Pulse type micro-sprinkling irrigation spray head

A sprinkler and pulse technology, applied in the field of farmland irrigation, can solve the problems of unsuitable national conditions, high input cost, energy loss, etc., and achieve the effect of being conducive to popularization and application, excellent anti-clogging performance, and excellent spray uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

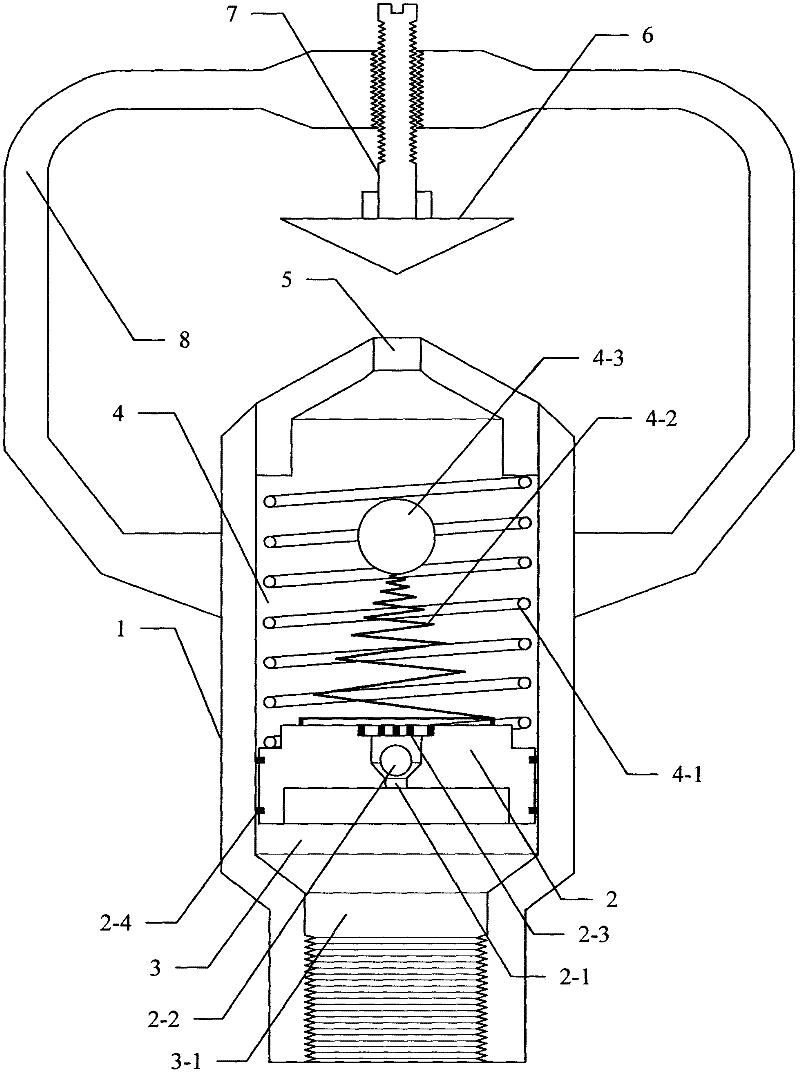

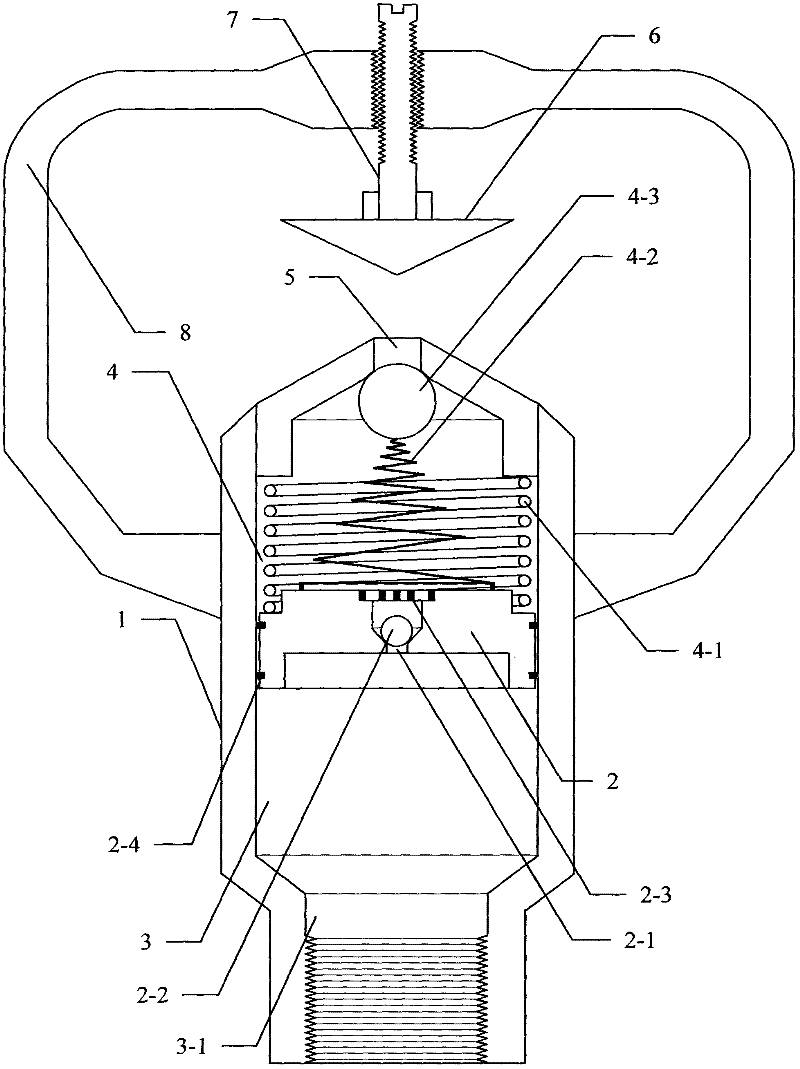

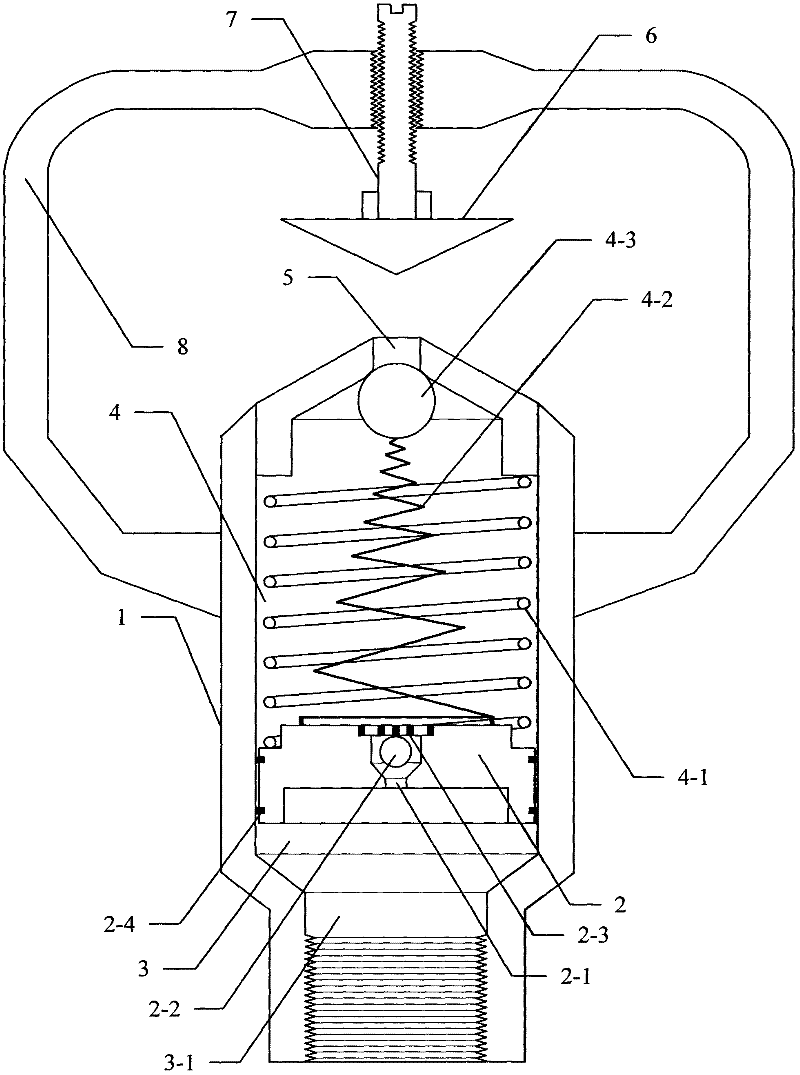

[0015] A pulse type micro-sprinkler irrigation nozzle, as attached figure 1 , 2 , 3, including: a housing 1, a piston 2, the piston 2 divides the inner chamber of the housing 1 into a water inlet chamber 3 and a compression chamber 4, and the water inlet chamber 3 communicates with the micro-spray water through the water inlet channel 3-1 Vertical pipe connection, the piston 2 is provided with a compression chamber 4 water supply check valve and an elastic water stop ring 2-4, the elastic water stop ring 2-4 is fixed on the outside of the piston 2, and the compression chamber 4 is provided with a compression spring 4-1 , tower spring 4-2, spherical elastic valve body 4-3, injection hole 5, compression spring 4-1 is sleeved outside the tower spring 4-2, and one end of compression spring 4-1 rests on the piston 2, and the other One end is against the inner wall of the housing 1 close to the injection hole 5, the large end of the tower spring 4-2 is fixed on the piston 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com