Aluminium-plastic film and application thereof

A technology of aluminum-plastic film and aluminum layer, applied in the field of aluminum-plastic film, can solve the problem that aluminum-plastic film does not have flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

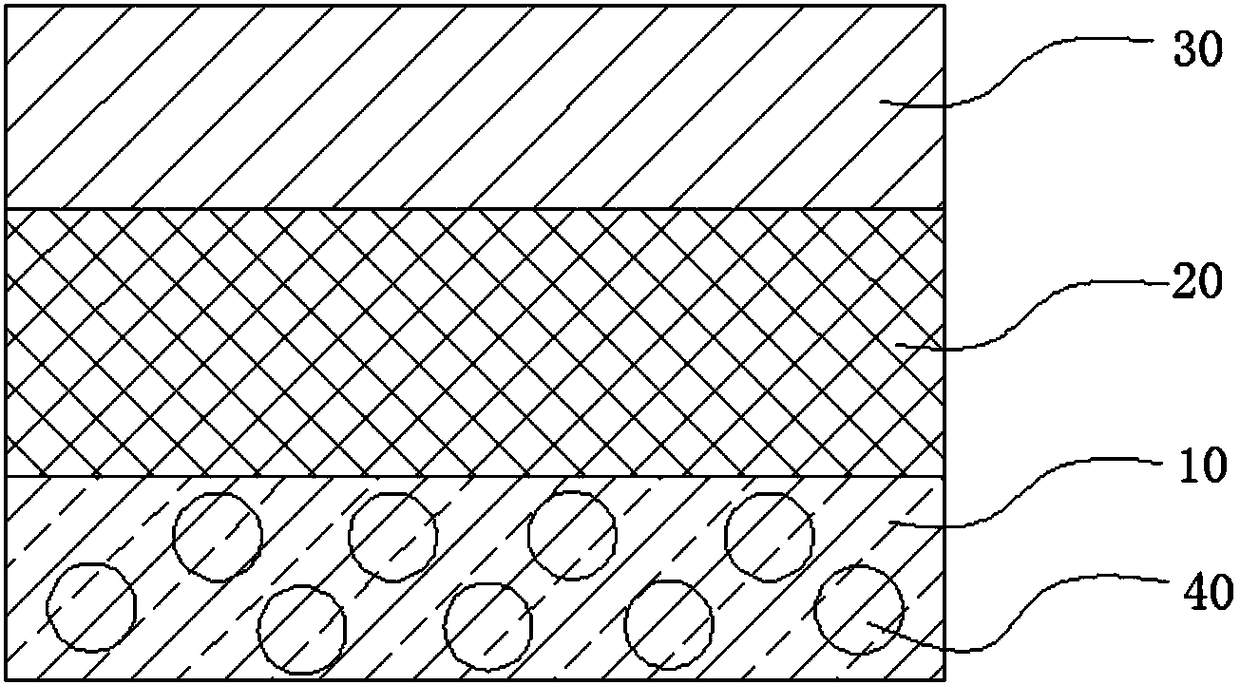

[0064] Such as figure 1 As shown, the present embodiment is an aluminum-plastic film, which mainly includes an outer protective layer 30 , an intermediate aluminum layer 20 and an inner adhesive layer 10 . Wherein, the protection layer 30 is a nylon layer, and the bonding layer 10 is a PP layer. The thickness of the PP layer in the aluminum-plastic film is 30 μm, and the flame retardant microcapsules 40 are embedded inside, and the flame retardant microcapsules 40 account for 40% of the total volume of the PP layer. Among them, the flame retardant microcapsule 40 has a particle size of 5-10 μm, and the capsule shell is polymerized by polyamide with a melting point temperature in the range of 110-130°C. The flame retardant material is tris-(2,2,2-trifluoro ethyl) phosphate.

[0065] The following uses the lithium iron phosphate lithium ion battery packaged in the aluminum plastic film as an example. The capsule shell will melt and release the tri-(2,2,2-trifluoroethyl) phosp...

Embodiment 2

[0067] This embodiment is an aluminum-plastic film, which mainly includes an outer protective layer, an intermediate aluminum layer and an inner adhesive layer. Wherein, the protective layer is a nylon layer, and the bonding layer is a PP layer. The thickness of the PP layer in the aluminum-plastic film is 25 μm, and the flame retardant microcapsules are embedded inside, and the flame retardant microcapsules account for 50% of the total volume of the PP layer. Among them, the particle size of the flame retardant microcapsule is 8-13 μm, the capsule shell is polymerized from polyethylene glycol and polyurea, the melting point temperature is 120-140°C, and the material of the flame retardant is triethyl phosphate.

Embodiment 3

[0069] This embodiment is an aluminum-plastic film, which mainly includes an outer protective layer, an intermediate aluminum layer and an inner adhesive layer. Wherein, the protective layer is a nylon layer, and the bonding layer is a PP layer. The thickness of the PP layer in the aluminum-plastic film is 20 μm, and the flame retardant microcapsules are embedded inside, and the flame retardant microcapsules account for 30% of the total volume of the PP layer. Among them, the particle size of the flame retardant microcapsule is 10-15 μm, the capsule shell is polymerized by polyvinyl chloride and polyethylene glycol, the melting point temperature is 140-150 ° C, and the material of the flame retardant is trimethyl phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com