Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

184results about How to "To achieve the purpose of flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fireproof door

InactiveCN102220829APrevent the spread of fireImprove life and property safetyFireproof doorsWater-setting substance layered productEngineeringElectrical and Electronics engineering

The invention relates to a fireproof door used on a building. The fireproof door comprises a door frame and door plates which are respectively arranged at two sides of the door frame. The fireproof door is characterized in that the door plates are respectively glued with the door frame through bonding layers and nailed with the door frame through connecting members, and at least one side of the door plates is a counter-fire side and is a fireproof plate. The invention has the outstanding substantive characteristics that 1, at least one door plate is the fireproof plate, so that a flame retardant purpose is achieved; 2, the door frame, door mullions and an unexposed side are made of flame retardant materials and cannot spontaneously ignite at a relatively higher temperature, and the fireproof effect of the fireproof door is further improved; 3, a heat insulating layer is filled in a cavity formed by the two door plates, the door frame and the door mullions, which is favorable to reducing the high temperature of the counter-fire side, transferring the heat of the counter-fire side to the unexposed side, preventing the temperature from gradually raising and promoting flame retardant wood to lie in an environment below the spontaneous ignition temperature as much as possible; and 4, a metal layer is also arranged on the outer side of the counter-fire side, and deformation phenomena which are caused as different parts of the door plates lose different contents of water are avoided.

Owner:支亮

Organic amine modified ammonium polyphosphate, preparation method and applications thereof

ActiveCN103382267AThe preparation method is matureEase of control and industrial productionAmmonium polyphosphateIon

The invention discloses organic amine modified ammonium polyphosphate. Organic amine modified ammonium polyphosphate is prepared through an ionic reaction between organic amine and ammonium polyphosphate. The structure formula is shown in the description, wherein the R of the formula is a straight chain alkyl or branch chain alkyl with a carbon number between 2 and 6, and the n is not smaller than 1. The invention also discloses a preparation method and applications of organic amine modified ammonium polyphosphate. The organic amine modified ammonium polyphosphate is obtained through modifying ammonium polyphosphate by organic amine in water and alcohol solution, is capable of being used alone as the expanding flame-retardant agent, is harmless to human bodies, can obtain excellent flame-retardant effects by mixing with polypropylene, polyethylene and epoxy resin, and the preparation process is pollution free.

Owner:SICHUAN UNIV

Nitrogen-phosphorus expanded type flame retardant and preparation method for application in aqueous polyurethane coating

ActiveCN110343413AImprove flame retardancyKeep the original natureFireproof paintsGroup 5/15 element organic compoundsChemistrySodium methoxide

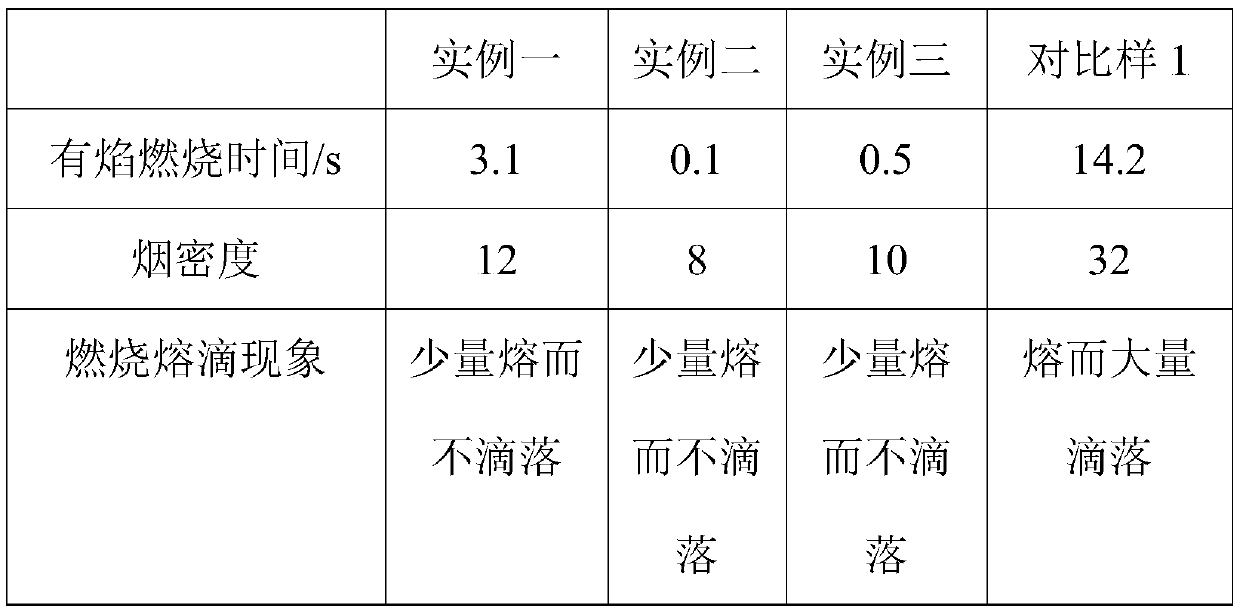

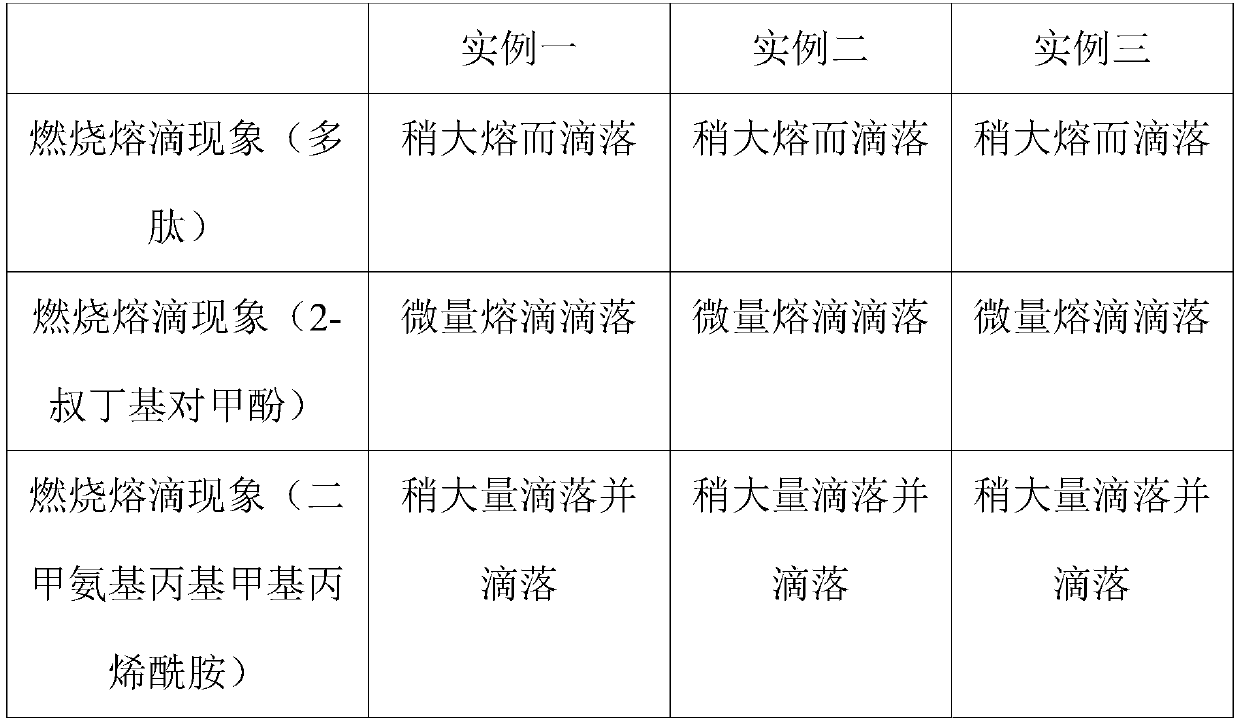

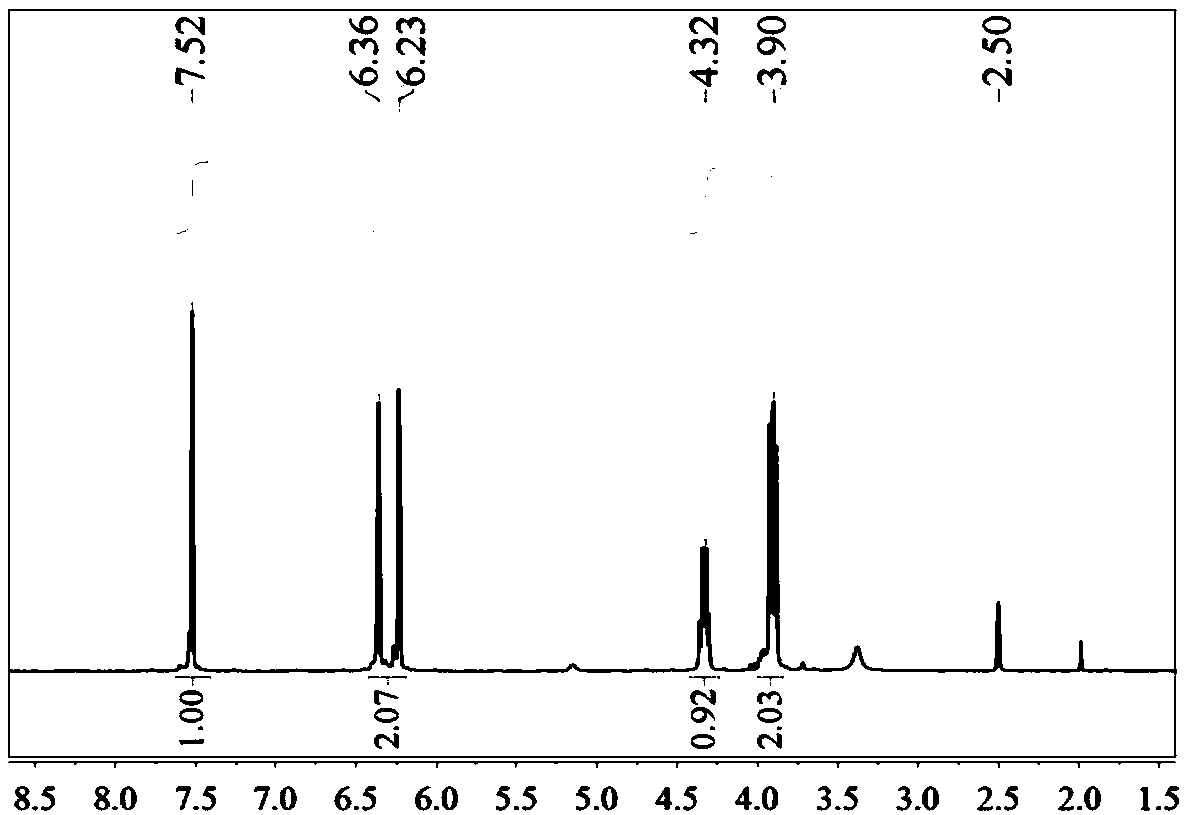

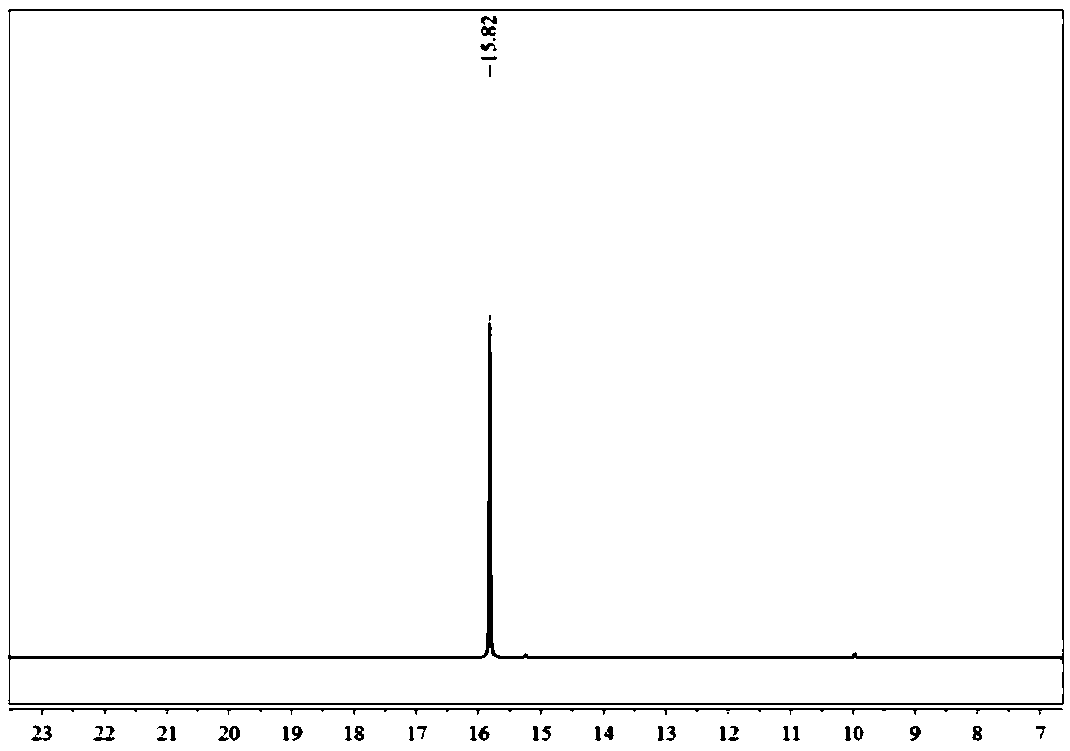

The invention relates to preparation of a nitrogen-phosphorus expanded type flame retardant and a method for application in preparing an aqueous polyurethane coating. The method comprises the following steps: mixing dimethyl phosphate, and alkali catalysts, namely sodium methoxide and acrylamide, performing a reaction so as to obtain an intermediate, adding a charcoal formation agent and a substance A, keeping the pH value of the solution to 6.5-7.0 in the stirring process, further adding a substance B and a substance C, performing a continuous stirring reaction, and performing concentration so as to obtain the nitrogen-phosphorus expanded type flame retardant; and preparing the aqueous polyurethane coating from the nitrogen-phosphorus expanded type flame retardant. By adopting the flame retardant provided by the invention, flame can be rapidly choked, and the flame retardancy of the nitrogen-phosphorus expanded type flame retardant can be improved by releasing smoke, controlling flamecombustion time and controlling densities of charcoal layers. In addition, the nitrogen-phosphorus expanded type flame retardant is grafted with polyurethane, so that the flame retardancy of the polyurethane can be further improved.

Owner:YANTAI UNIV

Thermal-resistant light-smoke halogen-free flame-retardant PC/ABS alloy material and preparation method thereof

The invention discloses a thermal-resistant light-smoke halogen-free flame-retardant PC (polycarbonate) / ABS (acrylonitrile-butadiene-styrene terpolymer) alloy material and a preparation method thereof. The alloy material comprises the following raw material in percentage by weight: 60%-80% of PC resin, 5%-20% of ABS resin, 6%-15% of halogen-free flame retardant, 5%-15% of thermal-resistant modifier, 0.1%-2% of inorganic complex antismoke agent, 0%-10% of flexibilizer and 1%-5% of other processing agents. According to the invention, the thermal-resistant light-smoke halogen-free flame-retardant PC / ABS alloy material can be obtained by a manner of adopting the PC and ABS resins as the substrates and using the synergistic interaction of the thermal-resistant modifier, the halogen-free flame retardant and the inorganic complex antismoke agent; and the alloy material can be widely applied to the industries, such as communications industries, automobile industries, building materials, decoration materials, cables and electrical appliance industries. The preparation method of the alloy material adopts the existing equipment, and the operation is simple, so that the method is suitable for industrial production.

Owner:中广核俊尔(上海)新材料有限公司 +1

Novel dust-inhibiting and fire-retarding covering agent for coal, and preparation method thereof

InactiveCN102464971ALow costEasy to produceOther chemical processesSpontaneous combustionSocial benefits

The invention discloses a novel dust-inhibiting and fire-retarding covering agent for coal, and a preparation method thereof. The dust-inhibiting and fire-retarding covering agent comprises components of, by mass: 4-5% of a film forming agent, 10-12% of a curing agent, 2-3% of a film forming auxiliary agent, 1-3% of a penetrant, 1-3% of a fire retardant, and 74-82% of water. The preparation method of the dust-inhibiting and fire-retarding covering agent comprises steps that: the film forming agent is added and dissolved in water under a certain temperature; the temperature is controlled; the solution is continuously stirred, and the curing agent, the film forming auxiliary agent, the penetrant, and the fire retardant are orderly added to the solution while stirring; the mixture is stirred, until a reaction is sufficiently carried out. The novel dust-inhibiting and fire-retarding covering agent is sprayed onto the surface of coal under a normal temperature, and other equipments and conditions are not required. Within a short time, a flexible and compact continuous high-molecular covering membrane is formed, such that phenomena of dust emission and spontaneous combustion during transportation and stacking processes can be avoided. Therefore, coal economic loss and environmental pollution can be effectively reduced; and great economic benefits and social benefits of environmental protection are provided.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation method of attapulgite modified bio-based polyurethane foam insulation material

The invention discloses a preparation method of an attapulgite modified bio-based polyurethane foam insulation material. The preparation method comprises the steps of compounding propanediol obtained by liquefying cellulosic biomass and attapulgite to obtain compound propanediol, and compounding modified attapulgite obtained through acid modification and organic modification and isocyanate to obtain compound isocyanate; mixing propanediol or compound propanediol, a foam stabilizer, a foaming agent and a catalyst uniformly to obtain a viscous mixture; quickly adding isocyanate or compound isocyanate to the viscous mixture in a stirring state, and aging the product at a certain temperature for a while after complete foaming and curing, thus obtaining a rigid polyurethane foam insulation material with a flame retardant function. The preparation method has the characteristics of simple process, low production cost, no need for special equipment, easiness in implementation of industrialization and the like. The polyurethane foam insulation material is a rigid foamed plastic with good flame retardance.

Owner:盱眙凹土能源环保材料研发中心 +1

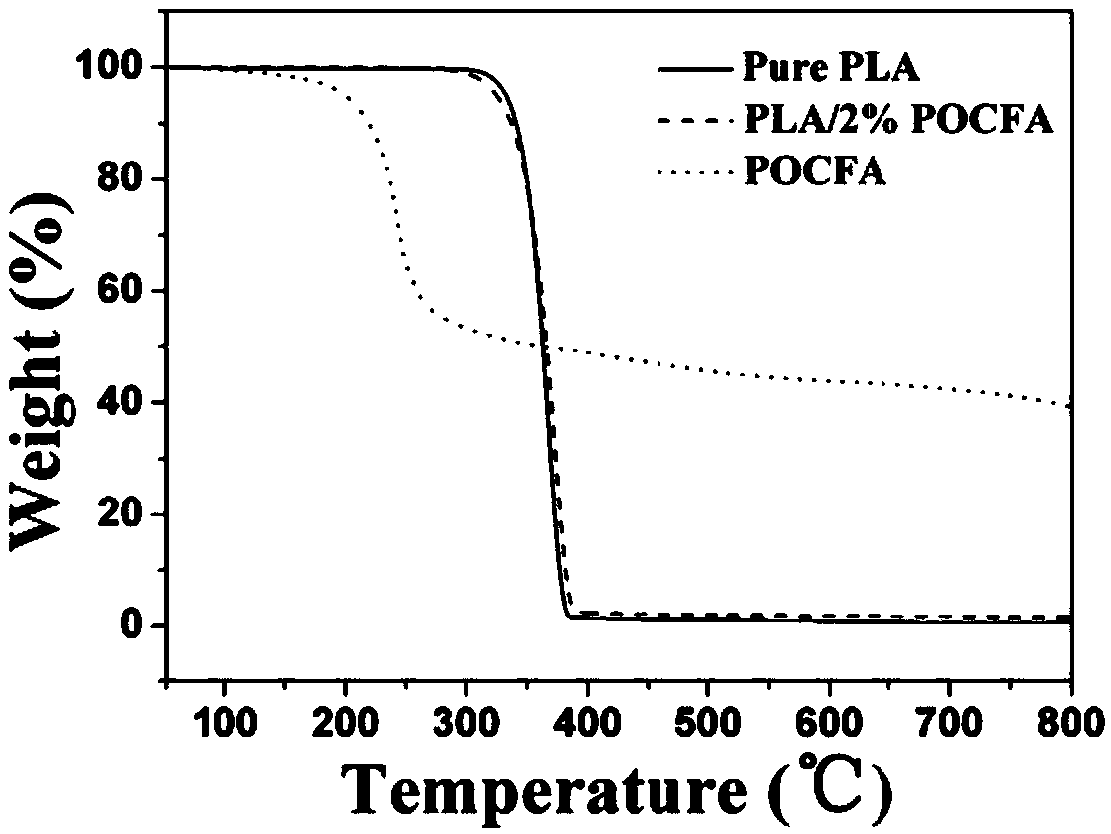

High-effective bio-based flame-retarding agent containing furan ring, and synthesis method and application of the flame-retarding agent

ActiveCN109280219AHigh yieldThe synthesis process is simpleGroup 5/15 element organic compoundsFuranSynthesis methods

The invention discloses a high-effective bio-based flame-retarding agent containing furan ring, and a synthesis method and an application of the flame-retarding agent. In the invention, with a bio-based compound containing furan ring and a phosphorus-containing compound being raw materials, the bio-based flame-retarding agent containing furan ring is prepared under protection by inert gas. The flame-retarding agent is very low in influence on thermo-stability of a resin matrix and can effectively improve crystallization property of the resin matrix, thereby improving mechanical strength and modulus of the material. When being applied to polymers, the flame-retarding agent has outstanding flame-retarding effect and can achieve flame retarding just by a less addition amount. The flame-retarding agent can alleviate thermal performance loss of a flame-retarding composite material and significantly improve crystallization and increase crystallization speed of the polymer matrix, thus significantly enhancing mechanical performance of the composite material. The flame-retarding agent can catalyze degradation of polylactic acid mainly in the manner of breaking molecular chains to form low-molecular-weight oligomers, then heat generated during combustion is released in the form of molten drops, thus achieving the flame retarding object.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

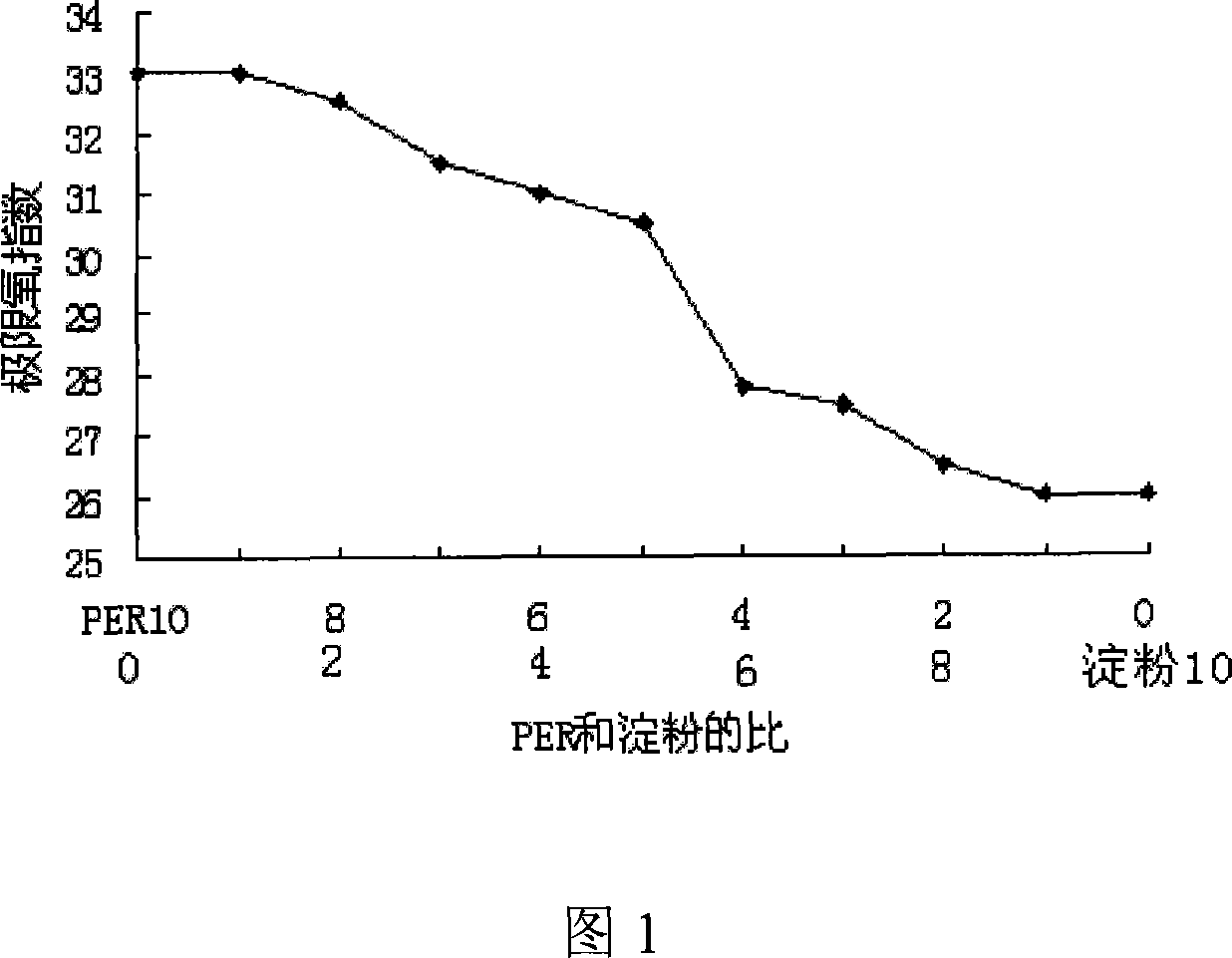

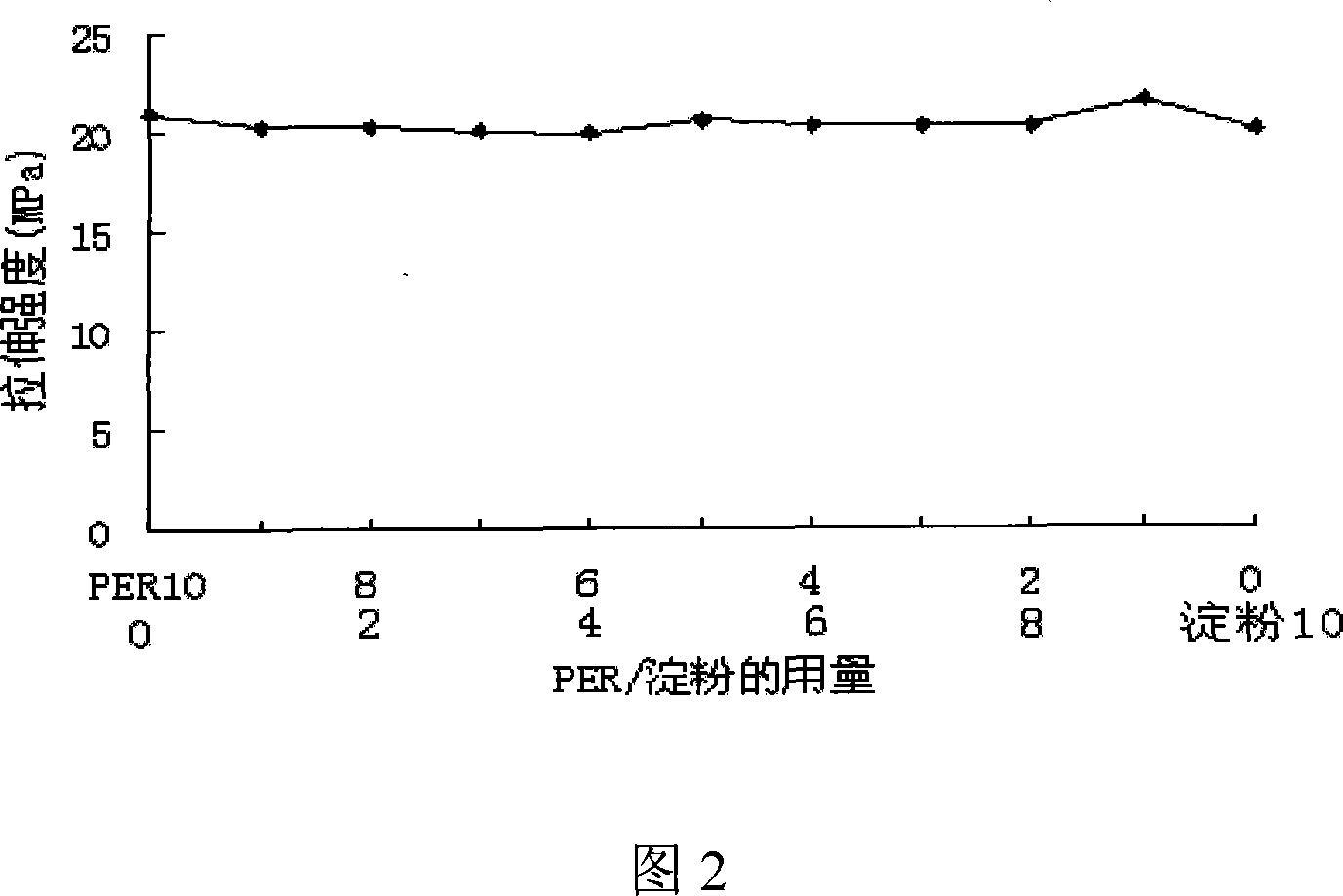

Non-bittern expanding flame-proof material and method for making same

InactiveCN101134830ARaise the maximum thermogravimetric rate temperatureIncrease the residual rate of thermogravimetric lossFireproof paintsHalogenPolypropylene

The present invention relates to one kind of no-halogen expanding fire retardant material and its preparation process. The no-halogen expanding fire retardant material consists of polypropylene and expanding fire retardant in 30-50 wt% of polypropylene. It is prepared through melting and rolling polypropylene at 160-170 deg.c, adding expanding fire retardant and additive and mixing for 8-15 min, hot pressing at 15 MPa and 180 deg.c for 2-5 min and cooling to set. The no-halogen expanding fire retardant material of the present invention has excellent fire retardant effect and high mechanical performance.

Owner:SOUTH CHINA UNIV OF TECH

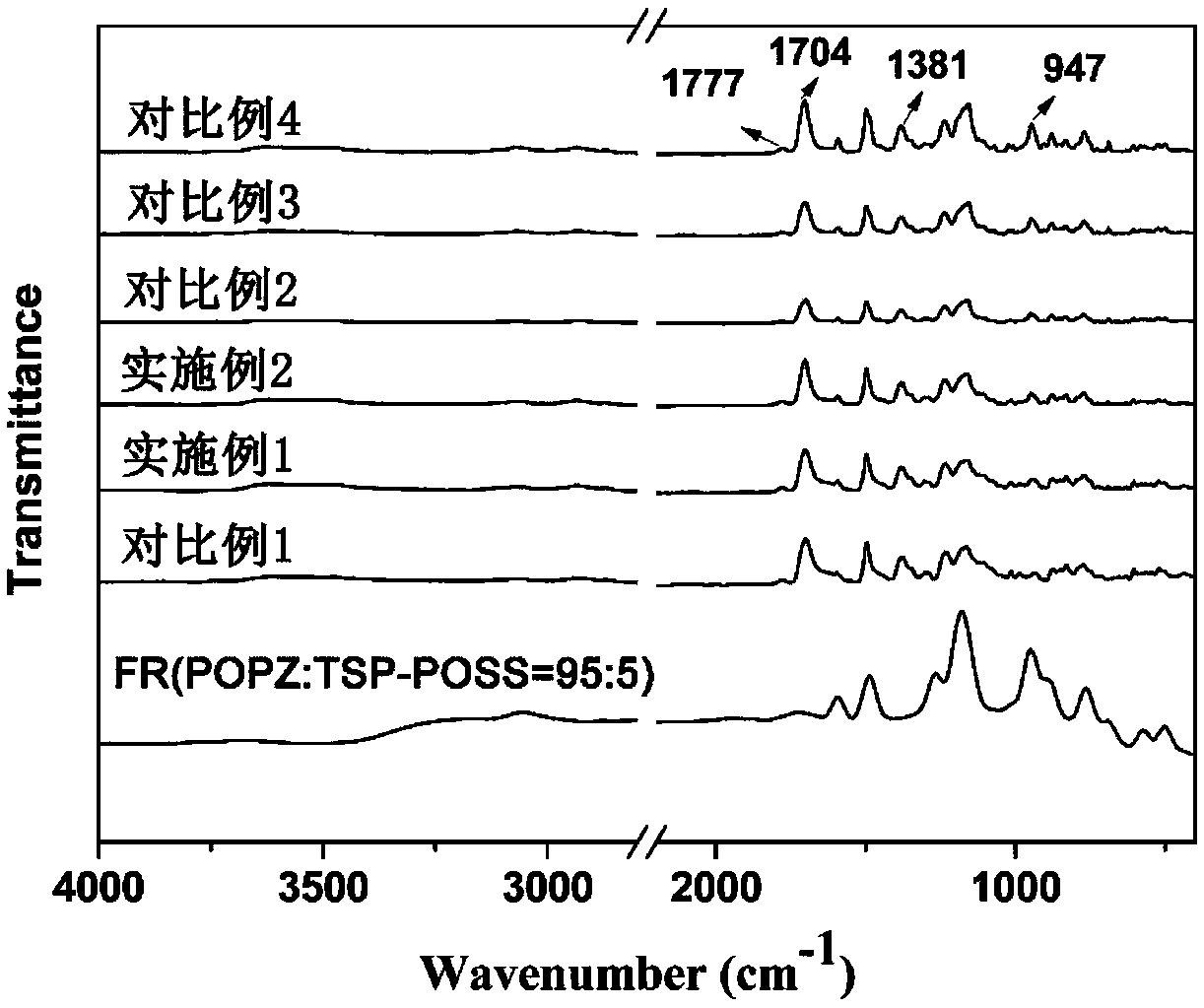

PI matrix resin and flame-retardant colorless transparent polyimide film prepared from same

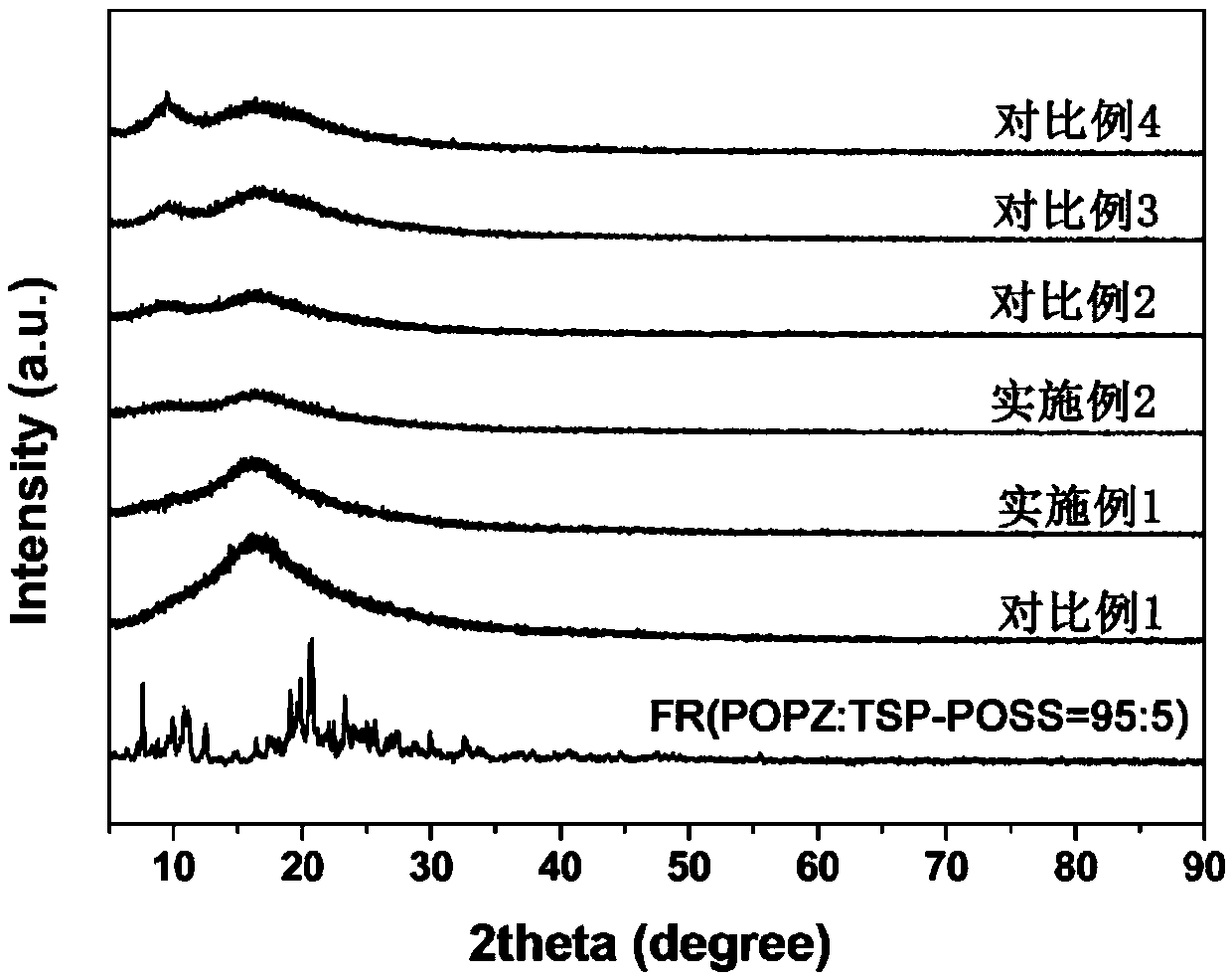

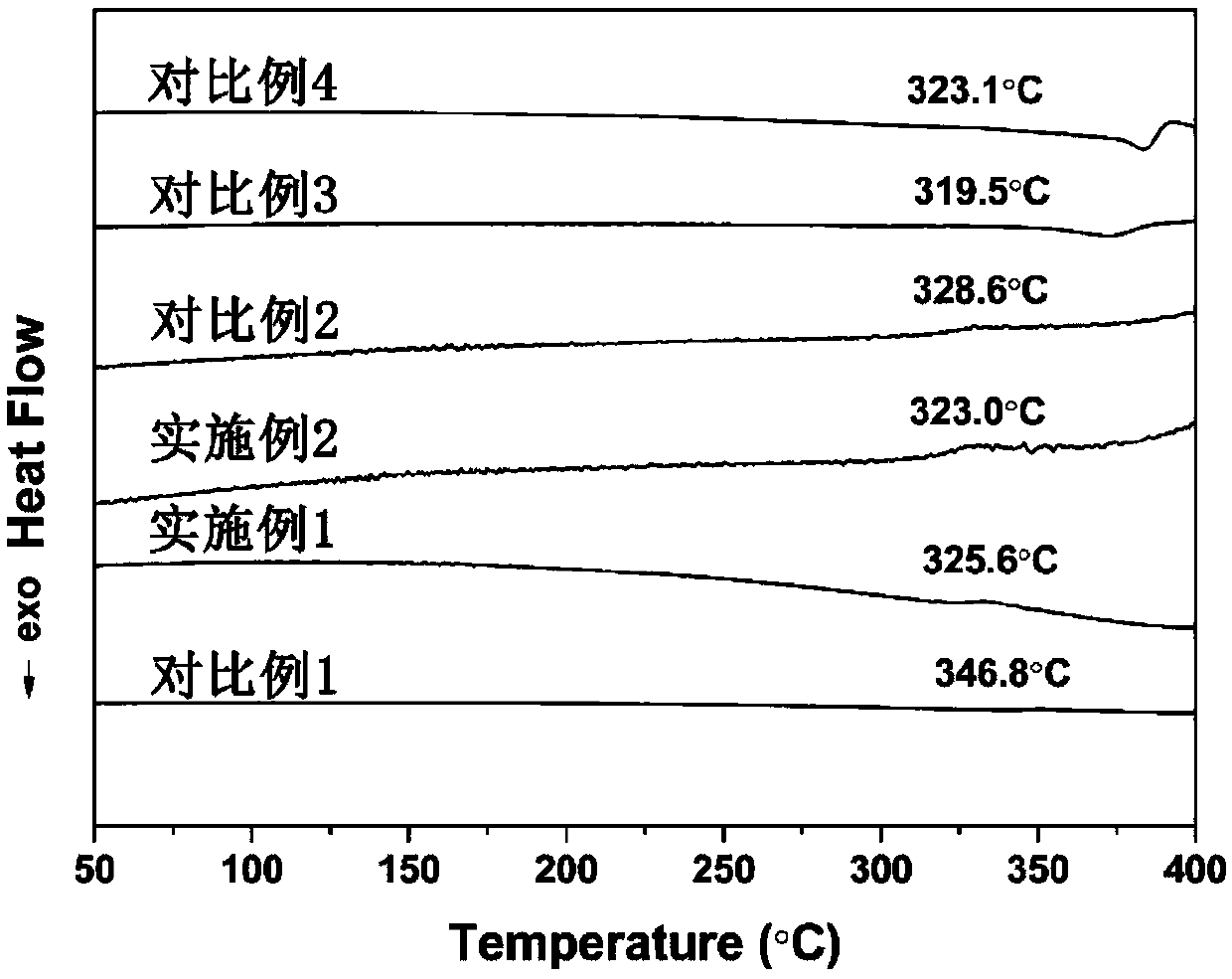

ActiveCN109575285AImprove solubilityIt is colorless and transparentThermal stabilityFlexible electronics

The invention belongs to the technical field of polymer materials, and particularly relates to a colorless transparent PI matrix resin, and further discloses a preparation method of the colorless transparent PI matrix resin as well as a flame-retardant colorless transparent polymide film prepared from the PI matrix resin. The flame-retardant colorless transparent polyimide film is prepared by adopting the prepared PI matrix resin as a matrix raw material and adding selected flame-retardant agent FR filler (POPZ+TSP-POSS) without changing the transparency of the resin film is excellent in heatresisting stability, high in glass transition temperature (Tg), high in transparency and excellent in flame-retardant properties, thereby achieving a flame-retardant purpose. The flame-retardant colorless transparent polyimide film prepared in the invention can be used as a flexible material to be applied to the technical fields such as solar panels, flexible printed circuit boards, microelectrons, cars and the like, and is wide in application prospect.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Flame-retardant artificial turf and preparation method thereof

ActiveCN103952963AFlame retardantImprove flame retardant performanceGround pavingsFlooring insulationsYarnCombustion

Owner:COCREATION GRASS CO LTD

Environment-friendly fireproof material for electrical equipment and preparation method thereof

ActiveCN106497339AReduce solubilityImprove thermal stabilityFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

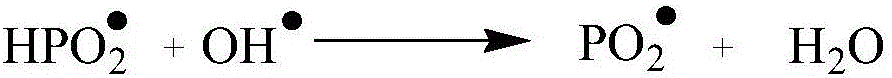

Fluorescent orange retardant double layer fabrics and weaving, arranging method thereof

InactiveCN105369436ASolve the flame retardant problemHigh color fastnessSynthetic resin layered productsCellulosic plastic layered productsModacrylicViscose

The invention discloses fluorescent orange retardant double layer fabrics and a weaving, arranging method thereof, and the method comprises the steps of taking 150D terylene filament that is dyed into fluorescent orange as an upper level warp yarn and an upper level filling yarn; taking 24S / 2 twin thread retardant modacrylic and aramid fiber yarn as a lower layer warp yarn and a lower layer filling yarn; a twill weave structure comprising an upper layer and a lower layer that are overlapped mutually is formed, wherein the upper level warp yarn and the upper level filling yarn employ a weaving method of two up one down, and the weaved organization is taken as the terylene filament surface layer; the lower layer warp yarn and the lower layer filling yarn employ a weaving method of two down one up, and the weaved organization is taken as the retardant modacrylic aramid fiber yarn inner layer; the retardant modacrylic aramid fiber yarn is formed by twisting the single thread of modacrylic 40-60%, 1414 aramid fiber 10-18%, retardant viscose glue 25-45%, and antistatic conductive filament 0.5-3% in weight percentage. The fabrics meet the fluorescence standard and has a very high retardant effect; no droplet is generated in the process of combustion, nor did a fusion hole; and the flame retardation problem of the fluorescent orange products is solved.

Owner:SHAOXING FAMOUS TEXTILE CO LTD

Coal mine underground rubber hose for drawing out methane and preparation method thereof

ActiveCN101725777AAvoid accidentsTo achieve the purpose of flame retardantFlexible pipesGas removalParaffin waxConductive channel

The invention relates to a coal mine underground rubber hose for drawing out methane, which is prepared by taking natural gum, neoprene and butadiene-acrylonitrile rubber used together as a rubber layer material of the rubber hose, taking acetylene carbon black, conductive channel black, conductive furnace black and extra conductive furnace black as antistatic agents, taking the mixture of carbon black N375, phthalic acid and dibutyl phthalate as a softening agent, taking the mixture of antimony trioxide, decabromo propyl ether, aluminum hydroxide and paraffin as a fire retarding agent, and adopting a process for manufacturing a conventional rubber hose. The coal mine underground rubber hose has antistatic and flame-retardant effects, and through the verifications of the National Coal Mine Support Equipment Quality Supervision and Inspection Center and the National Coal Mine Dustproof Ventilation Safety Product Quality Supervision and Inspection Center, the coal mine underground rubber hose meets the requirements on the safety performance inspection specification standards of HG / T2490-93 and MJ / 191-80 coal mine underground rubber hoses for drawing out the methane in the industry.

Owner:CHANGZHI ZETAI RUBBER & PLASTIC PRODS

Photocuring resin for investment casting in laser fast molding

The invention discloses a photocuring resin for investment casting in laser fast molding. The resin comprises the following materials in percentage by mass: 30 to 55 percent of unsaturated polyester, 20 to 35 percent of epoxy resin, 20 to 40 percent of active diluent and 1 to 6 percent of light initiator. A preparation process for the resin comprises the following steps of: adding the light initiator into the active diluent, dissolving in a water bath of 40 to 60 DEG C until the light initiator is transparent, adding the unsaturated polyester and the epoxy resin, and stirring and mixing for 1 to 2 hours. The resin has low viscosity, a mold shell does not crack during roasting, the thermogravimetric curve is flat in a roasting process, the gas evolution is uniform and the carbon residue is low.

Owner:湖南西交智造科技有限公司

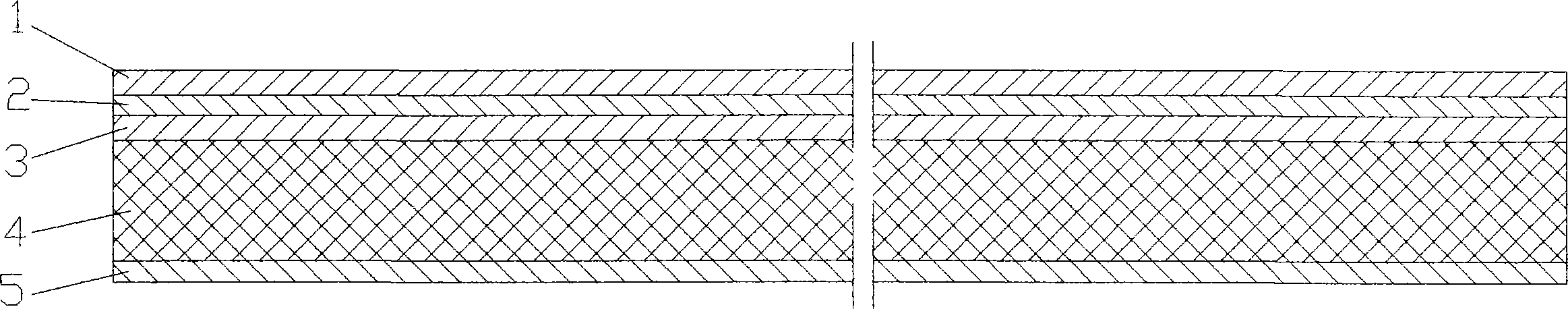

Fire retardant floor and its manufacture method

InactiveCN101240651ABlock deliverySolving Difficult-to-Glue ProblemsWood working apparatusFlooringAluminium silicatePre treatment

The present invention discloses a flame-retarding floor which is composed of an abrasion-resisting layer, a decorating layer, a flame-retarding layer, a base material layer and a balance layer from the top to the bottom, wherein the flame-retarding layer is composed of quartz cloth or alumina silicate fiber cloth or asbestos cloth. The invention further discloses a method for manufacturing the flame-retarding floor, which concretely comprises the following steps: firstly manufacturing the abrasion-resisting layer, the decorating layer, the balance layer and the base material with a well-known mode; then preprocessing the selected flame-retarding layer material; and finally adhering each layer with the adhesive for fixing, wherein when the flame-retarding layer is adhered firstly the resin acceptor is coated on the surface of the flame-retarding layer then the adhering is executed. When the floor is added with a flame-retarding layer at the state that the upper side of the floor is generated with high-temperature burning the flame-retarding layer can effectively prevent the transferring of the heat to the base material for preventing the ablating of the base material thereby obtaining the purpose of flame retarding. As the inorganic material layer has polymerization-inhibiting function to the adhesive, the using of the resin acceptor can effectively settle the problem that the veneering interface is hard to be laminated and the bonding strength is guaranteed.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Cortex-core protein and polyacrylonitrile compound fiber and method for wigs

ActiveCN102864521AWith hand feelFeel goodWigsConjugated cellulose/protein artificial filamentsPolyesterAcrylonitrile

The invention relates to a combination and a spinning method for making wigs. The combination comprises protein, acrylonitrile, polyester and olefin, and includes a cortex layer and a core layer, wherein the cortex is mixed by, by weight, 10-40% of protein, 0.05-1% of a wax dispersing agent and the balance amide or sulfone solvents; and the core layer is a polymer with a molecular weight of 45,000-70,000 copolymerized by, by weight, 35-45% of acrylonitrile, 35-45% of vinylidene chloride, 10-20% of acrylic ester, 6-10% of sulfonate, 0.3-4% of a flame retardant and 0.2-1% of azodiisobutyronitrile; and the cortex-core layer spinning solution is produced into protein composite fibers with a flame retardant performance through a bi-component composite spinning machine and a wet spinning process, and a limited oxygen index can reach 28-30. The composite fibers for the wigs can be used as fashionable hair products and advanced artificial furs; are good in skin affinity, moisture absorption, breathable performance and dyeing property; touch like real hair; and are simulation and super-real fiber with a flame retardant property.

Owner:SHANGHAI REBECCA FIBER MATERIAL TECH

Flame-retarding type active carbon and its preparation method

A flame-retarding activated carbon is prepared from the activated carbon (60-98 wt.%) and flame-retarding agent (2-40 wt%) through spraying flame-retarding agent onto activated carbon and baking at 80-200 deg.C. Its advantages are large specific surface area, high adsorbability and sure flame-retarding performance.

Owner:NO 63971 TROOPS PLA

Low-smoke bittern-free flame-retardant polyolefin material and braided fabric manufactured thereby

ActiveCN101230162ATo achieve the purpose of flame retardantIncrease temperatureCane mechanical workingHalogenPolyolefin

The invention relates to low smoke non-halogen flame-resistant polyolefine material and compound weaved cloth made of the low smoke non-halogen flame-resistant polyolefine material. The low smoke non-halogen flame-resistant polyolefine material is composed of polyolefine resin and inorganic flame retardant. The manufacturing process of the weaved cloth comprises the following steps: on one hand, polyolefine material is taken to be filled into a plastic extrusion molding machine, film is extruded through the plastic extrusion molding machine, and then cooled and cut, heated and directionally stretched, the pre-heating treatment is performed to the film to be shaped, and then the film is rolled, and woven in across warp and warp direction into plastic cloth; on the other hand, the low smoke non-halogen being flame-resistant polyolefine material is taken to be filled into a clothes rack type flat frame head plastic extrusion molding machine, and film coating is extruded through the clothes rack type flat frame head plastic extrusion molding machine; after two aspects are accomplished, the film coating is hot melt and continuously compressed into the low smoke non-halogen flame-resistant polyolefine weaved cloth through a compound rolling drum. The technology of the invention can improve the low smoke non-halogen flame-resistant performance and the anti-aging performance of the polyolefine plastic weaved cloth.

Owner:上海亚都塑料有限公司

Halogen-free flame retardation polycarbonate material and preparation method thereof

A halogen-free flame retardation polycarbonate material comprises, by weight, 70-90% of polycarbonate, 5-10% of other resins, 6-15% of a halogen-free flame retardant, 5-15% of a surface modifier, 3-10% of a flexibilizer, 0.6-2.5% of an antioxidant,0.4-2.5% of a lubricant and 0.3-1.2% of a weather resisting agent. The halogen-free flame retardation polycarbonate material fully performs a synergistic flame retardation effect, substantially improves the flame retardation performance of a PC material, has the advantages of high efficiency, no toxicity, low smoke and dropping resistance, excellent flame retardation performance, excellent mechanical performances, good processing fluidity, high thermal deformation temperature, good impact resistance, moderate cost, and suitableness for industrial application.

Owner:CIXI FALAIXIN PLASTIC FACTORY

Preparation method for halogen-free flame-retardant high-density polyethylene/ethylene-vinyl acetate polymer

InactiveCN103554598AImprove interfacial adhesionImprove mechanical propertiesPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a preparation method for a halogen-free flame-retardant high-density polyethylene / ethylene-vinyl acetate polymer. The preparation method specifically comprises the following steps: I, adding 2 to 4 parts by weight of silane coupling agent into 180 to 220 parts by weight of anhydrous alcohol, mixing the silane coupling agent and the anhydrous alcohol uniformly, heating the mixture to 70 to 90 DEG C, adding 100 parts by weight of dried expandable graphite into the solution, and stirring to obtain modified expandable graphite; II, uniformly mixing 5 to 15 parts by weight of modified expandable graphite, 70 parts by weight of high-density polyethylene, 30 parts by weight of ethylene-vinyl acetate polymer, 2.5 to 7.5 parts by weight of ammonium polyphosphate and 2.5 to 7.5 parts by weight of red phosphorus flame retardant master batch in a mixer to obtain a mixture; III, mixing and granulating the mixer by using a screw extruder, drying the extruded granules and performing injection molding on the dried granules. The prepared composite material has high flame retardant property and high mechanical property.

Owner:SOUTHWEST JIAOTONG UNIV

High carbon formation type low-smoke, zero-halogen and flame-retardant polyolefin cable material

InactiveCN108178864AGood flame retardant in bunchesStrong carbon forming abilityPlastic/resin/waxes insulatorsCarbon layerHalogen

The invention discloses a high carbon formation type low-smoke, zero-halogen and flame-retardant polyolefin cable material. The cable material is prepared from components in parts by weight as follows: 100 parts of basic resin, 120-190 parts of a hydroxide inorganic flame retardant, 0.5-5 parts of a lubricating agent, 0.1-0.8 parts of an antioxidant and 1-10 parts of a carbon forming agent. The mineral flame retardant of hydroxide is used as a gas source, the basic resin is used as a carbon source, meanwhile, multiple acid sources are added, and the cable material has the advantages of high carbon forming capacity and hard carbon layer, has a very excellent flame retardant effect and has very good flame retardant effects on electric wire and cable bundles when used in electric wire and cable sheaths.

Owner:中广核拓普(四川)新材料有限公司

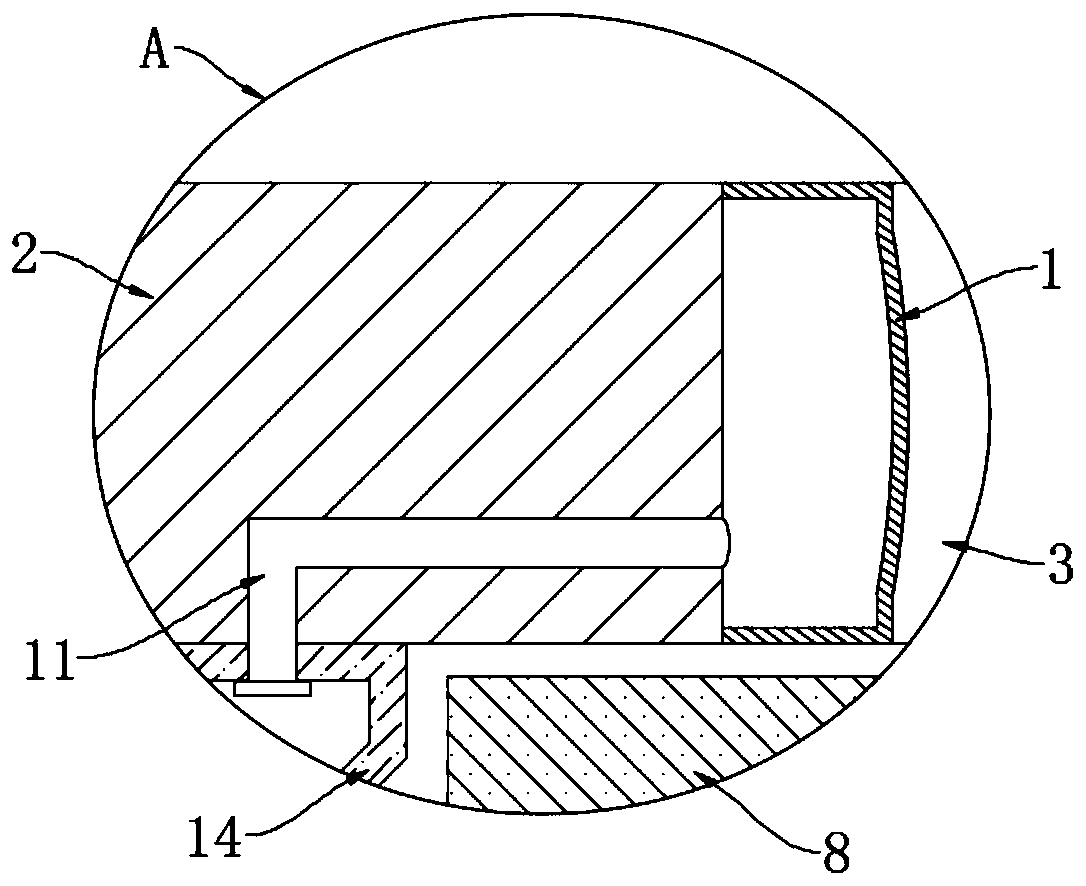

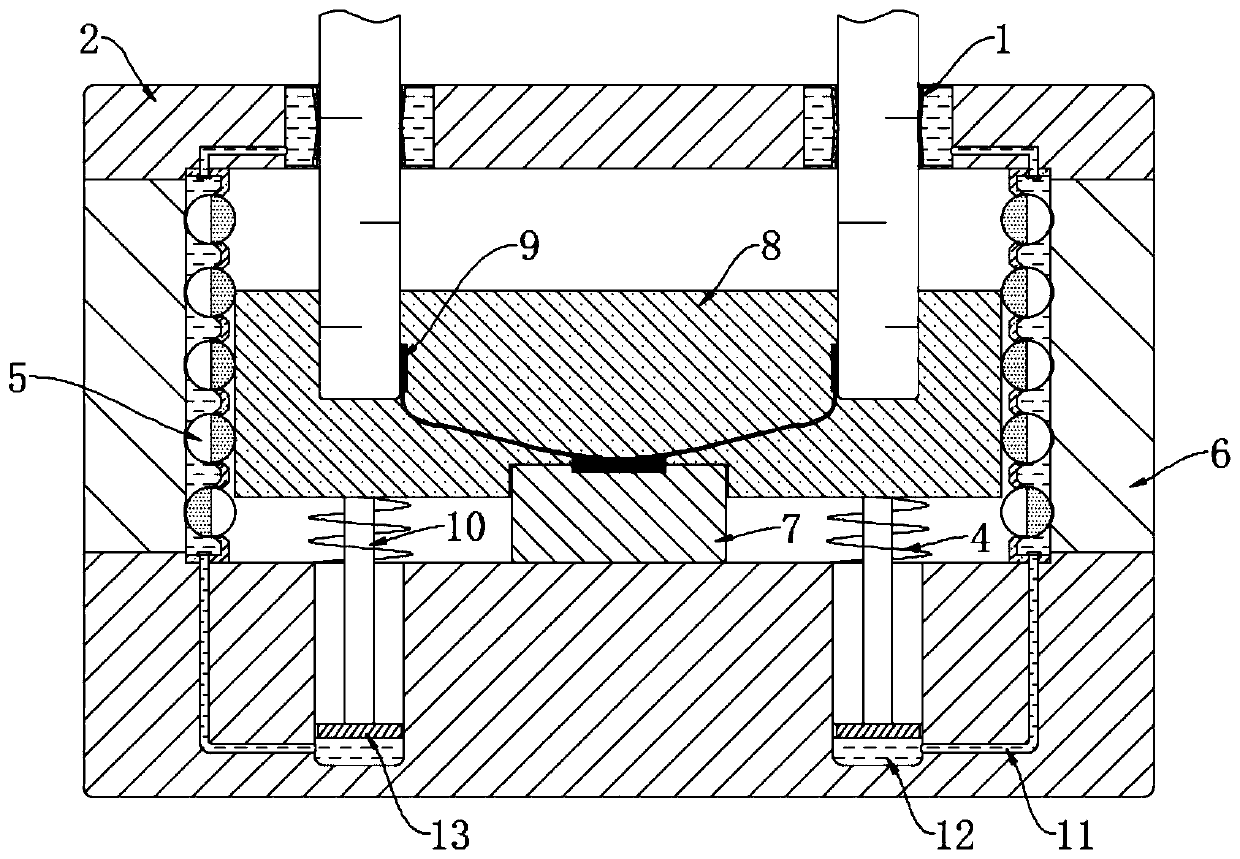

Anti-loosening socket with indication function

ActiveCN111446590AEasy to identifyReduce anxietyIncorrect coupling preventionLive contact access preventionEngineeringMetal sheet

The invention discloses an anti-loosening socket with an indication function. The socket comprises a socket body, jacks are symmetrically arranged on the socket body, and a groove body is arranged inthe socket body; two fixing frames are symmetrically mounted in the groove body; a plurality of indicating balls are rotatably mounted on each fixing frame; and a connecting plate is arranged betweenthe two fixing frames, two side walls of the connecting plate are connected with the corresponding indication balls in a rolling mode, a plurality of cooling fins are symmetrically embedded in the side walls of the socket body, and the multiple cooling fins located on the same side and the corresponding fixing frames jointly form a sealed cavity. After a plug is completely inserted, the color of the indication balls changes, a user can judge whether the plug is tightly inserted or not by observing the color change, and after the plug is inserted into the socket body, fasteners at the jacks extrude a metal sheet on the plug so that connection between the plug and the socket body is more stable, and the plug is not easy to loosen.

Owner:林高龙

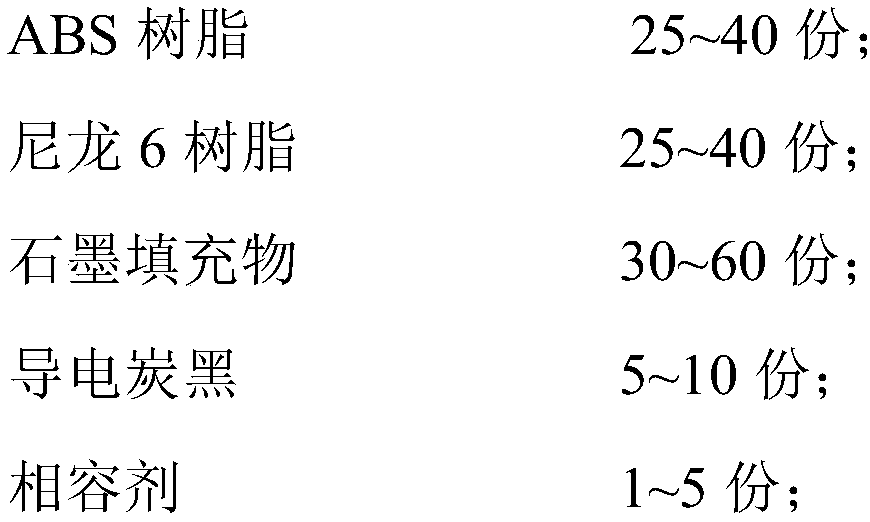

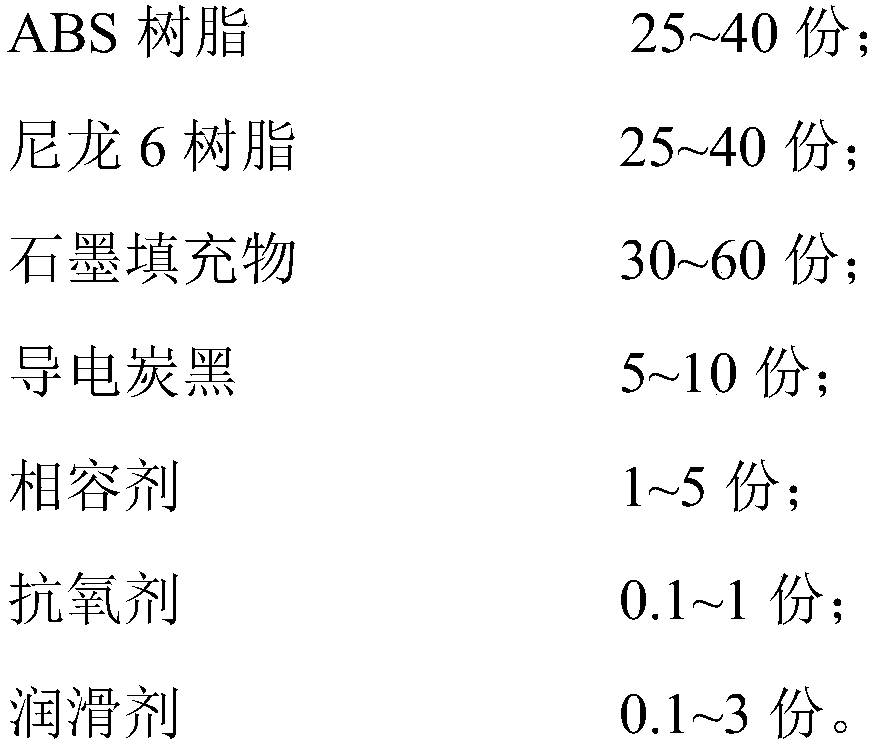

PA/ABS composite material and preparation method thereof

The invention provides a PA / ABS composite material. The PA / ABS composite material comprises the following components in parts by weight: 25-40 parts of ABS resin, 25-40 parts of nylon 6 resin, 30-60 parts of graphite fillers, 5-10 parts of conductive carbon black, 1-5 parts of a compatibilizer, 0.1-1 part of an antioxidant and 0.1-3 parts of a lubricant.

Owner:惠州市沃特新材料有限公司

Polyvinyl chloride-polypropylene flame-resistant composite material

The invention discloses a polyvinyl chloride-polypropylene flame-resistant composite material, which comprises the following raw materials: polyvinyl chloride resin, polypropylene resin, a stabilizer, a compatilizer, a compatibilizer, a coupling agent, a smoke suppressant, a lubricant and a toughening agent. According to the invention, butyl methacrylate grafted polypropylene polyvinyl chloride resin and polypropylene resin are organically combined together through the addition of the compatilizer, the advantages of the polyvinyl chloride resin and the polypropylene resin are well used to reach the purpose of flame resistance, and the tensile strength and modulus of elasticity in static bending of the flame-resistant composite material are also improved.

Owner:福建晟扬管道科技有限公司

Preparation method for light bomb-proof aramid fiber composite non-woven fabric chip

ActiveCN103911769AHigh flame retardant efficiencyImprove water resistance and easy precipitationNon-woven fabricsAramidFlame resistance

The invention discloses a preparation method for a light bomb-proof aramid fiber composite non-woven fabric chip. The preparation method for the bomb-proof aramid fiber composite non-woven fabric chip includes: spreading aramid fibers, uniformly and straightly arraying in parallel, coating, drying to obtain aramid fiber composite non-woven fabric, and regulating parameters of production equipment to produce the aramid fiber composite non-woven fabrics with different surface density; preparing multilayer composite aramid fiber composite non-woven fabric through increasing the compositing times of the aramid fiber composite non-woven fabric; combining the aramid fiber composite non-woven fabrics with different surface density and different composite layer number to obtain the bomb-proof chip. The light bomb-proof aramid fiber composite non-woven fabric chip has good buffer ability and fire resistance, is resistant to bomb and vibration, is light and convenient to carry, enables the personnel load to be reduced, and enables the fighting efficiency of the fighter to be improved.

Owner:JIANGSU LINRY NEW MSTAR TECH

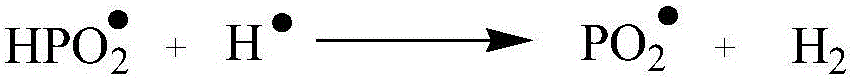

Method for solving problems of moisture absorption and stickiness of phosphorus coated fabric by adding inorganic components

ActiveCN105907210AImprove dehydration abilityTogether produce flame retardant effectFireproof paintsTextiles and paperFrostEmulsion

The invention discloses a method for solving problems of moisture absorption and stickiness of phosphorus flame-retardant coated fabric by adding inorganic components. The method is characterized by coating, drying and baking nap face fabric for chairs, wherein the coating comprises the components in proportion by weight: 40-55% of acrylic ester emulsion, 35-50% of phosphorus flame retardant, 4-10% of inorganic flame retardant synergist and 4-8% of thickener and water, and the glue amount of the fabric is 200-260g / m<2>. The method reduces the usage of the phosphorus flame retardant by adopting the inorganic flame retardant synergist, the flame retardant efficiency and water resistance of the phosphorus intumescent flame-retardant coating are improved, and simultaneously the defects of frost on the surface, satiny hand feeling, stickiness and the like of the original phosphorus flame-retardant coated fabric are improved.

Owner:SHANDONG TAIYANGNIAO SAFETY TECH CO LTD

Aerogel-modified high-strength fireproof mortar material and preparation method thereof

The invention discloses an aerogel-modified high-strength fireproof mortar material. The high-strength fireproof mortar material comprises cement, sand, polypropylene fibers, a composite reinforcing filler, a water reducing agent, a flame retardant and cellulose ether, wherein the sand is a mixture of hill sand and machine-made sand; the cellulose ether is a mixture of hydroxypropyl methyl cellulose ether and hydroxyethyl methyl cellulose ether; the composite reinforcing filler is a mixture of vitrified micro beads and a mesoporous nano-material mixed according to a certain mass ratio; the mesoporous nano-material is formed by taking nanometer titanium dioxide particles as a core layer and sequentially coating the surface of the core layer with a nitrogen-doped graphene aerogel layer and azirconium oxide / silicon oxide aerogel layer. The invention also discloses a preparation method of the high-strength fireproof mortar material. The mortar material provided by the invention not only has good fireproof performance, but also has good mechanical properties.

Owner:SUZHOU JUNYUE NEW MATERIAL TECH

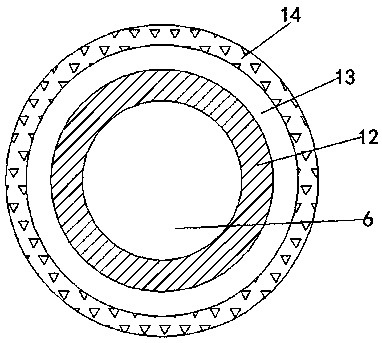

Flax yarn

The invention relates to the technical field of flax textiles and discloses a flax yarn. The flax yarn comprises a yarn body which comprises a yarn core, the yarn core is internally provided with an elastic yarn, flax fibers and single cores, a flax yarn layer is wound on the outer surface of the yarn core, a surface yarn is fixedly connected to the outer surface of an elastic yarn layer which iswound on the outer surface of the flax yarn layer, and a polyester fiber, a viscose fiber, fiber cotton and a flame-retardant cotton thread are spirally twisted on the outer surface of the yarn body.By simultaneous winding of the viscose fiber and the flame-retardant cotton thread with advantages of softness in hand feel, elasticity durability, great heat insulation performance, permanent flame retardation and the like in the yarn body, breakage of the yarn body due to looseness can be prevented, so that flame retardation is realized. By arrangement of the flax fibers, the flax yarn is excellent in wool touch, and defects of flax roughness, poor spinnability and drapability and the like are overcome.

Owner:盐城金科亚麻纺织有限公司

Preparation method of flame-retarding anti-cracking type graphite heat dissipation sheet

InactiveCN108218378AHas a fibrous structureImprove flame retardant performanceModifications by conduction heat transferFiberInsulation layer

The invention relates to a production method of graphite heat dissipation sheets and in particular relates to a preparation method of a flame-retarding anti-cracking type graphite heat dissipation sheet. The flame-retarding anti-cracking type graphite heat dissipation sheet is prepared by taking modified expanded graphite as a matrix and modified talcum powder and modified wollastonite fibers as areinforcing agent, and adding with silica sol, copper powder, iron powder and the like; firstly, graphite powder is modified by utilizing a concentrated sulfuric acid solution; the modified graphitepowder is blended with acetic anhydride and potassium permanganate to obtain expanded graphite; after the graphite is treated through concentrated sulfuric acid, a relatively good heat-insulation layer is formed, so that the flame-retarding property of the graphite heat dissipation sheet is improved; a pyrophosphoric acid acyloxy group is introduced into the surface of the graphite heat dissipation sheet so that the flame-retarding property of the graphite heat dissipation sheet is improved; polyethylene glycol stearate and the silica sol are continually used for modifying the wollastonite fibers; the contact area between the graphite heat dissipation sheet and the matrix is enlarged by adopting a coarse surface structure, and the bonding strength of an interface can be effectively improved, so that the anti-cracking performance of the graphite heat dissipation sheet is improved and the graphite heat dissipation sheet has a wide application prospect.

Owner:常州水精灵环保设备有限公司

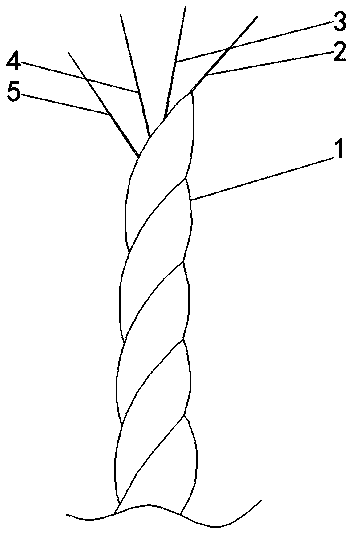

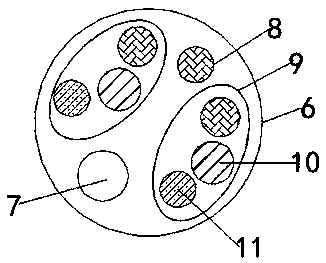

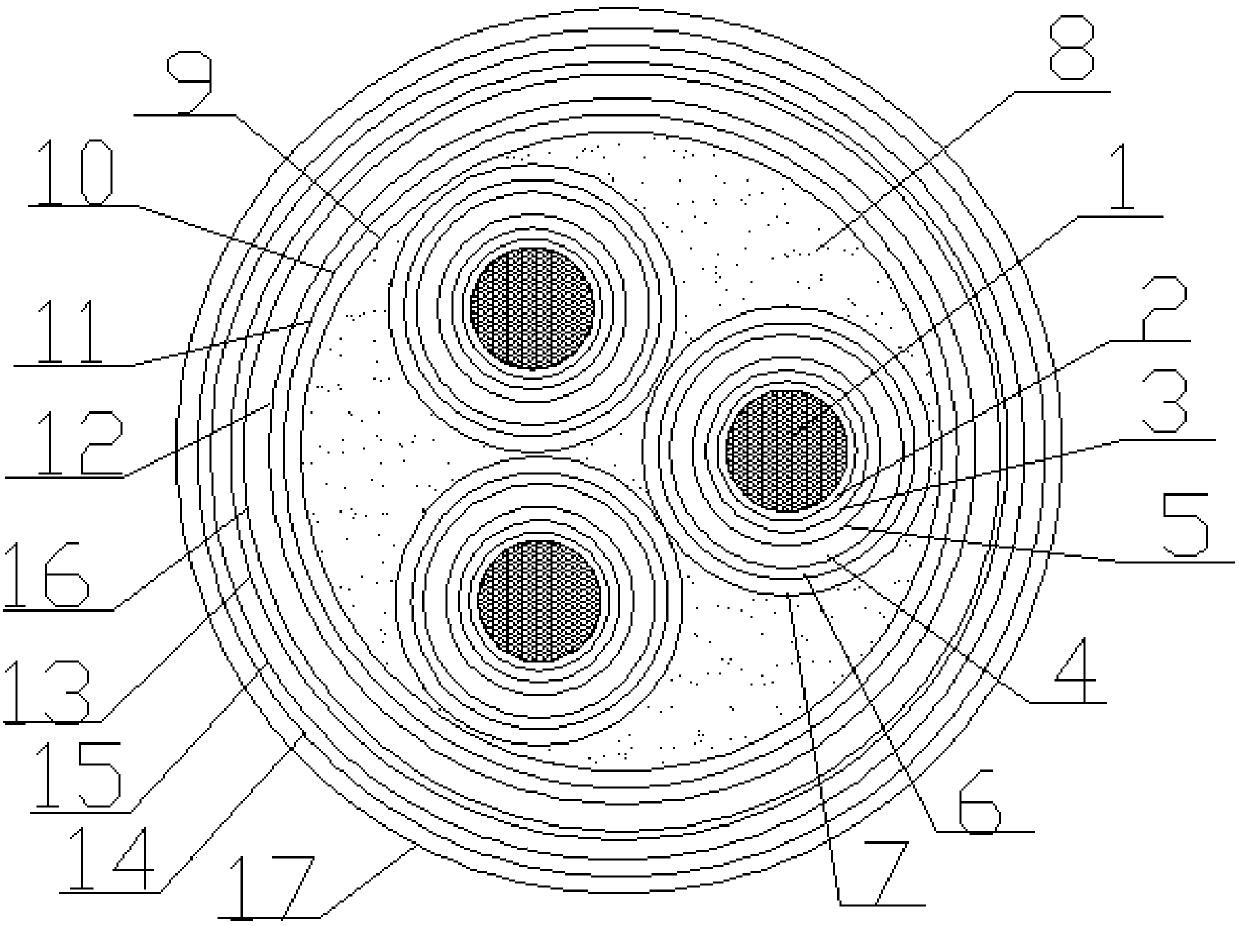

Medium-voltage fire-resistant power cable

InactiveCN107564612AExcellent flame retardantImprove fire resistancePlastic/resin/waxes insulatorsInsulated cablesFiberFirestop

The invention discloses a medium-voltage fire-resistant power cable, which comprises a cable core, wherein the cable core is formed by twisting a plurality of wire cores; each wire core comprises a conductor, a shielding layer, an insulating layer and an insulating shielding layer; the shielding layers, insulating layers and the insulating shielding layer are arranged outside the corresponding conductors; each conductor is formed by twisting a plurality of copper core conductors; a thermal insulating layer is also arranged outside each insulating layer; one insulating shielding layer is arranged outside each thermal insulating layer; a metal shielding layer wraps the outside of each insulating shielding layer; a fire-resistant layer is arranged outside each metal shielding layer; the partsamong the plurality of wire cores are filled with fillers; a ceramic fiber tape, an adiabatic cooling layer, a steel tape firestop layer, an oxygen barrier layer, an inner sheath and an outer sheathwrap the outside of the cable core; and the outer sheath wraps the inner sheath through a lubricating layer. The medium-voltage fire-resistant power cable is simple in structure, and has good flame retardant property and fire resistance; the voltage level of the cable is improved on the basis of ensuring the flexibility and the large-length processing performance of the cable; and safe and reliable operation of a power system is ensured.

Owner:JIANGSU PUCAO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com