Device for measuring parallel degree, distortion degree and center distance of large and small head holes of connecting rod of piston engine

A piston engine and measuring device technology, which is applied to measuring devices, fixing devices, mechanical equipment, etc., can solve the problems of not being easy to use, expensive and not portable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

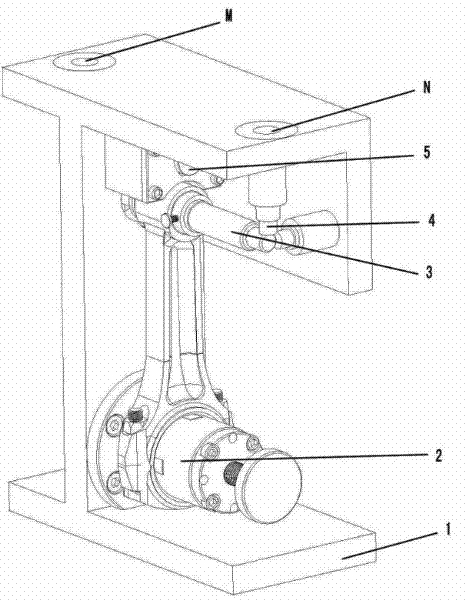

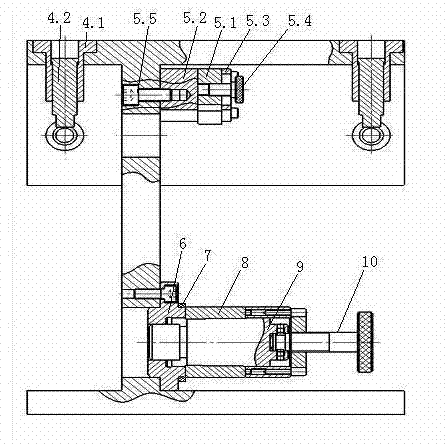

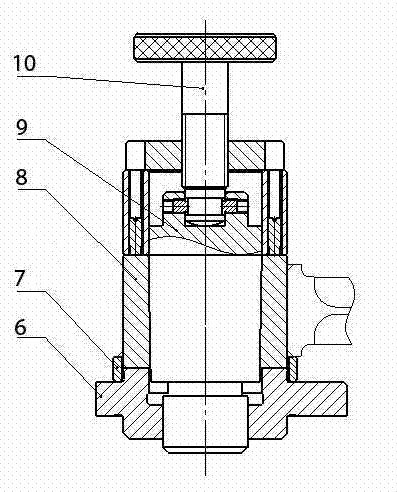

[0027] Such as figure 1 , figure 2 , image 3 , Figure 6 , Figure 7 As shown, the measuring device for parallelism, torsion, and center distance of the connecting rod of the piston engine includes a base 1, a connecting rod positioning mechanism 2, a connecting rod fastening mechanism 5, a measuring shaft 3, and a measuring contact 4; The base 1 has a bottom plate, a vertical vertical plate, a horizontal top plate, and a vertical side plate. The bottom plate, top plate, and vertical plate are combined into an "I" shape, and the side plate and the top plate are combined into an "L" shape. , the facade of the vertical plate, the top surface of the top plate, and the external surface of the side plate are three-dimensional reference planes; the connecting rod positioning mechanism is assembled on the lower part of the vertical plate, and the connecting rod is vertically arranged, and its low hole is sleeved on the positioning mechanism, so that The central axis of the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com