Carton manufacturing device

A technology for manufacturing devices and cartons, which is applied in the field of carton manufacturing devices, can solve problems such as slow folding, poor precision, and large folding errors, and achieve the effects of preventing quality problems, ensuring accuracy, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing, but should not be construed as limiting the present invention:

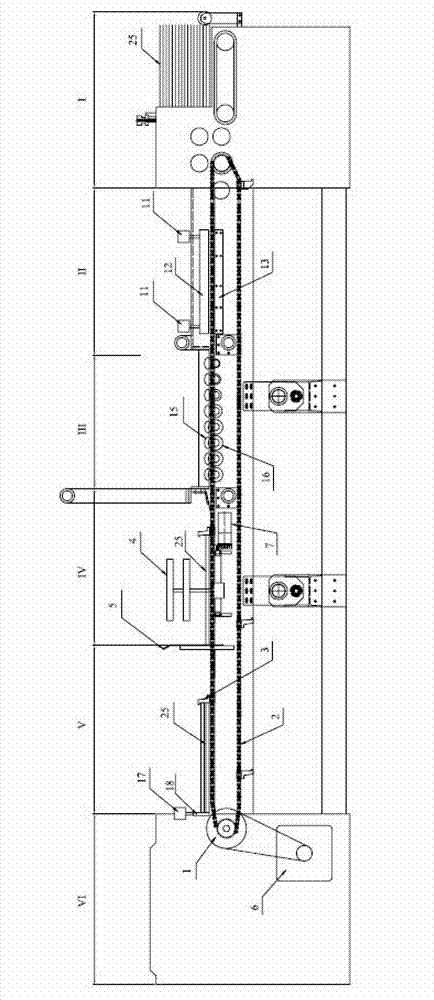

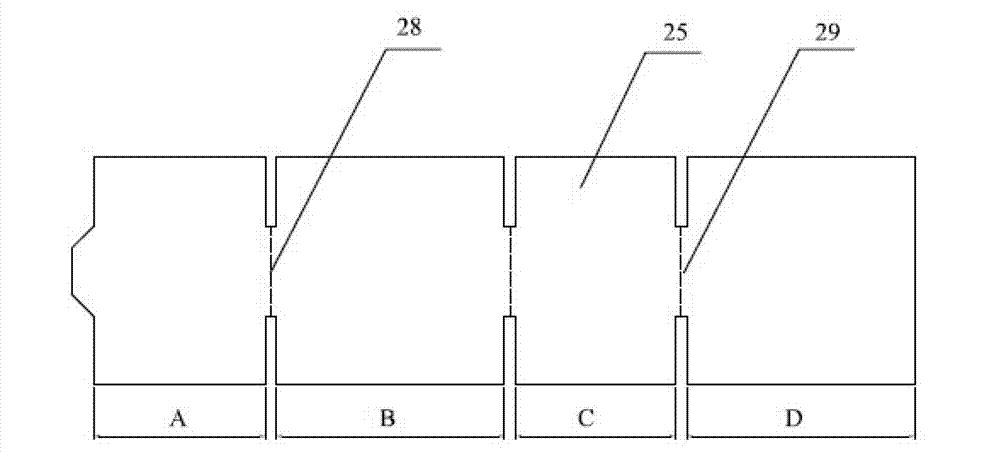

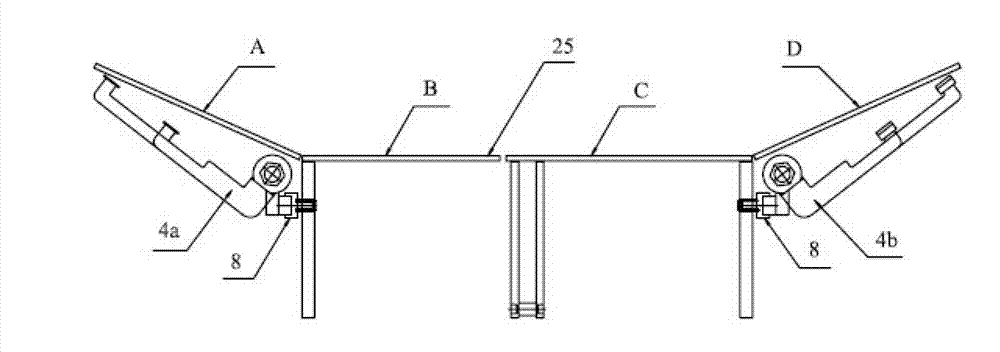

[0045] figure 1 It is a structural schematic diagram of the present invention, figure 2 is the unfolded cardboard schematic, image 3 is a schematic diagram of the structure of the robotic arm when it is not folded, Figure 4 It is a schematic diagram of the structure of the mechanical arm when it is folded, combined with figure 1 , figure 2 , image 3 , Figure 4As shown, a carton manufacturing device, which sequentially includes a paper feeding part I, a folding part II and a nail box gluing part IV from upstream to downstream, specifically includes a chain drive shaft 1, a chain 2, a cardboard conveying block 3, a mechanical The arm 4 and the positioning baffle 5, the chain driving shaft 1 is hung with multiple rows of chains 2, in use, the chains 2 are 2 or 3 or 4 rows, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com