Method for preparing dandelion phenol activity antibacterial agent and chitosan composite nanofiber felt

A technology of composite nanofibers and dandelions, which is applied in the directions of fiber processing, fiber chemical characteristics, rayon manufacturing, etc., achieves the effects of simple preparation, high porosity, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

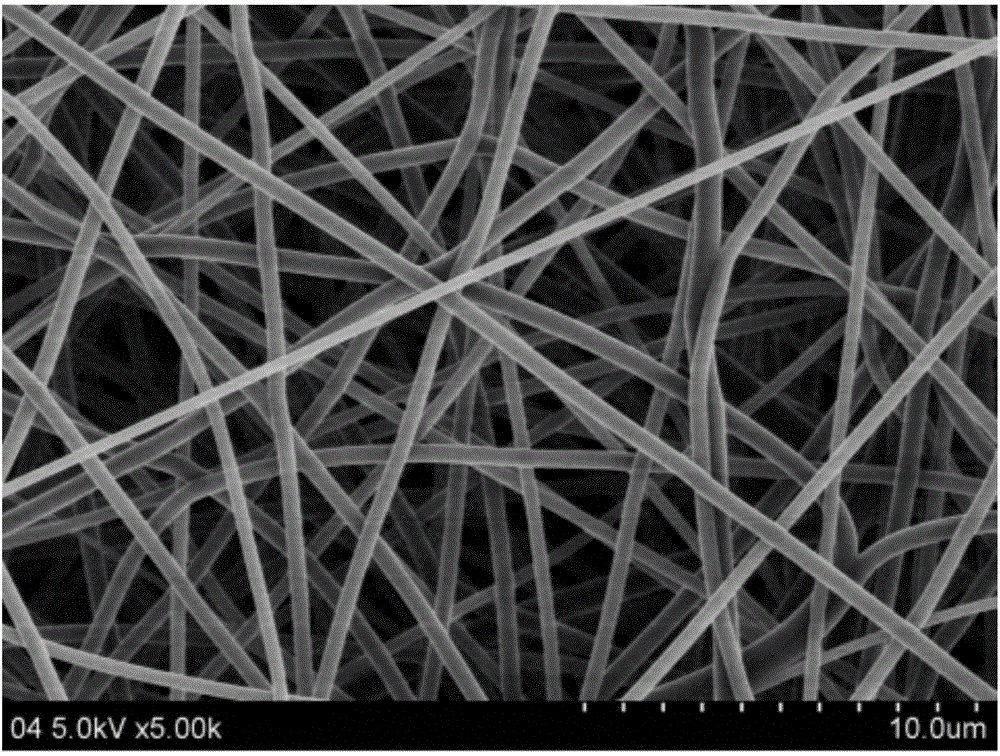

Image

Examples

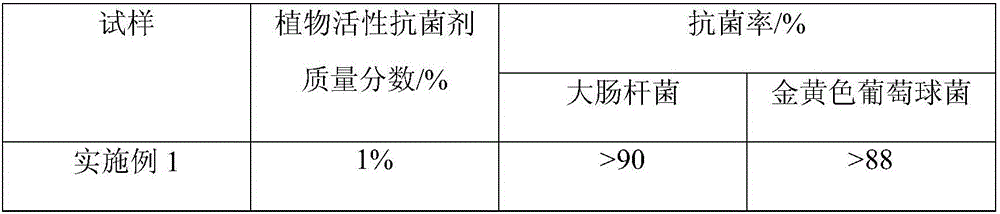

Embodiment 1

[0026] Take 500 grams of air-dried samples of dandelion medicinal materials, cut them into small pieces, heat and extract twice with 50% ethanol aqueous solution, use 8 times the amount for the first time, and use 6 times the amount for the second time. The first extraction was 2 hours, the second extraction was 1.5 hours, concentrated, loaded on the treated macroporous adsorption resin, washed with water until the color was lighter, and then eluted with 50% ethanol until the color was light, and the eluent was reduced. Compression recovery, spray drying to obtain raw material fine powder, that is, dandelion phenol active antibacterial agent.

[0027] Dissolve 0.6 gram of chitosan in 15 ml of formic acid (mass volume concentration 88%), and magnetically stir until completely dissolved to obtain a chitosan solution with a concentration of 0.04 g / ml.

[0028] Take 0.006 g of dandelion phenol active antibacterial agent and add it to the prepared chitosan solution and mix it, stir...

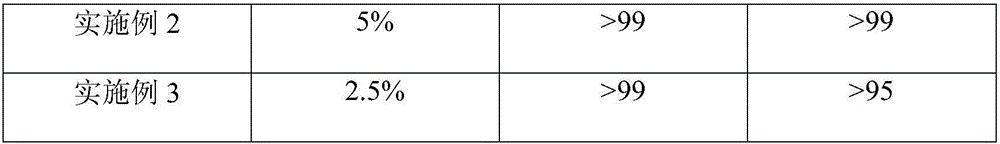

Embodiment 2

[0032] Take 1000 grams of fresh dandelion plants, wash and cut into small pieces, heat and extract three times with 50% ethanol aqueous solution, use 10 times the amount for the first time, use 8 times the amount for the second time, and use 6 times the amount for the second time. The first extraction was 3 hours, the second extraction was 2 hours, the third extraction was 1 hour, concentrated, loaded on the treated macroporous adsorption resin, washed with water until the color was lighter, and then eluted with 50% ethanol to The color is light, the eluent is recovered under reduced pressure, and the fine powder of the raw material is obtained by spray drying, that is, the active antibacterial agent of dandelion phenol is obtained.

[0033] Dissolve 0.75 gram of chitosan in 15 ml of formic acid (mass volume concentration 88%), and magnetically stir until completely dissolved to obtain a chitosan solution with a concentration of 0.05 g / ml.

Embodiment 3

[0038] Take 600 grams of air-dried dandelion medicinal samples, cut into small pieces, heat and extract twice with 50% ethanol aqueous solution, use 8 times the amount for the first time, and use 5 times the amount for the second time. The first extraction was for 3 hours, the second extraction was for 1.5 hours, concentrated, loaded on the treated macroporous adsorption resin, washed with water until the color was lighter, and then eluted with 50% ethanol until the color was light, and the eluent was reduced. Compression recovery, spray drying to obtain raw material fine powder, that is, dandelion phenol active antibacterial agent.

[0039] Dissolve 0.3 gram of chitosan in 10 ml of formic acid (mass volume concentration 88%), and magnetically stir until completely dissolved to obtain a chitosan solution with a concentration of 0.05 g / ml.

[0040] Take 0.003 g of plant active antibacterial agent and add it into the prepared chitosan solution and mix, magnetically stir for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com