Lapping device capable of improving mandrel diameter difference and lapping method of lapping device

A lapping and mandrel technology, which is applied in the field of lapping devices to improve the diameter difference of mandrels, can solve the problems of large diameter differences of optical fiber preforms, uneven distribution of mandrel diameters, scrapped optical fiber preforms, etc., and achieve the improvement of wire drawing qualification rate, optimize diameter uniformity, and improve the effect of diameter uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

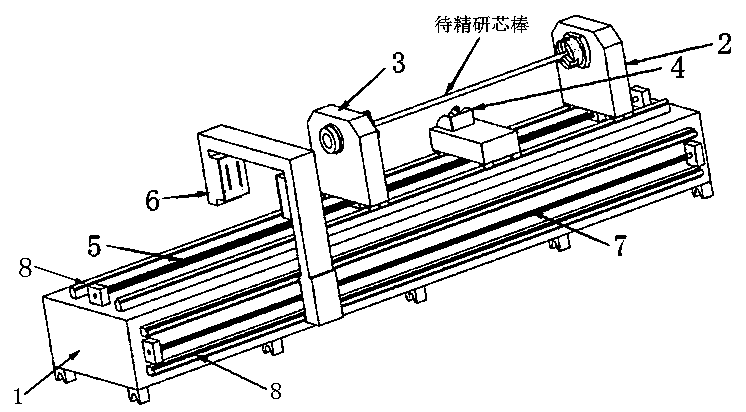

[0033] Specific embodiment 1: Carry out lapping on mandrels of up to standard length with wrinkled appearance or other defects and mandrels of up to standard length with uneven diameters. Such as figure 2 As shown, firstly carry out PK test on mandrel A with wrinkled appearance or other defects or non-uniform diameter and reach the standard length, then degrease, clean, dry, anneal and remove residual stress to obtain the mandrel to be lapped, and then fix it by The movable jaws of chuck 2 and sliding chuck 3 fasten the rods at both ends of mandrel A to be lapped, turn on the start switch, and the fixed chuck 2, sliding chuck 3, blowtorch 4 and diameter scanner on the lapping device 6 is electrically connected to the controller, click the "Start" button on the controller, the controller drives the diameter scanner 6 to move along the second drive screw 7 and the boss slideway 8 on the side bed surface of the lapping machine 1 to measure the The diameter of the mandrel A is l...

specific Embodiment 2

[0034] Specific embodiment 2: butt jointing and lapping of mandrels with insufficient segment lengths and uneven joint diameters. Such as image 3 As shown, the two mandrels C with insufficient segment length are firstly subjected to the mandrel PK test, followed by degreasing, cleaning, drying, annealing and residual stress removal treatment, and then the two mandrels C with insufficient segment length after the above treatment Fix on the fixed chuck 2 and sliding chuck 3 respectively, turn on the start switch, the fixed chuck 2, sliding chuck 3, blowtorch 4 and diameter scanner 6 on the lapping device are electrically connected to the controller, click on the controller Press the "Start" button on the button, the controller drives the blowtorch 4 to slide along the first transmission screw 5 and the boss slideway 8 on the upper surface of the lapping machine 1 to the docking ends of the two mandrels C with insufficient length, and manually ignites the blowtorch 4 Heat the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com