High-voltage flexible LED patch lamp tape and manufacturing technology and mounting method thereof

A technology of LED SMD lamps and LED SMDs, which is applied to lighting devices, components of lighting devices, slender light sources, etc., can solve the problems of potential safety hazards, large volume, and complicated installation, so as to improve the safety of use, The effect of simplifying the circuit structure and avoiding electric shock accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

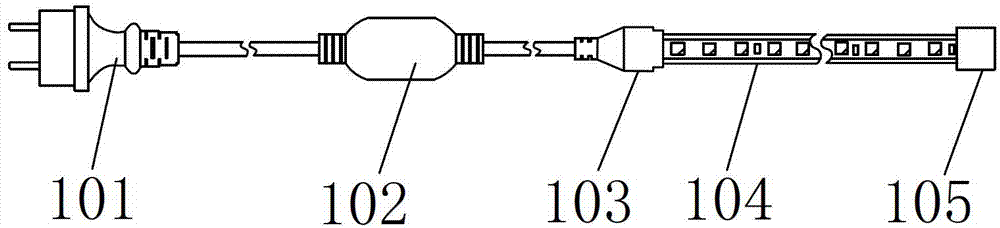

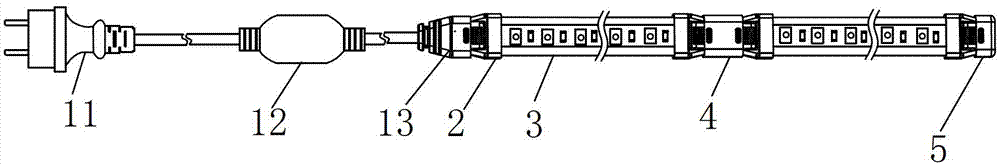

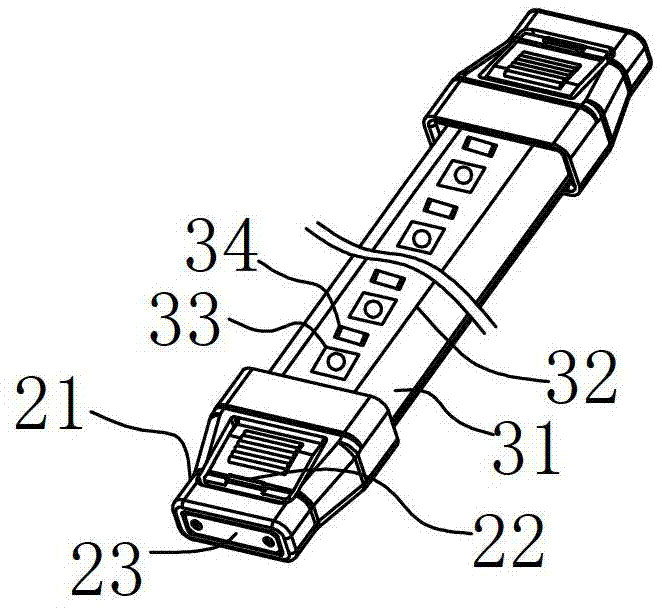

[0044] refer to Figure 2 to Figure 12 , a high-voltage flexible LED patch light strip of the present invention is mainly composed of a light strip unit 3 or more than one light strip unit 3 connected back and forth, the light strip unit 3 includes a transparent flexible sleeve 31 and is packaged in a transparent The double-sided flexible strip-shaped circuit board 32 in the flexible sleeve 31, specifically, the transparent flexible sleeve 31 preferably adopts a PVC sleeve with good waterproof performance, and the front assembly of the double-sided flexible strip-shaped circuit board 32 There are several LED patch lamp beads 33, and the LED patch lamp beads 33 are electrically connected through the printed conductive lines arranged on the front side of the double-sided flexible strip circuit board 32, and the reverse side of the double-sided flexible strip circuit board 32 is provided There are at least two printed power supply main lines, and the double-sided flexible strip c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com