Polyimide nanofiber membrane as well as preparation method and application thereof

A nanofiber membrane and polyimide technology, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, single-component synthetic polymer rayon, etc., can solve the problem of polyimide nanofiber membrane with large surface pore size and easy ion conduction. Through the diaphragm strength and other issues, to achieve the effect of reducing the diameter of nanofibers, good uniformity of film thickness, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

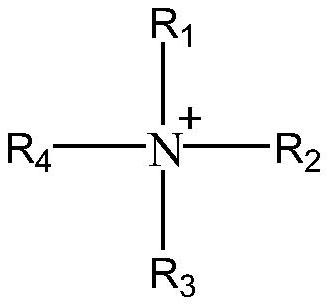

[0042] 1. Preparation of polyamic acid salt: Dissolve 4.05g of p-phenylenediamine (PDA) in 85g of N,N-dimethylacetamide (DMAc), at 25°C N 2 Stir under protection, after completely dissolving, add 10.95g of biphenyl tetraic acid dianhydride (BPDA), continue stirring for 1 hour after the addition, and obtain a polyamic acid (PAA) solution with a solid content of 15%. Add a certain amount of triethylamine to the PAA solution, the molar ratio of PAA and triethylamine is 1:2, and stir well for 2 hours to prepare a polyamic acid salt solution. The surface tension of the obtained solution is 28mN / m, and the apparent viscosity is 245Pa ·s.

[0043] 2. Preparation of spinning stock solution: slowly add the polyamic acid salt solution into 60 g of water, the surface tension of the mixed solution is 52 mN / m, and the apparent viscosity is 12 Pa·s.

[0044]3. Electrospinning: Using needleless electrospinning technology, add the above solution into the closed storage tank of the high-volta...

Embodiment 2

[0048] 1. Preparation of polyamic acid salt: Dissolve 2.70g of p-phenylenediamine (PDA) in 90g of N,N-dimethylacetamide (DMAc), at 25°C N 2 Stir under protection, and after complete dissolution, add 7.30 g of biphenyl tetraic acid dianhydride (BPDA), and continue stirring for 1 hour after the addition, to obtain a polyamic acid (PAA) solution with a solid content of 10%. Add a certain amount of triethylamine to the PAA solution, the molar ratio of PAA and triethylamine is 1:2, stir well for 2 hours to prepare a polyamic acid salt solution, the surface tension of the obtained solution is 22mN / m, and the apparent viscosity is 205Pa ·s.

[0049] 2. Preparation of spinning stock solution: slowly add the polyamic acid salt solution into 90 g of water, the surface tension of the mixed solution is 65 mN / m, and the apparent viscosity is 5 Pa·s.

[0050] The remaining steps are according to Example 1.

[0051] The obtained polyimide nanofibers had an average diameter of 6 nm, a diame...

Embodiment 3

[0053] 1. Preparation of polyamic acid salt: Dissolve 5.40g of p-phenylenediamine (PDA) in 80g of N,N-dimethylacetamide (DMAc), at 25°C N 2 Stir under protection, and after complete dissolution, add 14.60 g of biphenyl tetraic acid dianhydride (BPDA), and continue stirring for 1 hour after the addition, to obtain a polyamic acid (PAA) solution with a solid content of 20%. Add a certain amount of triethylamine to the PAA solution, the molar ratio of PAA and triethylamine is 1:2, stir well for 2 hours to prepare a polyamic acid salt solution, the surface tension of the obtained solution is 36mN / m, and the apparent viscosity is 280Pa ·s.

[0054] 2. Preparation of spinning stock solution: slowly add the polyamic acid salt solution into 40 g of water, the surface tension of the mixed solution is 41 mN / m, and the apparent viscosity is 20 Pa·s.

[0055] The remaining steps are according to Example 1.

[0056] The obtained polyimide nanofibers had an average diameter of 15 nm, a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com