Production method for improving section hardness uniformity of NSM30 plastic mold steel

A technology of plastic mold steel, NSM30, applied in the field of metallurgy, can solve the problems of long production cycle, high price and high use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

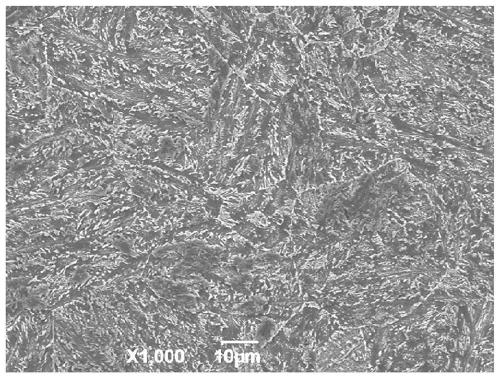

Embodiment 1

[0024] Select a 320mm thick NSM30 billet, the thickness of the steel plate is 170mm, the compression ratio is 1.88, its chemical composition and mass percentage are: C: 0.35%, Si: 0.42%, Mn: 1.20%, Cr: 1.45%, Mo: 0.18 %, P: 0.016%, S: 0.005%, Al: 0.035%, and the balance is iron.

[0025] The rolling process that present embodiment improves the uniformity of cross-section hardness of NSM30 plastic mold steel comprises the following steps:

[0026] (1) Adopt clean steel smelting method to reduce S and P content in steel, LF refining time is more than 40min, RH vacuum treatment, vacuum degree ≤5mbar and keep for more than 20min, after RH vacuum treatment, H≤1.0ppm. The continuous casting adopts light reduction technology to ensure the internal quality of the 320mm continuous casting slab. The superheating degree of continuous casting molten steel is 5°C to 30°C.

[0027] (2) The temperature of the billet into the furnace is ≥200°C, the preheating section is heated slowly, and t...

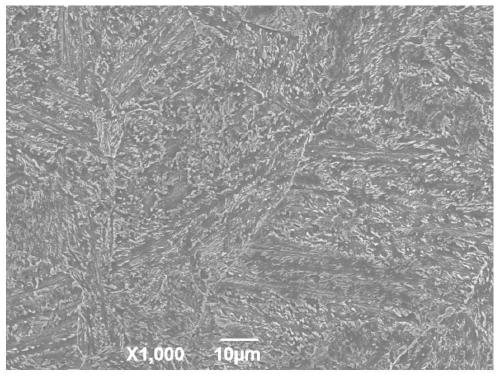

Embodiment 2

[0033] Select a 320mm thick NSM30 billet, the steel plate thickness is 140mm, the compression ratio is 2.28, its chemical composition and mass percentage are: C: 0.33%, Si: 0.39%, Mn: 1.26%, Cr: 1.48%, Mo: 0.22 %, P: 0.012%, S: 0.003%, Al: 0.030%, and the balance is iron.

[0034] The rolling process that present embodiment improves the uniformity of cross-section hardness of NSM30 plastic mold steel comprises the following steps:

[0035] (1) Adopt clean steel smelting method to reduce S and P content in steel, LF refining time is more than 40min, RH vacuum treatment, vacuum degree ≤5mbar and keep for more than 20min, after RH vacuum treatment, H≤1.0ppm. The continuous casting adopts light reduction technology to ensure the internal quality of the 320mm continuous casting slab. The superheating degree of continuous casting molten steel is 5°C to 30°C.

[0036] (2) The temperature of the billet into the furnace is ≥200°C, the preheating section is heated slowly, and the temp...

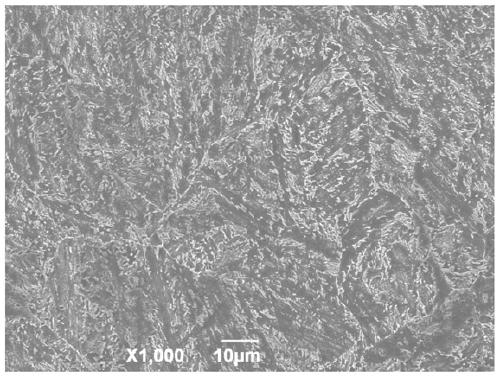

Embodiment 3

[0041] Select a 320mm thick NSM30 billet, the steel plate thickness is 120mm, the compression ratio is 2.67, its chemical composition and mass percentage are: C: 0.35%, Si: 0.42%, Mn: 1.20%, Cr: 1.45%, Mo: 0.18 %, P: 0.016%, S: 0.005%, Al: 0.035%, and the balance is iron.

[0042] The rolling process that present embodiment improves the uniformity of cross-section hardness of NSM30 plastic mold steel comprises the following steps:

[0043] (1) Adopt clean steel smelting method to reduce S and P content in steel, LF refining time is more than 40min, RH vacuum treatment, vacuum degree ≤5mbar and keep for more than 20min, after RH vacuum treatment, H≤1.0ppm. The continuous casting adopts light reduction technology to ensure the internal quality of the 320mm continuous casting slab. The superheating degree of continuous casting molten steel is 5°C to 30°C.

[0044] (2) The temperature of the billet into the furnace is ≥200°C, the preheating section is heated slowly, and the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com