Fire preventing and extinguishing gel for coal mine, and preparation method thereof

A technology for fire-fighting and coal mines, applied in fire-fighting equipment and other directions, can solve problems such as unfavorable fire-fighting work, deterioration of underground production environment, etc., and achieve the effects of controllable glue formation time, good viscoelasticity and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

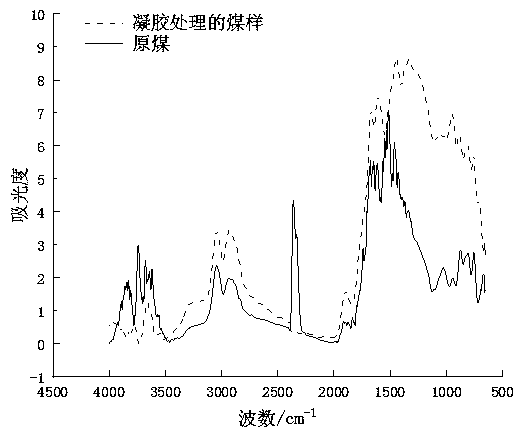

Image

Examples

Embodiment 1

[0034] 1) Prepare sodium carboxymethyl cellulose solution: at room temperature, slowly and evenly add 2 g sodium carboxymethyl cellulose to 100 ml of water, and stir rapidly while adding. You can stop stirring and let it stand for a period of time (10-20 hours) until the sodium carboxymethylcellulose is completely dissolved before use;

[0035] 2) Configure a zirconium chloride solution with a mass fraction of 20%, add citric acid at a ratio of zirconium tetrachloride: citric acid mass ratio of 2:1, and keep stirring until complete reaction to form a zirconium citrate solution;

[0036] 3) Prepare a certain amount of 5% sodium hydroxide solution;

[0037] 4) To the zirconium citrate solution prepared in step 2), titrate 5% sodium hydroxide solution at a rate of 30 drops per minute, and monitor its pH value until the pH value rises to about 7 to stop the titration. When there is white precipitation in the solution, after standing for a period of time, the solution becomes a cl...

Embodiment 2

[0043] 1) Prepare sodium carboxymethyl cellulose solution, add 2.5g sodium carboxymethyl cellulose evenly into 100 ml of water at room temperature, then transfer to a stirrer and stir at a speed of 900r / min, when there is no obvious When there are large lumps, you can stop stirring and let it stand for a period of time (10-20 hours) until the sodium carboxymethyl cellulose is completely dissolved before use;

[0044] 2) Prepare a zirconium tetrachloride solution with a mass fraction of 20%, and mix zirconium tetrachloride: citric acid at a mass ratio of 2:1 to prepare a zirconium citrate solution;

[0045] 3) Configure a sodium hydroxide solution with a mass fraction of 5%;

[0046] 4) Into the zirconium citrate solution prepared in step 2), drop sodium hydroxide solution at a rate of 30 drops per minute, monitor its pH value, stop the titration until the pH value rises to about 7, and let it stand until the solution Turn into a clear solution, and stir at a speed of 75r / min ...

Embodiment 3

[0052] 1) Prepare sodium carboxymethyl cellulose solution, add 3 g sodium carboxymethyl cellulose evenly into 100 ml water at room temperature, then transfer to a stirrer and stir at a speed of 1000 r / min, when there is no obvious When there are large lumps, you can stop stirring and let it stand for a period of time (10-20 hours) until the sodium carboxymethyl cellulose is completely dissolved before use;

[0053] 2) Prepare a zirconium tetrachloride solution with a mass fraction of 20%, and mix zirconium tetrachloride: citric acid at a mass ratio of 2:1 to prepare a zirconium citrate solution;

[0054] 3) Prepare a sodium hydroxide solution with a mass fraction of 5%;

[0055] 4) Into the zirconium citrate solution prepared in step 2), drop sodium hydroxide solution at a rate of 30 drops per minute, monitor its pH value, stop the titration until the pH value rises to about 7, and let it stand until the solution Turn into a clear solution, and stir at a speed of 100r / min dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com