Medium-voltage fire-resistant power cable

A power cable and fire-resistant technology, applied in the field of medium-voltage fire-resistant power cables, can solve the problems of inability to continuously produce large lengths, complicated cable production processes, and production process limitations, and achieve safe and reliable operation, good flame retardancy, and improved voltage levels. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

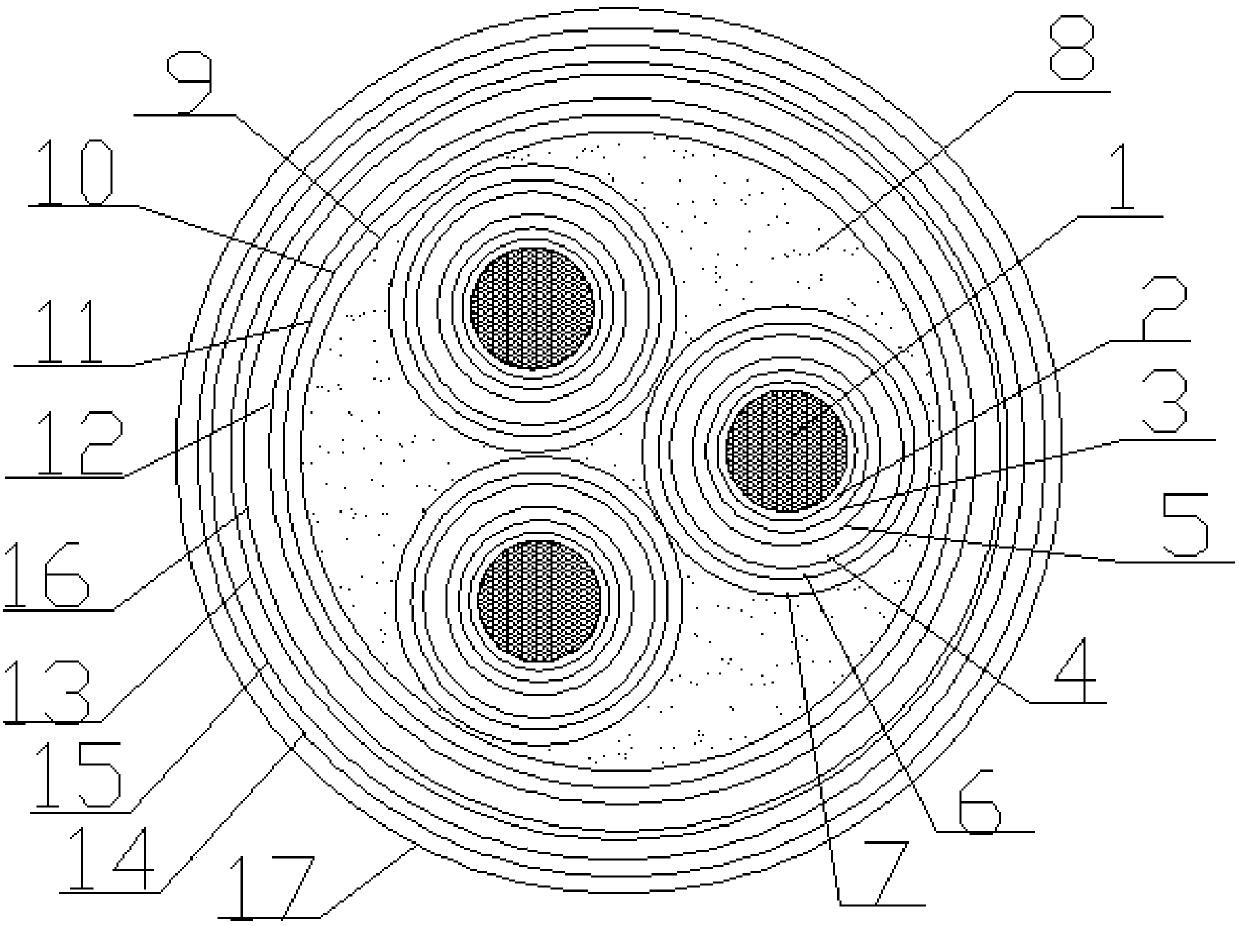

[0062] A medium-voltage fire-resistant power cable provided in this embodiment has a structure such as figure 1 As shown, including the cable core, the cable core is twisted by three wire cores, and the wire cores are closely arranged and twisted along the circumferential direction. The wire core is composed of conductor 1 and the shielding layer 2, insulating layer 3, and insulation The shielding layer consists of 4, of which:

[0063] The conductor 1 is formed by twisting several copper core conductors, the shielding layer 2 is arranged outside the conductor 1, the insulating layer 3 is arranged outside the shielding layer 2, and the insulating layer 3 is also provided with a heat insulation layer 5, and the heat insulation layer 5 is arranged outside the shielding layer 2. An insulating shielding layer 4 is provided, and a metal shielding layer 6 is wrapped around the insulating shielding layer 4, and a refractory layer 7 is arranged outside the metal shielding layer 6;

...

Embodiment 2

[0069] This embodiment provides the composition of the flame-retardant tape and the heat-insulating and cooling layer in Embodiment 1, specifically:

[0070] The flame retardant tape includes the following components in parts by mass:

[0071] Polyvinyl chloride: 15 parts, bromocarbon polyurethane resin: 10 parts, zinc borate modified phenolic resin: 15 parts, mica: 1 part, methylphenyldiethoxysilane: 7 parts, modified magnesium hydroxide: 5 parts Parts, chlorinated paraffin: 1 part, zinc borate: 3 parts, aluminum hydroxide: 2 parts, hexamethylcyclotrisilazane: 2 parts, glass flake: 1 part, tris(2,4-di-tert-butyl Phenyl) phosphite: 3 parts, modified vermiculite powder: 1 part, silicone oil: 4 parts, filler: 0.5 part;

[0072] The filler contains the following components by mass percentage: Y: 9%, Sc: 30%, Gd: 18%, Sm: 8%, Pr: 13%, and the balance La, which is the sum of the above components is 100%;

[0073]The specific production of modified magnesium hydroxide is as follow...

Embodiment 3

[0080] This embodiment provides the composition of the flame-retardant tape and the heat-insulating and cooling layer in Embodiment 1, specifically:

[0081] The flame retardant tape includes the following components in parts by mass:

[0082] Polyvinyl chloride: 18 parts, bromocarbon polyurethane resin: 13 parts, zinc borate modified phenolic resin: 20 parts, mica: 5 parts, methylphenyldiethoxysilane: 10 parts, modified magnesium hydroxide: 8 Parts, chlorinated paraffin: 3 parts, zinc borate: 6 parts, aluminum hydroxide: 4 parts, hexamethylcyclotrisilazane: 5 parts, glass flakes: 3 parts, tris(2,4-di-tert-butyl Phenyl) phosphite: 5 parts, modified vermiculite powder: 3 parts, silicone oil: 7 parts, filler: 1 part;

[0083] The filler contains the following components by mass percentage: Y: 11%, Sc: 38%, Gd: 20%, Sm: 10%, Pr: 15%, and the balance La, which is the sum of the above components is 100%;

[0084] The specific production of modified magnesium hydroxide is as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com