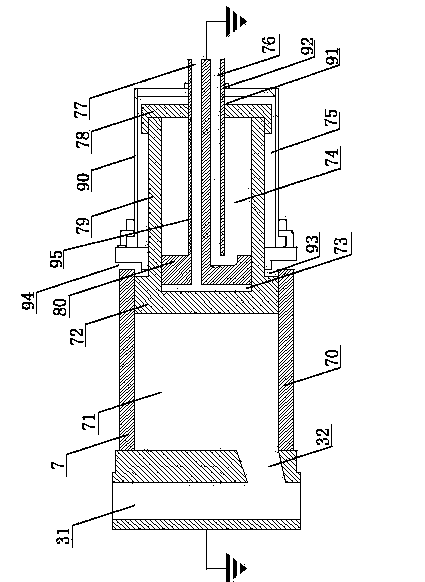

Mechanical type intermediate case vacuum-pumping and pressurization apparatus and application method thereof

The invention discloses a mechanical type intermediate case vacuum-pumping and pressurization apparatus and an application method thereof. One side of a roller in the apparatus is provided with a first hand-operated valve for opening a pollutant generator, the other side is provided with a second hand-operated valve for opening an intermediate case, the roller rotates around an axis, and a projection is arranged in the circumferential direction of the roller; the top portion of the intermediate case and the pollutant generator are connected, and the bottom of the intermediate case is connected with a pollutant case; and a piston rod in a cylinder is connected with the roller through a tensioning mechanism, and an accommodation chamber in the cylinder communicates with the intermediate case. The advantages are as follows: through rotation of the roller, the projection on the roller cooperates with the two hand-operated valves so that compressed air can conveniently penetrate into a pollutant generation source or the intermediate case and positive pressure is generated; the piston rod is driven to move through the rotation of the roller, so that negative pressure is generated in the intermediate case to enable pollutants to go into the intermediate case conveniently, or the positive pressure is generated to enable the pollutants to go into the pollutant case conveniently; and the whole apparatus is simple in structure, high in reliability and low in cost, and saves energy.

Owner:江苏中车华腾环保科技有限公司

Suction-exhaust drying recovering device for train toilet

InactiveCN102765401AReduce work intensityReduce operating costsSanitationPulp and paper industryDry box

The invention provides a suction-exhaust drying recovering device for a train toilet and belongs to the technical field of sanitary equipment. The suction-exhaust drying recovering device comprises a defecation container and a closestool cover arranged on the defecation container and is characterized in that a suction-exhaust drying box is arranged at the bottom of the defecation container, and a suction-exhaust port is arranged at the connecting position of the defecation container and the suction-exhaust drying box. The suction-exhaust drying recovering device is further provided with a negative pressure suction-exhaust device which is arranged on one side of the suction-exhaust drying box through a drying port in a connecting mode, an exhaust port is arranged on the other side of the suction-exhaust drying box, and a dirt discharging port is arranged at the bottom of the suction-exhaust drying box. The positions of the exhaust port, the suction-exhaust port, the dirt discharging port and the drying port are provided with valves. The suction-exhaust drying recovering device is simple and reasonable in structure and convenient to use, utilizes wind energy to directly suck, exhaust, dry and recycle excrement in the train toilet or household garbage in a train, effectively reduces the work intensity of railway maintainers, keeps railway tracks and the train environment to be clean, prolongs the service life of the railway tracks and reduces railway operation cost.

Owner:刘一诺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com