Array substrate, preparation method thereof and display panel

An array substrate and substrate substrate technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of poor TFT stability, uneven display screen, start-up voltage drift, etc., to improve working stability, Avoid short circuits and improve user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

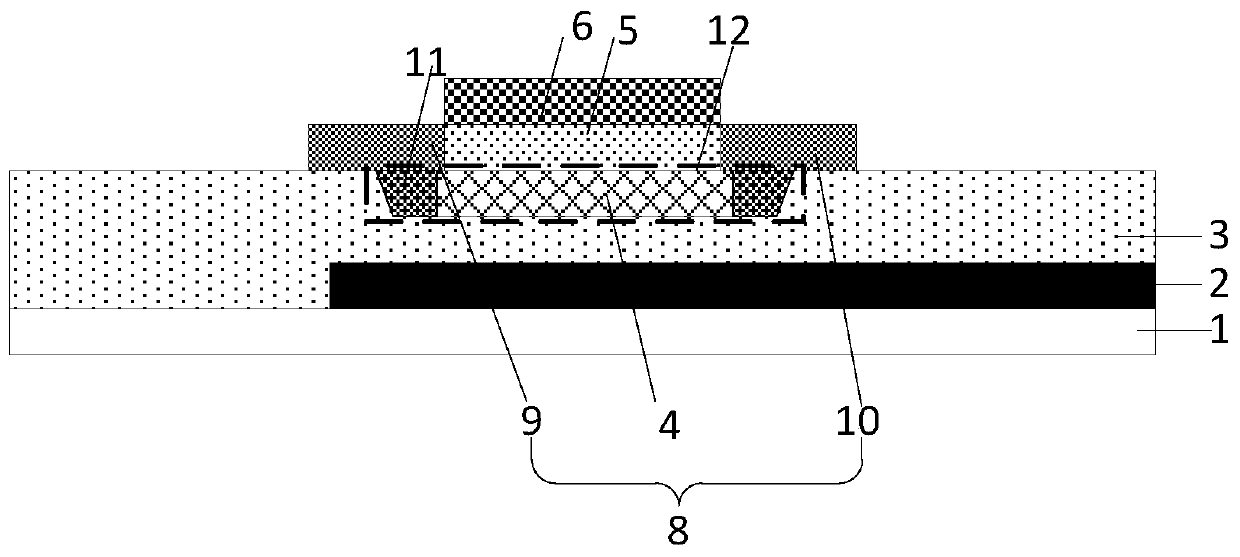

[0063] The embodiment of the present application provides an array substrate, such as figure 2 As shown, the array substrate includes: a base substrate 1, a light-shielding layer 2 on the base substrate 1, a buffer layer 3 on the light-shielding layer 2, and a buffer layer 3 on the buffer layer 3. a source layer 8, and a light shielding portion 11; the buffer layer 3 has a groove 12;

[0064] The active layer 8 includes: a semiconductor region 4, and a first conductorized region 9 and a second conductorized region 10 of the semiconductor region 4;

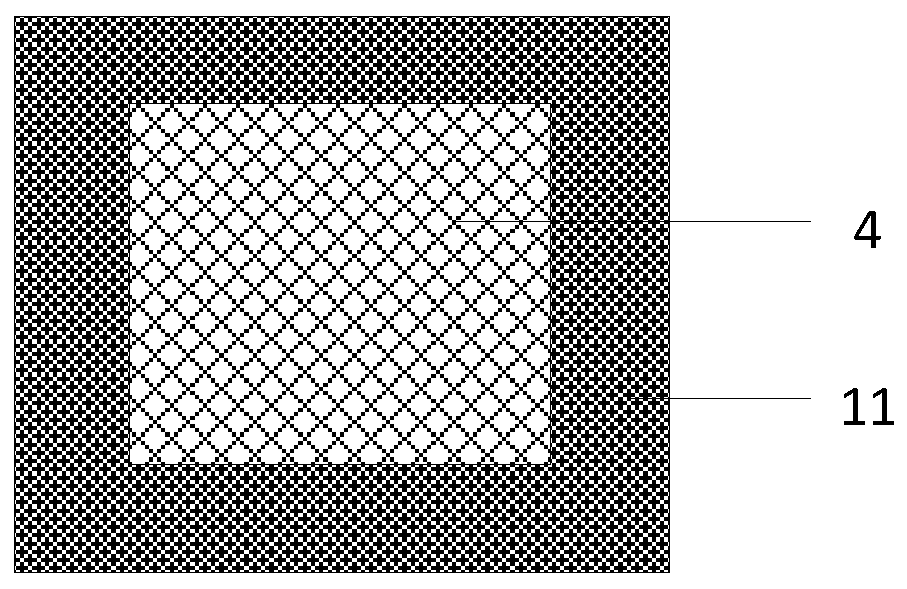

[0065] The semiconductor region 4 and the light shielding portion 11 fill the groove 12; as image 3 As shown, the shape of the orthographic projection of the light-shielding portion 11 on the base substrate 1 is ring-shaped, the side surface of the semiconductor region 4 is completely surrounded by the light-shielding portion 11, the first conductive region 9 and the The second conductive region 10 is located on the light shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com