Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

277results about How to "Play a flame retardant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sealing strip using epdm rubber as host material

ActiveCN101230248AReduce viscosityInhibitionEngine sealsOther chemical processesPolyethylene glycolEPDM rubber

The invention discloses a sealing strip which takes EPDM as the host material and the preparing method, which is characterized in that the composition contains the following constituents (expressed by wt percent): EPDM 26 percent, zinc oxide 1-1.5 percent, stearic acid 1-6 percent, polyethyleneglycol 0.5-1.6 percent, hydrafil 10-32 percent, zinc borate 5-16 percent, orthophosphoric lipid 3-16 percent, black carbon 7-20 percent, paraffin oil 7-21 percent, calcium oxide 2-5 percent, sulfur 0.25-0.5 percent and accelerant 0.65-1.5 percent. The invention ensures the mechanical performance and extrusion performance, is convenient for extrusion, adopts the hydrafil, the zinc borate, and a inflaming retarding system; is the most realistic non-halogen inflaming retarding; can produce a lot of crystal water on the surface of the burning substance; can separate the burning substance from contacting oxygen, and then can perform the inflaming retarding effect; can inhibit the gases produced by the burning substance, accordingly does not produce smog.

Owner:DANYANG WANBEN AUTOMOTIVE PARTS

Room-temperature moisture-curable single-component flame-retardant polyurethane sealant

ActiveCN102504752AGood flame retardantNo reduction in physical propertiesNon-macromolecular adhesive additivesOther chemical processesPlasticizerRoom temperature

The invention discloses a room-temperature moisture-curable single-component flame-retardant polyurethane sealant and a preparation method thereof. The sealant is prepared from the following raw materials in parts by weight: 30-55 parts of liquid polyether type polyurethane pre-polymer base stock, 10-30 parts of flame-retardant plasticizer, 0.1-1 part of silane coupling agent, 15-30 parts of flame-retardant powder, 10-30 parts of filler, 0.01-0.05 part of catalyst and 0.2-3 parts of methyl benzenesulfonyl isocyanate, wherein the liquid polyether type polyurethane pre-polymer base stock is prepared from the following raw materials in parts by weight: 32.8-57.64 parts of common polyether glycol, 28.82-54.67 parts of flame-retardant polyether glycol, 12.51-13.53 parts of polyisocyanates, and 0.01 part of catalyst. The room-temperature moisture-curable single-component flame-retardant polyurethane sealant is excellent in physical performance, thixotropic property and flame-retardant performance, and convenient for construction.

Owner:SHANDONG NORTH MODERN CHEM IND

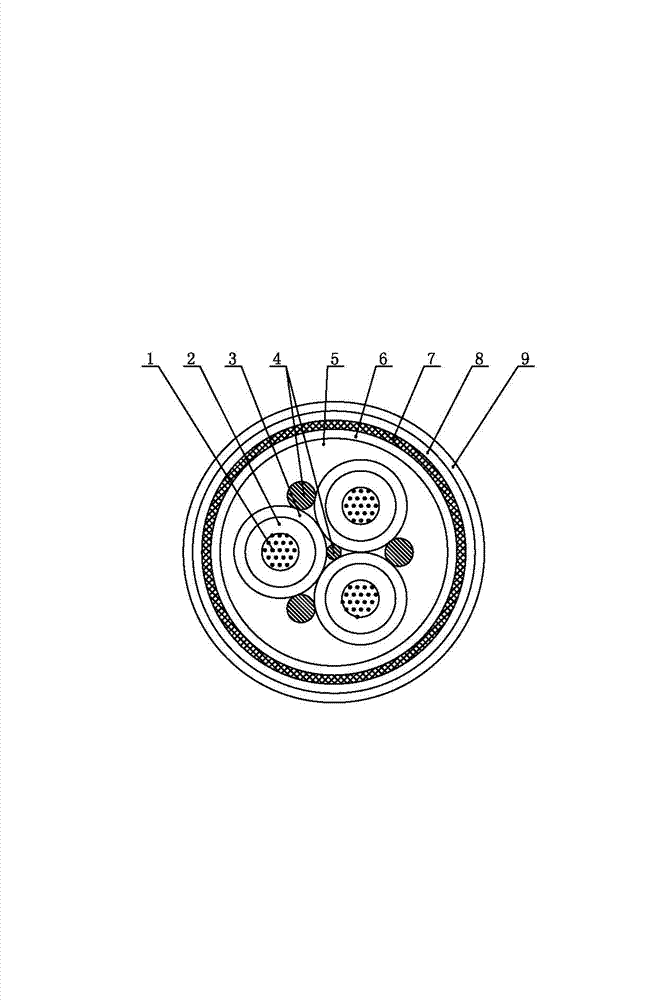

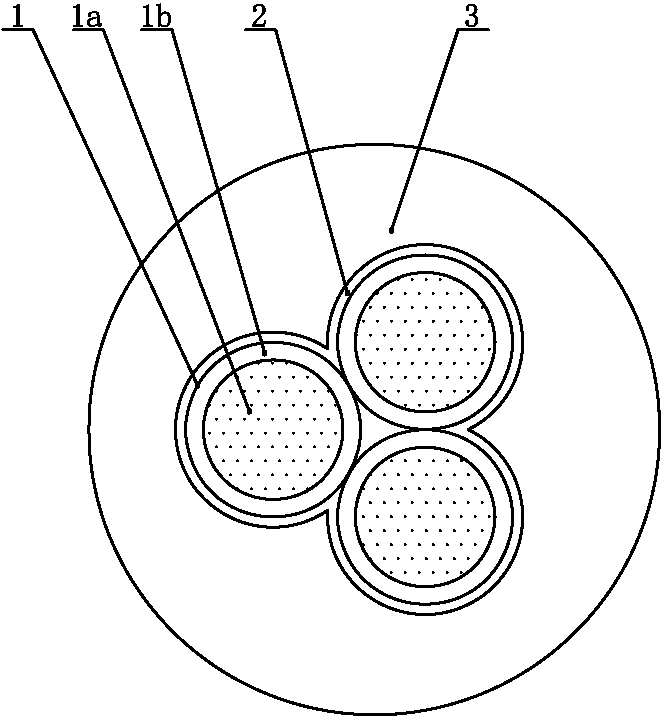

Shielding longitudinal watertight degaussing cable and production method thereof for ships

ActiveCN102855982AEnsure watertight effectImprove sealingInsulated cablesCable/conductor manufactureCopper conductorVulcanization

The invention discloses a shielding longitudinal watertight degaussing cable and a production method thereof for ships. A tinned copper wire is impregnated with a sealant and then twisted into a twisted copper conductor which is impregnated with a conductor sealant layer on the periphery, an electro-insulating rubber layer is extruded on the periphery of the conductor sealant layer to form insulation core wires, chloroprene rubber filling bars are filled into gaps between the insulation core wires, and a plurality of insulation core wires are twisted wholly into a cable core. A cable core inner sealant layer, an inner jacket rubber layer, an armor shielding layer and an outer jacket rubber layer are sequentially arranged on the periphery of the cable core. A single wire of the cable conductor is impregnated with the sealant, the twisted copper conductor is impregnated with the conductor sealant layer on the periphery, the cable core inner sealant layer is extruded on the periphery of the cable core to form multiple sealing, the chloroprene rubber filling bars swell during follow-up vulcanization and can fill in the gaps inside the cable core completely, and tangency between the insulation core wires can be avoided, so that the sealant can permeate to the inside of the cable core to guarantee the watertight effect when the cable core inner sealant layer is extruded.

Owner:嘉兴顾翔制冷设备有限公司

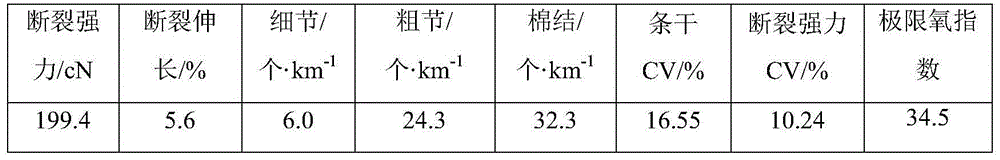

Flame retardant blended yarn and production method thereof

InactiveCN104404671AImprove flame retardant performanceIncrease added valuePhysical treatmentYarnCotton fibreSingle fiber

The invention relates to a flame retardant blended yarn and a production method thereof. According to weight percentage, the flame retardant blended yarn is formed by the following components through blending: 25-30% of flame retardant polyester filament yarns, 20-25% of flame retardant acrylic fibers, 20-30% of hemp fibers and 20-30% of cotton fibers. The production method includes: making hemp fibers and cotton fibers into card slivers respectively and tearing the card slivers into loose fibers, and making the card slivers into hemp / cotton blended combed silvers through second blowing carding in a single fiber type mixing way; making the flame retardant acrylic fibers into flame retardant acrylic card silvers; producing blended rough yarns by use of the hemp / cotton blended combed silvers and the flame retardant acrylic card silvers; producing flame retardant blended yarns by use of spun yarns in a core spun mode; producing the needed flame retardant blended yarns after plasma preprocessing and yarn flame retardant finishing. According to the flame retardant blended yarn and the production method thereof, the hemp fibers, the cotton fibers and two flame retardant fibers are selected for blending, and accordingly the produced yarns have excellent flame retardant performance as well as good antibacterial, moisture absorptive and ventilate wearing performances; the spun yarns are in the core spun mode so the tare effect is eliminated and the flame retardance is improved.

Owner:青岛博徕施纺织有限公司

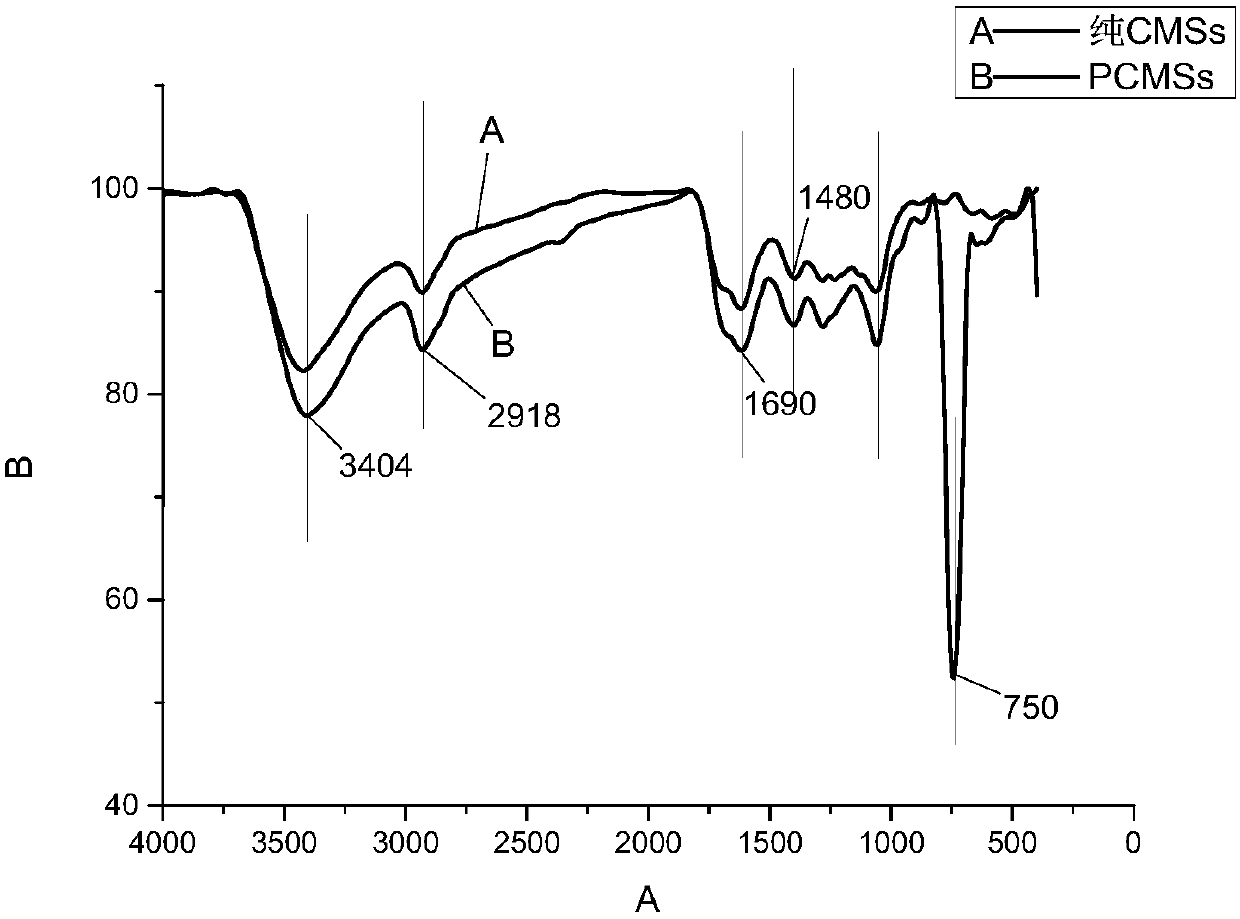

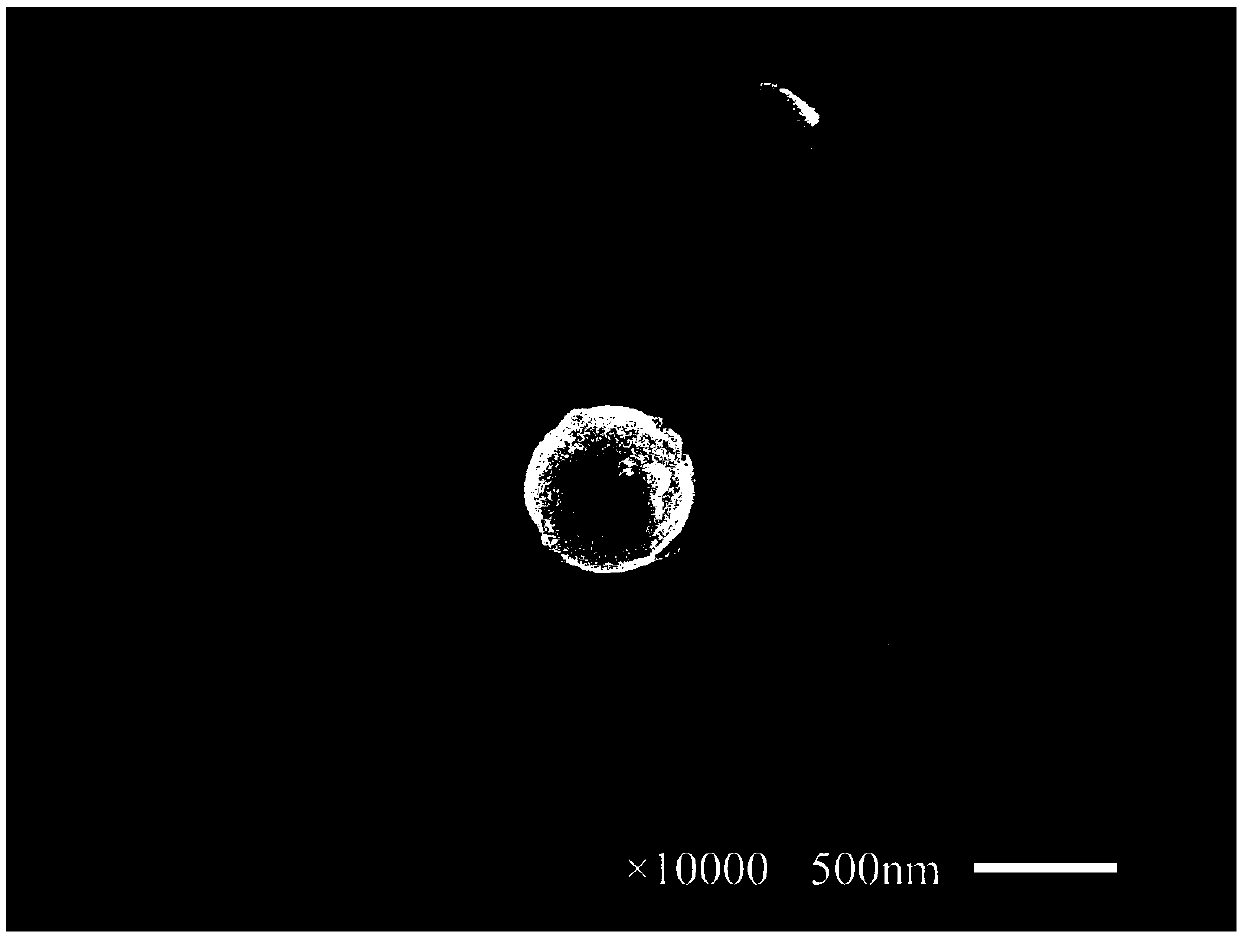

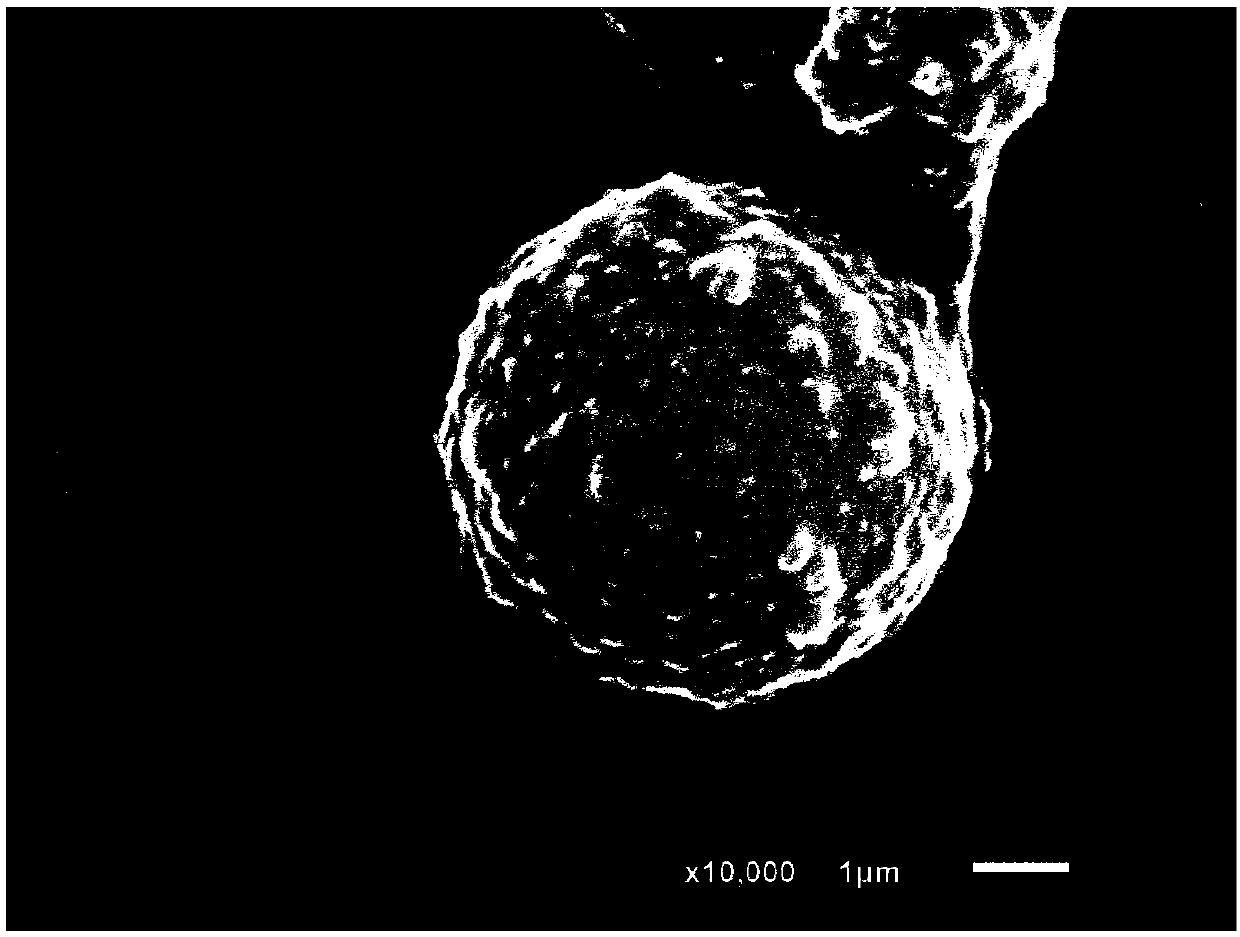

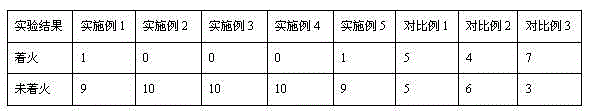

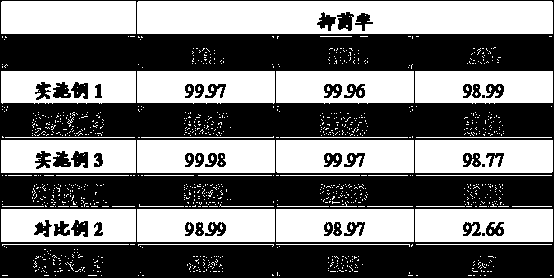

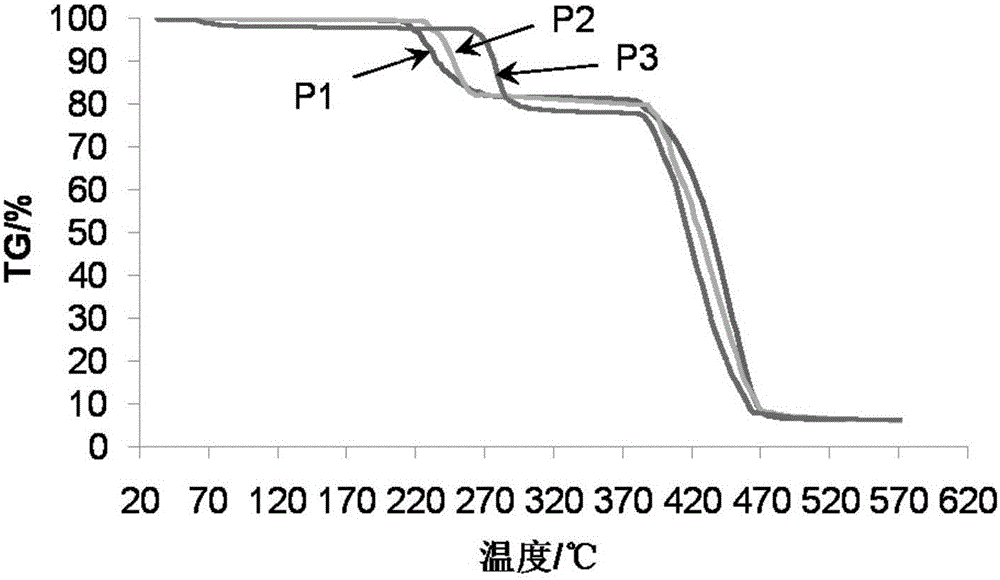

Flame-retardant PET (polyethylene terephthalate)/nanocarbon microsphere composite material and preparation method thereof

The invention relates to the field of flame-retardant polymer composite materials and preparation thereof, and in particular to a functionalized nanocarbon microsphere blending modified polyethylene terephthalate (PET) and a preparation method thereof. Nanocarbon microsphere flame retardant is first treated by low-temperature plasma, so that hydroxyl groups and carboxyl groups are generated on thesurface, phosphor-nitrogen flame retardant is grafted onto the surfaces of the nanocarbon microspheres, and the surface is then wrapped by a layer of PET by in-situ polymerization, so that a nanocarbon microsphere flame retardant which is highly compatible with the base material PET is prepared. PET and the prepared nanocarbon microsphere flame retardant are melted to be blended and molded by injection, and thereby the PET / functionalized nanocarbon microsphere composite material is prepared. The flame-retardant property of the PET / functionalized nanocarbon microsphere composite material prepared according to the invention is excellent, the heat resistance is increased, moreover, the tensile strength is also improved to a certain degree, and the defects of phosphor-nitrogen intumescent flame retardants, i.e. poor durability and poor compatibility between carbon microspheres and base material PET, are overcome.

Owner:JIANGSU YUXING FILM TECH +1

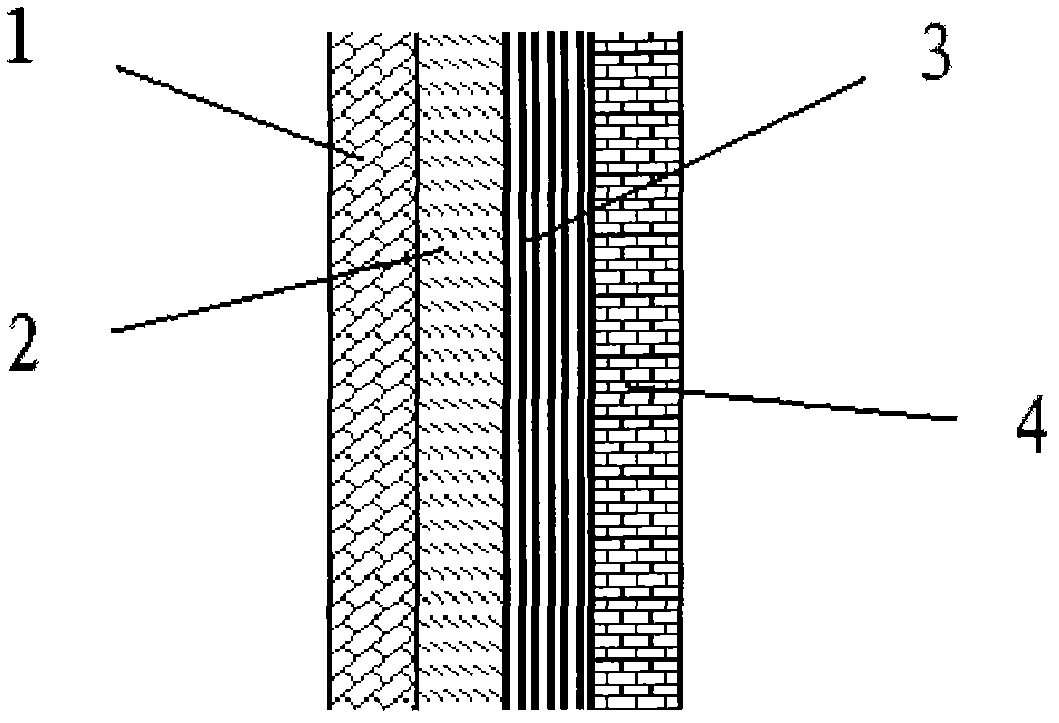

Fireproof silicone rubber composite material and preparation method thereof

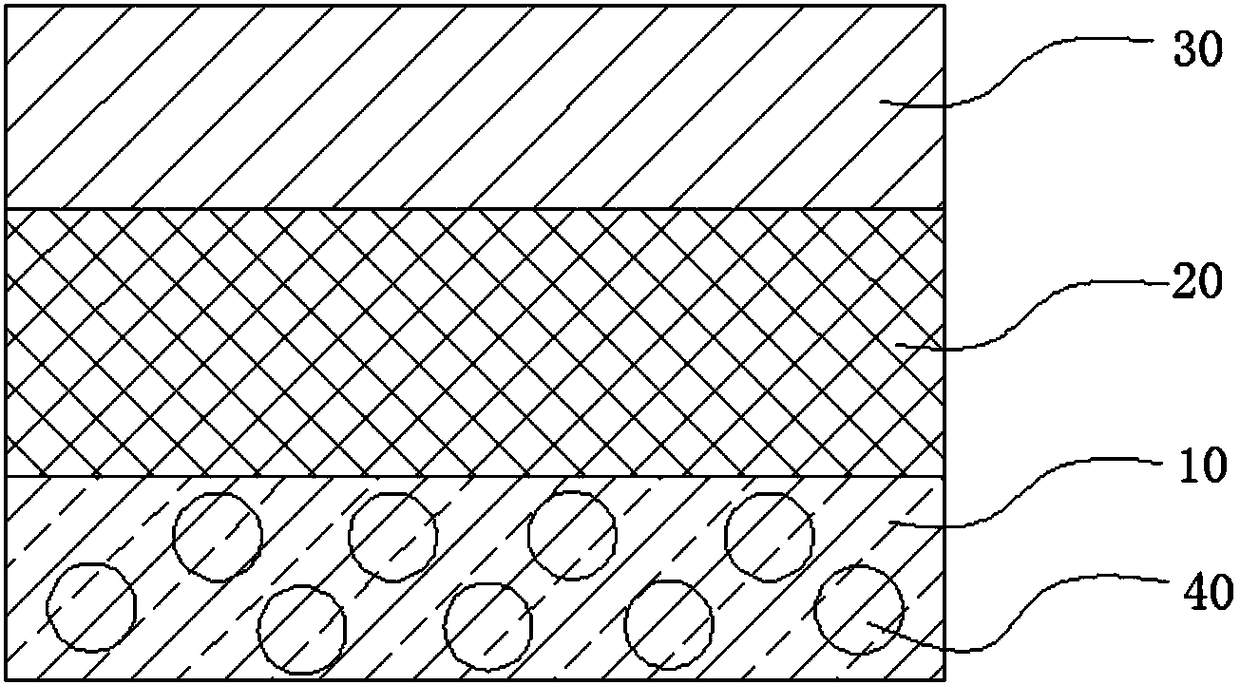

InactiveCN101564923AHas smoke suppressant propertiesDon't burnLaminationLamination apparatusAirplaneHot pressing

The invention relates to a fireproof silicone rubber composite material and a preparation method thereof and is applicable to the firewall of an airplane, the internal fire prevention equipment of other high-speed transport vehicles, military related equipment and the like. The fireproof silicone rubber composite material is characterized in that: the fireproof silicone rubber composite material is obtained by the hot-pressing and composition of a silicone rubber fireproof isolation layer (1), a silicone rubber flame-retardant cooling layer (2), a silicone rubber ablation-resistant layer (3) and a silicone rubber substance layer (4); and the silicone rubber fireproof isolation layer, the silicone rubber flame-retardant cooling layer, the silicone rubber ablation-resistant layer and the silicone rubber substance layer are arranged from outside to inside in sequence. The fireproof silicone rubber composite material has the advantages of good fireproof effect and good heat insulation effect.

Owner:WUHAN UNIV OF TECH

Silicone rubber fireproof sealing material and preparation method thereof

InactiveCN101565625AHas smoke suppressant propertiesDon't burnFireproof paintsPolymer scienceAdhesive

The invention relates to a silicone rubber fireproof sealing material and a preparation method thereof. The silicone rubber fireproof sealing material is characterized by consisting of a component A and a component B; when in use, the component A is mixed with the component B according to a weight ratio of 1:1 so as to obtain the silicone rubber fireproof sealing material; the component A is made from raw materials including a substrate, fireproof fillings, reinforced materials, a crosslinking agent and an adhesive; the portions by weight of each raw material of the component A are as follows: 100 portions of the substrate, 100 to 300 portions of the fireproof fillings, 50 to 100 portions of the reinforced materials, 3 to 8 portions of the crosslinking agent and 1 to 100 portions of the adhesive; the component B is made from raw materials including a substrate, fireproof fillings, reinforced materials, a catalyst and an adhesive; the portions by weight of each raw material of the component B are as follows: 100 portions of the substrate, 100 to 300 portions of the fireproof fillings, 50 to 100 portions of the reinforced materials, 0.2 to 0.4 portion of the catalyst and 1 to 100 portions of the adhesive; and the substrate is polydimethylsiloxane. The silicone rubber fireproof sealing material has good flame-retardant and fireproof effects.

Owner:WUHAN UNIV OF TECH

Fire-retardant ceramic diaphragm for lithium battery and preparation method thereof

ActiveCN104485436AImprove high temperature resistanceImprove securitySecondary cellsCell component detailsPolymer scienceLithium-ion battery

The invention discloses a fire-retardant ceramic diaphragm for a lithium battery. The ceramic diaphragm comprises a diaphragm substrate which is formed by compounding polypropylene (PP) and polyimide (PI). A fire retardant is added into the diaphragm substrate, and then a ceramic powder is coated on the surface of the diaphragm substrate. The ceramic diaphragm for a lithium battery has excellent high temperature resistance, and also can maintain excellent processing characteristics. Through support of a surface rigid oxide of the diaphragm, triple protection is formed. Thus, safety is further raised.

Owner:中国东方电气集团有限公司

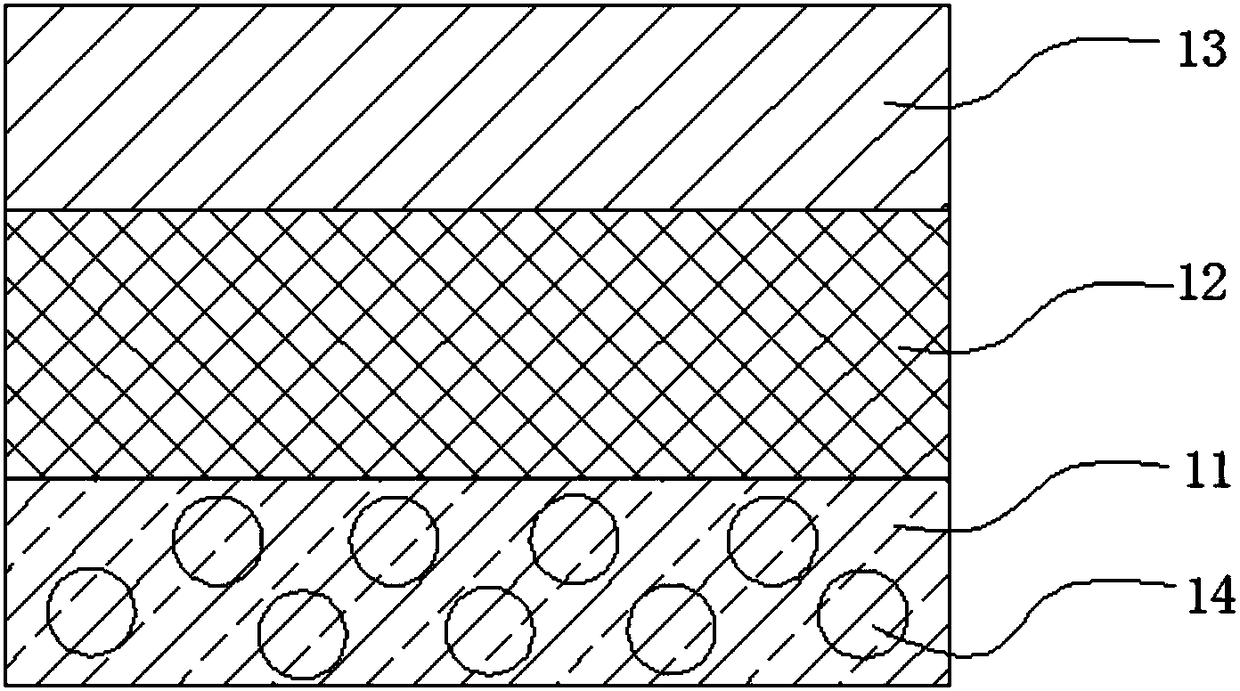

Flame-retardant antibacterial environment-friendly PVC artificial leather

InactiveCN108894005AImproves smoothness and densityImprove smoke densityFurniture partsFootwearSolventSmoke

The invention relates to flame-retardant antibacterial environment-friendly PVC artificial leather which comprises a base cloth layer, a middle layer and a PVC surface layer. The base cloth layer andthe middle layer are bonded through a bonding layer, the middle layer is a smoke-inhibiting flame-retardant layer, a PVC foaming layer coats the middle layer, a surface treatment agent coats the PVC foaming layer, and the PVC surface layer is formed after the surface treatment agent is cured; an environment-friendly layer coats the PVC surface layer. By arranging a bacteriostatic flame-retardant layer and the environment-friendly layer, PVC has excellent flame-retardant and antibacterial performance. In addition, waterborne polyurethane resin is adopted to replace conventional solvent-type polyurethane, so that the problem of serious environment protection in the process of solvent-type synthetic leather is solved effectively.

Owner:南通中奥车用新材料有限公司

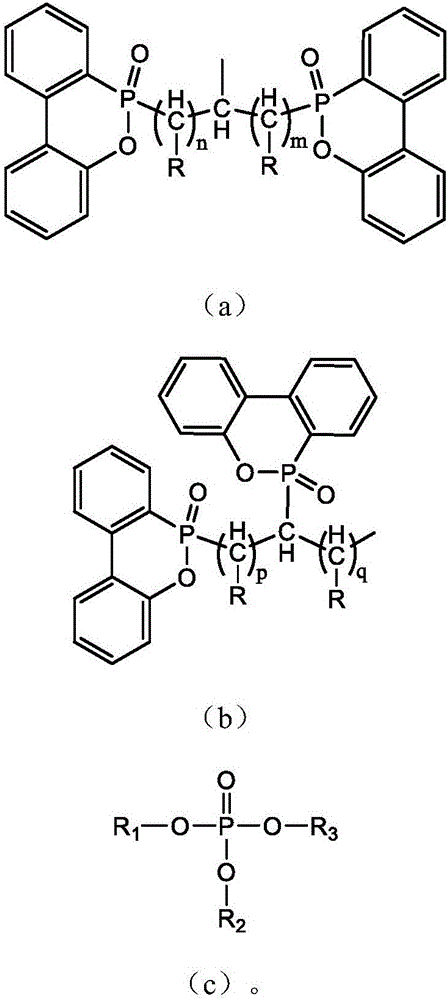

Composite structural phosphorus fire retardant containing poly-DOPO cyclic phosphate and preparation method thereof

ActiveCN106432340AHigh flame retardant efficiencyEasy to synthesizeGroup 5/15 element organic compoundsChemistryAlkane

The invention discloses a composite structural phosphorus fire retardant containing poly-DOPO cyclic phosphate and preparation method thereof; the structural formula of the composite structural phosphorus fire retardant includes not less than 1 organophosphorus ester and not less than 2 DOPO cyclic phosphates. The DOPO is mixed with polyhydroxy alkane or substituted chain hydrocarbon, wherein there are not less than 3 hydroxide radicals of polyhydroxy alkane, and not less than 3 hydroxy carbons in the substituted chain hydrocarbon; heating a mixture to 195-210 DEG C under the protection gas and reacting for 14-17 hours, cooling to room temperature; and then adding halogenated oxygen phosphor or incomplete esterified halogenated oxygen phosphor; then raising temperature to 55-65 DEG C and reacting for 1.5-3 hours; cooling to room temperature and obtaining the composite structural phosphorus fire retardant. The invention provides fire retarding effect at two decomposing temperatures, wherein the one is appeared within 230 and 310 DEG C and the other one is appeared after 345 DEG C; the composite structural phosphorus fire retardant is simple in compound, convenient to use, high in phosphorus content, and better in fire retarding effect.

Owner:淮安丹文化工科技有限公司

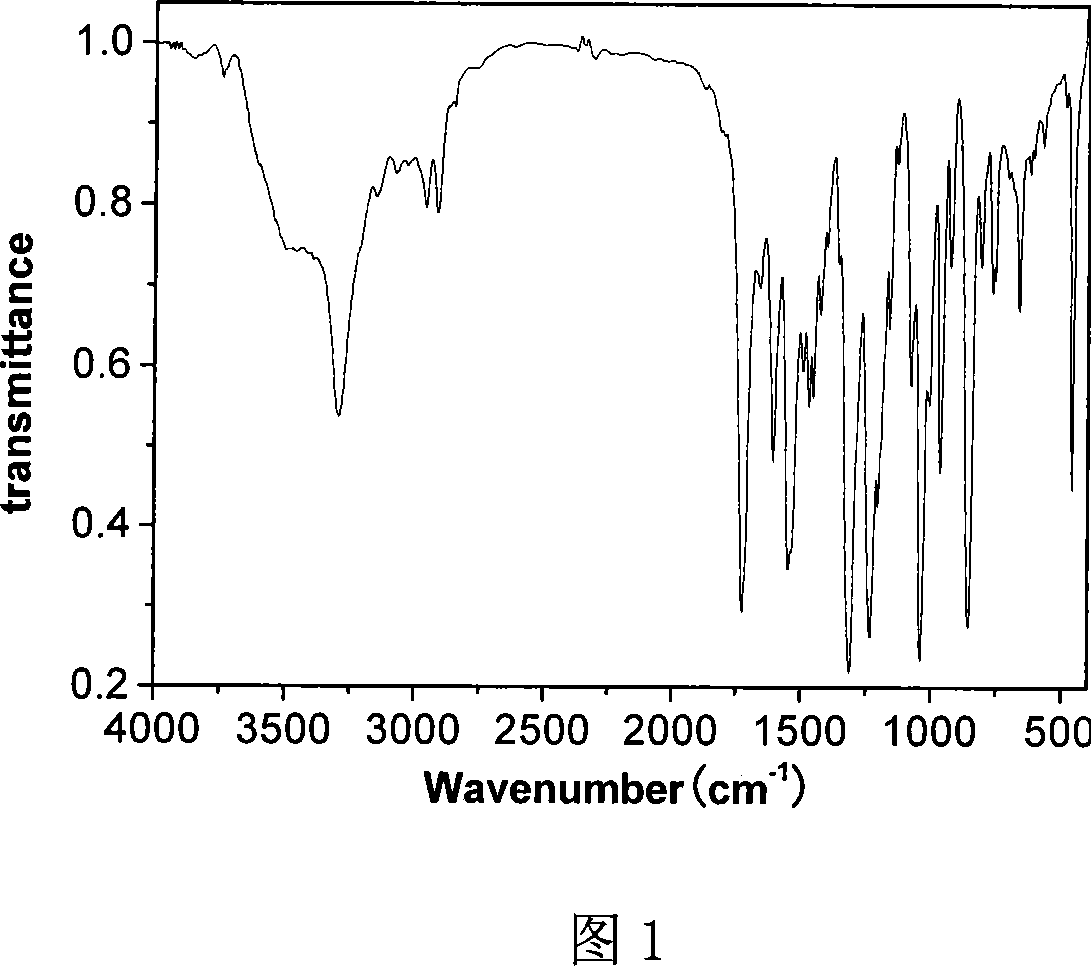

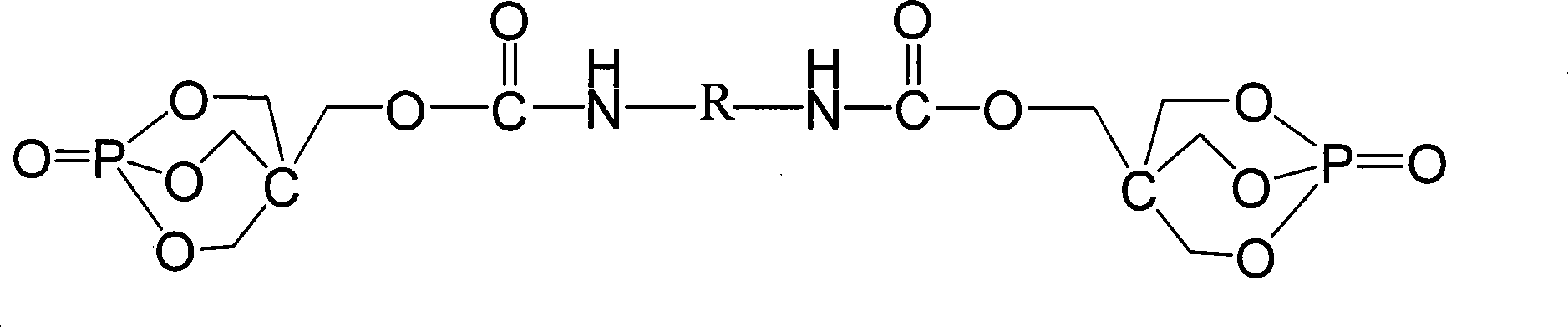

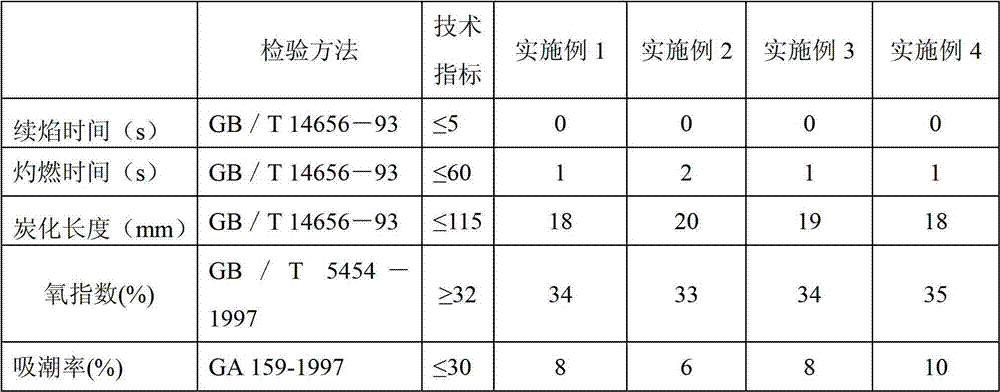

Method for synthesizing monomolecular phosphorus-nitrogen expansion type fire retardant

InactiveCN101168547AConducive to the protection of the environmentGood application prospectPhosphorus organic compoundsSolventChemistry

The invention relates to a method for synthesizing a monomolecular phosphorus-nitrogen expansion flame retardant, which is characterized by: reacting pentaerythritol and phosphorus oxychloride at 80-120°C for 2-12 hours, adding the first solvent during the reaction, and the reaction ends After cooling, filtering, washing, and vacuum drying for 12-24 hours to obtain a white solid, the white solid is 1-oxo-4-hydroxymethyl-1-phospho-hetero-2,6,7-trioxabicyclo [2, 2, 2] octane (PEPA); then add the white solid (PEPA) into the second solvent, stir rapidly to dissolve it, then add isocyanate substances dropwise, and add the catalyst dropwise at the same time, stirring continuously, the reaction The time is 1 to 12 hours, the reaction temperature is 20 to 100°C, the solution changes from clear to turbid, the product is poured into ice water, an appropriate amount of inorganic acid is added dropwise, the pH value is adjusted to be acidic, a white solid is precipitated, and then washed with a washing solvent for 3 The filtered product was vacuum-dried to obtain a white or light yellow solid with a yield of 90-96%. It has the advantages of no halogen, non-toxicity, environmental protection, good application prospects and the like.

Owner:SHUNDE POLYTECHNIC

Environment-friendly fireproof coating and preparation method thereof

ActiveCN112961528AImprove decomposition efficiencySolve the problem of poor foaming performanceFireproof paintsFiberFire retardant

The invention discloses an environment-friendly fireproof coating and a preparation method thereof, and relates to the field of building coatings. The environment-friendly fireproof coating is prepared from the following raw materials: a macromolecular emulsion film forming matter, an inorganic film forming matter, an intumescent organic flame retardant, a non-intumescent inorganic heat-insulating filler, an intumescent inorganic heat-insulating filler, reinforced fibers, nano rare earth oxide, a coupling agent, a coalescing agent, a dispersing agent, a thickening agent, a pH regulator, deionized water and the like, wherein the intumescent organic flame retardant is an intumescent flame retardant containing N-P cage type macromolecules. The coating is excellent in fireproof performance, high in expansion multiple and fireproof performance, long in fire-resistant time and excellent in waterproof performance. The invention further discloses a preparation method of the environment-friendly fireproof coating.

Owner:DACHANG BBMG COATING CO LTD

Flame-retardant paper

InactiveCN102852042AImprove flame retardant performanceNo reversionSpecial paperPaper/cardboardCarboxymethyl celluloseMoisture absorption

The invention discloses a flame-retardant paper. According to the invention, a flame-retardant liquid is sprayed on a single surface of a raw paper. The flame-retardant liquid is prepared from the raw materials of, by weight: 8-10 parts of aluminum hypophosphite, 8-10 parts of aluminum hydroxide, 8-10 parts of antimony trioxide, 8-10 parts of white carbon black, 3-5 parts of calcium stearate, 1 part of sodium carboxymethyl cellulose, and 100 parts of water. According to the invention, an environment-friendly halogen-free flame-retardant is adopted. The flame-retarding effect is good, and halogenation and moisture absorption phenomena are prevented. The flame-retardant paper has a good flame-retarding effect.

Owner:SHANDONG CHANGXING GROUP

Aluminium-plastic film and application thereof

ActiveCN108155307AFlame retardant in timeStop burning fireSecondary cellsJackets/cases materialsAluminiumFire retardant

The invention provides an aluminium-plastic film and application thereof and relates to the technical field of flame-retardant package. The aluminium-plastic film and application provided by the invention have the beneficial effects that flame-retardant agent microcapsules are embedded in the aluminium-plastic film; by utilization of the aluminium-plastic film, the technical problem that due to noflame-retardant property, the aluminium-plastic film in the prior art can prevent a lithium ion battery effectively from burning and causing joint burning due to temperature rise, so that the flame-retardant purpose is achieved.

Owner:SOUNDON NEW ENERGY TECH CO LTD

Extra light ship cable penetrating A-level refractory sealing mortar

The invention relates to extra light ship cable penetrating A-level refractory sealing mortar, which is mainly used for fireproofing and sealing when a ship cable penetrates through a cabin wall and a deck, and belongs to the technical field of refractory sealing materials. The refractory sealing mortar is prepared by stirring and mixing adhesive, plasticizer, flame retardant, synergist, powder, fiber and foam filling agent according to a certain proportion to obtain a viscoelastic soft cluster; when being used, the sealing mortar is filled in a hole and is compacted and flattened; and the sealing mortar has a certain strength and toughness after being solidified. The refractory sealing mortar has the following advantages that (1) the weight is extra light, and the proportion is 1.05-1.10*10<3>Kg / m<3>; (2) the oxygen index is greater than or equal to 35; (3) the refractory sealing mortar belongs to a single component system, and operations such as mixing is not needed before use; (4) the refractory sealing mortar can be solidified at room temperature; (5) halogen is not contained, and irritant gas and smog cannot be produced in a combustion process; (6) asbestos is not contained; (7) the refractory sealing mortar is certificated through ship A60 type refractory; and (8) the construction is convenient and quick.

Owner:SHANGHAI UNIV

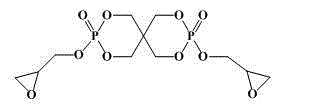

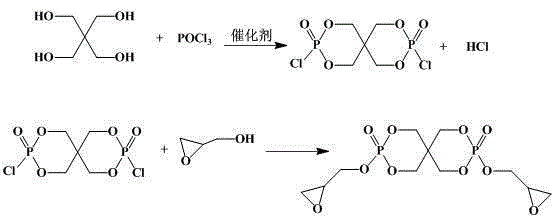

Halogen-free epoxy resin flame retardant and preparation method thereof

ActiveCN105111687AHigh phosphorus contentPlay a flame retardant effectGroup 5/15 element organic compoundsEpoxyChemical synthesis

The invention provides a halogen-free epoxy resin flame retardant and a preparation method thereof, relating to a chemical synthesis agent and a preparation method thereof. Preparation raw materials include pentaerythritol (PER), phosphorus oxychloride and glycidol. The method for preparing the flame retardant comprises the following two steps: I. reacting PER and phosphorus oxychloride (POCl3) under certain conditions to generate an intermediate PER diphosphonic chloride diphosphate (SPDPC); and II. stirring SPDPC and glycidol to react for a certain time under the condition of inert gas import and carrying out filtration, washing, rotary evaporation, drying and other treatment on the product, thus obtaining a milk white liquid. The halogen-free epoxy resin flame retardant and the preparation method have the beneficial effects that the obtained compound has a halogen-free structure and has good compatibility with epoxy resin; epoxy groups at the two ends of the compound have smaller effects on the mechanical properties of cured products; the compound can conduce to effectively improving the mechanical properties of epoxy resin, is also environment-friendly and is an environment-friendly flame retardant; and the process is simple in production conditions, higher in product purity and yield and simple and convenient in after-treatment process.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Environment-friendly type flame-proof asphalt mastic stone mixture for tunnel

The invention discloses an environment friendly type tunnel flame-proof pitch water chestnut ether broken stone mixed material, which comprises the following steps: counting with the total weight proportion of the pitch mixed material as 0. 3%-0. 5% mineral fiber, 1. 0%-1. 2% organic fire retardant, 5. 5%-6. 0% pitch, 92. 3-93. 2% broken stone; choosing the mineral fiber with the density not less than 2. 5g / cm3 and strength for extension as 3500MPa; choosing the elastic modulus of the mineral fiber as 85GPa, percentage of breaking elongation as 2. 5%, the highest working temperature at 500 deg. c and the length more than 6mm; choosing the organic fire retardant with the density at 1. 2-2. 0g / cm3 and the effective content not less than 70%; setting the fusion temperature of the organic fire retardant not less than 120 deg. c, the moisture percentage less than 5% and the fire point not less than 260 deg. c. This mixed material can prevent burning of tunnel pitch water chestnut ether broken stone mixed material (SMA) pavement effectively, which possesses environmental protection function.

Owner:SOUTHEAST UNIV

Production method of flame-retardant modified wood

InactiveCN104760101AImprove flame retardant performanceGood compatibilityWood treatment detailsPressure impregnationOxygenFire retardant

The invention discloses a production method of flame-retardant modified wood. The method comprises the following steps: 1, firstly, preparing a flame retardant and then adding the flame retardant into modified urea resin liquid to ensure that a mixture is completely dissolved to prepare wood impregnation liquid; 2, performing waiting treatment by using the wood impregnation liquid obtained in the step 1 by means of vacuum pressurization; and 3, drying to obtain the modified wood. The production process is simple, and the treating liquid can be recycled, so that the size stability of the wood subjected to the treatment is obviously improved, the physical and mechanical property can be obviously improved, the weight grain rate of the wood is 20-43 percent, the oxygen index can be improved by 30-70 percent, and the flame retardant performance of the wood can be kept for a long time.

Owner:广西宾阳县荣良农业科技有限公司

Preparation method for modified magnesium-aluminium hydrotalcite cable fillers

InactiveCN108314821AImprove corrosion resistanceImprove high temperature resistancePlastic/resin/waxes insulatorsHeat resistanceHydrotalcite

The invention discloses a preparation method for modified magnesium-aluminium hydrotalcite cable fillers and belongs to the technical field of preparation of cable fillers. The preparation method disclosed by the invention has the beneficial effects that firstly a tetraethoxysilane hydrolysis method is utilized for preparing silica sol, and since the silica sol contains silicon dioxide, oxygen inthe air can be effectively isolated from a base material to prevent contact; in addition, bismaleimide resin has heat resistance, and is easily cured on the polyethylene surface to form a triazine-ring structure, so that the compatibility of self-made magnesium-aluminium hydrotalcite with the base material is improved; meanwhile, the self-made magnesium-aluminium hydrotalcite particles are uniformly dispersed on the surface of the base material, so that the surface temperature of the base material is reduced and the flame-retardant effect is achieved; furthermore, in the heat-absorbing and decomposing process of the self-made magnesium-aluminium hydrotalcite, an alkali porous composite oxide is obtained, and can be combined with a carbonized product on the surface of the base material to form a protective film, so that the invasion of heat and oxygen can be effectively prevented, the flame retardance of the cable fillers can be further improved and the application prospect is wide.

Owner:谢新昇

Salt corrosion resistant and twisting resistant power cable for ocean wind power and manufacturing method of power cable

ActiveCN103227008AReduce tensionEliminate voidsPower cablesInsulating conductors/cablesCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant power cable for ocean wind power and a manufacturing method of the power cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a power cable insulated core; a plurality of power cable insulated cores are mutually stranded to form a power cable core; the power cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The power cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the power cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the power cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

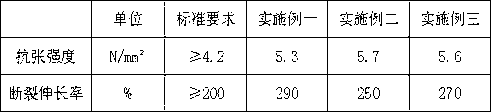

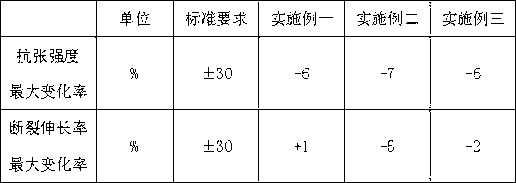

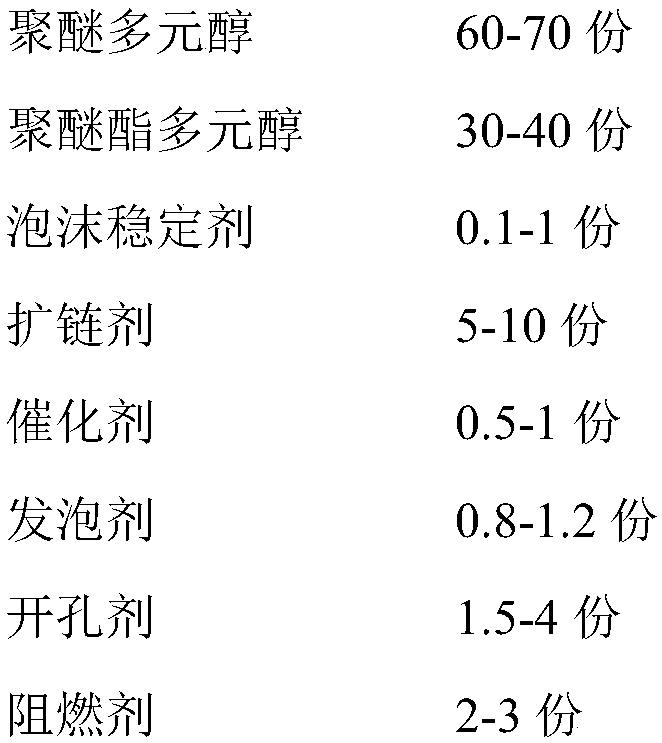

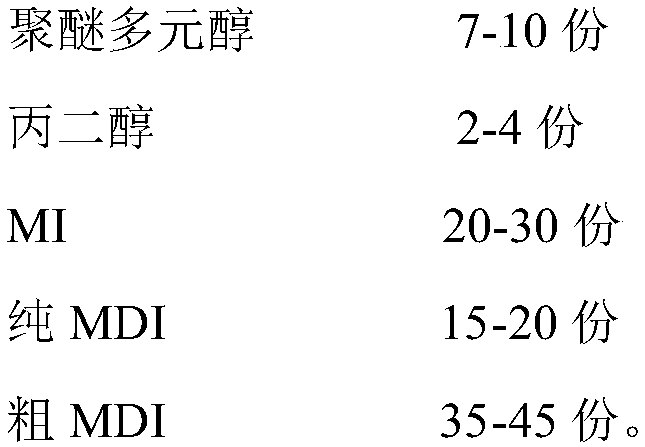

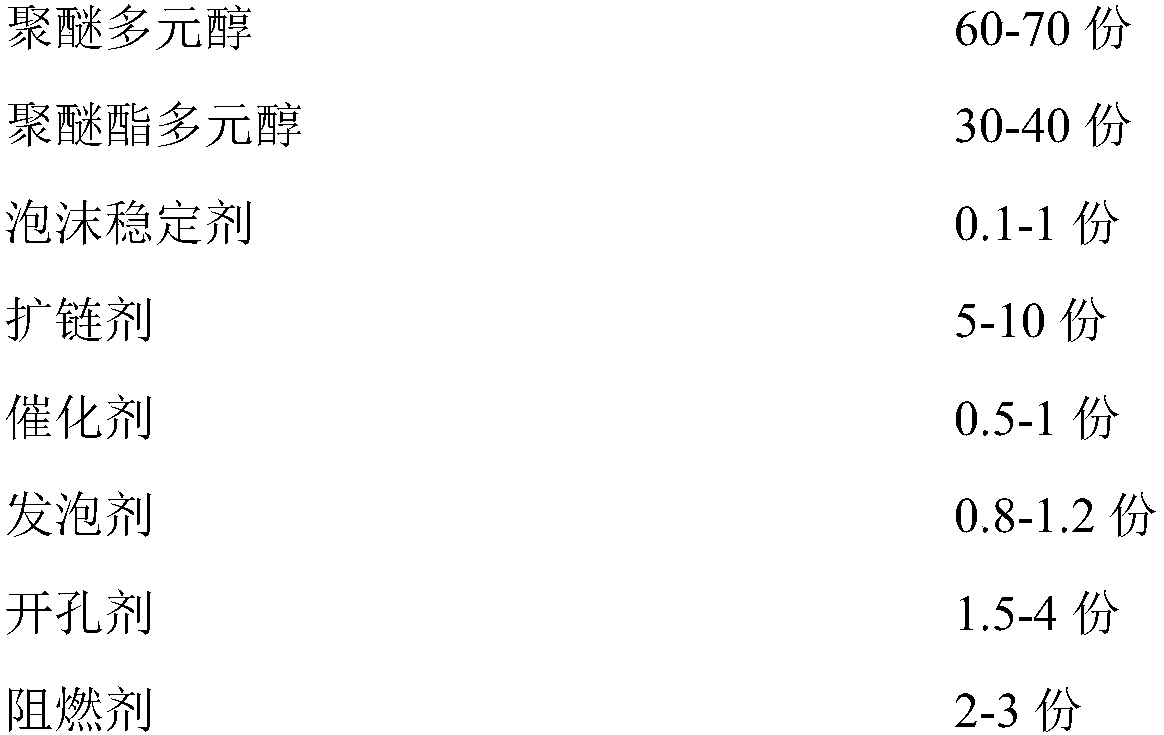

Polyurethane composition for car steering wheel and preparation method of polyurethane composition

InactiveCN108047422AHarm reductionIn line with the concept of environmental protectionPolyesterPolyol

The invention belongs to the technical field of polyurethane and particularly relates to polyurethane composition for a car steering wheel and a preparation method of the polyurethane composition. Thepolyurethane composition is prepared from a component A and a component B in the weight ratio being 100:(40-50), wherein the component A is prepared from raw materials in parts by weight as follows:60-70 parts of polyether polyol, 30-40 parts of polyether ester polyol, 0.1-1 part of a foam stabilizer, 5-10 parts of a chain extender, 0.5-1 part of a catalyst, 0.8-1.2 parts of a foaming agent, 1.5-4 parts of an opening agent and 2-3 parts of a flame retardant; the component B is prepared from raw materials in parts by weight as follows: 7-10 parts of polyether ester polyol, 2-4 parts of propylene glycol, 20-30 parts of MI, 15-20 parts of pure MDI and 35-45 parts of crude MDI. Polyether ester polyol is taken as a raw material, so that the polyurethane composition has the performance of polyester and can provide the flexibility of polyether, and the overall performance and comfort of a product are improved; a non-metal catalyst is used, and harm to human bodies is reduced; sodium hydroxide nanofiber can have a certain flame retardant effect. The preparation method is scientific, reasonable and simple and easy to operate.

Owner:SHANDONG INOV POLYURETHANE

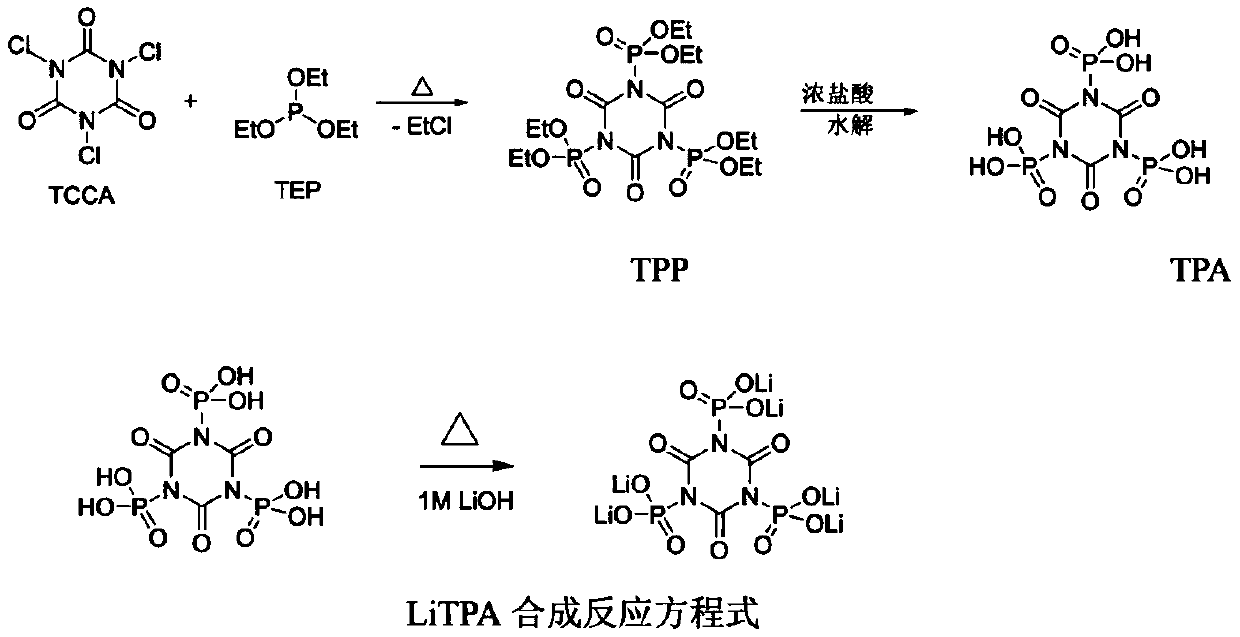

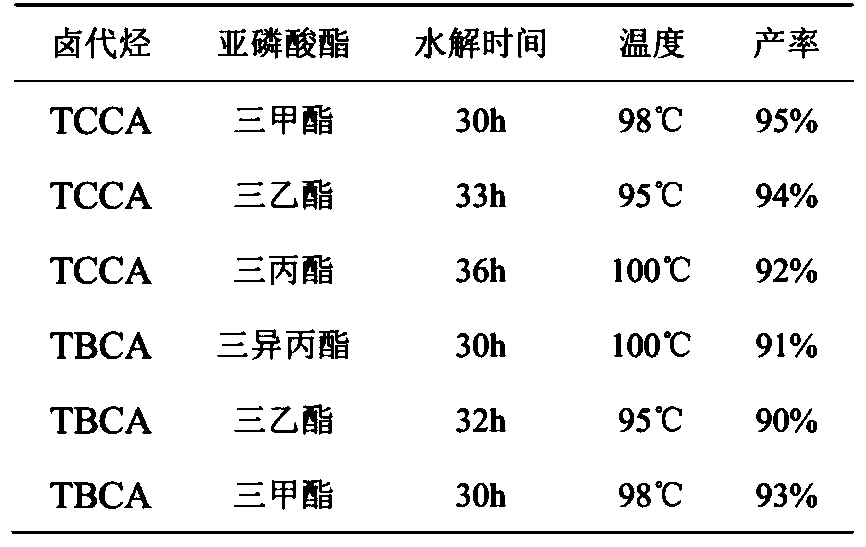

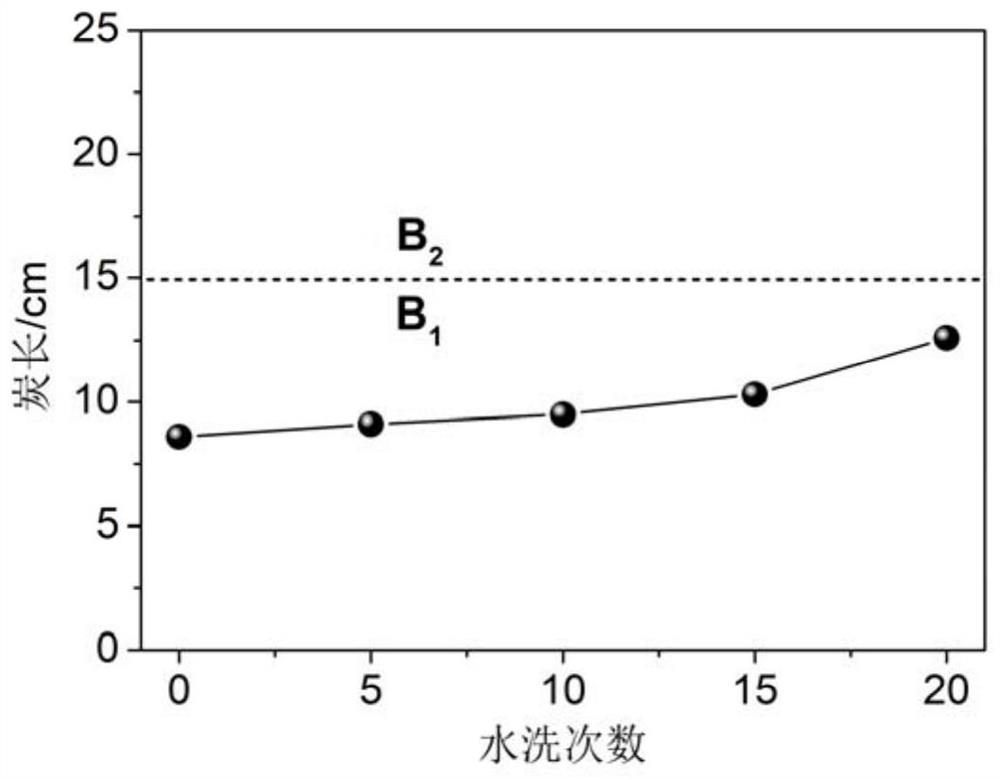

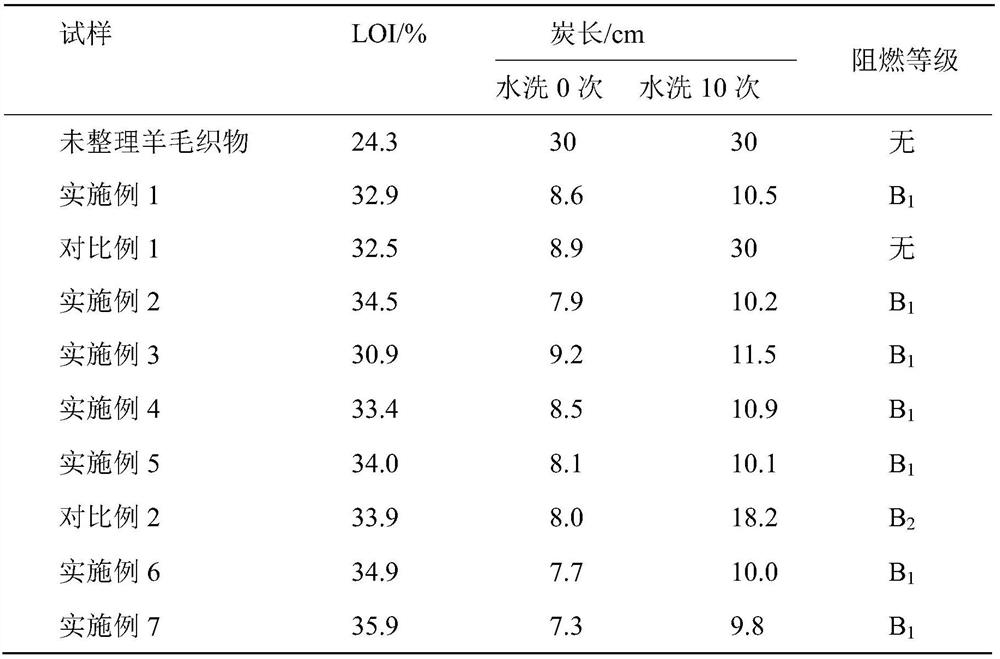

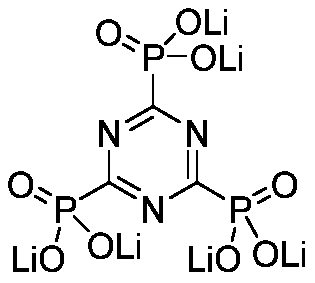

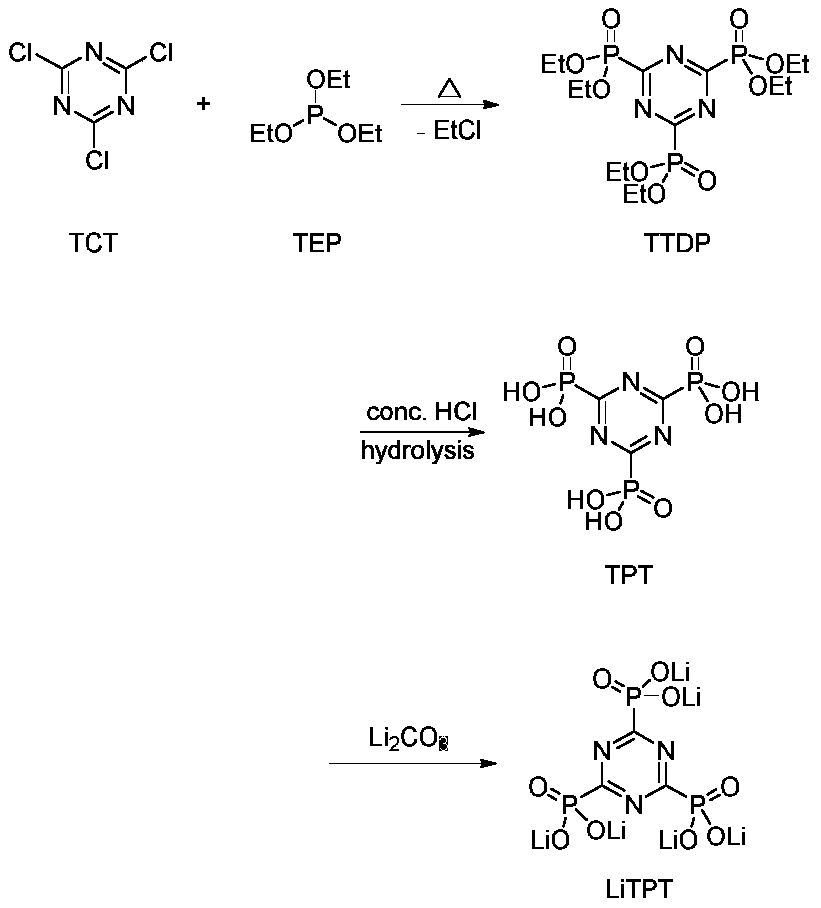

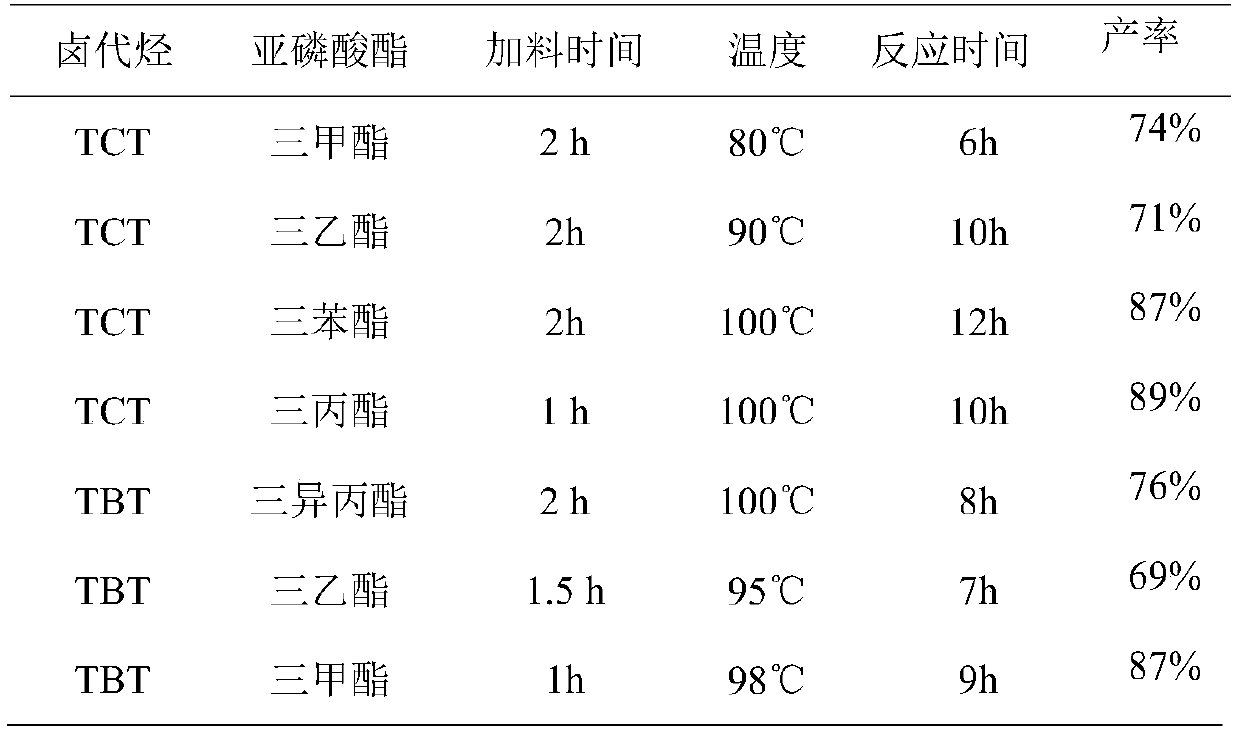

Preparation method of flame-retardant electrolyte by using 2,4,6-trioxo-1,3,5-triazine-triphosphate lithium salt and compound thereof

ActiveCN111205322ARaw materials are cheap and easy to getMild conditionsGroup 5/15 element organic compoundsSecondary cells servicing/maintenancePhosphorous acidElectrolytic agent

The invention provides a preparation method of a lithium ion battery flame-retardant electrolyte obtained by compounding high-phosphoric-acid lithium-containing 2,4,6-trioxo-1,3,5-triazine-triphosphate lithium salt, a solvent, an additive and the like. The content of phosphate groups and lithium ions is high, a plurality of lithium ion attachment sites are provided on the premise of realizing a flame-retardant effect, the concentration of lithium ions in the electrolyte is increased, and the use of the flame-retardant additive is reduced. The preparation method is characterized by comprising the following steps: firstly, replacing high-activity chlorine on trichloroisocyanuric acid with phosphite triester to obtain a phosphate compound; hydrolyzing the ester compound to obtain a phosphategroup product; dissolving a lithium salt, the intermediate phosphate and other additives in an organic solvent, and compounding to obtain the novel flame-retardant lithium ion battery electrolyte. Thenovel electrolyte can be used for electrolytes of a lithium ion battery, a lithium oxygen battery and a lithium sulfur battery.

Owner:SHANDONG UNIV OF TECH

Antiflaming ultraviolet curing coating

InactiveCN104927624AImprove wear resistanceImprove adhesionFireproof paintsPolyurea/polyurethane coatingsPolyesterCombustion

The invention relates to the field of coatings, particularly to antiflaming ultraviolet curing coating which comprises the following raw materials in parts by weight: 55-65 parts of polyurethane-acrylate resin, 10-15 parts of polyester acrylate, 10-15 parts of graphene, 5-10 parts of a nanoscale magnesium hydrate fire retardant, 3-6 parts of titanium dioxide, 0.2-0.5 part of an anti-greening agent, 3-5 parts of a photoinitiator, 10-15 parts of a reactive diluent, 3-5 parts of a thickening agent, 0.3-0.6 part of a flatting agent, 0.2-0.5 part of an anti-settling agent and 1-1.5 parts of a defoamer. The antiflaming ultraviolet curing coating has excellent flame retardant efficiency, does not release toxic or cancerogenic substances during combustion, and further has the advantages of super durability, abrasion resistance and antibacterial property.

Owner:CHENGDU NASHUO TECH

Finishing process of formaldehyde-free flame-retardant wool product

ActiveCN112411184ASufficient sourceLow toxicityHeat resistant fibresAnimal fibresAldehydeAddition reaction

The invention relates to a finishing process of a formaldehyde-free flame-retardant wool product. The finishing process comprises the following steps: immersing the wool product in a solution containing aromatic aldehyde, controlling the wool product and the aromatic aldehyde to carry out a Schiff base reaction to obtain an intermediate product, immersing the intermediate product in a solution containing phosphite ester, controlling the intermediate product and phosphite ester to carry out a Pudovik addition reaction to prepare the flame-retardant wool product. By means of chemical reactions among the aromatic aldehyde, the phosphite ester and the wool product, the phosphite ester is firmly fixed on wool fibers through covalent bonds. The aromatic aldehyde adopted in the method is a natural product, the phosphite ester is high in flame retardant efficiency, technological operation is simple, and reaction conditions are mild. The flame-retardant wool product prepared by the method has the advantages of excellent flame-retardant effect, favorable water washing resistance, low toxicity of the used flame retardant and mild treatment conditions, ensures the environment friendliness andsafety of the flame-retardant wool product in a use process, does not release formaldehyde, and has important practical application value.

Owner:SUZHOU UNIV

Preparation method of flame-retardant electrolyte for lithium ion battery

ActiveCN111193067ARaw materials are cheap and easy to getMild conditionsSecondary cells servicing/maintenanceOrganic electrolytesPhosphoric Acid EstersLithium oxide

The invention relates to a preparation method of a flame-retardant electrolyte for a lithium ion battery. The electrolyte is a novel flame-retardant electrolyte which is compounded by taking melaminering-containing lithium triphosphonate with a novel structure as a main component. The preparation method comprises the following steps: reacting 2, 4, 6-trichloro-1, 3, 5-triazine (cyanuric chloride,TCT) with phosphite ester, performing hydrolyzing to introduce three phosphate groups, and reacting the ternary phosphonic acid with lithium hydroxide, lithium oxide or lithium carbonate to obtain the novel cyanuric ring-containing lithium triphosphonate. A lithium salt, an intermediate phosphate and other additives are dissolved in an organic solvent for compounding to obtain the novel flame-retardant lithium ion battery electrolyte. The novel electrolyte can be used for electrolytes of a lithium ion battery, a lithium oxygen battery and a lithium sulfur battery.

Owner:SHANDONG UNIV OF TECH

Preparation method of flame-retardant medium-density fiberboard

InactiveCN107571356AImprove mechanical propertiesHigh densityWood treatment detailsDomestic articlesFiberSlurry

The invention discloses a preparation method of a flame-retardant medium-density fiberboard and belongs to the technical field of building material preparation. According to the preparation method, salix fibers and biogas slurry are mixed for mildewing, washing and drying are conducted, and pre-treated salix fibers are obtained; then the pre-treated salix fibers are mixed with a saturated impregnation solution containing sodium nitrite and ammonium chloride for impregnation, then liquid nitrogen freezing is conducted, and frozen salix fibers are obtained; then the frozen salix fibers are fumigated through nitrogen carrying trimethyl aluminum and dried, and the fumigated salix fibers are obtained; and finally the fumigated salix fibers and resin adhesives are mixed and then laid to form a board blank, graded pressing formation and cutting are conducted, and accordingly the flame-retardant medium-density fiberboard is obtained. The obtained flame-retardant medium-density fiberboard has both the excellent flame-retardant performance and the excellent physical and mechanical performance.

Owner:CHANGZHOU DINGRI ENVIRONMENTAL PROTECTION TECH

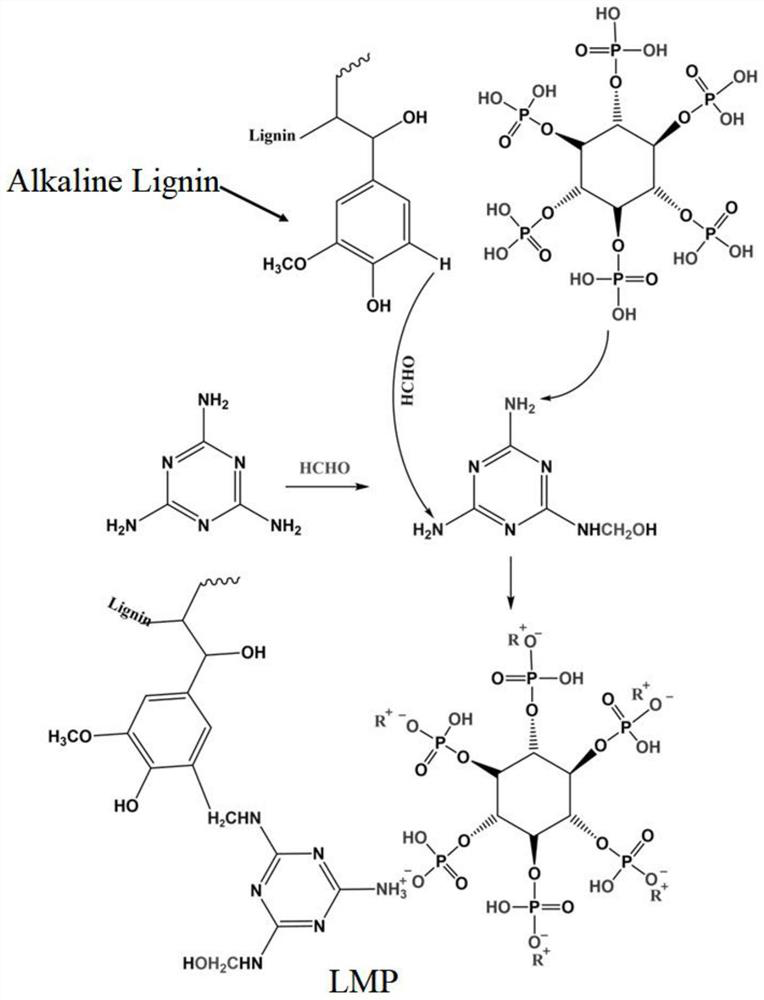

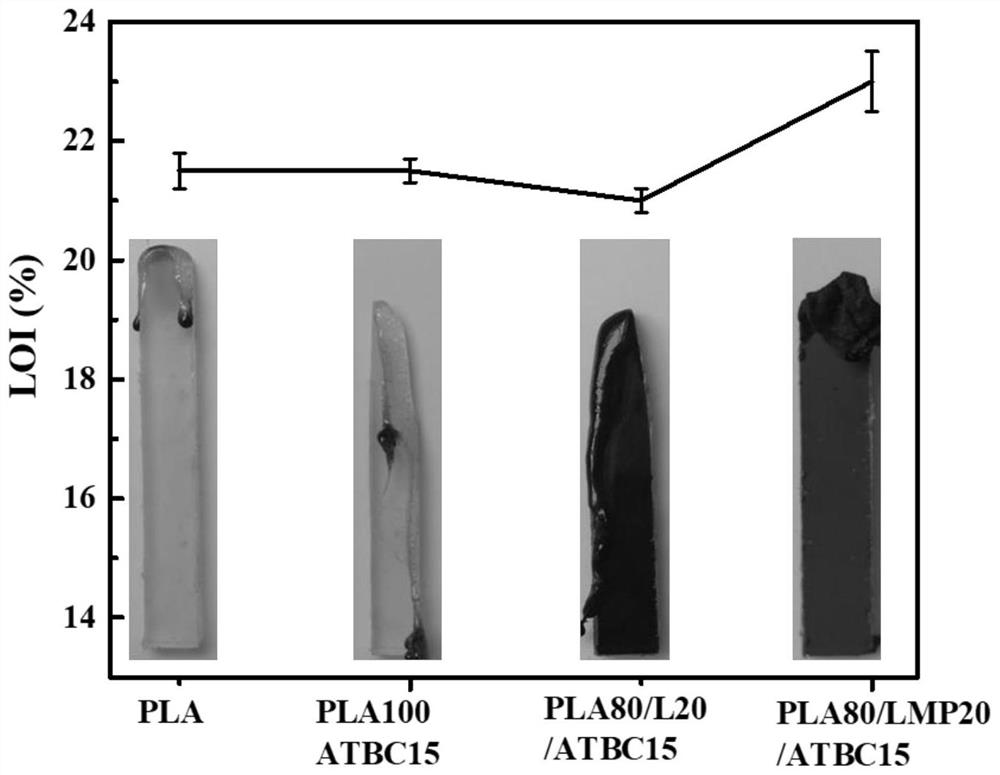

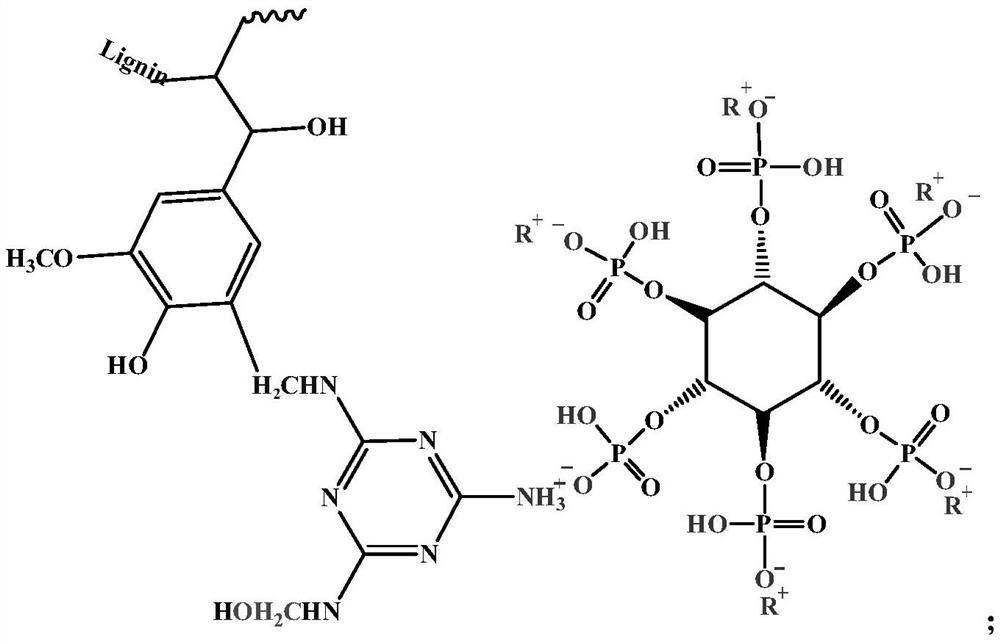

Modified lignin, preparation method and application of modified lignin in toughening flame-retardant composite material

The invention discloses modified lignin, a preparation method and application of the modified lignin in toughening flame-retardant composite materials, and belongs to the field of flame retardants andbio-based flame-retardant materials. The preparation method comprises the following steps of: adding melamine and formaldehyde into water according to a mass ratio of 1: (0.08-0.5), and carrying outa stirring reaction for 0.5-2 h at a temperature of 60-90 DEG C; gradually adding the alkaline lignin, formaldehyde and phytic acid into the solution obtained in the step (1) according to the mass ratio of (0.25-2): (0.13-1.0): (0.25-2): 1, reacting for 3-5 hours at the temperature of 50-90 DEG C, filtering and drying to obtain modified lignin; and blending polymer resin, modified lignin and a plasticizer to obtain the toughened flame-retardant composite material. The preparation method of the modified lignin toughened flame-retardant composite material is high in production efficiency, simplein process, excellent in performance, environment-friendly and easy to realize industrial production.

Owner:JIANGNAN UNIV

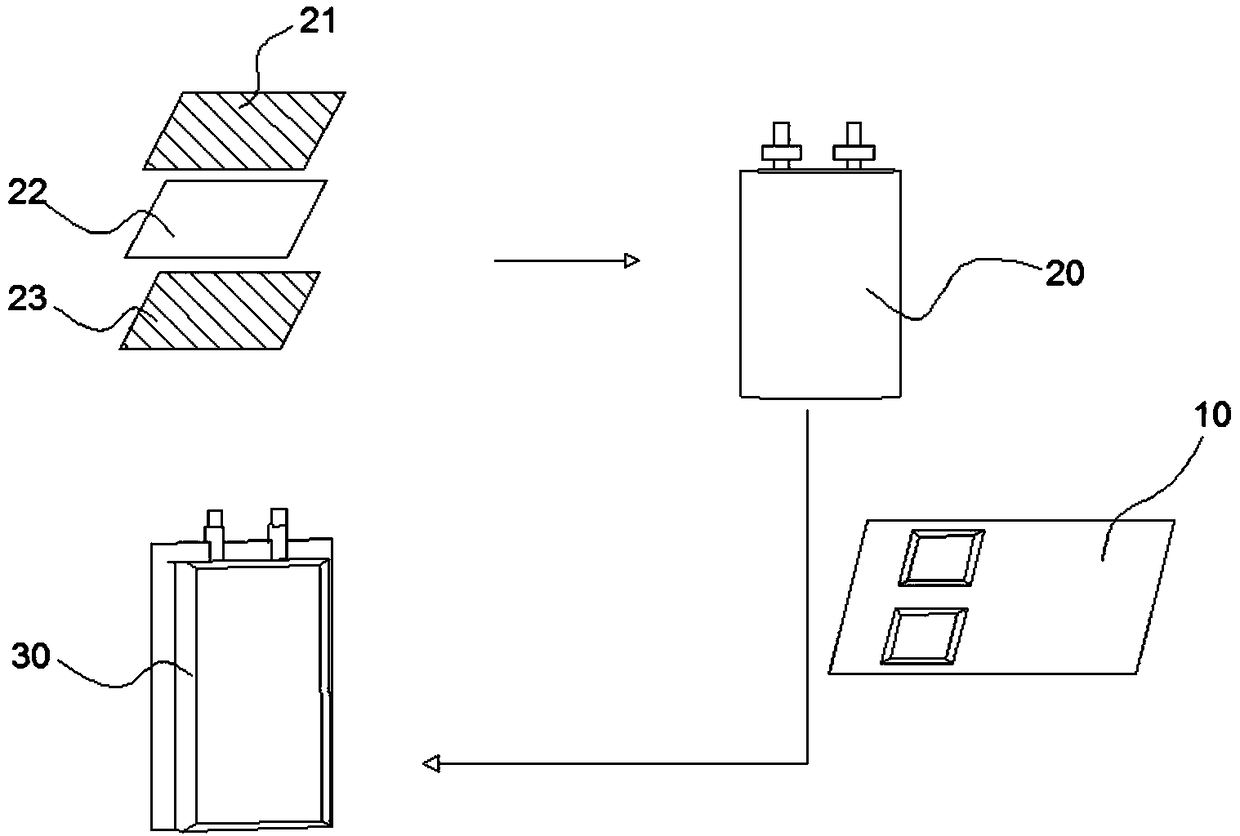

Storage battery and storage battery pack

InactiveCN108091782AWith self-flame retardant effectImprove securityBattery isolationSecondary cellsPlastic filmElectrochemistry

The invention provides a storage battery and a storage battery pack, and relates to the technical field of battery. The storage battery includes an electric core and an aluminum plastic film for encapsulating the electric core, and a flame retardant microcapsule is embedded in the aluminum plastic film. With use of the storage battery, the technical problem of poor electrochemical performance of astorage battery caused when a flame retardant is added in an electrolyte solution of the storage battery to improve the flame retardancy in the prior art can be solved, and the effect of improving the flame retardancy of the storage battery without reduction of the electrochemical performance of the battery can be achieved.

Owner:桑德新能源技术开发有限公司 +1

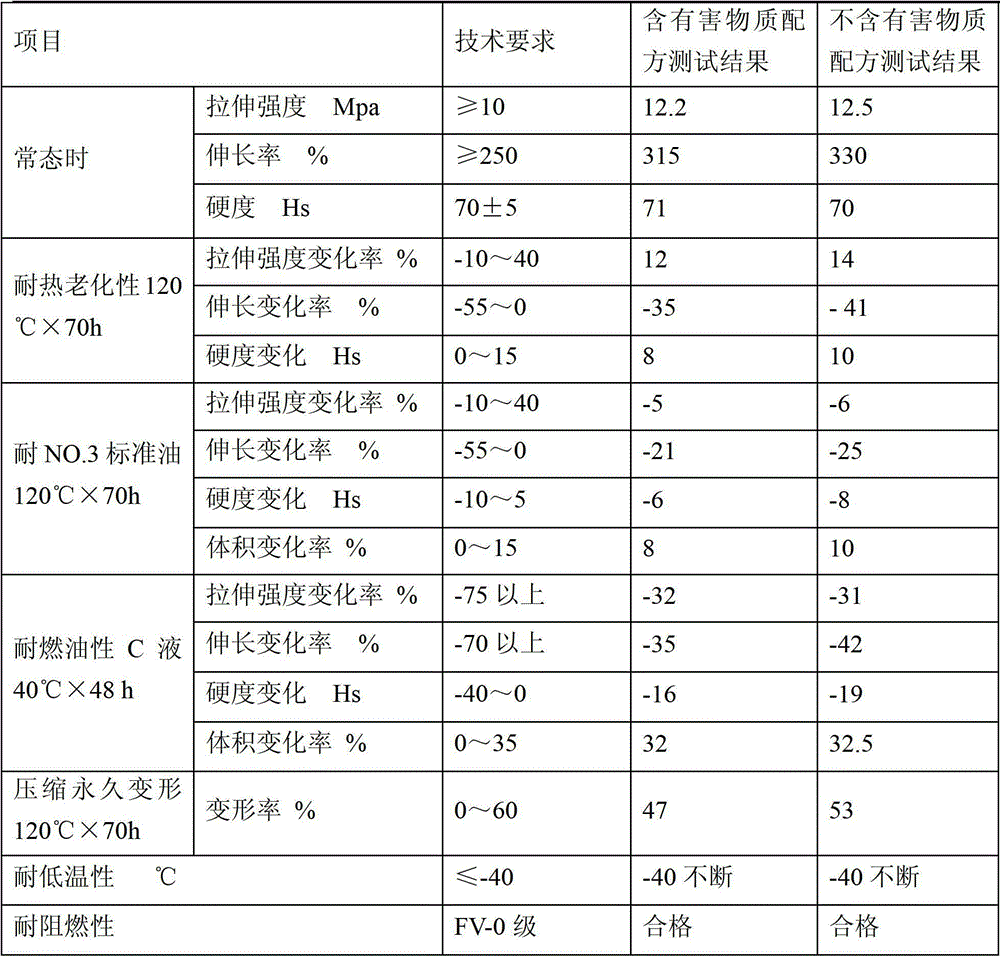

Environment-friendly flame-retardant type epichlorohydrin-rubber pipe formula

The invention relates to a formula of an environment-friendly flame-retardant type epichlorohydrin-rubber pipe, which comprises the following components in parts by weight: 30-70 parts of epichlorohydrin rubber C, 30-70 parts of epichlorohydrin rubber H, 1-8 parts of age inhibitor RD, 0.5-7.5 parts of age inhibitor MB, 1-7 parts of acid-absorbing agent DHT-4A, 2-10 parts of calcium oxide, 3-9 parts of diantimony trioxide, 7-13 parts of decabromodiphenyl ethane, 5-12 parts of lead-free vulcanizing agent H2, 35-55 parts of fast-extruding carbon black N550 and 1-9 parts of ATBC (Acetyl Tributyl Citrate). The environment-friendly flame-retardant type epichlorohydrin-rubber pipe also comprises 1-7.5 parts of anti-roll-bonding agent SPR 66. The environment-friendly flame-retardant type epichlorohydrin-rubber pipe can achieve the effect of flame retardance and simultaneously has the effect of environmental protection, and environment-friendly requirements in many aspects are met. Moreover, the requirements of European standards are met by the formula, and requirements on the required performances of products are achieved.

Owner:TIANJIN BINHAI NEW DISTRICT DAGANG TIANLI RUBBER HOSE

Method for processing silicon rubber composite material

InactiveCN102152553AHas smoke suppressant propertiesDon't burnLaminationLamination apparatusWork in processSilicon

The invention relates to a method for processing a silicon rubber composite material, which is characterized in that semi-finished products of a silicon rubber fireproof isolating layer (1), a silicon rubber flame-retardant cooling layer (2), a silicon rubber ablation-resistant layer (3) and a silicon rubber body layer (4) are respectively prepared in the method firstly, and then the semi-finished products are laminated in a mould of a laminating machine in turn to process the composite material in a molding way under certain conditions. The silicon rubber composite material has better flame-retardant and fireproof effects, and is suitable for serving as a fireproof silicon rubber material for manufacturing fire division walls required in special environments of aircrafts, as well as interior fireproof materials of high-speed vehicles and buildings, military equipment, fire-fighting equipment and the like.

Owner:WUJIANG LANGKE CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com