A kind of polylactic acid elastic superfine fiber nonwoven material and its preparation method and application

A technology of non-woven materials and ultra-fine fibers, which is applied in non-woven fabrics, cellulose/protein conjugated artificial filaments, fiber treatment, etc., can solve the problem of destroying the biodegradable properties of polylactic acid, high production costs, and complex production processes and other issues, to achieve the effect of enhancing mechanical properties, saving resources, and enriching application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

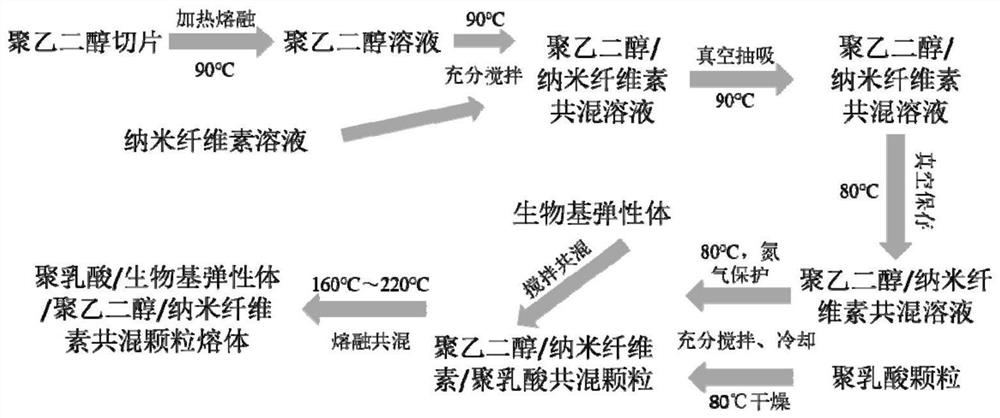

[0045] A kind of preparation method of polylactic acid elastic microfiber nonwoven material, its raw material preparation process is as follows figure 1 As shown, the specific preparation steps are as follows:

[0046] (1) Preparation of polyethylene glycol / nanocellulose blend solution:

[0047] First, a certain amount of polyethylene glycol slices with a molecular weight of 6000 was heated in a water bath at 90°C to fully dissolve it into a liquid state; then it was blended with the nanocellulose solution at a ratio of 1:1, and stirred for 2 hours under heating to make it fully mixed; Vacuum suction device, under the condition of heating in a water bath at 100°C, the water vapor is fully evaporated to obtain a polyethylene glycol / nanocellulose blend solution; then the prepared polyethylene glycol / nanocellulose blend solution is sealed at 80°C Stored in a vacuum oven for later use.

[0048] (2) Preparation of polylactic acid / polyethylene glycol / nanocellulose blended raw mate...

Embodiment 2

[0060] A preparation method of polylactic acid elastic superfine fiber nonwoven material, the steps are as follows:

[0061] The preparation method of this example is the same as that of Example 1, the difference is that the ratio of polylactic acid particles to thermoplastic polyurethane elastomer after polyethylene glycol / nanocellulose treatment in step (3) is 6:4, and the obtained The characteristic test results of polylactic acid elastic microfiber nonwoven materials with the ratio of polylactic acid / thermoplastic polyurethane elastomer / polyethylene glycol / nanocellulose at 6:4:1:1 are shown in Table 1.

Embodiment 3

[0063] A preparation method of polylactic acid elastic superfine fiber nonwoven material, the steps are as follows:

[0064] The preparation method of this example is the same as that of Example 1, the difference is that in step (3) the bio-based elastomer is a thermoplastic polyester elastomer, and the polylactic acid particles treated with polyethylene glycol / nanocellulose are mixed with thermoplastic polyester The blending ratio of ester elastomer is 7:3, and the characteristic test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com