Bushing temp controller

A technology of temperature control device and shaft sleeve, which is applied in the direction of temperature control by electric means, manufacturing tools, glass manufacturing equipment, etc. It can solve problems such as instability, inability to adjust the current flow of shunt circuits, and complicated temperature adjustment operations, and achieve spinning The effect of high efficiency of wire operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same element in each figure, and overlapping description is abbreviate|omitted. In addition, the dimensional ratios in the drawings do not necessarily match the descriptions.

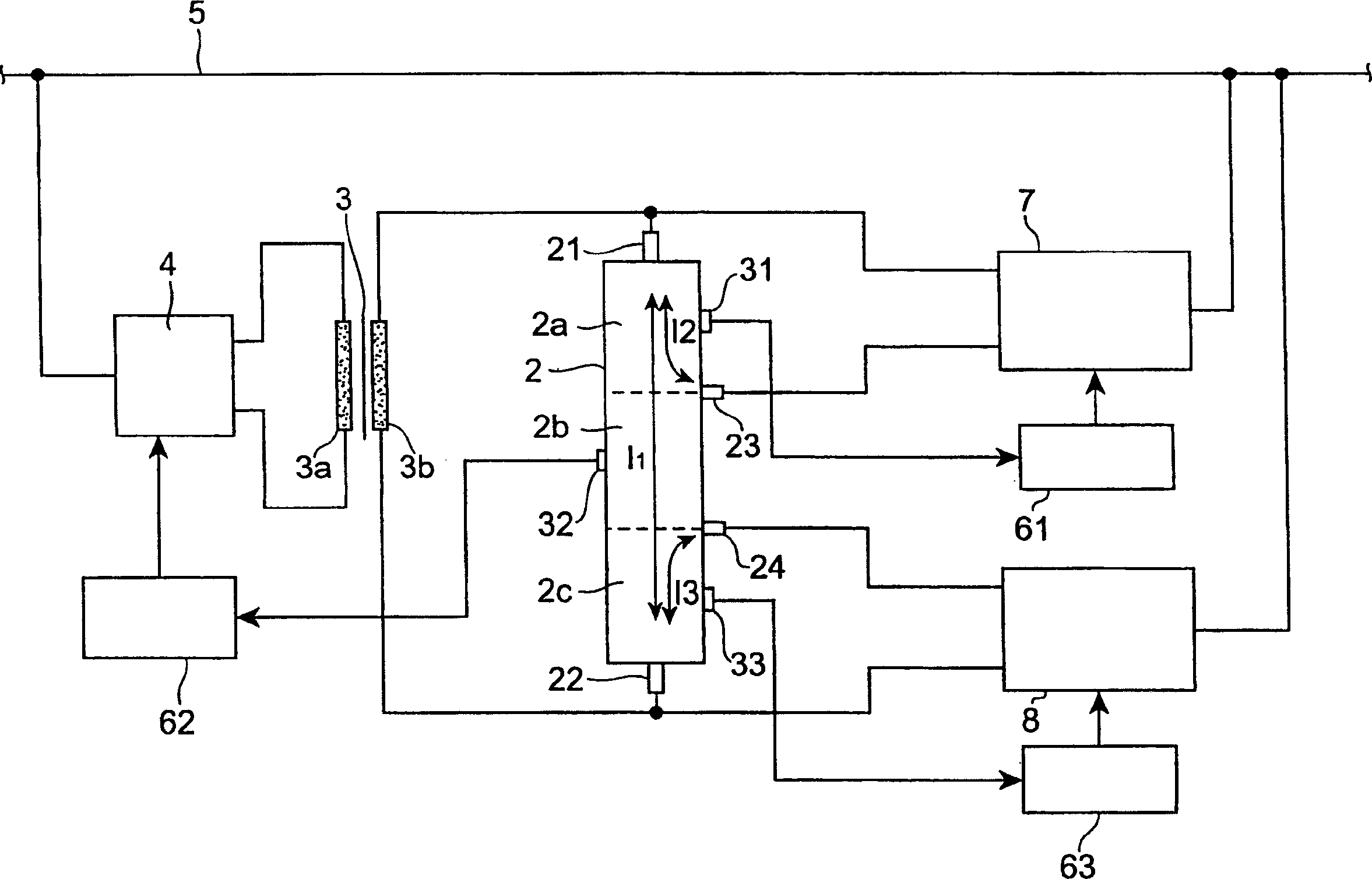

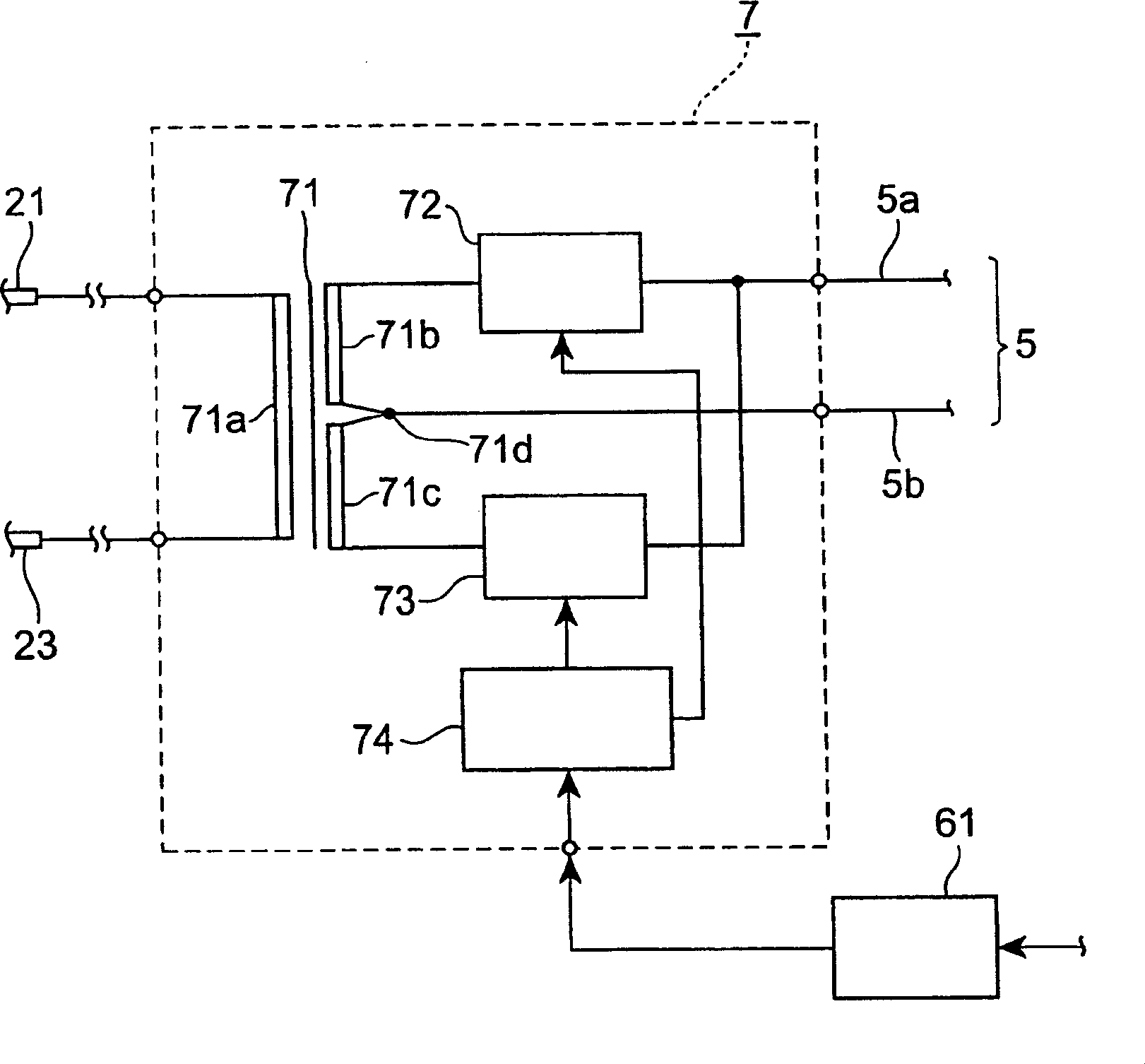

[0022] figure 1 It is a schematic diagram showing the configuration of the sleeve temperature control device according to the present embodiment.

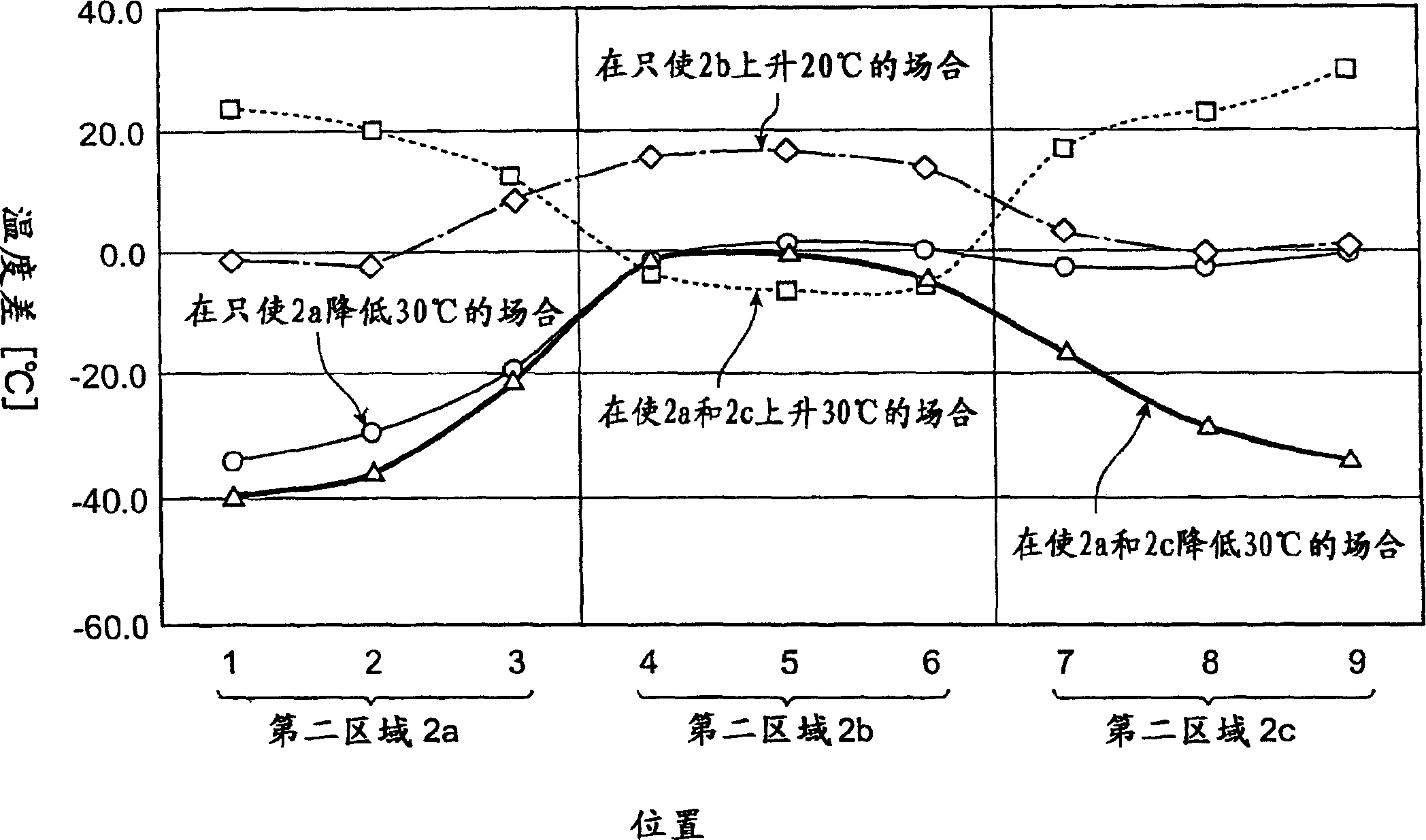

[0023] As shown in this figure, the sleeve temperature control device 1 according to this embodiment is a device for controlling the temperature of the sleeve 2, and controls the temperature of the sleeve 2 by passing a predetermined current through the sleeve 2 and adjusting the current flow amount. The temperature of the bushing 2 means. The bushing 2 is a container for storing molten glass, and the molten glass is flowed out from a plurality of holes (not shown) formed in the bottom to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com