Storage battery and storage battery pack

A battery and cell technology, applied to battery components, batteries, secondary batteries, etc., can solve the problems of poor electrochemical performance of batteries, achieve the effect of maintaining electrochemical performance, improving safety performance, and good packaging status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

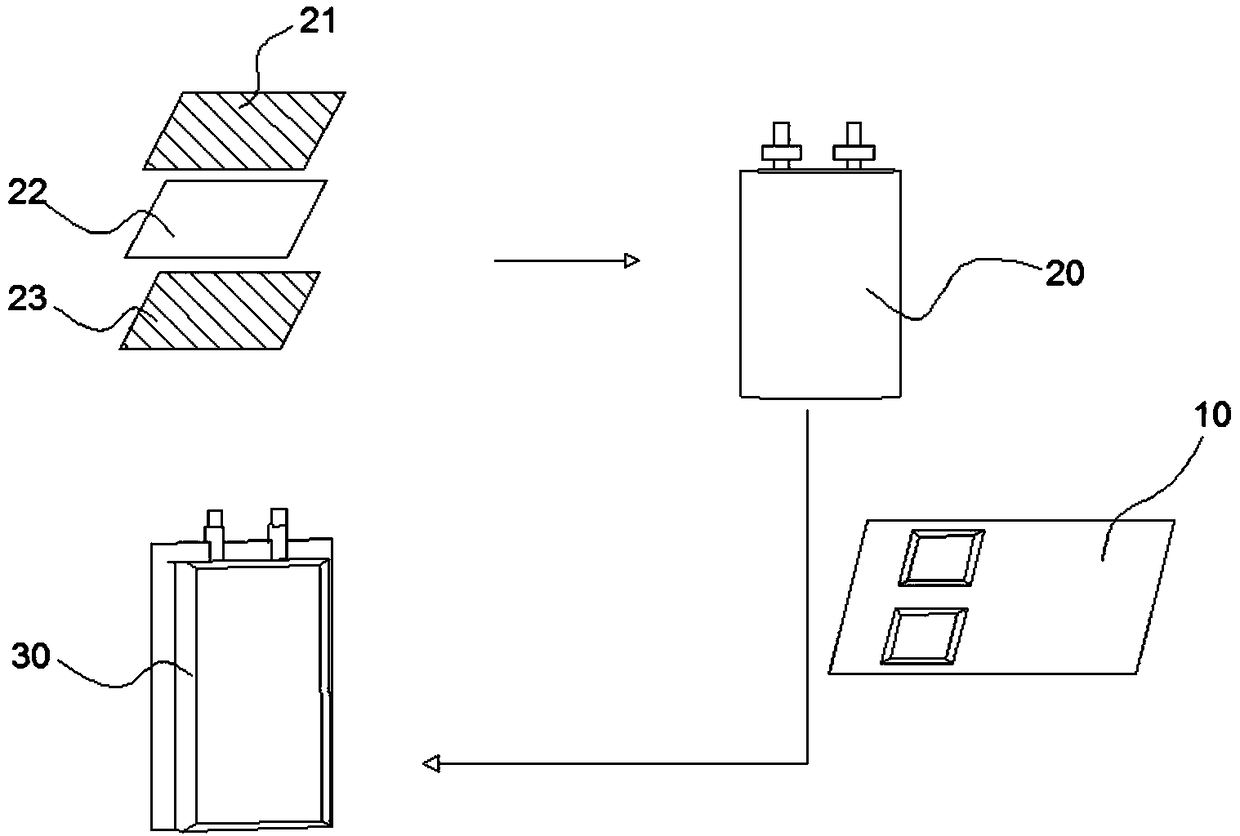

[0071] Such as figure 1 As shown, the present embodiment is a storage battery 30, the storage battery 30 is a lithium iron phosphate lithium ion battery, including a battery cell 20 and an aluminum-plastic film 10 for packaging the battery cell, wherein the battery cell 20 includes a positive pole piece 21, Negative pole piece 23, separator 22 and electrolyte between the positive pole piece and the negative pole piece.

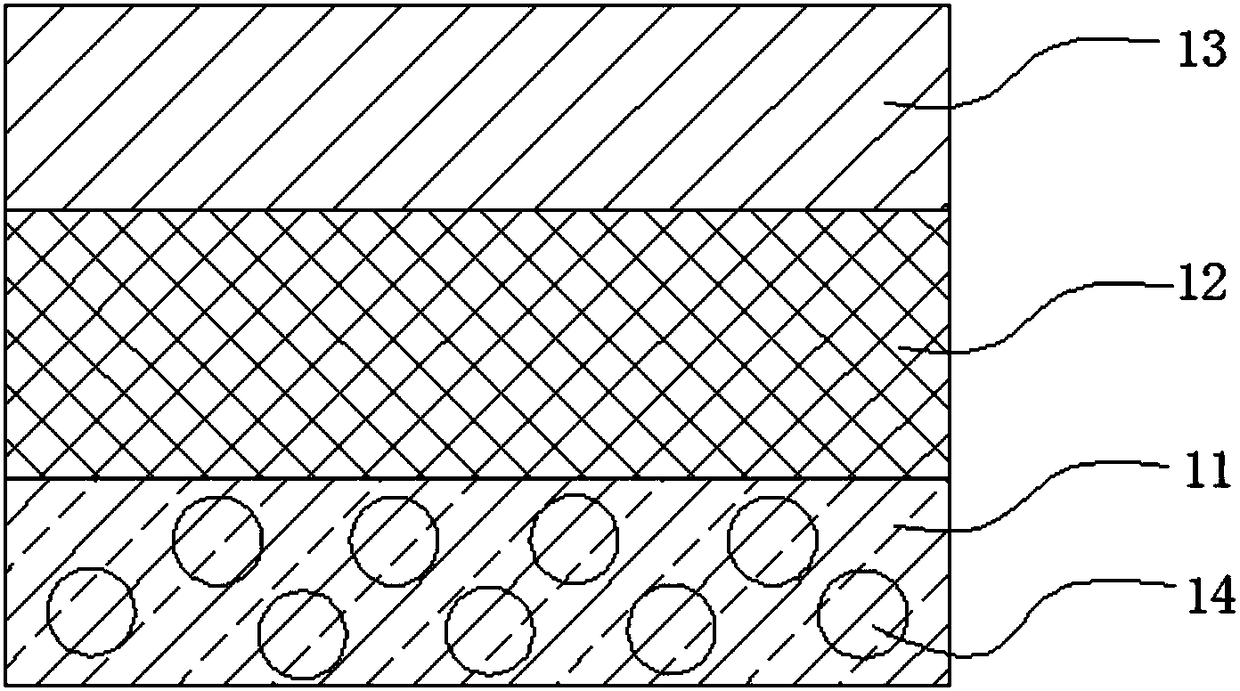

[0072] Such as figure 2 As shown, the aluminum-plastic film 10 mainly includes an outer protective layer 13 , an intermediate aluminum layer 12 and an inner adhesive layer 11 . Wherein, the protective layer 13 is a nylon layer, and the bonding layer 11 is a PP layer. The thickness of the PP layer in the aluminum-plastic film is 20 μm, and the flame retardant microcapsules 14 are embedded inside, and the flame retardant microcapsules 14 account for 40% of the total volume of the PP layer. Among them, the flame retardant microcapsule 14 has a particle size o...

Embodiment 2

[0075] This embodiment is a storage battery, which is a lithium iron phosphate lithium ion battery, and its structure is the same as that of the storage battery in Embodiment 1.

[0076] The aluminum-plastic film in this embodiment mainly includes an outer protective layer, a middle aluminum layer and an inner adhesive layer. Wherein, the protective layer is a nylon layer, and the bonding layer is a PP layer. The thickness of the PP layer in the aluminum-plastic film is 25 μm, and the flame retardant microcapsules are embedded inside, and the flame retardant microcapsules account for 50% of the total volume of the PP layer. Among them, the particle size of the flame retardant microcapsule is 8-13 μm, the capsule shell is polymerized from polyethylene glycol and polyurea, the melting point temperature is 120-140°C, and the material of the flame retardant is triethyl phosphate.

Embodiment 3

[0078] This embodiment is a storage battery, which is a lithium iron phosphate lithium ion battery, and its structure is the same as that of the storage battery in Embodiment 1.

[0079] The aluminum-plastic film in this embodiment mainly includes an outer nylon layer, a middle aluminum layer and an inner PP layer. The thickness of the PP layer in the aluminum-plastic film is 20 μm, and the flame retardant microcapsules are embedded inside, and the flame retardant microcapsules account for 30% of the total volume of the PP layer. Among them, the particle size of the flame retardant microcapsule is 10-15 μm, the capsule shell is polymerized by polyvinyl chloride and polyethylene glycol, the melting point temperature is 140-150 ° C, and the material of the flame retardant is trimethyl phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com