Flue gas displacement reinforced goaf gas extraction and goaf fire preventing and controlling method

A gas drainage and goaf technology, which is applied in the fields of flue gas displacement to enhance gas drainage in goafs and fire prevention in goafs, and can solve the problems of poor gas drainage effects and spontaneous combustion disasters in goafs To achieve the effect of solving the problems of air leakage and spontaneous combustion, solving the problem of gas exceeding the limit, and improving the concentration of gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

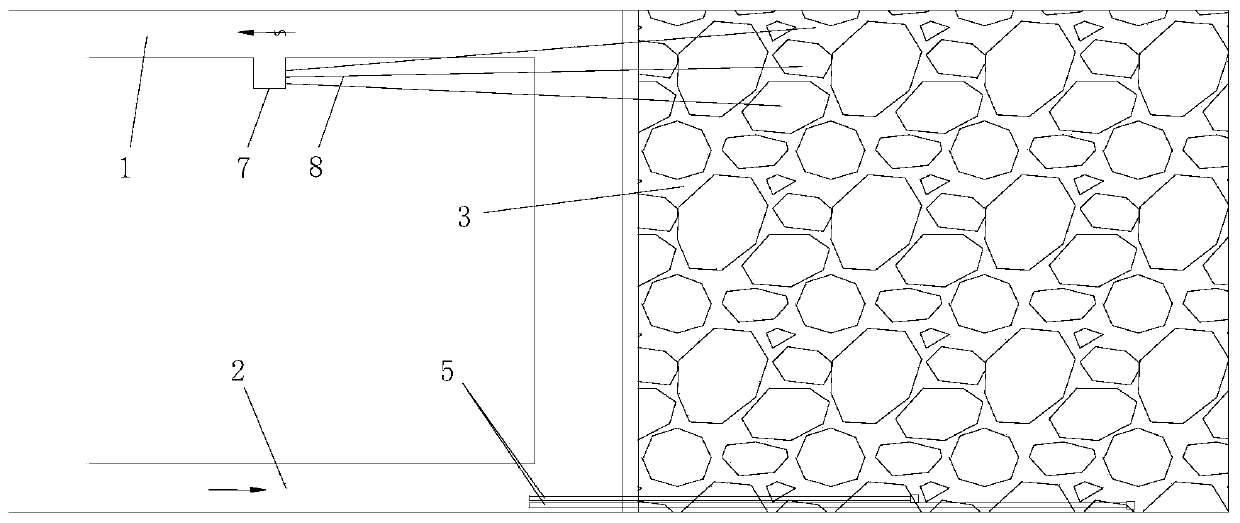

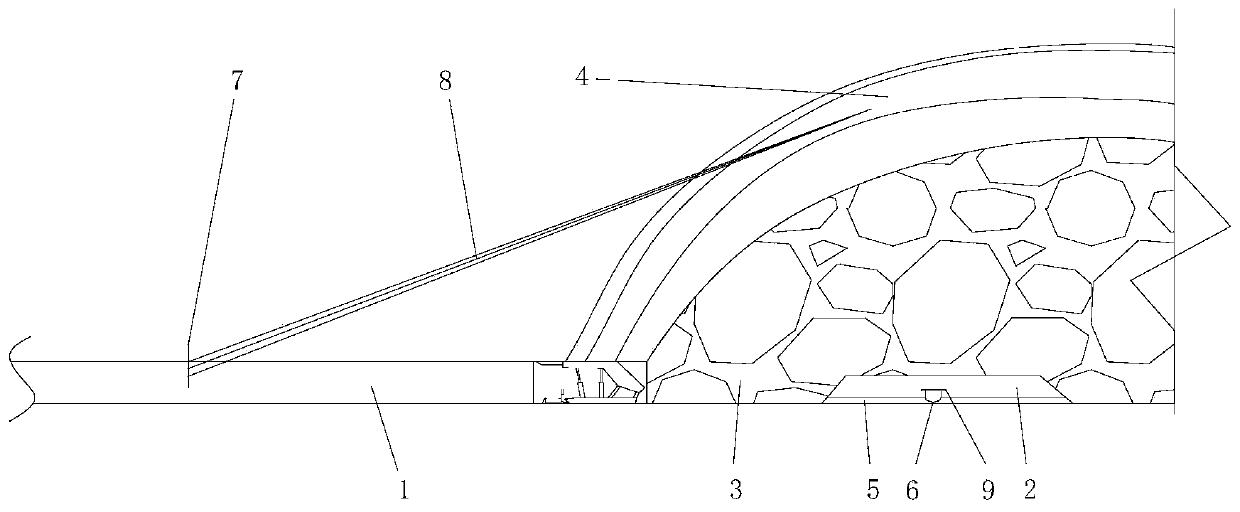

[0025] Such as figure 1 , figure 2 and image 3 As shown, the flue gas displacement of the present invention enhances goaf gas extraction and goaf fire prevention and control method, comprising the following steps:

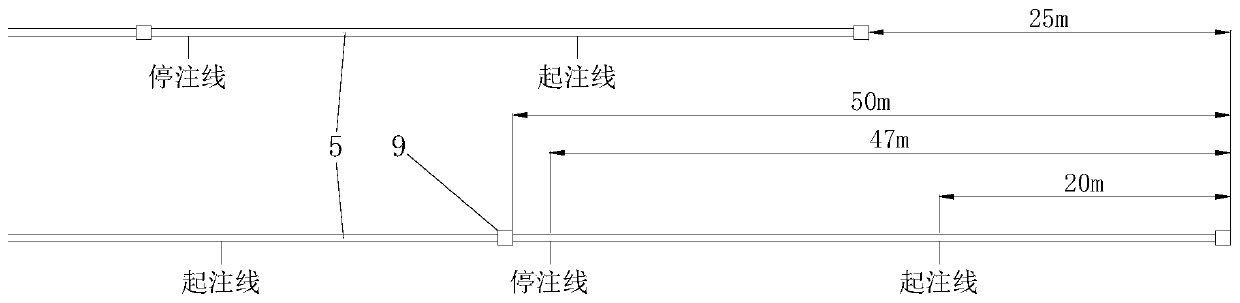

[0026] a. On the outside of the air inlet lane 2 of the working face, two gas injection pipelines 5 are laid side by side along the side of the lane on the floor along the direction of the laneway. The material of road 5 is seamless steel pipe, and the gas injection pipeline 5 in the smoke release port is specially processed into a flower tube style, and the end port of the gas injection pipeline 5 is sealed. The smoke release port 6 set on the gas injection pipeline 5 should be 20-30cm higher than the coal seam floor, mark the start line and stop line on the gas injection pipeline 5, and bury it in the goaf 3 along with the recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com