Rotary needleless spinning device

A rotary, needle-spinning technology, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of easy change of physical or chemical properties of the solution, unstable spinning, etc., and achieve the physical or chemical properties of the solution. Stable, guaranteed physical or chemical properties, guaranteed uniformity of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

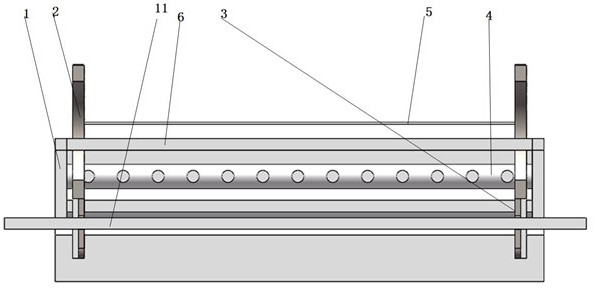

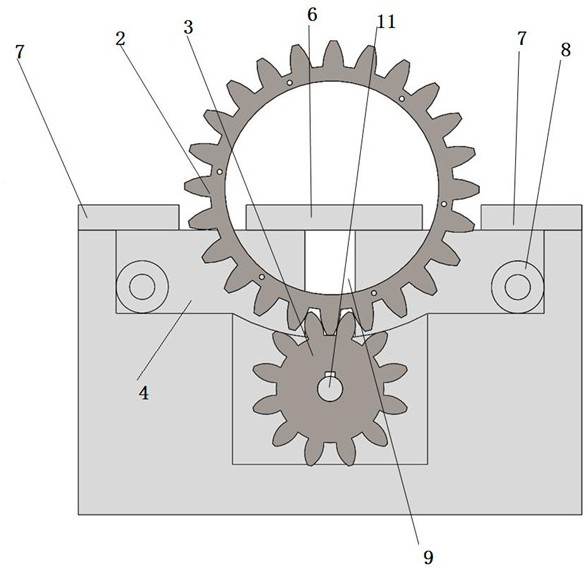

[0029] A rotary needleless spinning device, such as Figure 1-3 As shown, the device body 1 is included, the device body is provided with a hollow disc 2, a rotating gear 3 and a solution tank 4, the hollow disc is provided with an electrode wire 5, and the rotating gear can drive the hollow disc to rotate , so as to drive the electrode wire on the hollow disc to rotate; the solution tank is arranged below the hollow disc, and when the hollow disc rotates, a part at the lower part is always in the solution tank, so that the hollow The electrode wire on the disc can walk through the solution in the solution tank, and take part of the liquid when it rotates out of the liquid surface.

[0030] The device body is also provided with an electrode inner cover plate 6 and an electrode outer cover plate 7, and the electrode inner cover plate covers the inner side of the hollow disk and the cavity above the apex of the rotating gear; the overall height of the electrode outer cover plate...

Embodiment 2

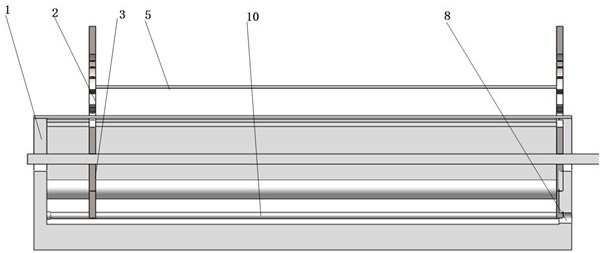

[0039] A rotary needleless spinning device, such as Figure 4 As shown, the device body 1 is included, the device body is provided with a hollow disc 2, a rotating gear 3 and a solution tank 4, the hollow disc is provided with an electrode wire 5, and the rotating gear can drive the hollow disc to rotate , so as to drive the electrode wire on the hollow disc to rotate; the solution tank is arranged below the hollow disc, and when the hollow disc rotates, a part at the lower part is always in the solution tank, so that the hollow The electrode wire on the disc can walk through the solution in the solution tank, and take part of the liquid when it rotates out of the liquid surface.

[0040] The device body is also provided with an electrode inner cover plate 6 and an electrode outer cover plate 7, and the electrode inner cover plate covers the inner side of the hollow disk and the cavity above the apex of the rotating gear; the overall height of the electrode outer cover plate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com