Titanium dioxide nanotube array film, preparation method thereof and photoelectric device

A technology of nanotube array and titanium dioxide, which is applied in the field of materials, can solve problems such as the difficulty in preparing large-sized and complete titanium dioxide nanotube array films, and achieve excellent photoelectric performance and application value, smooth film layers, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

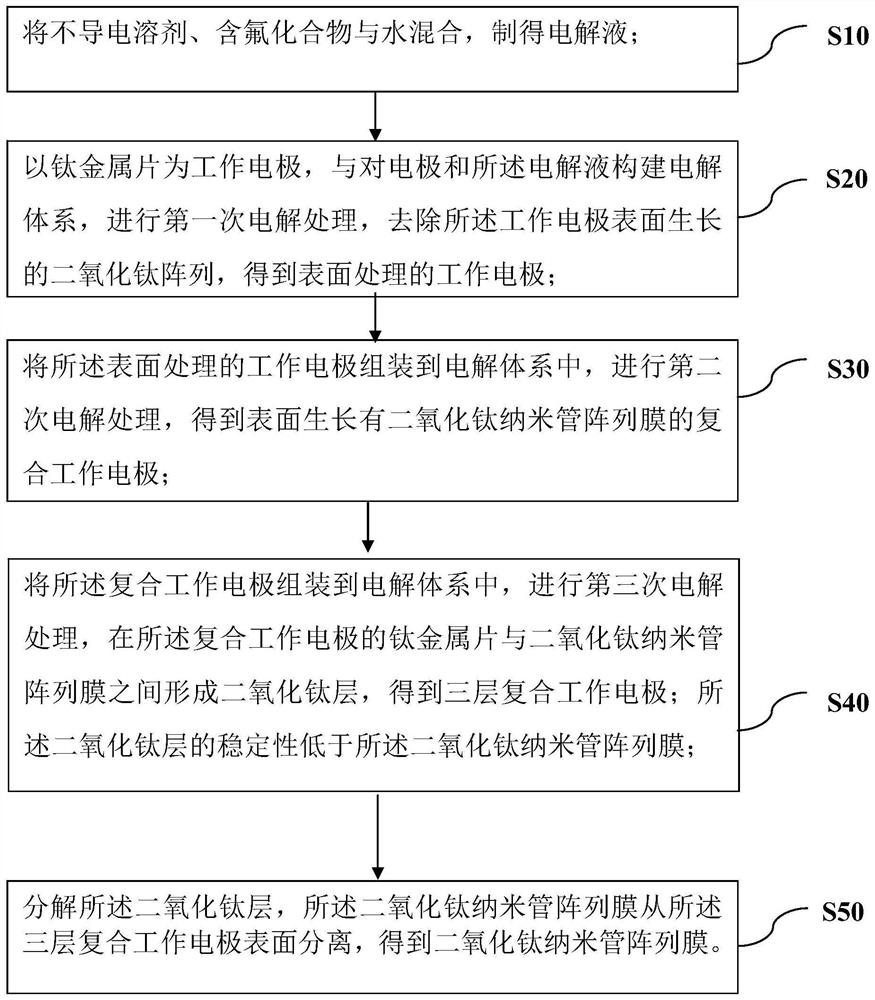

[0045] as attached figure 1 As shown, the first aspect of the embodiment of the present application provides a method for preparing a titanium dioxide nanotube array film, comprising the following steps:

[0046] S10. mixing a non-conductive solvent, a fluorine-containing compound and water to prepare an electrolyte;

[0047] S20. Using the titanium metal sheet as the working electrode, constructing an electrolytic system with the counter electrode and electrolyte, performing the first electrolytic treatment, removing the titanium dioxide array grown on the surface of the working electrode, and obtaining a surface-treated working electrode;

[0048] S30. Assembling the surface-treated working electrode into the electrolytic system, performing a second electrolytic treatment, and annealing to obtain a composite working electrode with a titanium dioxide nanotube array film grown on the surface;

[0049] S40. Assemble the composite working electrode into the electrolysis system,...

Embodiment 1

[0079] A titanium dioxide nanotube array film, the preparation of which comprises the steps of,

[0080] ① Cut the titanium sheet into a size of 3cm×3cm. Ultrasonic cleaning is performed on the cut titanium sheet, first in acetone for 10 minutes, then in 10% hydrochloric acid for 10 minutes, and finally in ethanol for 10 minutes, after ultrasonic cleaning, place it in an oven at 60°C to dry .

[0081] ②Preparation before anodic oxidation: Anodic oxidation is carried out with a two-electrode system. The opposite electrode uses the same titanium metal sheet as the anode, and the back of the titanium metal sheet on the anode is pasted with insulating tape.

[0082] Preparation of electrolyte: use ethylene glycol as solvent, solute ammonium fluoride (NH 4 F) and deionized water, add the NH of solvent quality 0.1% 4 F, adding 2% deionized water by solvent volume, the preparation sequence is to NH 4 F added deionized water, NH 4 After F is completely dissolved, add ethylene gly...

Embodiment 2

[0088] A titanium dioxide nanotube array film, the preparation of which comprises the steps of,

[0089]① Cut the titanium sheet into a size of 5cm×5cm. Perform ultrasonic cleaning on the cut titanium sheet, first ultrasonic cleaning in acetone for 20 minutes, then ultrasonic cleaning in 5% hydrochloric acid for 20 minutes, and finally ultrasonic cleaning in ethanol for 20 minutes, after ultrasonic cleaning, place it in an oven at 60°C to dry .

[0090] ②Preparation before anodic oxidation: Anodic oxidation is carried out with a two-electrode system. The opposite electrode uses the same titanium metal sheet as the anode, and the back of the titanium metal sheet on the anode is pasted with insulating tape.

[0091] Preparation of electrolyte: use ethylene glycol as solvent, solute ammonium fluoride (NH 4 F) and deionized water, add the NH of solvent mass 0.5% 4 F, adding 1% deionized water by solvent volume, the preparation sequence is to NH 4 F added deionized water, NH 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com