Train washing water treatment and reuse method and device

A technology for water treatment and trains, applied in water supply installations, indoor sanitary piping installations, transportation and packaging, etc., can solve problems such as aggravating and increasing the volume load of train waste boxes, waste of water resources, etc. Benefit and cost balance, the effect of small processing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

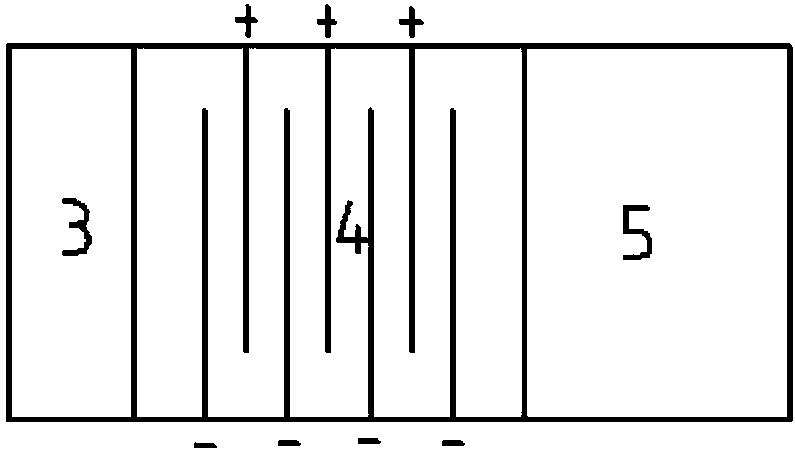

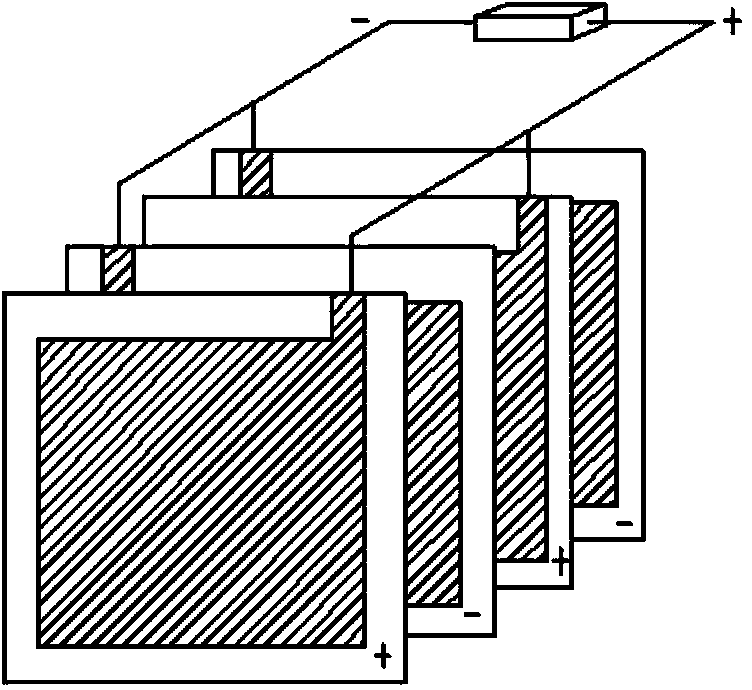

[0038] figure 1 Among them, a device for reusing passenger train washing water after treatment, including a washing basin 1, a screen filter 2, an electrolysis processor water inlet buffer 3, an electrolysis processor electrolytic oxidation zone 4, and an electrolysis processor water collection District 5, and automatic control device 16, in addition the train vacuum bathroom has the auxiliary cooperation of flushing water pressurized tank 18, vacuum pipeline 20 and train water tank 19, realizes washing water treatment reuse. They are connected sequentially through pipes and pump valves.

[0039] Such as figure 1 The washing basin 1 washes and drains water through a screen filter 2 to intercept large particles, hair, solid particles, etc. with a diameter greater than 1mm, and then enters the water inlet buffer 3 of the electrolytic processor, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com