Track slab banding and pressing process for plate-type ballastless tracks

A slab-type ballastless track and ballastless track technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of large external environmental pollution, difficult control of construction quality, complicated process steps, etc., and achieve high construction quality and installation. Layout reusable effects with simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

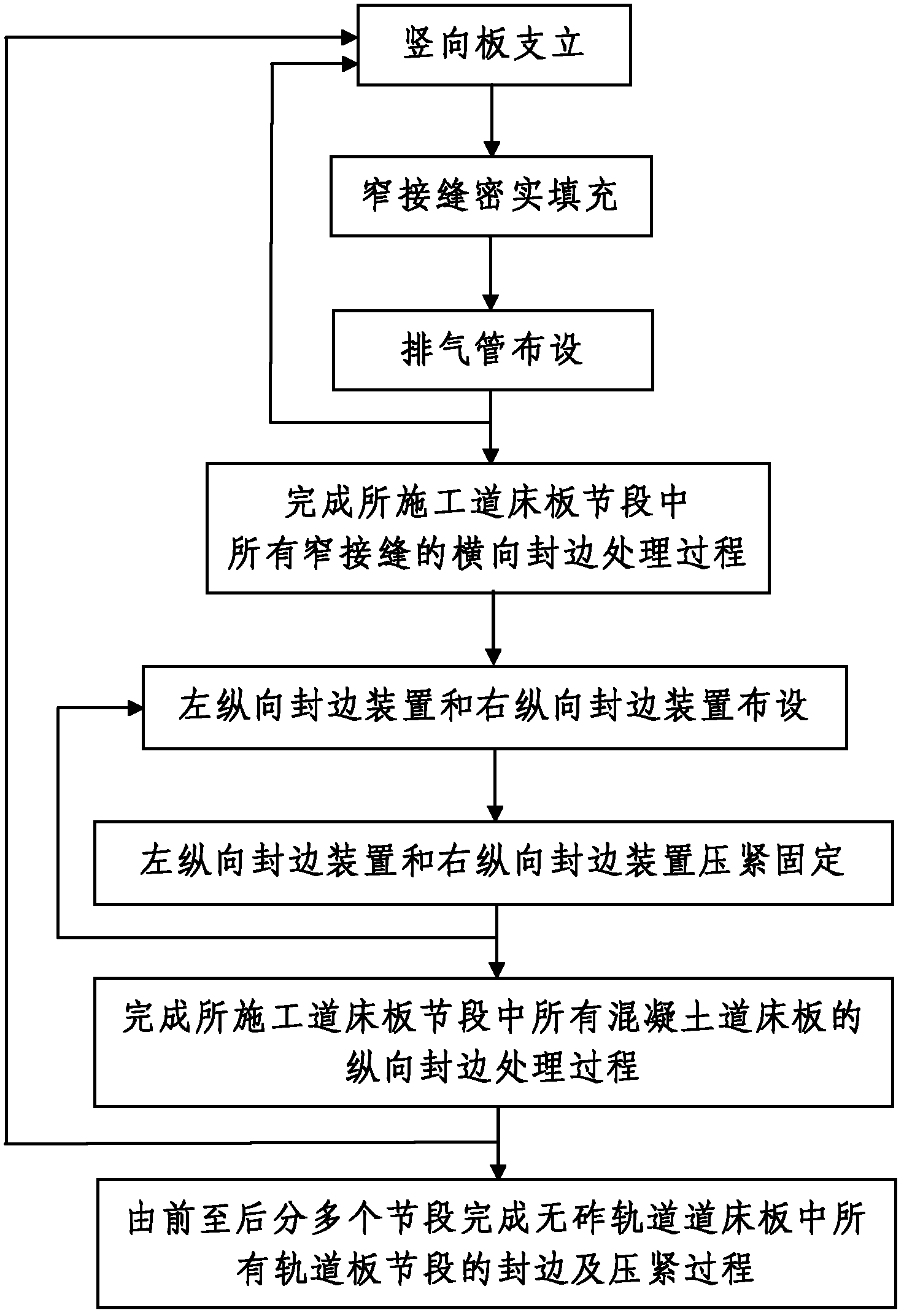

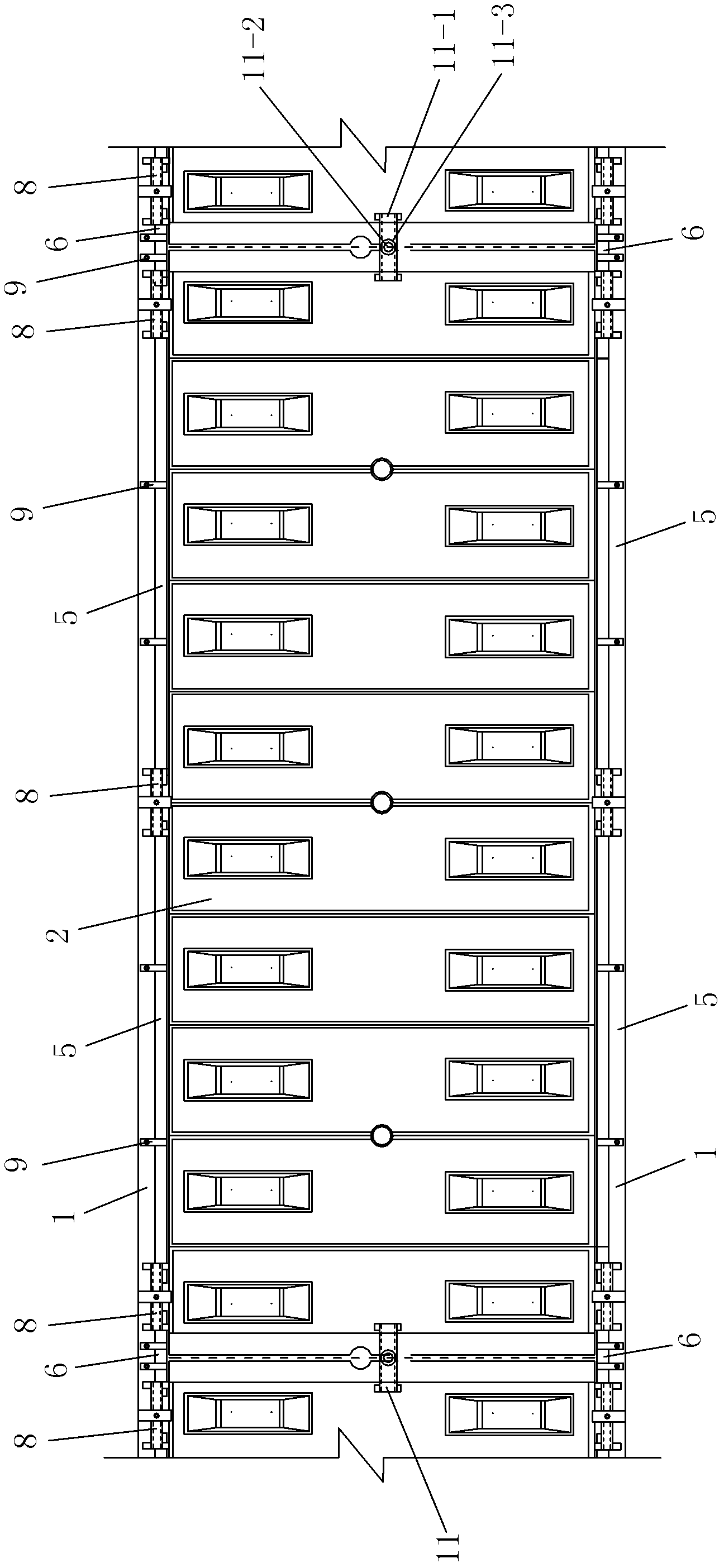

[0055] Such as figure 1 The track slab edge sealing and compacting process of a slab-type ballastless track is shown, and the track slab of the completed ballastless track is sealed and compacted in multiple segments along the extension direction of the construction line from front to back , and the track slab of the ballastless track is correspondingly divided into a plurality of track slab segments; To the multiple concrete track slabs 2 that are continuously laid out, the multiple concrete track slabs 2 are all laid on the base plate 1 that has been constructed; The process includes the following steps:

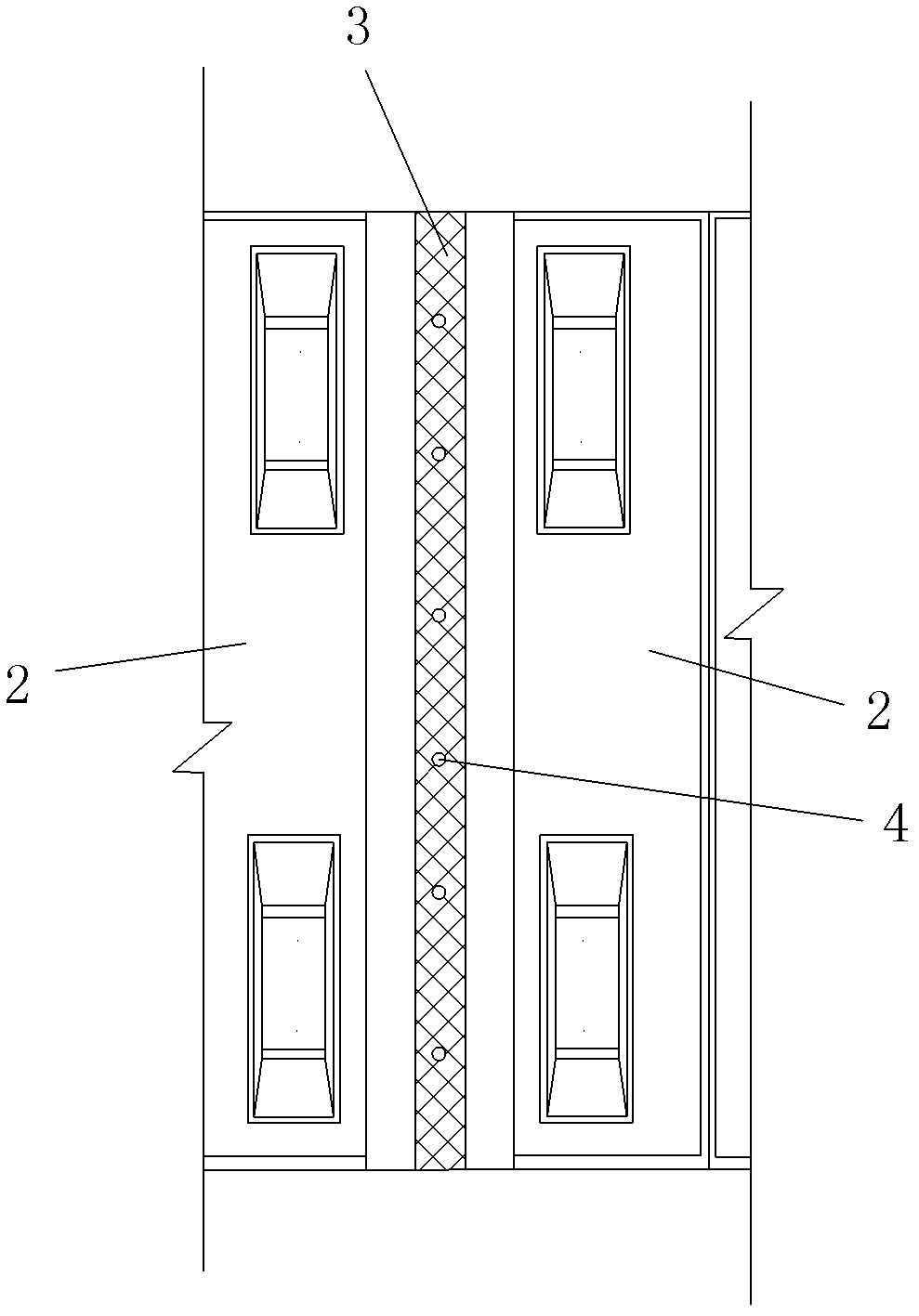

[0056] Step 1. Horizontal edge sealing of track slabs: edge sealing is performed on the narrow joints between two adjacent concrete track slabs 2 in the constructed track slab segment, and all narrow joints in the constructed track slab segment The edge banding treatment methods are the same; for any processed narrow joint in the constructed track slab segment, the edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com