System and method for reducing carbon fiber spinning stoste bubbles

A technology of spinning stock solution and carbon fiber, which is applied in spinning solution filtration, fiber treatment, filament forming treatment, etc., can solve the problems such as poor gas removal effect, achieve low cost, small fluctuation range of raw silk strength, average Effect of Tensile Strength Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

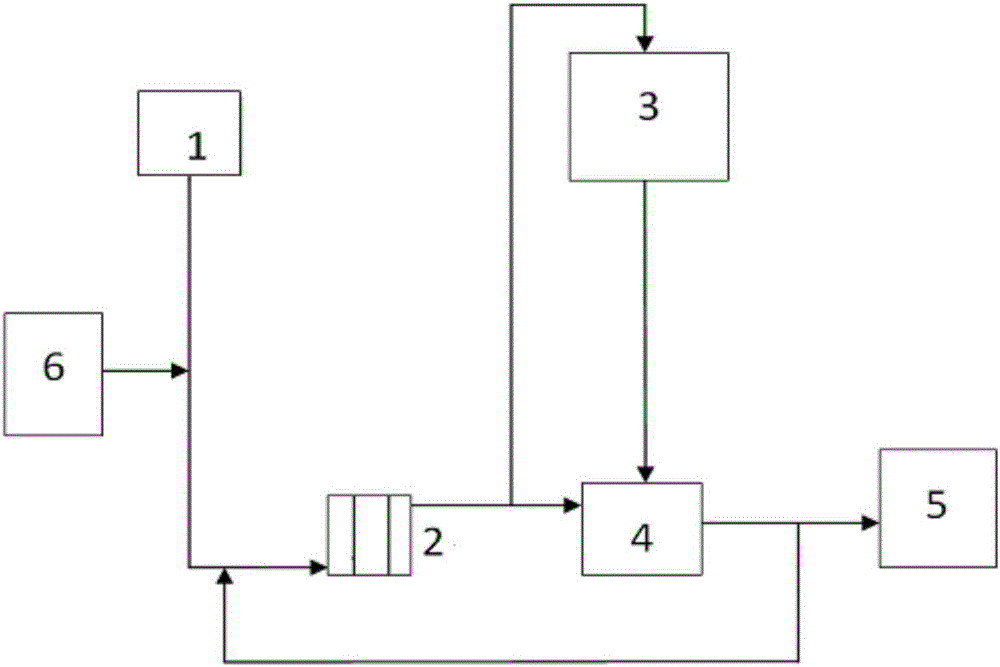

Image

Examples

Embodiment 1

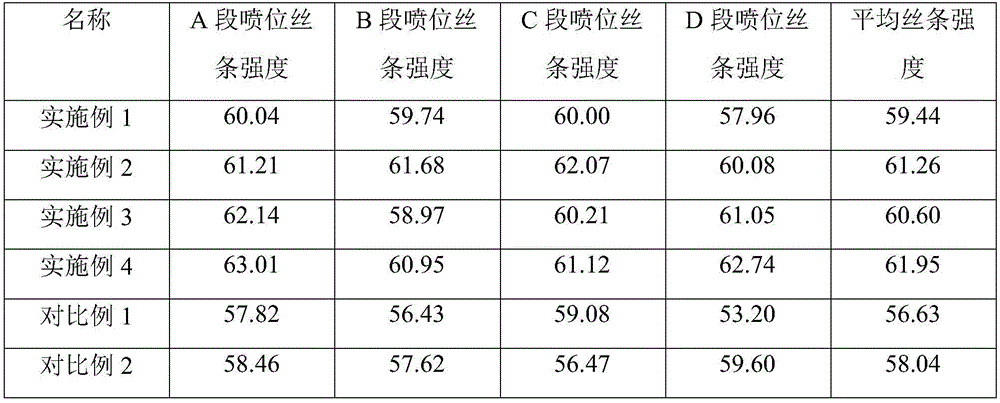

[0027] Intrinsic viscosity is the spinning dope of 1.4dl / g from two-stage single-degassing tower 1 (umbrella) in 2m 3 After flowing out per hour, it flows into the buffer tank 3 after passing through the stock solution preheater 2. The temperature of the spinning stock solution is 70°C, and the volume of the buffer tank 3 is 18m 3 , and then enter the three-stage single-degassing and degassing tower 4 (umbrella), the spinning stock solution temperature is 70 ° C, enter the spinning unit 5 after the three-stage de-singling and degassing tower 4, and spin, and the spinning speed is 70m / min. The tensile strength of the obtained 24K filaments is shown in Table 1 below.

Embodiment 2

[0029] The spinning stock solution with an intrinsic viscosity of 1.4dl / g is taken from the second-stage single-degassing and degassing tower 1 at a rate of 2m 3 After flowing out per hour, it flows into the buffer tank 3 after passing through the stock solution preheater 2. The temperature of the spinning stock solution is 85°C, and the volume of the buffer tank 3 is 30m 3 , enters the three-stage single-separation and degassing tower 4, the spinning stock solution temperature is 85°C, and after passing through the three-stage single-separation and degassing tower 4, enters the spinning unit 5 for spinning at a spinning speed of 70m / min. The tensile strength of the obtained 24K filaments is shown in Table 1 below.

Embodiment 3

[0031] The spinning stock solution with an intrinsic viscosity of 2dl / g is taken from the second-stage single-degassing and degassing tower 1 at a rate of 2m 3 After flowing out per hour, it flows into the buffer tank 3 through the stock solution preheater 2, the temperature of the spinning stock solution is 100°C, and the volume of the buffer tank 3 is 30m 3, enters the three-stage single removal and degassing tower 4, and the spinning stock solution temperature is 100° C. After passing through the three-stage single removal and degassing tower 4, it enters the spinning unit 5 for spinning at a spinning speed of 40 m / min. The tensile strength of the obtained 48K filaments is shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com